Wire rod for deep drawing cold drawn spring steel wire and preparation method thereof

A technology of spring steel wire and wire rod, which is applied in the field of spring steel, can solve the problems of high rate of broken wires in drawing and the inability to realize deep drawing, etc., and achieve the effect of increasing tail area shrinkage, good application prospects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

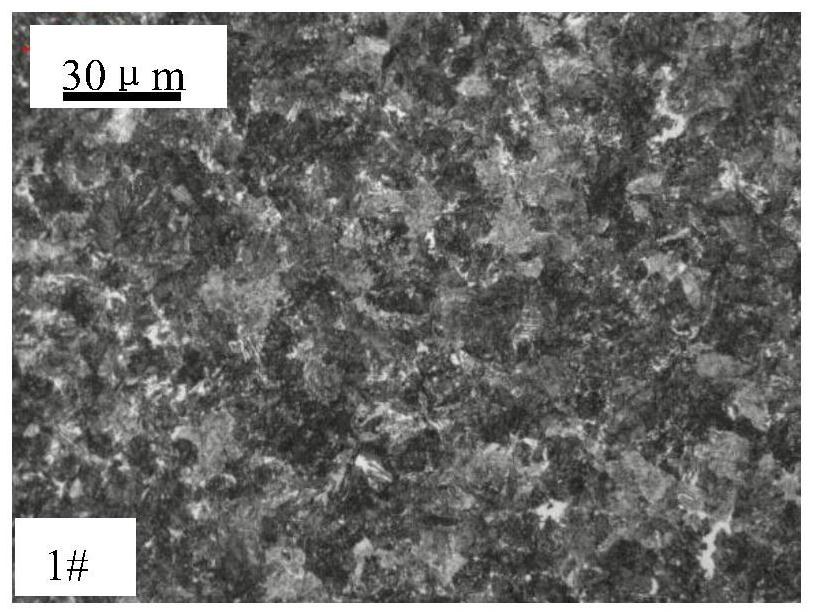

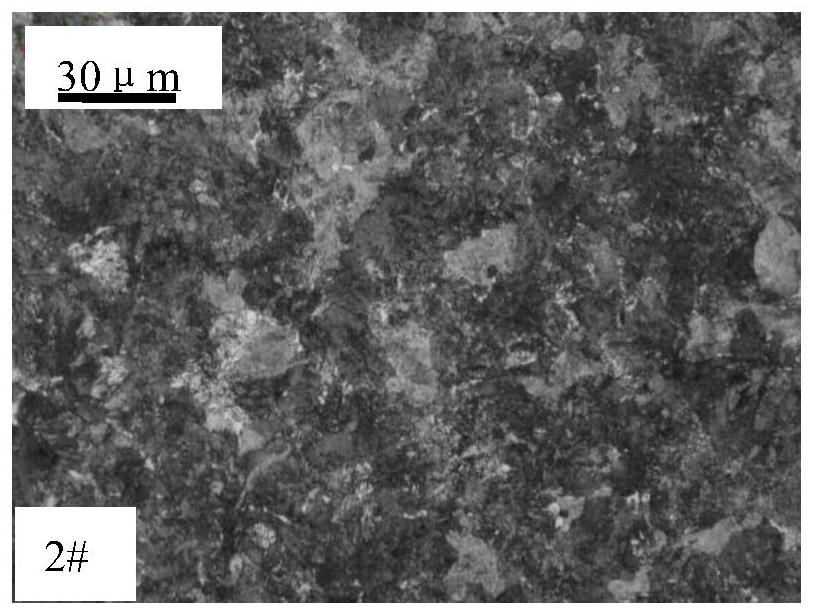

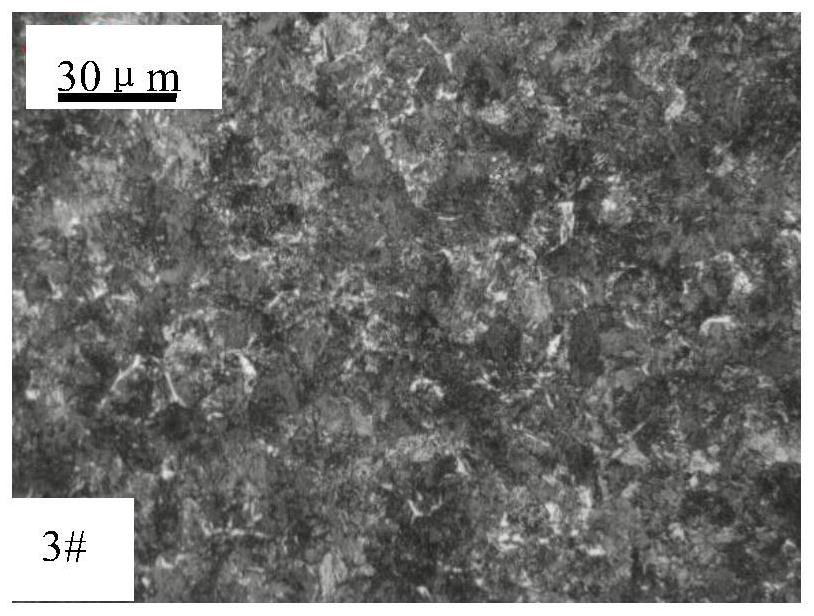

Image

Examples

preparation example Construction

[0032] The second aspect of the present invention provides a method for preparing the above-mentioned wire rod for deep-drawing and cold-drawing spring steel wire, the steps comprising:

[0033] S1. Electric furnace smelting: pure oxygen smelting throughout the whole process, using low N carburizer to increase carbon, electric furnace end point control C: 0.06% ~ 0.10%, adding deoxidizer to the electric furnace to obtain water oxygen activity ≤ 20×10 -6 molten steel;

[0034] S2, LF furnace refining: the molten steel obtained in S1 is refined in an LF furnace, and the oxygen activity of the LF molten steel is controlled to be ≤10×10 -6 ;

[0035] S3, continuous casting: the carbon segregation index of the control center is 1.00-1.15 to obtain a steel billet meeting the chemical composition requirements described in claim 1;

[0036] S4. The steel billet is rolled after being heated in a heating furnace, and the product is obtained by controlled cooling after rolling. The rol...

Embodiment 1

[0039]This embodiment provides a wire rod for deep drawing and cold drawn spring steel wire and a preparation method thereof. Hot-rolled wire rods are rolled into hot-rolled wire rods through electric furnace smelting, LF furnace refining, continuous casting, heating furnace heating, rolling, and controlled cooling. The specific production steps are: scrap steel sorting→electric furnace→LF→VD→continuous casting 150 billet→inspection→150mm×150mm billet→heating→high pressure water descaling→rough rolling unit→intermediate rolling unit→pre-finishing rolling unit→water tank→ Finishing mill → water tank → reducing and sizing unit → water tank → laying head → Stelmore cooling → coil collection → P&F line → cutting head, tail → quality inspection, sampling → bundling → weighing → marking → coil unloading → storage. Its specific production process is as follows:

[0040] Electric furnace smelting: Tapping slag is used to keep the slag from entering the ladle; aluminum block is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com