Egg yolk separating device for extracting lecithin

A separation device and lecithin technology, applied in the field of separation, can solve the problems of incomplete dissolution and extraction of egg yolk, reduction of extraction rate, reduction of purity of lecithin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

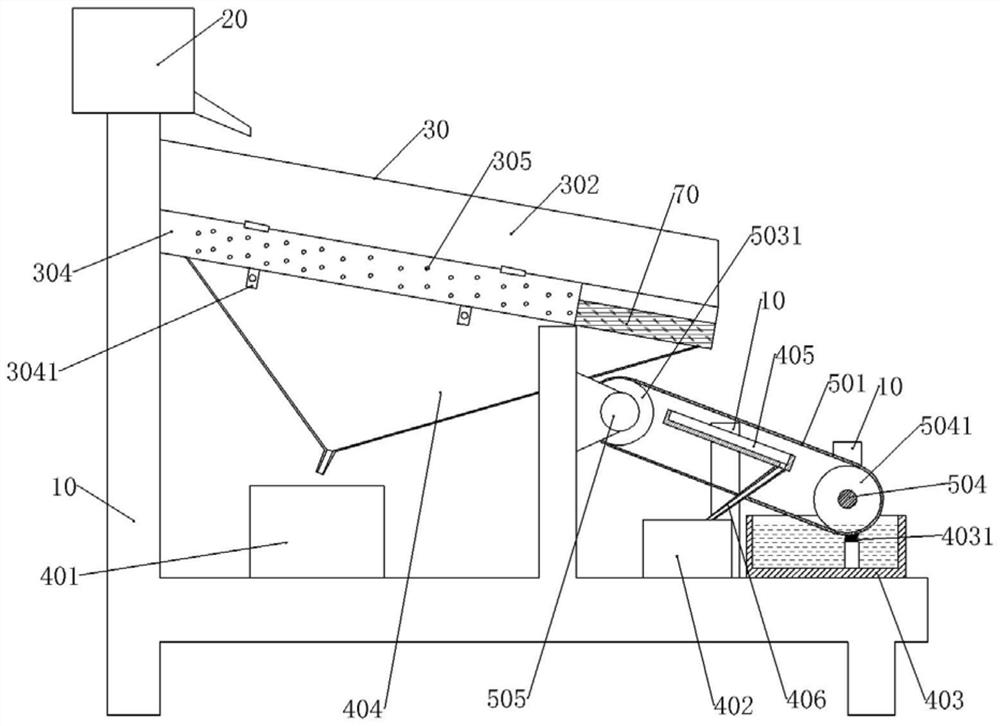

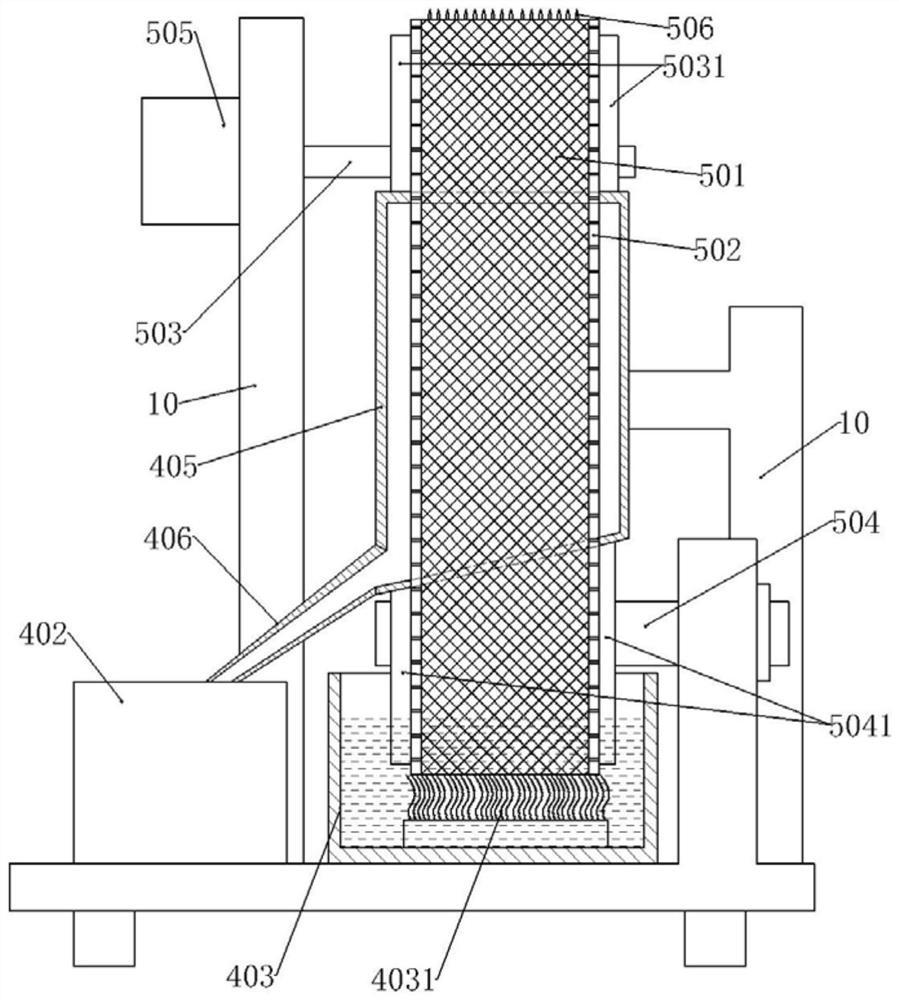

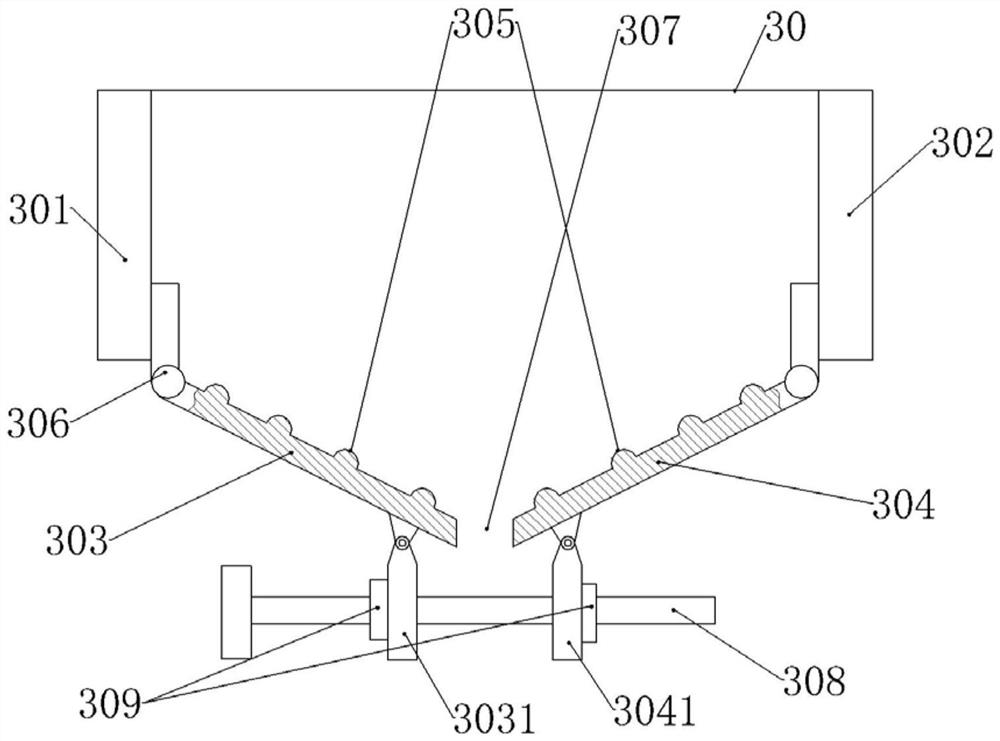

[0024] The reference numerals in the drawings of the description include: frame 10, feed hopper 20, separation tank 30, left side plate 301, right side plate 302, left movable plate 303, left connecting plate 3031, right movable plate 304, right connecting plate Plate 3041, arc-shaped protrusion 305, hinge 306, leaking seam 307, bolt 308, nut 309, egg white collecting box 401, egg yolk collecting box 402, cleaning tank 403, cleaning brush 4031, egg white collecting plate 404, egg yolk collecting plate 405 , diversion tube 406, annular mesh plate 501, mesh 5011, chain 502, driving shaft 503, driving sprocket 5031, driven shaft 504, driven sprocket 5041, drive motor 505, pointed object 506, adsorption chamber 60, air pipe 601, adsorption hole 602, adsorption cloth strip 70.

[0025] A kind of egg yolk separation device used for lecithin extraction of the present embodiment, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com