Smelting process for improving near-surface flaw detection defects of shaft rudder system steel

A near-surface, shaft-rudder system technology, applied in the field of steel, can solve problems such as restricting the development of shaft-rudder systems and ship parts, and achieve the effects of improving the qualified rate of flaw detection, reducing the scrap rate and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

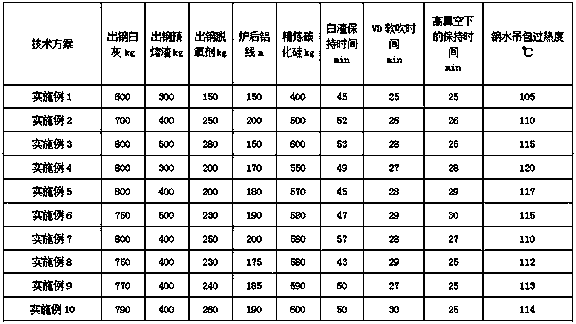

[0038] A smelting process for improving near-surface flaw detection defects of shaft and rudder steel, comprising the following steps:

[0039] 1) Converter tapping carbon ≥ 0.06%, tapping phosphorus ≤ 0.012%; converter tapping temperature 1610-1660°C.

[0040] Add steel core aluminum 150-280 kg during the tapping process; add lime 600-800 kg; add pre-melted slag 300-500 kg; feed aluminum wire 150-200 meters after tapping.

[0041] 2) SiC deoxidation for refining, 400-600 kg; refining white slag time: 43-60 minutes;

[0042] 3) Holding time under high vacuum: 25-30 minutes. During the vacuum holding period, it is necessary to observe that the molten steel surface is obviously exposed to ensure the vacuum degassing effect.

[0043] 4) After the VD is broken, feed 250-300 meters of manganese nitride wire; feed 40-80 meters of calcium wire. VD soft blowing time: 25-30 minutes;

[0044] 5) When pouring molten steel, the superheat of the hanging bag: 105-120°C; add 100-200 kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com