Feeding device for gas flow equipment

A feeding device and equipment technology, applied in lighting and heating equipment, tobacco preparation, transportation and packaging, etc., can solve the problems of polluted air ducts, fan radiators and filter screens, outlet moisture fluctuations, and material liquid loss, etc., to achieve Reduce the difficulty of air lock processing and assembly, reduce air intake, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

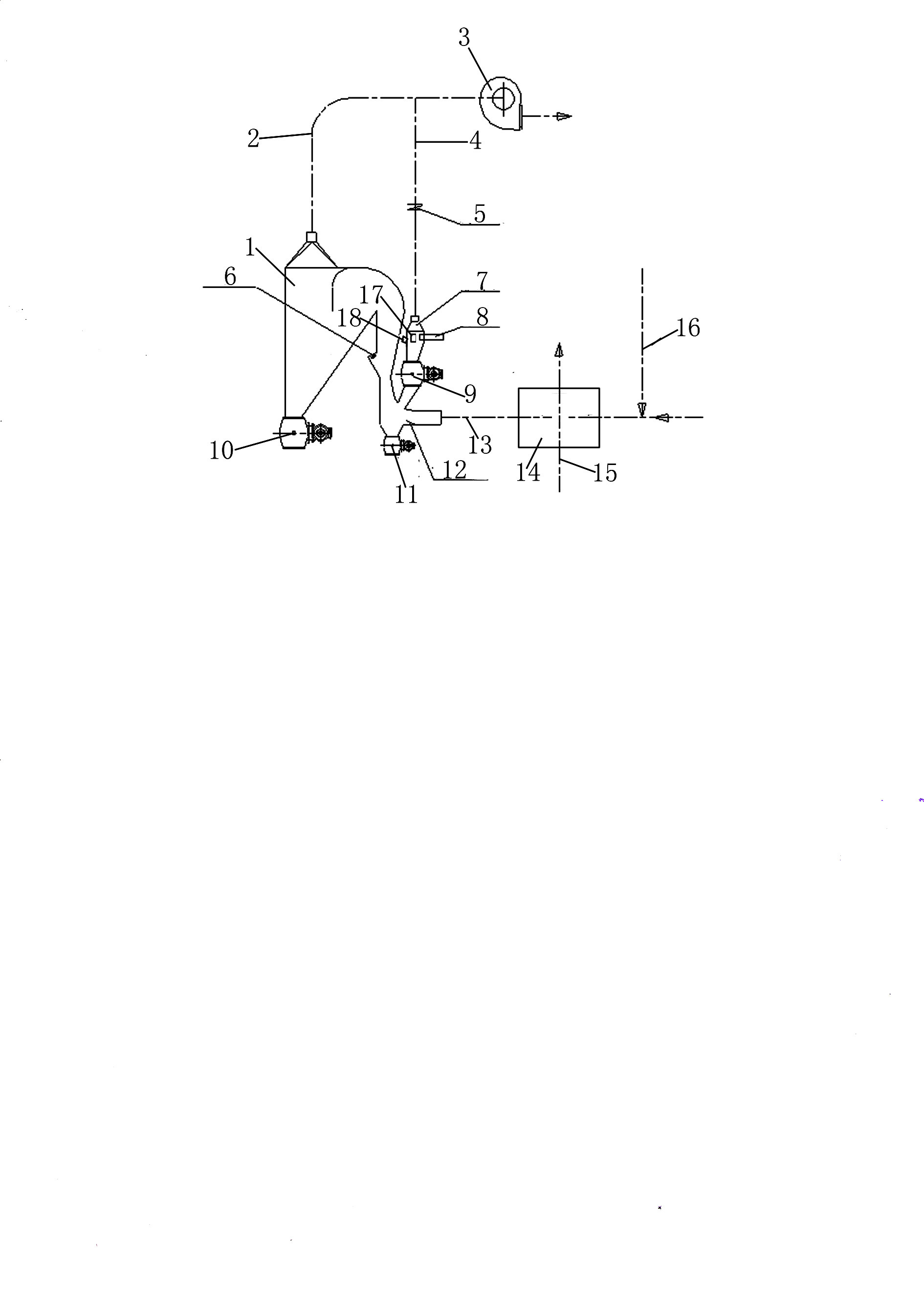

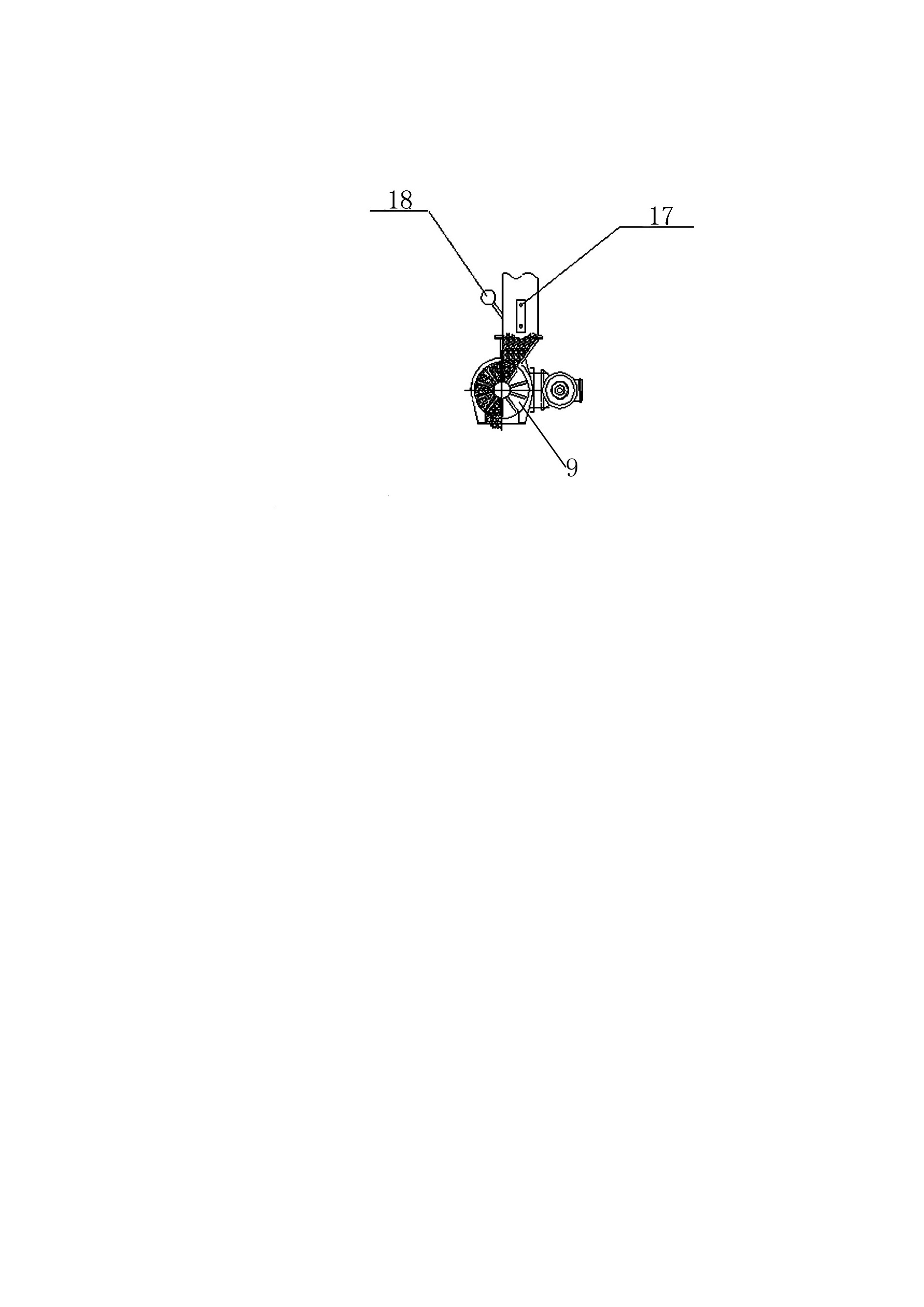

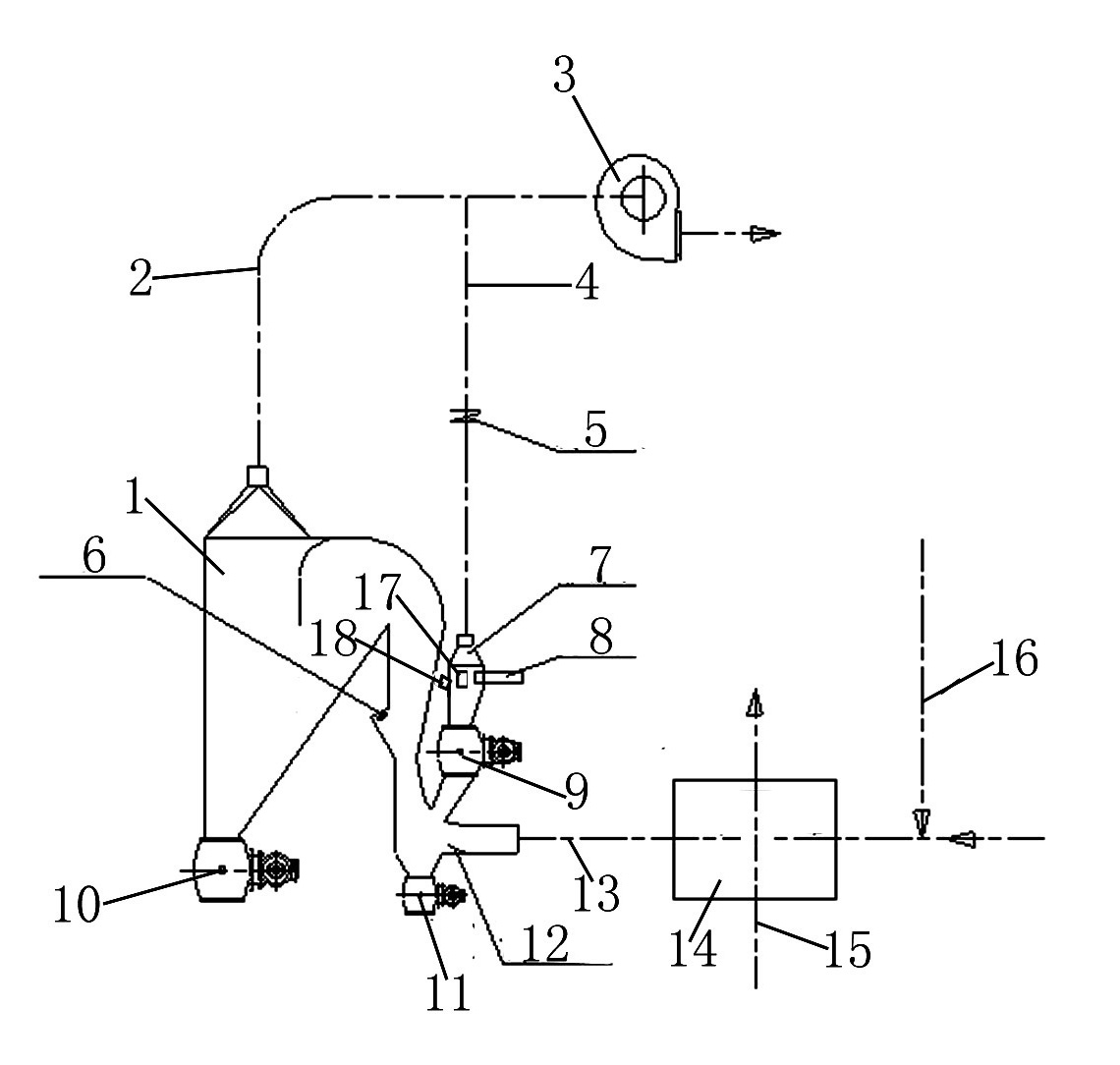

[0012] See figure 1 , figure 2 The feeding device of the given airflow drying equipment includes a feeder 1 which is a bifurcated cylinder, and the upper part of the feeder 1 is connected with a moisture discharge fan 3 through a moisture discharge pipe 2 . The lower part of one of the cylinders of the blanker 1 is equipped with a discharge air lock 10, and the lower part of the other cylinder of the blanker 1 has a three-way interface, and the lower interface of one of the three-way interfaces is equipped with a miscellaneous air lock 11. A regulating valve 12 is installed in the horizontal interface of the second of the three-way interface, and the horizontal interface of the second of the three-way interface is connected to the moisture exhaust process gas pipeline 13, and the moisture exhaust process gas pipeline 13 is connected to the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com