Method for controlling nitrogen content of high-permeability-grade oriented electrical steel belt

A technology of oriented electrical steel and high magnetic permeability, which is applied in the field of steelmaking, can solve the problems of difficult to meet, high cost, unstable nitrogen absorption rate, etc., and achieve the requirements of simple method, strong applicability, and secondary recrystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

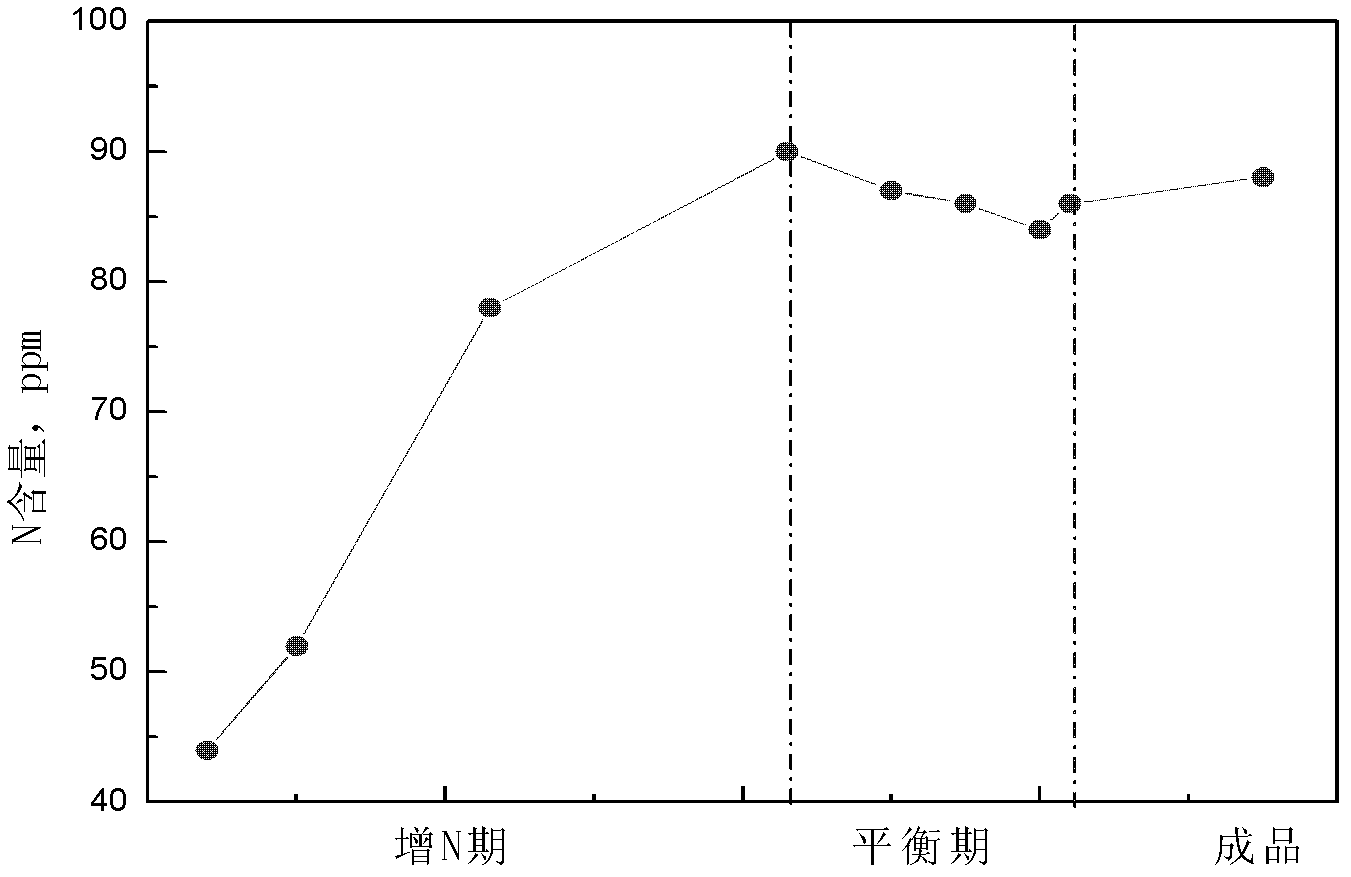

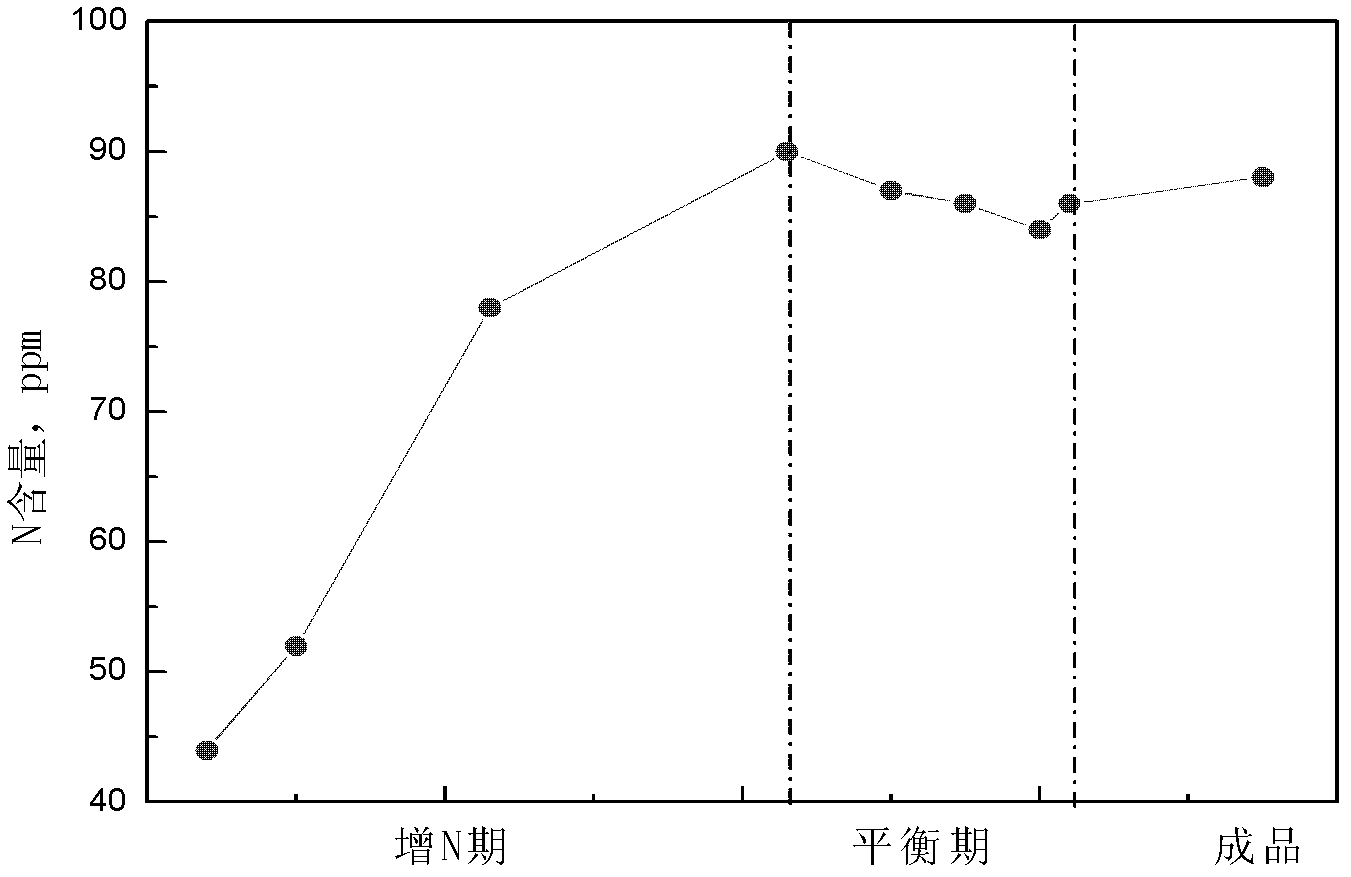

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] The invention provides a method for controlling the nitrogen content of a high-permeability grade-oriented electrical steel strip, which specifically includes the following steps:

[0019] (1) After the molten steel reaches the RH refining furnace, it is connected to the bottom blowing nitrogen gas, and the molten steel is blown with nitrogen, and the flow rate of the bottom blowing nitrogen gas is 18-60m 3 / h.

[0020] (2) In the initial stage of RH refining treatment, the ultimate vacuum treatment is adopted, the RH ultimate vacuum degree is ≤200Pa, the RH vacuum chamber adopts nitrogen circulation throughout, and the nitrogen circulation flow rate is 50-100m 3 / h.

[0021] (3) After 12-15 minutes of ultimate vacuum treatment, according to the initial nitrogen content of molten steel, reset the RH vacuum degree to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com