9% Ni steel matched nickel-based welding rod special for overhead welding

A nickel-based electrode, 9%ni technology, used in welding media, welding equipment, welding/cutting media/materials, etc., to achieve stable mechanical properties, excellent low-temperature impact toughness, and low porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these examples.

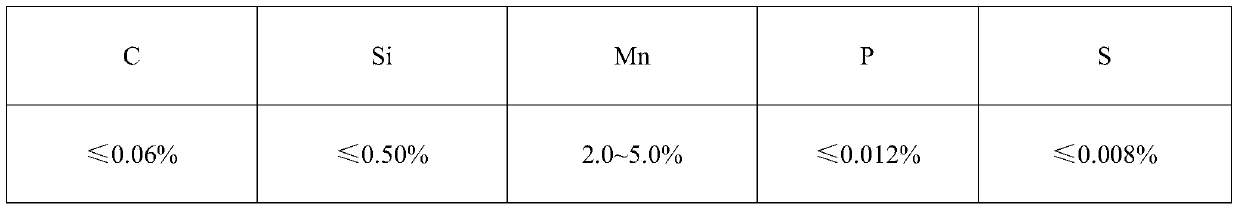

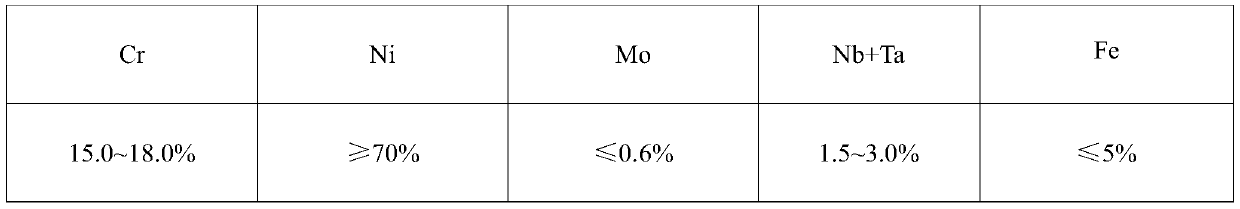

[0054] A nickel-based welding rod for 9% Ni steel for overhead welding, consisting of a welding core and a coating, the coating is coated on the outer wall of the welding core, and the coating accounts for 0.3 to 0.5 of the total weight coefficient of the welding rod; the welding core is made of nickel chromium Iron welding core; its welding core composition (% by weight) is shown in Table 1:

[0055] Table 1: Solder Core Composition

[0056]

[0057]

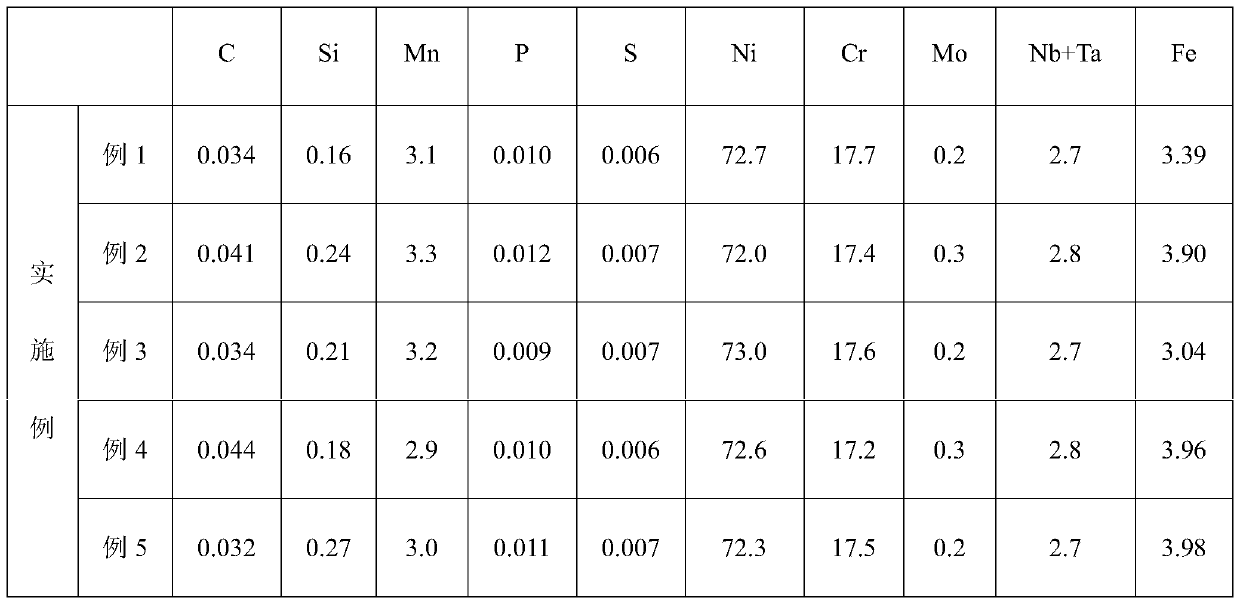

[0058] Table 2: Solder core composition (weight percentage %) in embodiment 1~5

[0059]

[0060] The coating uses high alkalinity CaCO 3 -MgCO 3 -CaF 2 For the low hydrogen slag system, the proportion of the coating to the total weight of the electrode is 0.3-0.5, and the diameter of the core wire is 2.6mm and 3.2mm. The compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com