Production method of conductive carbon black for environment-friendly cable shielding material

A cable shielding, conductive carbon black technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of production method of environment-friendly type cable shielding material conductive carbon black comprises the following steps:

[0029] 1) Raw material control: the raw material oil used by the raw material is a mixed oil of anthracene oil and ethylene tar, wherein the weight percentage of anthracene oil and ethylene tar is 8:2, control potassium ion content=2ppm in the anthracene oil and ethylene tar, sodium Ion content=10ppm; Toluene insolubles in anthracene oil=0.5%, density ρ20 is 1.13 / cm3, viscosity E80=1.5, moisture=1%, fraction before 210°C=5%, fraction before 360°C=60%; The characteristics of ethylene tar in the raw oil are: toluene insolubles=1.0%, density ρ20 is 1.04= / cm3, viscosity E80=9, moisture=0.5%, fraction before 210°C=20%, fraction before 360°C =70%; Environmentally friendly non-cross-linked cable shielding materials have higher requirements on high-temperature electrical properties of products, and high-temperature electrical p...

Embodiment 2

[0039] Embodiment 2: Compared with Example 1, the main difference is that the characteristics of anthracene oil in the raw oil are: toluene insolubles=0.3%, density ρ20 is 1.15g / cm3, viscosity E80=1.3, moisture=0.5%, The fraction before 210°C=3%, the fraction before 360°C=70%; the characteristics of ethylene tar in the raw material oil are: toluene insolubles=0.3%, density ρ20 is 1.1g / cm3, viscosity E80=7, moisture = 0.3%, the fraction before 210°C = 17%, the fraction before 360°C = 75%; the anthracene oil is extracted from coal tar, and the ethylene tar is ethylene cracking raw material and high temperature product in steam cracking process products of condensation;

[0040] In the process of cracking and preparing carbon black, in the multi-stage reactor, the volume ratio of air and natural gas is adjusted to 20:1, the combustion temperature in the combustion section of the reactor is increased to 2500°C, and the flow rate of raw material oil is 4000kg / h. The internal flue ...

Embodiment 3

[0042] Embodiment 3: The difference from Example 1 is: the characteristics of anthracene oil in the raw oil are: toluene insolubles=0.35%, density ρ20 is 1.14g / cm3, viscosity E80=1.1, moisture=0.7%, 210°C The fraction before = 4%, the fraction before 360°C = 75%; the characteristics of ethylene tar in the feed oil are: toluene insolubles = 0.5%, density ρ20 is 1.05g / cm3, viscosity E80 = 6, moisture = 0.35 %, the fraction before 210°C=15%, the fraction before 360°C=80%;

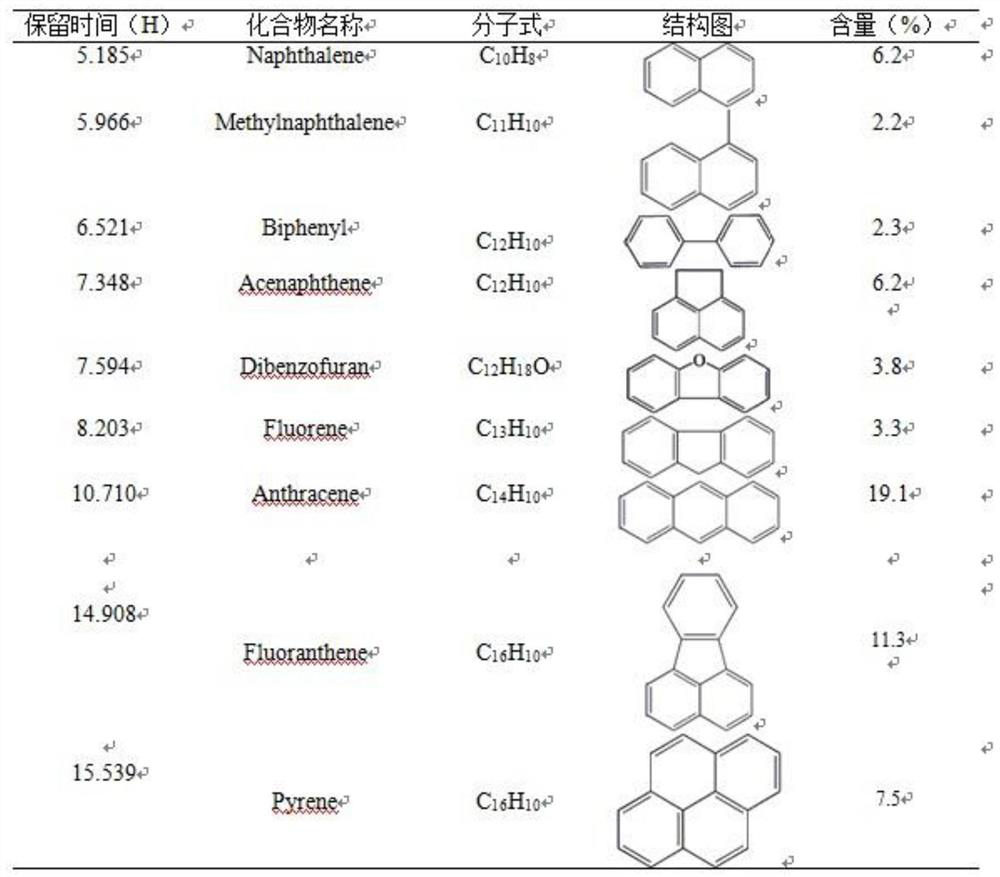

[0043] Analyzing by gas chromatography the content ≥ 2% components in the anthracene oil of the above characteristic specifications, whether these components in the anthracene oil react sufficiently during the high-temperature cracking reaction will affect the formation of functional groups on the surface of carbon black and the surface purity, and affect the carbon black. Black surface properties, it can be found that most of the rings with ≥ 2% components are between 2-4. Such a component composition ensures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com