A kind of short bast fiber spinning wet spinning blending method

A fiber-like and bast-like technology, applied in the field of bast-like fiber short-spun wet-spinning blending, can solve performance damages such as unfavorable development of diversification of flax products, unsuitable for the production of high-count, high-end products, and blended fiber strength and elongation. and other problems, to achieve the effect of diversification, improvement of spinnability, and smoothness of yarn body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Adopt the present invention to spin the blended yarn of 25tex flax short hemp 65 / polyester 35, main technology is: earlier the blended hemp automatic line (or on the jute returning silk machine) of short hemp fiber is carried out blending hemp, and raw material is preliminarily opened, Remove impurities, humidify, and make hemp rolls. Then comb the hemp to make short hemp slivers. After needle combing, the short fluff and hemp particles in the hemp sliver are removed by a combing machine, and then the needle carding strips are made into rovings. After the rovings are boiled and bleached, they are wet-spun It is mixed with polyester roving on the spinning frame, dried and wound to obtain the desired blended yarn.

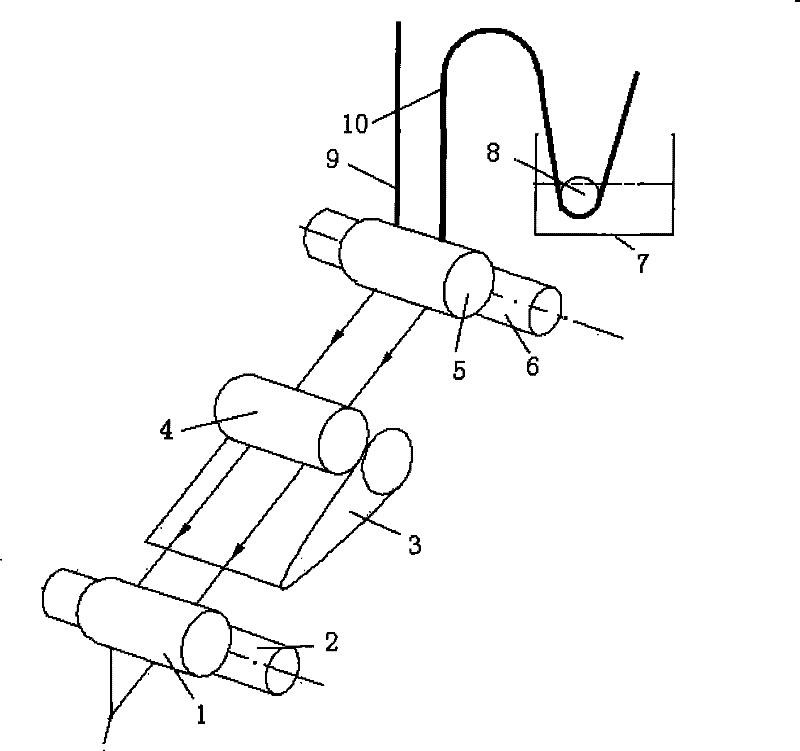

[0024] like figure 1 As shown, it is a schematic diagram of the blending of flax roving and polyester roving. The mixing method of flax roving and polyester roving on the spinning frame is: after the flax roving 9 is boiled and bleached, it is mixed with the ...

Embodiment 2

[0026] Adopt the present invention to spin the blended yarn of 30tex flax short hemp 60 / viscose glue 40, main process is: first the mixed hemp automatic line of short hemp fiber (or on the jute returning silk machine) is carried out blending hemp, and preliminary raw material is opened , remove impurities, humidify, and make hemp rolls. Then comb the hemp to make short hemp slivers. After needle combing, the short fluff and hemp particles in the hemp sliver are removed by a combing machine, and then the needle carding strips are made into rovings. After the rovings are boiled and bleached, they are wet-spun It is mixed with viscose roving on the spinning frame, dried and wound to obtain the required blended yarn.

[0027] Wherein, the mixing method of flax roving and viscose roving on the spinning frame is the same as the mixing method of flax roving and polyester roving in Example 1, except that the viscose fiber roving is directly fed into the drafting area of the spinning...

Embodiment 3

[0031] Spinning 25tex flax 50 / polyester 50 by adopting the present invention, the main process is: first the mixed flax automatic line (or on the jute silk returning machine) of short flax fiber is mixed flax, and preliminarily carries out opening, impurity removal, humidification to raw material, makes Into hemp rolls. Then comb the hemp to make short hemp slivers, and then go through the combing machine to remove the short fluff and hemp particles in the hemp sliver, and then go through the needle carding slivers to make rovings, which are then wet-spun spun yarns after the boiling and bleaching process It is mixed with polyester filament on the machine, dried, and wound to obtain the required blended yarn.

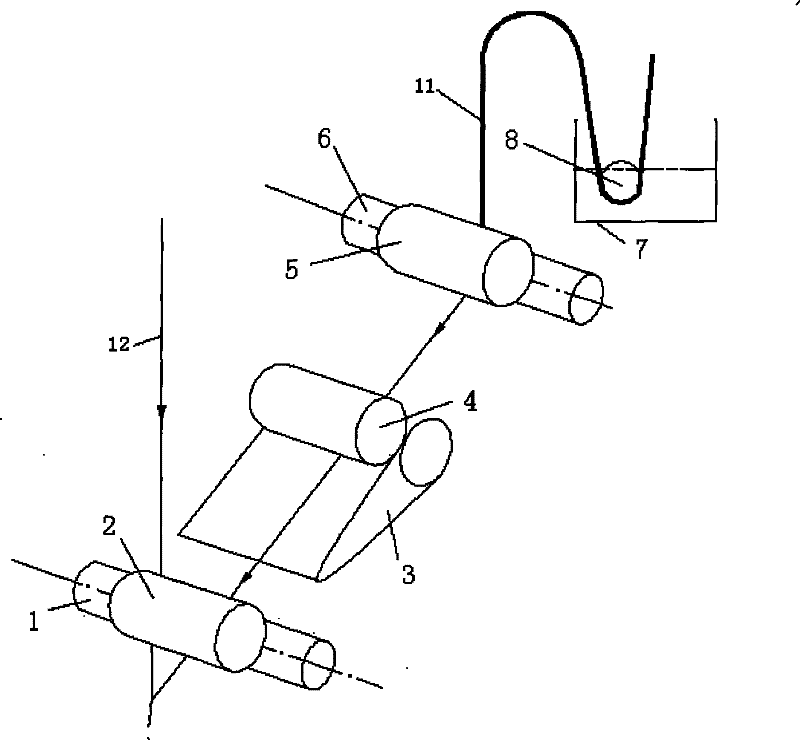

[0032] like figure 2 As shown, it is a schematic diagram of flax roving and polyester filament blending. The mixing method of flax roving and polyester filament is: the flax roving 11 passes through the water tank 7 (which is provided with a guide roller 8) after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com