Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "High moisture permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer polyporous foam dressing material and its producing method

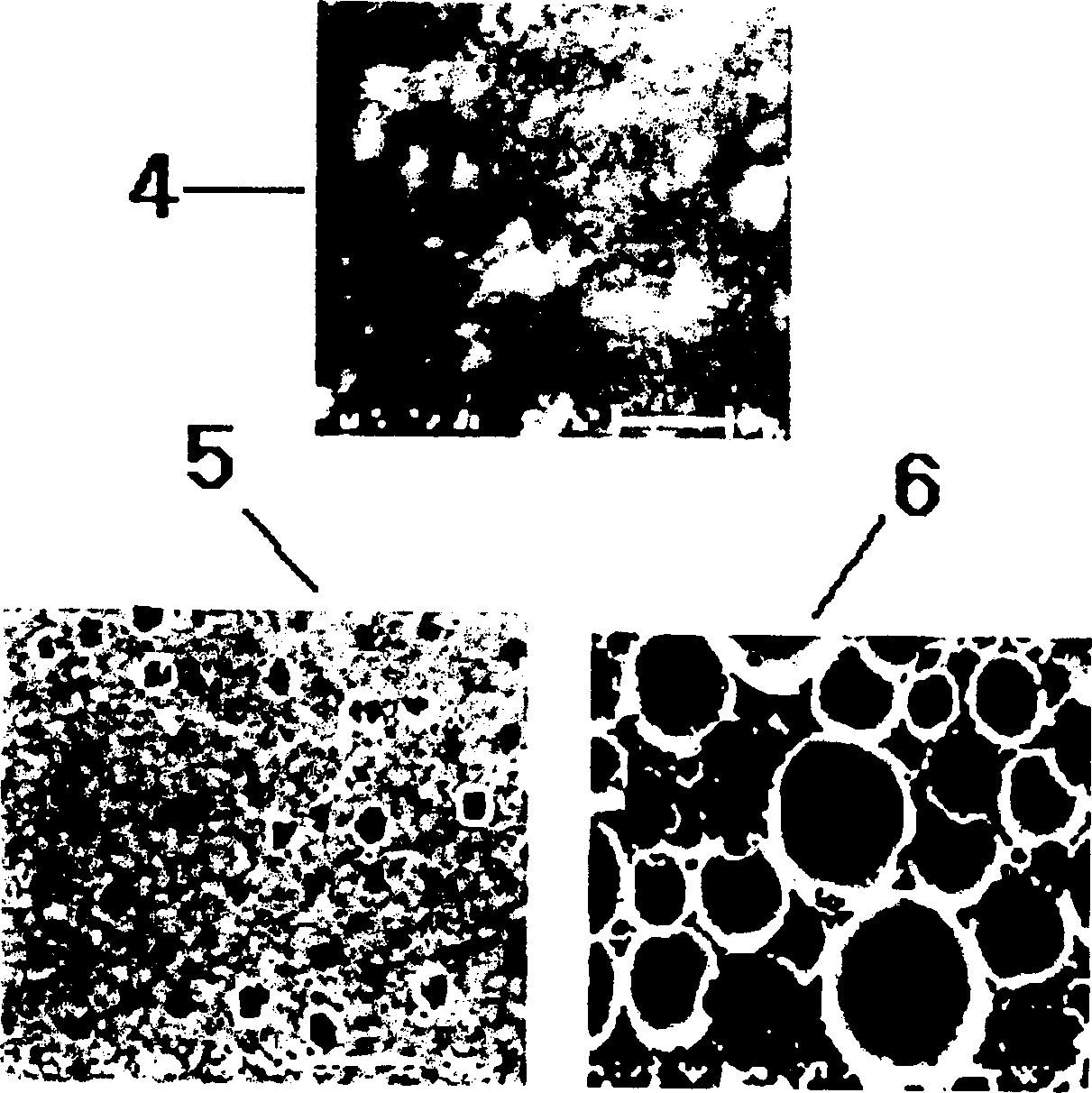

The present invention relates to a multimicroporous foamed dressing with multilayer structure and its preparation method. The thickness of said dressing is 1-7 mm, and its structure contains the following three layers: first layer is outside protective film layer whose thickness is 10-90 micrometer, second layer is internal absorption foamed layer with several holes whose diameter is 80-400 micrometer and third layer is wound-contacting layer with several microfine pores whose average diameter is below 60 micrometer, and its thickness is 0.1-200 micrometer. Its preparation process is simple and includes the following steps: firstly, mixing 40-75 wt% of polyurethane prepolymer, 15-45 wt% of foaming agent, 5-35 wt% of cross-linking agent and 0.5-15wt% of additive containing surfactant, humectant, releasing agent, bactericide and pigment, stirring them, injecting them into mould, foaming and moulding.

Owner:株式会社界优维

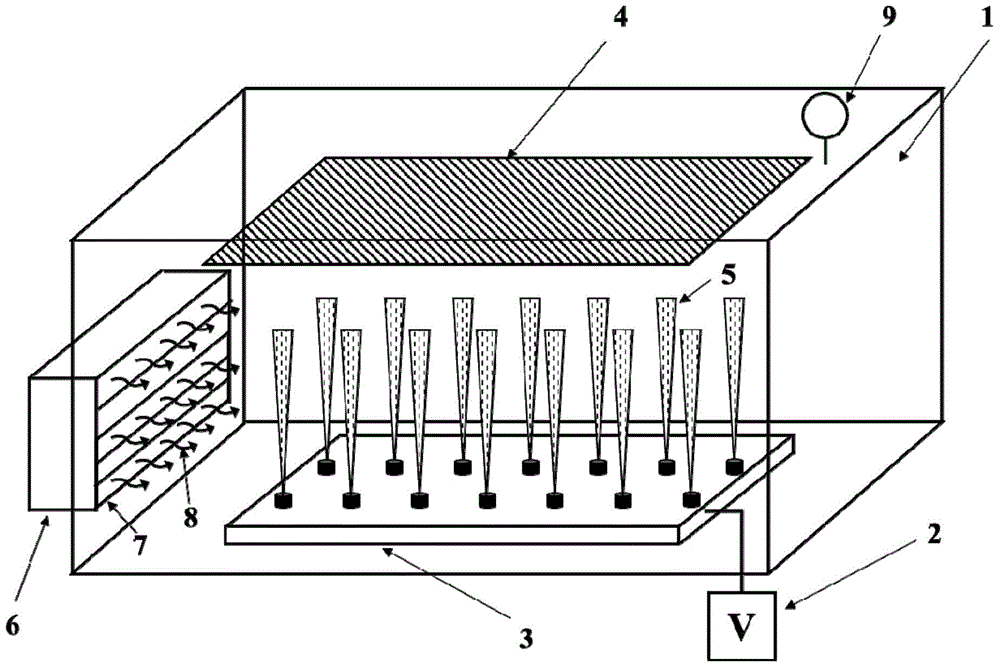

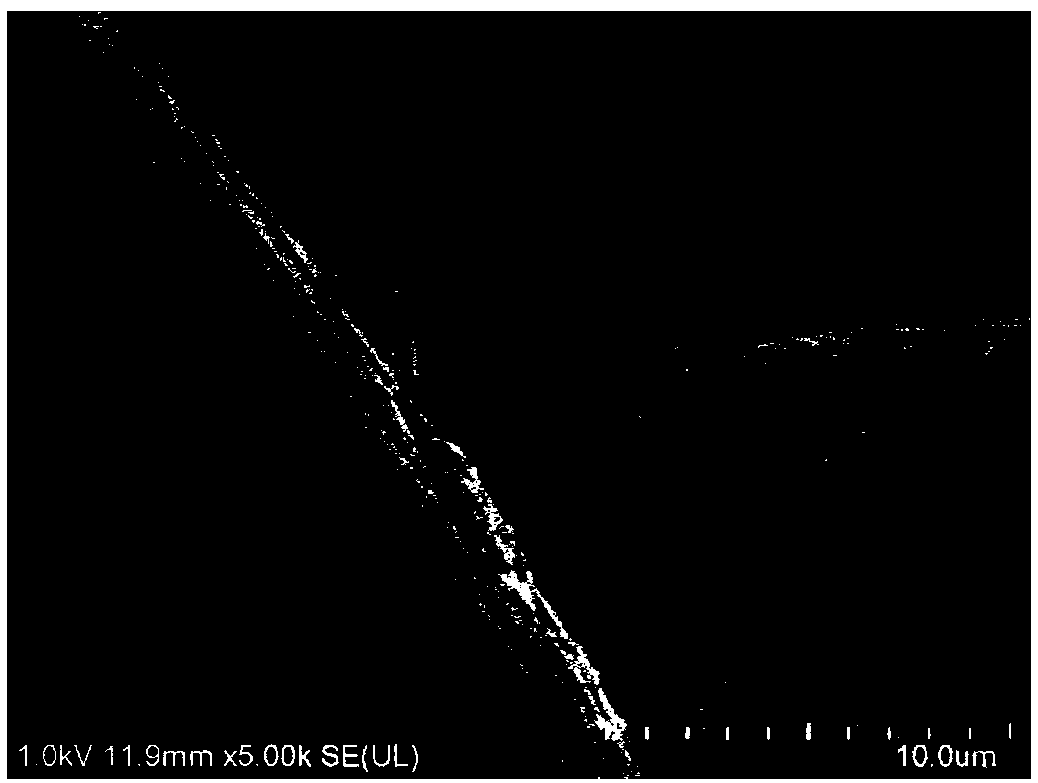

Electrostatic spinning method and device of fiber-based waterproof moisture-permeable film high in moisture-permeable flux

ActiveCN104452109AGood waterproof and moisture permeabilityPorosity is easy to controlNon-woven fabricsPorosityFiber

The invention relates to an electrostatic spinning method and device of a fiber-based waterproof moisture-permeable film high in moisture-permeable flux. The electrostatic spinning method includes that during electrostatic spinning, polymer solution jet flow is injected at a certain included angle with air of a certain temperature and / or lateral air flow of non-solvent steam, and polymer molecules in the jet flow are quickened to be separated and solidified into fibers; water-pressure resistance of the electrostatic spinning film, namely the fiber-based waterproof moisture-permeable film high in moisture-permeable flux is greater than or equal to 100kPa, and the moisture-permeable flux is greater than or equal to 15000g / m<2> / d. The electrostatic spinning device is composed of an electrostatic spinning box, a high-voltage direct-current power supply, an electrostatic spinning hydraulic system, a spinning jet and a receiving base material, and a steam generation and air supply system is mounted on one side of the electrostatic spinning box. The fiber-based waterproof moisture-permeable film produced by the method has the advantages of small bore diameter, controllable adhesion degree and high porosity; the film is high in water-pressure resistance and moisture-permeable flux when used in the waterproof and moisture-permeable areas, and is wide in actual application prospect.

Owner:DONGHUA UNIV

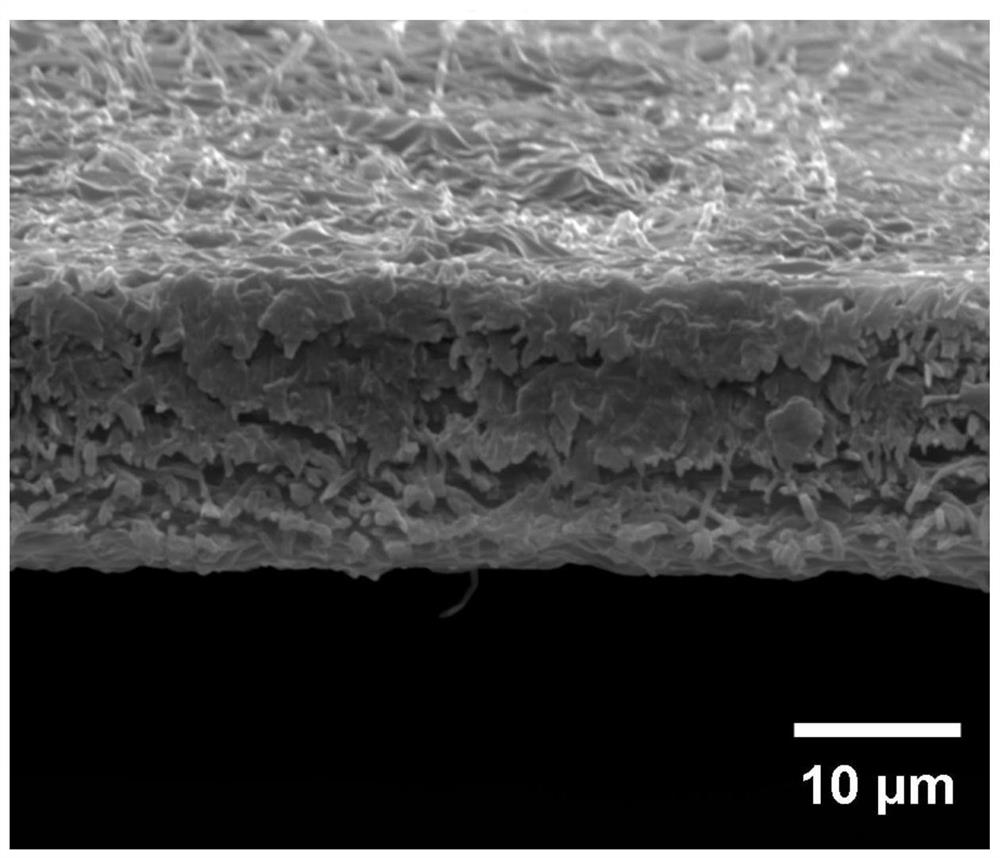

Ultra-high-flux nano-fiber waterproof gas-permeable membrane and preparation method thereof

ActiveCN107326653AAvoid destructionAvoid attenuationLiquid repellent fibresNon-woven fabricsPorosityFiber

The present invention relates to an ultra-high-flux nano-fiber waterproof gas-permeable membrane and a preparation method thereof, and belongs to the field of textile technology material synthesis. The ultra-high-flux nano-fiber waterproof gas-permeable membrane is prepared from the following two components such as bifunctional group-modified nano-silica particles and a polymer nano-fiber membrane, wherein the nano-fiber membrane uses the bifunctional group-modified nano-silica particles as the adhesive between fibers, such that the rub resistance of the membrane material can be enhanced, the nano-fiber surface roughness can be increased, and the water resistance of the fiber membrane can be increased. According to the present invention, the prepared ultra-high-flux nano-fiber waterproof gas-permeable membrane has characteristics of small pore size, high porosity and enhanced adhesion structure, can provide advantages of high water resistance, high moisture permeable flux and high strength in the waterproof and moisture permeation field, has the moisture permeation flux of more than or equal to 18000 g / m<2> / d, has the water resistance of more than or equal to 100 kPa, and has wide practical application prospects.

Owner:温明昊

Regenerated cotton snowflake blended yarn and blending technology thereof

The invention relates to the regenerated cotton spinning technical field, in particular to a regenerated cotton snowflake blended yarn and a blending technology thereof. The regenerated cotton snowflake blended yarn is prepared through the blending technology by using regenerated cotton, fine staple cotton and regenerated polyester as raw materials, the cotton blending percents of regenerated polyester, fine staple cotton and regenerated cotton are 35%, 24% and 41%; and the regenerated cotton accounting for 41% comprises the following components by weight percent: 19% of fly cotton, 4% of flat strips and 18% of comb noil. The blending technology comprises the following specific steps: 1) blending cotton; 2) blowing; 3) carding; 4) drawing; 5) roving; and 6) spinning. Compared with the prior art, deodorization cotton and fine staple cotton are used for blending and the parameters of the blending equipment are adjusted, thus the deodorization cotton blended yarn has good deodorization function, the yarn evenness and strength are increased and neps are reduced. Therefore, the moisture conductivity, air permeability and aesthetic property of the deodorization cotton blended yarn can be increased.

Owner:SHANGHAI SHENAN TEXTILE

Special high-temperature resistant waterproof air and moisture permeable resin for coating printing and preparation method thereof

InactiveCN103265682AImprove heat resistanceGood flexibilityFibre treatmentMoisture permeabilitySilsesquioxane

The invention discloses special high-temperature resistant waterproof air and moisture permeable resin for coating printing and a preparation method thereof. The resin is prepared by the following steps of: obtaining a prepolymer through a reaction between polyether polyol and diisocyanate; and modifying the prepolymer by use of polyhedral oligomeric silsesquioxane to obtain the resin, wherein the average molecular weight of the resin is 50000-150000g / mol, the viscosity is 60000-100000cps / 25 DEG C, and the solid content of the resin is 30-55%. In the polyurethane resin prepared by the method disclosed by the invention, the moisture permeability can reach 7500g / m<2>.24H, and the water pressure resistance is greater than 10000mmH2O; moreover, the polyurethane resin has the processing characteristic of tolerating a temperature of 200-230 DEG C for continuous 30S during coating printing; and the resin has highly-permeable coating and soft and smooth handfeel, and is washable and very suitable for the direct coating and coating printing technology of fabric coating processing.

Owner:宜兴市华夏化工材料有限公司

Preparation method of flexible polyhydroxyl polyester fibers

ActiveCN103774267AAdequate responseReduce wasteArtificial thread manufacturing machinesFilament/thread formingPolyethylene glycolMoisture absorption

The invention relates to a preparation method of flexible polyhydroxyl polyester fibers. The preparation method comprises the steps of mixing dihydric alcohol, polyhydroxyl and polyethylene glycol macromolecules according to certain molar ratio, esterfying in different stages, wherein slightly excessive acid is used in a first esterfying stage to ensure that parts of polyhydric alcohol, which has low ability to be involved esterification reaction, can be fully reacted and grafted into a polyester molecular chain; supplementing dihydric alcohol to regulate terminal carboxyl group of copolyester in a second esterfying stage, and then carrying out condensation polymerization to prepare flexible polyhydroxyl polyester; and performing melt spinning to the flexible polyhydroxyl polyester to prepare the flexible polyhydroxyl polyester fiber. The flexible polyhydroxyl polyester fiber has good moisture absorption performance and softening property, and the fiber can be dyed in a mild condition and has good dyeing performance due to the polyhydroxyl active sites in fiber and ether bonds in flexible chain polyethylene glycol; the flexible polyhydroxyl polyester fiber can be widely applied to preparation of antistatic moisture-absorption and sweat-releasing fibers and used as a closed-fit fabric. The modification effect is remarkable and the method is particularly suitable for melt direct-spinning process.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Polyester yarn having high moisture conductivity performance and manufacturing method thereof

InactiveCN101158074AImproved capillary wickingIncrease the number of poresFilament/thread formingYarnPorosityYarn

The invention relates to a terylene yarn with high moisture-transmitting property and a production method thereof. The terylene yarn is made by blended spinning of a straight-line section terylene fiber and a cruciform section terylene fiber. The production steps include (1) the straight-line section terylene fiber and the cruciform section terylene fiber are selected based on the ratio of fiber number; (2) the terylene yarn is produced after treatment of fiber strand and mixing. Number of inner capillary porosity and capillary wicking of the produced terylene are greatly increased and the moisture-transmitting property is obviously improved. The terylene yarn can be used for producing high moisture-transmitting fabric textile separately or together with other fiber yarn, thereby being widely applicable to fields of cloths, decoration and industry.

Owner:DONGHUA UNIV

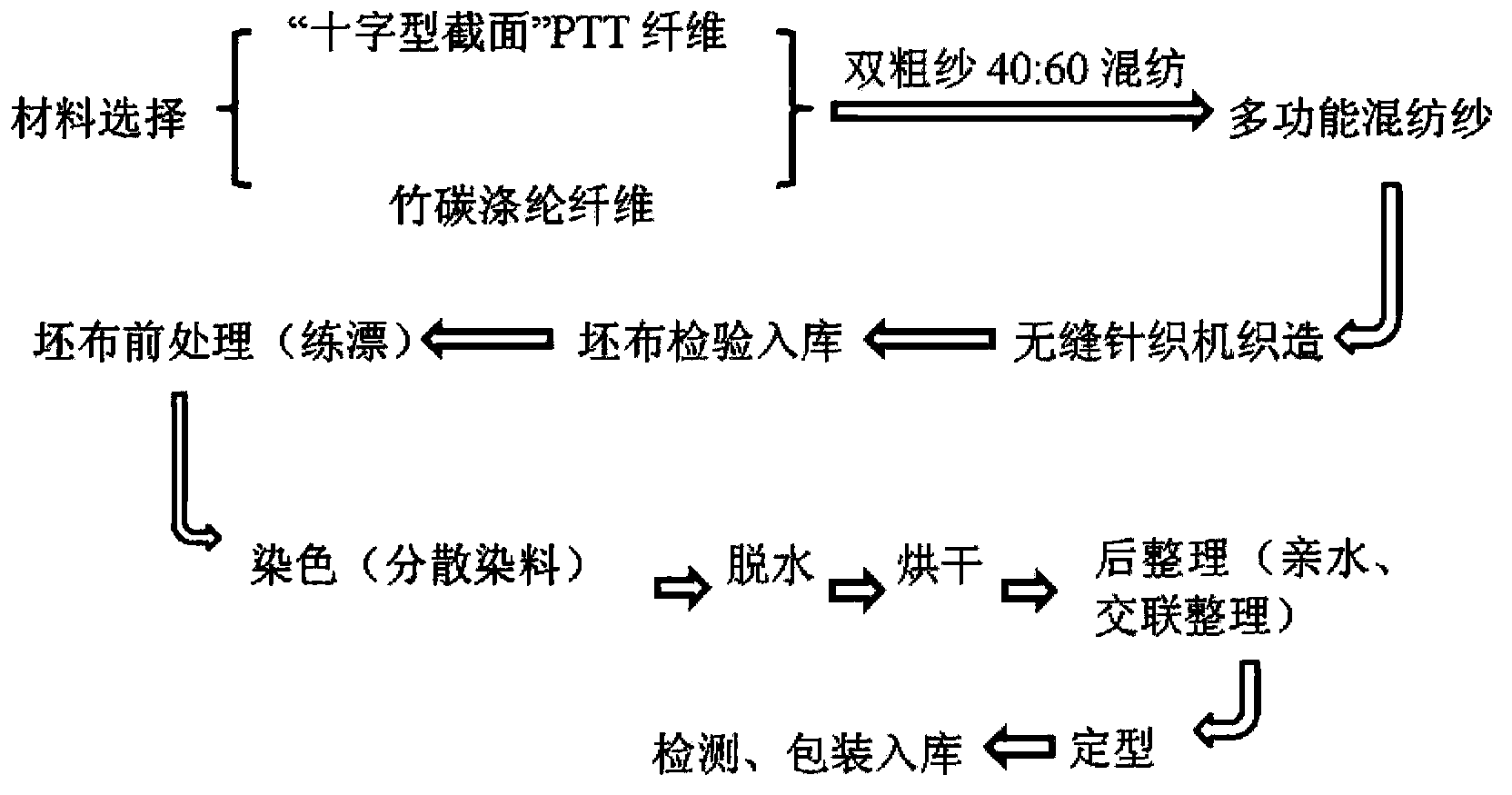

PTT fibre blending yarn with bamboo carbon terylene fibre and cross section and production thereof

A multiple function bamboo-carbon terylene fiber / cross-section PTT fiber (60-40%) union is made by the process: (1) the density of the single fiber thread of the bamboo-carbon terylene fiber is 1-3D; (2) cospinning the bamboo-carbon terylene fiber with the 60-40% cross-section PTT fiber which the density of the single thread is 1-3D. it can solve the problem of the bad moisture absorption and feeling the glassy smooth of the fabric made from the bamboo-carbon terylene fiber, so it can be used for the sports wear and the summer wear.

Owner:DONGHUA UNIV

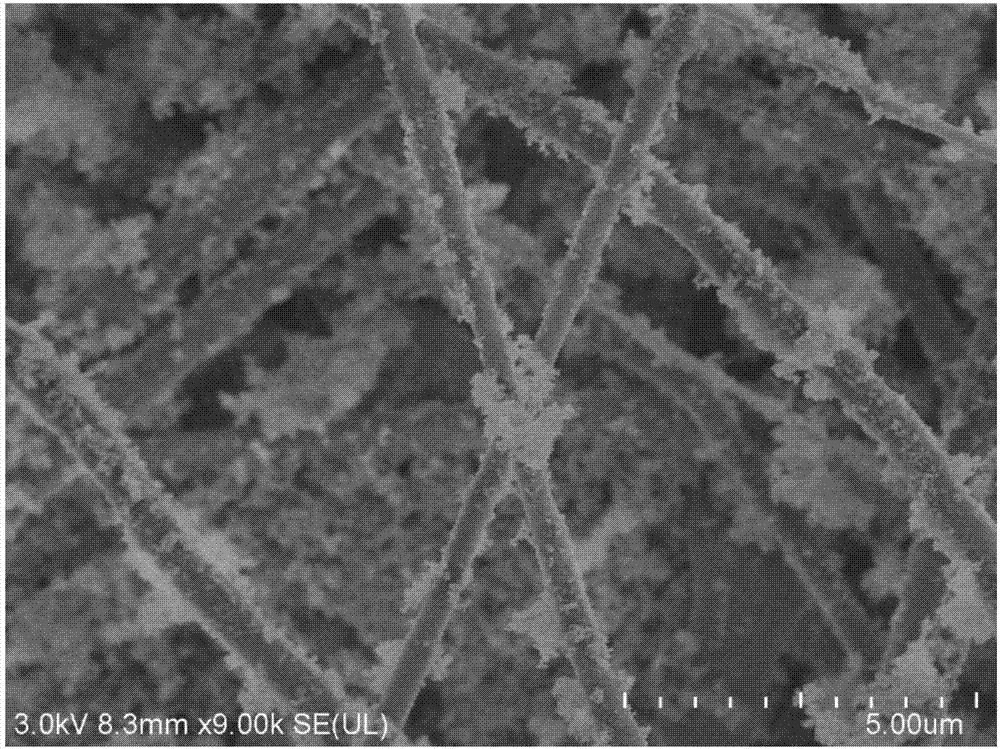

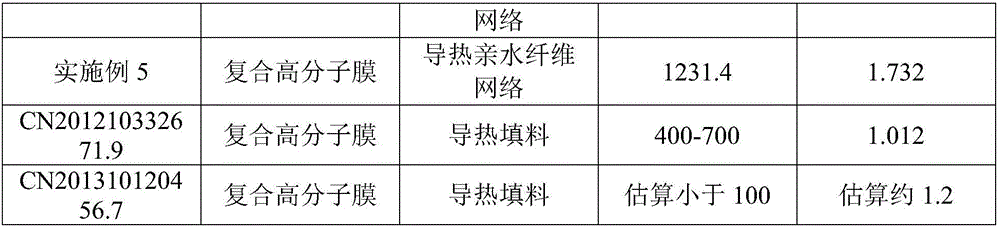

Total heat exchange membrane and preparation method thereof

ActiveCN106521975AHigh moisture permeabilityImprove sensible heat exchange capacityTextile/flexible product manufactureIndirect heat exchangersPolymer scienceMoisture permeability

The invention provides a total heat exchange membrane and a preparation method thereof, and also provides a total heat exchange core, a total heat exchanger and an air-handling unit. The total heat exchange membrane includes a heat conduction hydrophilic porous structure membrane and a hydrophilic polymer composite material coated on the heat conduction hydrophilic porous structure membrane, wherein the heat conduction hydrophilic porous structure membrane is mainly prepared from heat conduction hydrophilic composite fiber by nonwoven fabric process or lamination process, the heat conduction hydrophilic composite fiber includes hydrophilic fiber and high thermally conductive filler, and the hydrophilic polymer composite material comprises a hydrophilic high polymer material and filler. The total heat exchange membrane provided by the invention utilizes heat conduction hydrophilic fiber network as the substrate or skeleton of the total heat exchange membrane, and the substrate or skeleton is coated with the hydrophilic polymer composite material, thus improving the moisture permeability and heat conductivity of the total heat exchange membrane.

Owner:中安瑞材(北京)科技有限公司

Super-hydrophobic water-proof moisture-permeable nanometer fiber material and preparation method thereof

InactiveCN109629113AHigh moisture permeabilitySuperhydrophobicElectro-spinningConjugated synthetic polymer artificial filamentsPorosityFiber

The invention belongs to the field of high polymer materials, and particularly relates to a super-hydrophobic water-proof moisture-permeable nanometer fiber material and a preparation method thereof.The super-hydrophobic water-proof moisture-permeable nanometer fiber material is prepared from super-hydrophobic electrospinning nanometer fibers of a three-dimensional through porous structure through mutually staggered arrangement, wherein the super-hydrophobic electrospinning nanometer fibers are a blend of polystyrene, polyurethane and a hydrophobe modified silicon dioxide. The preparation method comprises the steps that the polystyrene, the polyurethane and the hydrophobe modified silicon dioxide are uniformly dispersed into an organic solvent to form a spinning solution, and preparationis conducted through electrospinning. The fiber film is small in diameter, interfiber pores are small, the porosity is high, the moisture permeable flux is high, the water-proof performance is improved, the moisture permeable performance is improved, and the super-hydrophobic water-proof moisture-permeable nanometer fiber material has wide application prospects in the outdoor and protective fields.

Owner:SHANGHAI UNIV OF ENG SCI

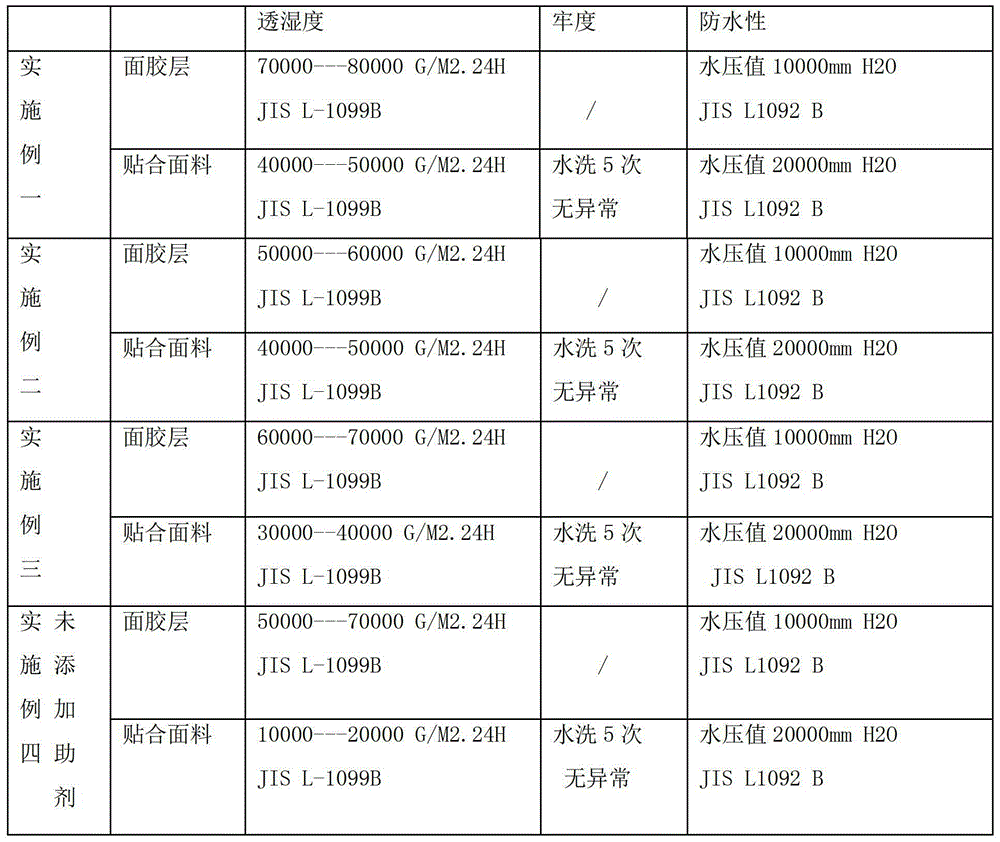

Fitting layer for improving moisture permeability of fitting fabric and preparation method of fitting layer

ActiveCN103334307AGood moisture permeability and waterproof performanceKeep dryFibre treatmentWaxSolvent

The invention discloses a fitting layer for improving the moisture permeability of a fitting fabric and a preparation method of the fitting layer. The fitting layer comprises a bottom adhesive layer and a surface adhesive layer, wherein the bottom adhesive layer comprises the following components by weight ratio: 100 parts of double-liquid type polyurethane resin, 10-50 parts of a bottom adhesive solvent, 1-10 parts of a polyisocyanate bridging agent, 0-5 parts of an accelerator, 5-30 parts of a one-liquid type polyurethane addition agent, 5-20 parts of a single-component moisture reactive polyurethane (PUR) addition agent and 0-5 parts of a softening agent and a tear-resistant agent; the surface adhesive layer comprises the following components by ratio: 100 parts of one-liquid type polyether polyurethane resin, 10-50 parts of a surface adhesive solvent, 0-2 parts of a release agent and 0-5 parts of a wax synthetic amorphous silica antisticking agent. By utilizing the fitting layer, the moisture-permeable and water-proof property of the fitting fabric reaches 40K / 20K.

Owner:TRYD TEXTILE FIBER TECH

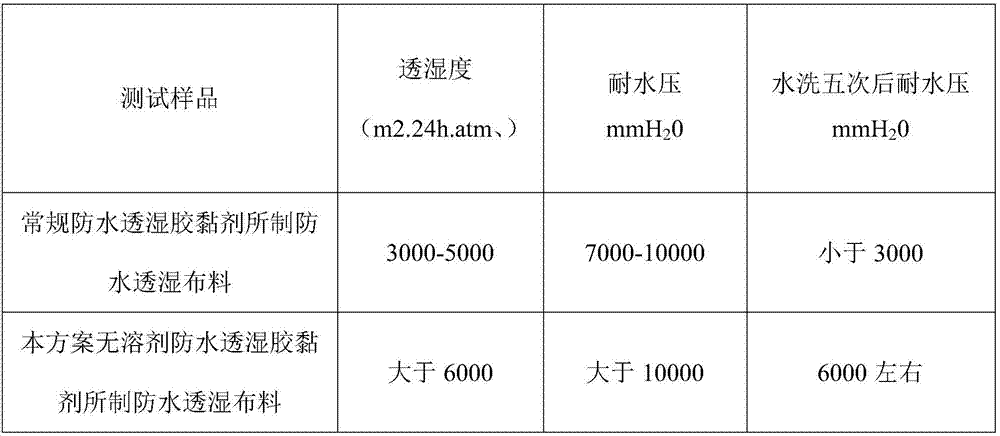

Blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin and preparation method thereof

ActiveCN107417874ALong storage time and stableImprove hydrolysis resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsAntioxidantSolvent free

The invention relates to the technical field of polyurethane resin preparation, in particular to blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin and a preparation method thereof. The blocked double-component, solvent-free, waterproof and moisture-permeable polyurethane resin comprises components A and B, wherein the component A is prepared from toluene isocyanate, 4,4-diphenylmethane diisocyanate, an antioxidant, neopentyl glycol polyester polyol, polytetrahydrofuran polyol, polyoxyethylenepolyol, an organic bismuth catalyst and diacetylmonoxime through reactions; the component B is a mixture of diethylenetriamine and isophorone diamine, and the weight percentage of diethylenetriamine is 40%-70%; the weight ratio of the component A to the component B is 1:(0.05-0.1). The waterproof and moisture-permeable polyurethane resin has long storage time and stable finished product performance and has excellent moisture permeability, hydraulic pressure resistance and wash resistance.

Owner:ZHEJIANG JOYA POLYMER TECH

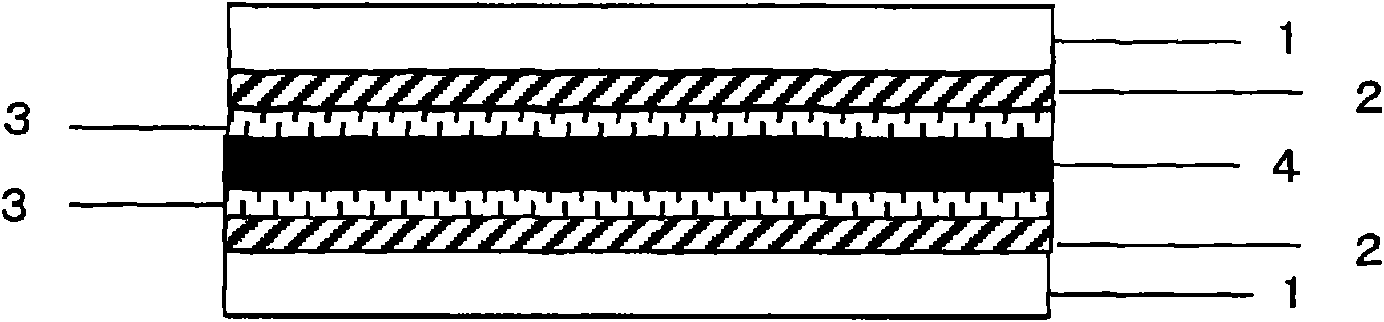

Disposable wearing article

InactiveCN1655748APrevent leakageAvoid heat and humidityAbsorbent padsBaby linensPlastic filmEngineering

A disposable wearing article 1A comprises a liquid-pervious topsheet 2, a liquid-impervious backsheet 3 and a liquid-absorbent panel 4 interposed between the top- and backsheets 2, 3. The backsheet 3 is formed by a breathable and hydrophobic first fibrous nonwoven fabric layer f2 underlying the panel 4, a breathable and liquid-impervious plastic film f4 underlying the first fibrous nonwoven fabric layer f2 and a breathable and hydrophobic second fibrous nonwoven fabric layer f3 underlying the film f4. In a zone occupied by the panel 4, the first fibrous nonwoven fabric layer f2 is intermittently joined to an under surface of the panel 4 by means of a hot melt adhesive and the film f4 is intermittently joined to the first fibrous nonwoven fabric layer f2 by means of the hot melt adhesive.

Owner:UNI CHARM CORP

Production technology of PTT fiber seamless knitted underwear with high wicking function

ActiveCN103361867AHigh moisture permeabilityStrong moisture wickingWeft knittingDyeing processYarnPolytrimethylene terephthalate

The invention belongs to the field of functional knitted product production, and relates to a production technology of PTT (Polytrimethylene Terephthalate) fiber knitted seamless underwear with a high wicking function. The production technology comprises the steps that a PTT fiber with the crossed cross section and a bamboo carbon polyester fiber are taken as raw materials; two rough yarns and a double rough yarn feeding technology are adopted to manufacture a blended yarn; the blended yarn is knitted by a seamless knitting machine to form seamless knitted underwear grey cloth; and the seamless knitted underwear grey cloth is subjected to scouring and bleaching pretreatment, then dyeing treatment, and dehydration, drying, afterfinish and shaping treatment to from a PTT fiber seamless knitted underwear product with the high wicking function. The PTT fiber seamless knitted underwear with the high wicking function has the significant characteristics of moisture absorption, wicking, easiness in curing, bacteriostasis and the like; particularly, a wicking speed, the fastness to washing, the dimensional stability and the like of the product reach design requirements very well; and the design rationality of the product, the practicability of the product, the scientific rationality of the production technology and the significance of economic and social benefits are reflected.

Owner:浙江芬雪琳针织服饰有限公司

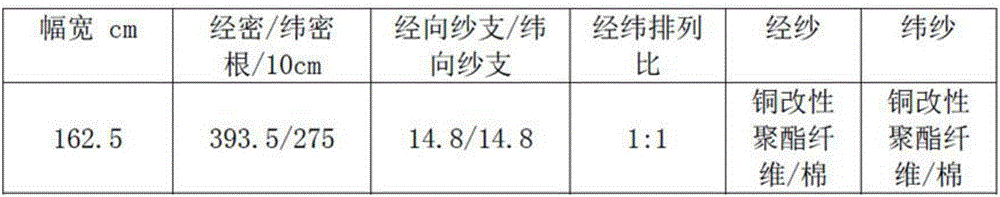

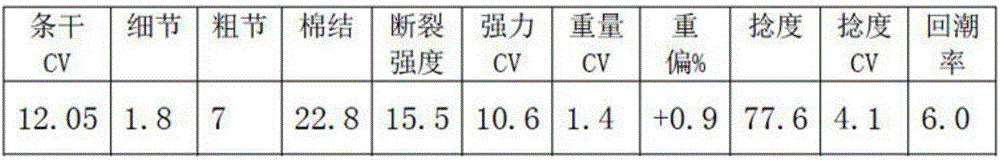

Antibacterial non-dyeing ecological multielement color modulation series yarn and fabric

The invention provides antibacterial non-dyeing ecological multielement color modulation series yarn and fabric. The antibacterial non-dyeing ecological multielement color modulation yarn is formed through blending of copper-modified polyester fibers, original ecological viscose fibers and other common fibers. The yarn count of the antibacterial non-dyeing ecological multielement color modulation yarn is 9.8-36tex; the antibacterial non-dyeing ecological multielement color modulation fabric is woven from the antibacterial non-dyeing ecological multielement color modulation yarn through warping, sizing, drafting and weaving. The raw materials for the yarn include the original ecological viscose fibers with a natural khaki primary color, the copper-modified polyester fibers with a green-red color and excellent antibacterial and bacteriostatic functions, and other common fibers, so that the biological chromatography requiring no dyeing treatment is realized and the excellent antibacterial and bacteriostatic effects are achieved. The fabric is woven from the yarn of the invention; the selected yarn has colors itself and has the excellent antibacterial effect, so that the fabric achieves the combined effects of bacterium resistance, environmental protection, practicability and aesthetic effect.

Owner:RUGAO CITY DINGYAN TEXTILE

Superfine fiber fabric and manufacturing process thereof

ActiveCN109154135ARich apparent colorTwo-color effect realizedDomestic upholsteryLayered productsColor effectEngineering

Superfine fiber fabric comprises a base portion and a surface portion. The base portion is composed of fixed island type sea-island filament or / and common filament; the surface portion is composed ofshort fibers. The fabric has a non-woven structure in which the base portion and the surface portion are mutually complexed. The invention relates to a manufacturing process of the superfine fiber fabric, wherein the fixed island-type sea-island filament or / and an ordinary filament of the base portion thereof are knitted by a weft knitting, warp knitting or weaving process, and then a napping layer is formed on the surface of the superfine fiber fabric by a napping treatment; the napping layer is covered by the short fiber; the non-woven structure is formed by the non-woven complex technologybetween the short fibers and the napping layer on the surface of the matrix; after immersion, drying, shedding, dyeing and post-treatment, the superfine fiber fabric is obtained. The superfine fiber fabric fills in the blank of needle punched non-woven fabrics with thickness less than 0.5 mm, and has very good two-color effect and high-grade beauty.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

Aspergillus flavus infection resistance method for xanthan gum composite membrane covered peanuts

InactiveCN103053686ABarrierInhibition of germinationSeed preservation by coatingBiotechnologyAspergillus flavus

The invention discloses an aspergillus flavus infection resistance method for xanthan gum composite membrane covered peanuts, comprising the following steps of adding peanut shell powder into a citric acid solution, conducting microwave extraction, leaching and concentrating the solution; adding absolute ethyl alcohol into the solution; standing, centrifuging, precipitating, freezing and drying; smashing to obtain peanut water-soluble dietary fiber; adding the peanut water-soluble dietary fiber into distilled water, and mixing uniformly; adding the xanthan gum under a stirring condition; removing bubble in vacuum to obtain xanthan gum water-soluble dietary fiber composite membrane coating materials; coating the coating materials on peanuts; packaging the peanuts; and storing the peanut at a normal temperature. The xanthan gum composite membrane covered peanuts prepared by the method can resist the aspergillus flavus infection, restrains the growth of the aspergillus flavus, prevents the peanut fat from being oxidized and is stored for a long term and suitable for industrial production.

Owner:QINGDAO JIADE FOODS

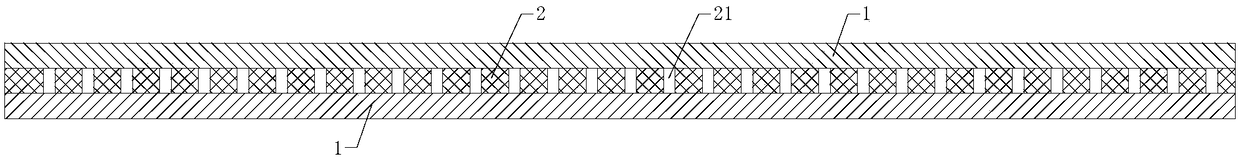

Compound spunlace non-woven fabric

InactiveCN109177353AReasonable structureHigh tensile strengthSynthetic resin layered productsCellulosic plastic layered productsCompound structureAdditional values

The invention discloses a compound spunlace non-woven fabric. The compound spunlace non-woven fabric has a three-layer compound structure; spunlace non-woven fabric layers are served as upper and lower layers; a reinforced layer is served as a middle layer; the upper spunlace non-woven fabric layer, the middle reinforced layer and the lower spunlace non-woven fabric layer are integrally fixed. Thecompound spunlace non-woven fabric disclosed by the invention has a reasonable structure; the three-layer compound structure is adopted; the spunlace non-woven fabric layers are served as upper and lower layers, the reinforced layer is served as the middle layer and the three layers are integrally fixed through spunlace, so that the problem of low strength of the traditional spunlace non-woven fabric is relieved and the tensile strength of the spunlace non-woven fabric is greatly promoted; uniform small holes are densely distributed in the reinforced layer, so that the moisture conductivity of the compound non-woven fabric is enhanced, the strength of the spunlace non-woven fabric is promoted and the additional value of the product is increased under the condition that the performances ofthe spunlace non-woven fabric are not changed.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

Waterproof moisture-permeable film and preparation method and application thereof

ActiveCN113123128AHigh porosityStrong structural adjustabilityLiquid repellent fibresNon-woven fabricsFiberEngineering

The invention provides a waterproof moisture-permeable film and a preparation method and application thereof. The waterproof moisture-permeable film takes a fiber film as a base material, has the advantages of wide spinnable raw material range, small fiber membrane aperture, high porosity, strong structure adjustability and the like, and can obtain higher water pressure resistance and moisture-permeable flux compared with waterproof and moisture-permeable fabrics. A blocked solvent isocyanate cross-linking agent is utilized, after the cross-linking agent is deblocked, the cross-linking agent and active groups in a waterproof agent are subjected to a cross-linking reaction, hydrophobic chain segments are stably coated on the surface of the fiber, and the durability of a waterproof agent coating is improved. After 50 times of abrasion circulation, the contact angle is not obviously changed, the water pressure resistance and the moisture-permeable flux are basically kept unchanged after 30 times of washing, and the waterproof moisture-permeable film has a wide application prospect in the fields of outdoor jackets, field military garments and medical treatment and public health.

Owner:WUYI UNIV

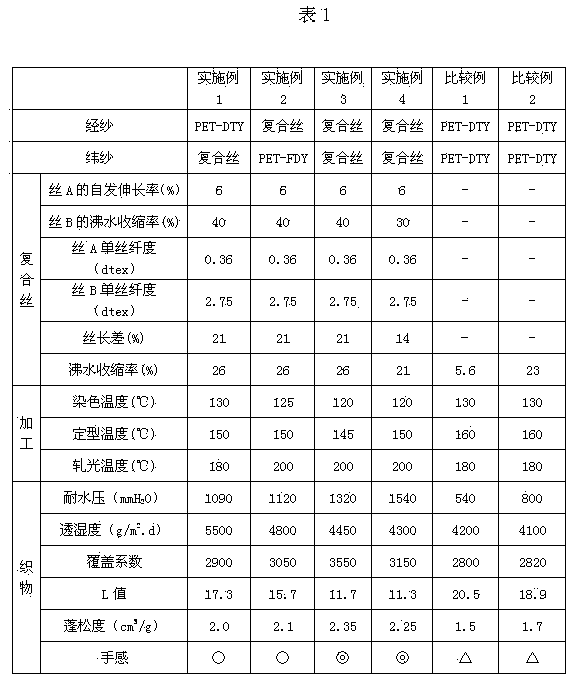

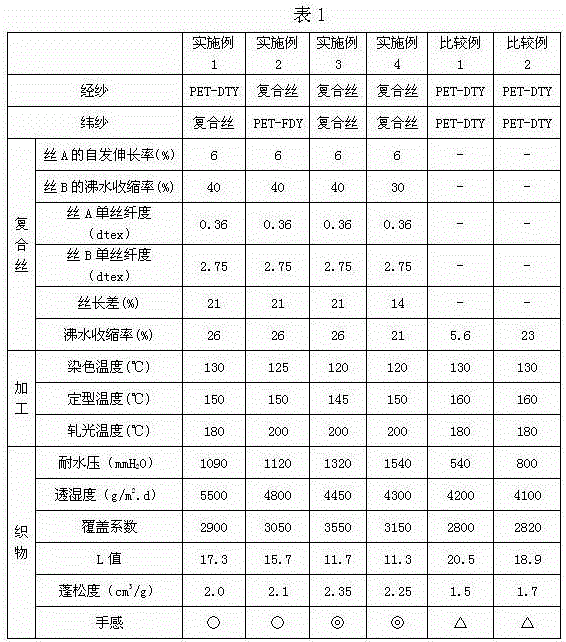

Waterproof and moisture permeable fabrics and production method thereof

ActiveCN103774320AHigh water pressure resistanceHigh moisture permeabilityHeating/cooling textile fabricsWoven fabricsYarnMoisture permeability

The invention discloses waterproof and moisture permeable fabrics and a production method thereof. Yarns of at least one type of the warp direction and the weft direction of the waterproof and moisture permeable fabrics are formed by composite filaments which are formed by spontaneous elongation filaments A and high shrinkage filaments B; the sum of covering coefficients of the warp direction and the weft direction of the waterproof and moisture permeable fabrics is more than 2700; the waterproof pressure in the preliminary stage is more than 1000 mmH2O; the moisture permeability is more than 3500 g / m<2>.d. The waterproof and moisture permeable fabrics are plump and soft in touch, comprise a certain body, are comfortable to wear and good in windproof and rainproof function and are ideal materials for sports and leisure.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

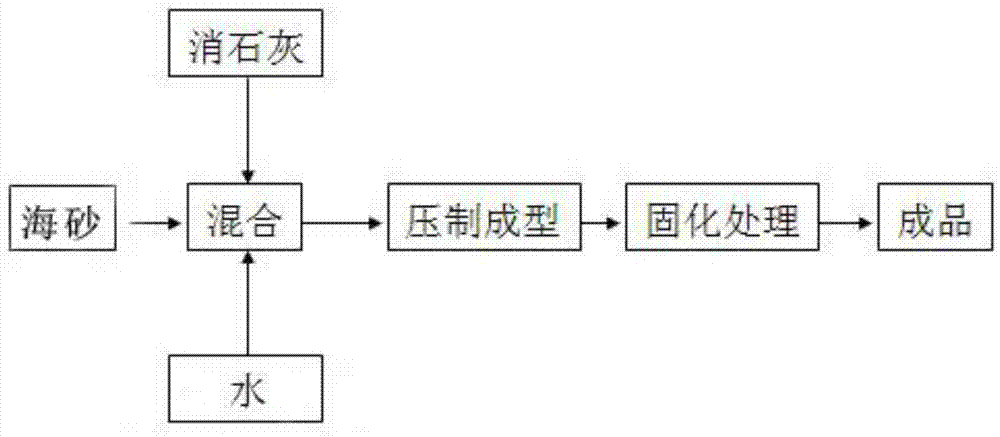

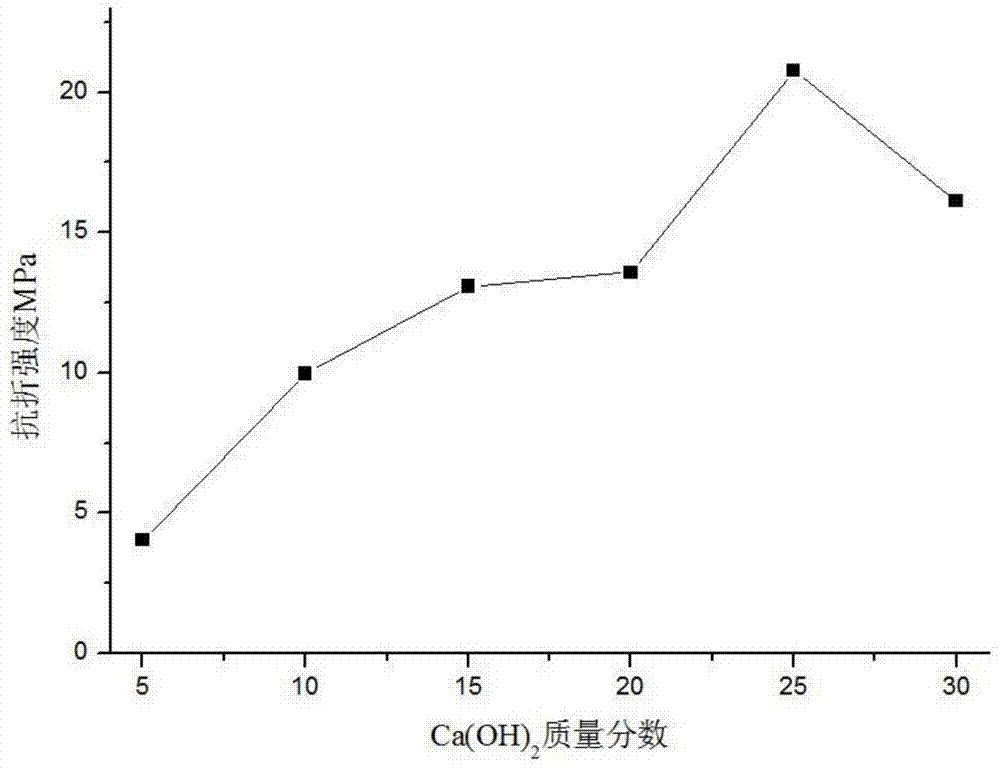

Method for wet-type burning sea sand to produce high strength building material

The invention relates to a method for wet-type burning sea sand to produce a high strength building material. The method comprises the following steps: weighing sea sand and slaked lime at a weight ratio of 60-90%: 10-40%, stirring and mixing uniformly, adding sea water, mixing, and performing compression moulding to obtain the building material proximate matter green body; demoulding the green body and performing wet type burning to obtain the building material proximate matter product. Through detection, the breaking strength is 20-24MPa, the adding amount of sea water is 5-20% of sea sand and slaked lime; sea sand is a dinas which is directly exploited on the sea land and corroded by the sea water without being desalted; the wet-type burning process comprises the steps of putting the green body in a hydrothermal reactor, and performing hydrothermal solidification for 9-24h at the temperature of 120-240 DEG C. The local material sea sand in the coastal city and the island with rich reserves and low utilization rate is solidified to form a wall brick, a floor tile, a square brick, an artificial fish reef and an ocean river reinforcing dam; the island building cost and time are greatly saved and the method is particularly suitable for the development and construction of a remote island (such as Nansha islands).

Owner:TONGJI UNIV

Skin-friendly low-permeability ES composite short fiber for hot air non-woven fabric surface layer and preparation method of skin-friendly low-permeability ES composite short fiber

InactiveCN110055618AIncrease irritationOptimize raw material contentFilament/thread formingConjugated synthetic polymer artificial filamentsFiberIrritation

The invention discloses a skin-friendly low-permeability ES composite short fiber for a hot-air non-woven fabric surface layer. The ES composite short fiber has a skin-core structure and consists of acore layer and a skin layer, wherein the core layer comprises the following raw materials in parts by weight: 85-90 parts of polypropylene, 5-9 parts of ethylene propylene copolymer, 14-18 parts of acrylic acid-acrylamide super absorbent resin and 6-11 parts of inulin; and the skin layer comprises the following raw materials in parts by weight: 80-85 parts of polyethylene, 10-15 parts of methyl methacrylate grafted modified polyethylene, 8-12 parts of ethylene propylene copolymer, 4-7 parts of polyvinyl alcohol, 7-15 parts of superfine pearl powder and 12-17 parts of sodium polyacrylate superabsorbent resin. The skin-friendly low-permeability ES composite short fiber for the hot air non-woven fabric surface layer has the advantages of skin-friendly property, moisture absorption, breathability, elasticity, no irritation to skin, sanitation, antibiosis and the like; and the amount of reverse osmosis after water absorption is small, and the skin-friendly low-permeability ES composite short fiber belongs to the low reverse osmosis type.

Owner:福建省福地化纤科技有限公司

Waterproof and moisture-permeable composite TPU film

PendingCN112497877AHigh moisture permeabilityImprove waterproof performanceSynthetic resin layered productsLaminationPolymer sciencePtru catalyst

The invention discloses a waterproof and moisture-permeable composite TPU film, which comprises the following raw materials by weight: 100-120 parts of thermoplastic polyurethane; 50-70 parts of polystyrene; 40-60 parts of polyisobutylene; 50-60 parts of dimethyl terephthalate; 50-60 parts of ethylene glycol; 10-20 parts of a catalyst; 30-40 parts of polypropylene; 50-60 parts of triethanolamine;3-5 parts of azodiisobutyronitrile; 10-20 parts of methanol; 25-35 parts of polytetrafluoroethylene; 5-9 parts of a curing agent; and the balance of water. The raw materials are put into a reaction kettle for reaction according to the steps. According to the invention, the composite TPU film integrating moisture permeability and waterproofness can be realized, and a material layer A in the composite TPU film can enable the composite TPU film to have higher strength, durability and chemical corrosion resistance.

Owner:浙江长鸿纺织科技有限公司

Method for preparing moisture-absorbent and quick-drying fabric

ActiveCN111118624AImprove moisture transfer efficiencyImprove transfer efficiencyWeft knittingFilament/thread formingYarnThermodynamics

The present invention relates to a method for preparing moisture-absorbent and quick-drying fabric. The method comprises: preparing fully-drawn yarn of textured yarn: in the process of preparing the round sheath-core composite fiber from high-viscosity PET and low-viscosity PET according to the FDD process, changing spinneret holes from circular to trilobal, performing cooling by using cross air blow, controlling the arrangement of the trilobal spinneret holes on a spinneret plate to meet certain conditions, and performing relaxation heat treatment to obtain the fully-drawn yarn of the textured yarn; and taking the cotton fiber and the fully-drawn yarn of the textured yarn as the raw materials for processing, wherein the processing process is: weaving on the machine, finalizing the designin advance, performing pre-treatment, performing dyeing, performing soft treatment, and performing scutching and setting. The prepared moisture-absorbent and quick-drying fabric has the moisture absorption that: a water absorption rate is greater than or equal to 250%, a drip diffusion time is less than or equal to 1.9 seconds, and a wicking height is greater than or equal to 142mm; and the quick-drying performance that: a evaporation rate is greater than or equal to 0.38g / h. According to the method provided by the present invention, the problem of increasing the moisture conductivity of thefiber without using functional finishing is solved, and the moisture absorption and quick-drying performance of the fabric can be improved as a whole.

Owner:JIANGSU HENGLI CHEM FIBER

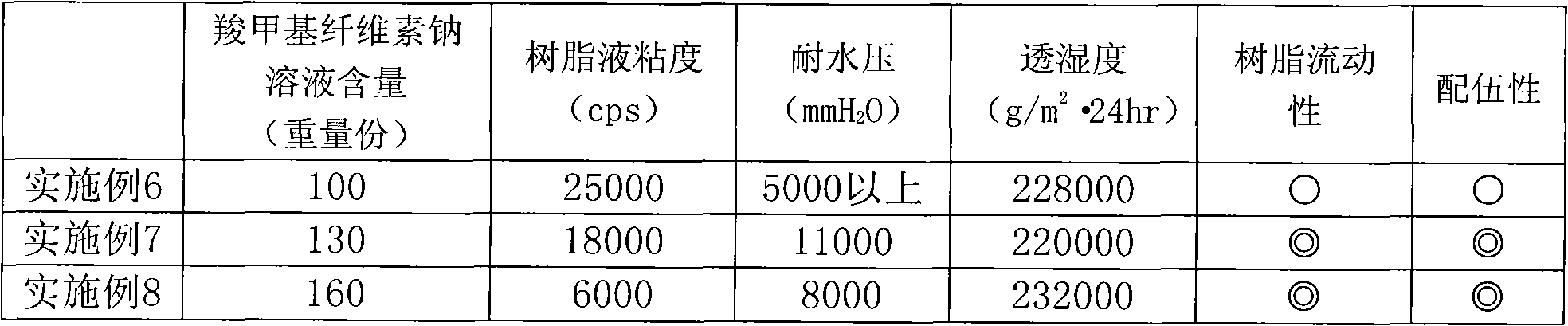

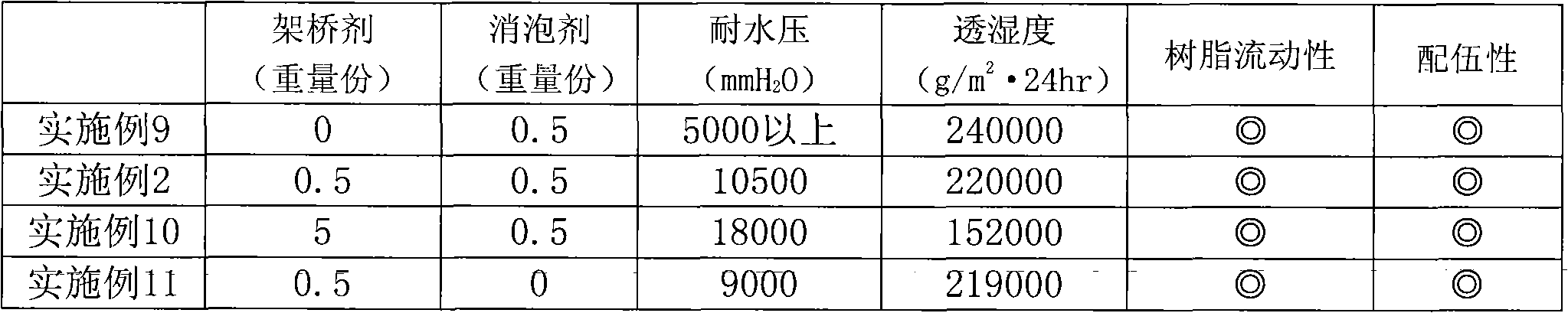

Functional membrane, production method and fabric

ActiveCN103030963ASolve pollutionImprove waterproof performanceSynthetic resin layered productsMicrometerMoisture permeability

The invention discloses a functional membrane, a production method and a fabric using the functional membrane. The functional membrane is mainly formed by waterborne polyurethane resin and sodium carboxymethylcellulose, the thickness of the functional membrane is 5-50 micrometers, the water pressure resistance of the functional membrane is more than 5000mmH2O, and the moisture permeability of the functional membrane is 150000-250000g / m.24hr. The fabric, to which the functional membrane is attached, has higher water resistance, air permeability and moisture permeability, feels soft and is suitable for various outdoor sport suits.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Microstructure condensation cloth for all-weather water collection

ActiveCN114165941AReduce evaporation lossLow costWater conservationRefrigeration machinesFiberWater use

The invention discloses a micro-structure condensation cloth for all-weather water collection, which is characterized in that the micro-structure condensation cloth overcomes gravity to realize continuous directional water transportation on the premise of not consuming extra energy by constructing a microscopic spine structure on the surface of a fiber prepared from a radiation refrigeration composite material, so that all-weather condensed water collection is realized. Compared with the prior art, the micro-structure condensation cloth not only has the functional characteristics of excellent directional water transportation capacity, radiation refrigeration performance and the like, but also has the excellent structural characteristics of softness, light weight, large surface area and the like, and a condensation device with a controllable shape and structure can be constructed; a user can design different structures according to actual requirements so as to adapt to complex application requirements of multiple scenes. The method can be applied to areas where available surface water resources are deficient due to drought, semi-drought, water pollution, water and soil loss and the like, the problem of water shortage can be relieved to a certain extent, and a candidate choice is provided for production and domestic water.

Owner:ZHEJIANG UNIV

Preparation method of special fluorine-containing dispersed resin mixture and microporous film

ActiveCN103483748BHigh nanofiber contentHigh physical and mechanical strengthSynthetic resin layered productsTetrafluoroethylenePolymer science

The invention discloses a preparation method for a special fluorine-containing dispersion resin mixture. The method comprises the following steps: blending a tetrafluoroethene homopolymer dispersion emulsion with a fluorine-containing hot-meltable processing dispersion emulsion according to a dry weight ratio of 19: 1 to 3: 7; then diluting an obtained blend with deionized water into a blended emulsion with solid content of 10 to 20%; and successively carrying out demulsification through high-speed stirring, coagulation and drying so as to obtain the special fluorine-containing dispersion resin mixture. The mixture is blended with lubricating oil so as to prepare a fluorine-containing microporous film. The fluorine-containing microporous film has high content of nanometer silk fiber and high physical and mechanical strength; when the microporous film is applied in the industries of filtration and clothes and compounded with a fabric, an obtained composite fabric has high water-pressure resistance, moisture permeability and air permeability and excellent tensile strength and can better realize market acceptance.

Owner:烟台海德新材料有限公司

Wet-method production process for micro-porous membrane

InactiveCN110183717AMeet the requirements of waterproof and moisture permeabilityImprove ventilationMoisture permeabilityPorous membrane

The invention discloses a wet-method production process for a micro-porous membrane. The process comprises the steps of firstly, preparing a mixed solution of a DMF system according to a set ratio andset operating steps, coating PP or PET release paper with the mixed solution, dipping the coated PP or PET release paper in a DMF aqueous solution and clear water, and separating out silicon dioxidefrom a coating through a gel state of PU-DMF-H2O; and carrying out pressurizing through a pressurizing roller, replacing DMF remaining in the coating in a replacement tank, and carrying out three-stepdrying to completely evaporate the DMF in the coating. The micro-porous membrane prepared by the process has the air permeability (JIS standard cc) of 0.205 to 0.226 and the moisture permeability B-1of 21,423 g / m<2> / 24h to 32,769 g / m<2> / 24h. The water pressure resistance (JIS standard) is higher than 15,000mm and can meet the requirements of a majority of functional clothing on waterproofing andmoisture permeability. The micro-porous membrane has a micro-porous structure with uniform diameter and low wet impedance. The micro-porous membrane has no swelling property and good film surface strength. A film mentioned in the invention is made from a polyurethane material, and the material is naturally decomposed in 3 to 5 years due to action of humidity and microbes when the material is buried in soil.

Owner:JIAXING DEYONG TEXTILES CO LTD

Polarizing plate protective film, polarizing plate and resistive touch panel

InactiveCN101568862ALow moisture permeabilitySmall size changePolarising elementsCoatingsEngineeringPolarizer

Disclosed is a polarizing plate protective film which is obtained by forming a silane coupling agent layer on one side of a cyclic olefin resin film. Also disclosed are a polarizing plate wherein such a protective film is arranged on one side or both sides of a polarizer through the isocyanate silane coupling agent layer, and a resistive touch panel using such a polarizing plate.

Owner:GUNZE LTD

A kind of waterproof and moisture-permeable fabric and production method thereof

ActiveCN103774320BHigh water pressure resistanceHigh moisture permeabilityHeating/cooling textile fabricsWoven fabricsYarnPolymer science

The invention discloses a waterproof and moisture-permeable fabric and a production method thereof. The yarn in at least one of the warp and weft directions of the fabric is a composite yarn formed of spontaneously elongated yarn A and high-shrinkage yarn B; and the warp and weft of the fabric are The sum of the covering coefficients in the direction is above 2700, the initial water pressure resistance is > 1000mmH2O, and the moisture permeability is > 3500g / m2.d. Feel plump and soft, with a certain body. It is comfortable to wear, has good windproof and rainproof functions, and is an ideal material for sports and leisure.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com