Super-hydrophobic water-proof moisture-permeable nanometer fiber material and preparation method thereof

A nanofiber, super-hydrophobic technology, applied in fiber processing, conjugated synthetic polymer rayon, non-woven fabrics, etc., can solve the problem of not taking into account the moisture permeability, high porosity, and unable to meet the practical application needs in the field of outdoor and protection and other problems, to achieve the effect of increasing moisture permeability, reducing losses, and improving waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of Octadecyltrichlorosilane Modified Silica (OTS-SiO 2 ) nanoparticles

[0036] 1g SiO 2 Nanoparticles were mixed with 100mL of absolute ethanol, and after ultrasonic treatment for 1h, stirred at 400rpm and room temperature for 30min to obtain uniform SiO 2 ethanol dispersion;

[0037] Mix 2mL of octadecyltrichlorosilane (OTS) with 8mL of absolute ethanol to obtain a mixed solution of octadecyltrichlorosilane and ethanol;

[0038] to SiO 2 Add a mixed solution of octadecyltrichlorosilane and ethanol to the ethanol dispersion, continue to react at 50°C for 24h, centrifuge and wash with absolute ethanol three times, and dry in a vacuum oven at 80°C for 24h to obtain octadecyltrichlorosilane modified Silica nanoparticles, the FTIR image is as follows figure 1 Shown, octadecyltrichlorosilane modified silica particles at 781cm -1 、1080cm -1 SiO 2 Si-O-Si and Si-O stretching vibration peaks at 1467cm -1 、2847cm -1 、2909cm -1 A new absorption peak ap...

Embodiment 2

[0047] (1) Preparation of octadecyltrichlorosilane modified silica nanoparticles: the process is the same as in Example 1 step (1), and the FTIR characteristic peaks of octadecyltrichlorosilane modified silica nanoparticles are the same as in Example 1.

[0048] (2) Preparation of spinning solution: the process is the same as step (2) of Example 1, the difference is that polystyrene and polyurethane with a mass ratio of 4:1 are added to N,N-dimethylformamide (DMF) solvent , a polystyrene / polyurethane (PS / PU) solution with a concentration of 10 wt % was obtained.

[0049] Disperse octadecyltrichlorosilane modified silica nanoparticles in N,N-dimethylformamide (DMF) to obtain a 10wt% concentration of octadecyltrichlorosilane modified silica dispersion .

[0050] (3) Preparation of waterproof and moisture-permeable fiber membrane by electrospinning: the process is the same as step (3) of Example 1.

Embodiment 3

[0053] (1) Preparation of octadecyltrichlorosilane modified silica nanoparticles: the process is the same as in Example 1 step (1), and the FTIR characteristic peaks of octadecyltrichlorosilane modified silica nanoparticles are the same as in Example 1.

[0054] (2) Preparation of spinning solution: the process is the same as step (2) of Example 1, the difference is that polystyrene and polyurethane with a mass ratio of 4:1 are added to N,N-dimethylformamide (DMF) solvent , magnetically stirred for 5 h to obtain a polystyrene / polyurethane (PS / PU) solution with a concentration of 20 wt %.

[0055] Octadecyltrichlorosilane-modified silica nanoparticles were dispersed in N,N-dimethylformamide (DMF) to obtain a 15wt% concentration of octadecyltrichlorosilane-modified silica dispersion .

[0056] (3) Preparation of waterproof and moisture-permeable fiber membrane by electrospinning: the process is the same as step (3) of Example 1.

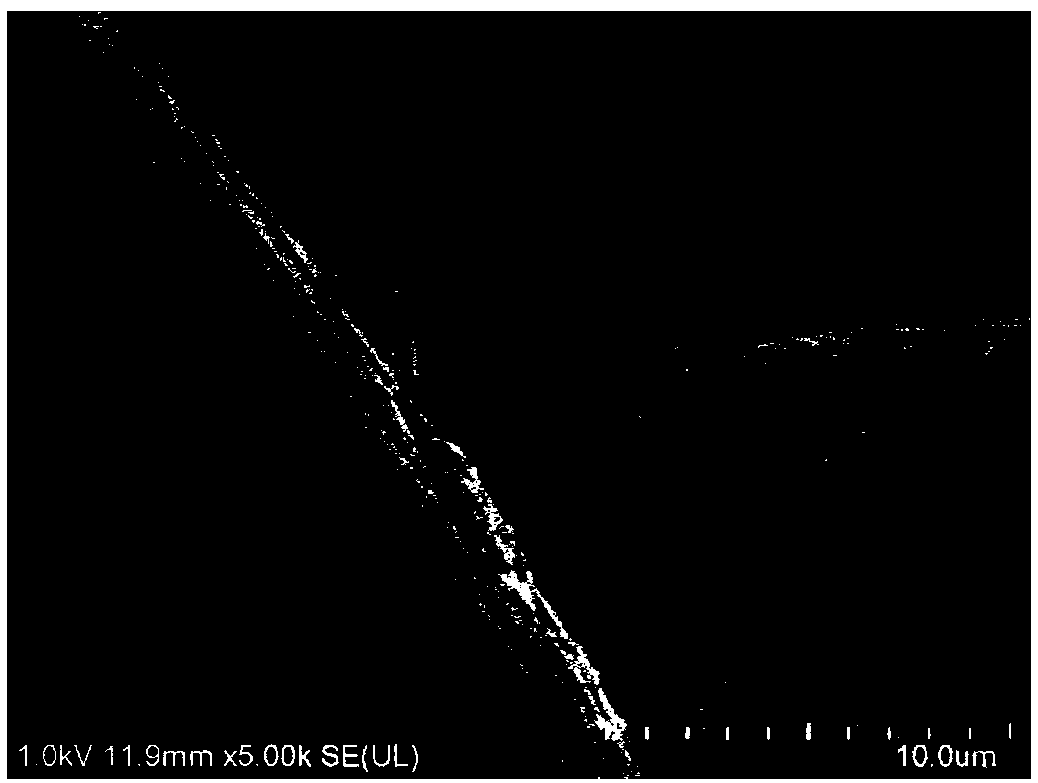

[0057] Prepared PS / PU / OTS-SiO 2 The SEM imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

| water pressure | aaaaa | aaaaa |

| water pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com