Manufacturing method of moisture-conducting and temperature-conducting wicking polyester fibers

A technology of polyester fiber and manufacturing method, which is applied in the field of manufacturing moisture-conducting, temperature-conducting and wicking polyester fibers, can solve the problems of poor tow restraint, weak structure, and easy damage, and reduce broken filaments, reduce and Silk, the effect of improving the degree of irregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for manufacturing moisture-conducting and temperature-conducting core-absorbing polyester fibers. The process flow is: polyester melt is transported to the spinning box → metering pump metering → multi-arc "ten"-shaped spinneret holes extrusion → cooling → clustering Oiling → coiling;

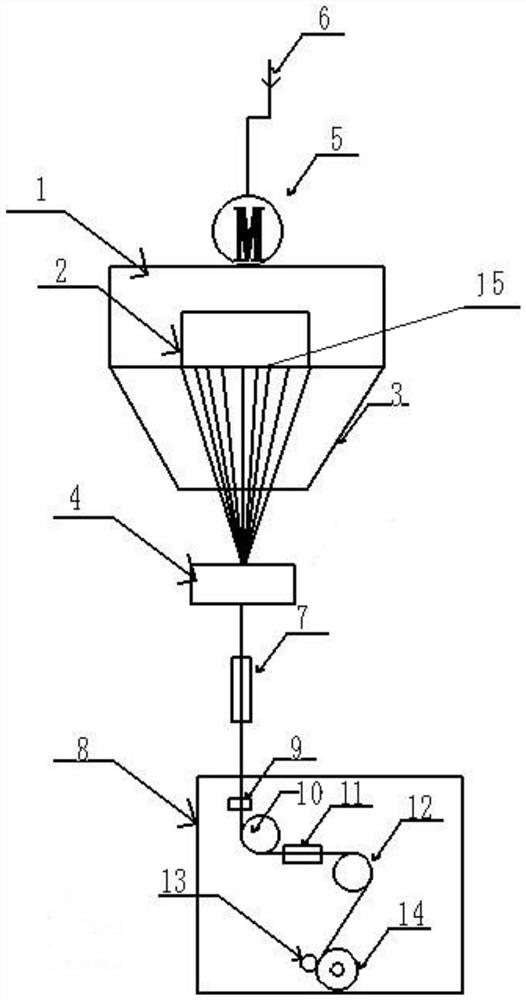

[0045] Such as figure 1 As shown, the production equipment used includes a spinning box 1, a ring blowing cooling device 3, an oiling device 4, a spinning tunnel 7 and a winding machine 8 arranged sequentially from top to bottom;

[0046] A metering pump 5 (which is connected to the melt pipeline 6) and a spinning assembly 2 are arranged in the spinning box 1; a spinneret 15 is arranged at the bottom of the spinning assembly 2;

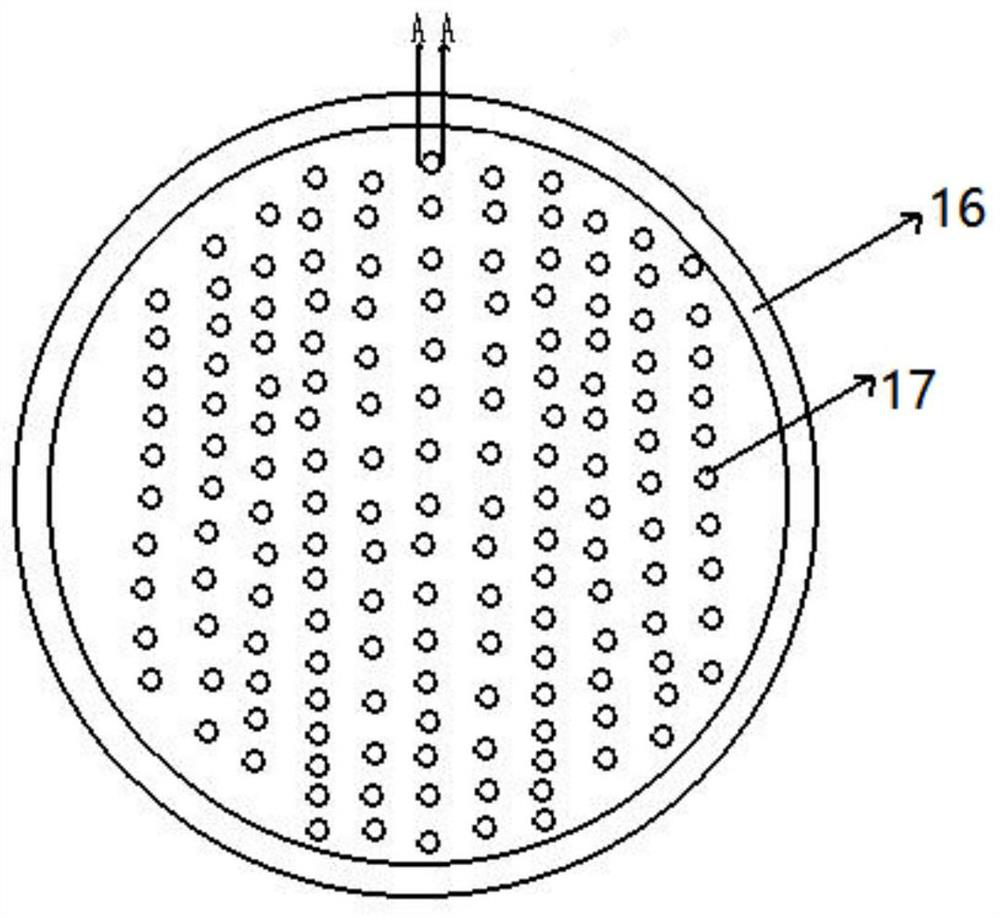

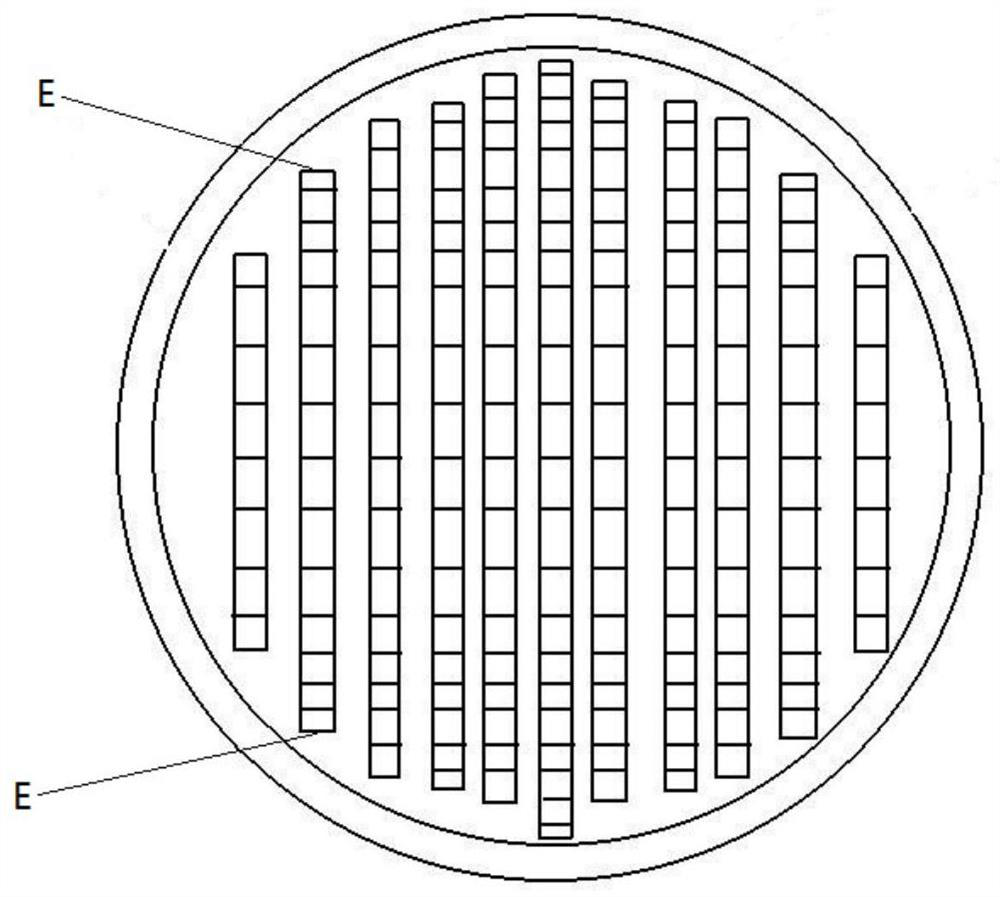

[0047] Such as figure 2 , 3 , 4 and 7, the spinneret 15 includes the spinneret body 16; the spinneret channel on the spinneret body 16 is formed by connecting the guide hole 17, the bottom hole 18 and the spinneret hole 19 in sequence, and the botto...

Embodiment 2

[0061] A method for manufacturing moisture-conducting and temperature-conducting core-absorbing polyester fibers. The process flow is: polyester melt is transported to the spinning box → metering pump metering → multi-arc "ten"-shaped spinneret holes extrusion → cooling → clustering Oiling → coiling;

[0062] The production equipment used includes a spinning box, a ring air cooling device, an oiling device, a spinning tunnel and a winding machine arranged in sequence from top to bottom;

[0063] A metering pump and a spinning assembly are installed in the spinning box; a spinneret is installed at the bottom of the spinning assembly;

[0064] The spinneret includes the spinneret body; the spinneret channel on the spinneret body is sequentially connected by the guide hole, the bottom hole and the spinneret hole, and the longitudinal section of the bottom hole is hyperbolic; the feed of the spinneret body There are multiple grooves arranged in a matrix on the surface, and each g...

Embodiment 3

[0070] A method for manufacturing moisture-conducting and temperature-conducting core-absorbing polyester fibers. The process flow is: polyester melt is transported to the spinning box → metering pump metering → multi-arc "ten"-shaped spinneret holes extrusion → cooling → clustering Oiling → coiling;

[0071] The production equipment used includes a spinning box, a ring air cooling device, an oiling device, a spinning tunnel and a winding machine arranged in sequence from top to bottom;

[0072] A metering pump and a spinning assembly are installed in the spinning box; a spinneret is installed at the bottom of the spinning assembly;

[0073] The spinneret includes the spinneret body; the spinneret channel on the spinneret body is sequentially connected by the guide hole, the bottom hole and the spinneret hole, and the longitudinal section of the bottom hole is hyperbolic; the feed of the spinneret body There are multiple grooves arranged in a matrix on the surface, and each g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Irregularity | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

| Irregularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com