Preparation method of high-heat-conduction hexagonal boron nitride/polyimide composite material

A technology of hexagonal boron nitride and polyimide, which is applied in the field of composite material preparation, can solve problems such as poor compatibility, and achieve the effects of improved thermal conductivity, higher operating temperature, and lower equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of surface modified hexagonal boron nitride

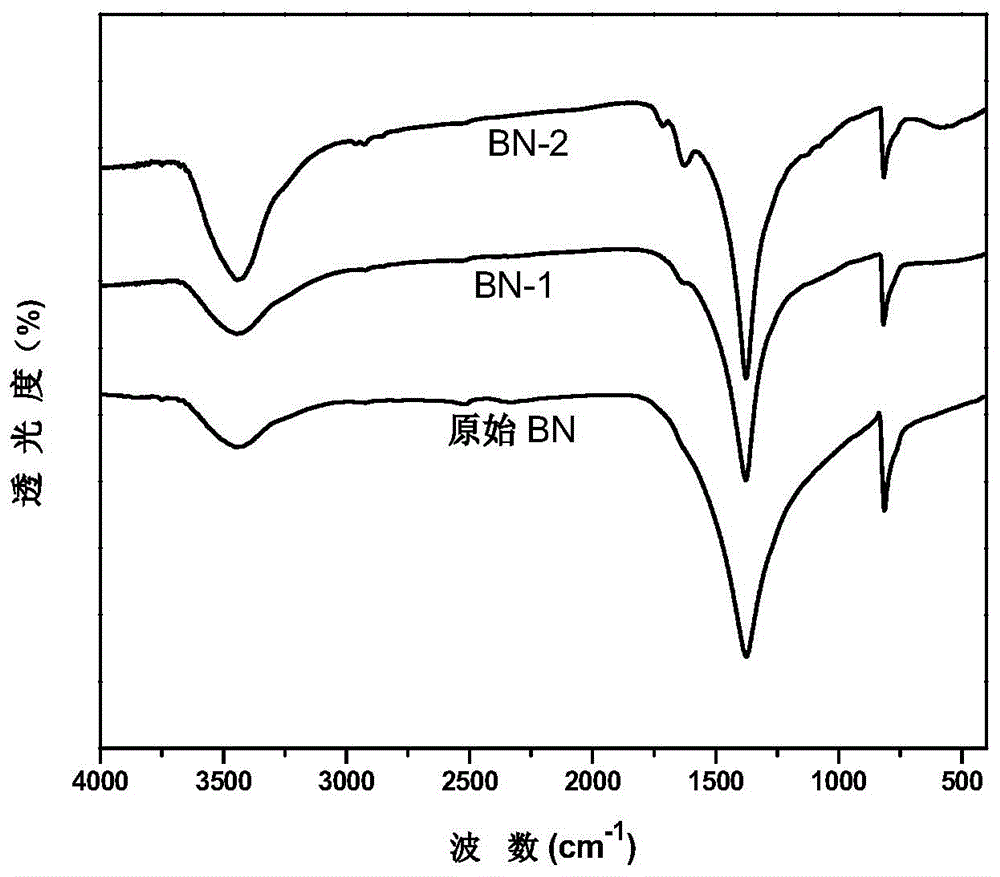

[0032] (1) After mixing 2g h-BN with 30ml concentrated nitric acid (65-68% solute mass fraction) and 90ml concentrated sulfuric acid (95-95% solute mass fraction), ultrasonically disperse at room temperature for 2h, then react in a water bath at 70°C After 72h, the product was washed with water to neutrality after the reaction was completed, and the pretreated hexagonal boron nitride product was obtained after drying, which was recorded as BN-1. After drying in an oven, an infrared test was carried out, as shown in figure 1 shown.

[0033](2) Put the activated 4A molecular sieve into N,N-dimethylacetamide for 24h, then distill under reduced pressure, collect fractions at about 75°C to obtain anhydrous N,N-dimethylacetamide.

[0034] (3) Add 1g of BN-1 to a 250ml three-necked flask, add 100ml of N,N-dimethylacetamide solvent treated in step (2) under nitrogen protection, and stir ultrasonically for 2 hours, so...

Embodiment 2

[0041] 1. Preparation of surface modified hexagonal boron nitride

[0042] (1) After mixing 2g h-BN with 30ml concentrated nitric acid (65-68% solute mass fraction) and 90ml concentrated sulfuric acid (95-95% solute mass fraction), ultrasonically disperse at room temperature for 2h, then react in a water bath at 70°C After 72 hours, after the reaction, the product was washed with water until neutral, and dried to obtain a pretreated hexagonal boron nitride product, which was designated as BN-1.

[0043] (2) Put the activated 4A molecular sieve into N,N-dimethylacetamide for 24h, then distill under reduced pressure, collect fractions at about 75°C to obtain anhydrous N,N-dimethylacetamide.

[0044] (3) Add 1g of BN-1 to a 250ml three-necked flask, add 100ml of N,N-dimethylacetamide solvent treated in step (2) under nitrogen protection, and stir ultrasonically for 2 hours, so that the hexagonal boron nitride is evenly dispersed in N,N-dimethylacetamide solvent.

[0045] (4) Un...

Embodiment 3

[0049] 1. Preparation of surface modified hexagonal boron nitride

[0050] (1) After mixing 2g h-BN with 30ml concentrated nitric acid (65-68% solute mass fraction) and 90ml concentrated sulfuric acid (95-95% solute mass fraction), ultrasonically disperse at room temperature for 2h, then react in a water bath at 70°C After 72 hours, after the reaction, the product was washed with water until neutral, and dried to obtain a pretreated hexagonal boron nitride product, which was designated as BN-1.

[0051] (2) Put the activated 4A molecular sieve into N,N-dimethylacetamide for 24h, then distill under reduced pressure, collect fractions at about 75°C to obtain anhydrous N,N-dimethylacetamide.

[0052] (3) Add 1.5g of BN-1 to a 250ml three-necked flask, add 150ml of N,N-dimethylacetamide solvent treated in step (2) under nitrogen protection, and stir ultrasonically for 2h, so that the hexagonal boron nitride is uniformly Dispersed in N,N-dimethylacetamide solvent.

[0053] (4) Un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com