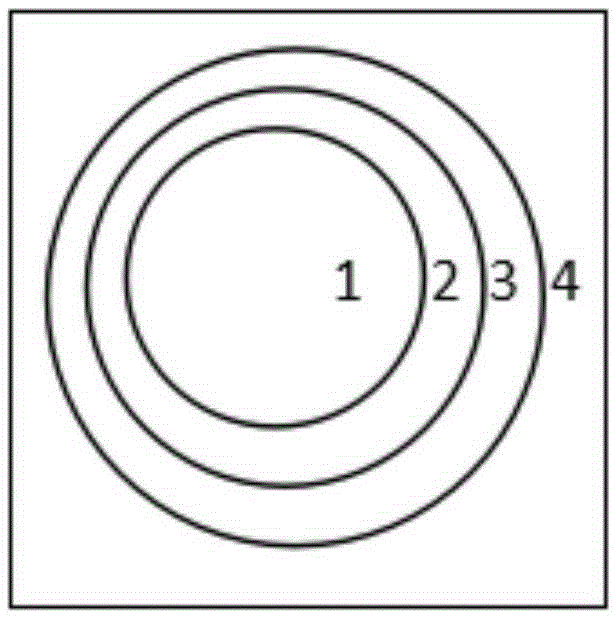

Polymer-based dielectric energy storage composite film material with core-shell structure and preparation method

A technology of composite thin film and shell structure, which is applied in the field of polymer-based dielectric energy storage composite thin film materials and preparation, can solve problems that need to be developed, and achieve the goal of reducing interface polarization, alleviating uneven electric field distribution, and high dielectric constant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

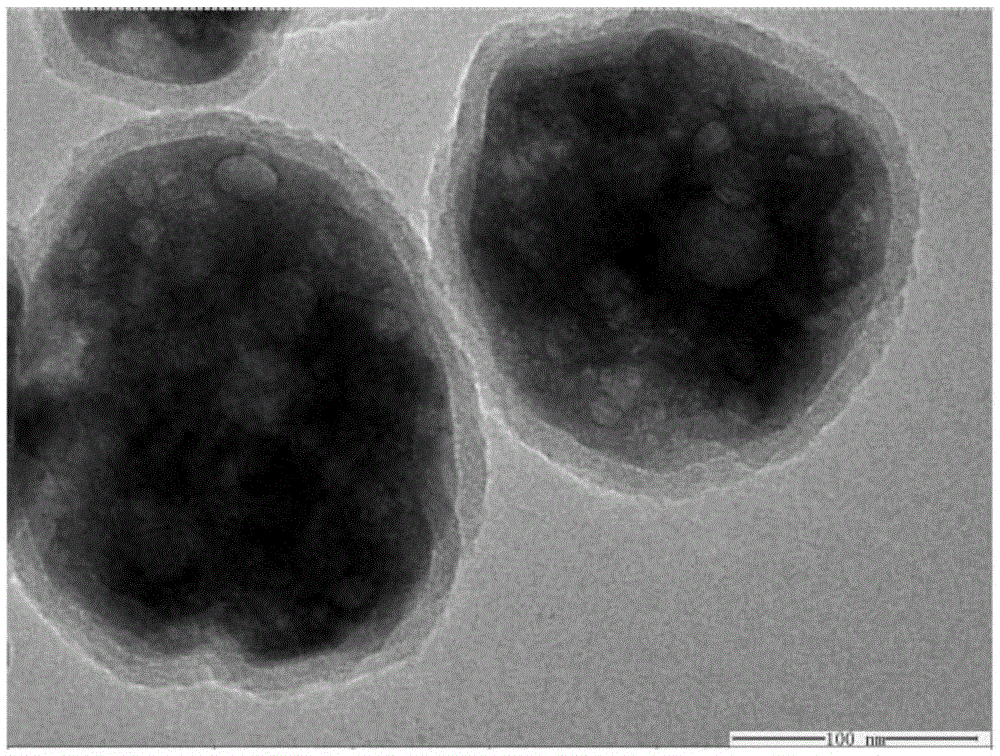

Embodiment 1

[0067] Weigh 3gBaTiO 3 Put it into a three-necked flask, add 70ml of hydrogen peroxide, and reflux with magnetic stirring at 106°C for 8h. Centrifugal washing, drying, and grinding to obtain hydroxylated barium titanate (BaTiO 3 -OH); Weigh 1gBaTiO 3 -OH, dissolve in 200ml of ethanol, add 0.01g of PVP, stir for 3h while ultrasonic, add 4.5ml of ammonia water, adjust the pH to 8~9; take 1ml of tetraethyl orthosilicate and dissolve in 6ml of ethanol, add a few drops of acetic acid , the dissolved solution was added dropwise to BaTiO 3 -PVP solution, stirred for 3 hours while ultrasonic, centrifuged, washed, dried and ground. The obtained particles were calcined at 600 °C for 2 h to obtain surface-coated silica (SiO 2 ) shell filler. Weigh 0.0937g of nanoparticles and place them in DMF, an organic solvent, and disperse them with ultrasonic vibration until the nanofillers form a stable suspension in the solvent; add 0.5g to the suspension and stir to dissolve it completely; ...

Embodiment 2

[0069] Weigh 3gBaTiO 3 Put it into a three-necked flask, add 70ml of hydrogen peroxide, and reflux with magnetic stirring at 106°C for 8h. Centrifugal washing, drying, and grinding to obtain hydroxylated barium titanate (BaTiO 3 -OH); Weigh 1gBaTiO 3 -OH, add 80ml of isopropanol as a solvent, ultrasonication for 1h, drop 2~5 drops of TC-2 after the filler is evenly dispersed, and magnetically stir and reflux at 120°C for 4h to obtain BaTiO with TC-2 attached to the surface 3 (BT-TC-2) Weigh 0.4725g of Ba(OH) 2 and 0.397g of Sr(OH) 2 , solvent isopropanol, drop a few drops of acetic acid, ultrasonically dissolve, the dissolved Ba(OH) 2 and Sr(OH) 2 Add the solution dropwise into the BT-TC-2 solution, stir it magnetically for 0.5h, then add 0.0015mol / L tetra-n-butyl titanate solution dropwise to the solution; then add sodium hydroxide solution dropwise to adjust the pH to 9.8, Magnetically stirred and refluxed at 120°C for 24h, centrifuged, washed, and dried; the prepared ...

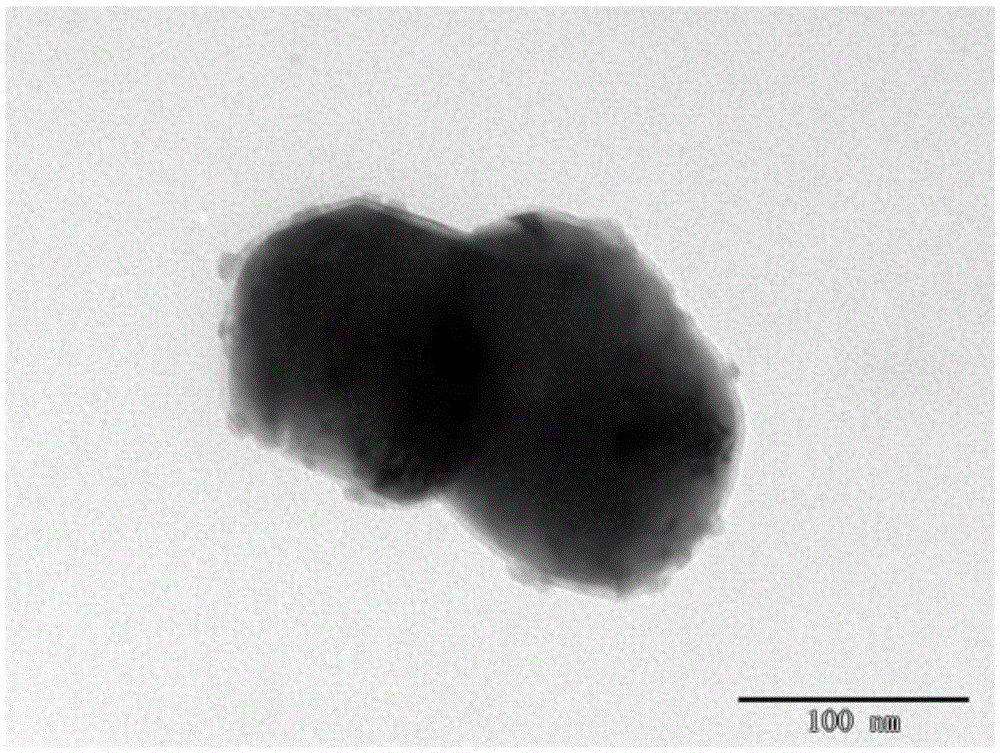

Embodiment 3

[0071] Weigh 3gBaTiO 3 Put it into a three-necked flask, add 70ml of hydrogen peroxide, and reflux with magnetic stirring at 106°C for 8h. Centrifugal washing, drying, and grinding to obtain hydroxylated barium titanate (BaTiO 3 -OH); weigh 1g of BaTiO 3 -OH, dissolved in 80ml of isopropanol, stirred with ultrasound for 30min to promote its dissolution, added dropwise an appropriate amount of TC-2, magnetically stirred at 70°C for 2h, centrifuged, and dried; the obtained nanoparticles were calcined at 600°C for 2h , to obtain surface-coated TiO 2 Shell BaTiO 3 (BTTO); Weigh 1gBTTO, put it into 80ml of isopropanol and ultrasonically stir for 30min, then add an appropriate amount of TC-2 dropwise, and stir magnetically at 70°C for 2h to obtain surface-modified BTTO-TC-2; weigh 0.0937gBTTO-TC -2 Nanoparticles are placed in an organic solvent (such as DMF), and dispersed by ultrasonic vibration until the nanofiller forms a stable suspension in the solvent; add 0.5g to the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com