High-thermal-conductivity die casting aluminum alloy and preparation method thereof

A technology of casting aluminum alloy and high thermal conductivity, which is applied in the field of metal materials, can solve the problems of the thermal conductivity gap of Al-Mg-Si deformed aluminum alloy, etc., and achieve the effect of improving thermal conductivity, meeting the scope of industrial applications, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

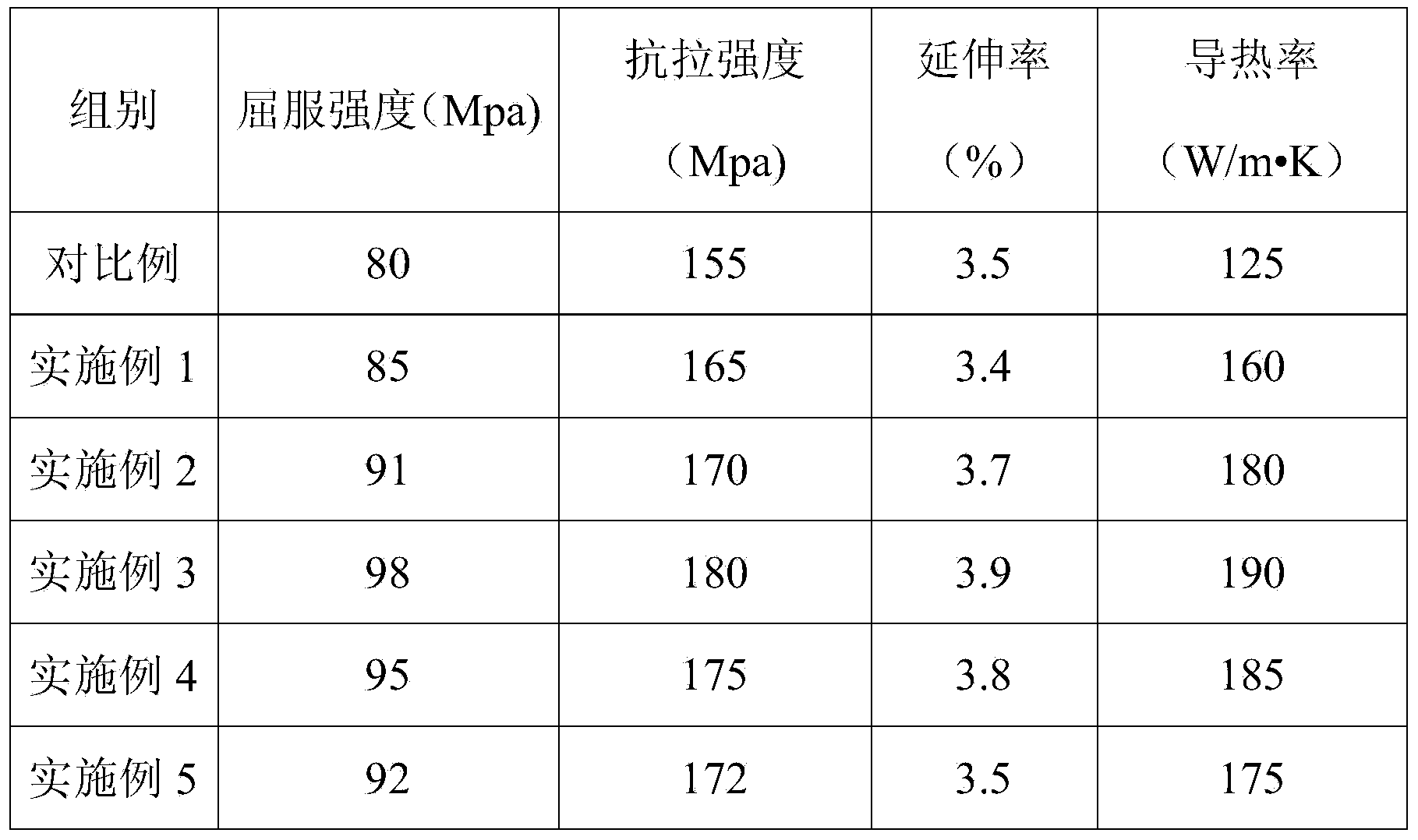

Examples

Embodiment 1

[0021] The weight percent of each component of the high thermal conductivity die-casting aluminum alloy in Example 1 of the present invention is: silicon: 10.5wt%; cobalt: 0.1wt%; iron: 0.2wt%; boron: 0.01wt%; titanium: 0.05wt%; The total sum of other impurities is less than or equal to 0.2%, and the balance is aluminum.

[0022] The preparation method of the high thermal conductivity die-casting aluminum alloy according to Example 1 of the present invention comprises the following steps:

[0023] 1) Drying: Dry the prepared raw materials: pure aluminum (purity ≥99.9wt%), aluminum-silicon master alloy, aluminum-iron master alloy, aluminum-boron master alloy, aluminum-titanium master alloy and cobalt oxide powder. , where Al and Co are dried at 100°C, while AlSi, AlFe, AlB and AlTi master alloys are dried at 150°C, and cobalt oxide powder is dried at 200°C;

[0024] 2) Melting: Use a crucible resistance furnace for melting, first preheat the resistance furnace to 200°C, and th...

Embodiment 2

[0027] The weight percent of each component of the high thermal conductivity die-casting aluminum alloy in Example 2 of the present invention is: silicon: 11wt%; cobalt: 0.2wt%; iron: 0.3wt%; boron: 0.02wt%; titanium: 0.03wt%; others The total sum of impurities is less than or equal to 0.2%, and the balance is aluminum.

[0028] The preparation method of the high thermal conductivity die-casting aluminum alloy in Example 2 of the present invention is the same as that in Example 1, but the inert gas used is nitrogen to obtain the die-casting alloy ingot A2.

Embodiment 3

[0030] The weight percent of each component of the high thermal conductivity die-casting aluminum alloy in Example 3 of the present invention is: silicon: 12wt%; cobalt: 0.3wt%; iron: 0.35wt%; boron: 0.04wt%; titanium: 0.01wt%; The total sum of impurities is less than or equal to 0.2%, and the balance is aluminum.

[0031] The preparation method of the high thermal conductivity die-casting aluminum alloy of Example 3 of the present invention is the same as that of Example 1, but the inert gas used is neon gas, and the die-casting alloy ingot A3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com