Glass fiber-reinforced polypropylene material with shallow shrinkage mark and low warpage as well as preparation method and application thereof

A polypropylene material, low warpage technology, applied in the field of modified plastics, can solve the problems of reduced impact strength, slow cooling and solidification speed, poor physical properties of materials, etc., achieve high bending strength and flexural modulus, and increase cooling and solidification speed , the effect of high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

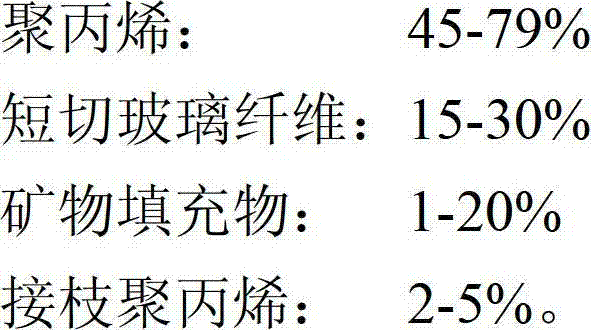

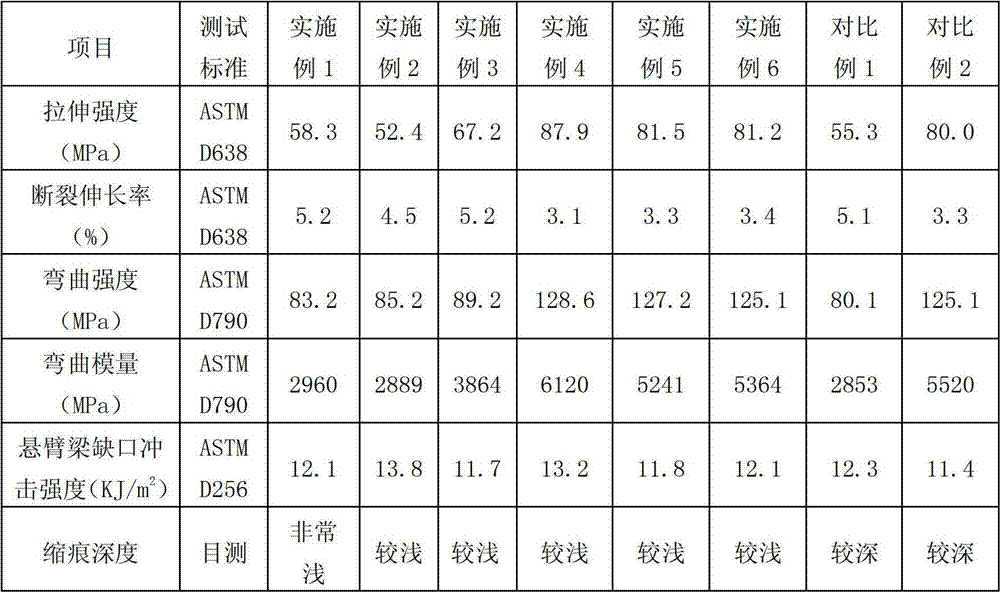

[0026] A glass fiber reinforced polypropylene material with shallow sink marks and low warpage, its raw material composition is as shown in table 1, and its preparation method comprises the following steps:

[0027] Mix raw materials other than chopped glass fiber and feed from the main feed port of the twin-screw extruder; chopped glass fiber is fed from the side feed port of the twin-screw extruder; raw materials are fed in the extruder After melting, extruding and granulating, a glass fiber reinforced polypropylene material with shallow sink marks and low warpage can be obtained. The pellets were injection molded into mechanical specimens for testing, and the test results are shown in Table 2.

[0028] In Table 1, the melt index of homopolypropylene is 5g / min (230°C, 2.16kg), the melt index of copolymerized polypropylene tree is 50g / min (230°C, 2.16kg), and the melt index of high crystalline polypropylene is 15g / min (230°C, 2.06kg). The melt index of polypropylene grafted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com