Process for producing twin crystal inducement plastic steel material with high carbon content

A technology of twinning induced plasticity and iron and steel materials, applied in metal rolling, manufacturing tools, temperature control, etc., can solve the problems of limited application range, low material performance, etc., achieve low cost, simple preparation method, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The steel plate is prepared by traditional vacuum smelting and hot rolling process

[0027] Its composition is: C%=0.63wt%, Mn%=23.6wt%, Si%=0.20wt%, P%=0.009wt%, S%=0.0065wt%, Al%=0.036wt%, the balance is Fe .

[0028] Smelting process: Vacuum smelting in an electromagnetic induction furnace, filled with argon for protection, and cast into a 90mm slab.

[0029] Rolling process: the heating temperature of the steel material is 1200°C, and the heat preservation is 3 hours for homogenization treatment. Hot rolled on a 350 two-roll hot rolling mill to obtain a hot-rolled sheet with a thickness of about 3.5mm and a total deformation of 95%. / s), can obtain tensile strength 1001MPa, yield strength 535MPa, while elongation reaches 52% hot-rolled sheet.

Embodiment 2

[0031] Steel plates are prepared by traditional vacuum smelting and hot rolling and cold rolling processes

[0032] Smelting process: Vacuum smelting in an electromagnetic induction furnace, filled with argon for protection.

[0033]Rolling process: The heating temperature of the steel material is 1200℃, and the temperature is kept for 3 hours for homogenization treatment. Hot-rolled on a 350 two-high hot rolling mill to obtain a hot-rolled sheet with a thickness of about 3 mm, the total deformation is 95%, and the opening and final rolling temperatures are 1100 ° C and 950 ° C, respectively, and cooled on a 430 four-high cold rolling mill. The test sheet was rolled and cold rolled to a thickness of 1.0 mm, and the cold rolling reduction ratio was 66.7%.

[0034] Heat treatment process: 1.0mm thick cold-rolled steel sheet is kept in a heating furnace at 700°C for 20 minutes, and then cooled to room temperature at a rate of 10°C / s.

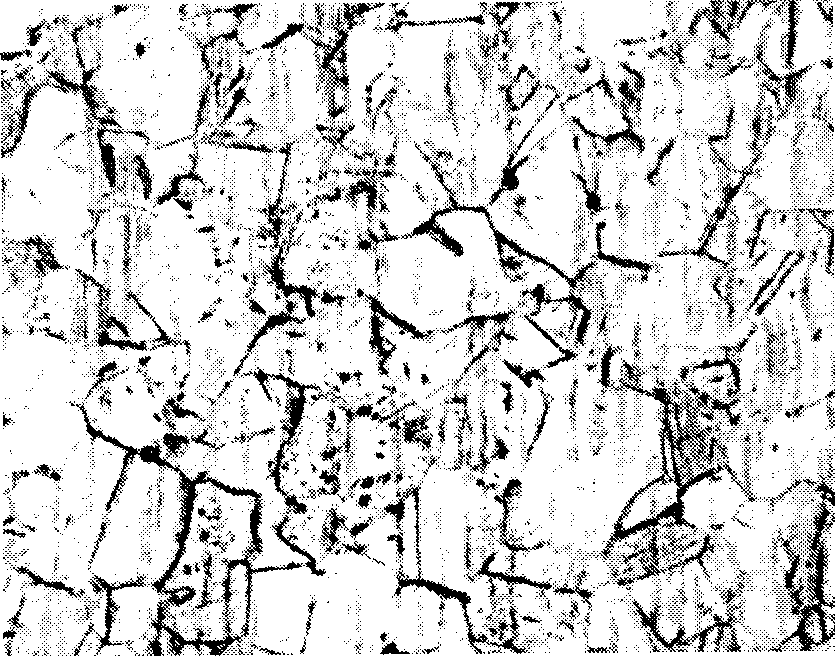

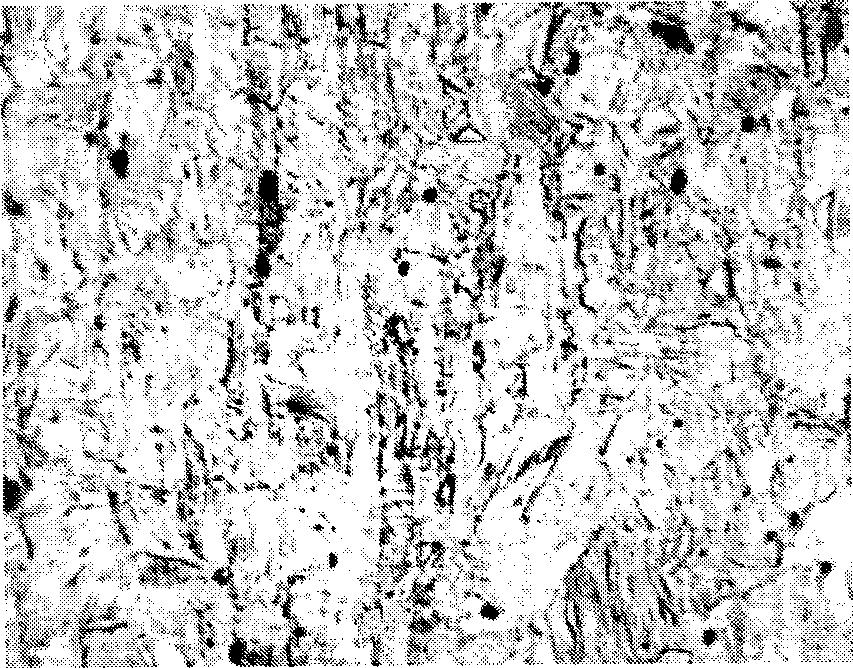

[0035] The optical microstructure observed...

Embodiment 4

[0041] The difference from Example 1 and Example 2 is that the composition of the steel material is: C%=0.44wt%, Mn%=21.44wt%, Si%=0.10wt%, P%=0.006wt%, S% =0.0055wt%,Al%=0.026wt%,

[0042] The balance is Fe. 经过实施例1和例2的加工过程,

[0043] The cold rolling reduction rate is 71.4%, the thickness of the cold rolling sheet is 1.06mm, the heat treatment temperature is 750°C, the temperature is kept for 15 minutes, and the temperature is cooled to room temperature at a rate of 30°C / s.

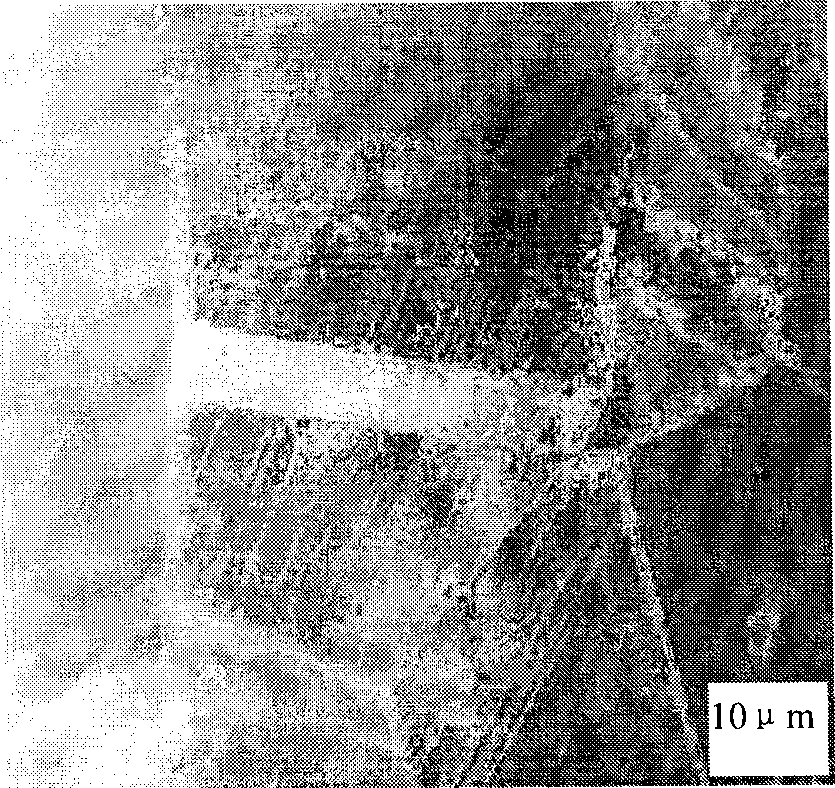

[0044] A high-strength and high-plastic twin-induced plasticity steel was prepared under this process condition. The steel material also has a microstructure of annealing twins and stacking faults in the austenite matrix as observed by transmission electron microscopy, and its grain size is 2-5 μm. . The yield strength of the steel material at room temperature is 465MPa, the tensile strength is 1040MPa, and the elongation is 61.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com