Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Compact and inexpensive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

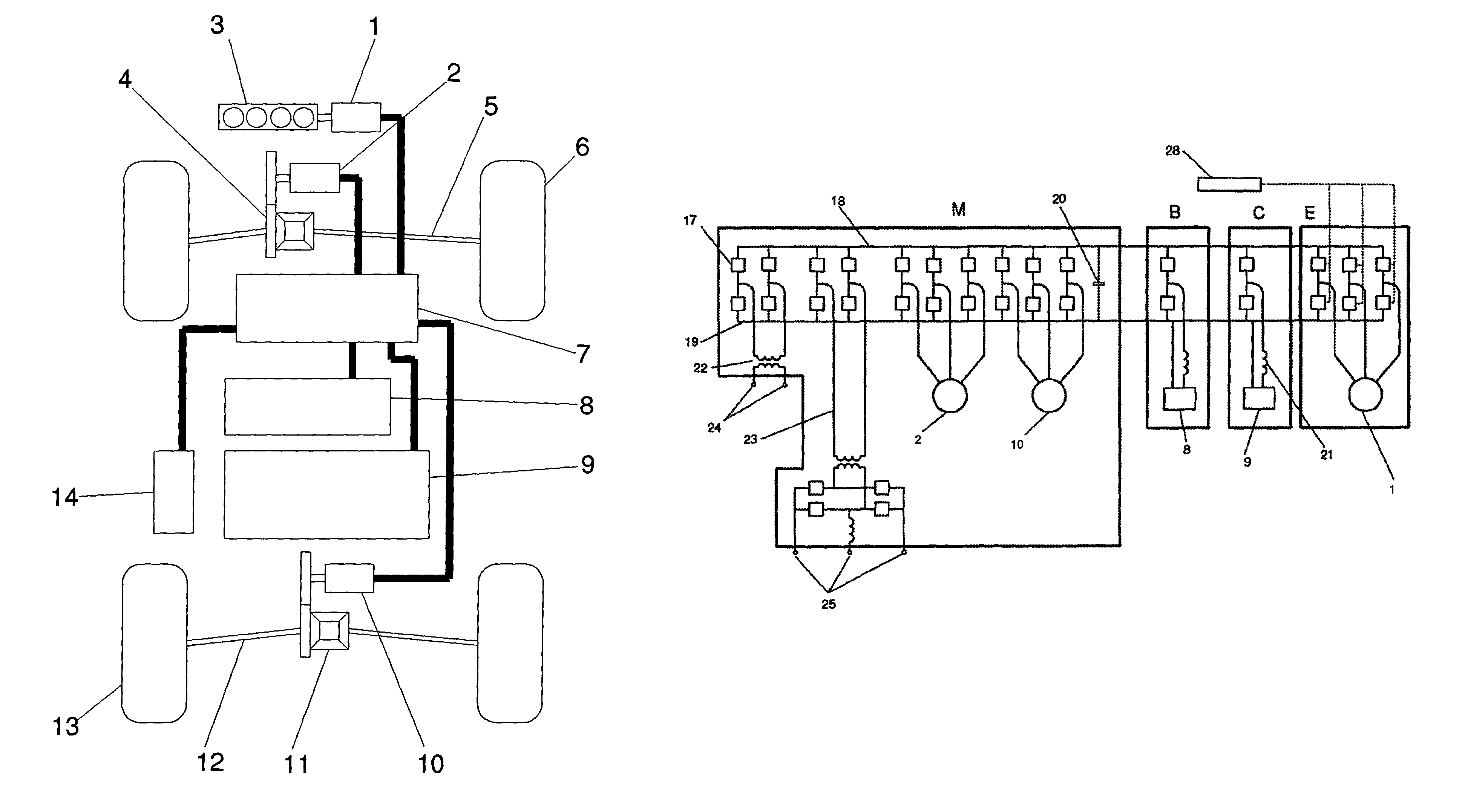

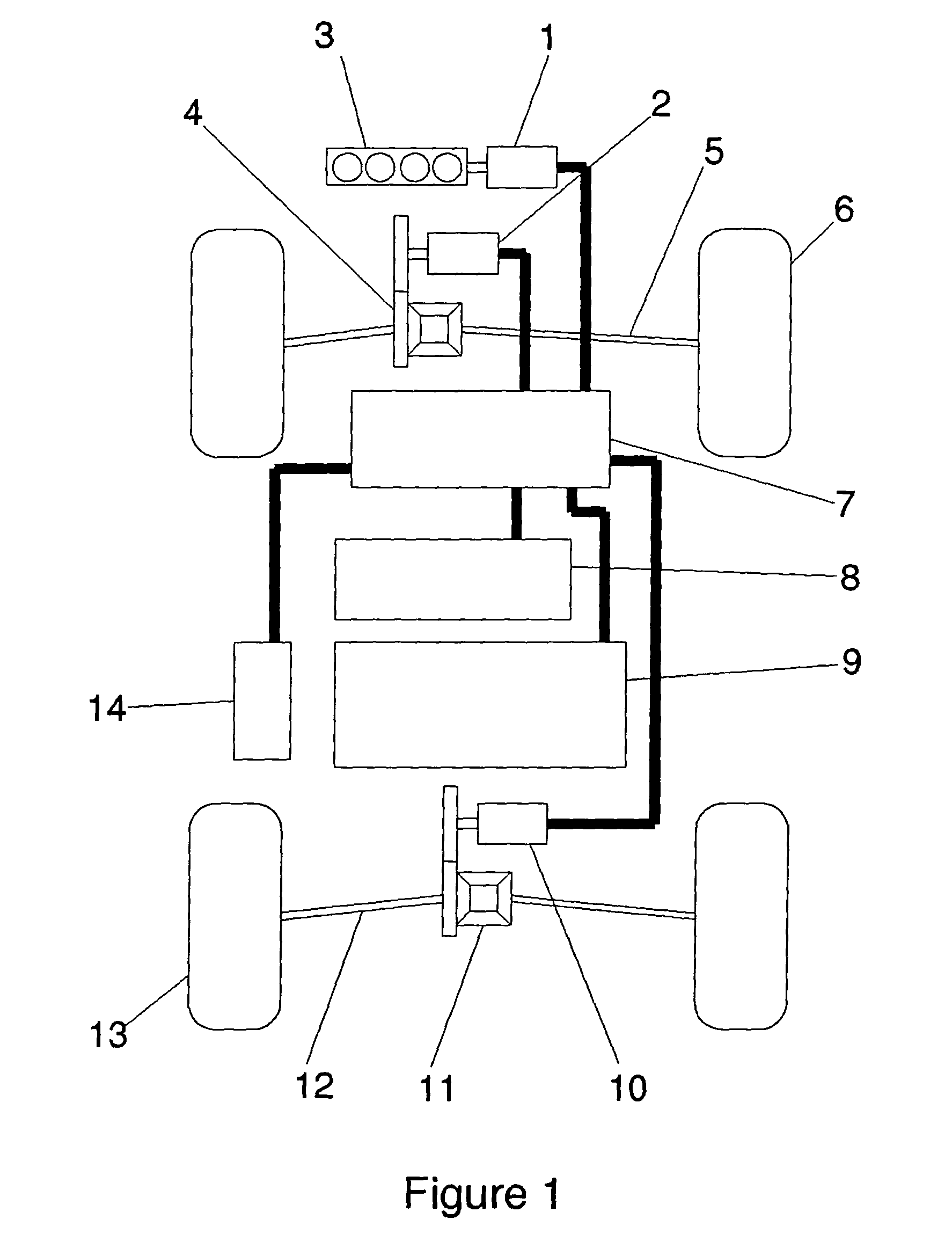

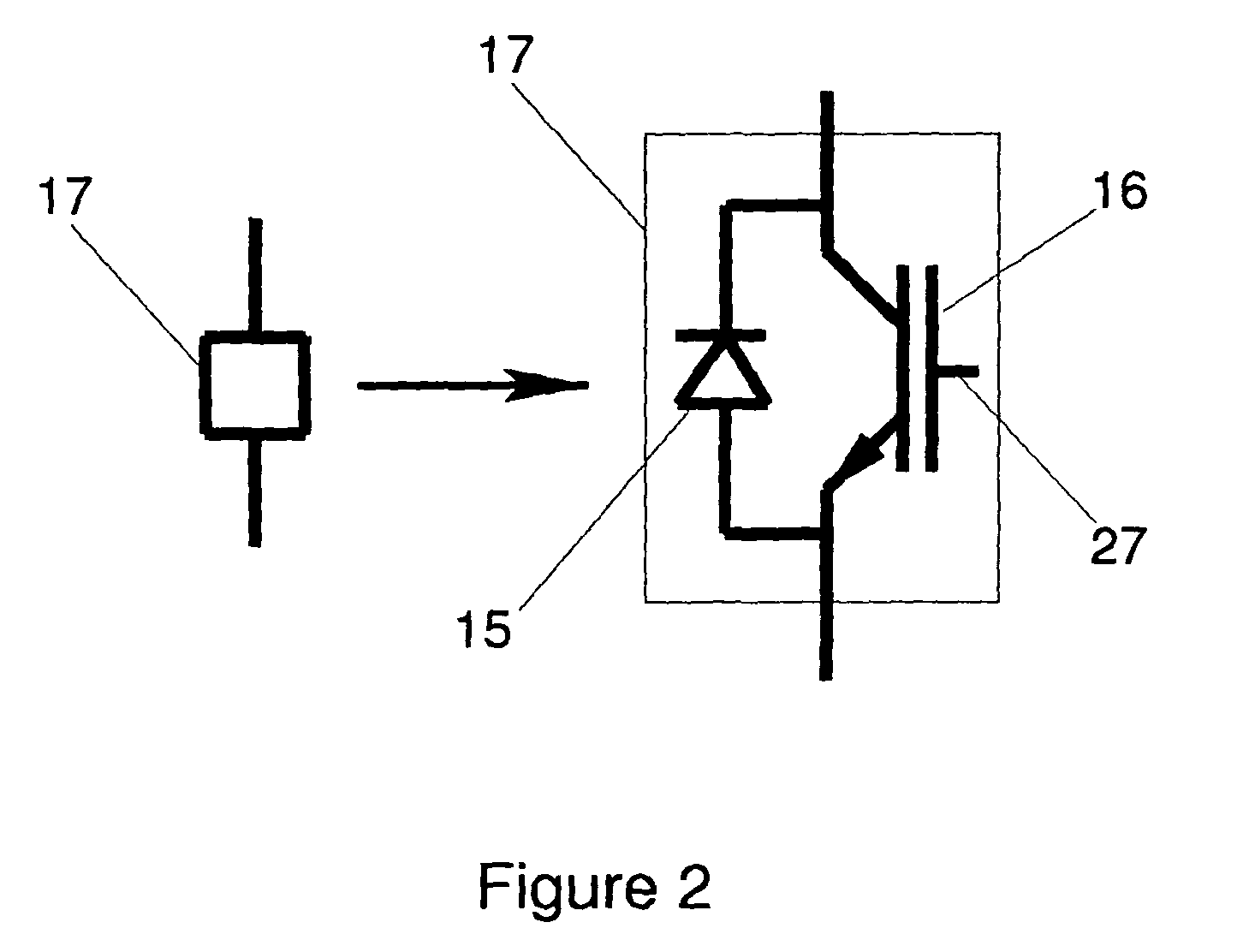

Method and apparatus for power electronics and control of plug-in hybrid propulsion with fast energy storage

InactiveUS7740092B2Compact and inexpensiveInterconnection becomes expensivePlural diverse prime-mover propulsion mountingPower to auxillary motorsElectrical batteryDistribution power system

A plug-in hybrid propulsion system includes a fast energy storage device that preserves battery life, where the energy storage elements of the hybrid drive train may be charged with externally supplied electricity as well as energy from the engine or regenerative braking. Electronic switches, passive electronics, an enclosure, controller circuitry, and / or control algorithms are used to manage the flow of power between a fuel powered engine, a battery, a fast energy storage system, traction motors; a charger, ancillary systems, an electrical distribution system, and / or a drive train.

Owner:AFS TRINITY POWER CORP

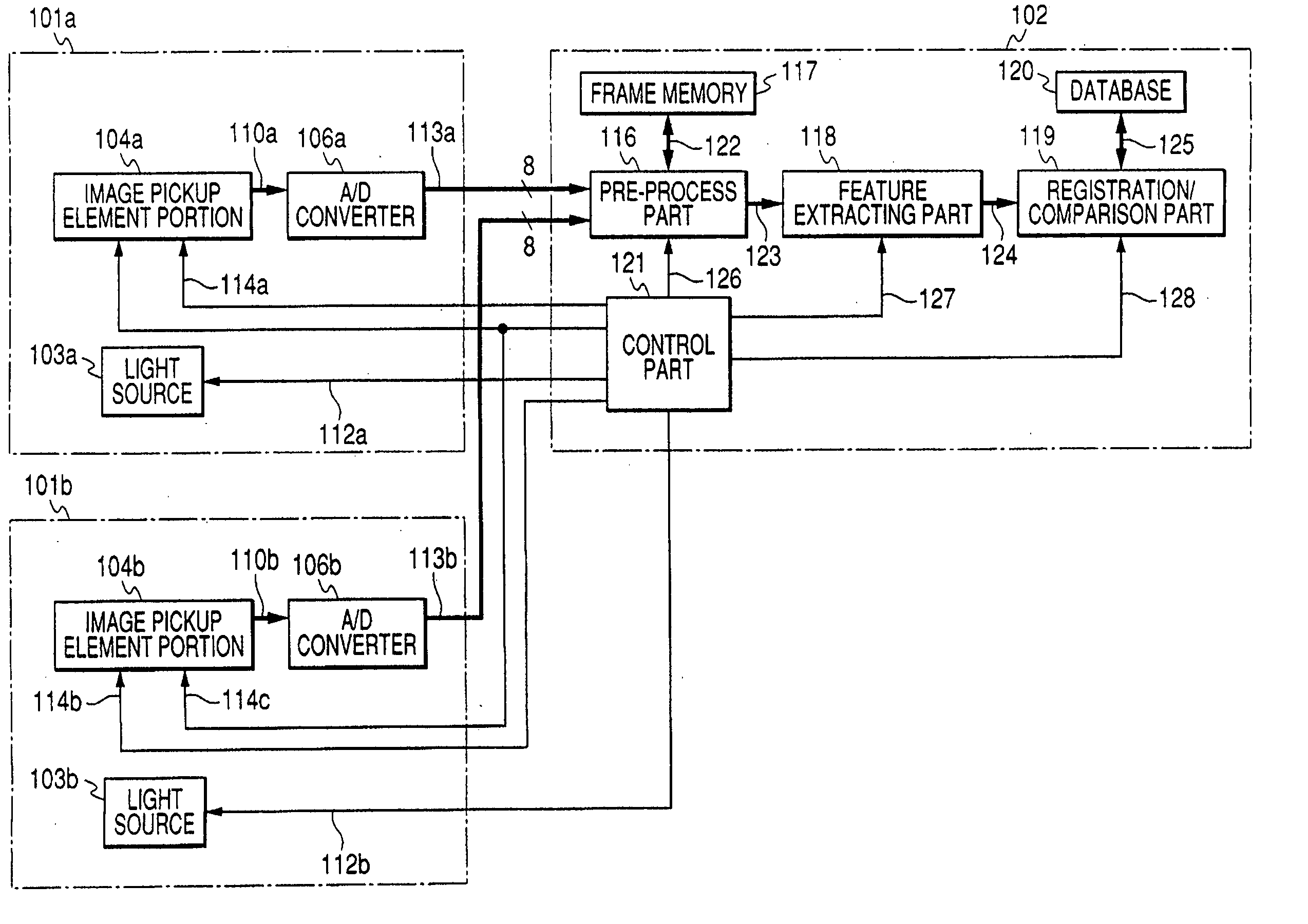

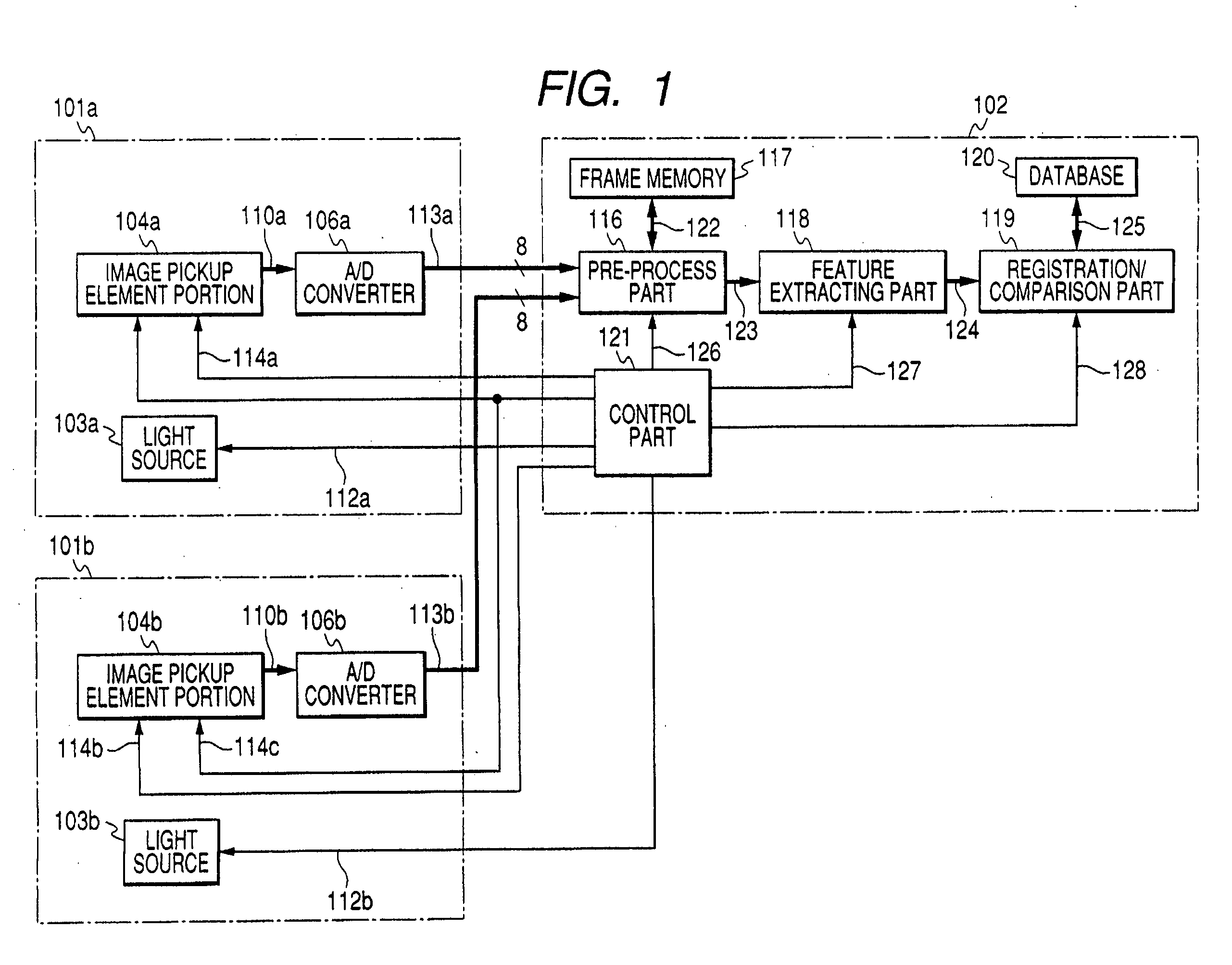

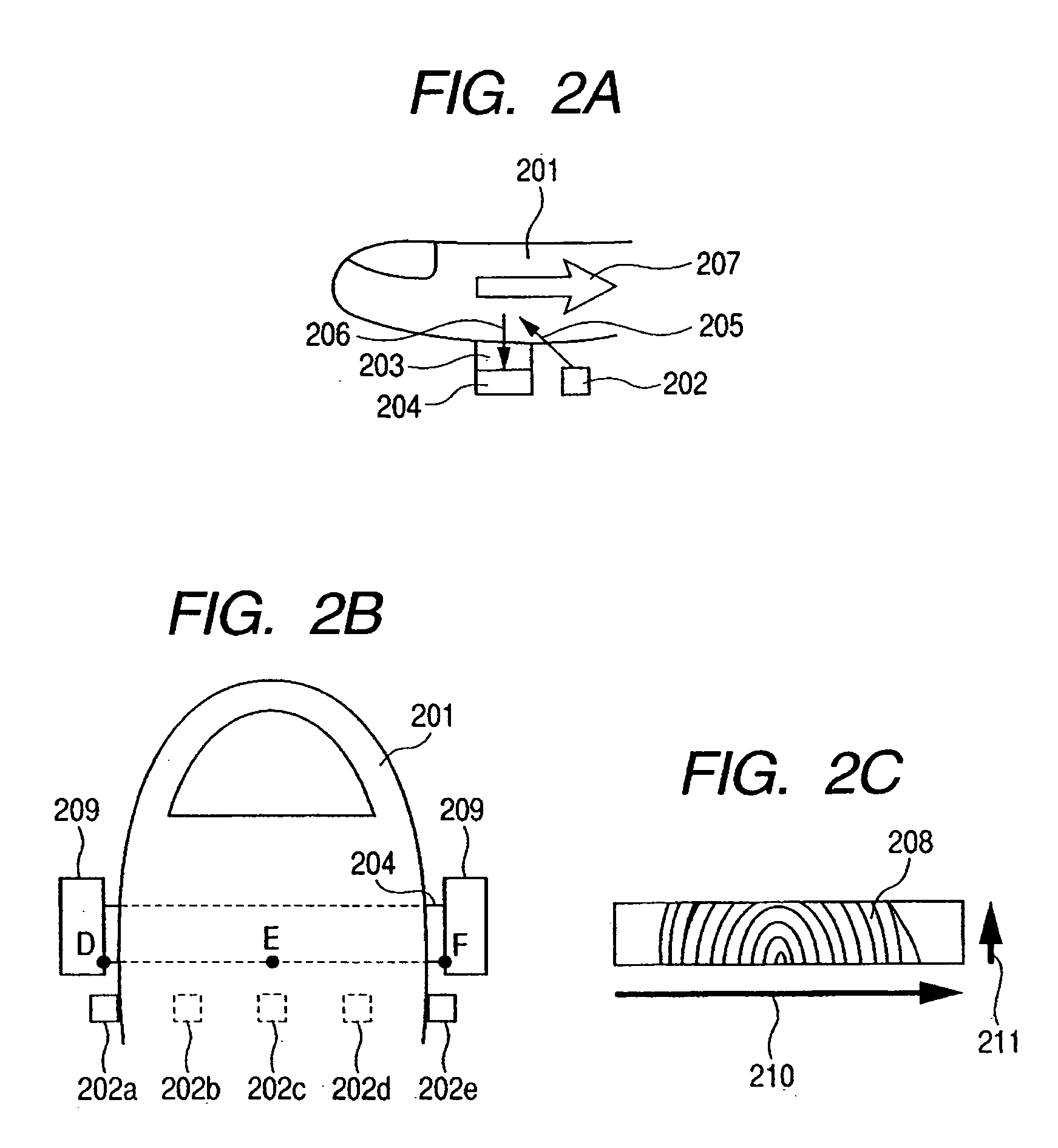

Biometric authenticating apparatus and image acquisition method

InactiveUS20060182318A1Avoid mistakesHigh precision measurementSubcutaneous biometric featuresBlood vessel patternsBiometricsComputer science

The invention provides a biometric authentication apparatus made compact and inexpensive while retaining convenience of use, and also a biometric authentication apparatus capable of preventing mutual interference of plural different authenticating methods thereby attaining a high authenticating precision. The invention provides a biometrics authentication apparatus for executing different plural biometric authentications including first image acquisition means; second image acquisition means; control means for controlling operations of the first and second image acquisition means, and an authentication part which executes an authentication utilizing image data obtained from the image acquisition parts. In at least a part of the authentication part, a common transfer path is provided for the image data obtained from the first image acquisition means and the image data obtained from the second image acquisition means.

Owner:CANON KK

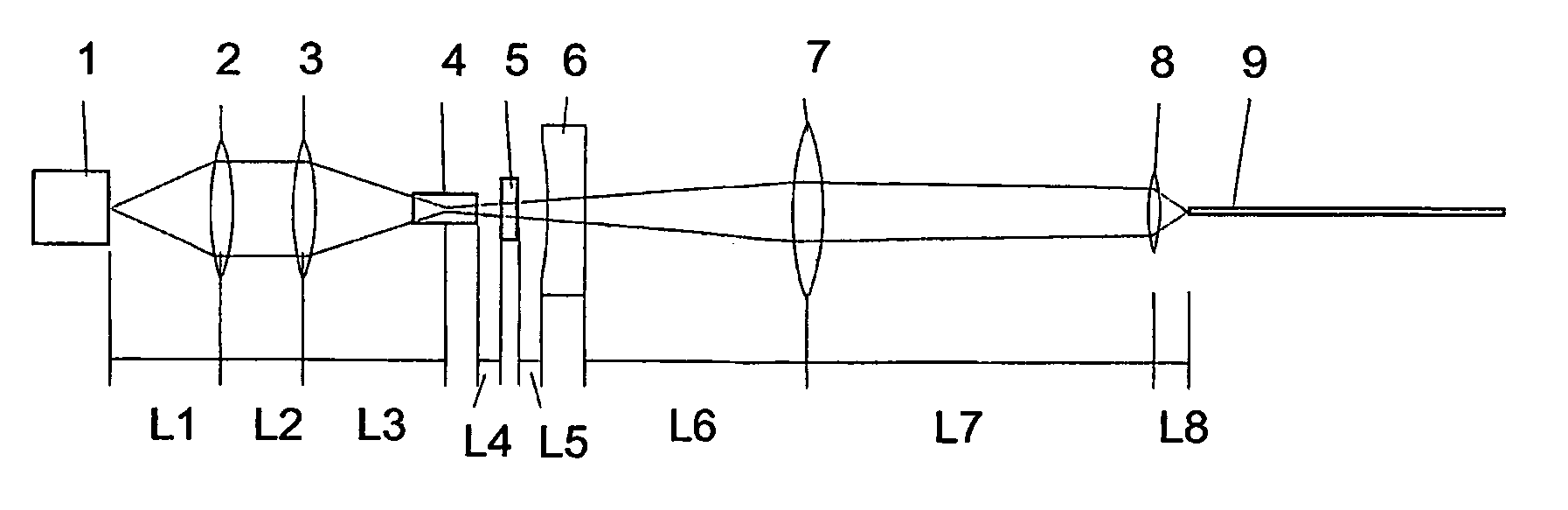

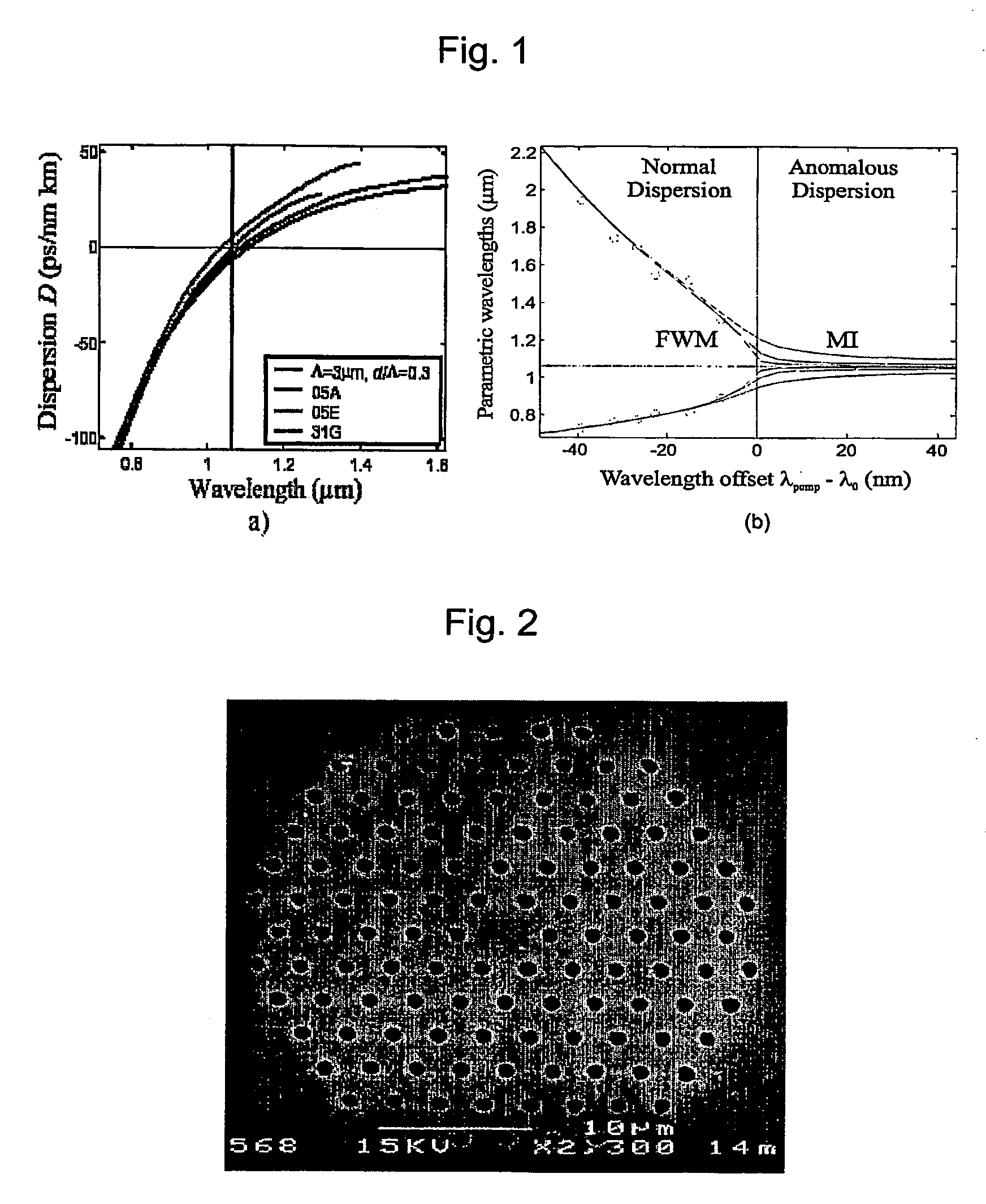

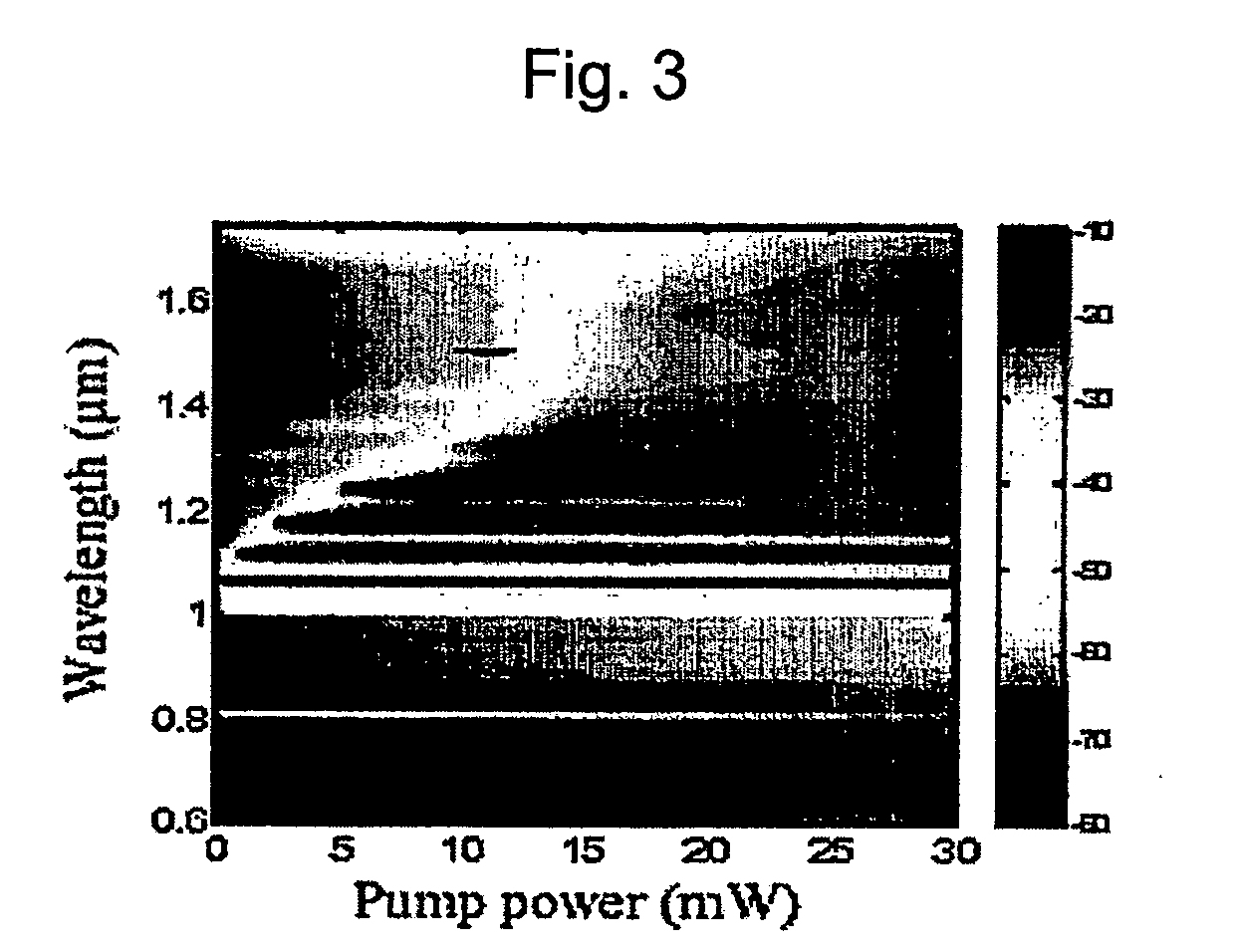

Broad spectrum light source

ActiveUS7787503B2Compact and inexpensiveLaser using scattering effectsSemiconductor lasersFiberLength wave

The light includes a laser (4), which operates at or near its fundamental wavelength and produces pulses of a duration longer than 0.5 ns, and a micro-structured optical fibre (9) arranged to guide the pulses, wherein the light is generated by the pulses in the fibre (9). The light source may e.g. be useful in applications such as spectral testing of fibre components and spectral analysis of chemical and biological samples.

Owner:NKT PHOTONICS

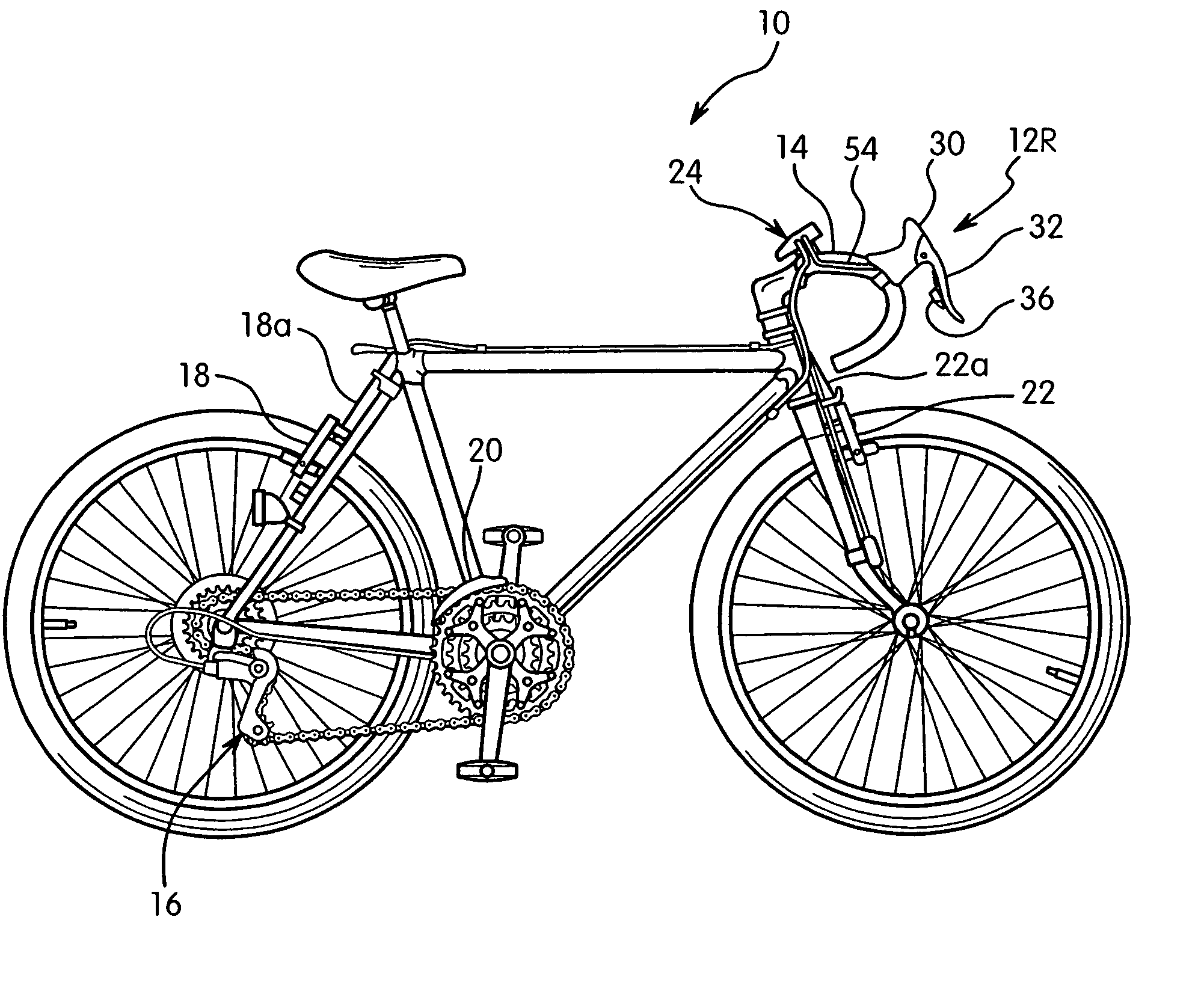

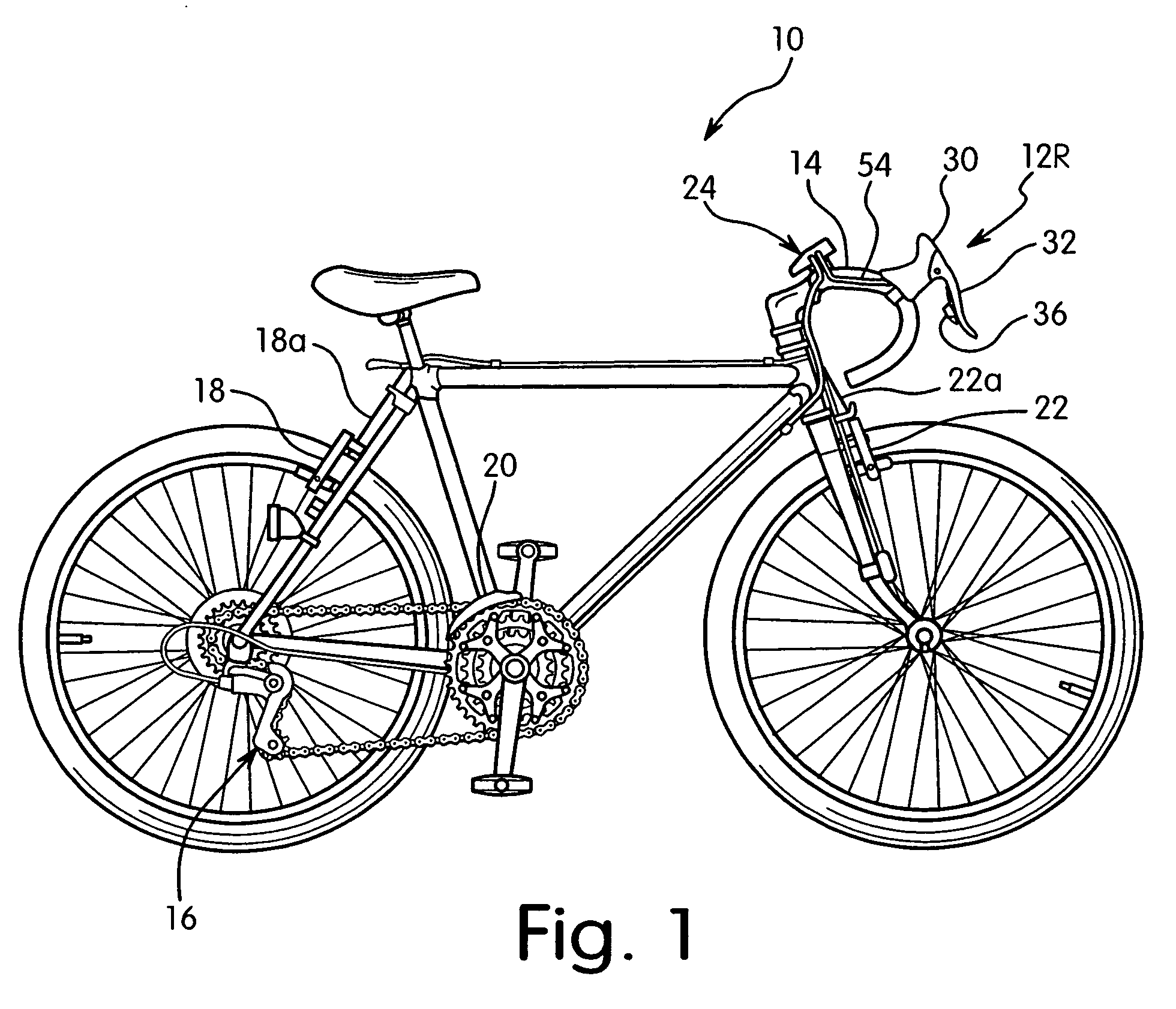

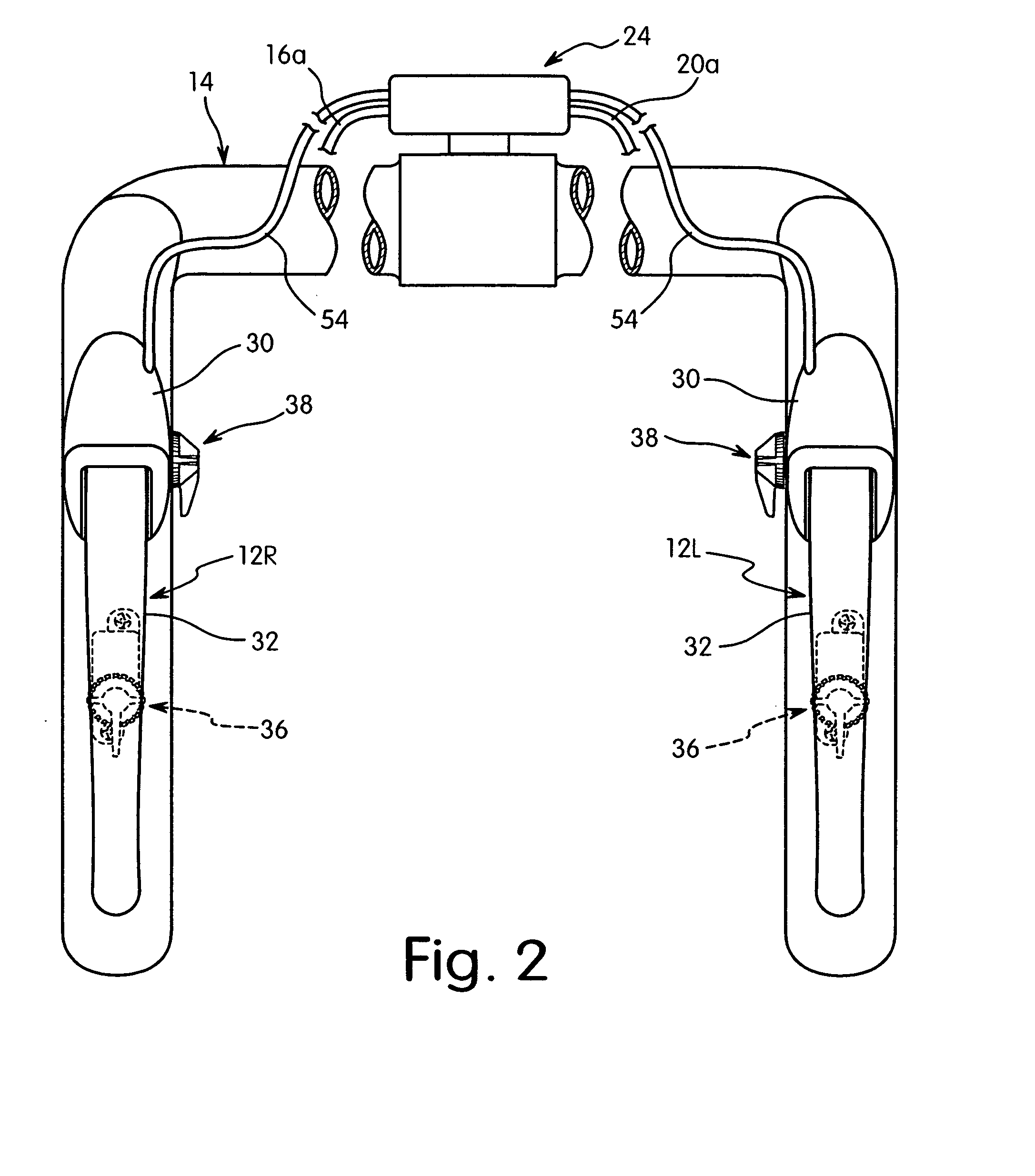

Bicycle operating component with electrical shift control switch

InactiveUS20070137361A1Easy to operateCompact and inexpensiveEmergency actuatorsMechanical apparatusEngineeringControl switch

A bicycle operating component includes an electrical shift control switch. The electrical shift control switch includes a mounting portion and an operating member. The operating member is movably coupled to the mounting portion. The operating member is arranged to move relative to the mounting portion in an actuating direction from an original position. The electrical shift control switch is configured to operate a bicycle shift mechanism in a first direction when the operating member is moved from the original position in the actuating direction and also to operate the bicycle shift mechanism in a second direction when the operating member is moved from the original position in the actuating direction. Preferably, a controller is operatively coupled to the electrical shift control switch in order to actuate the bicycle shift mechanism depending on the stroke of the operating member or the amount of time moved in the actuating direction.

Owner:SHIMANO INC

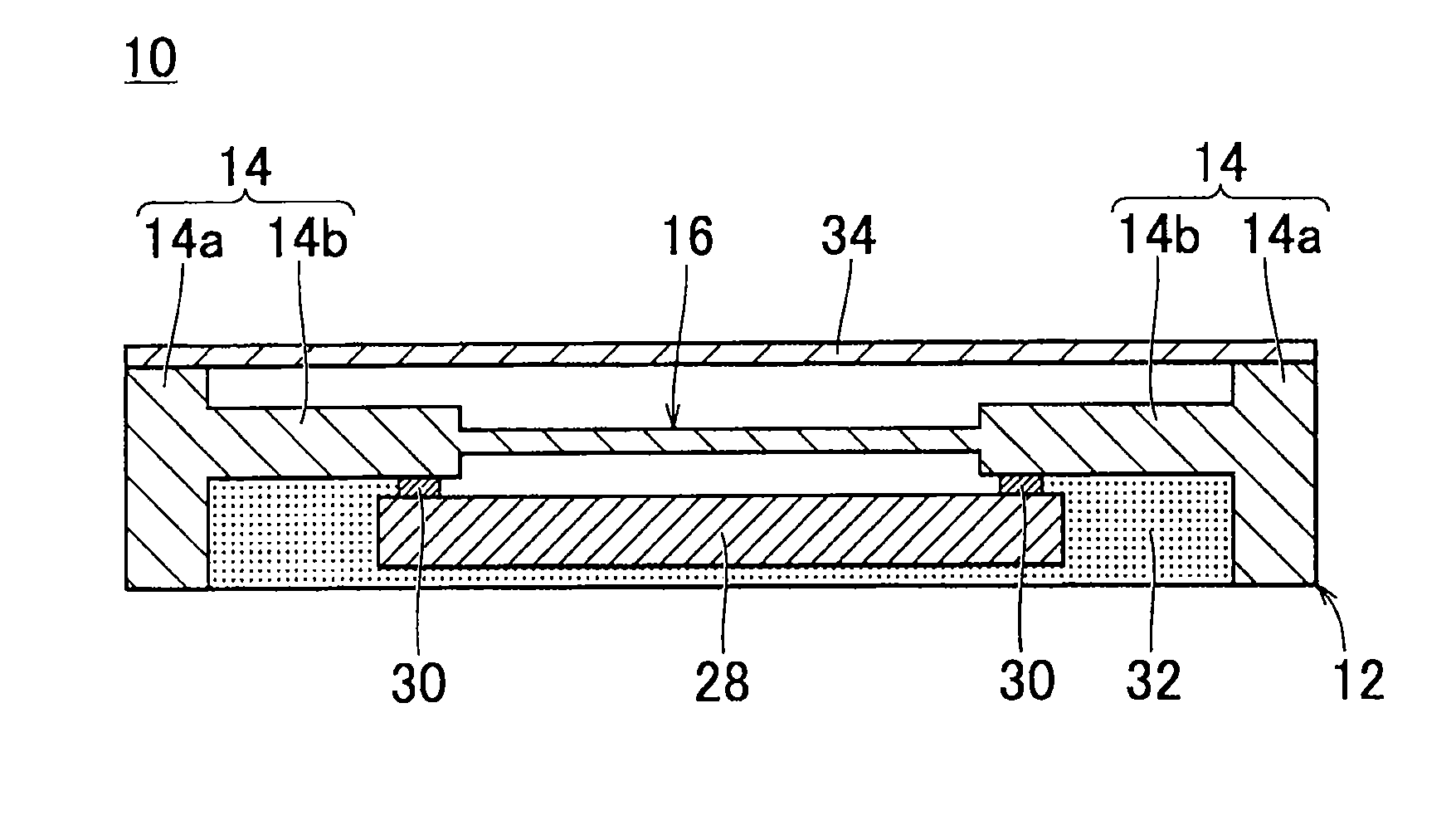

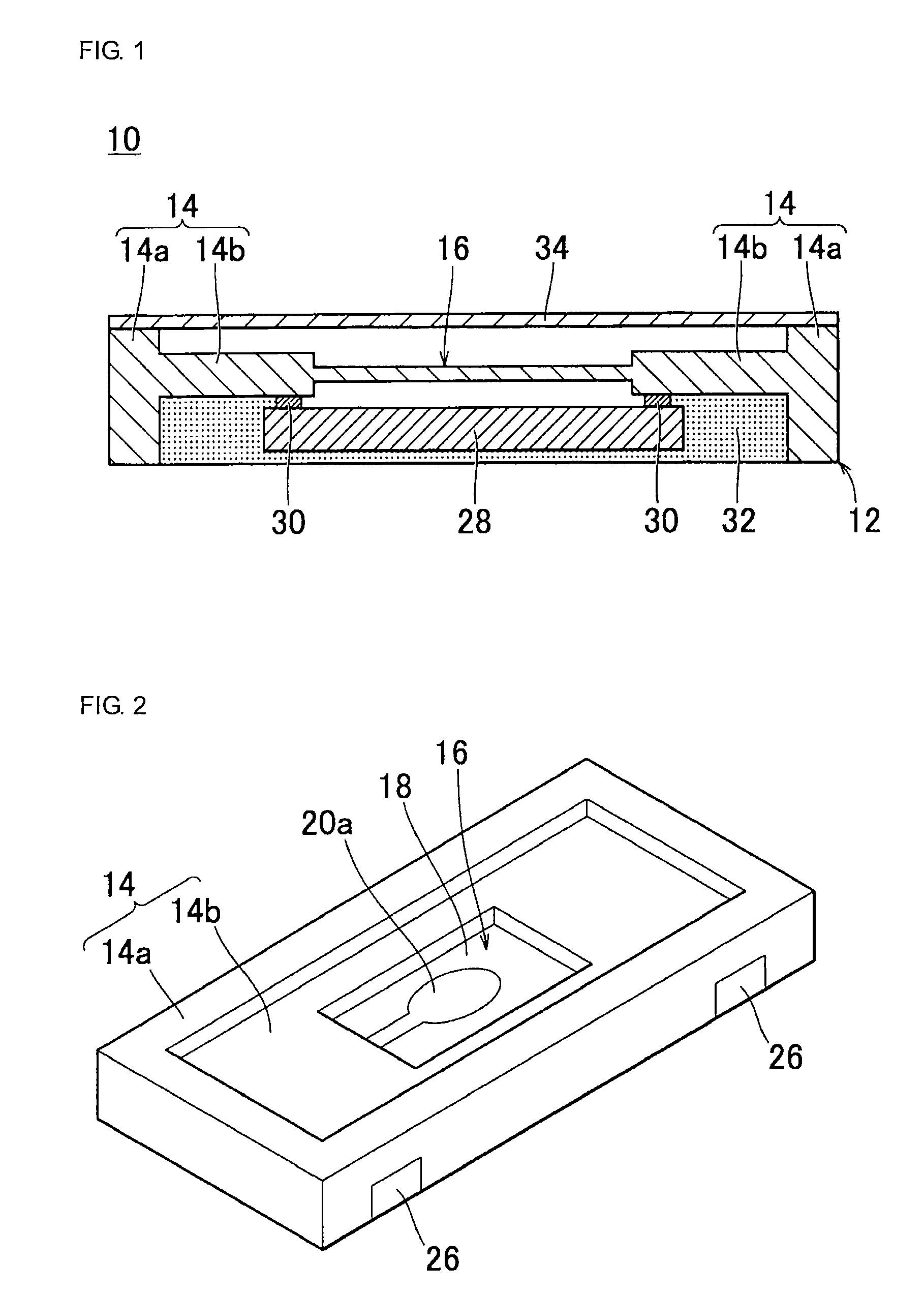

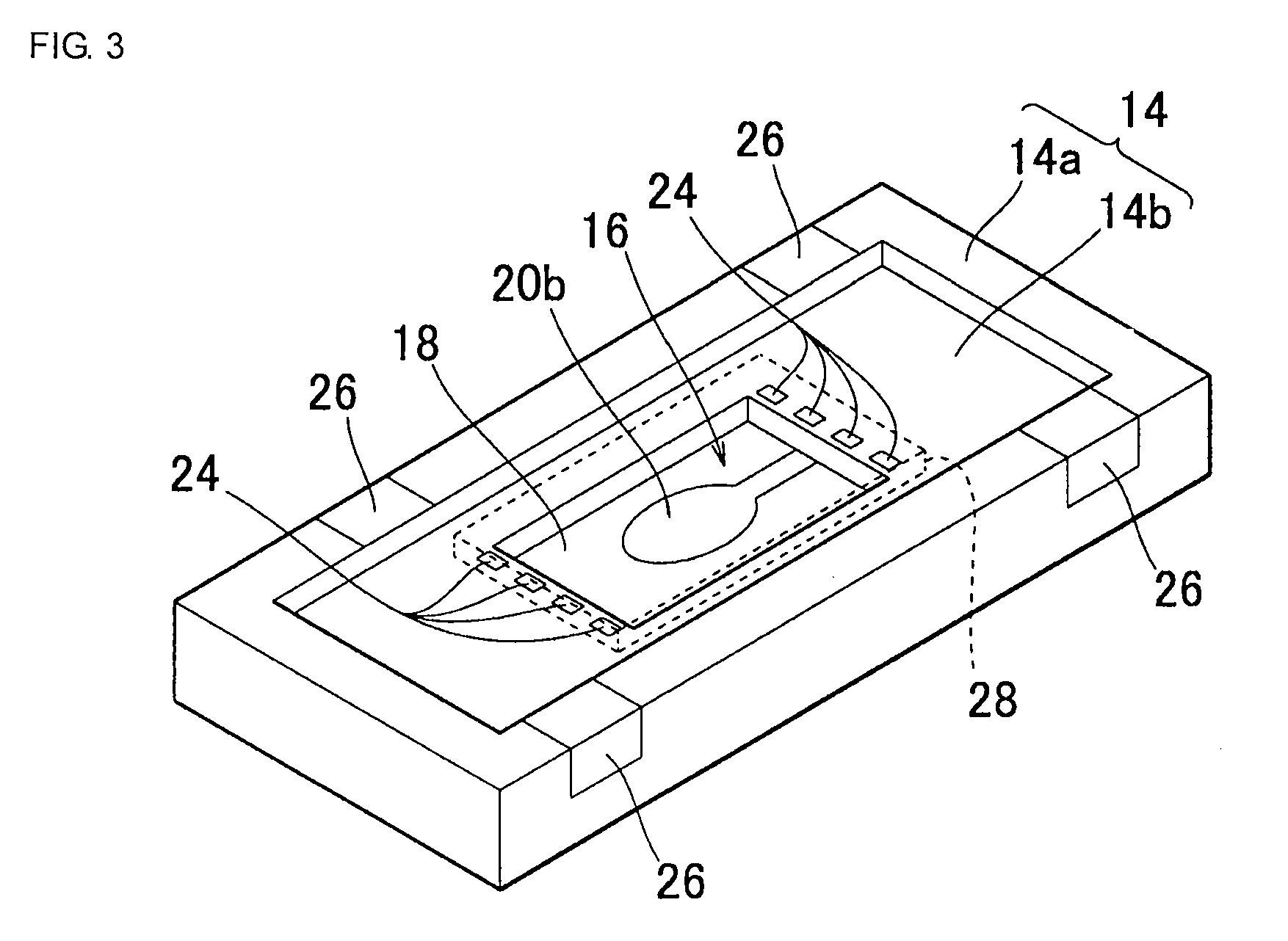

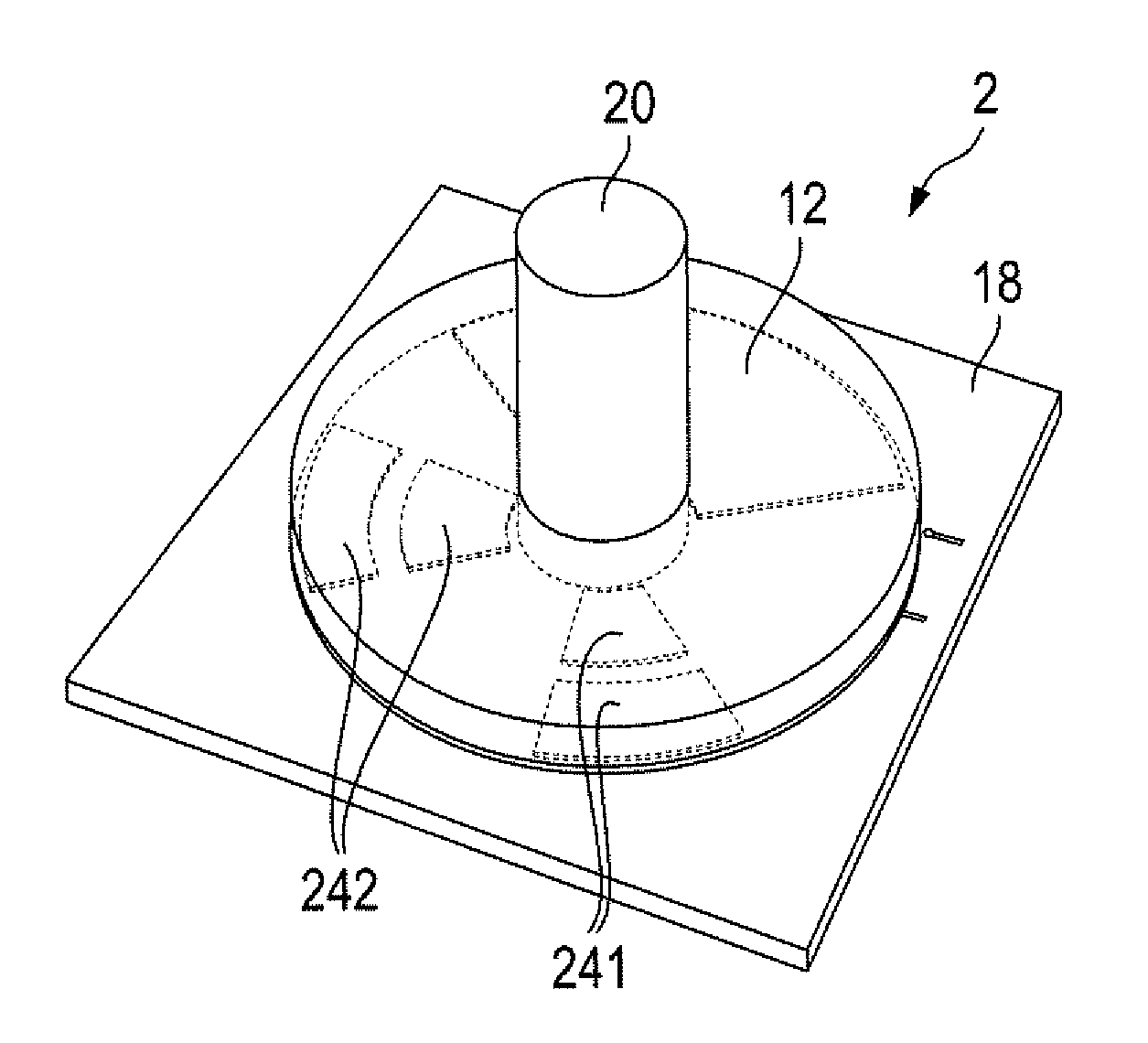

Vibrator module

ActiveUS7557493B2Compact and inexpensiveReduce leakageImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringCeramic

A vibrator module includes a frame having an outer frame and an inner frame. A vibrator unit is formed inside the inner frame. The frame and the vibrator unit are formed of a piezoelectric ceramic or the like as one piece. On one side of the vibrator unit, an IC is mounted so that a hollow portion is provided between the vibrator unit and the IC. The periphery of the IC is filled with a resin material. On the other side of the vibrator unit, a top cover serving as a sealing material is mounted so that a hollow portion is provided between the vibrator unit and the top cover.

Owner:MURATA MFG CO LTD

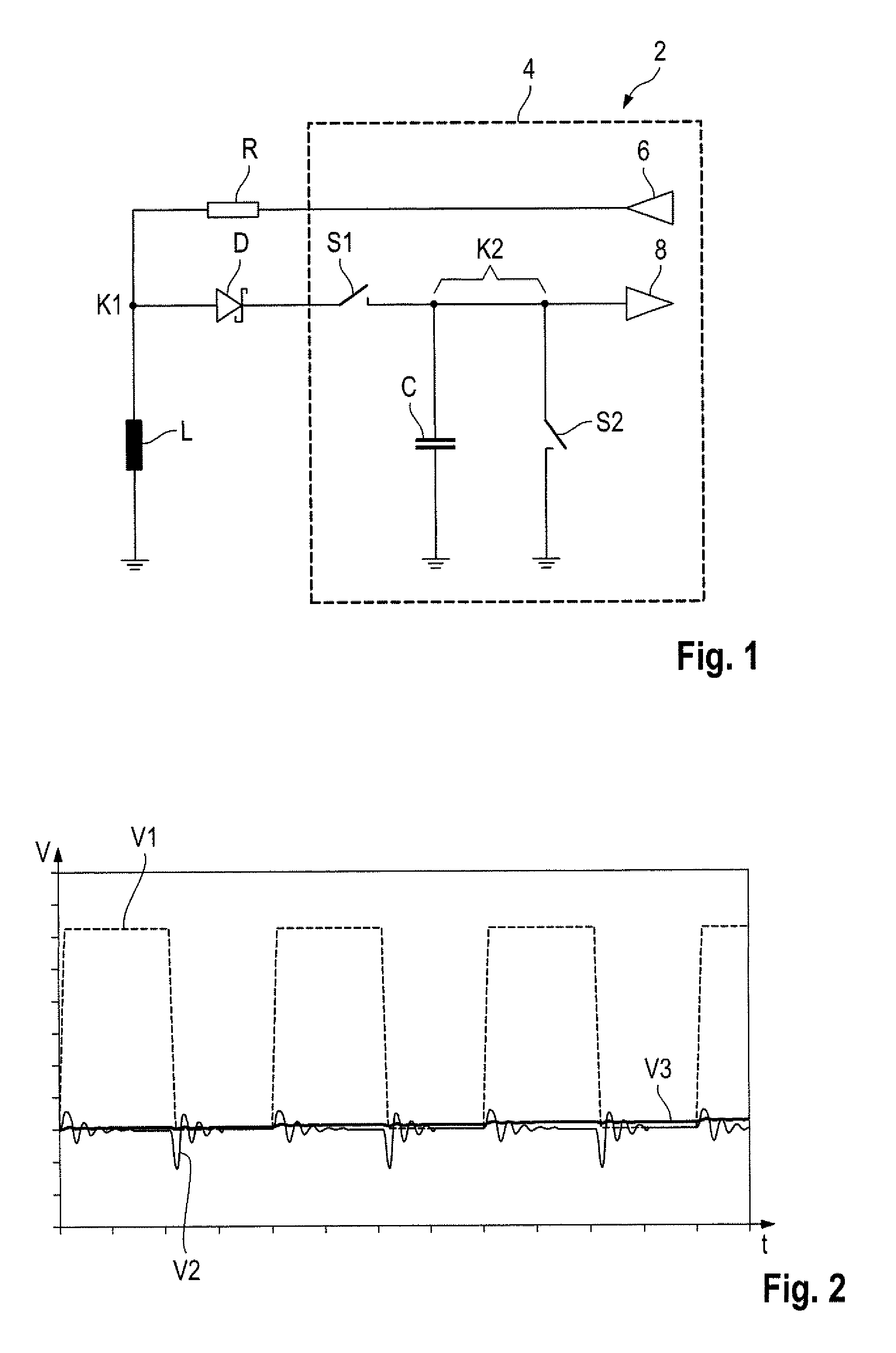

Position sensor, actuator-sensor device and method for the inductive detection of a position

ActiveUS20130127449A1Reduce voltageSmall dimensionElectric/magnetic position measurementsUsing electrical meansActuatorControl theory

A position sensor for the inductive detection of a position of a first component comprising a reference coil with respect to a second component comprising a reference body. A control and processing unit of the position sensor is coupled to the reference coil and is designed for issuing an output signal generating a current impulse in the reference coil. In addition, the control and processing unit is designed for evaluation of an oscillation generated by the current impulse in the reference coil as an input signal indicating the position of the reference body.

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

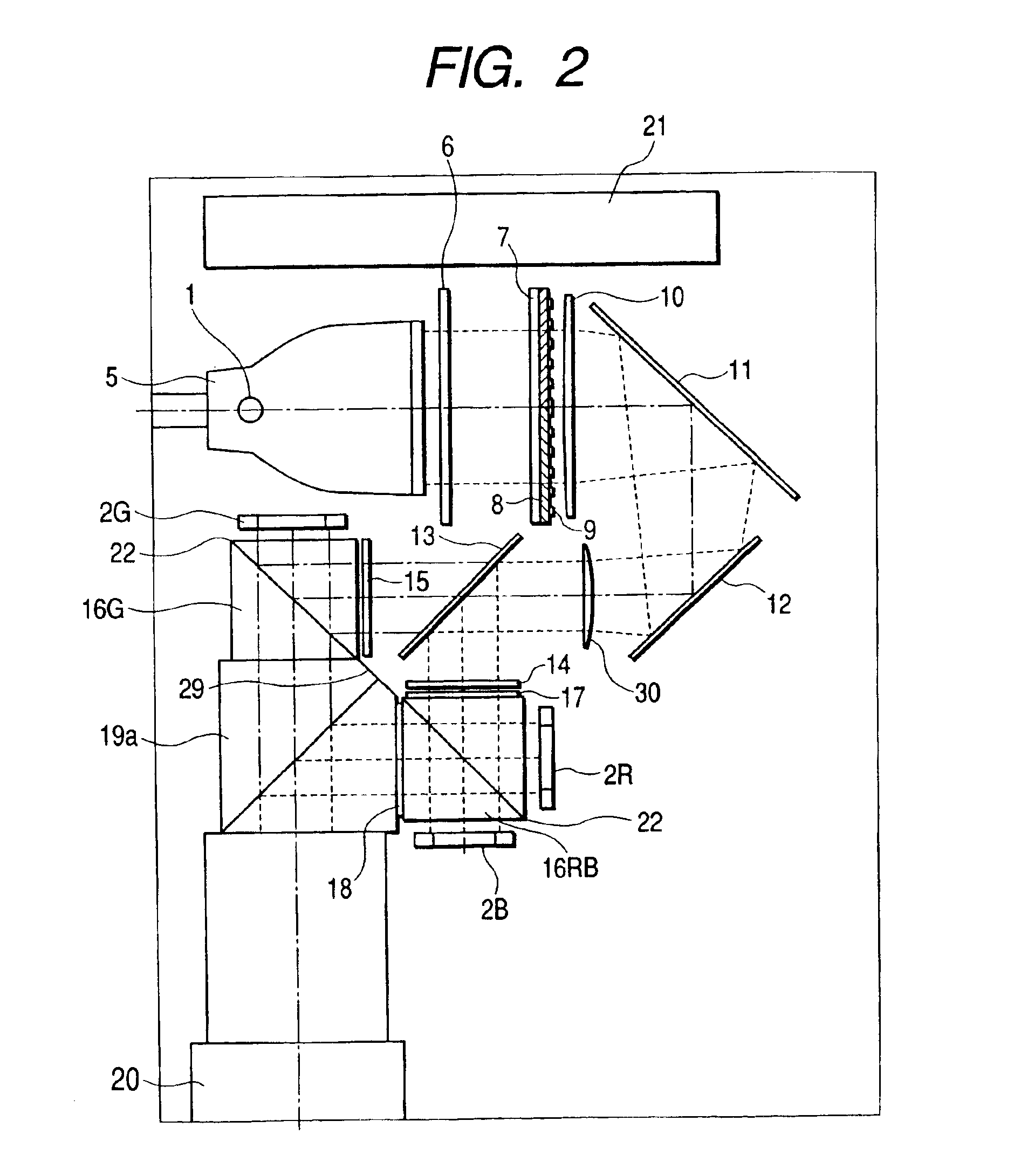

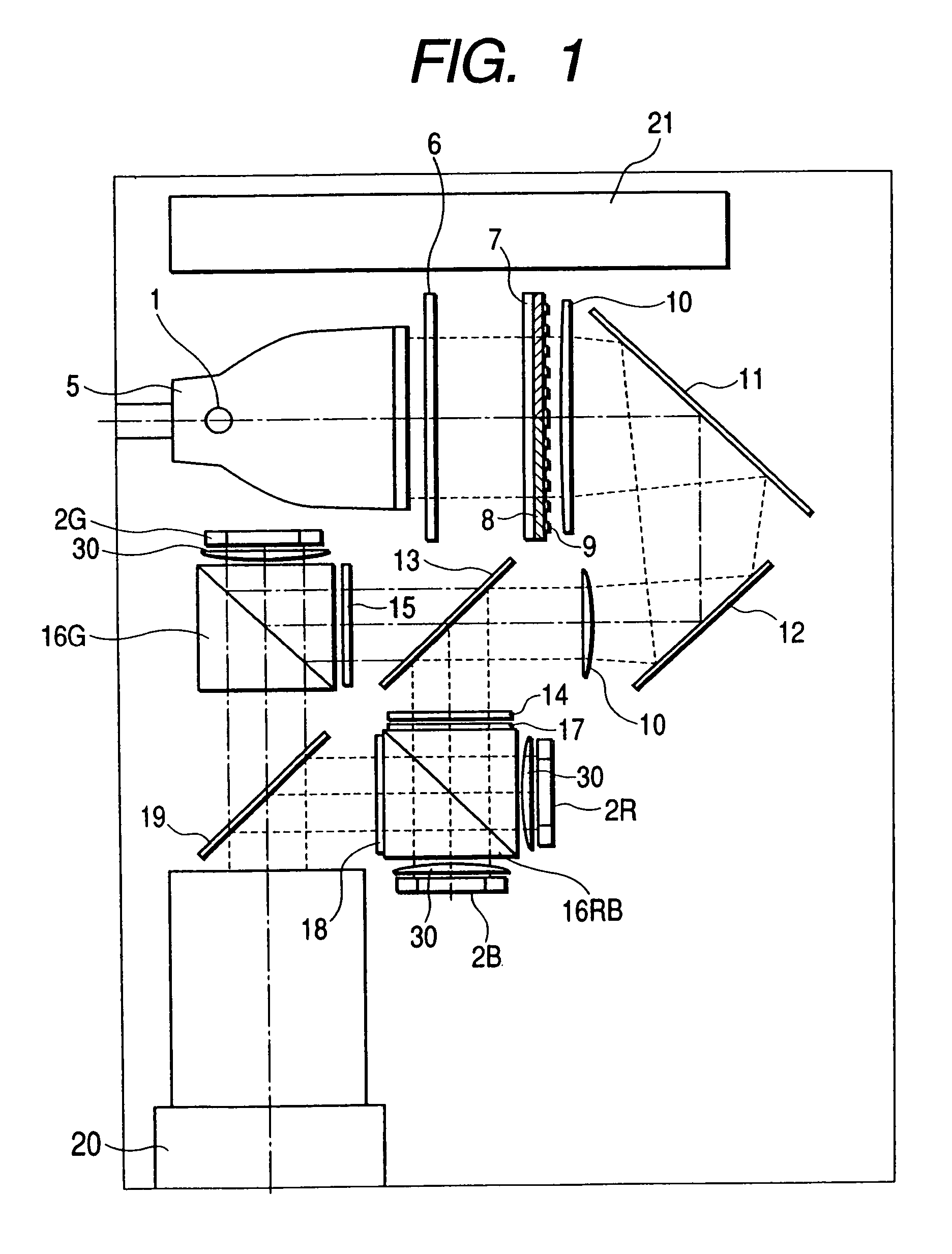

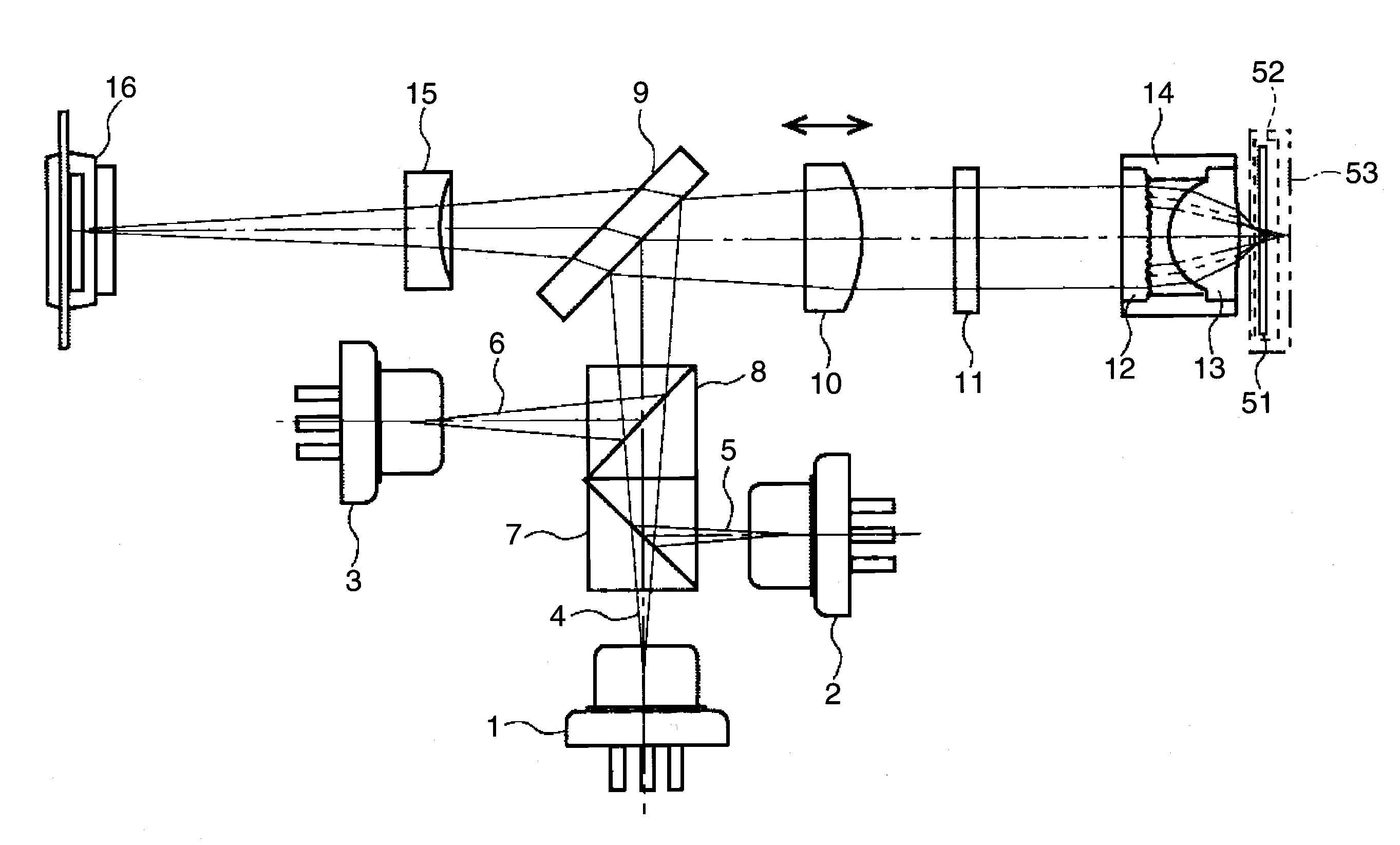

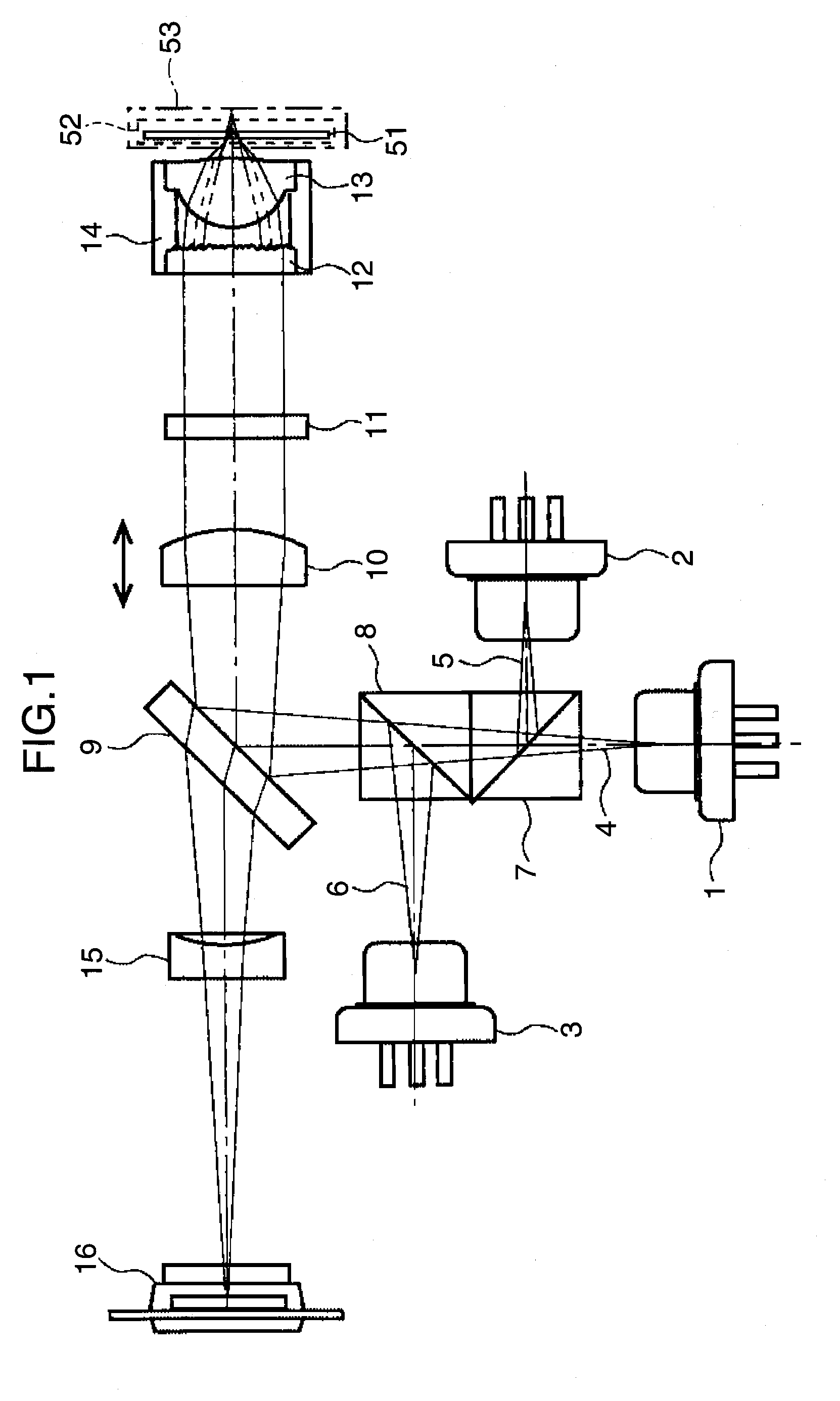

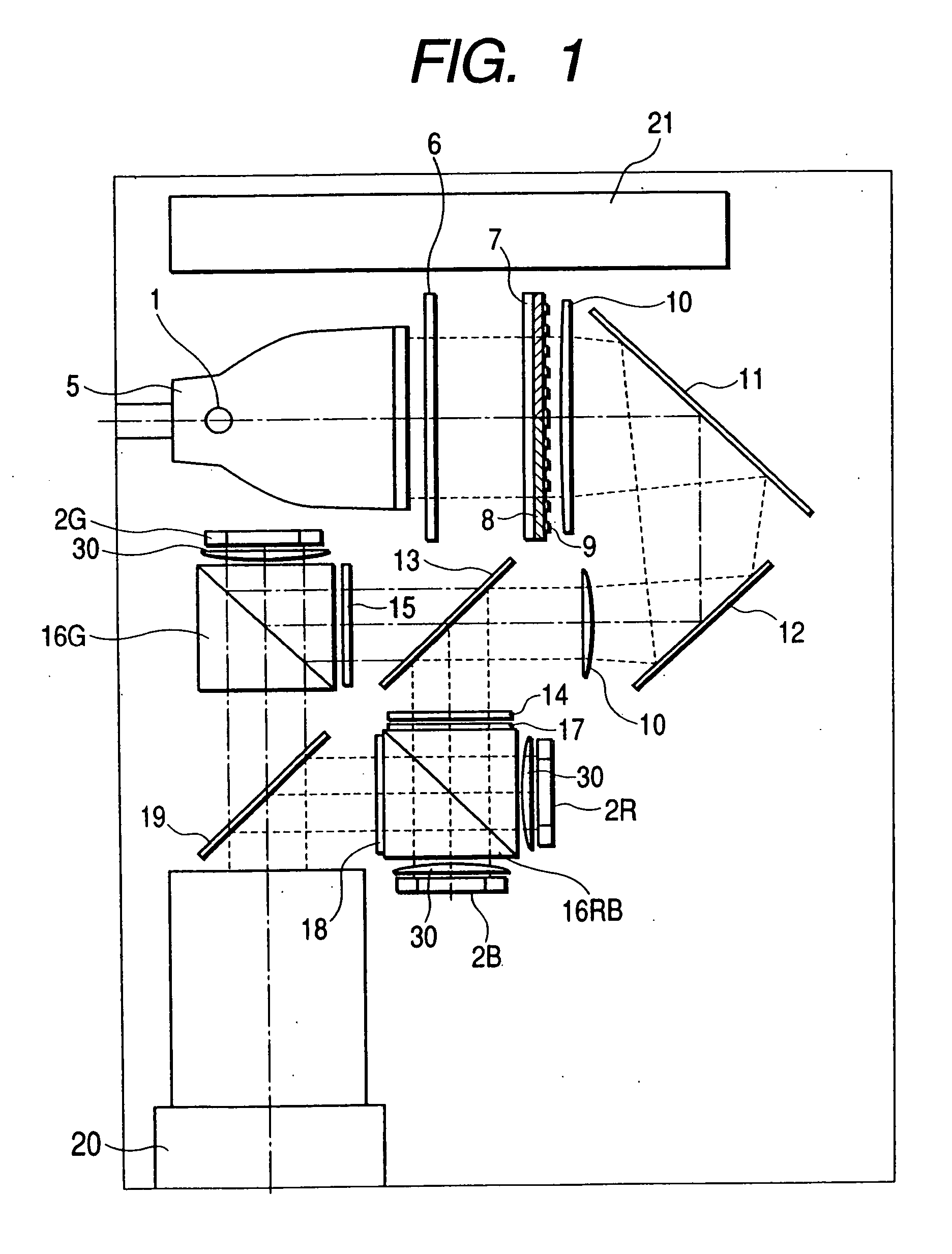

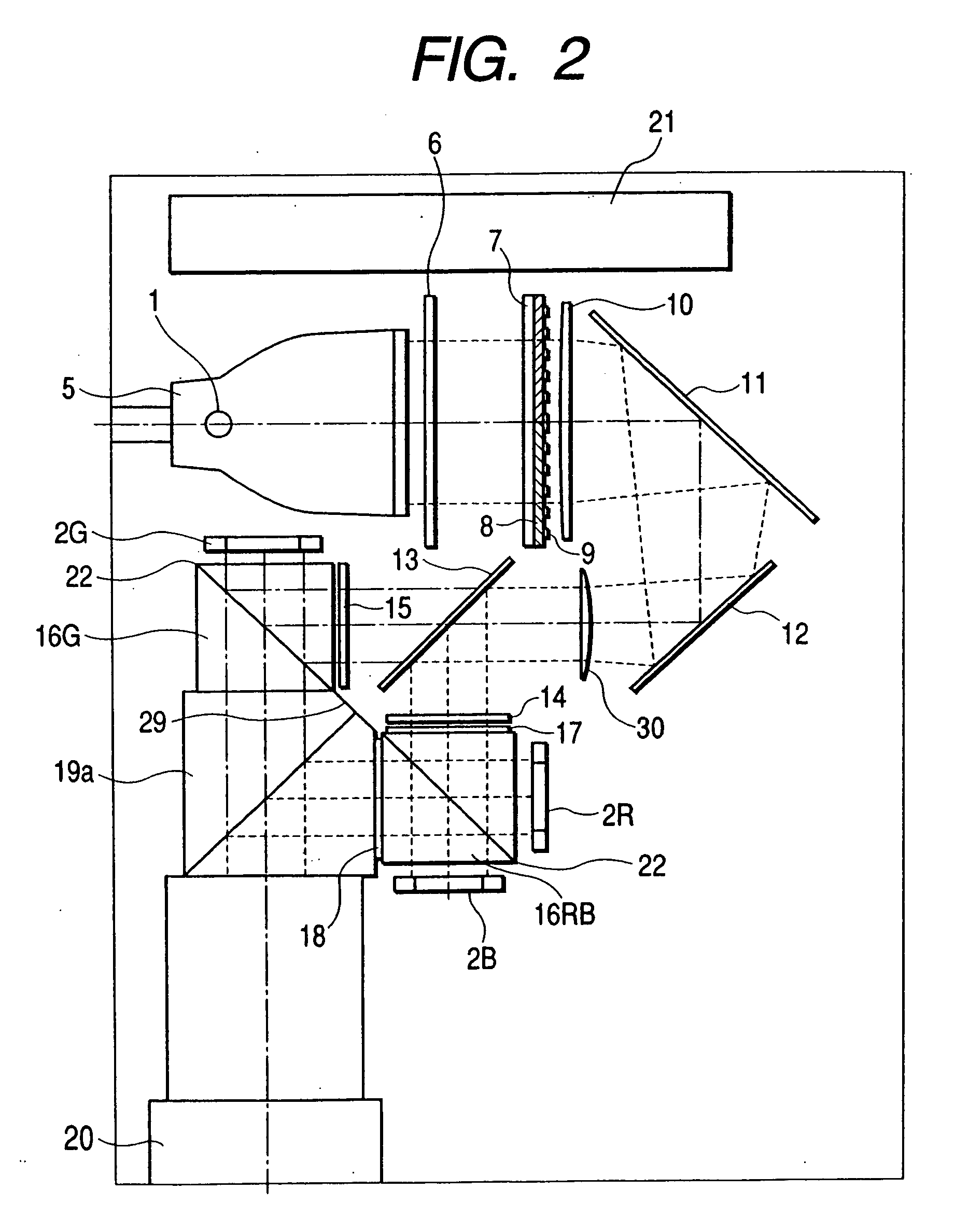

Image display device

InactiveUS6926411B2Small sizeReduce weightTelevision system detailsBuilt-on/built-in screen projectorsBeam splitterDisplay device

An image display device has three reflective image display elements for red, green and blue to form an optical image according to a video signal from light output from a light source, and an optical system to supply light onto the display elements and to combine and output the light reflected from the display elements. The image display device includes a first polarity converting unit to convert luminous flux from the light source to S polarized light, a first polarized beam splitter, and second polarized beam splitter. The reflective image display element for green is provided in a vicinity of the first polarized beam splitter, and the light reflected by the first polarized beam splitter and input to the reflective image display element for green is S polarized light. The light output from the reflective image display element for green permeates the first and second polarized beam splitters.

Owner:MAXELL HLDG LTD

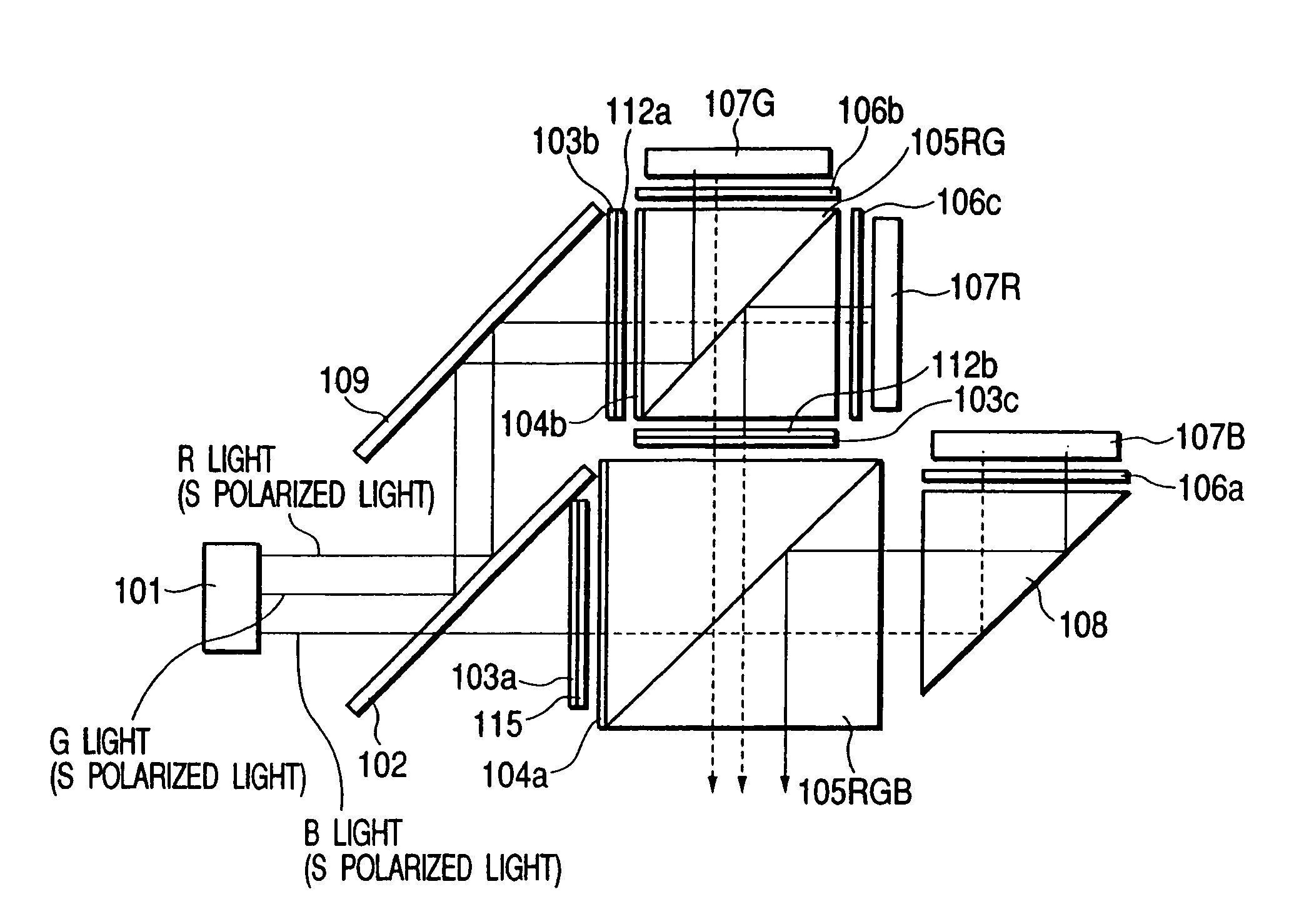

Image display device

InactiveUS7044607B2Reduce weight and sizeMaintain brightnessTelevision system detailsBuilt-on/built-in screen projectorsBeam splitterDisplay device

An image display device has three reflective image display elements for red, green and blue to form an optical image according to a video signal from light output from a light source, and an optical system to supply light onto the display elements and to combine and output the light reflected from the display elements. The image display device includes a first polarity converting unit to convert luminous flux from the light source to S polarized light, a first polarized beam splitter, and second polarized beam splitter. The reflective image display element for green is provided in a vicinity of the first polarized beam splitter, and the light reflected by the first polarized beam splitter and input to the reflective image display element for green is S polarized light. The light output from the reflective image display element for green permeates the first and second polarized beam splitters.

Owner:MAXELL HLDG LTD

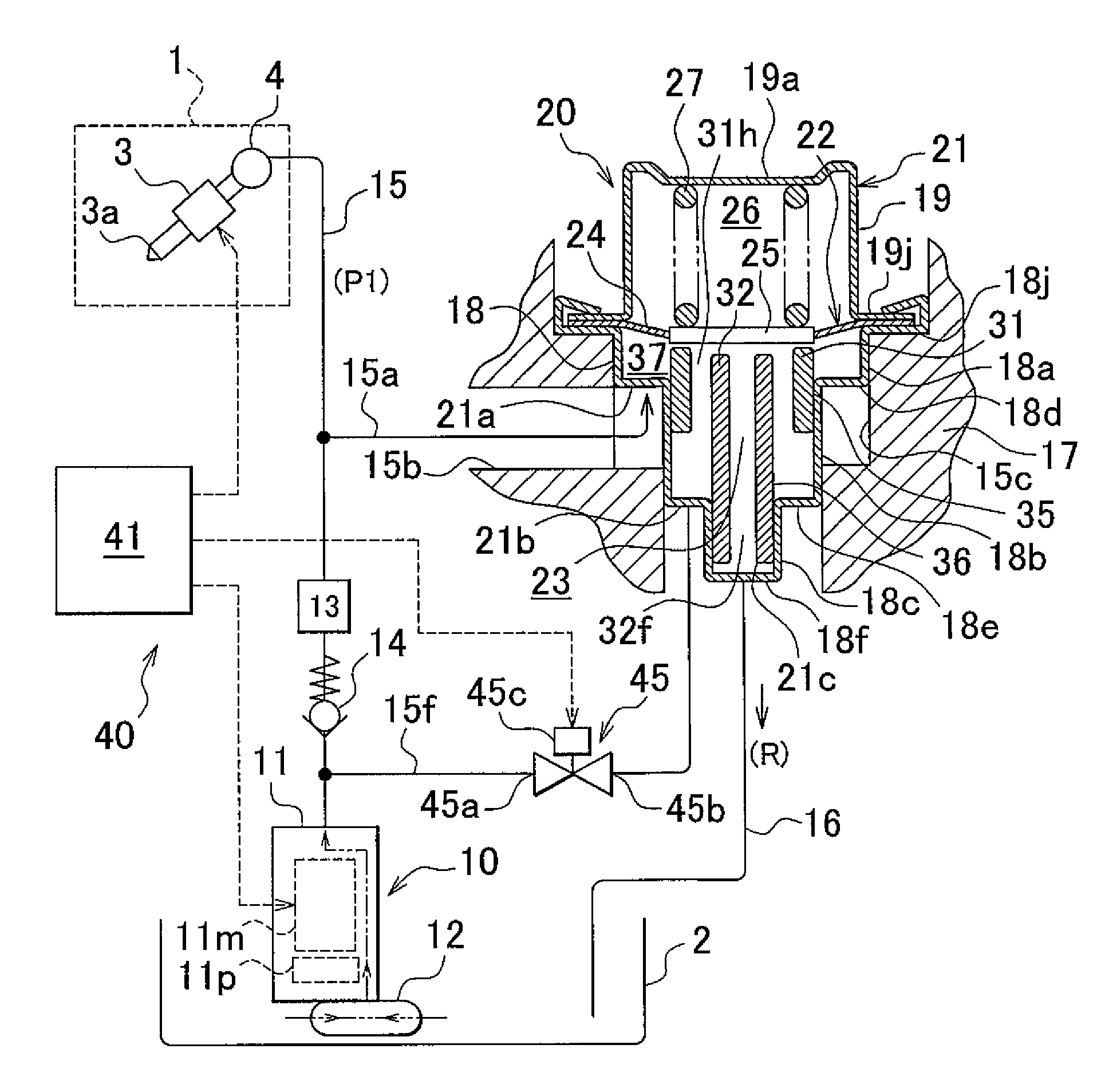

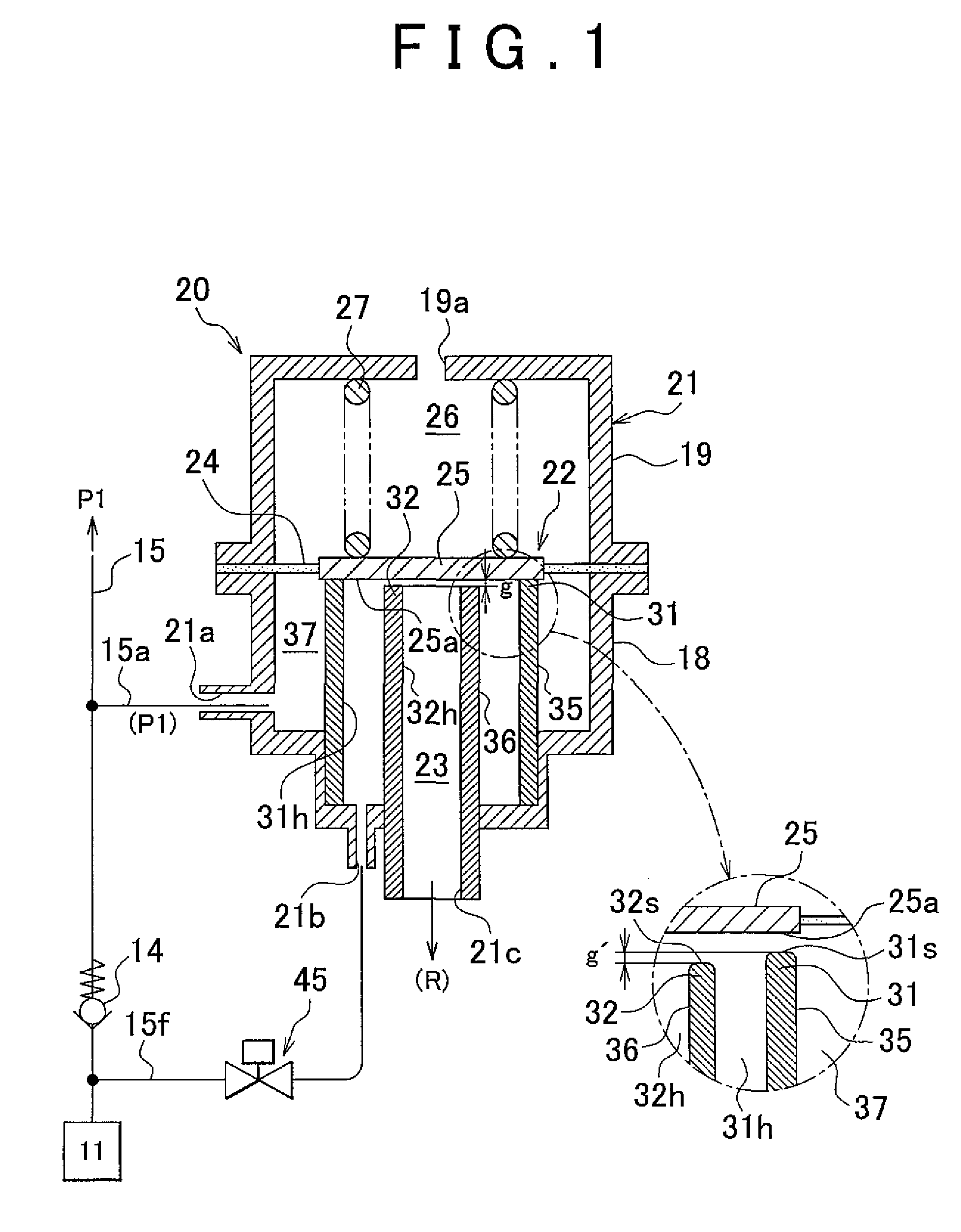

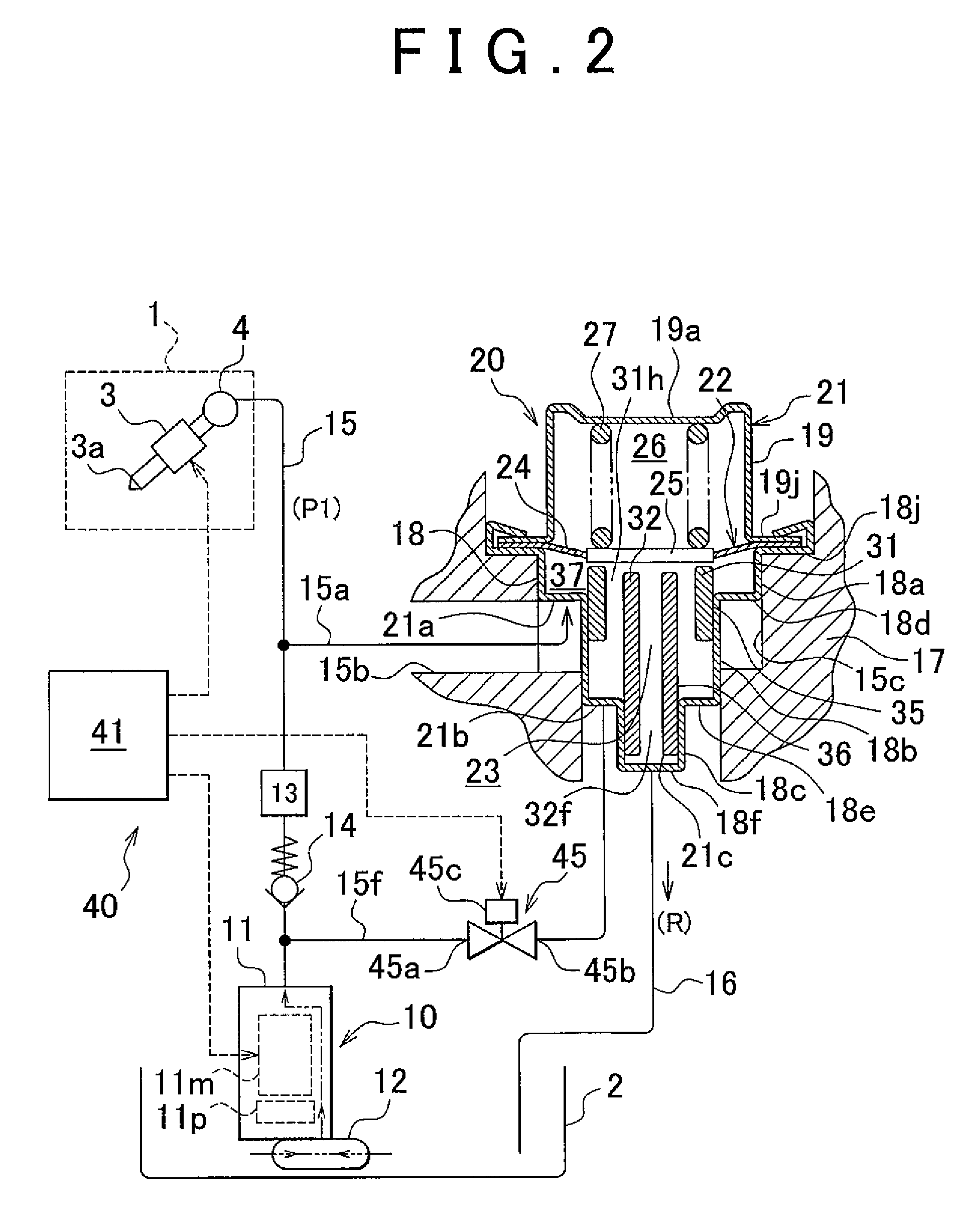

Fluid pressure regulating device and fuel supply system using same

InactiveUS20110297126A1Low costSimple configurationCheck valvesLow pressure fuel injectionEngineeringFuel supply

A fluid pressure regulating device is i) provided with a pressure regulating member that forms a pressure regulating chamber inside a housing having introduction side and discharge side fuel passages, and communicates these passages according to introduced fuel pressure, and ii) is able to regulate the fuel pressure introduced into a fuel passage to a set pressure. The housing is provided with outer and inner annular valve seat portions that separate the fuel passages inside the pressure regulating chamber, and form another fuel passage inside the pressure regulating chamber. Different clearances are set between the pressure regulating member, and the outer annular valve seat portion and the inner annular valve seat portion, such that when the pressure regulating member abuts against one of the valve seat portions, a small gap is formed between the other valve seat portion and the pressure regulating member.

Owner:TOYOTA JIDOSHA KK +1

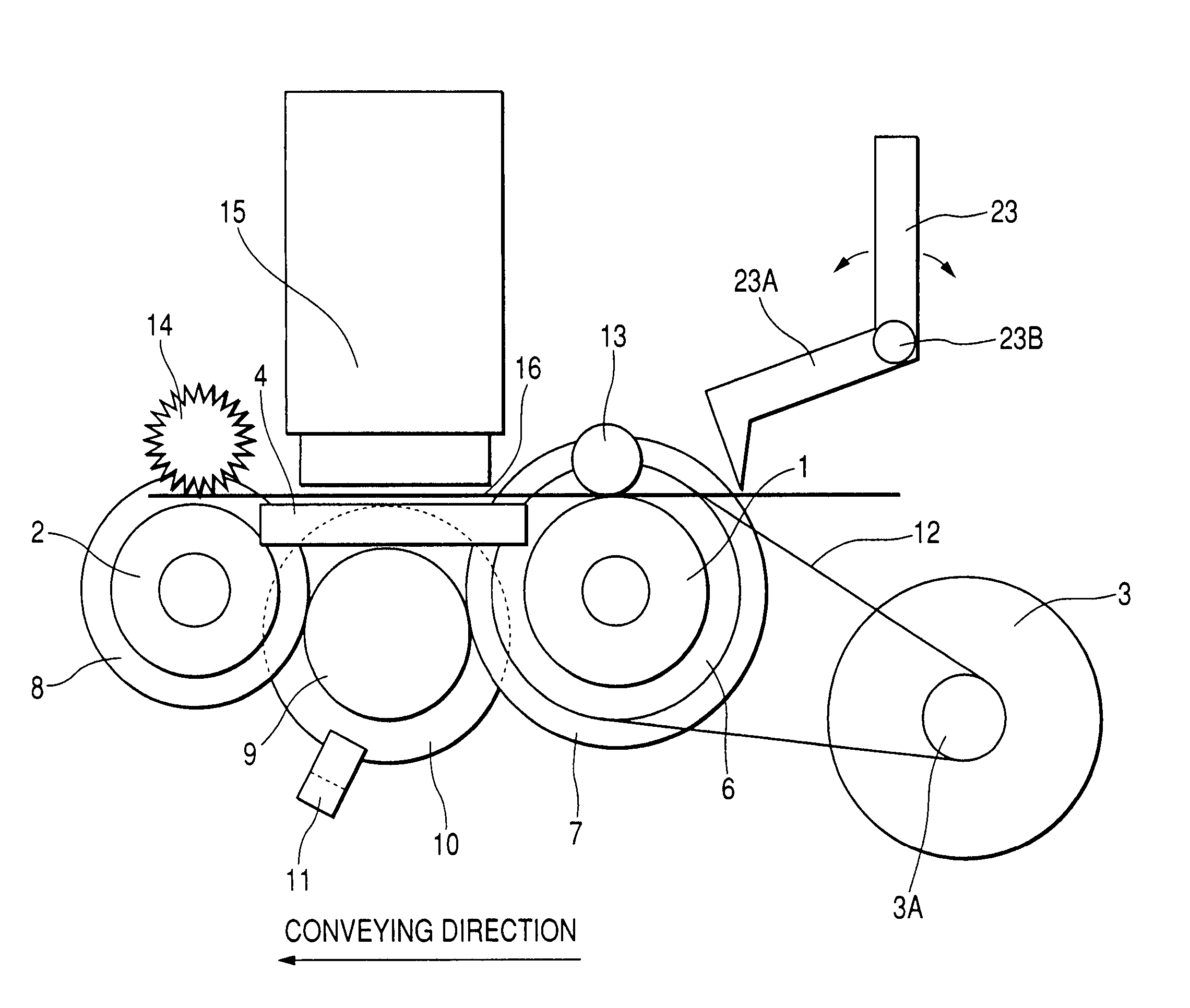

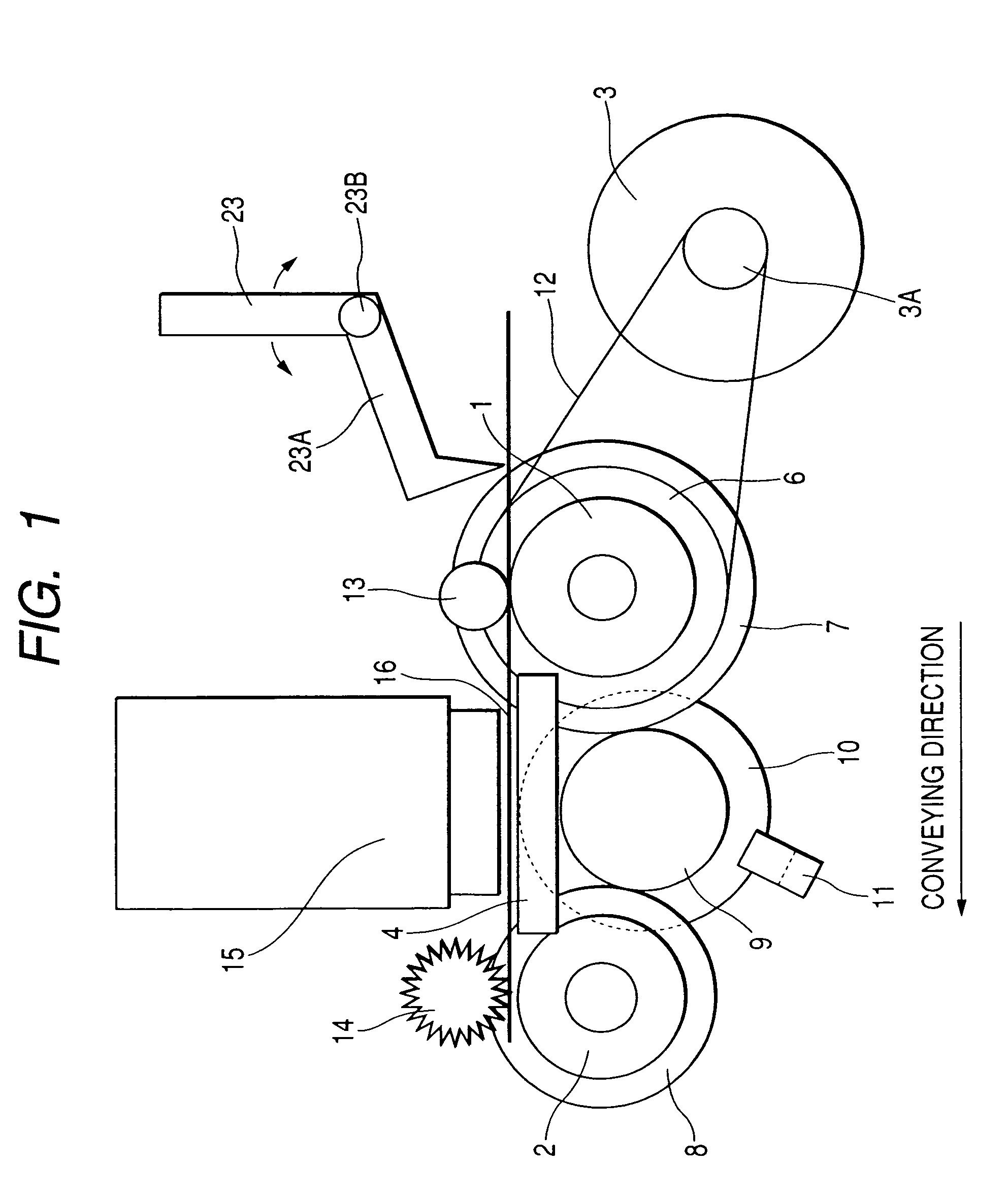

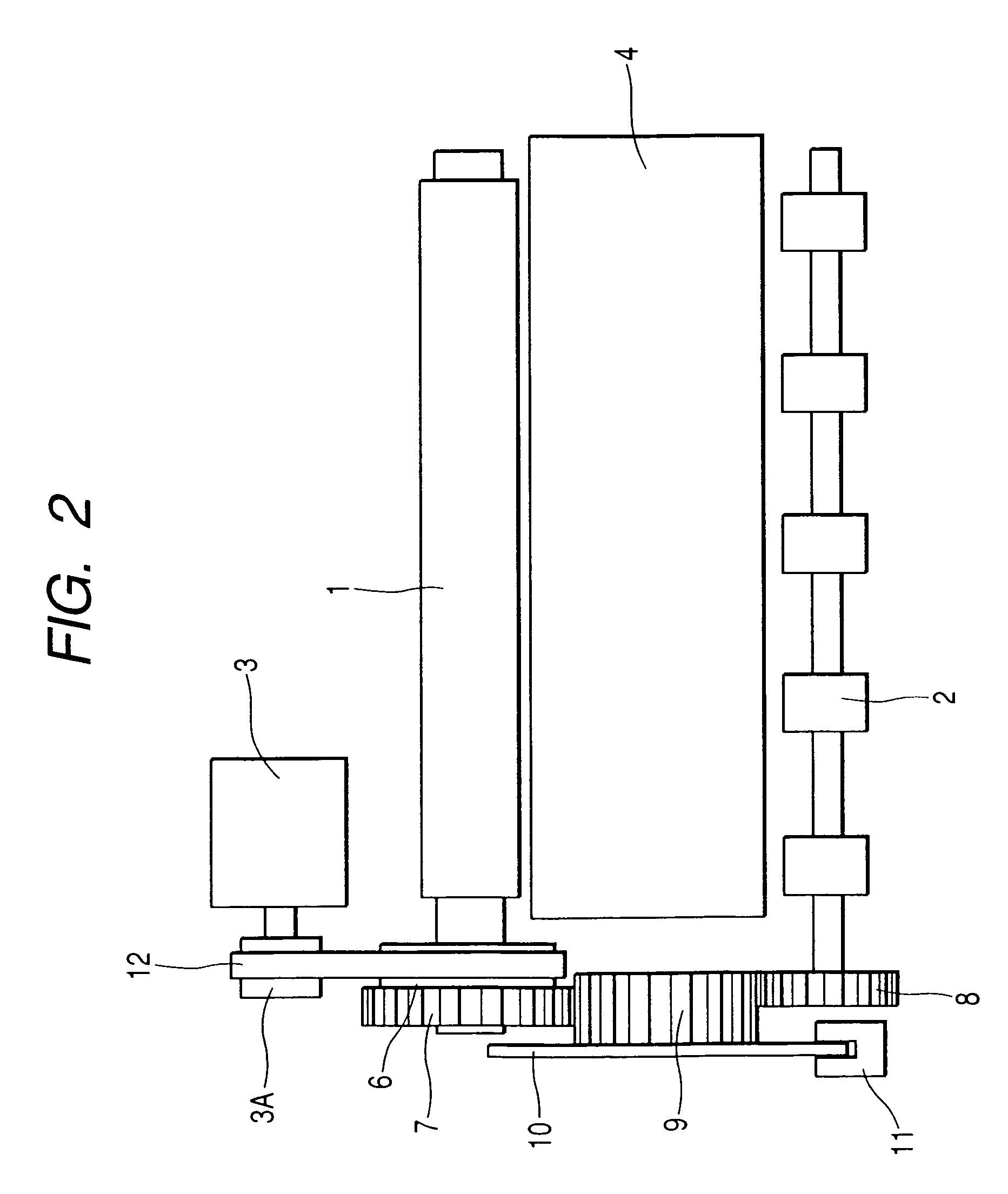

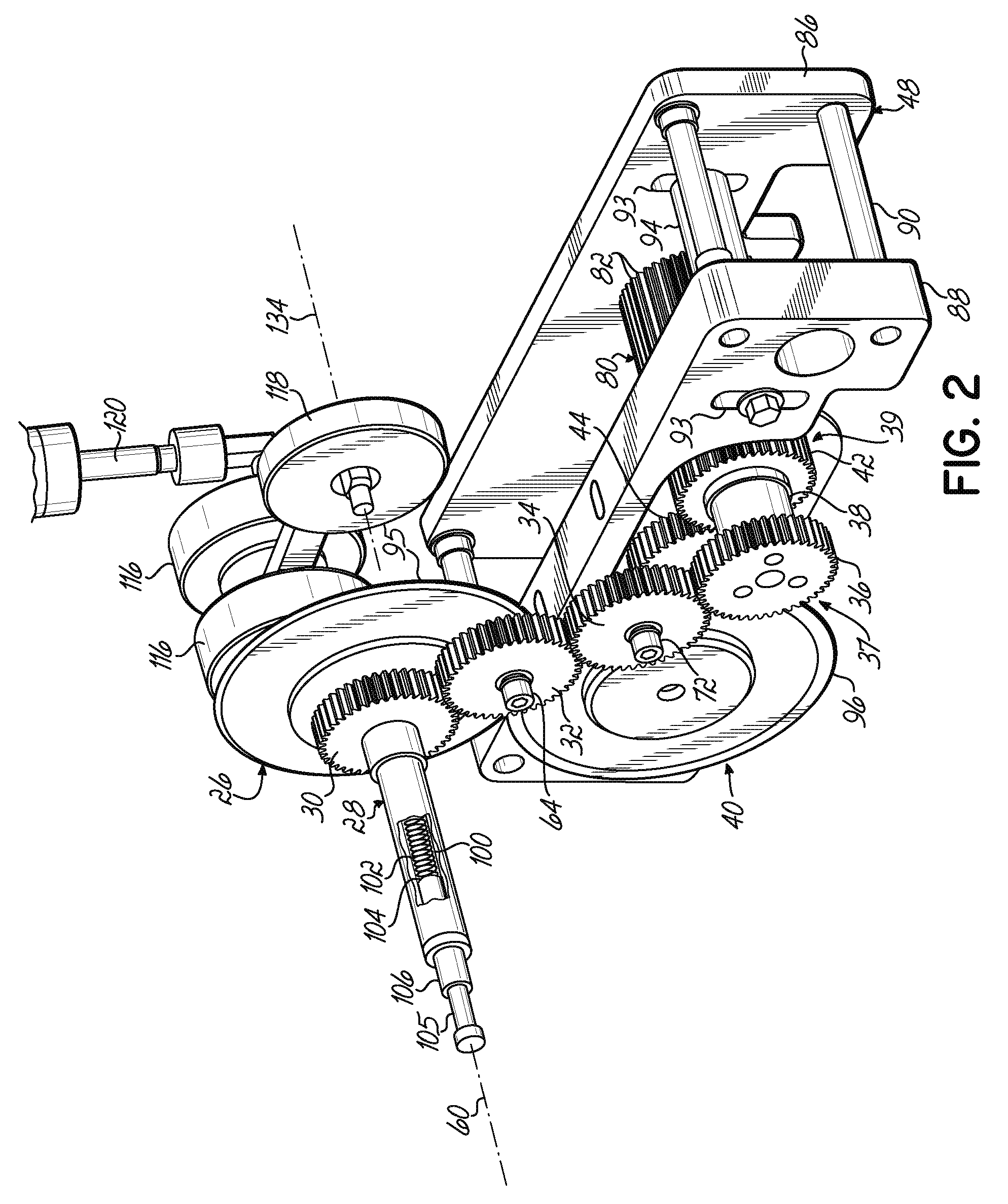

Recording apparatus

InactiveUS7401913B2High conveying precisionCompact and inexpensiveSpacing mechanismsElectrographic process apparatusGear wheelEngineering

Owner:CANON KK

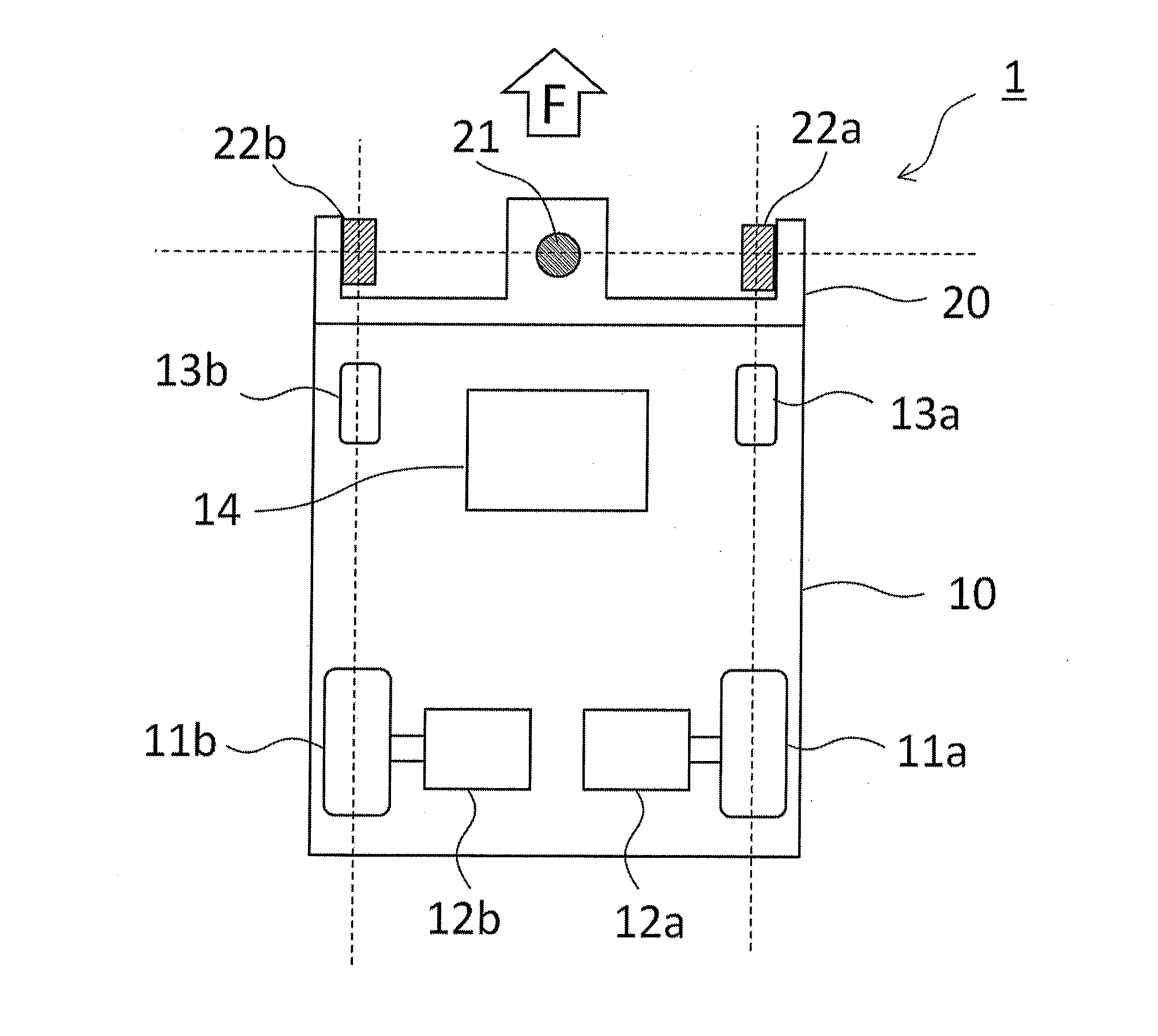

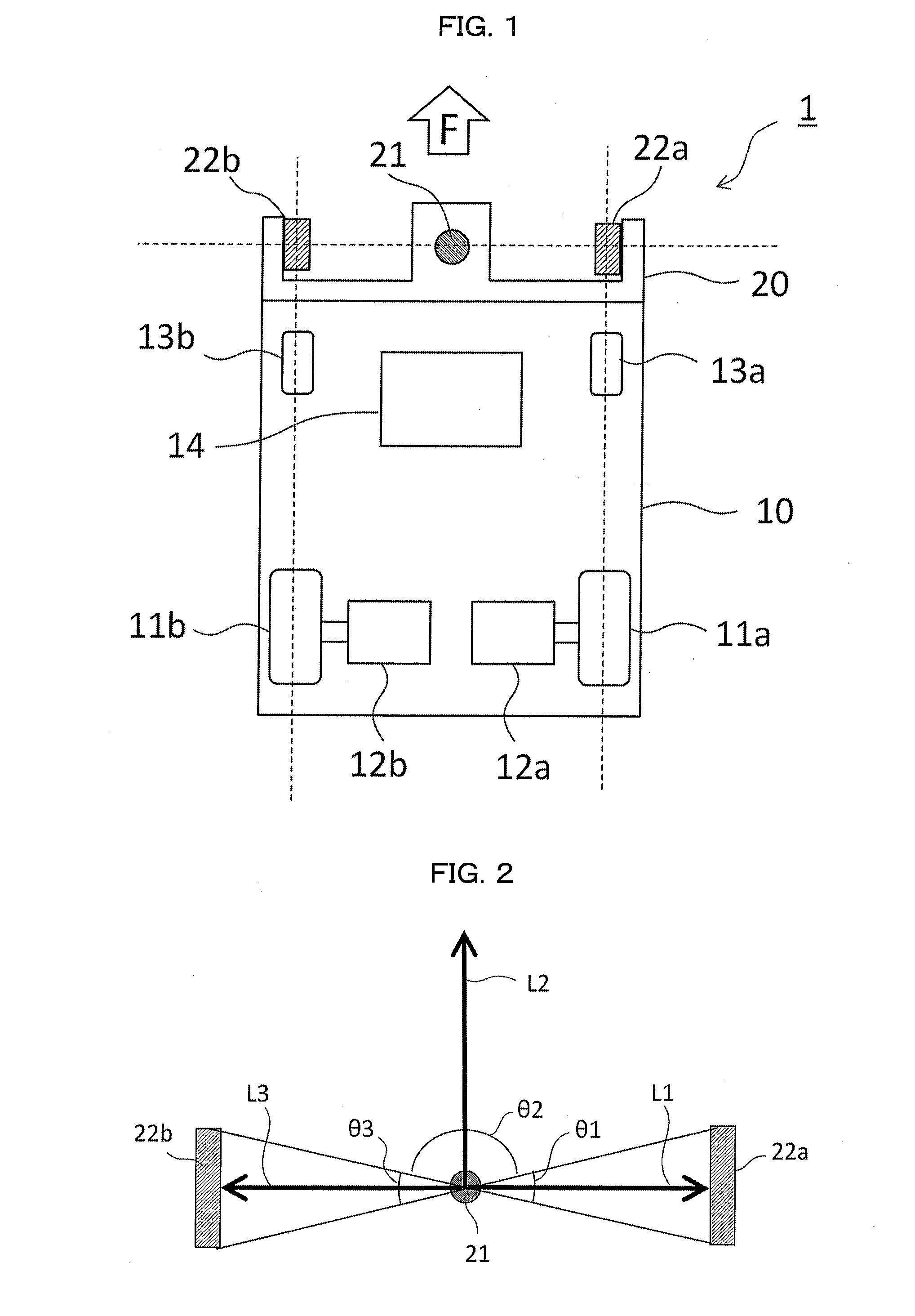

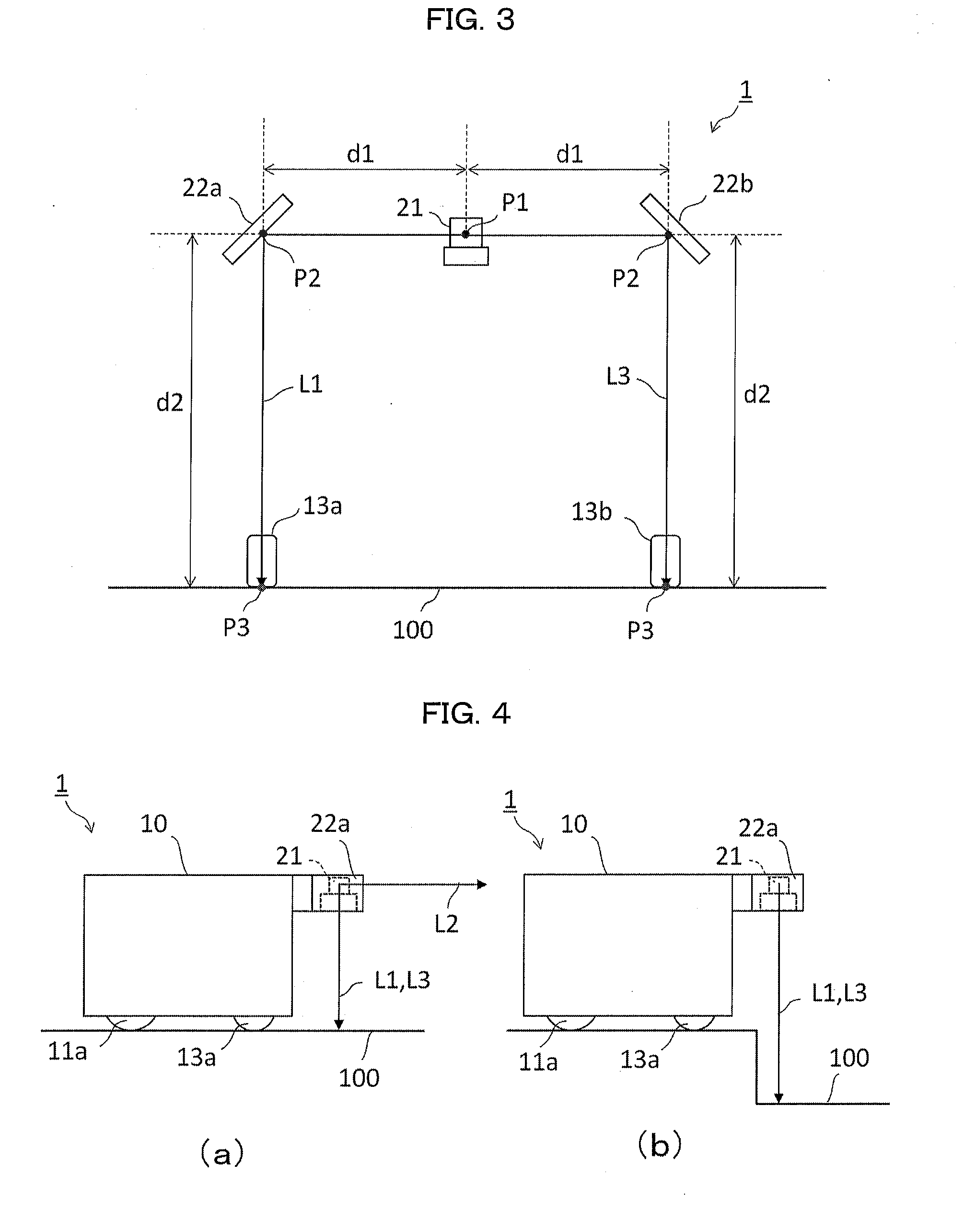

Autonomous mobile device and method for controlling same

InactiveUS20160170412A1Compact and inexpensiveAutonomous decision making processAnti-collision systemsLaser scanningLaser ranging

In order to realize an autonomous mobile device which is compact and inexpensive and which is capable of almost simultaneously detecting (i) an obstacle present ahead of the autonomous moving device and (ii) a difference in level of a floor surface, an autonomous mobile device (1) of the present invention is an autonomous mobile device (1) which moves while detecting (i) an obstacle present ahead of the autonomous mobile device (1) and (ii) a difference in level of a floor surface, including: a laser range finder (21) which measures a distance to an object present in a scan area by scanning the scan area while emitting a laser beam in parallel to the floor surface; and mirrors (22a, 22b) each of which is provided within the scan area scanned by the laser range finder (21) and each of which reflects part of the laser beam to the floor surface.

Owner:SHARP KK

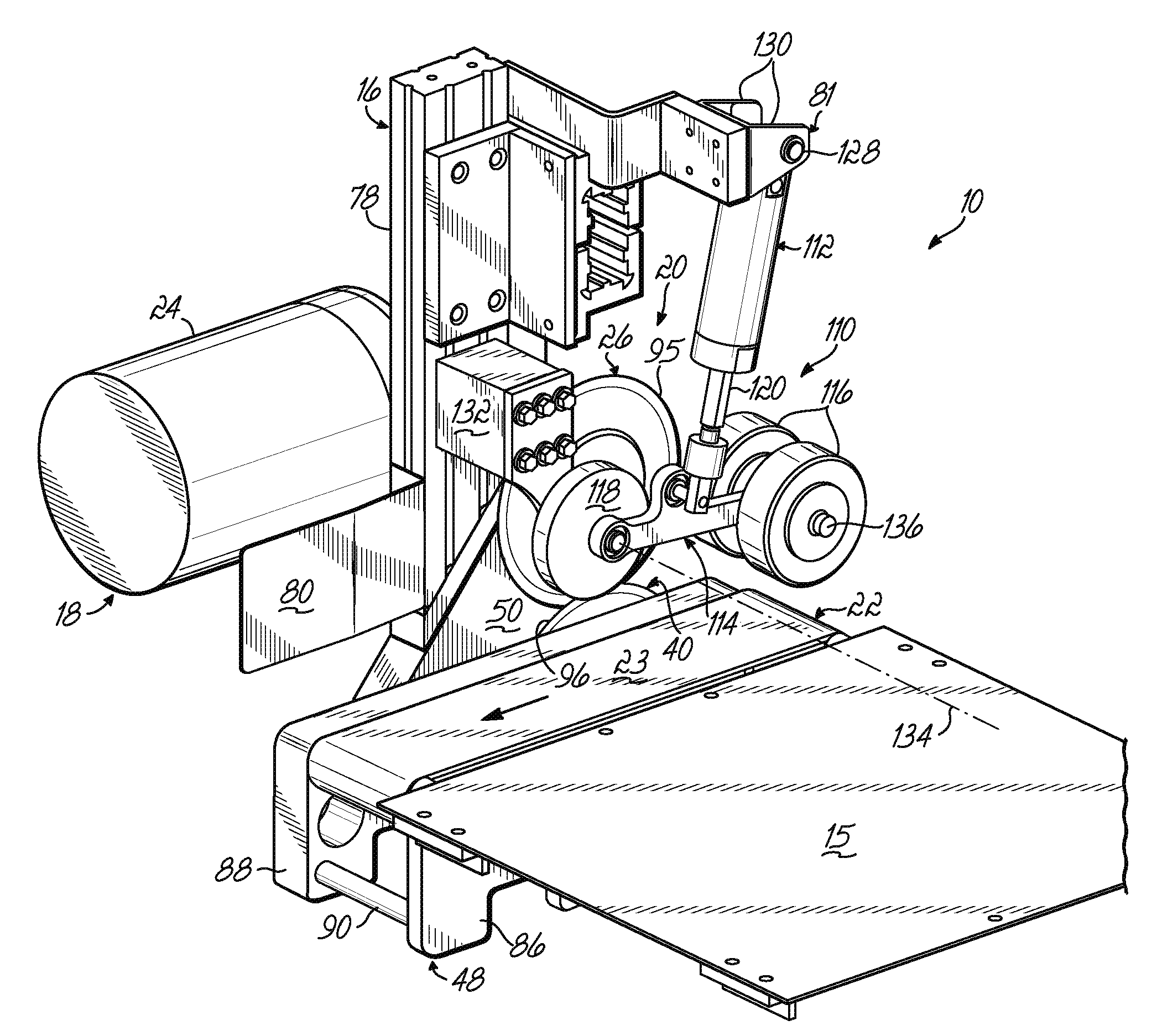

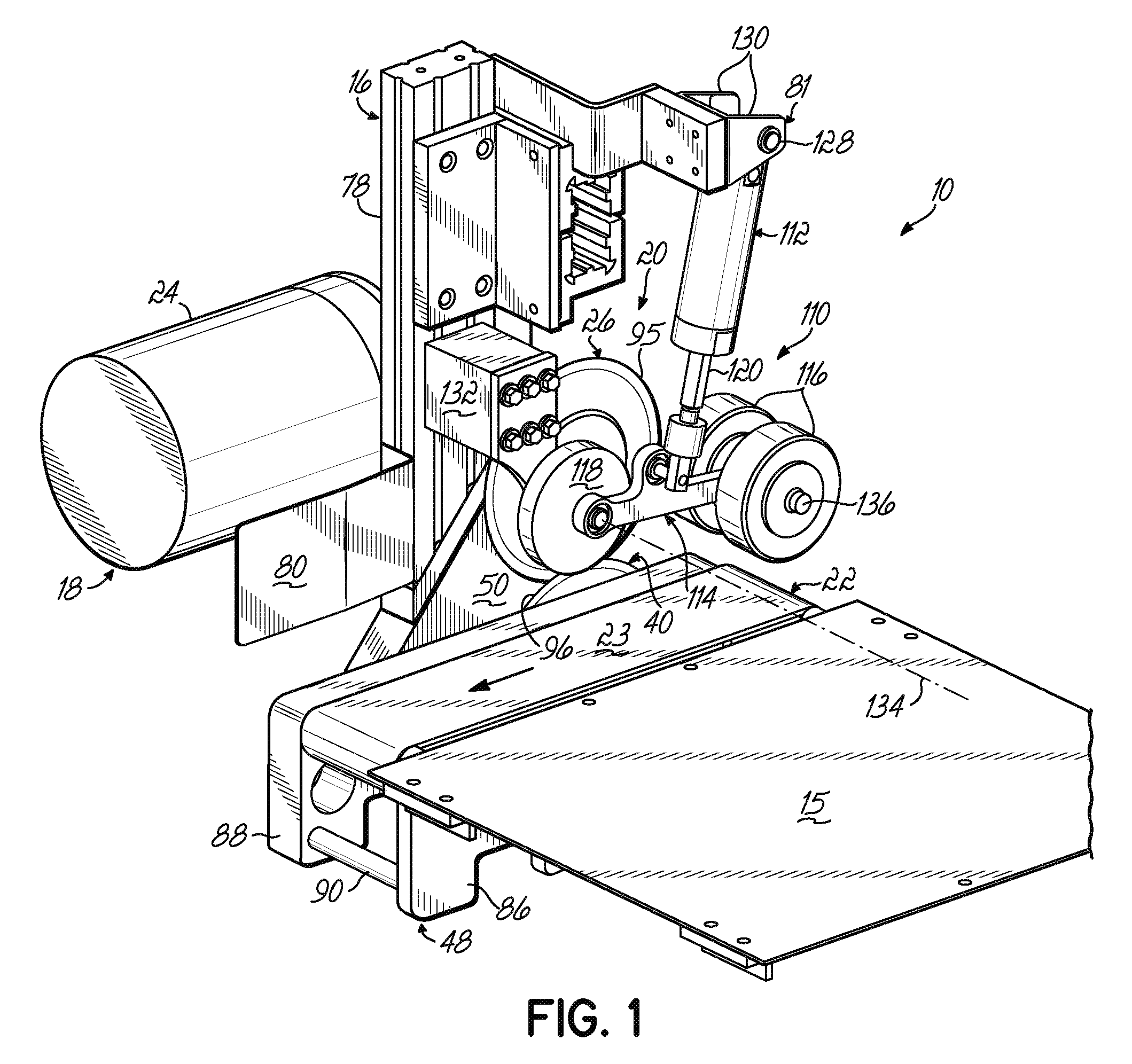

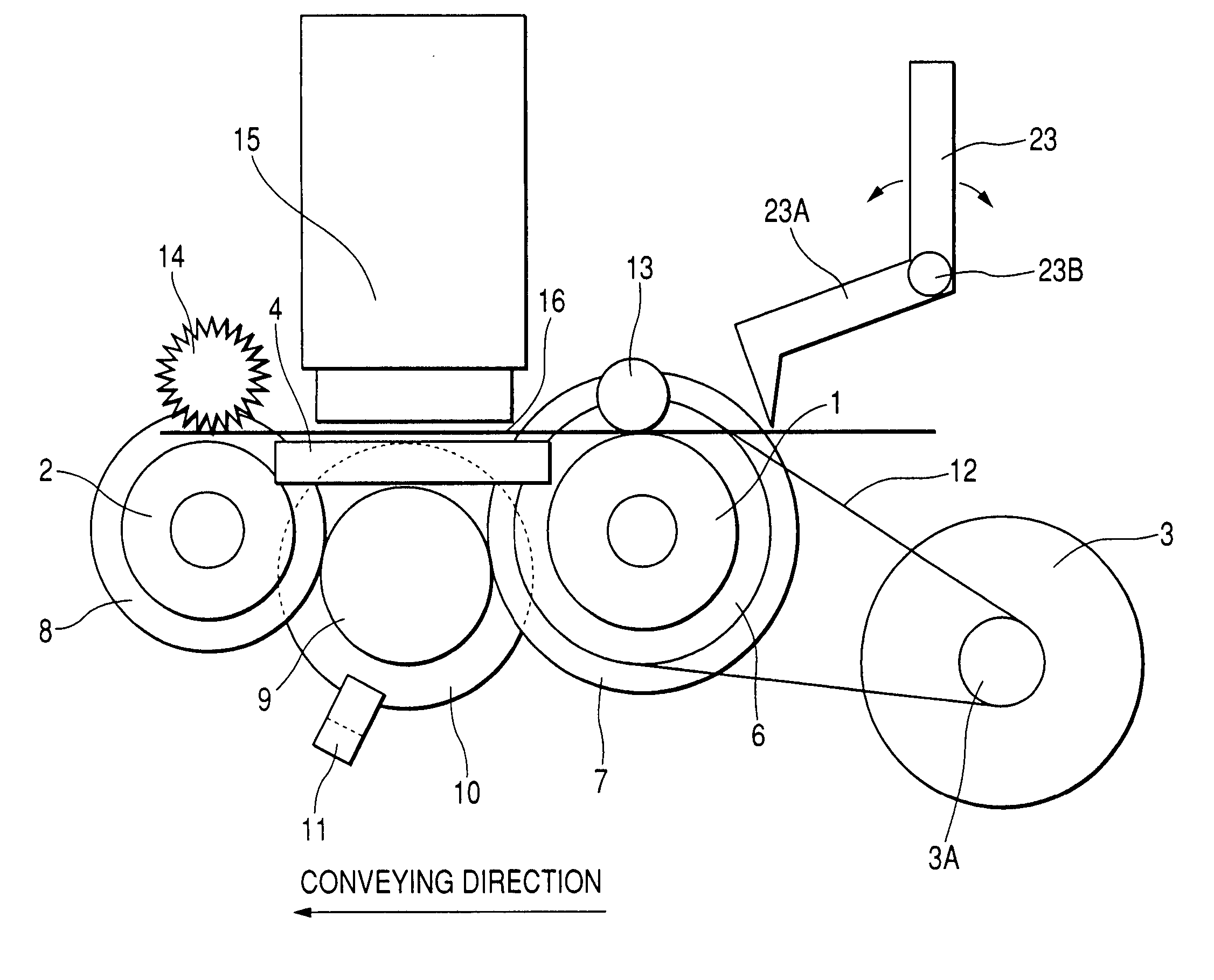

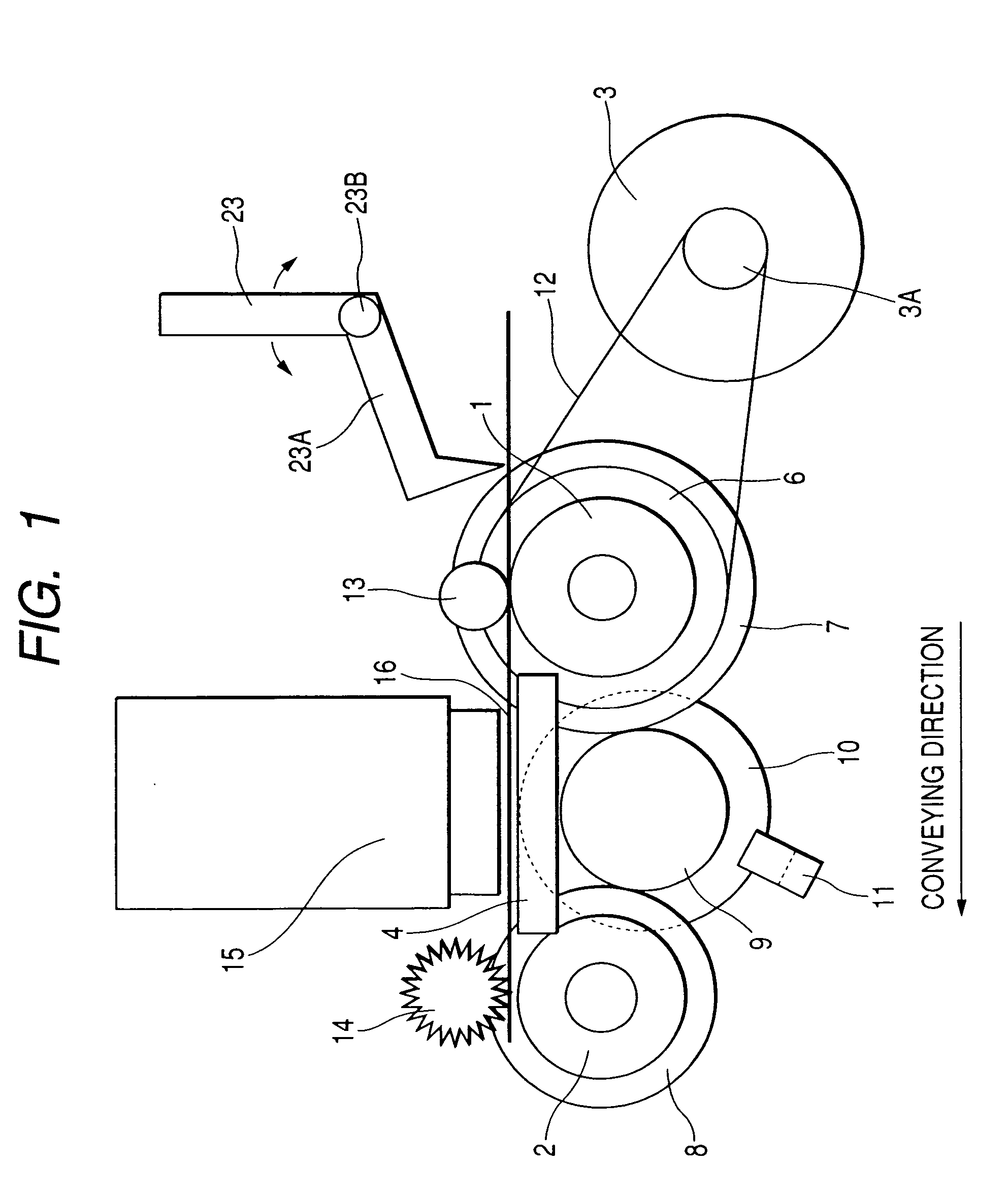

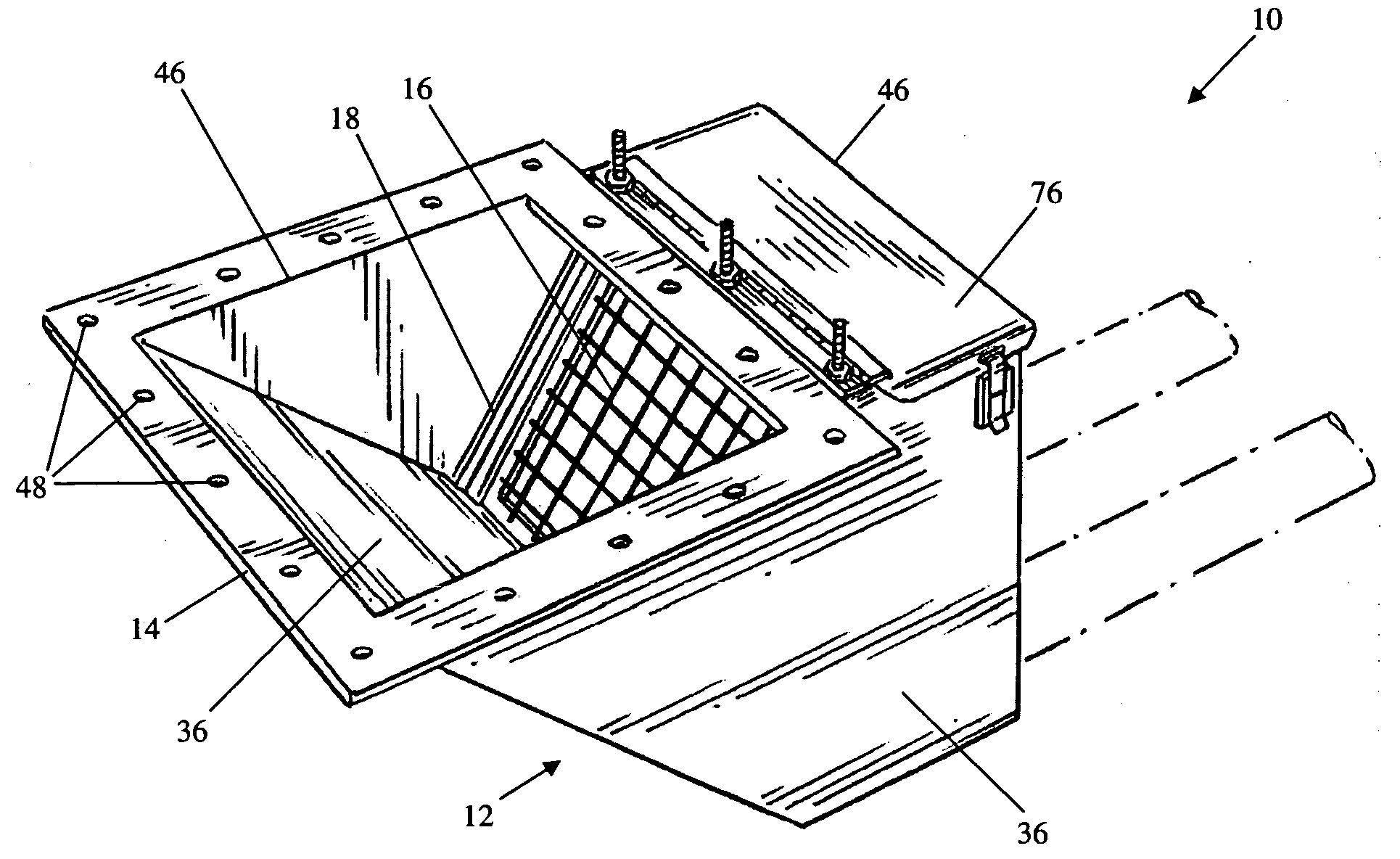

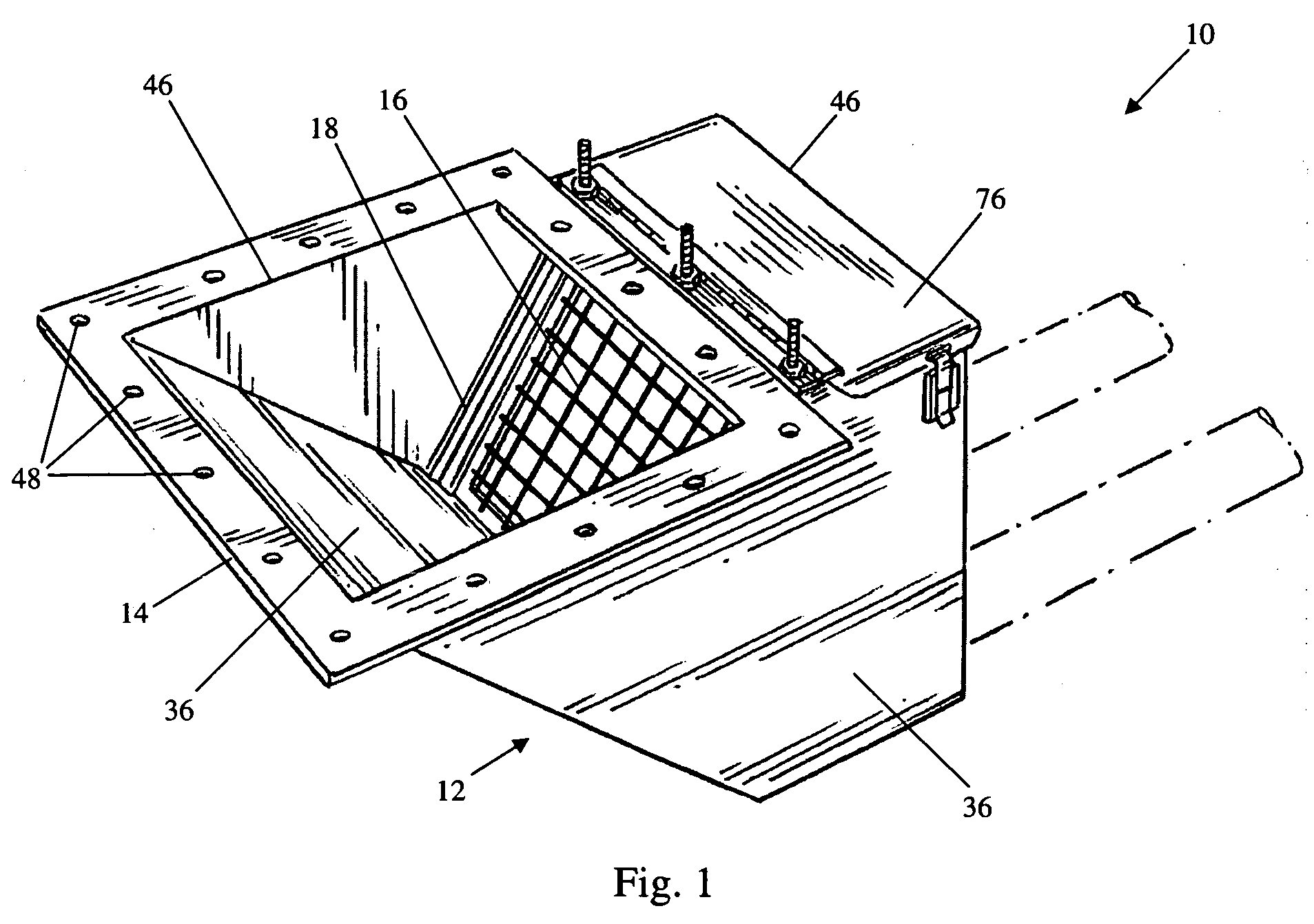

Soft Goods Slitter and Feed System for Quilting

InactiveUS20080264317A1Reliable feedingCompact and inexpensiveWorkpiece carriersLeather sewingEngineeringActuator

An apparatus is provided for feeding and slitting mattress covers, quilts and other soft goods supported on a table. The apparatus has a first slitting wheel rotatable by a motor. A second slitting wheel is rotatable by the motor and contacts the first slitting wheel to provide a cutting action. The apparatus further includes a conveyor operable by the motor for conveying the soft goods past the slitting wheels, and a compression assembly having an actuator, a swing arm, and wheels for compressing the soft goods and holding the soft goods against the conveyor to preventing slippage or twisting.

Owner:L & P PROPERTY MANAGEMENT CO

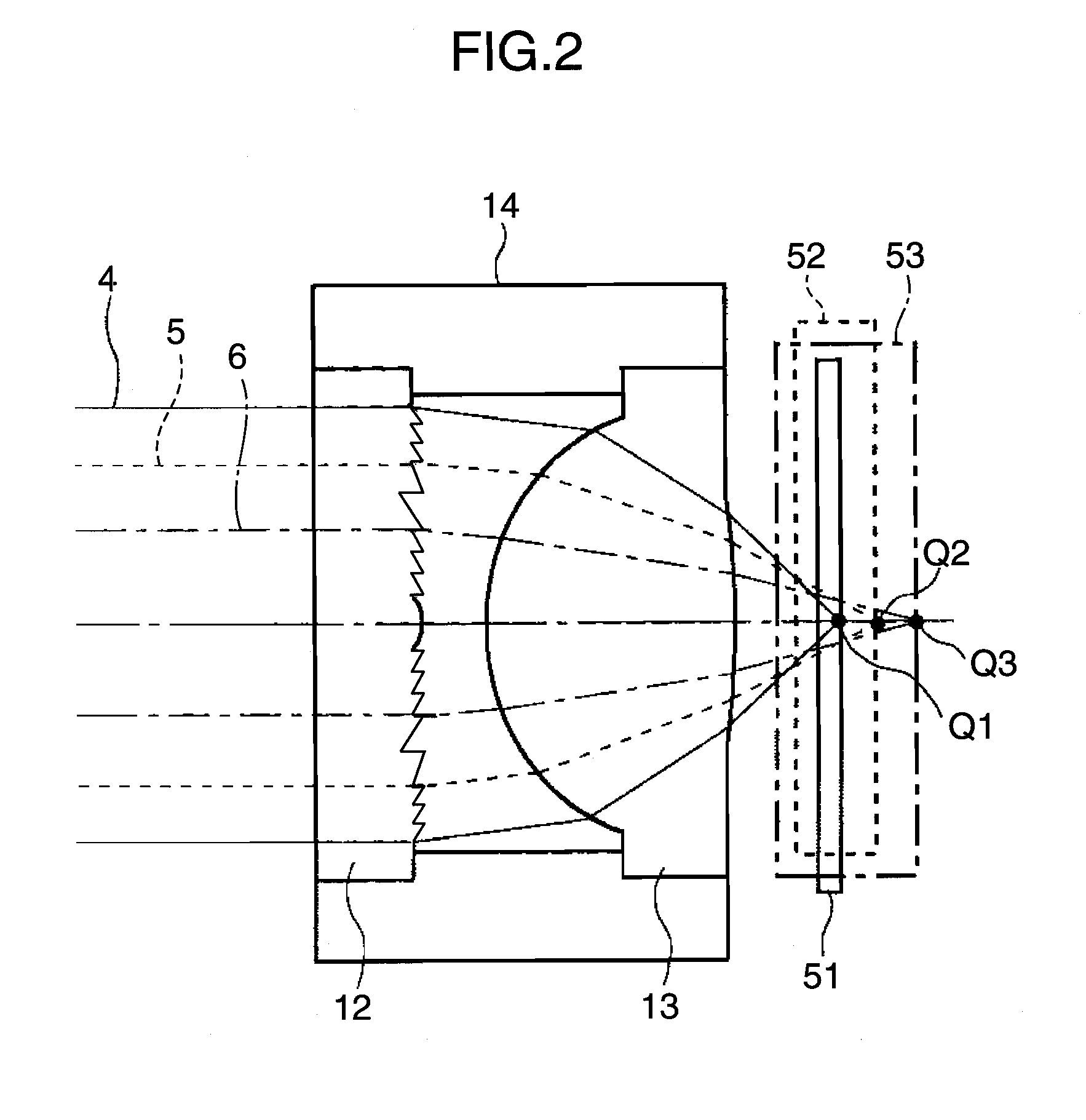

Optical head and optical disc device

ActiveUS20100157777A1Stable compatible playbackCompact and inexpensiveOptical beam sourcesRecord information storageBlue lightDiffraction efficiency

A compact and inexpensive optical head that enables stable compatible playback and compatible recording with optical discs of different kinds with the use of a single objective lens is achieved. The order of diffracted light at which the diffraction efficiency by a diffraction element forming the objective lens becomes the maximum is set to the third order for blue light, the second order for red light, and the second order for infrared light in the inner peripheral portion of the diffraction element, and to the sixth order for blue light, the fourth order for red light, and the third order for infrared light to limit the aperture for infrared light in the intermediate peripheral portion. In the outer peripheral portion, the aperture for red light is limited by setting the order to an integer other than multiples of 3 for blue light.

Owner:PANASONIC CORP

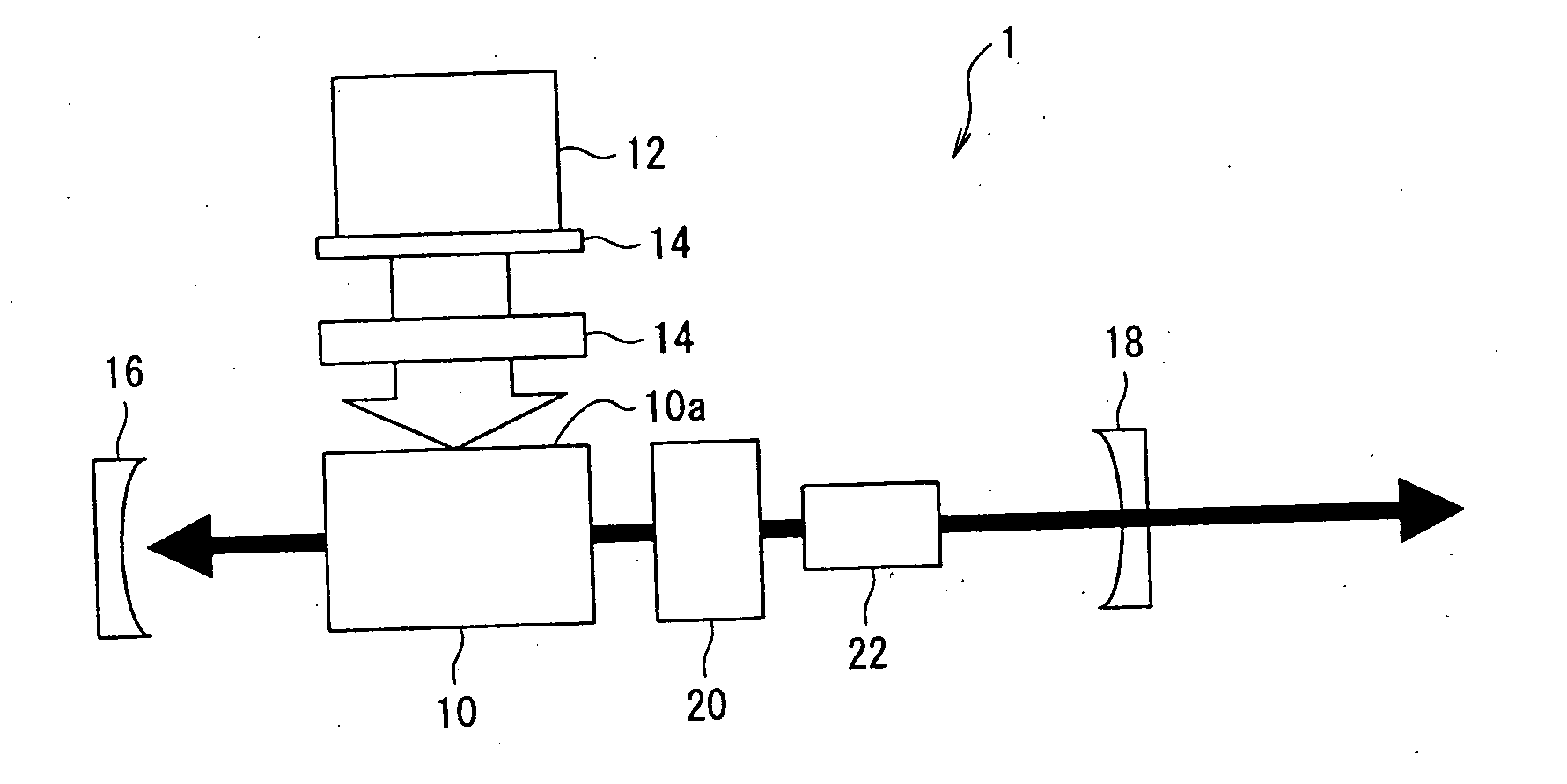

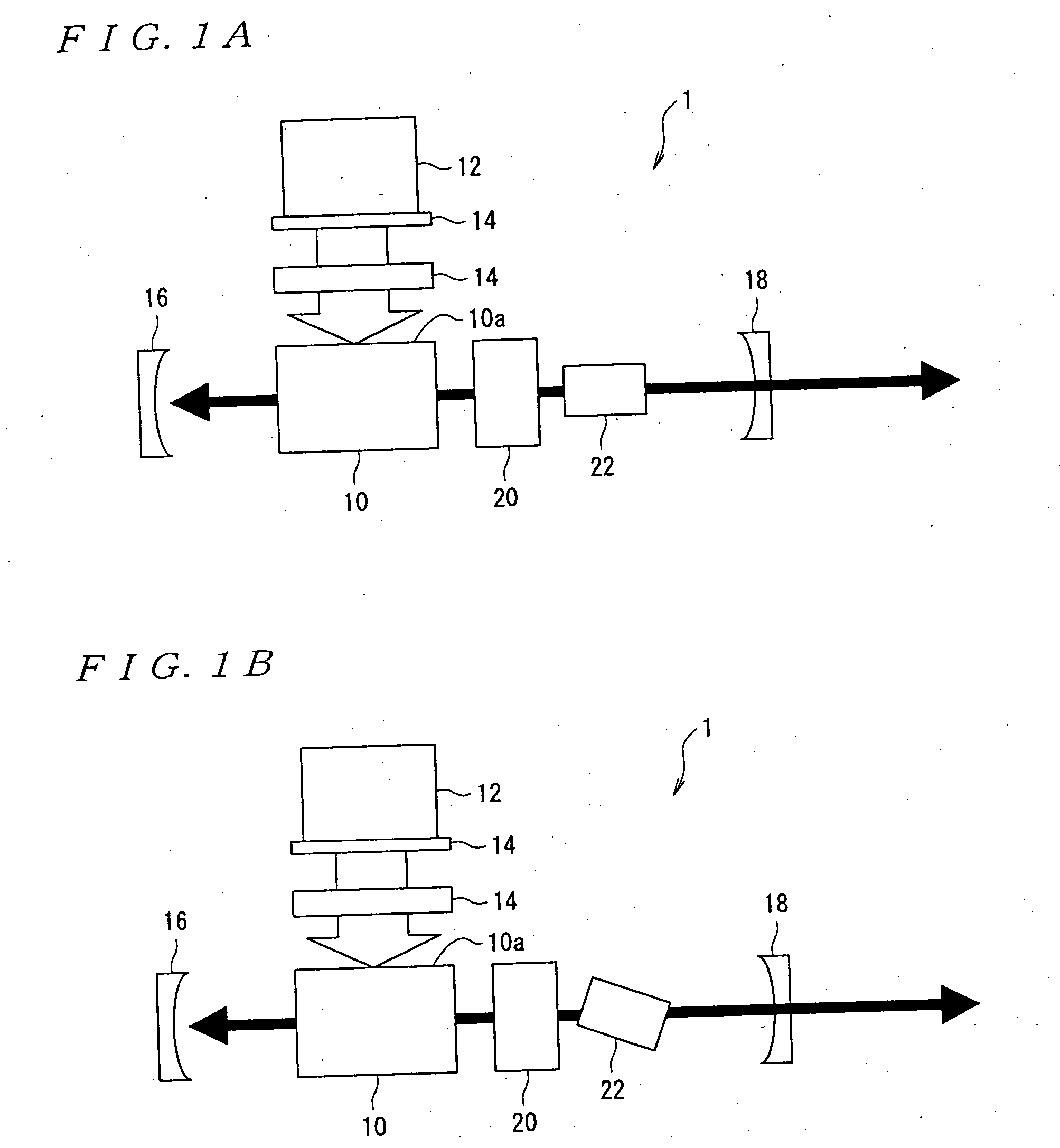

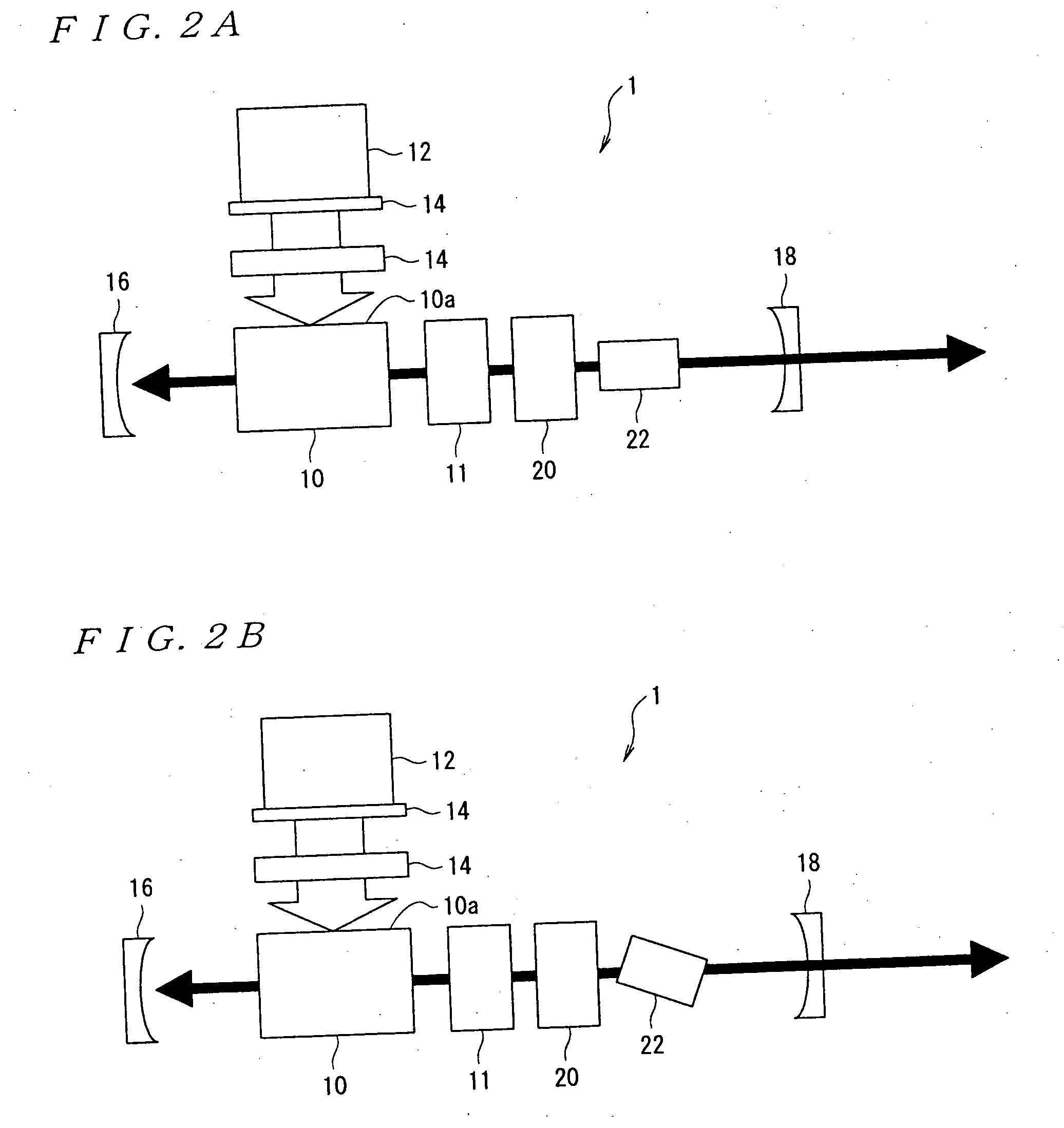

Laser apparatus

InactiveUS20060039422A1Excel in oscillation efficiencyExcel in reliabilityLaser using scattering effectsLength waveRaman scattering

A compact and inexpensive laser apparatus capable of obtaining laser beams of multiple wavelengths from a single solid crystal at the same time and excelling in reliability and efficiency is to be provided. A laser apparatus 1 uses a solid crystal consisting of a Raman effect substance as a laser medium 10, and is equipped with a laser oscillator 12 for exciting the laser medium 10 to generate laser beams, a reflector 16, a laser output mirror 18, for resonating the laser beam generated from the laser medium 10 and a harmonic element 22 for enabling by angle adjustment a single wavelength to be extracted out of multiple oscillation wavelengths.

Owner:FURUKAWA COMPANY

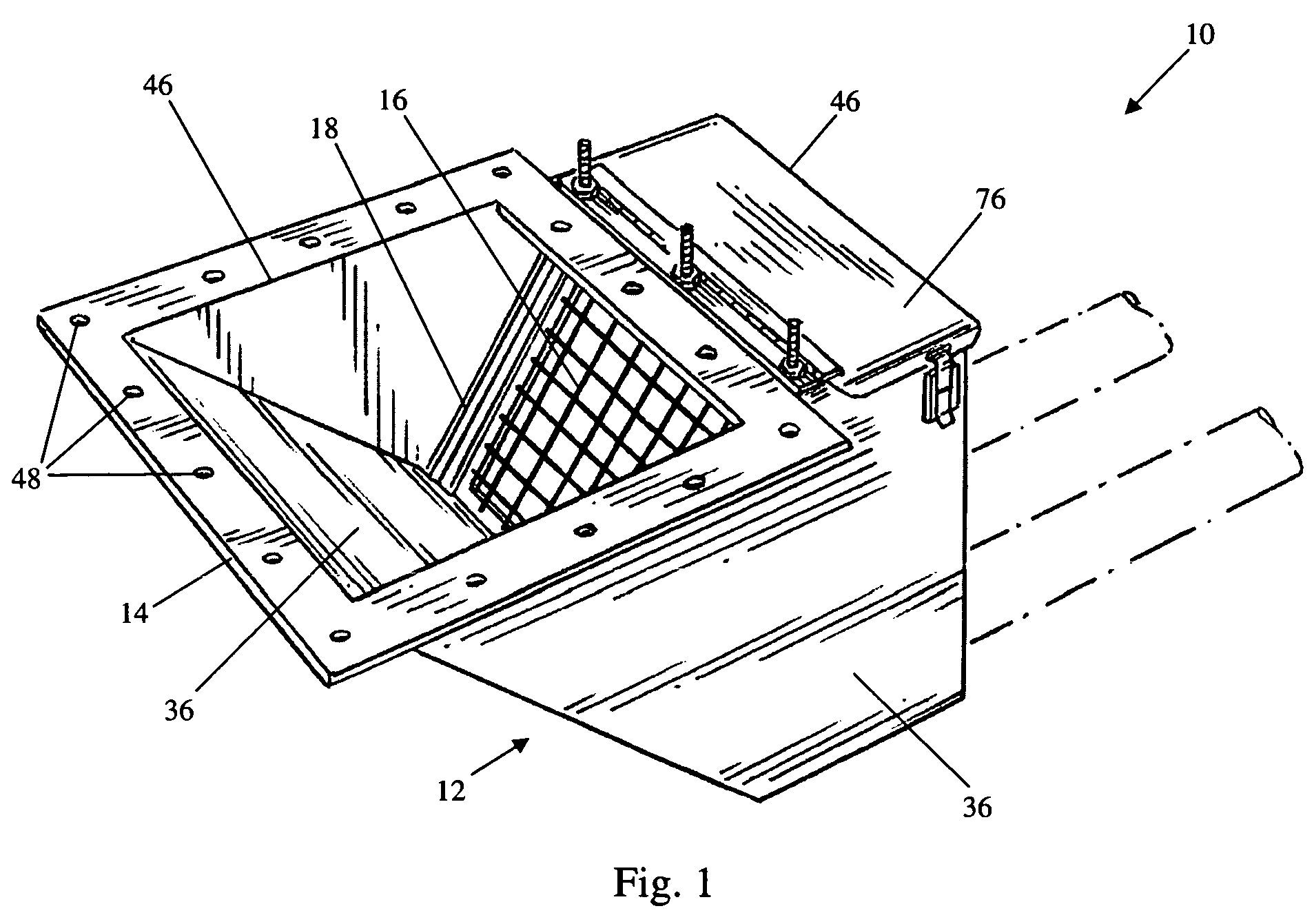

Filtering flow box for mounting to a silo

InactiveUS7819253B2Conveniently replacedCompact and inexpensiveSievingDomestic stoves or rangesEngineeringTower

Owner:ALLEY INDS

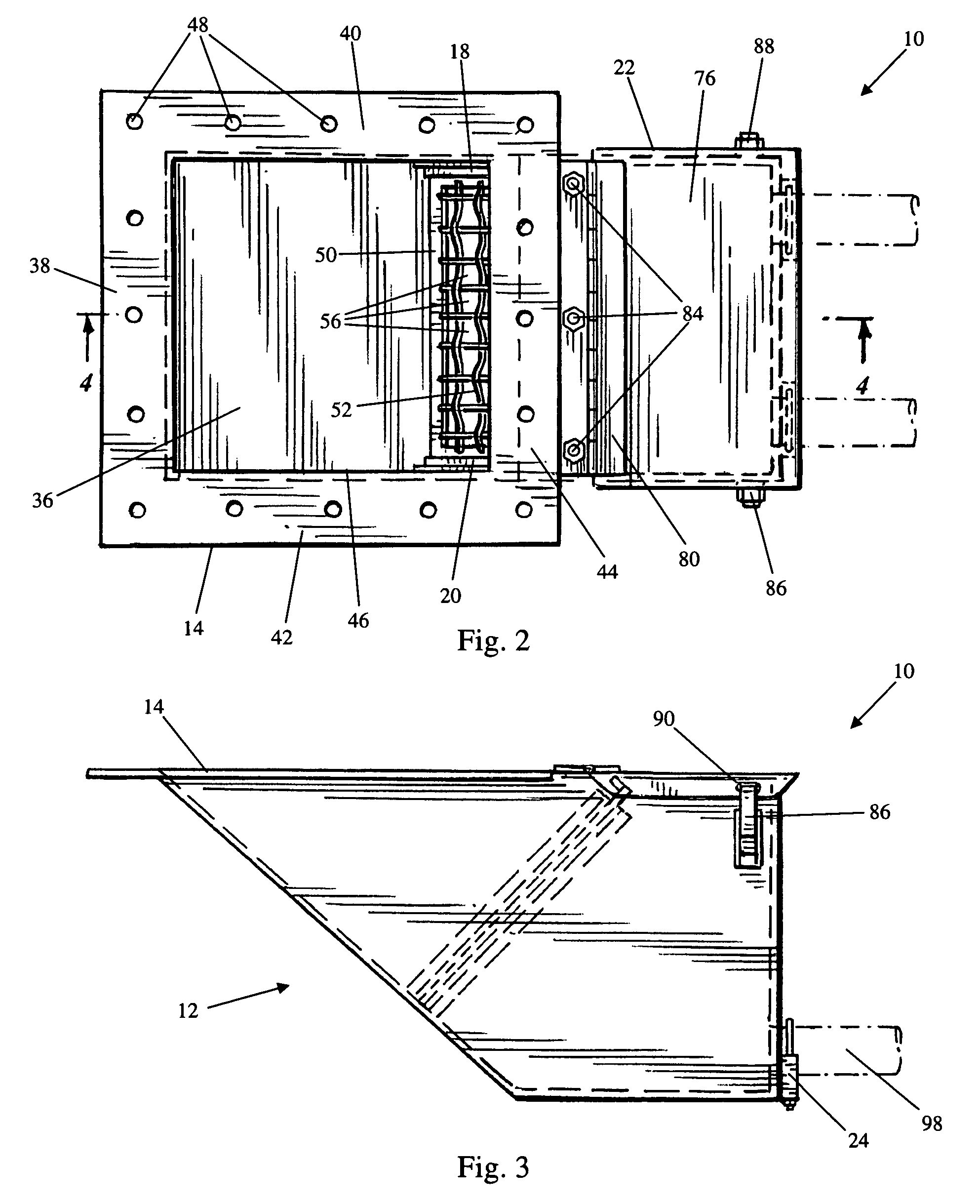

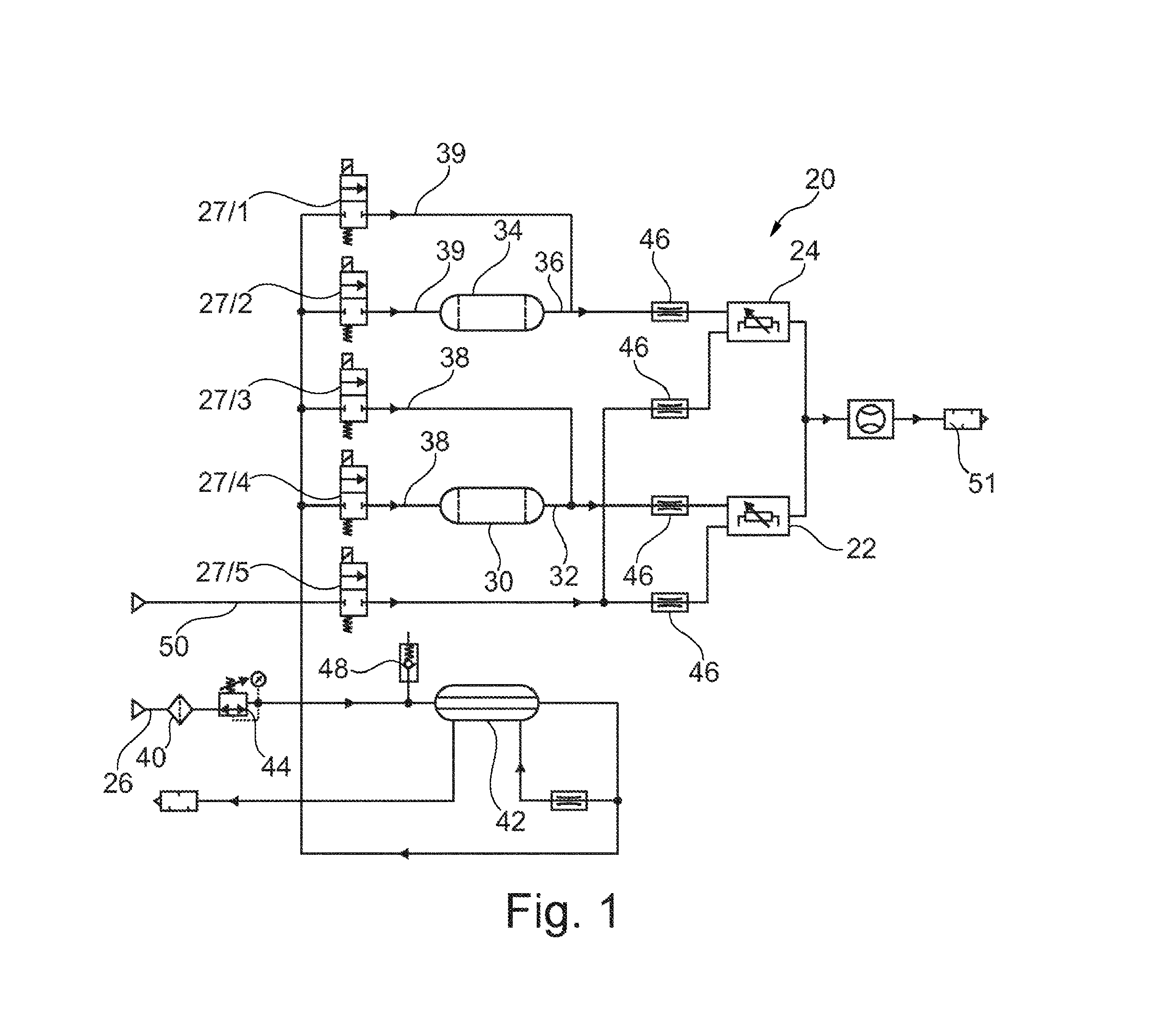

Device for measuring residual oil

InactiveUS20150369784A1Extended service lifeImprove stabilityTesting/calibration apparatusMaterial analysis by electric/magnetic meansResidual oilSemiconductor

The invention relates to a measuring device for detecting amounts of hydrocarbon in gases, and comprising—a first sensor (22) for determining the amount of hydrocarbon in a first measurement gas flow (38) and for producing a corresponding first measurement result,—a second sensor (24) for determining the amount of hydrocarbon in a second measurement gas flow (39) and for producing a corresponding second measurement result, and—an evaluation unit for evaluating the measurement results of the two sensors (22, 24),—the first sensor (22) being a metal oxide semiconductor gas sensor and carrying out measurements continuously, and—the second sensor (24) being a photoionisation sensor and carrying out measurements intermittently. (FIG. 1) The invention also relates to a method for recording the amount of hydrocarbon in a gas flow.

Owner:BEKO TECHNOLOGIES GMBH

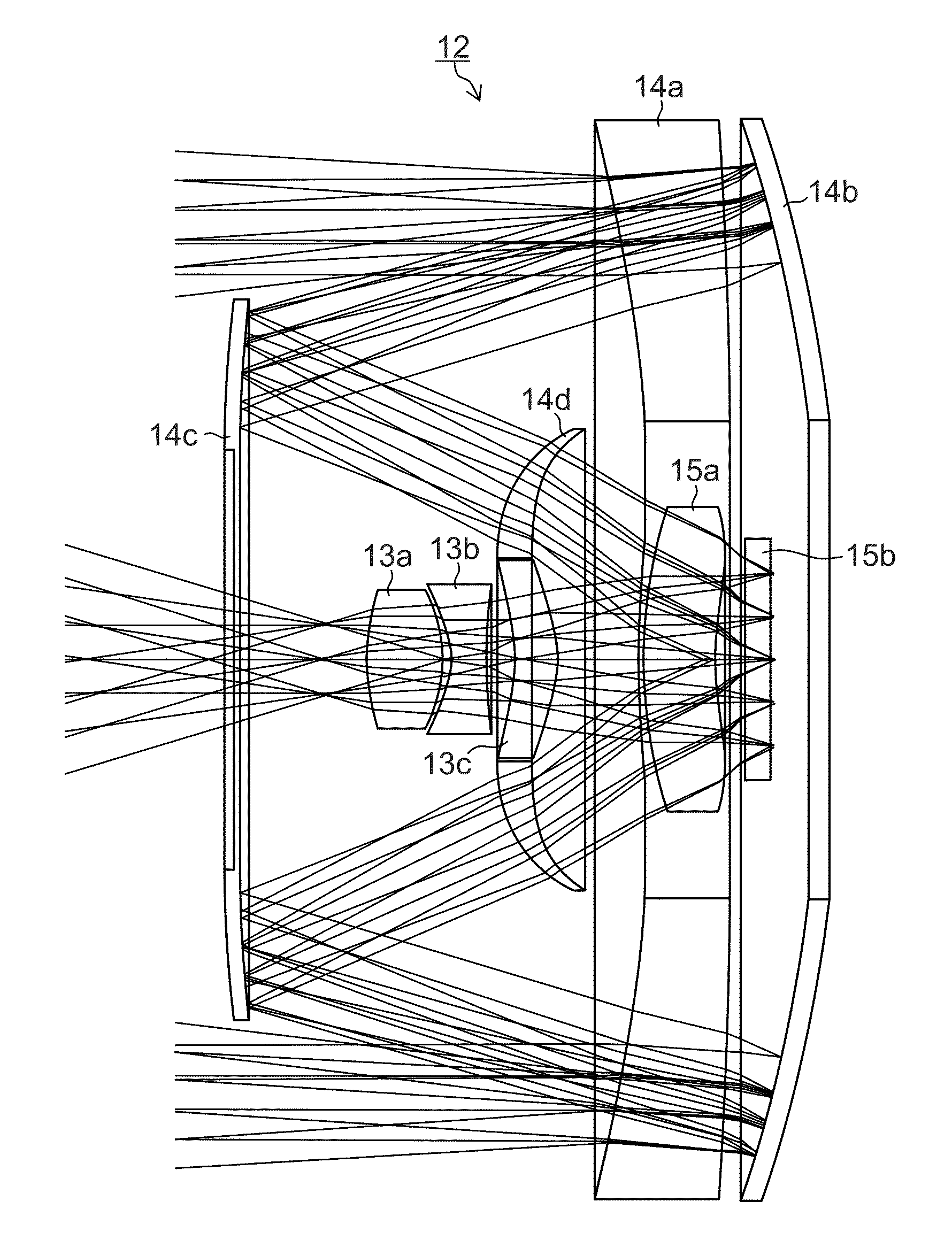

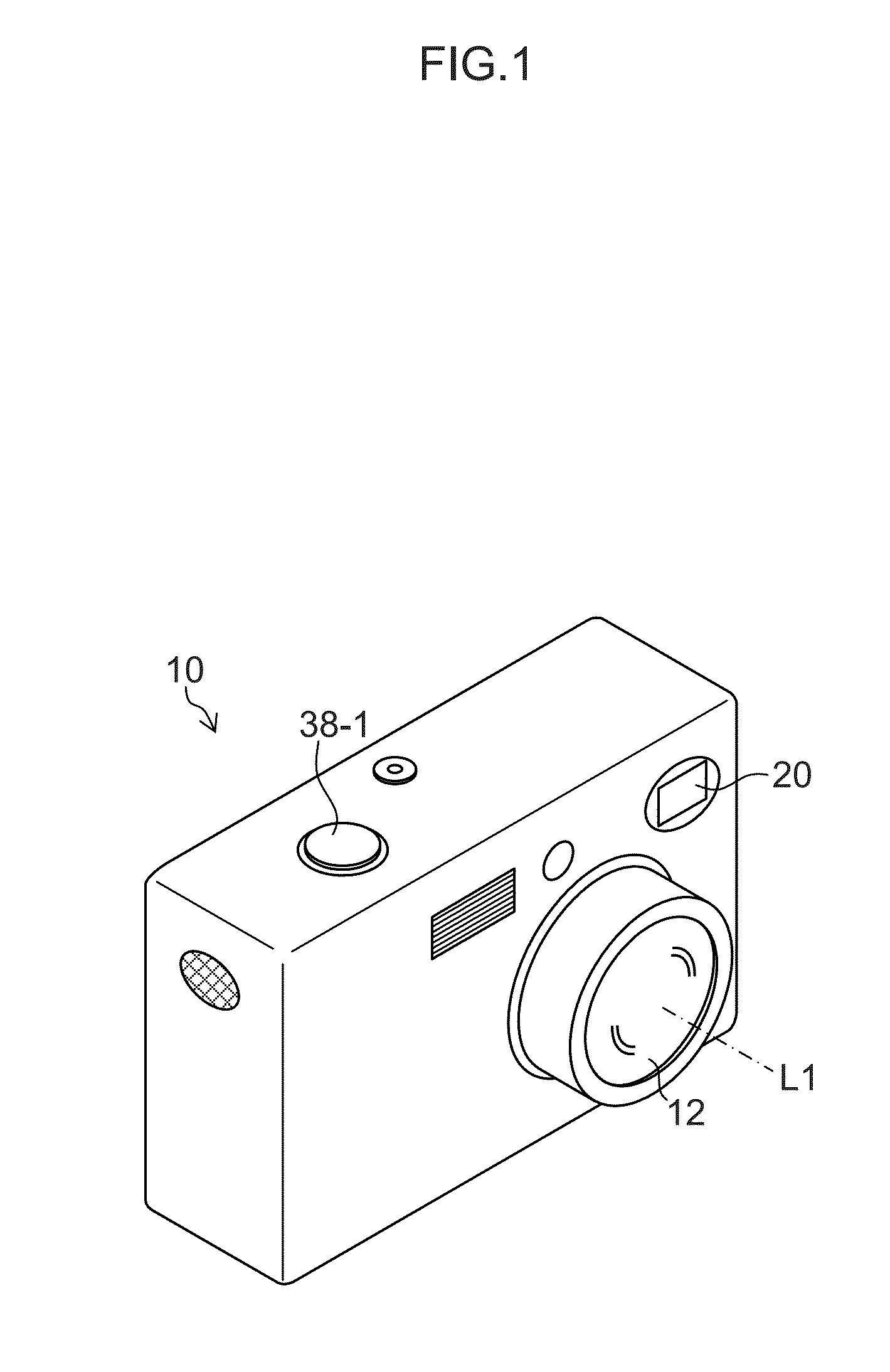

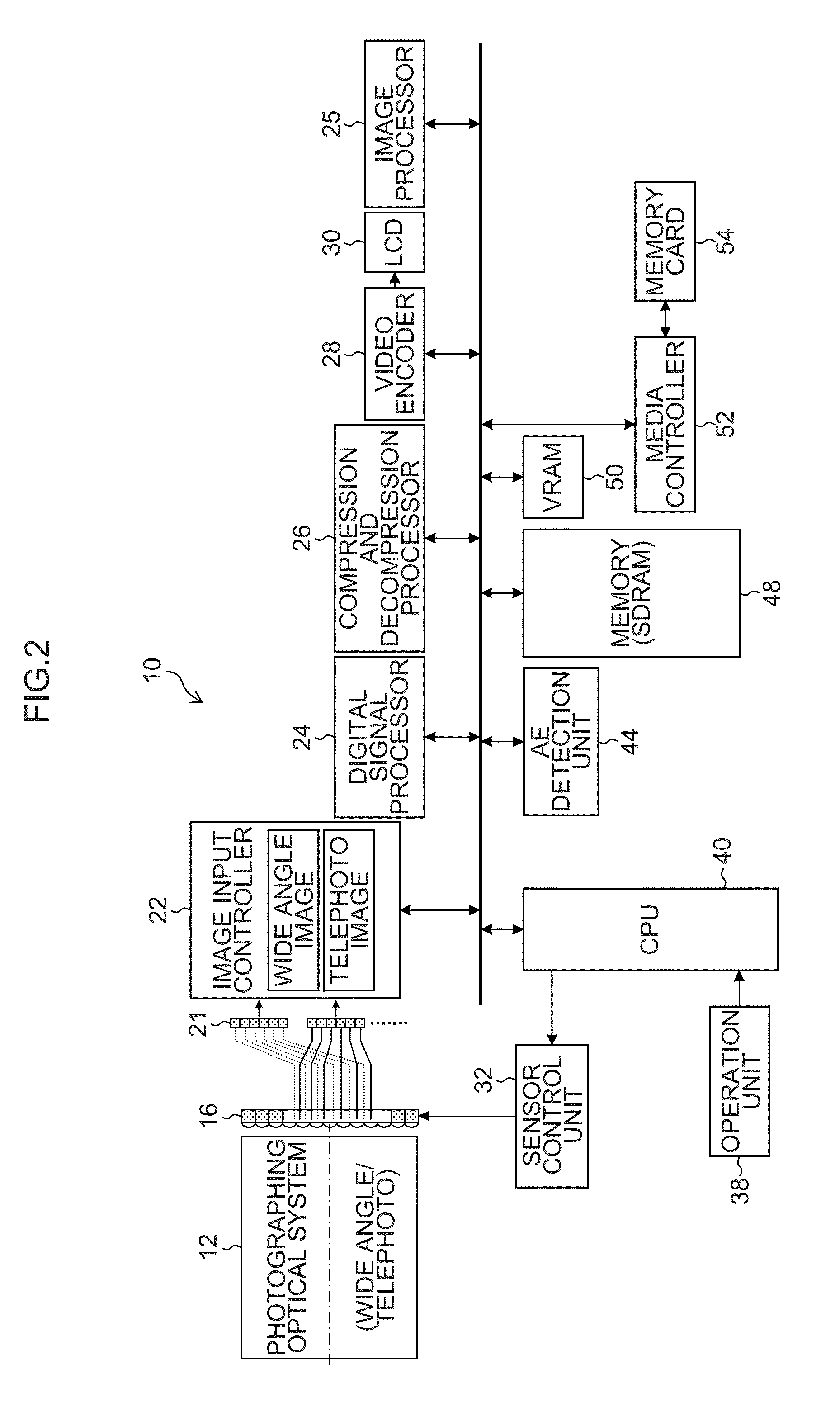

Image pickup device

ActiveUS20150338606A1Compact and inexpensiveTelevision system detailsTelevision system scanning detailsLight fluxOptical axis

An image pickup device includes a photographing optical system having a central optical system disposed at a central region and a circular optical system disposed at an outer portion of the central optical system which are arranged along the same optical axis, a directional sensor having plural pixels including two-dimensionally arranged photoelectric conversion elements, the directional sensor including plural pixels for selectively receiving light beams of light fluxes which are incident via the central optical system and the circular optical system by applying pupil division, an image readout device that acquires from the directional sensor each of an image signal representing a first image received via the central optical system and an image signal representing a second image received via the circular optical system.

Owner:FUJIFILM CORP

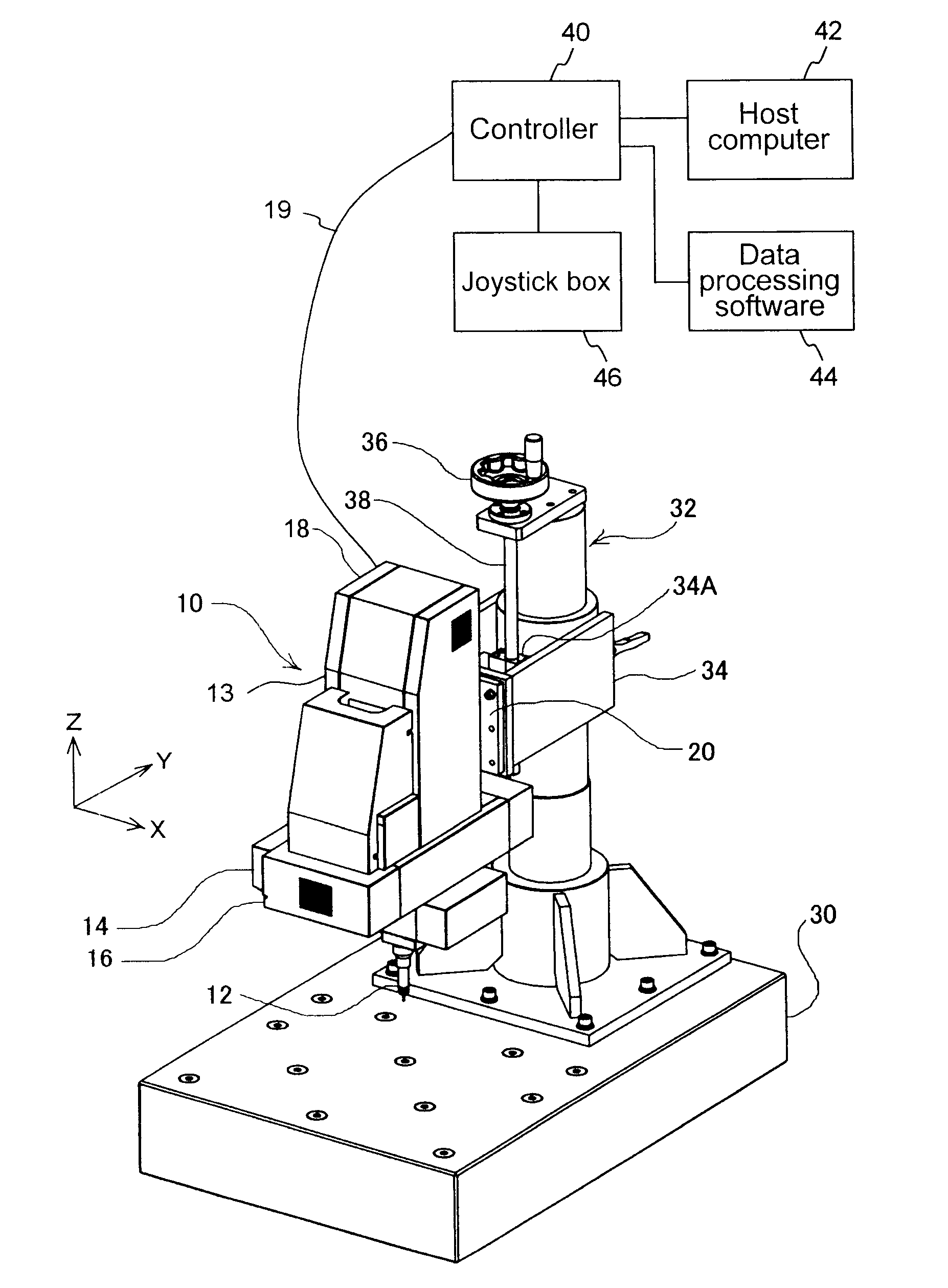

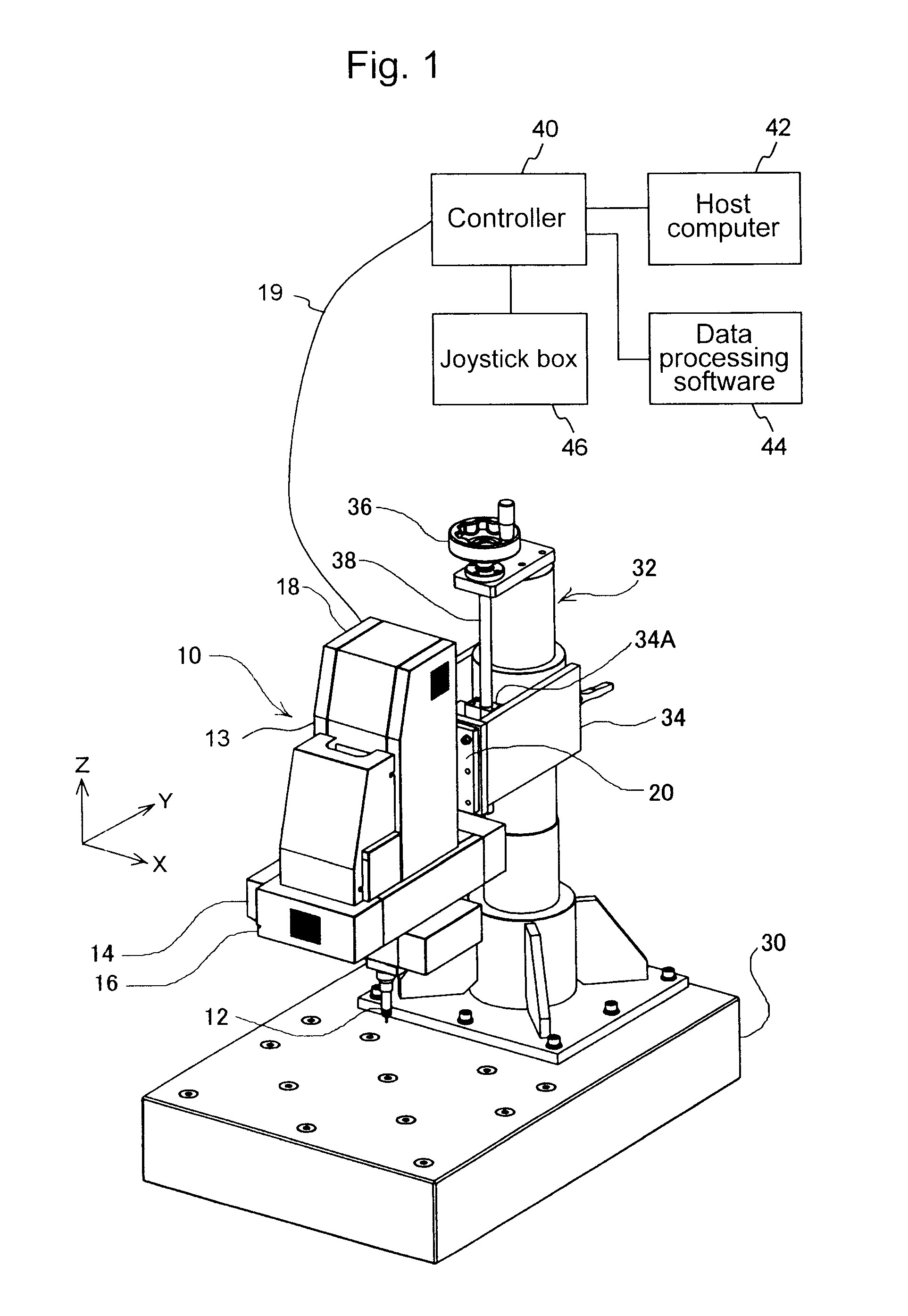

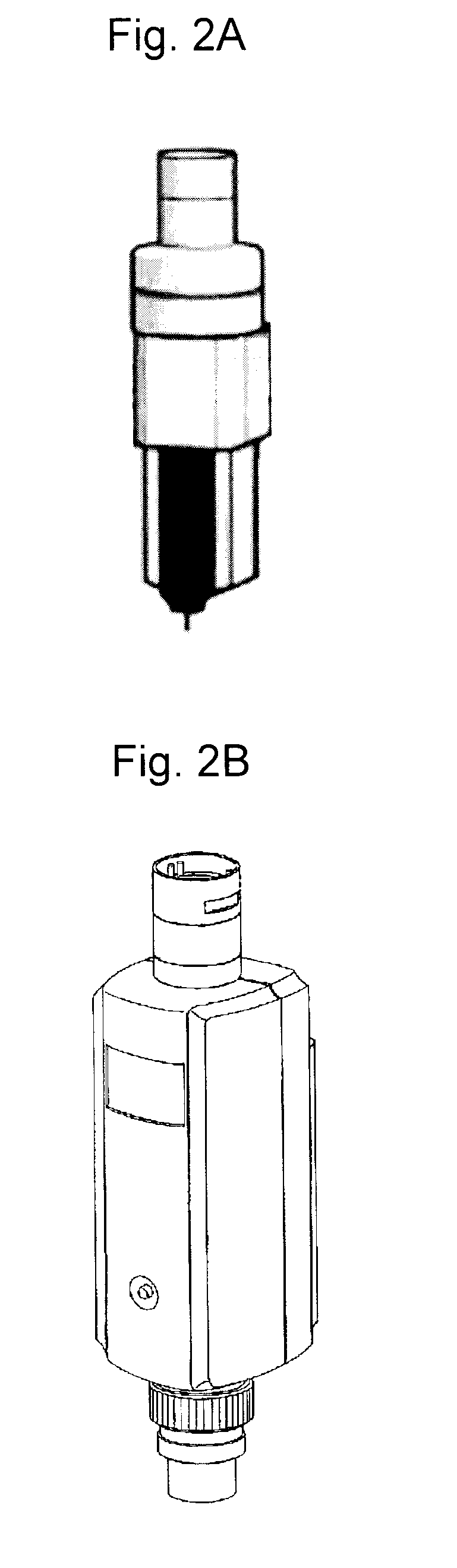

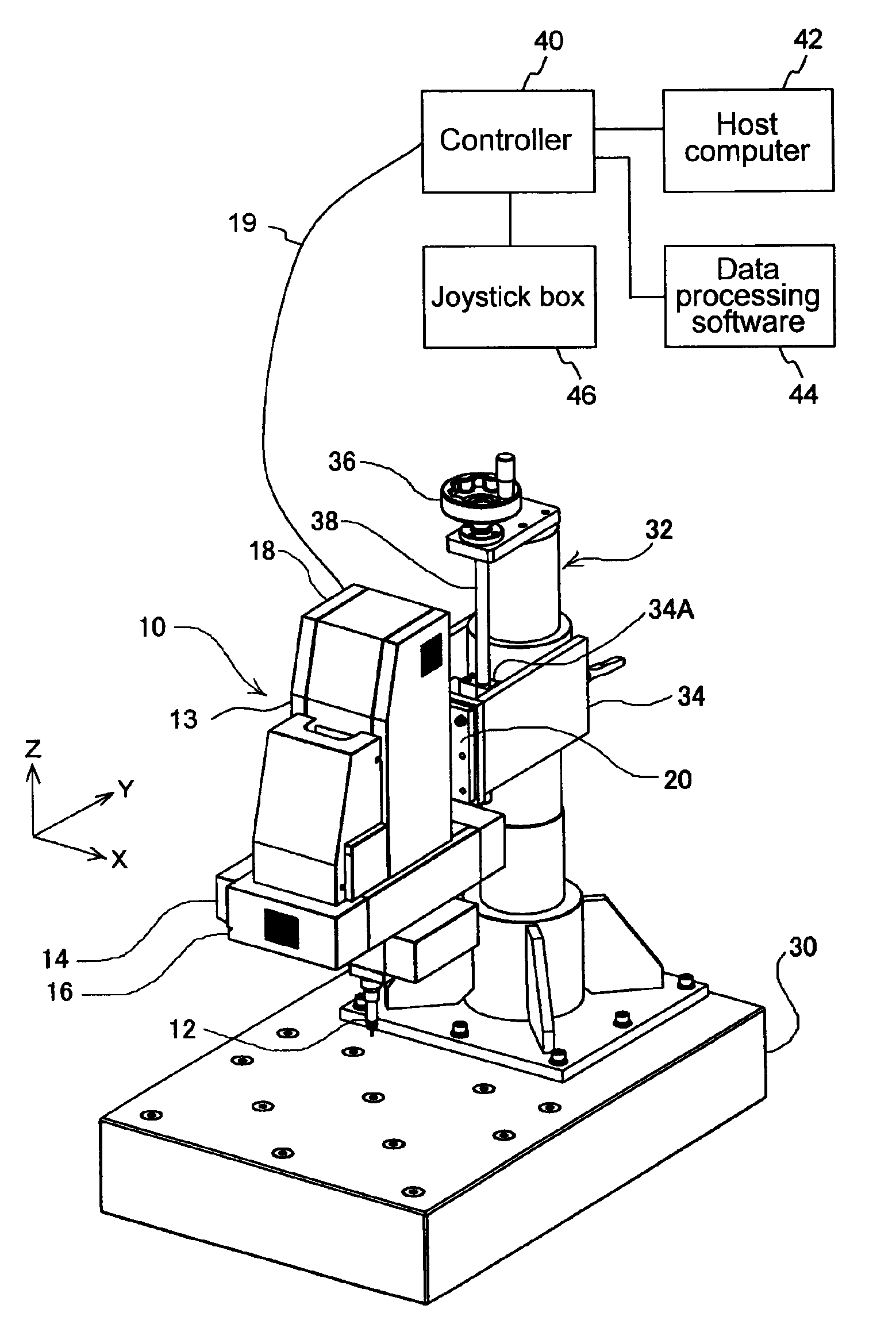

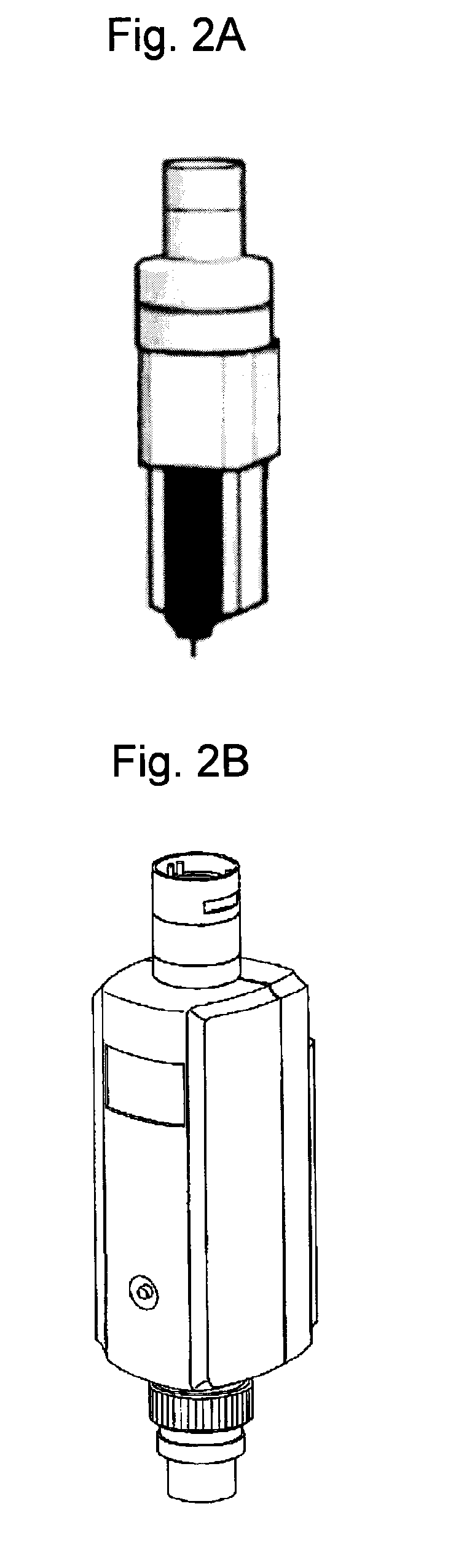

Coordinates measuring head unit and coordinates measuring machine

ActiveUS20120073154A1Low costImprove accuracyMechanical measuring arrangementsNumerical controlEngineering

A coordinates measuring head unit is provided, which is compact, inexpensive, and capable of performing high-precision measurements at high speeds, and facilitates, for example, measurements conducted on machine tools or in-situ measurements on transport lines. The head unit includes: drive means (an X-axis drive section, a Y-axis drive section, and a Z-axis drive section), an integrated housing for accommodating the drive means, and fixture means (fixture surface). The drive means allows a probe to be moved by computer numerical control along a plurality of drive axis, which are orthogonal to each other, and abut against a measuring target to measure the dimensions of the measuring target. The fixture means is provided on one of side surfaces of the housing to attach one of the drive means to a support (a support on a stand secured to a base).

Owner:MITUTOYO CORP

Coordinates measuring head unit and coordinates measuring machine

ActiveUS8650767B2Easy to measureCompact and inexpensiveMechanical diameter measurementsNumerical controlEngineering

Owner:MITUTOYO CORP

Recording apparatus

InactiveUS20050270353A1Improve recording accuracyImprove image qualitySpacing mechanismsElectrographic process apparatusElectric machineryRecording media

Owner:CANON KK

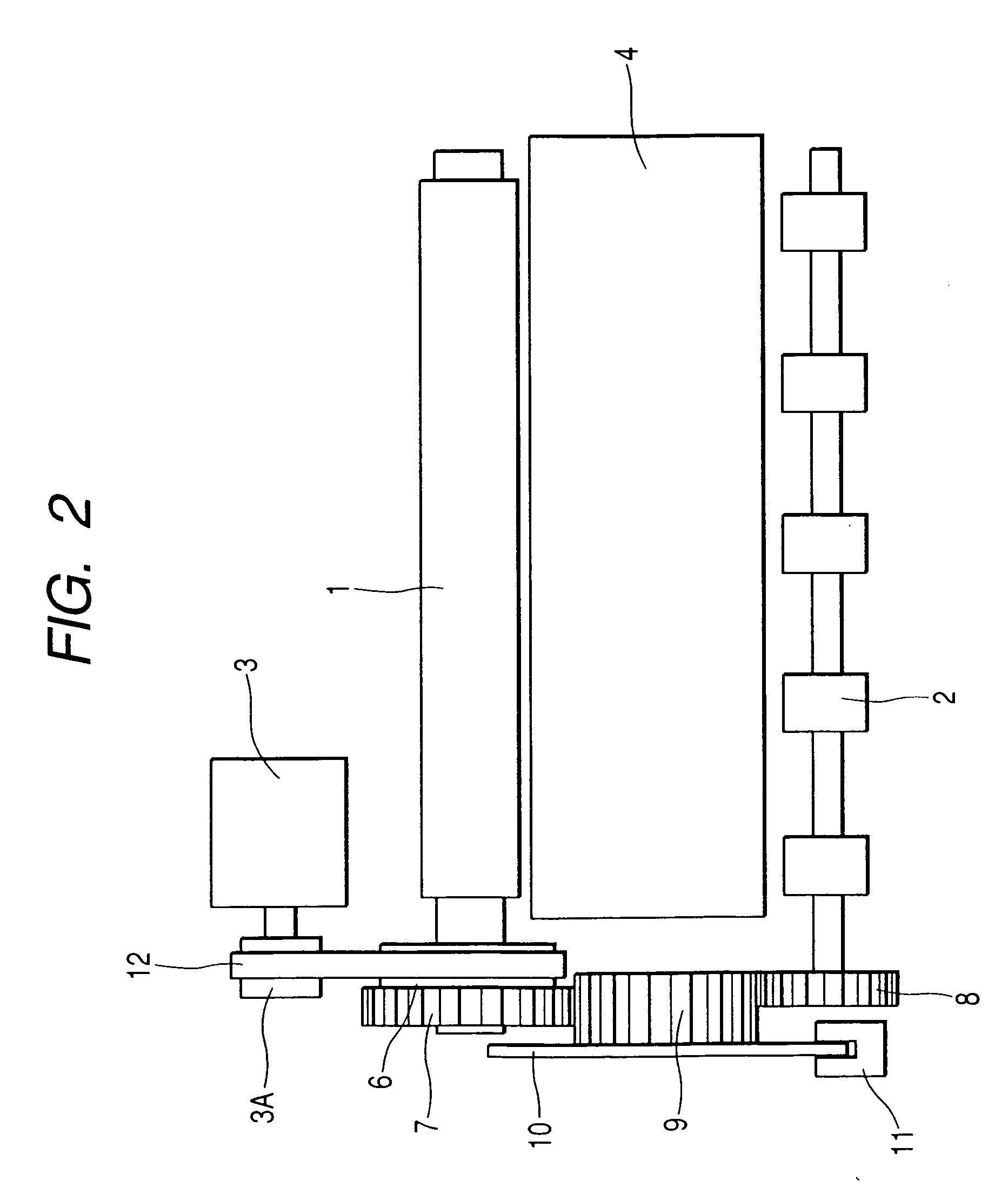

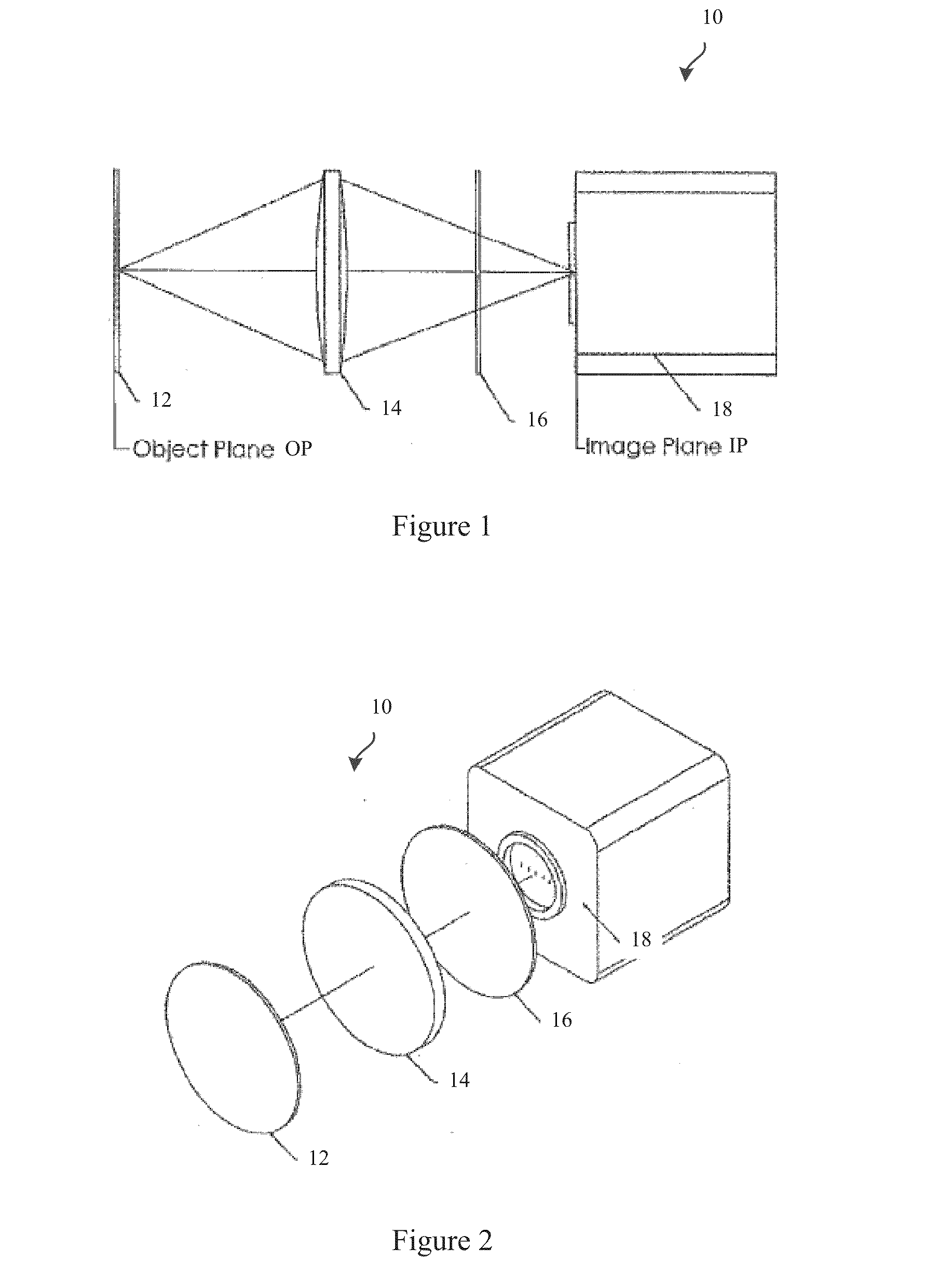

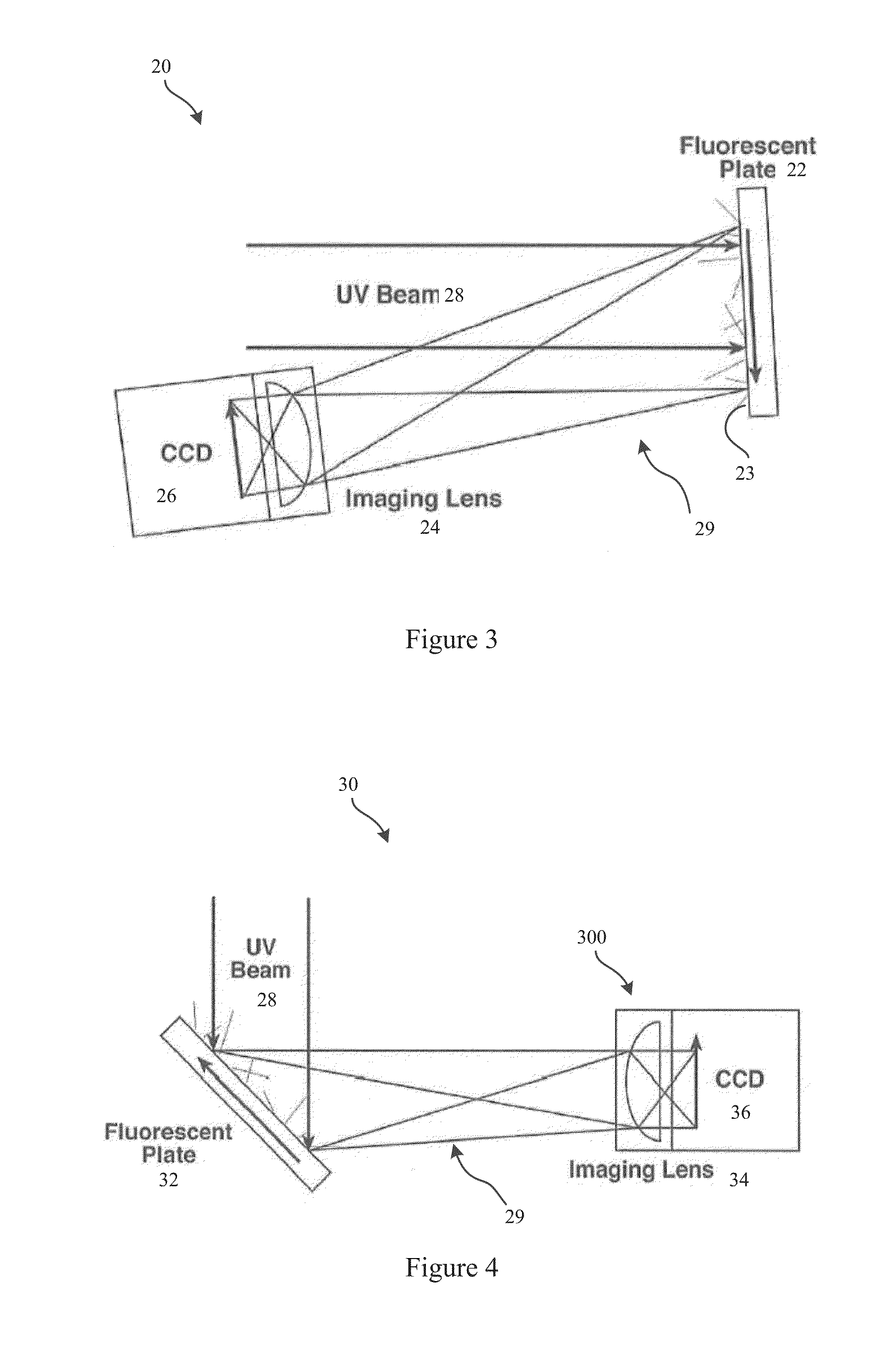

Systems, Devices, and Methods for Calibration of Beam Profilers

InactiveUS20160025555A1Compact and inexpensiveLaser surgeryPhotometry using reference valueLight beamEngineering

Embodiments generally describe systems, devices, and methods for focusing and calibrating beam profilers. A test object is provided that may include an internal housing rotatable within an external housing. The internal housing may house a light source, a collimator, a filter, and / or a diffuser. A plate may be mounted to the internal housing and may include a plurality of markings. In some embodiments, to focus a beam profiler, the test object may be positioned adjacent the converter plate of a beam profiler. Marker images may be captured and a focus quality may be assessed therefrom. A position of the converter, objective, and / or camera of the beam profiler may be adjusted based on the focus quality. To calibrate, images of the markings in several rotational positions may be captured and used for calibration. The markings may be rotated to several positions by rotating the internal housing relative to the external housing.

Owner:AMO MFG USA INC

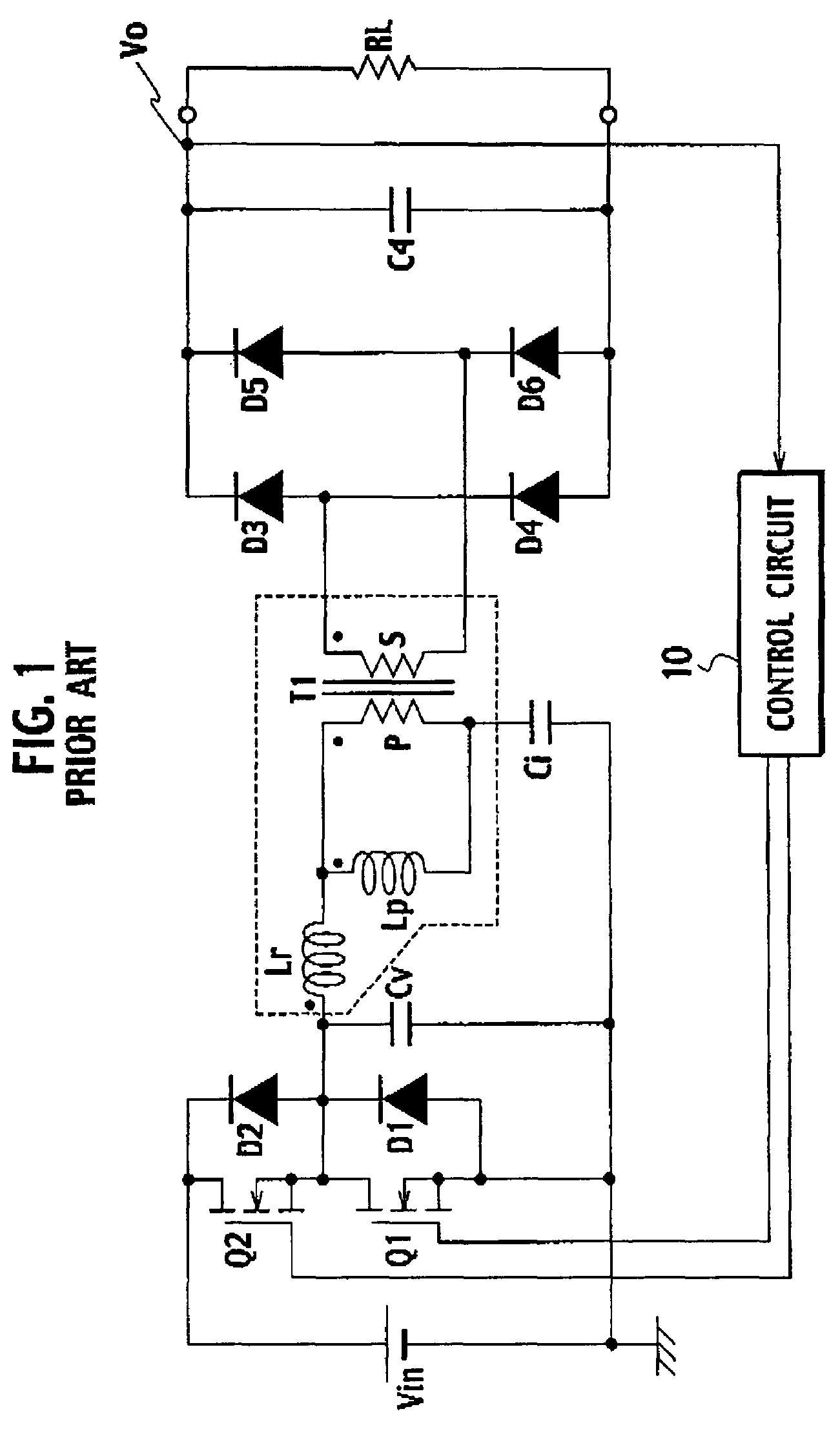

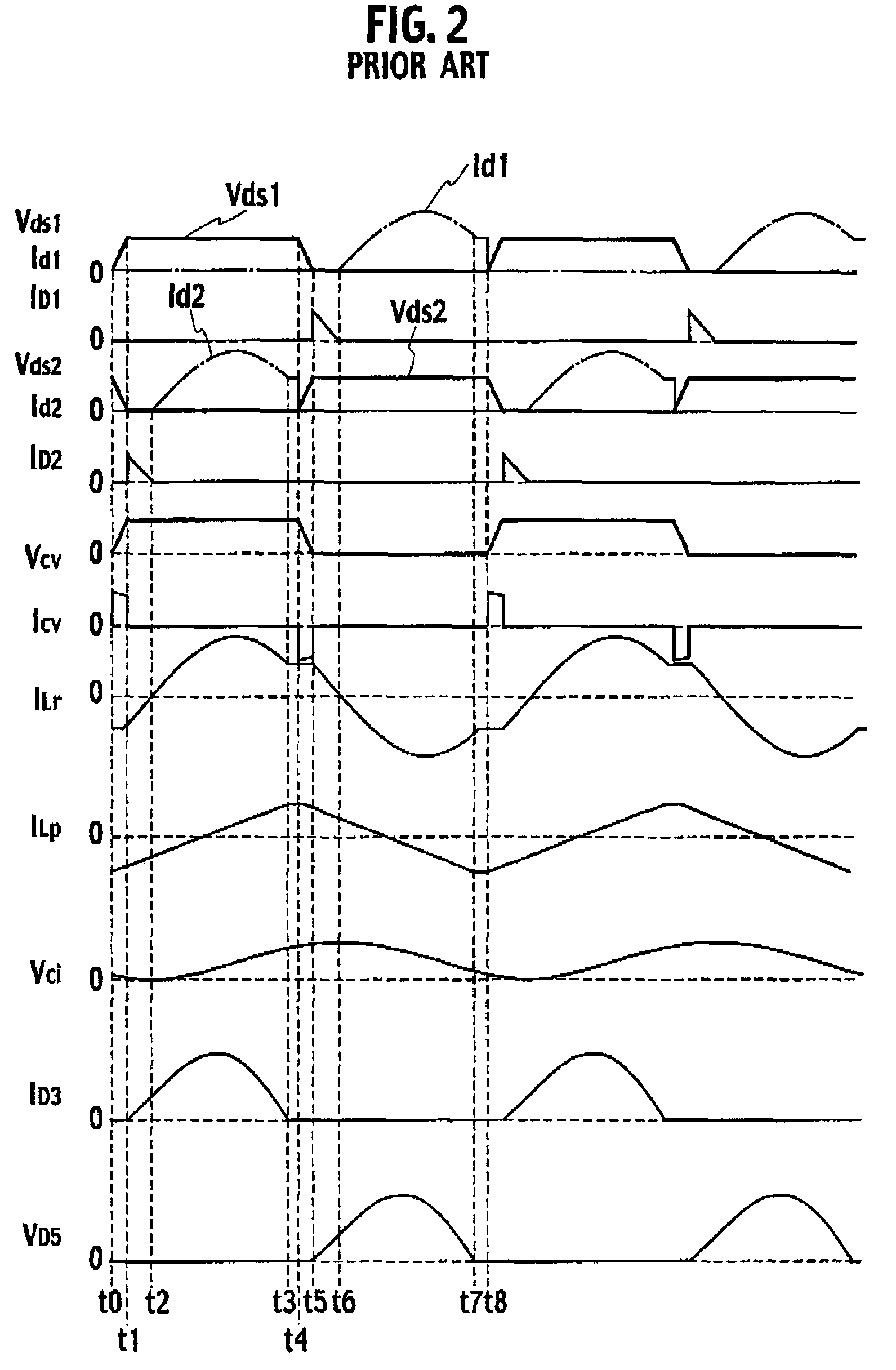

Direct-current converter

InactiveUS7583520B2Improve efficiencySimplify a driving circuitEfficient power electronics conversionDc-dc conversionEngineeringAlternating current

A direct-current converter includes a high-frequency converting circuit converting voltage of a direct-current power source to alternating-current voltage, a transformer having primary and secondary windings P, S and a rectification smoothing circuit rectifying and smoothing voltage induced in the secondary winding. This converting circuit includes other transformer having first and second windings n1, n2, switching element Q1 having a source connected to a negative pole of the power source and a drain connected to a positive pole thereof through winding n1, and switching element Q2 having a source connected to the negative pole of the power source and a drain connected to the positive pole thereof through winding n2, element Q2 being turned on / off alternately to element Q1 being turned on / off. Winding P is connected to a point between winding n1 and the drain of element Q1 and another point between winding n2 and the drain of element Q2.

Owner:SANKEN ELECTRIC CO LTD

Refrigerator

InactiveUS20080148764A1Reduce the temperatureIncrease the number ofPositive displacement pump componentsDomestic cooling apparatusAir cycle machineWorking fluid

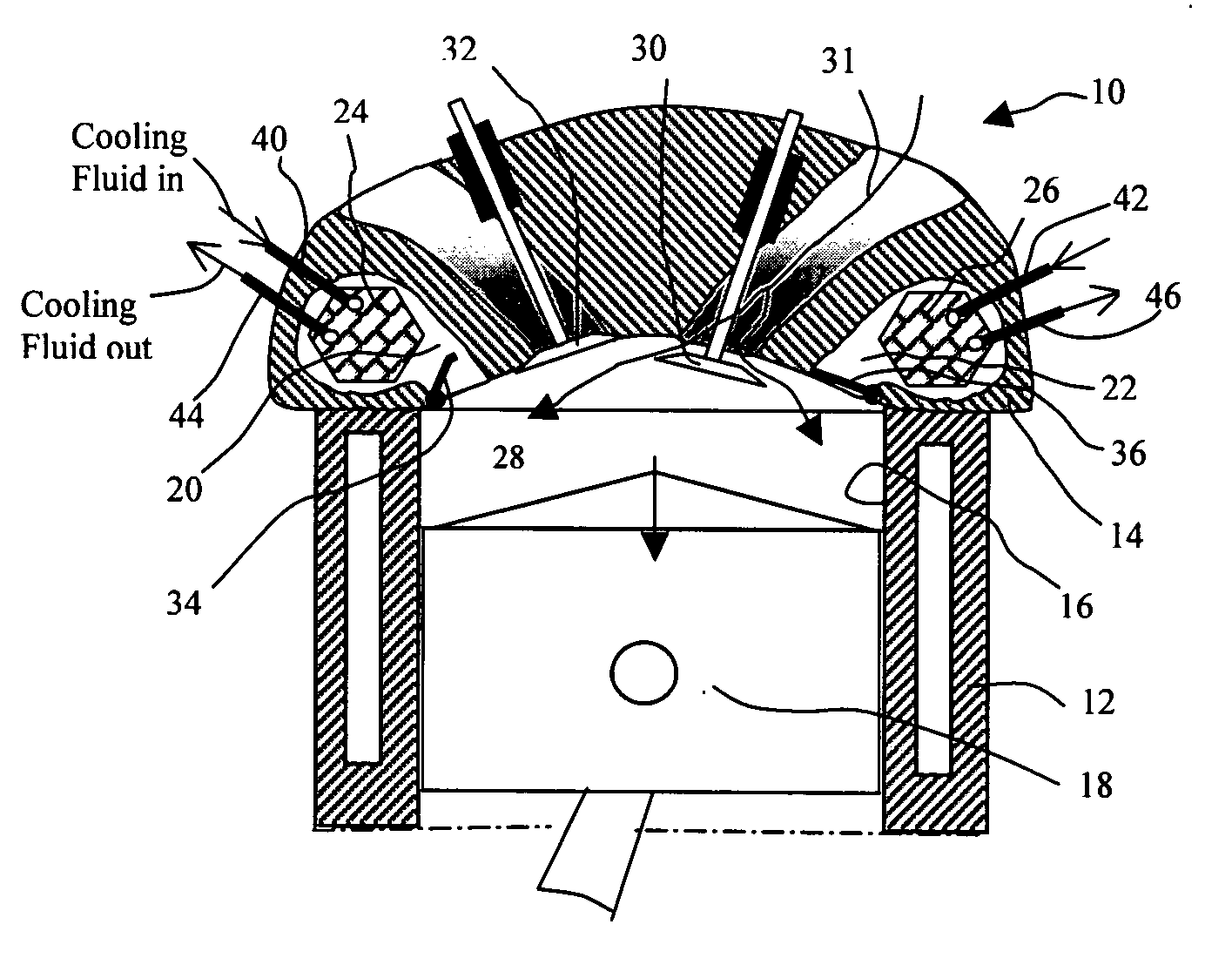

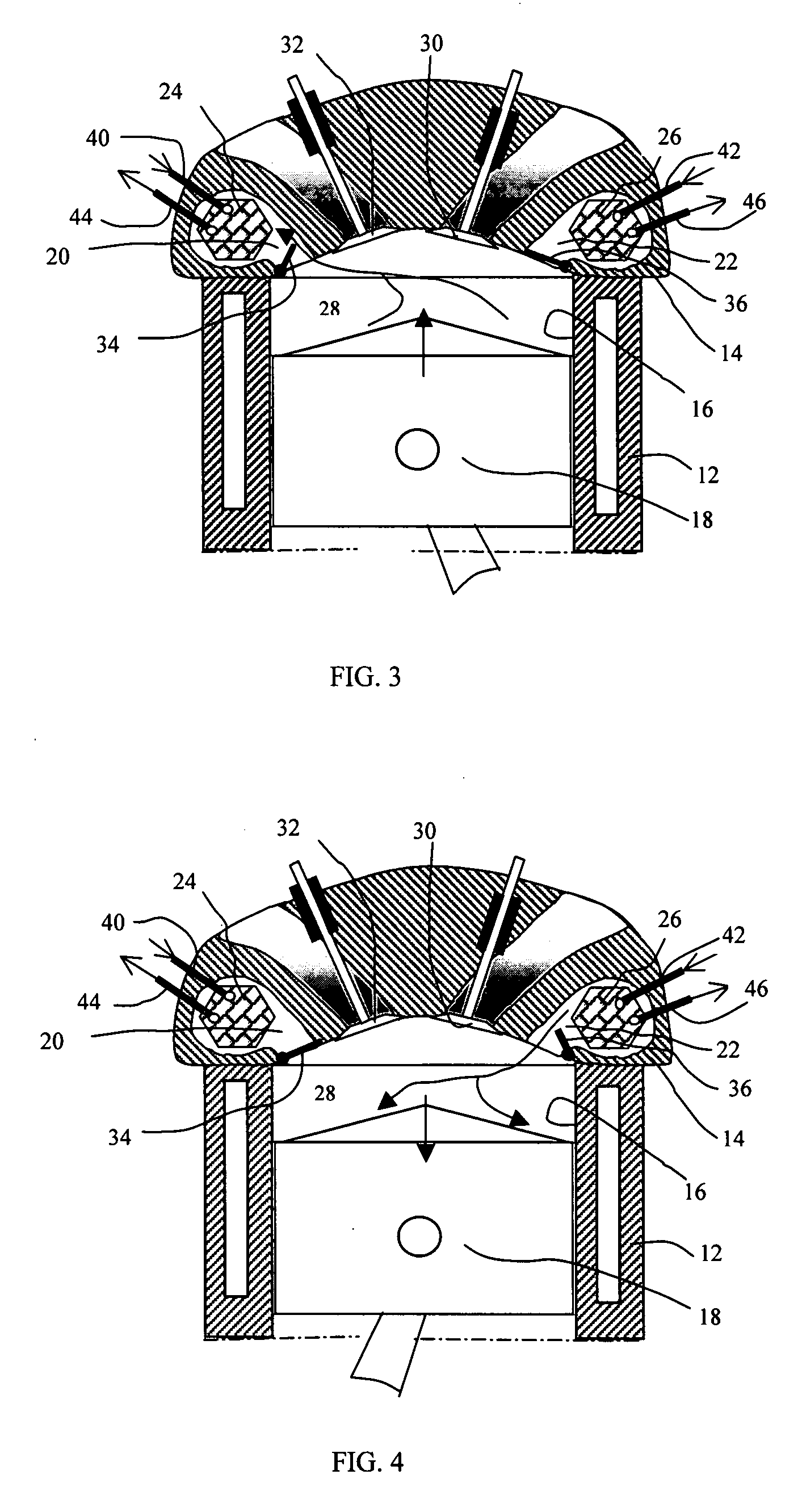

This invention provides a refrigerator using a gaseous working fluid such as air and based upon the well-developed structure of reciprocating compressors or rotating engines. The invention combines the compression functionality of a compressor and the expansion functionality of a turbine in an air cycle machine into a single refrigeration unit having a simple mechanical structure, and provides a significantly increased heat removal time period before the expansion stroke to reduce the temperature of the working fluid under a substantially constant volume without increasing the number of strokes per discharge in a cycle. Moreover, the need of using a man-made chemical as the working fluid is eliminated. Said refrigerator system comprises at least a piston and cylinder assembly including a piston reciprocatingly mounted within the cylinder space, and at least two cooling chambers associated with said cylinder. Each said cooling chamber has therewithin a heat exchanger unit that facilitates heat transfer from the working fluid to a heat sink, a port leading to said cylinder space, and a cooling-chamber valve, said valve opening or closing said port to establish or block communication between said chamber and cylinder space. Said refrigerator is adapted to operate on a cycle having 4n essential strokes for a refrigerator utilizing intake and discharge strokes for respective intake and discharge purposes, or 2n essential strokes for a refrigerator utilizing a scavenging process for discharge and intake purposes, where n is the number of cooling chambers associated with each cylinder. For a refrigerator having intake and discharge strokes, each said cooling chamber has an associated compression stroke, an expansion stroke, and between said compression and expansion strokes a time period of 4(n-1) strokes available for heat transfer from the working fluid enclosed within the cooling chamber to the heat sink. For a refrigerator utilizing a scavenging process for discharge and intake, each said cooling chamber has an associated compression stroke, an expansion stroke, and between said compression and expansion strokes a time period of 2(n-1) strokes available for heat transfer from the working fluid enclosed within the cooling chamber to the heat sink. In both cases, during the time period of heat transfer between the enclosed working fluid and heat sink, said piston would provide strokes for the working fluid associated with another cooling chamber. Additionally, the structure of a rotating refrigerator based on the structure of a rotary engine is disclosed.

Owner:CAO YIDING

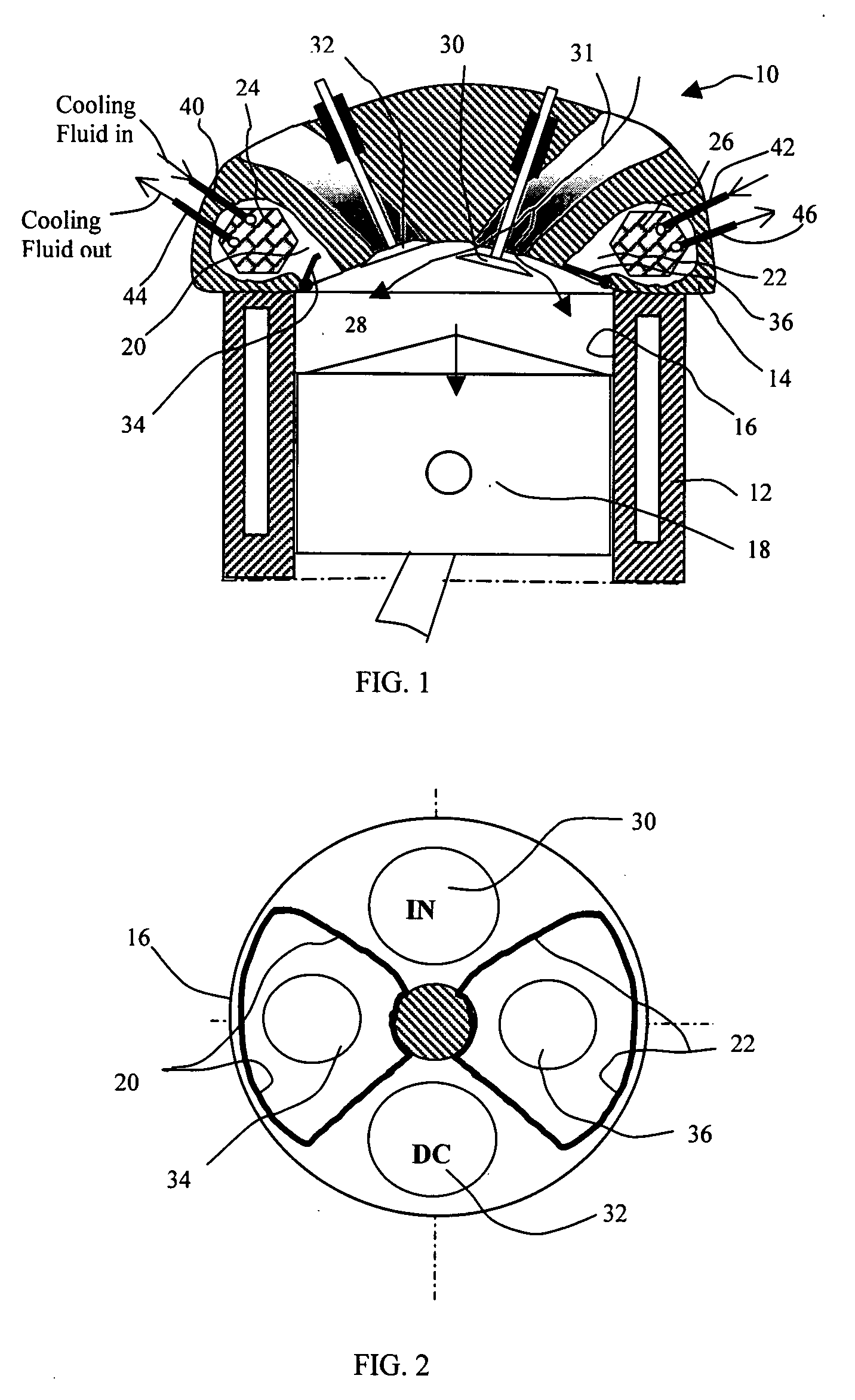

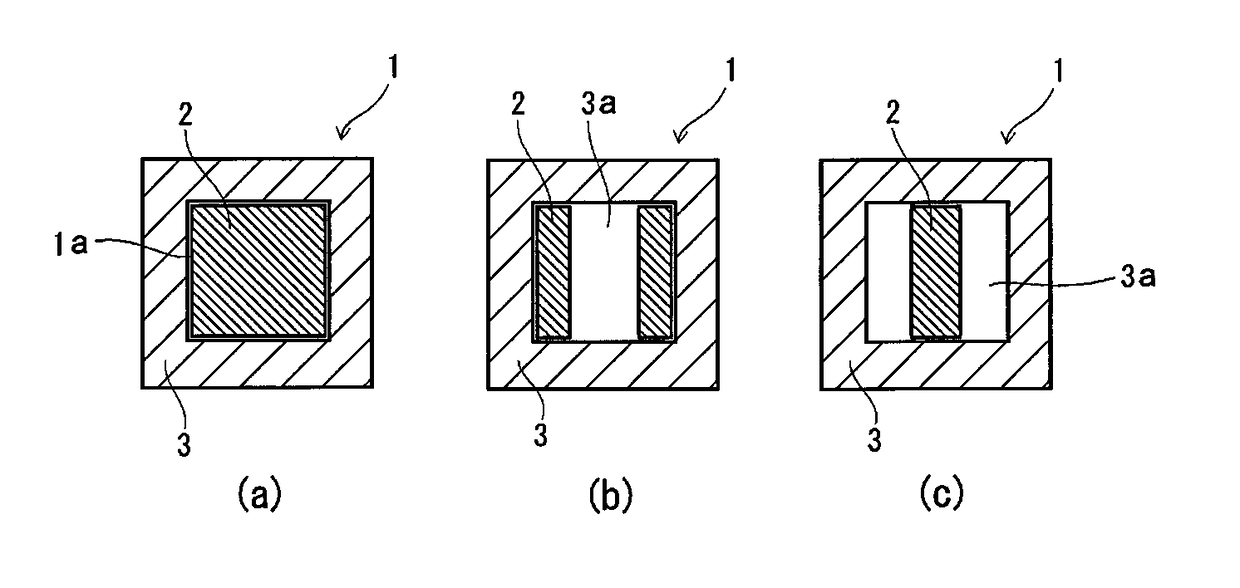

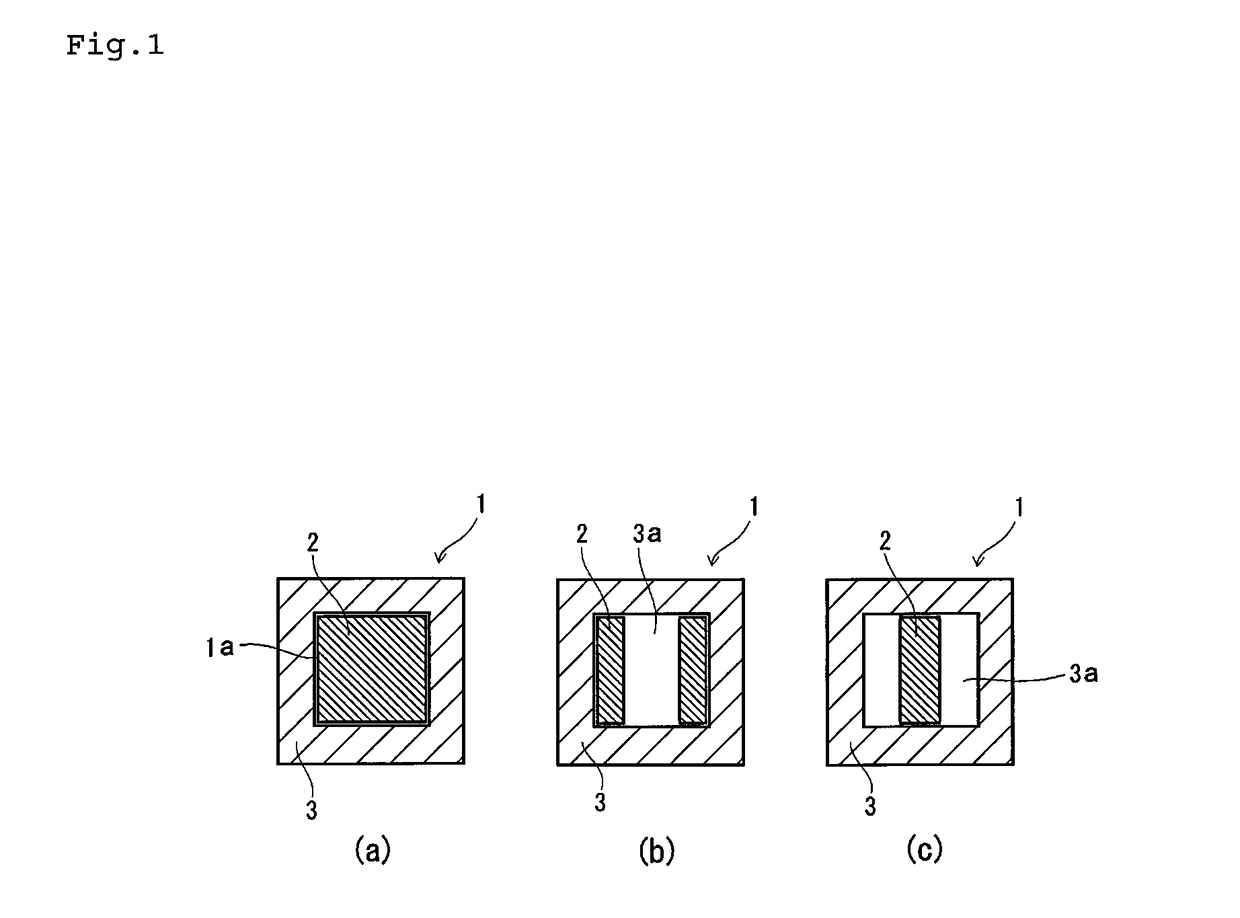

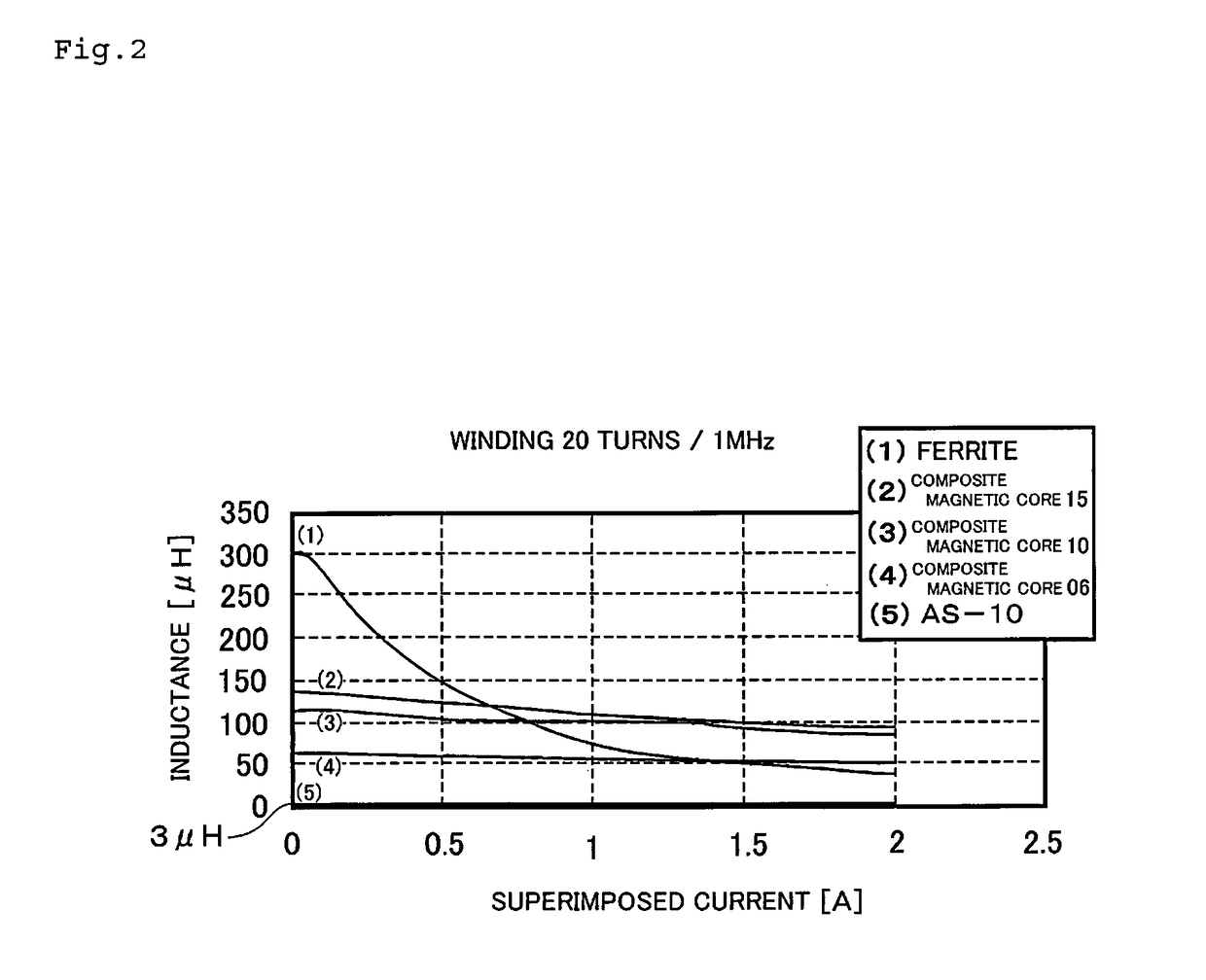

Composite magnetic core and magnetic element

InactiveUS9620270B2High magnetic flux densityEasily compression-moldedInorganic material magnetismTransformers/inductances magnetic coresCompression moldingInjection moulding

The present invention provides a composite magnetic core, containing magnetic powders poor in its moldability, which can be configured arbitrarily and has a magnetic characteristic excellent in direct current superimposition characteristics and a magnetic element composed of the composite magnetic core and a coil wound around the circumference thereof. A compressed magnetic body (2) obtained by compression-molding magnetic powders is combined with an injection-molded magnetic body (3) obtained by mixing a binding resin with magnetic powders having surfaces thereof electrically insulated and by injection-molding a mixture of the magnetic powders and the binding resin. The compressed magnetic body (2) is press-fitted into the injection-molded magnetic body (3) or bonded thereto at a combining portion thereof to obtain the combined body. The combined body is composed of the injection-molded magnetic body (3) constituting a housing in which the compressed magnetic body (2) is disposed.

Owner:NTN CORP

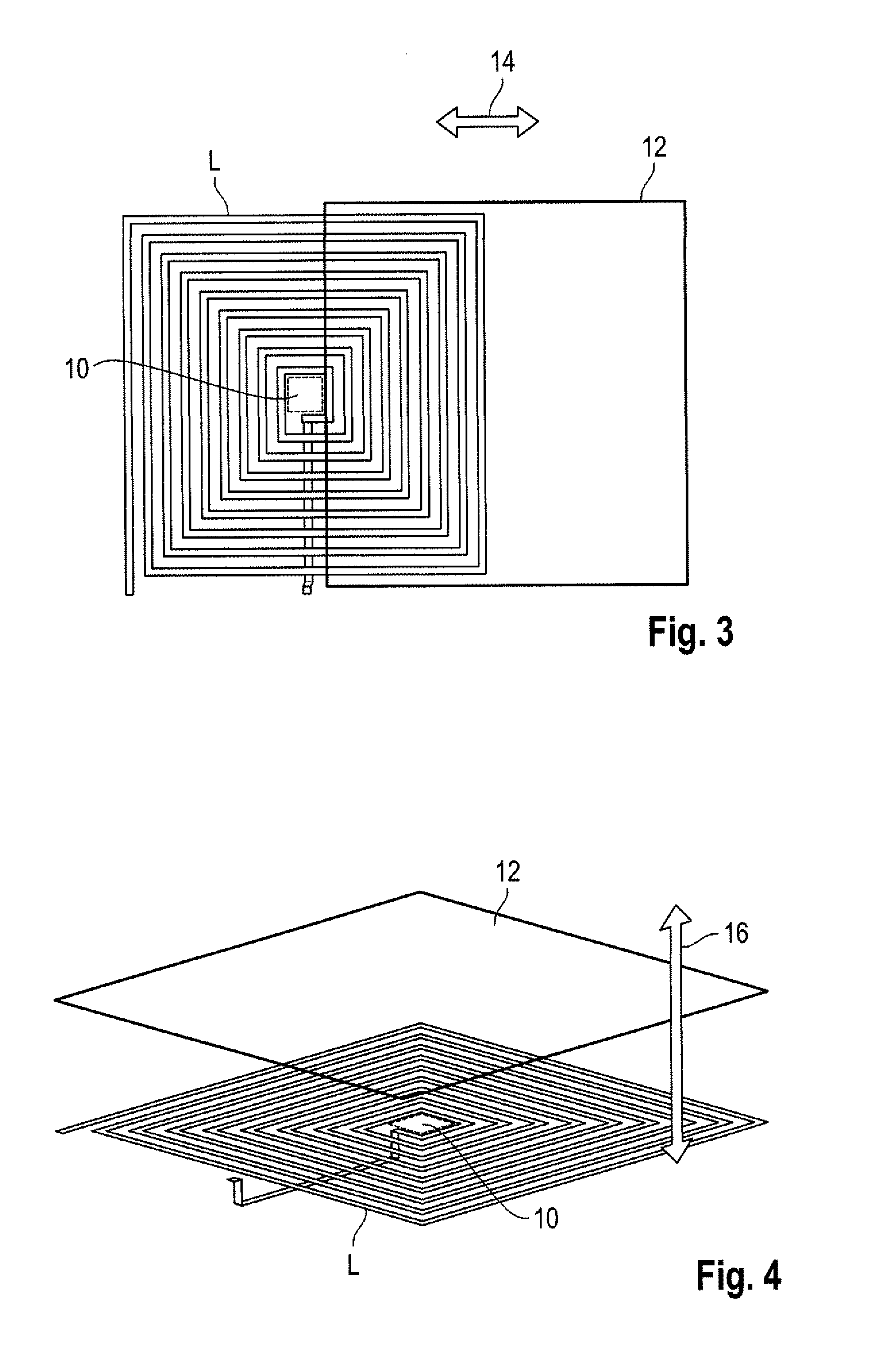

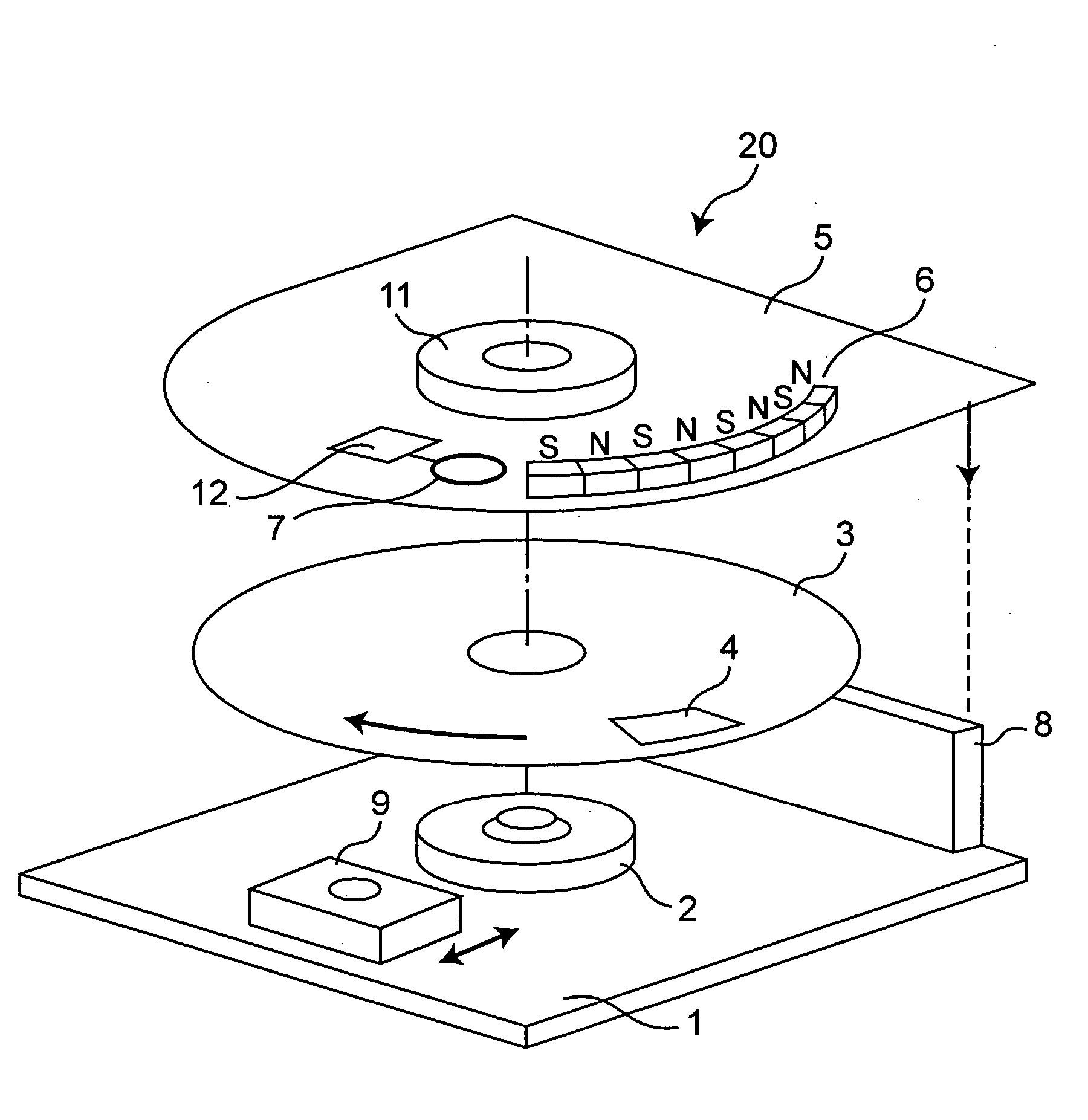

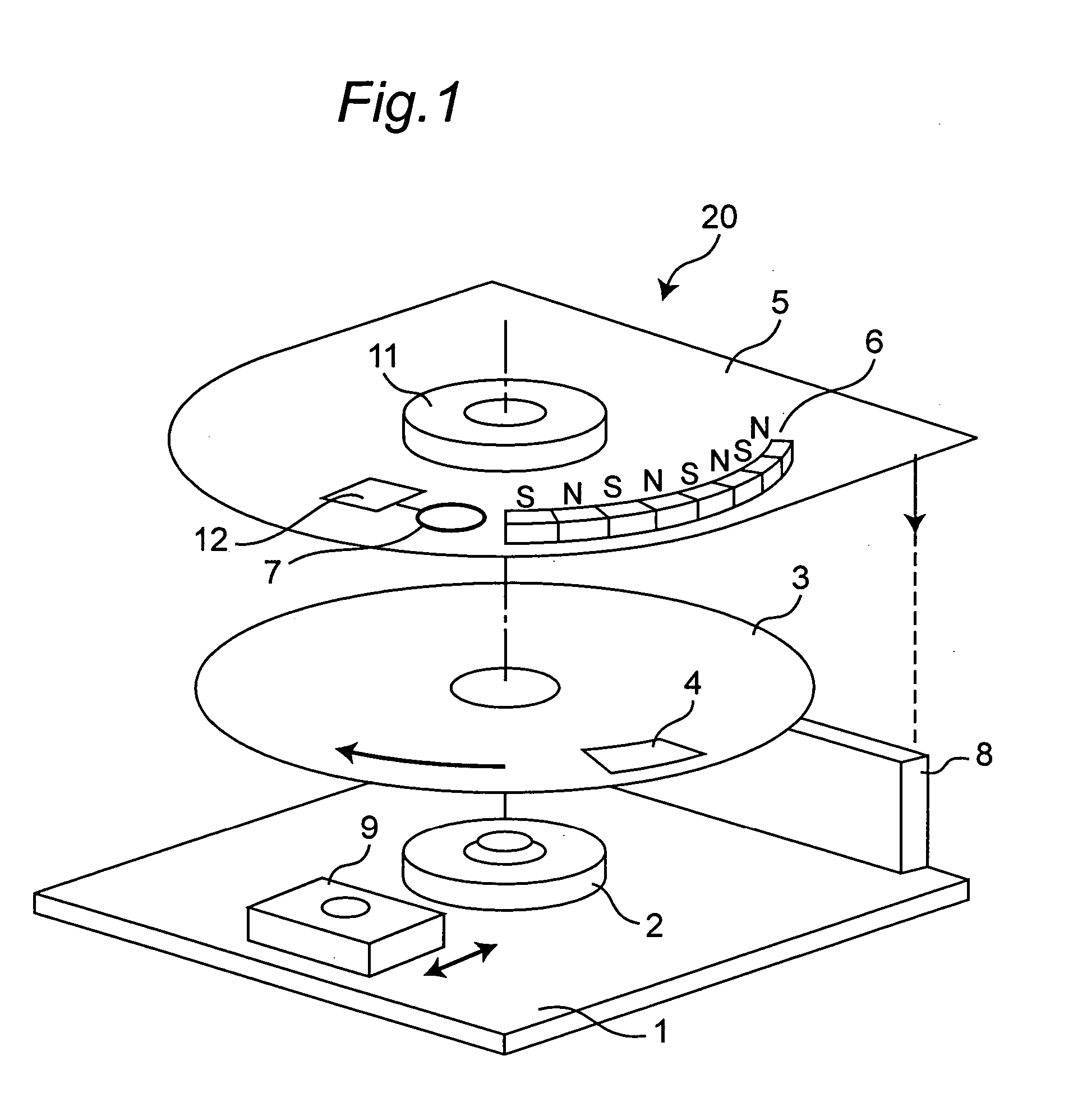

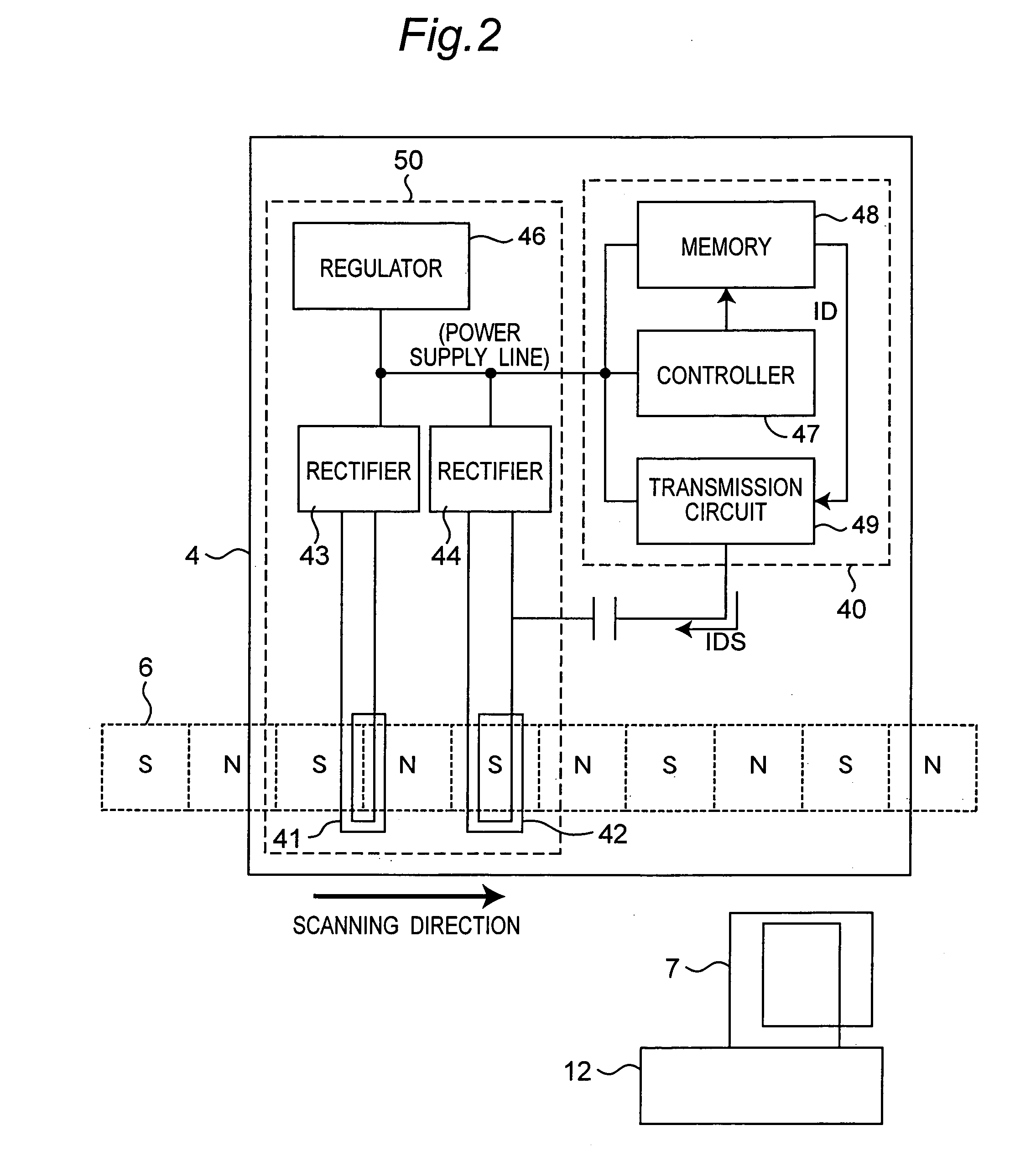

Product identification system using IC tag units, and a digital content management system

InactiveUS20050242182A1Compact and inexpensiveCurrent smoothingRecord information storageSensing record carriersDigital contentManagement system

An IC tag unit has an IC unit for storing unique identification information, a first coil operable to produce a first induction current by electromagnetic induction resulting from movement relative to a magnetic field in which north and south poles are separated by a specific distance, a first rectifier operable to produce a first rectified current by rectifying the first induction current, and a regulator operable to generate a specific voltage from the first rectified current and supplying the voltage to the IC unit.

Owner:PANASONIC CORP

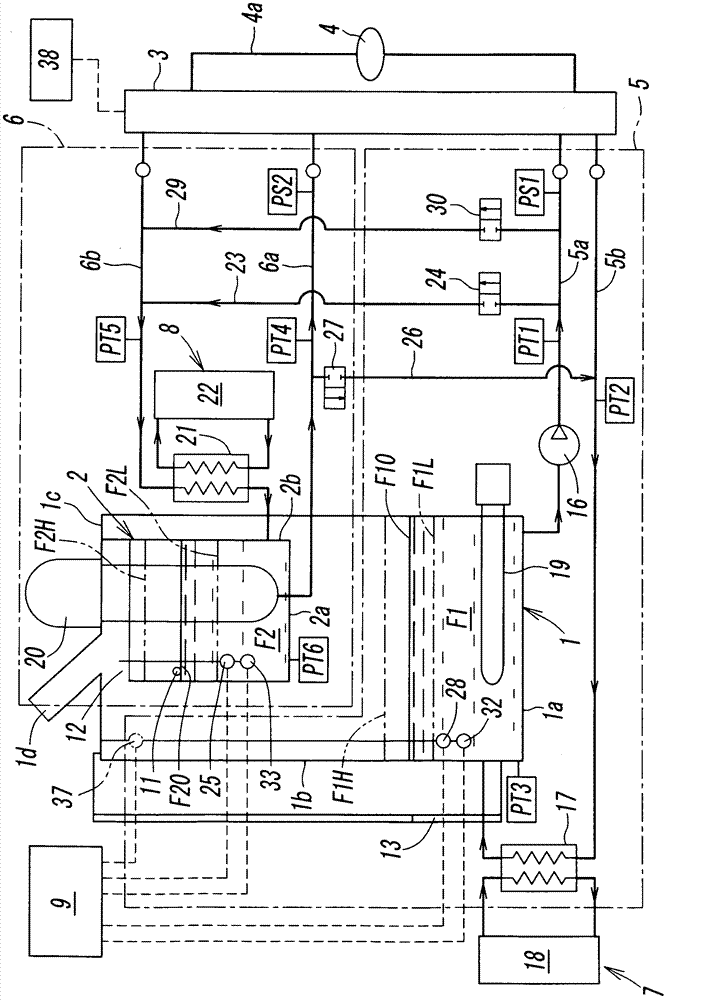

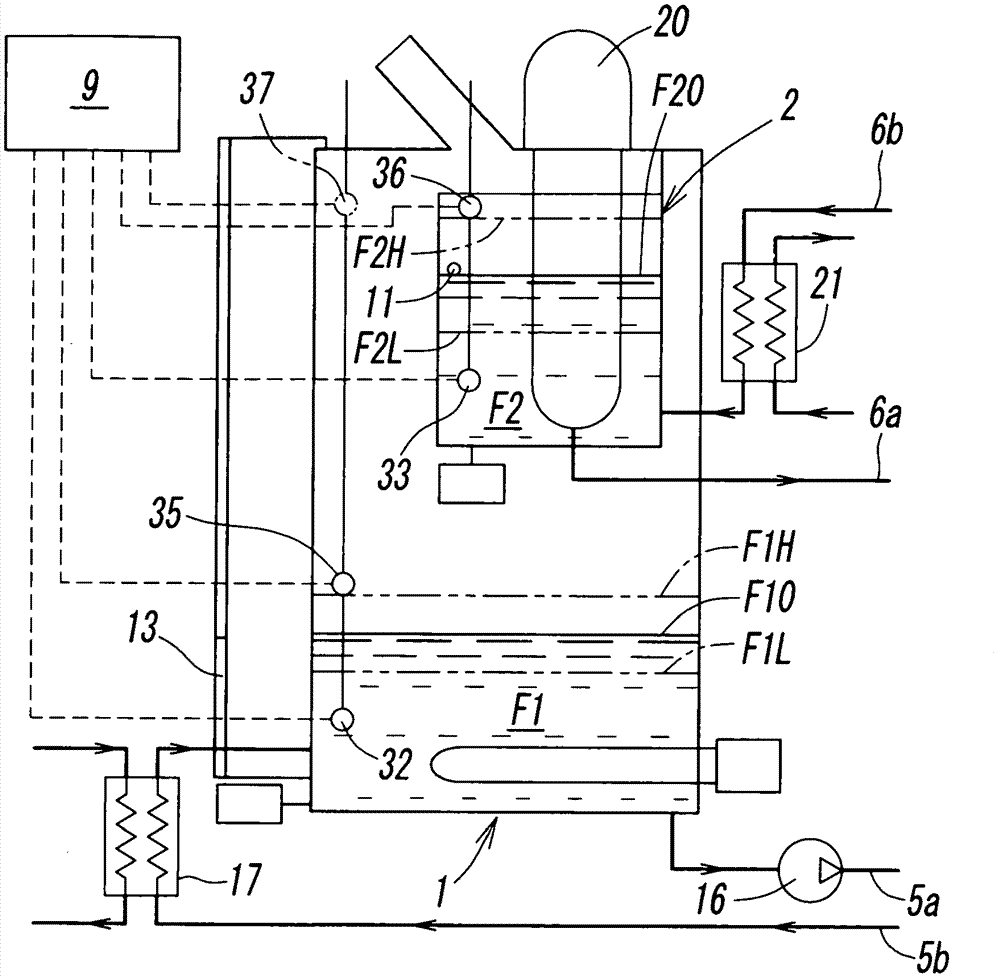

Cyclically liquid feeding apparatus

ActiveCN102737732AEasy temperature adjustmentCompact and inexpensiveLevel controlLighting and heating apparatusLiquid level sensor

The invention provides a cyclically liquid feeding apparatus. An outer tank and an inner tank having liquid at different temperatures, and a load are connected to each other via outer and inner tank liquid circulating channels and a valve unit. A first opening-and-closing valve is connected to a first bypass flow-channel connecting an outer tank feed channel and an inner tank feedback channel, a second opening-and-closing valve is connected to a second bypass flow channel connecting an inner tank feed channel and an outer tank feedback channel to detect the liquid level of the liquid in the outer tank and the liquid level of the liquid in the inner tank by a liquid level sensor. The liquid levels are adjusted by selectively opening the first opening-and-closing valve and the second opening-and-closing valve when the liquid levels in both tanks become uneven in the process of cyclically feeding the liquid from the tanks to the load.

Owner:SMC CORP

Image display device

InactiveUS20050243280A1Reduce weight and sizeMaintain brightnessTelevision system detailsBuilt-on/built-in screen projectorsBeam splitterOptoelectronics

An image display device has three reflective image display elements for red, green and blue to form an optical image according to a video signal from light output from a light source, and an optical system to supply light onto the display elements and to combine and output the light reflected from the display elements. The image display device includes a first polarity converting unit to convert luminous flux from the light source to S polarized light, a first polarized beam splitter, and second polarized beam splitter. The reflective image display element for green is provided in a vicinity of the first polarized beam splitter, and the light reflected by the first polarized beam splitter and input to the reflective image display element for green is S polarized light. The light output from the reflective image display element for green permeates the first and second polarized beam splitters.

Owner:MAXELL HLDG LTD

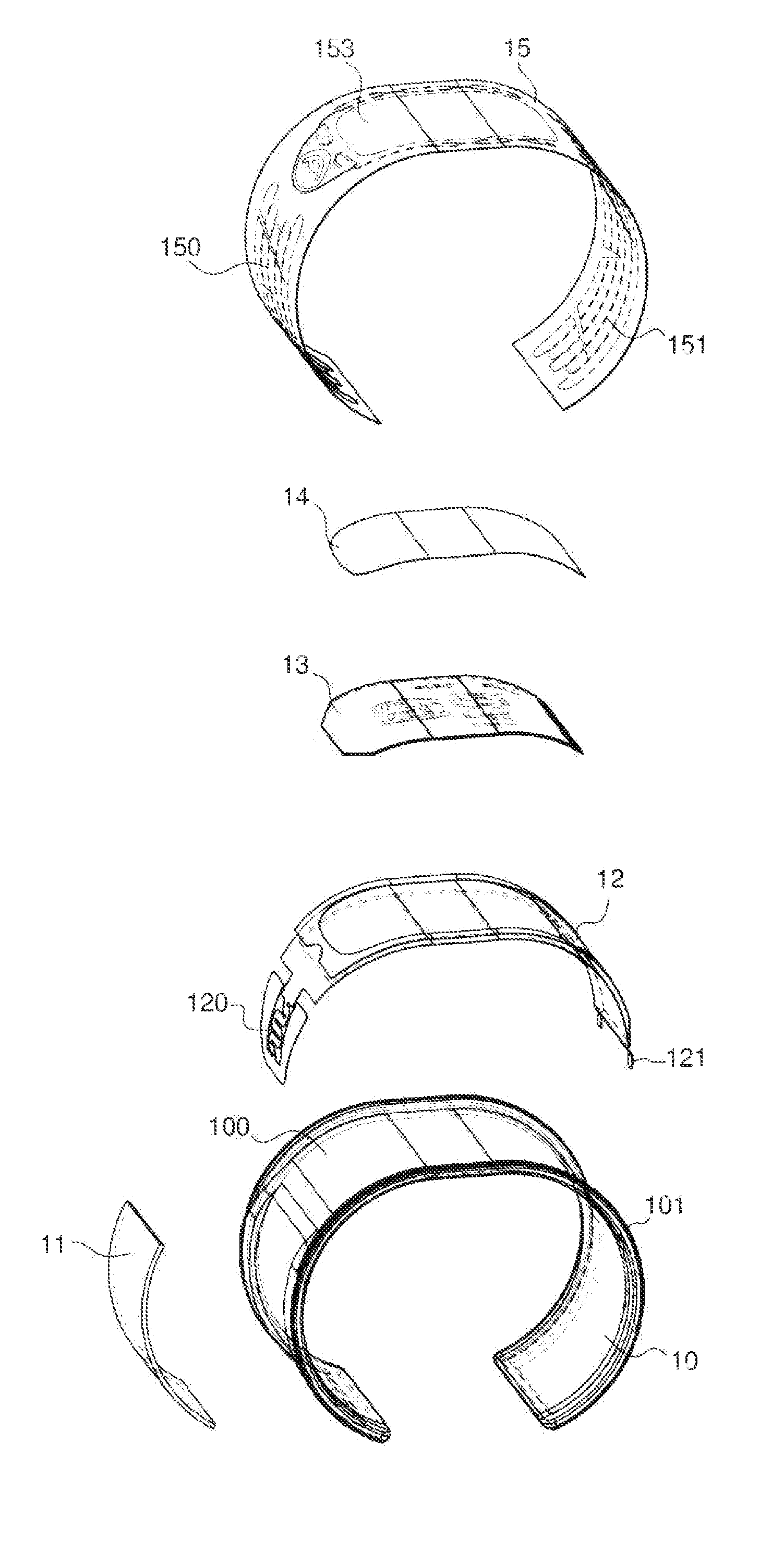

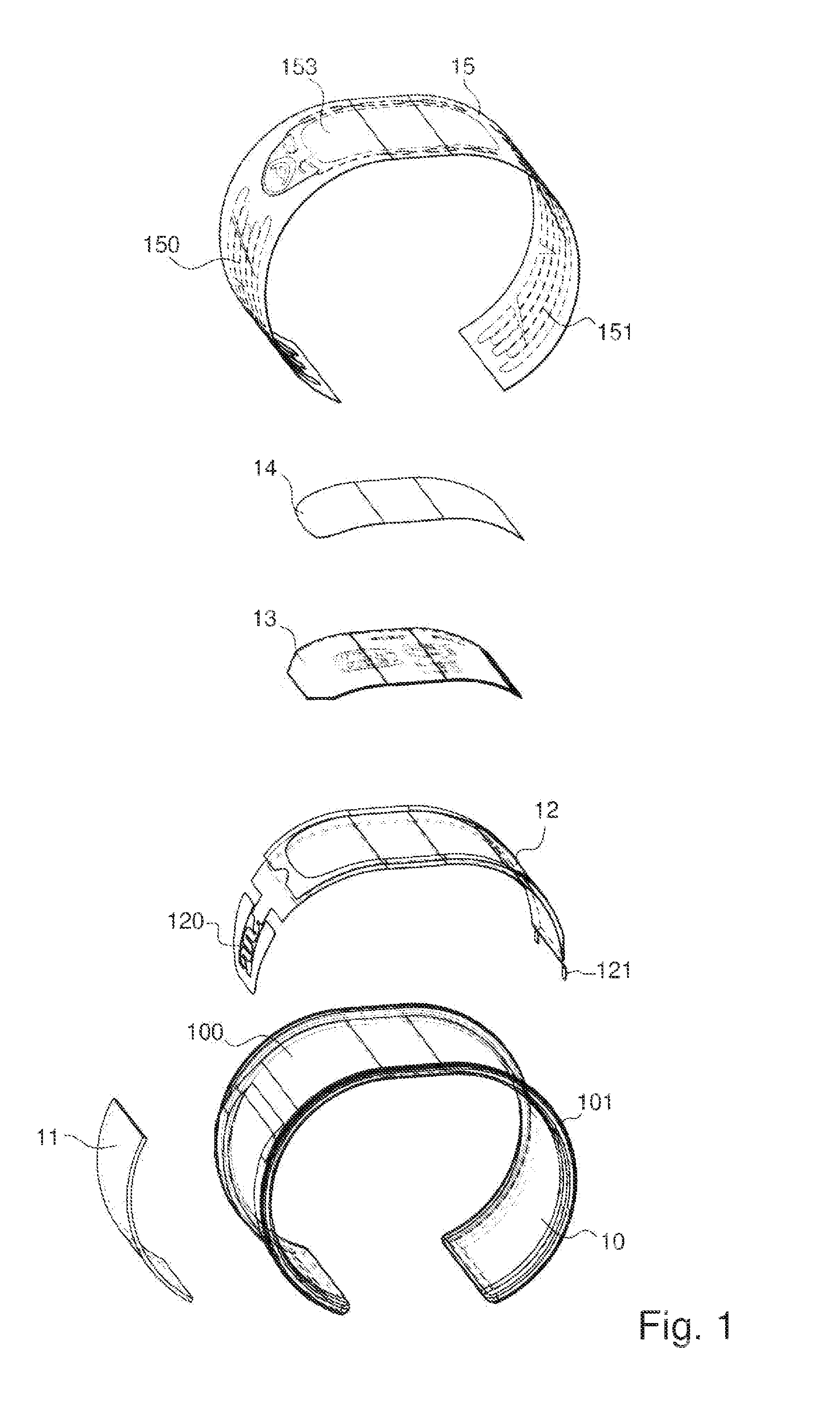

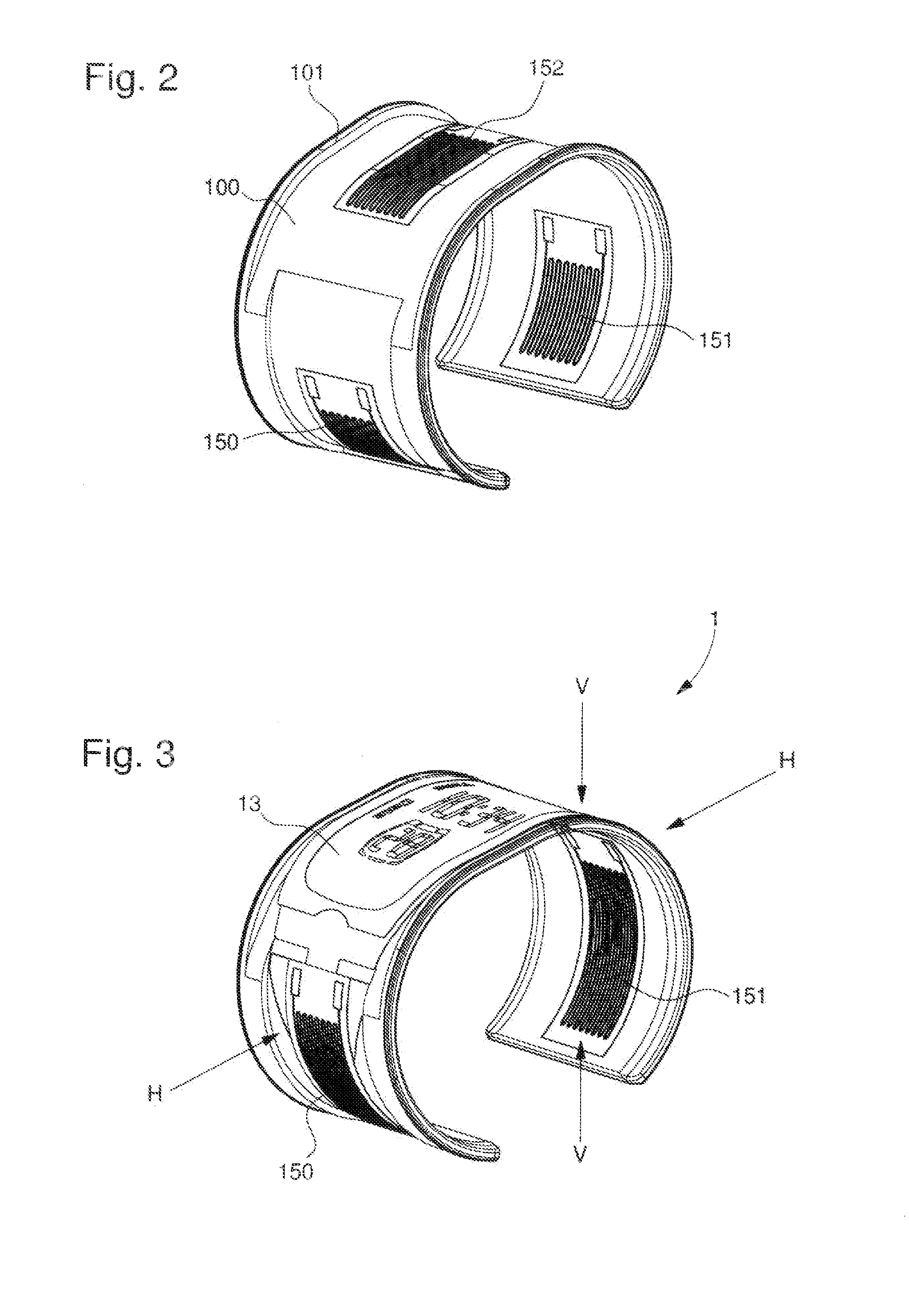

Portable electronic device for information display

InactiveUS20160011709A1Easy to operateCompact and inexpensiveTime-pieces with integrated devicesPower supply for data processingControl signalEngineering

The invention relates to a portable electronic device capable of displaying information, attached to the wrist and including:a bracelet formed by a flexible element,an electronic assembly,display means,an energy source.According to the invention, the device includes control means including at least one strain gauge, capable, by the application of pressure to the strain gauge, of generating a control signal which is applied to said electronic assembly, the direction and the position of the pressure on said strain gauge permitting the display of information and / or activation of a predetermined function.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

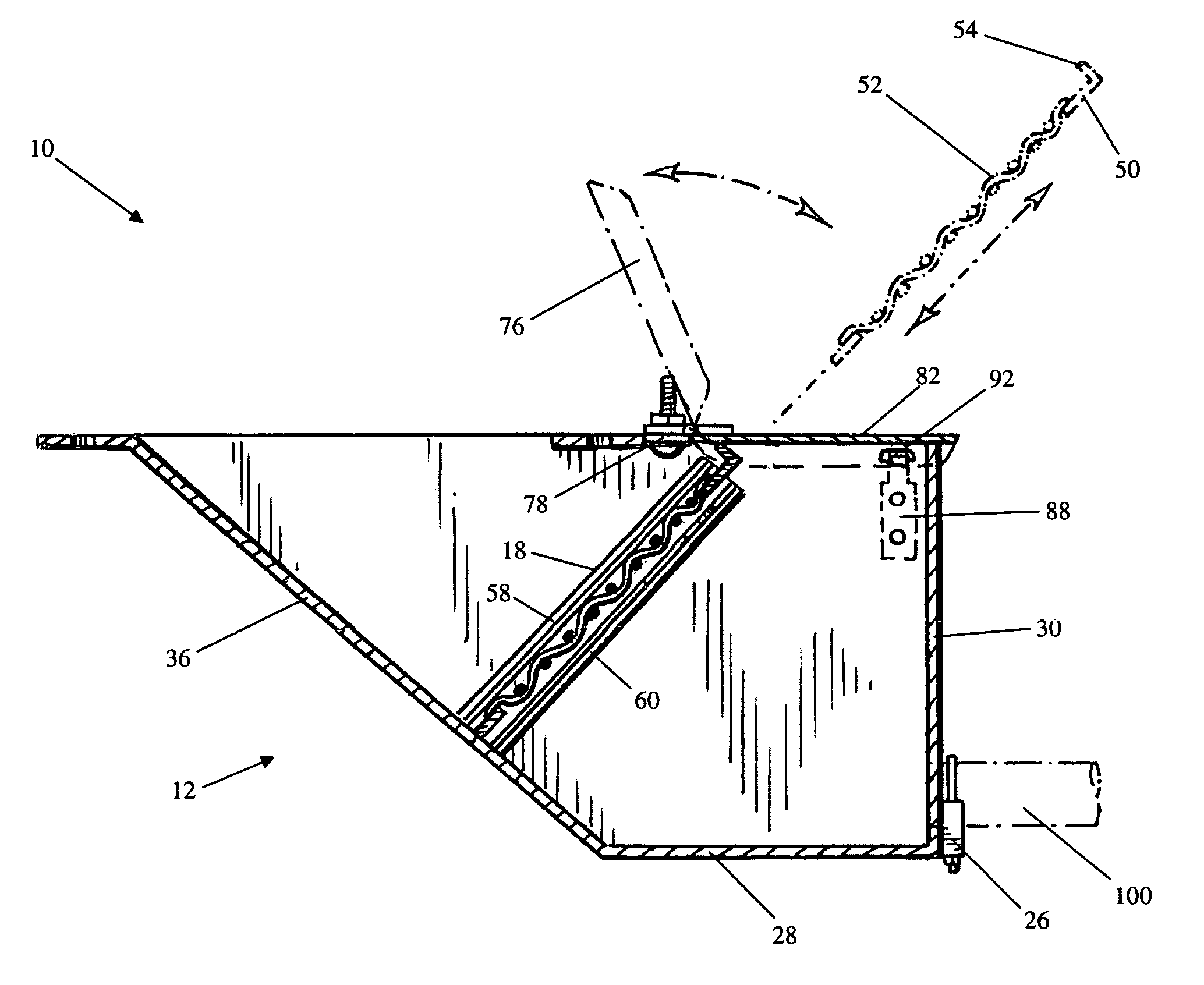

Filtering flow box for mounting to a silo

InactiveUS20090255857A1Conveniently replacedCompact and inexpensiveSievingDomestic stoves or rangesTowerSilo

A filtering flow box for receiving a supply of plastic pellets from a bottom-unloading tower silo and removing undesirable plastic strands (“angel hair”) from the pellets before they are processed for manufacturing. The box has an angled entry wall for laterally channeling pellets to an angled filter. The pellets pass through the filter and angel hair collects on the filter's upstream surface. The filter can be removed from the box at an angle having a vertical component for cleaning, thus allowing any pellets that have accumulated on top of the filter to fall back into the box.

Owner:ALLEY INDS

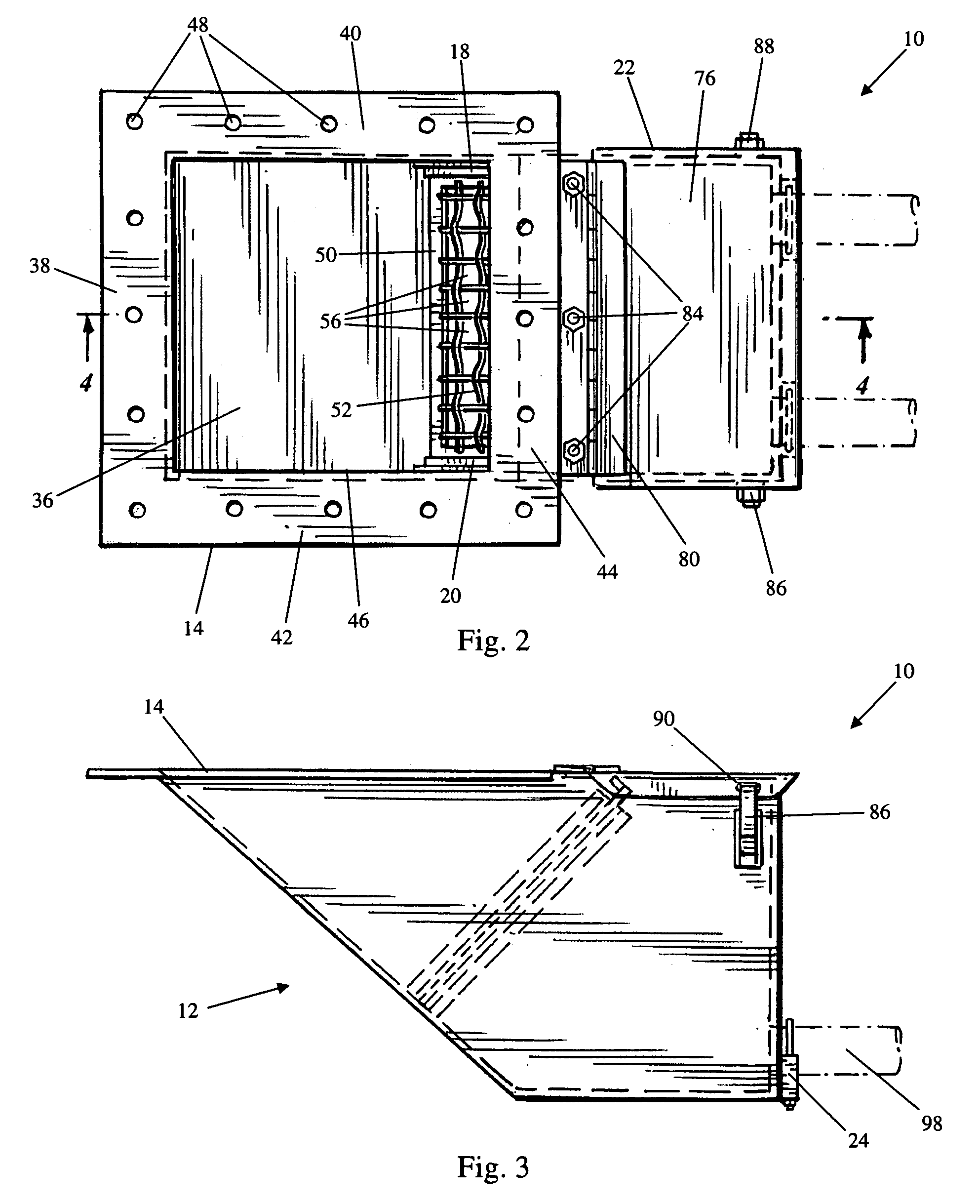

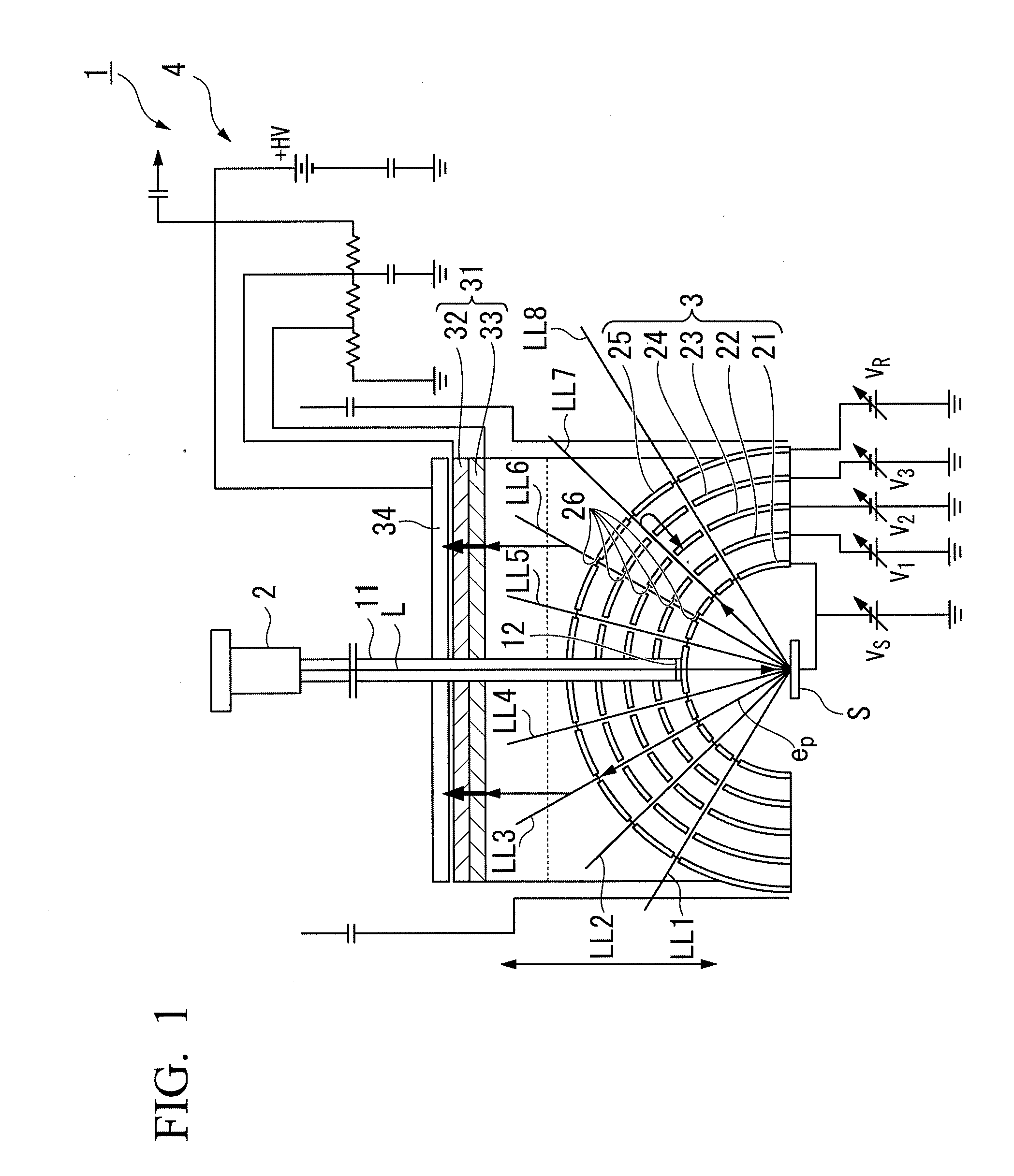

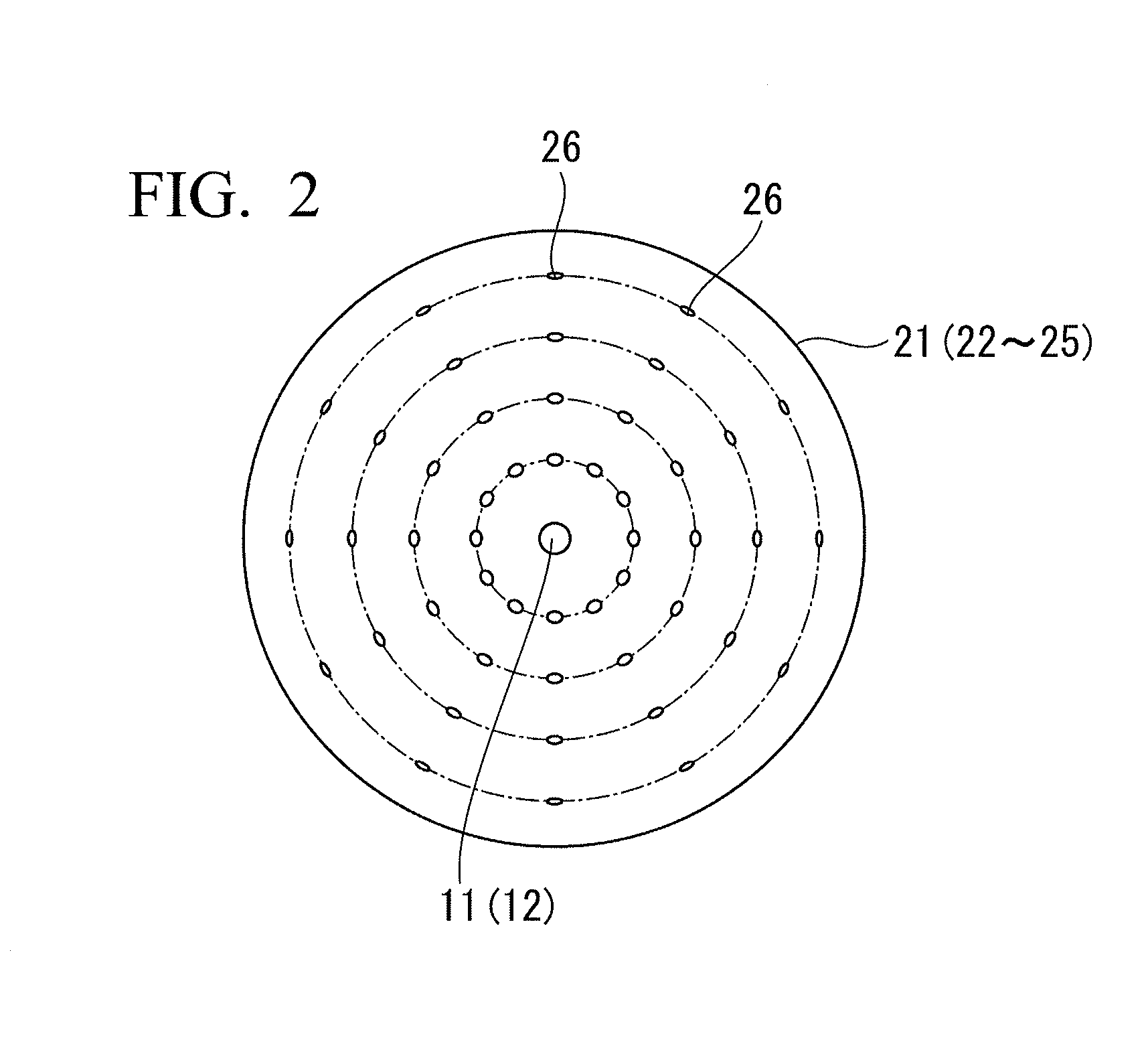

Electrode member, electron energy analyzer, photoelectron energy analyzer, and temperature measuring apparatus

InactiveUS20120155509A1Integrated electron energyHigh sensitivity measurementStability-of-path spectrometersMaterial analysis using wave/particle radiationEnergy analyserMolecular physics

Disclosed is an electrode member which has spherical sections, each of which configures a part of a sphere, and a plurality of spherical electrode sections wherein the radiuses of the spherical sections are different from each other. The spherical electrode sections are disposed in a state wherein the center points of the respective spheres match each other and the spherical electrode sections are insulated from each other such that voltages can be independently applied thereto. Electron-passing openings for straightly taking out electrons, which are moving from the center point, to the outside of the electrode are formed at positions where the spherical electrode sections and a plurality of straight lines radially extending from the center point intersect each other.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com