Novel well cementation truck

A new type of cementing technology, applied in the field of new cementing vehicles, can solve the problems of complex operation, unsatisfactory, time-consuming, etc., and achieve the effect of flexible and efficient movement, optimized space layout, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

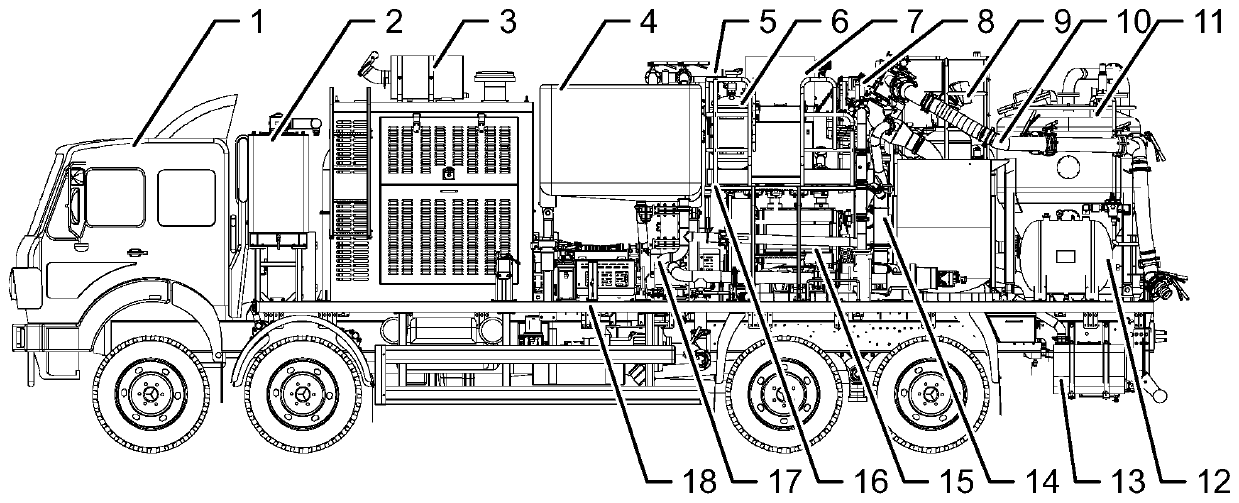

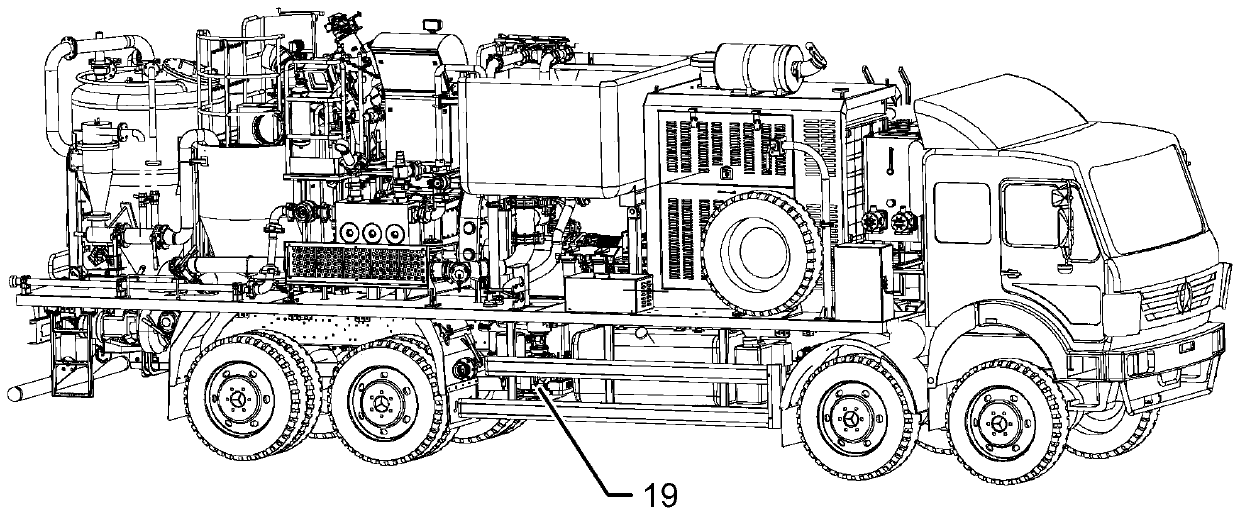

[0018] like figure 1 and figure 2 As shown, a new type of cementing vehicle includes a loading body 1, an electrical system 8, a plunger pump 15, a clean water manifold 17, a mud manifold 14 and a high pressure manifold. The loading body 1 is provided with a beam 18, and the A hydraulic system 2, a power transmission system 3, a metering tank 4, an operating platform 16 and a mixing system 9 are sequentially installed on the beam 18, an air circuit system 5 and an operating system 7 are sequentially installed on the operating platform 16, and the electrical system 8 supplies power to the cementing vehicle, and the plunger pump 15, clean water manifold 17, mud manifold 14 and high pressure manifold are all arranged under the operation platform 16, and the clean water manifold 17 is the The pump 15 and the mixing system 9 provide clean water, the mud manifold 14 provides mud for the plunger pump 15, and the plunger pump 14 injects mud into the well through the high-pressure ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com