Automatic assembling machine for electronic components

A technology for electronic components and assembly machines, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency and inability to rivet electronic components, and achieve less product loss, safe and reliable cycle automatic assembly, and stamping effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

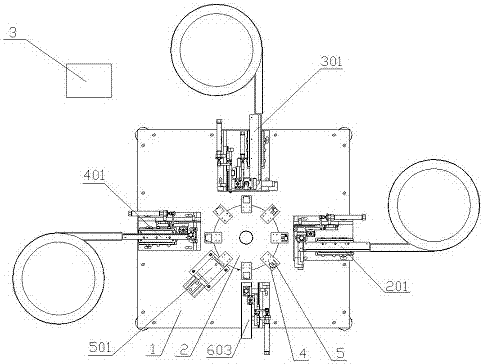

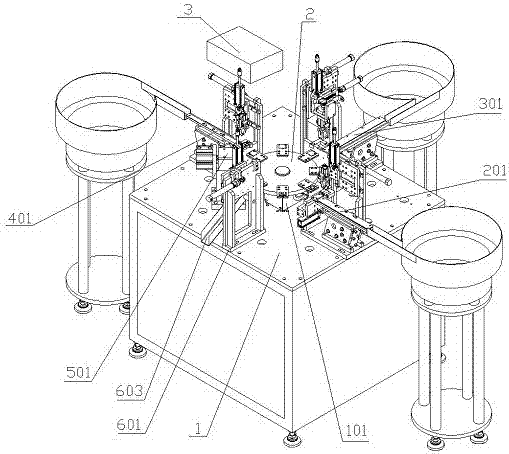

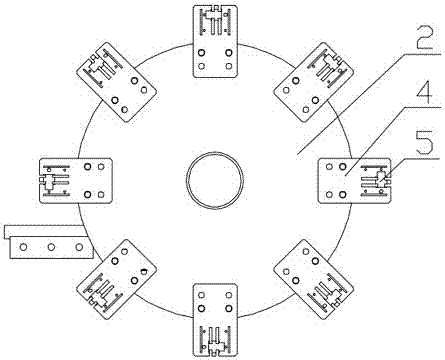

[0036] Such as Figure 1 to Figure 5The shown automatic assembly machine for electronic components includes a frame 1, a turntable 2 arranged on the frame, and a PLC controller 3, and a drive component for driving the turntable 2 to rotate is set on the frame 1, and the drive component includes a divider 101 , transmission belt 102, motor 103, when the motor 103 starts to work, the input shaft of the divider 101 is driven by the transmission belt 102 connected to the main shaft of the motor 103 to rotate, and the output shaft of the divider 101 drives the turntable 2 connected on the output shaft to rotate A plurality of templates 4 are evenly arranged on the turntable 2 along the circumferential direction, one end of the template 4 is fixedly connected to the turntable 2, and the other end of the template 4 is provided with a groove 5 for placing electronic components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com