Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

273results about "Work-collecting devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

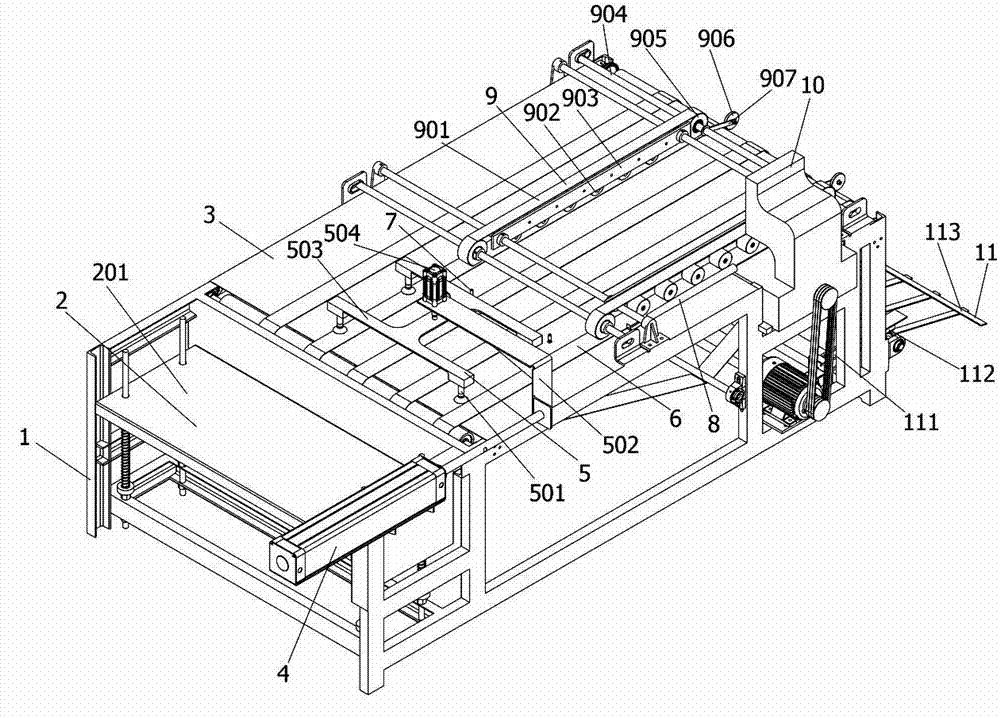

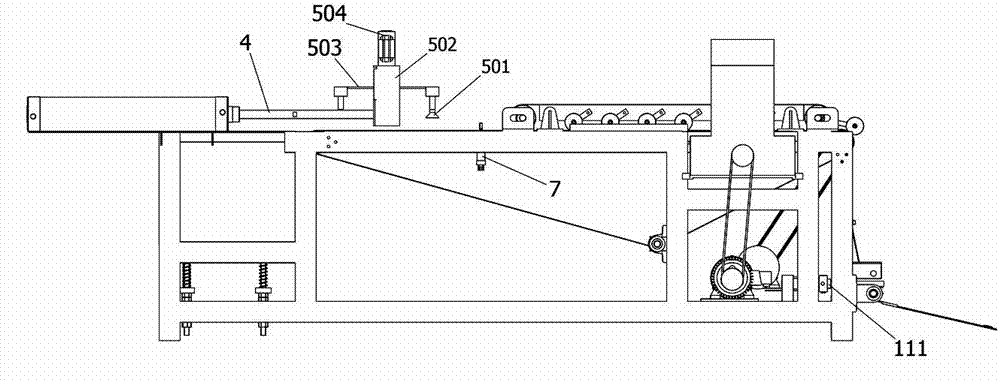

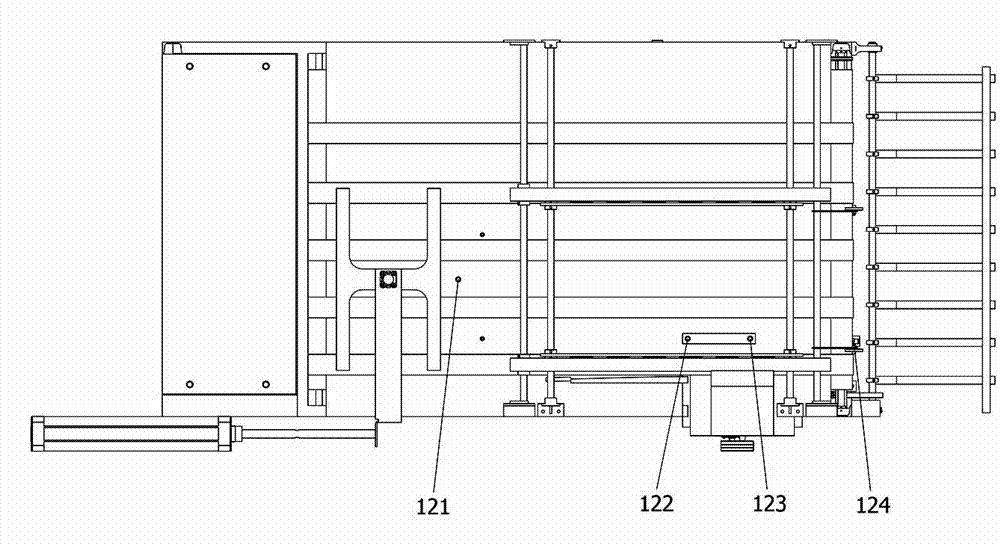

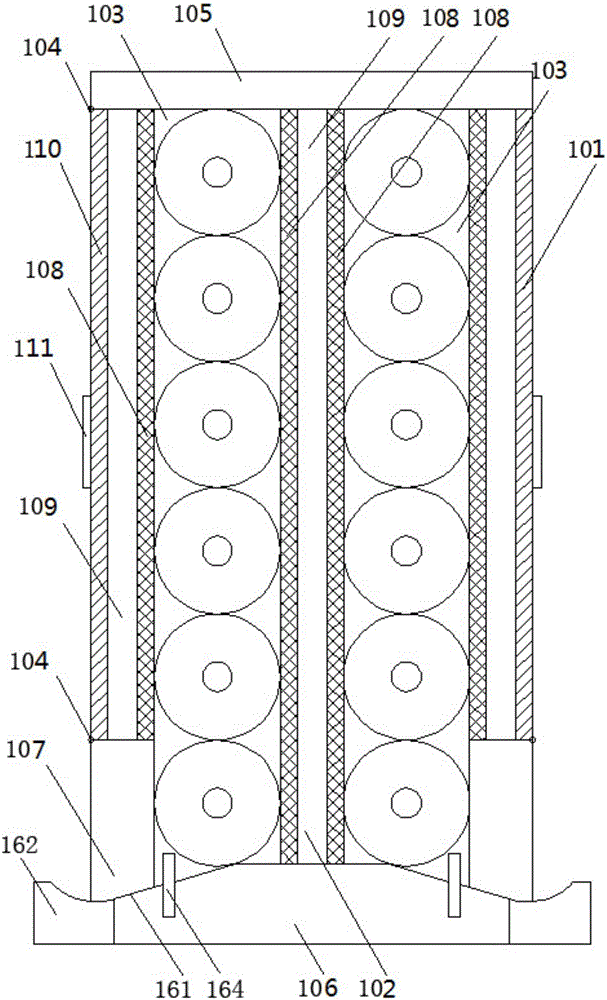

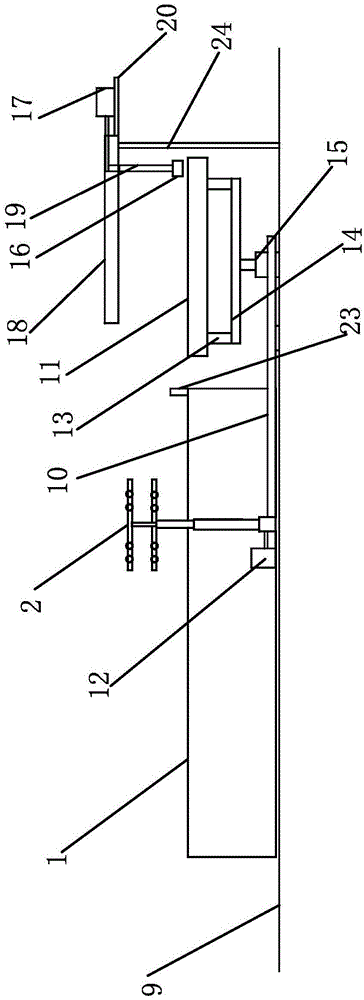

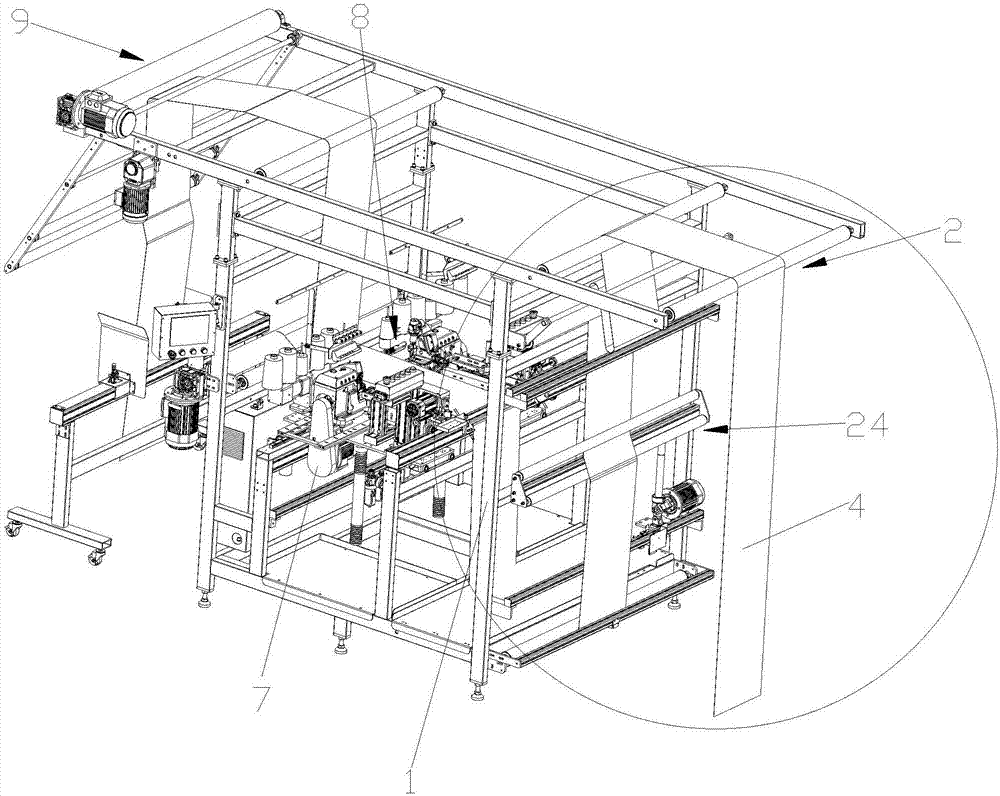

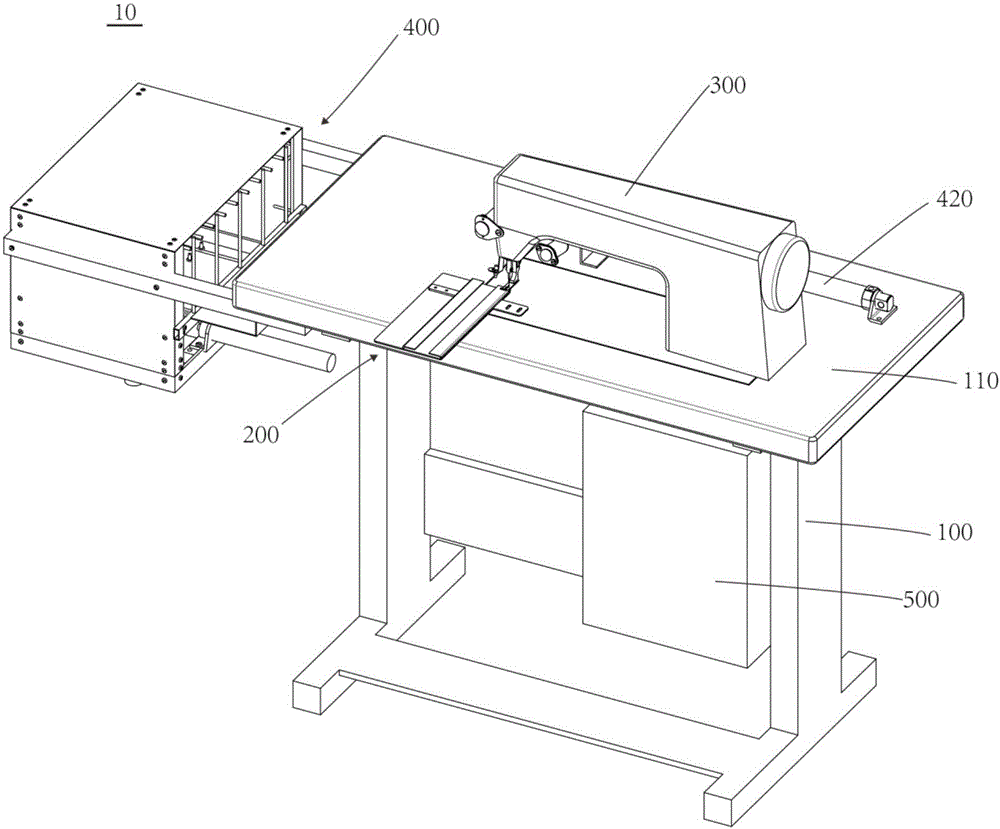

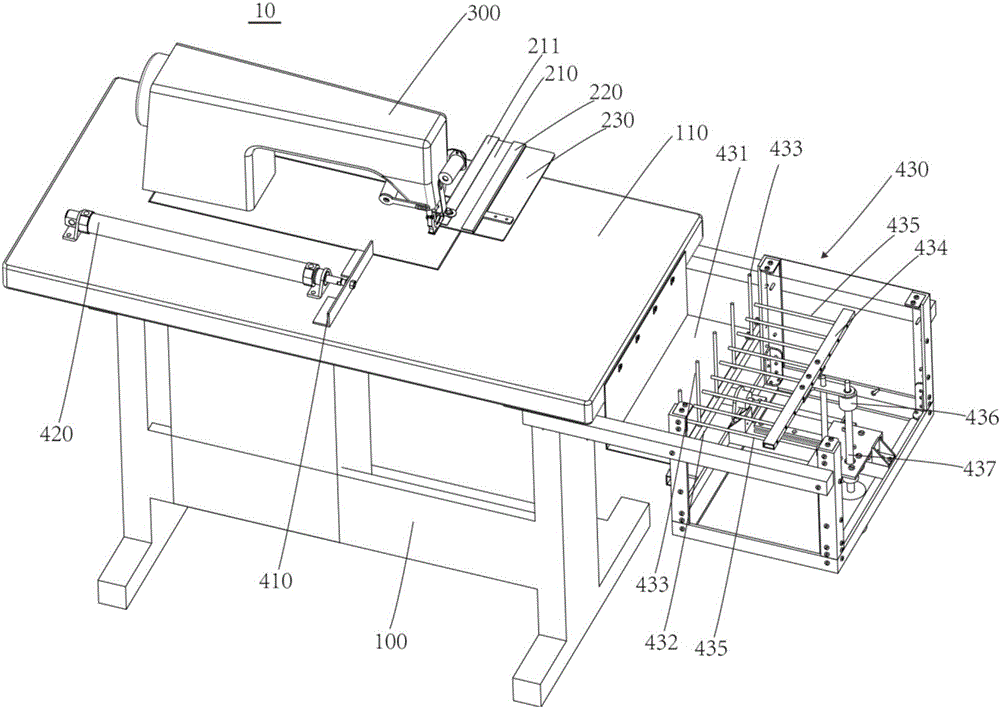

Automatic bag sewing machine

InactiveCN103882629AReduce labor costsShorten the lengthWork-feeding meansWork-collecting devicesReciprocating motionAutomation

The invention discloses an automatic bag sewing machine which comprises a rack assembly, a conveying assembly, a suction cup feeding assembly and a pressing wheel assembly. The rack assembly is located at the feeding end of the conveying assembly, and woven bags to be sewn are placed on the rack assembly. The suction cup feeding assembly is installed above the conveying assembly and the rack assembly and can reciprocate above the conveying assembly and the rack assembly so that the woven bags to be sewn can be moved from the rack assembly onto the conveying assembly. The pressing wheel assembly is installed on the conveying assembly so that the woven bags moving on the conveying assembly can be tightly attached to the conveying assembly to be flattened. A hemmer and a sewing machine body are installed on at least one side of the conveying assembly. The automatic bag sewing machine has the advantages of being simple and compact in structure, high in automation degree, good in consistency of sewn products, capable of reducing the labor cost and the like.

Owner:重庆市巨恒塑料有限公司

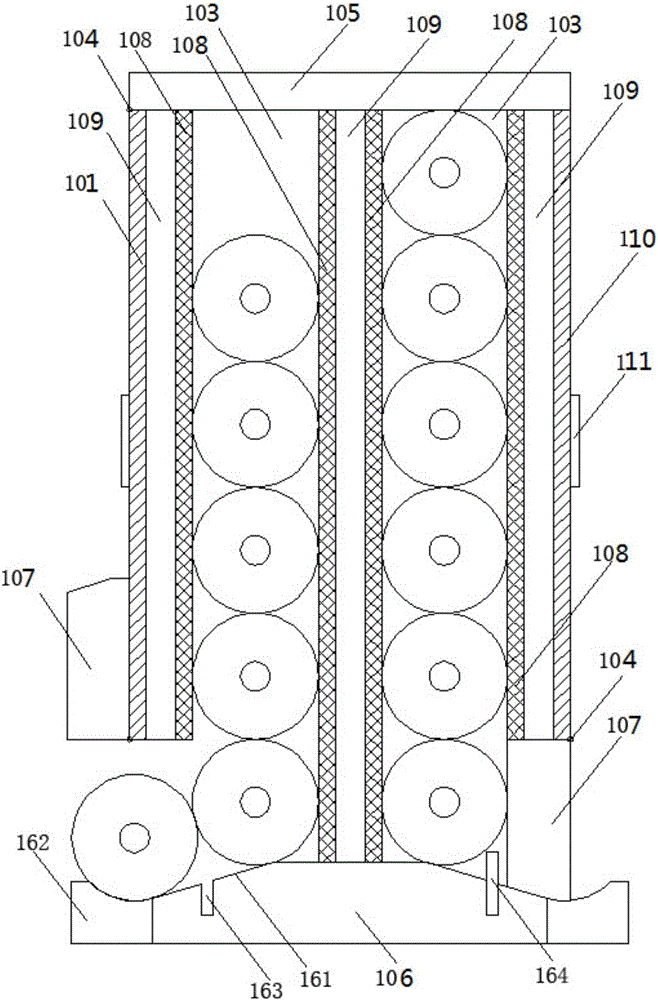

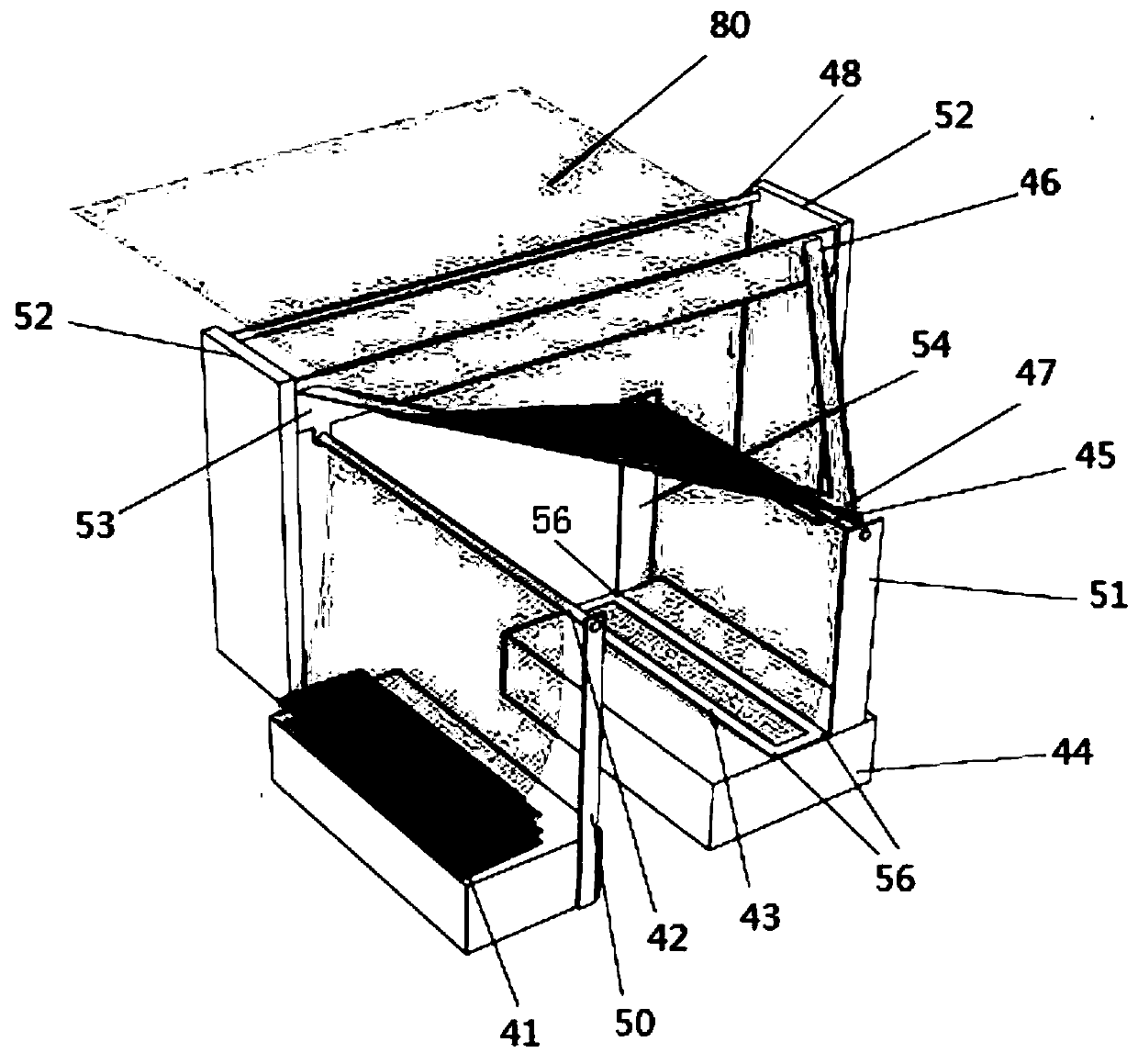

Complete equipment for tailoring

ActiveCN106367938AEasy to storeKeep drySevering textilesWork-collecting devicesEngineeringDrying Agents

The invention discloses complete equipment for tailoring. The complete equipment comprises a fabric storage cabinet, a fabric cutting machine, a sewing machine, a button sewing machine and an ironing machine, wherein the fabric storage cabinet comprises a cabinet body; the cabinet body is divided into left and right fabric accommodating cavities by virtue of a drying agent separator which is arranged at the center of the cabinet body, and the length of each fabric accommodating cavity is equal to the diameter of the fabric; the top end of the cabinet body is connected with a cover plate through a rotary hinge; a base is arranged at the bottom end of the cabinet body; and bottom ends of left and right side walls of the cabinet body are respectively connected with an upward lifting door through the rotary hinge. The fabric storage cabinet can be used for greatly reducing the time for searching fabrics, the dryness of the environment in the cabinet body is effectively maintained, and long-term fabric storage is facilitated.

Owner:MEISHENG CULTURE INNOVATION HLDG

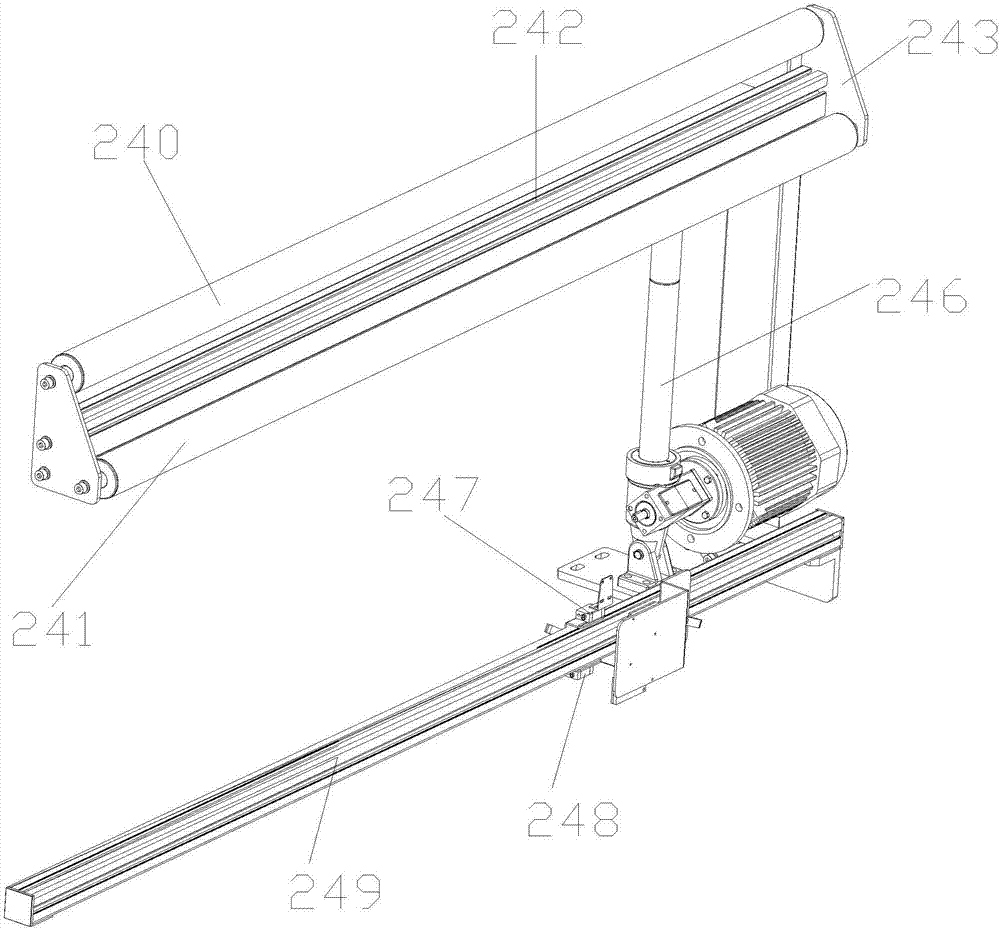

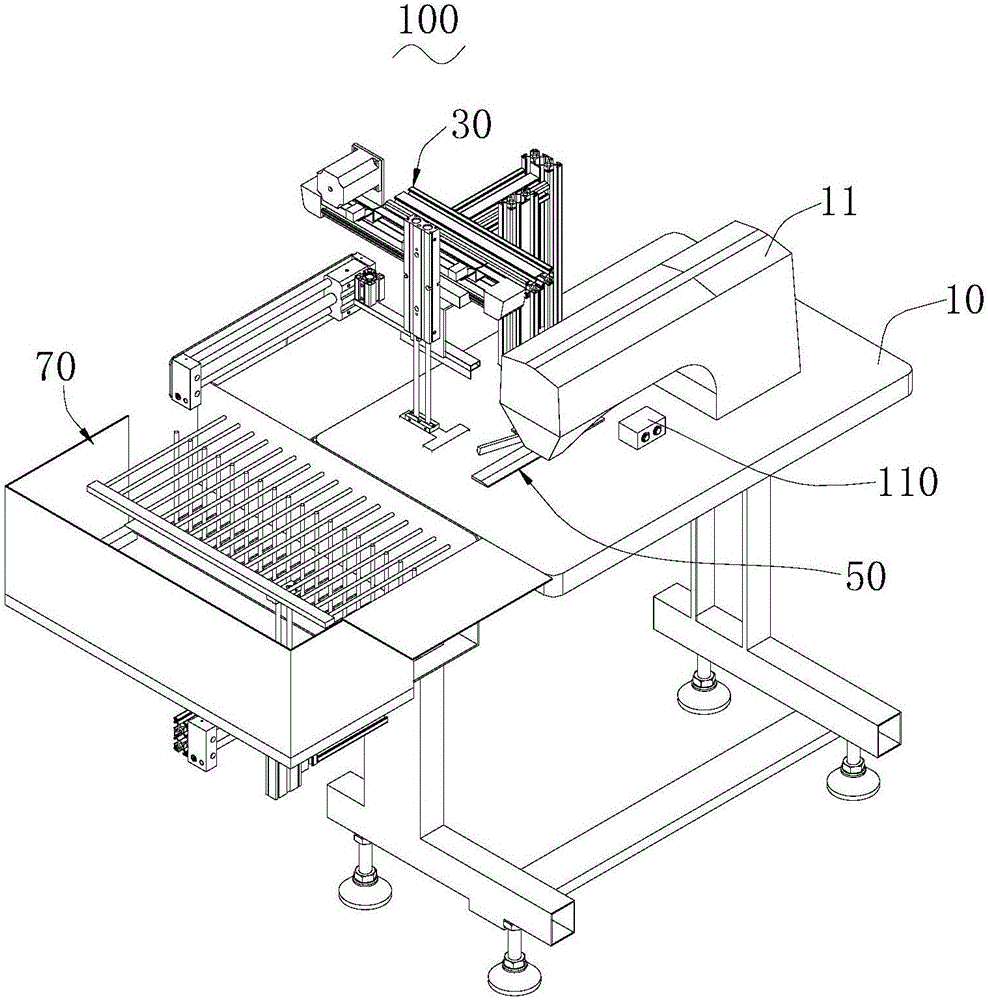

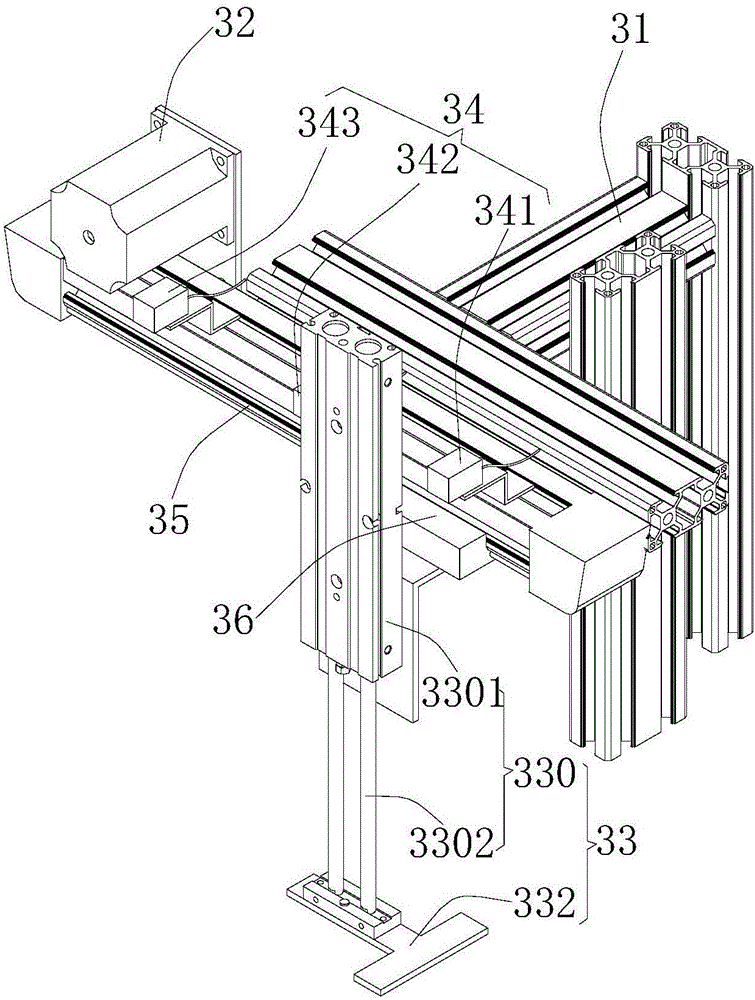

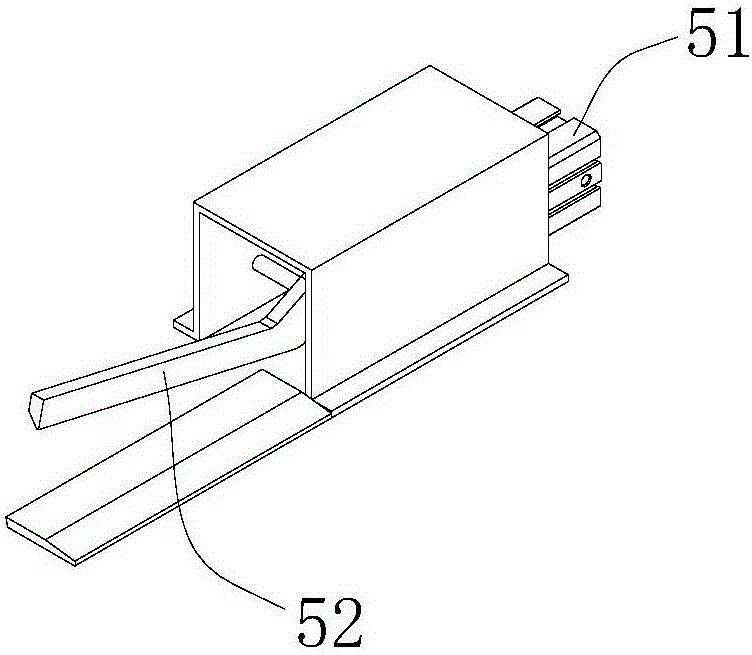

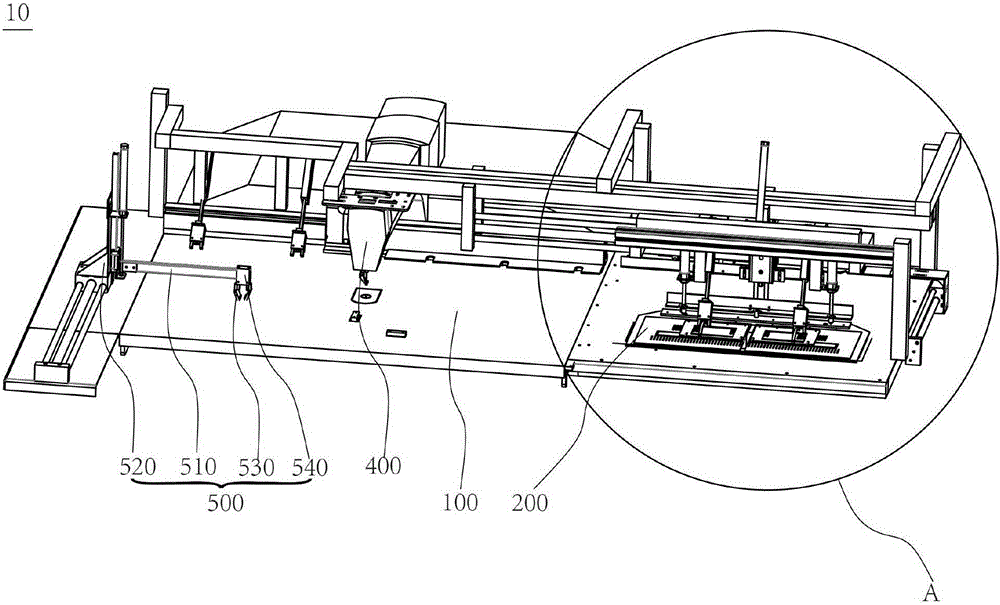

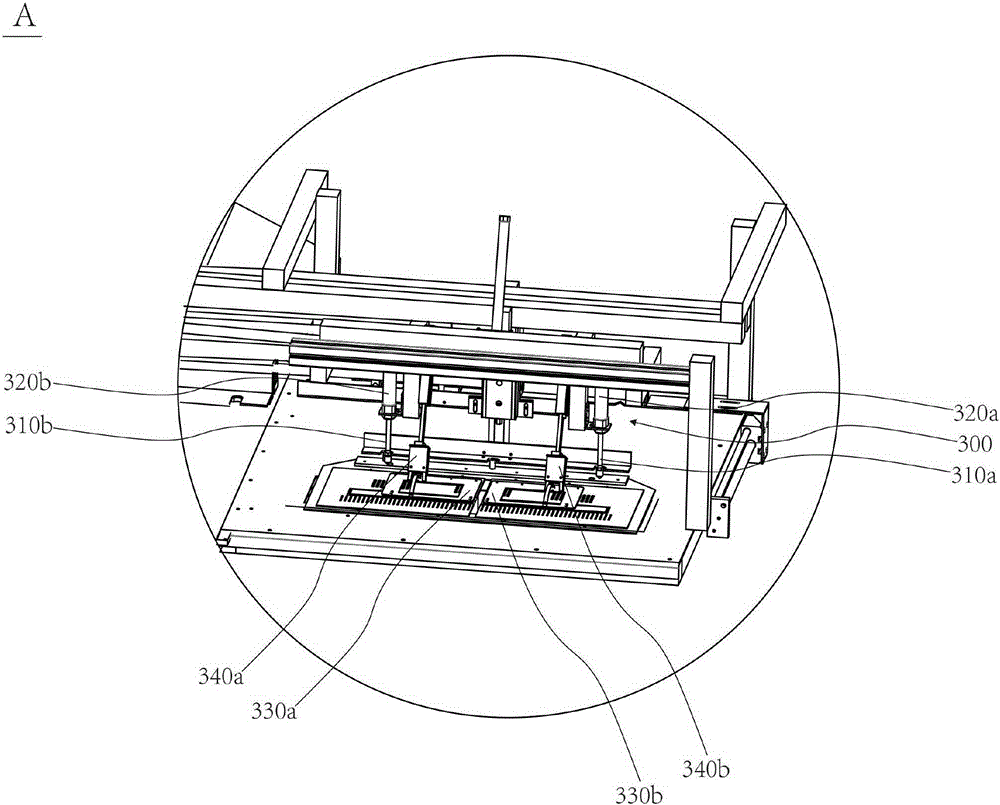

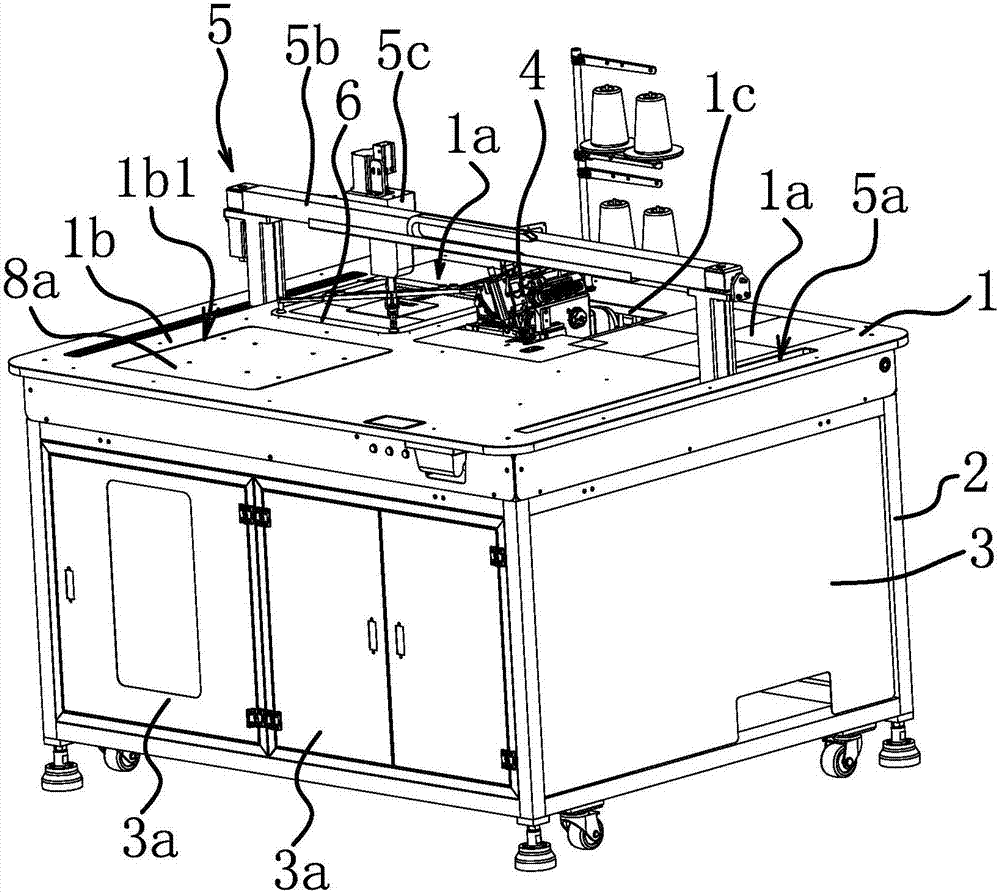

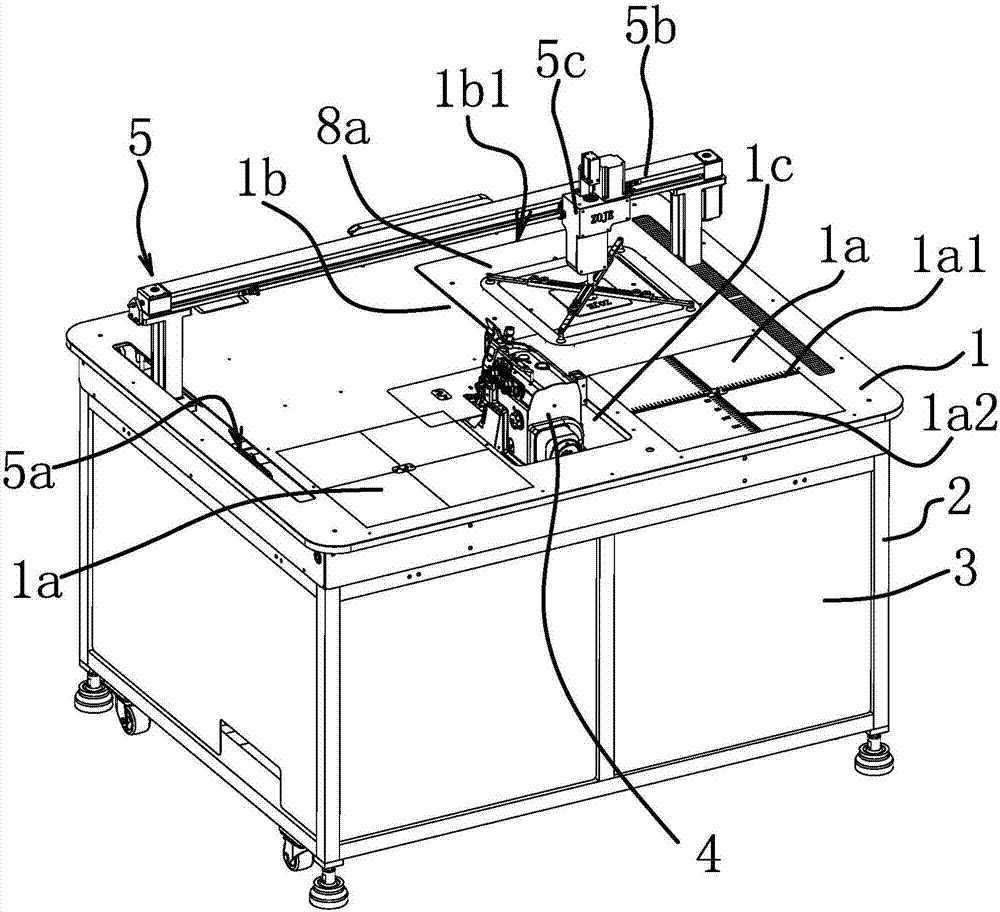

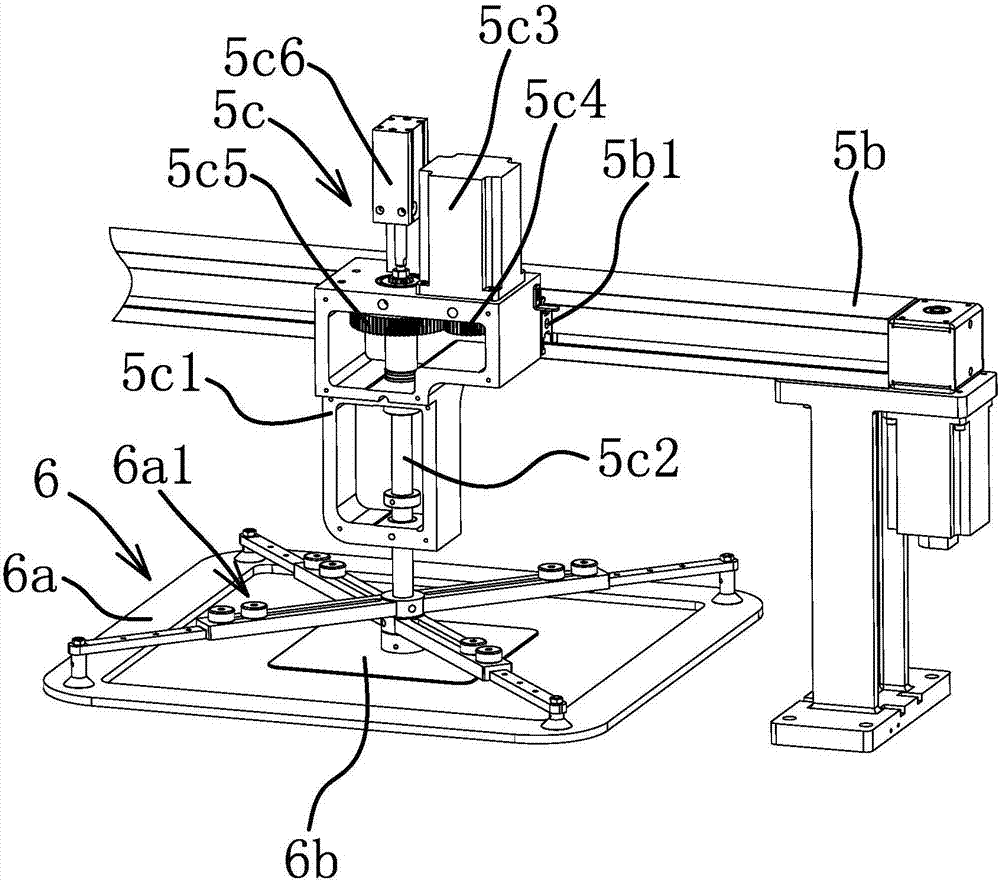

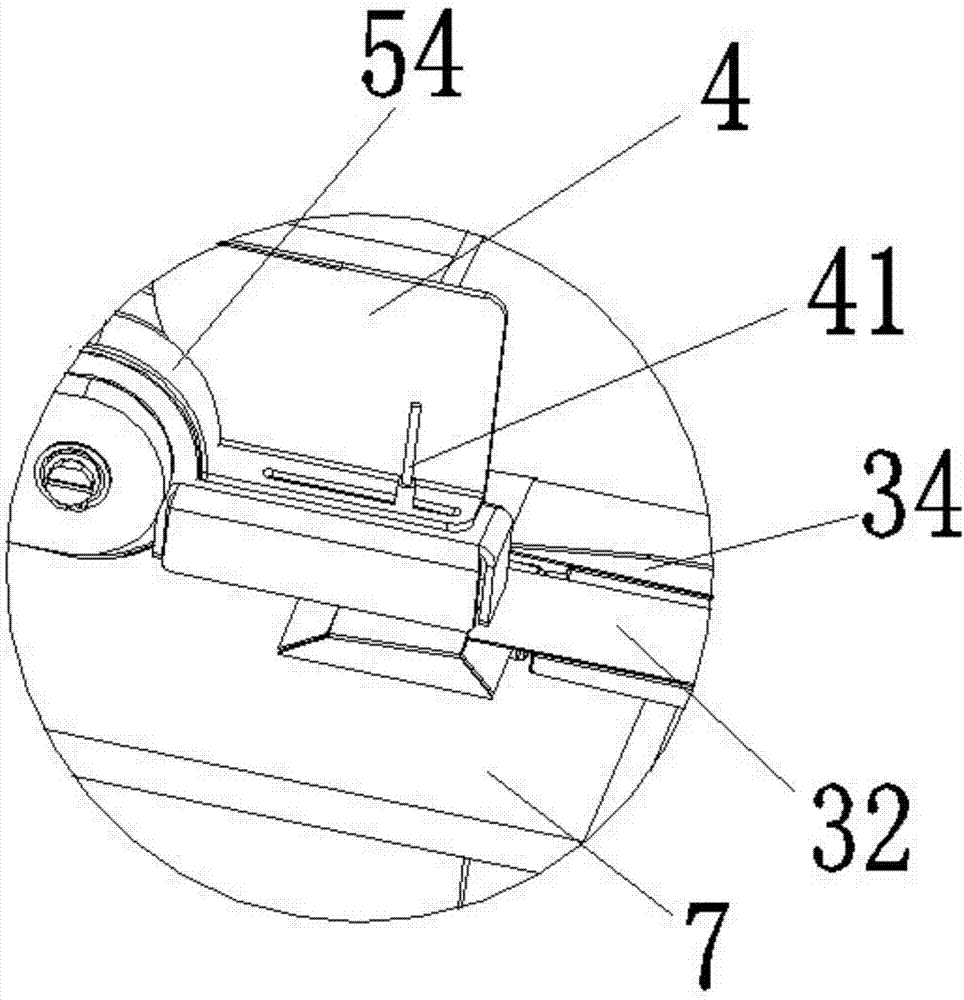

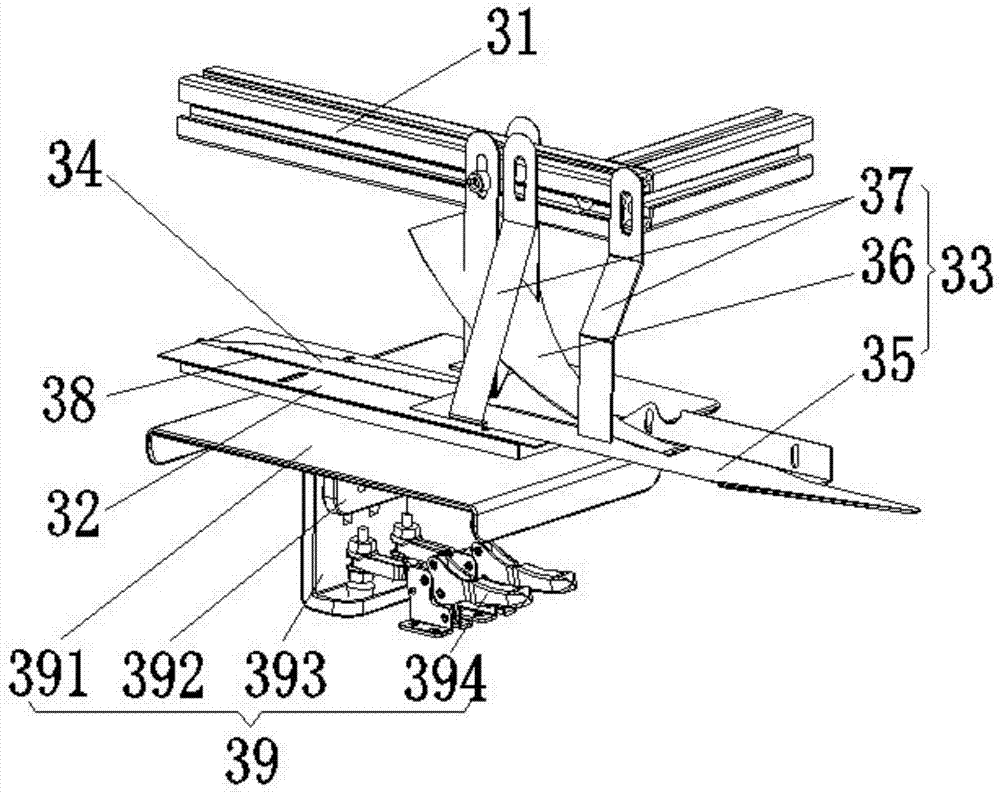

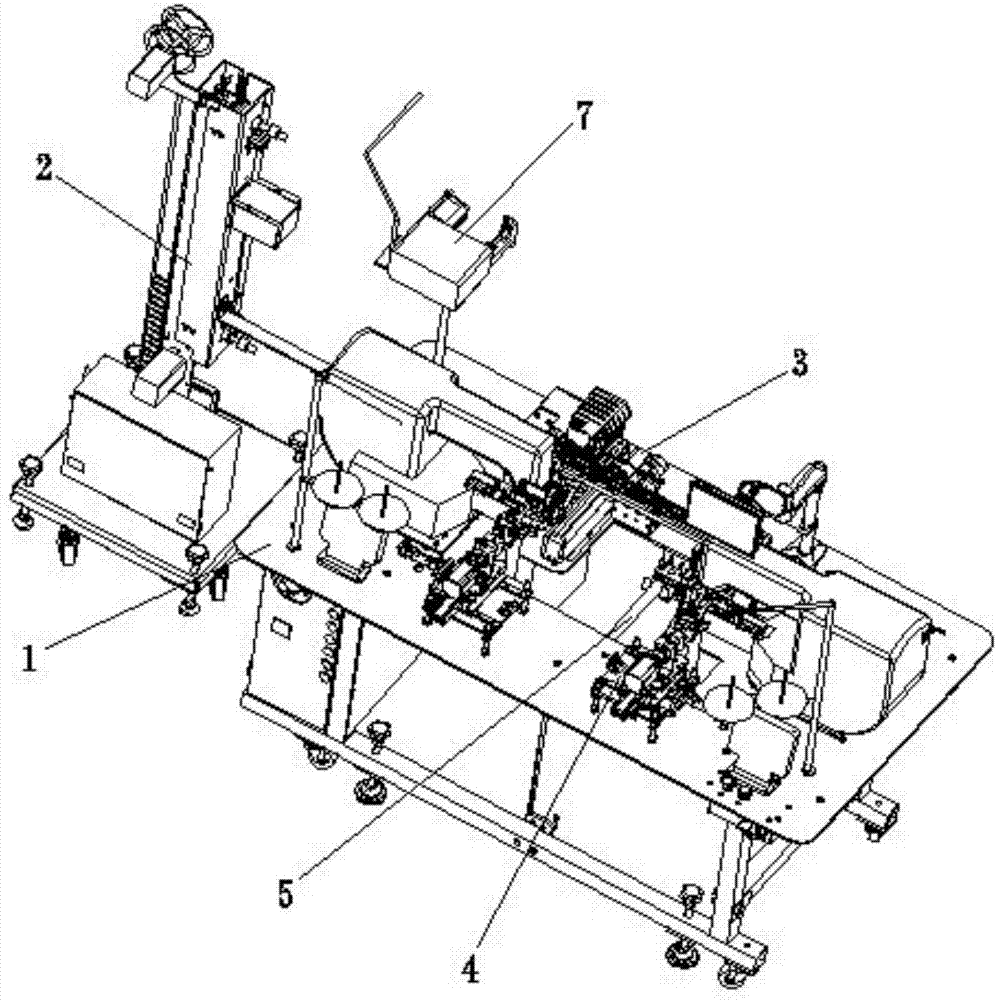

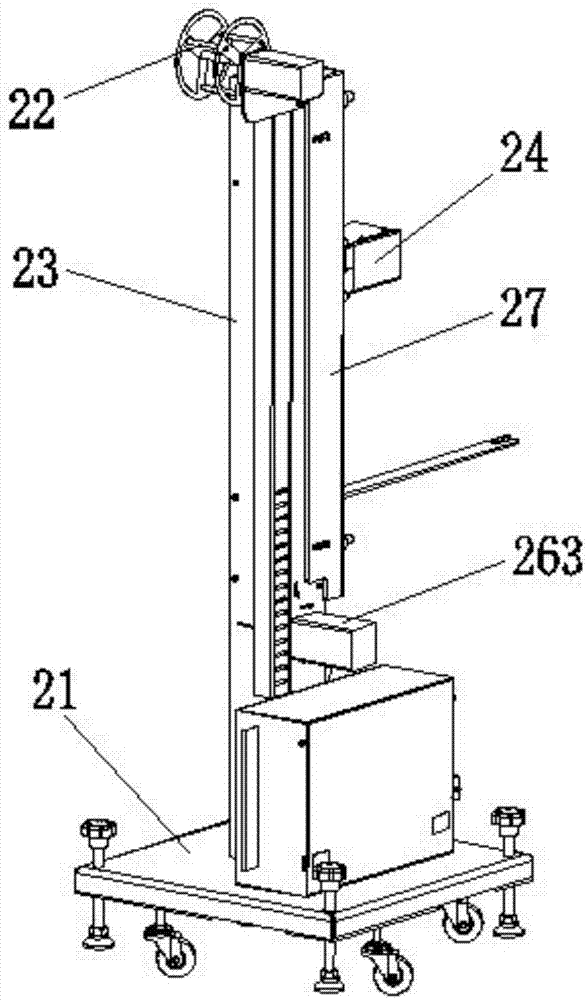

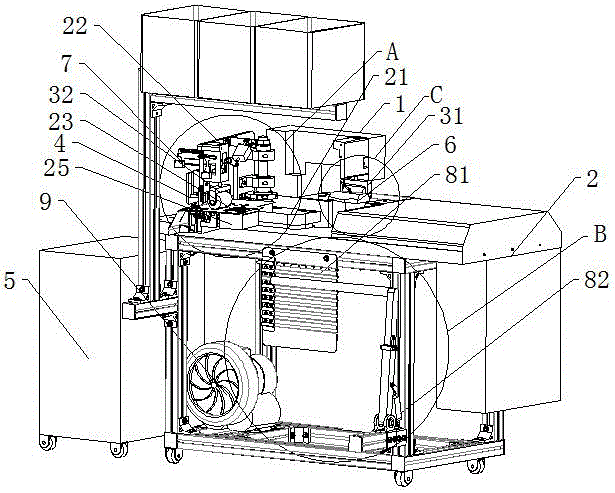

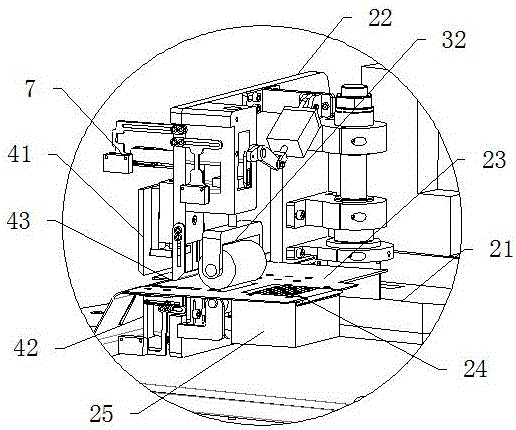

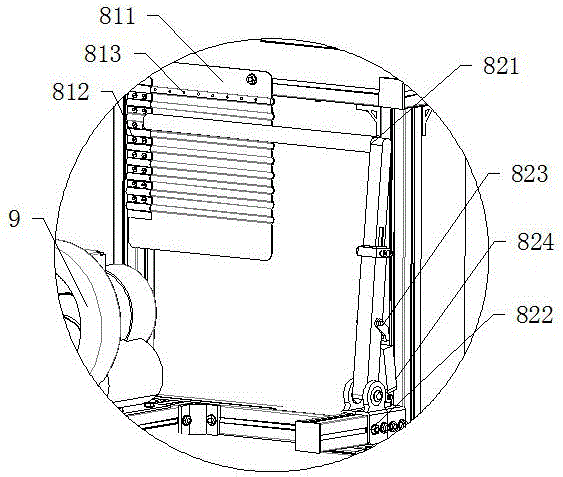

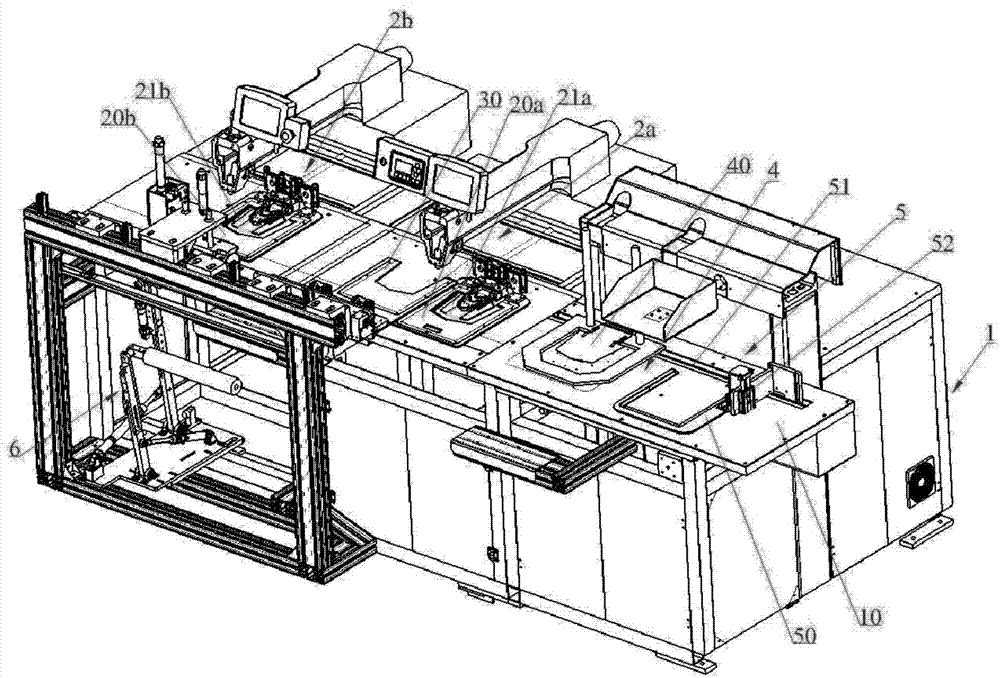

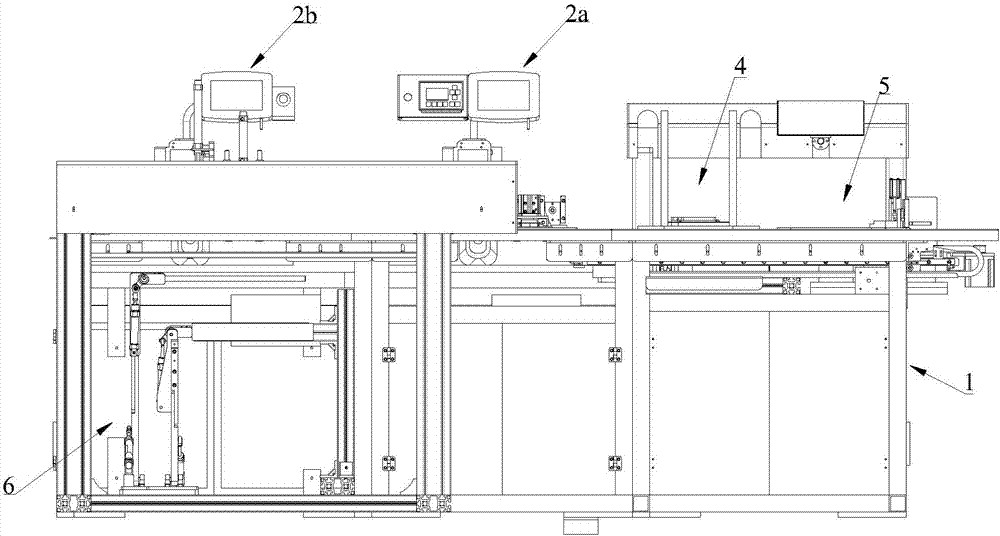

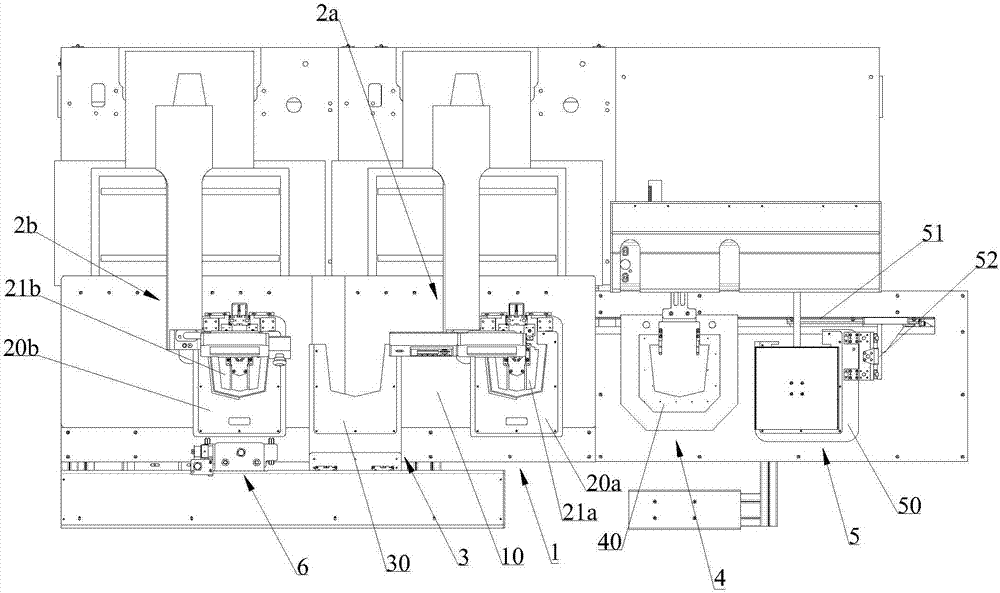

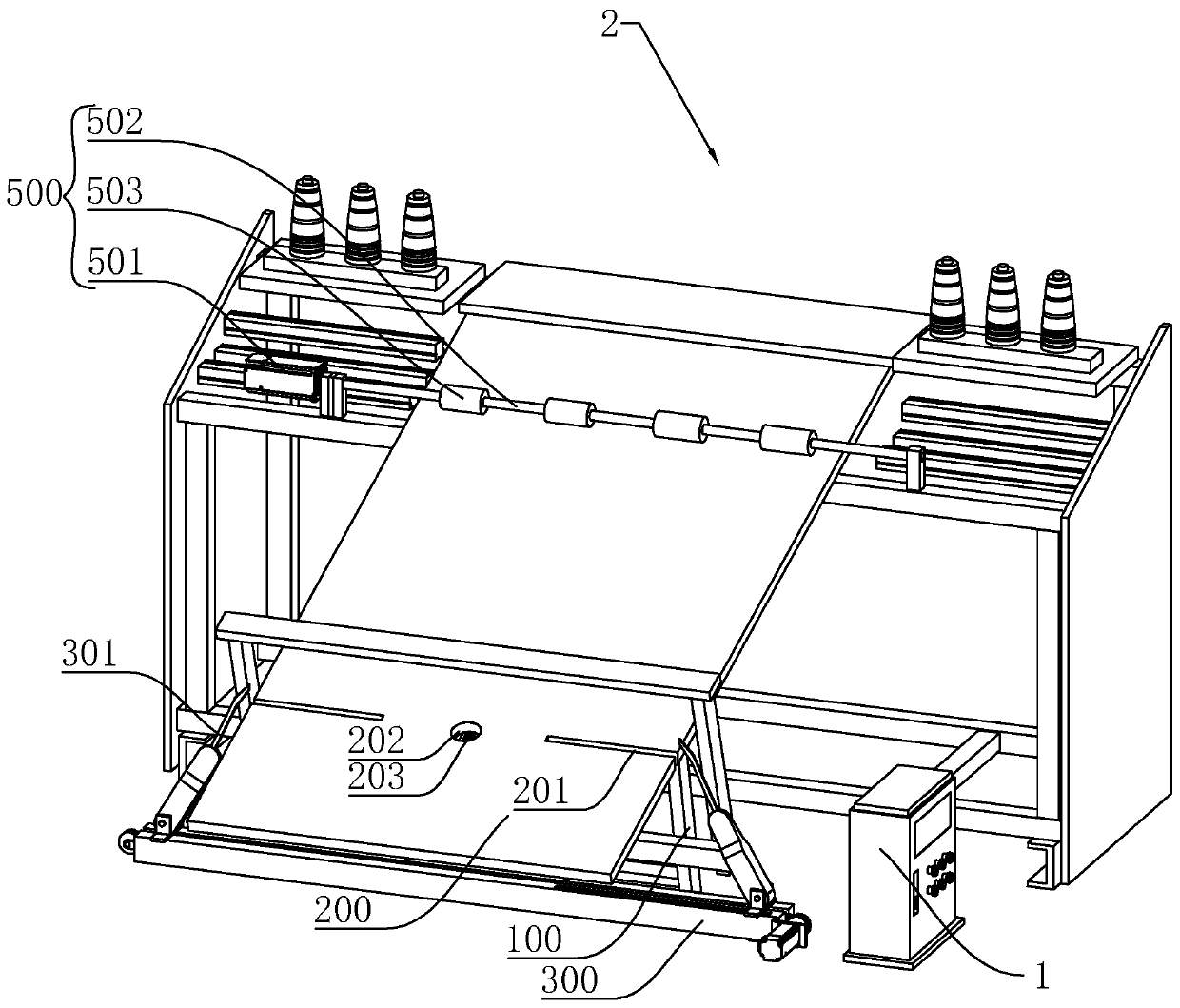

Automatic sewing equipment

ActiveCN107475909AKeep tidy and organizedRealize fully automatic sewingProgramme-controlled sewing machinesWork-feeding meansEngineeringAutomatic testing

The invention provides automatic sewing equipment. The automatic sewing equipment is provided with a rack, a sewing unit, a discharging unit, a sewing material separating unit, a sewing material clamping unit, a sewing material moving unit and a collecting unit. After an operating worker places a pile of cutting pieces (multiple pieces of sewing material vertically stacked) to be sewed on a cloth placing platform, subsequently a piece of sewing material on the top layer on the cloth placing platform is separated out by the sewing material separating unit, the separated sewing material is clamped by the sewing material clamping unit and transferred to a platform plate, the sewing material on the platform plate is transferred to a sewing machine by the sewing material moving unit, the sewing material is sewed by the sewing machine, and the sewed sewing material is supported by the collecting unit, so that full automatic sewing is achieved, it is only necessary for the operating worker to place a pile of cutting pieces on the cloth placing platform, the labor cost and the manpower cost are greatly reduced, it is effectively ensured that a sewing workshop of a clothing factory is clean and orderly, and the requirements of modern production are met.

Owner:JACK SEWING MASCH CO LTD

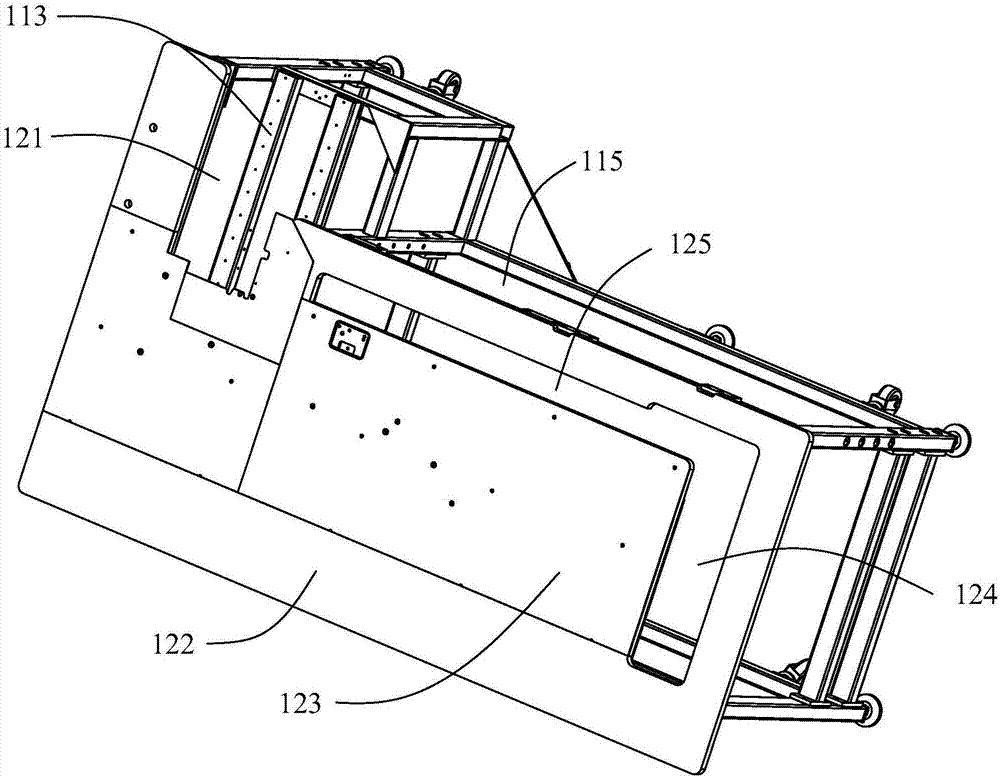

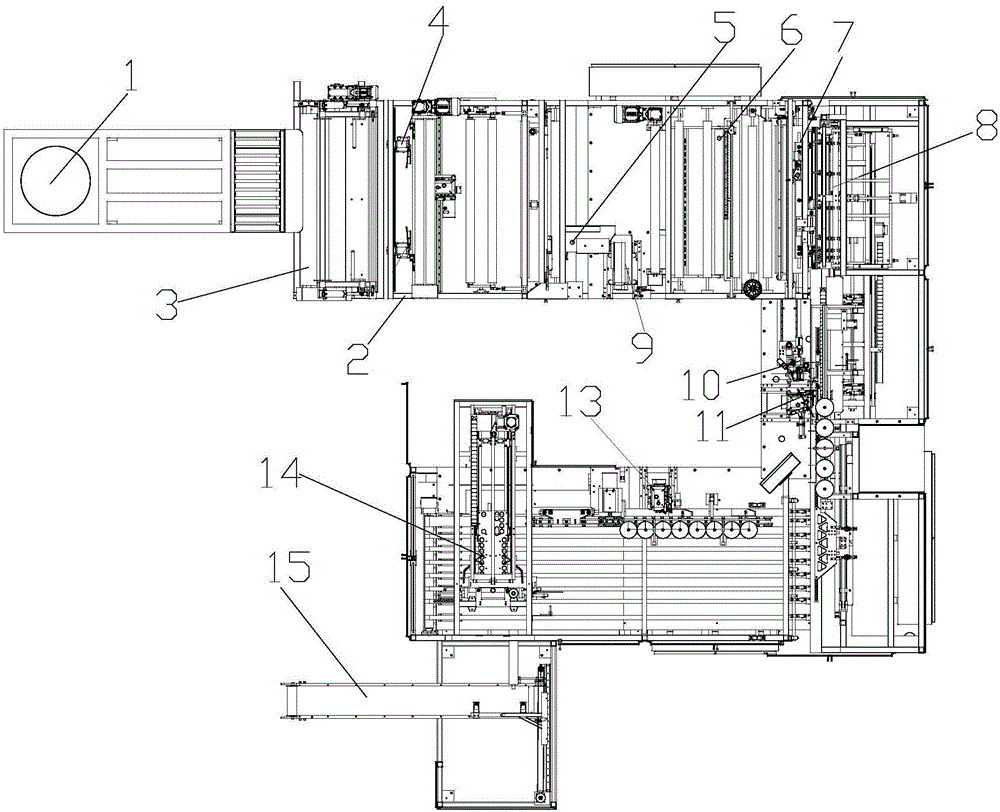

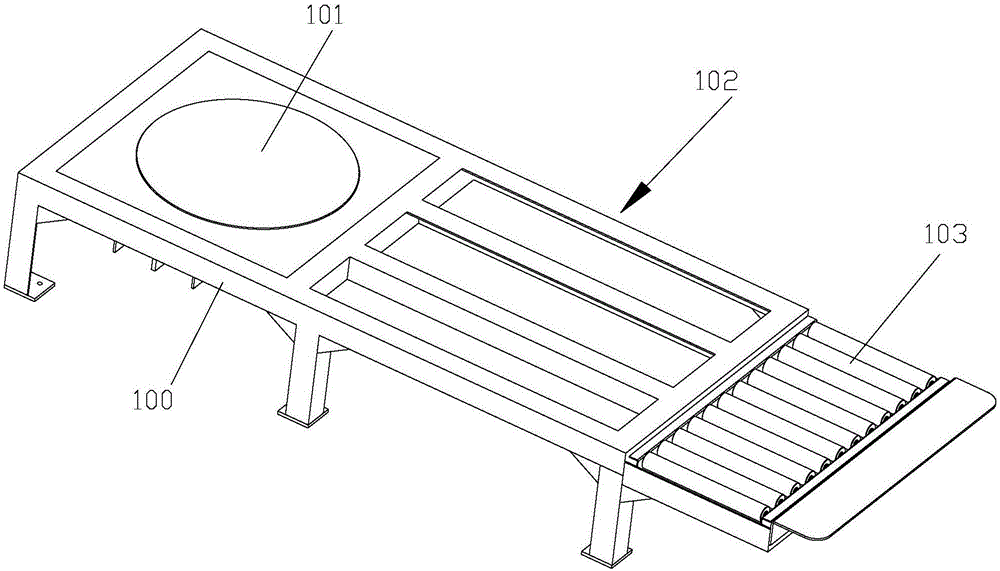

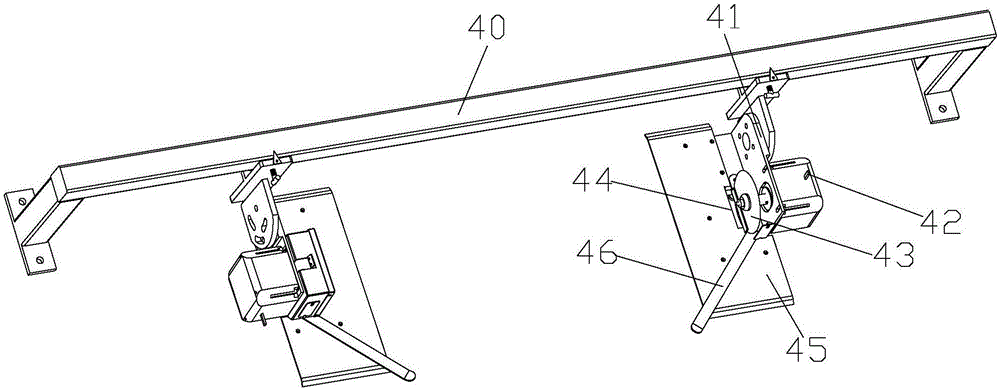

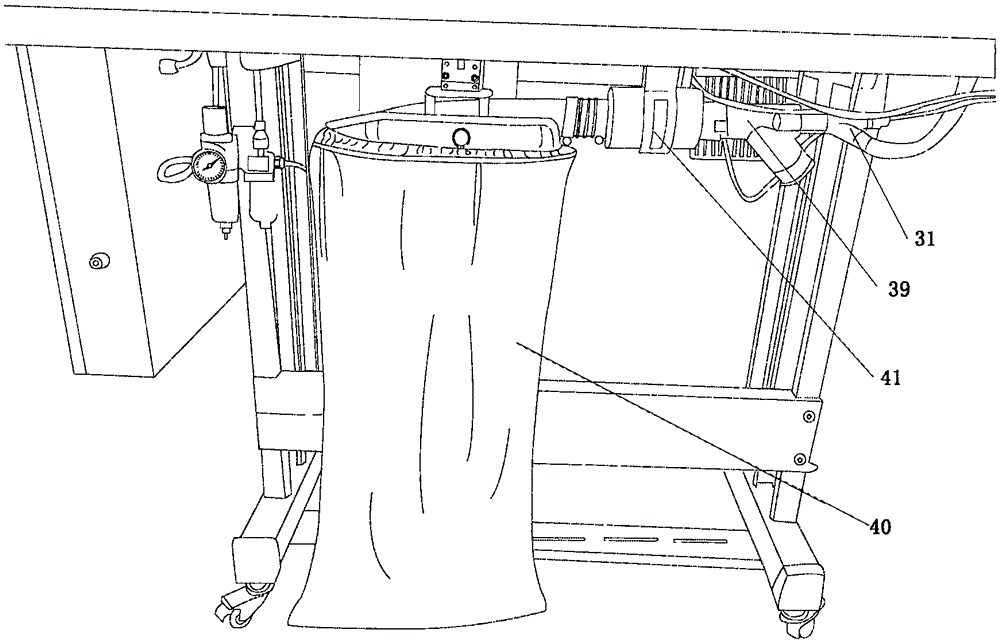

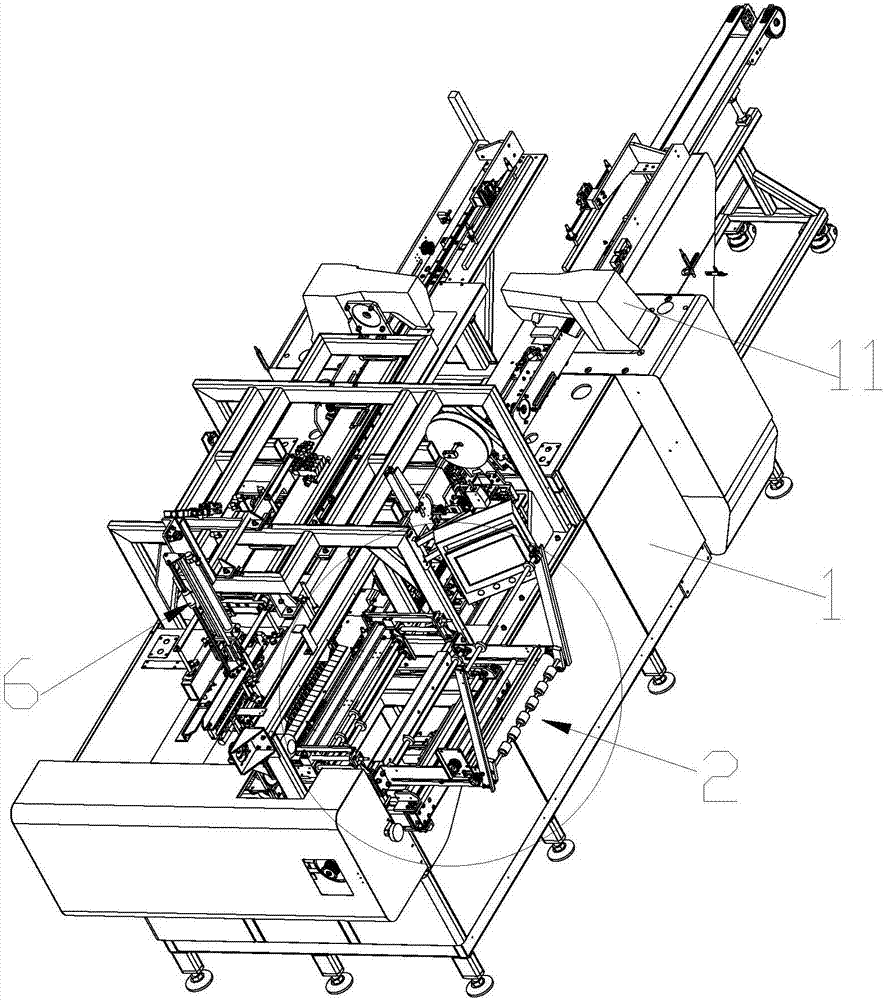

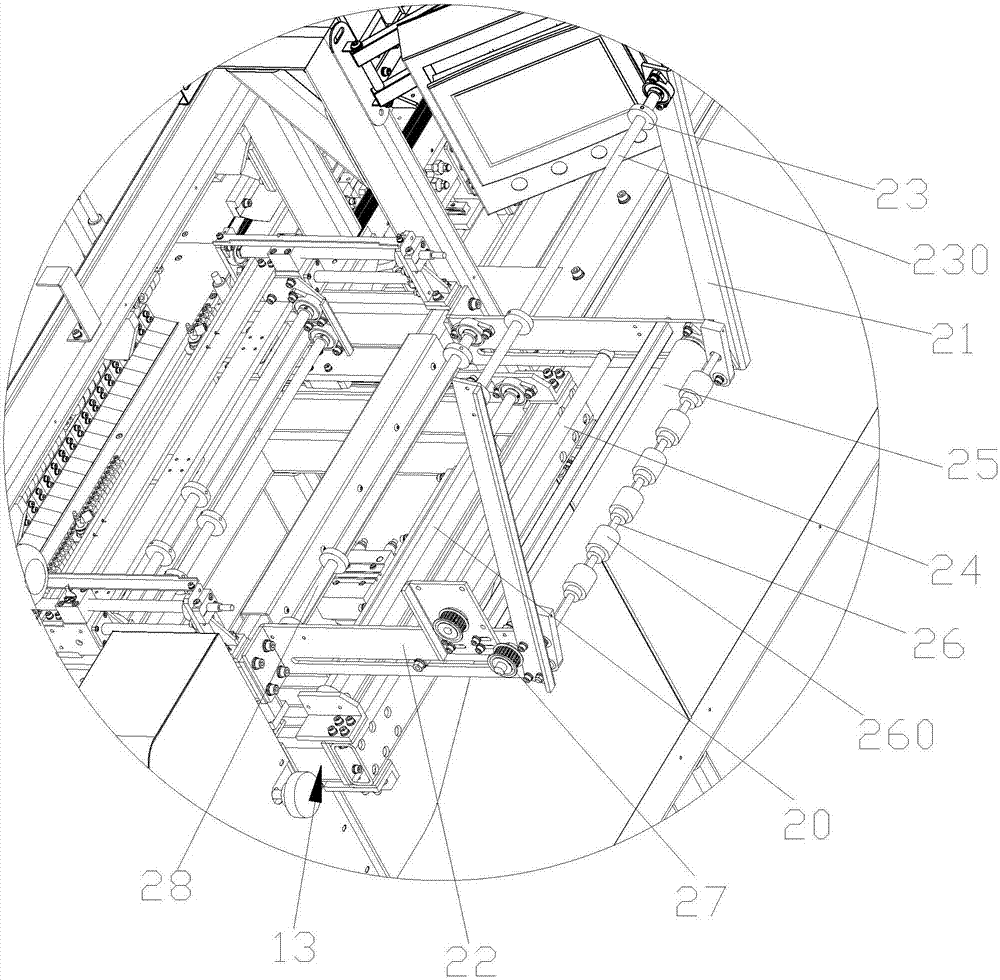

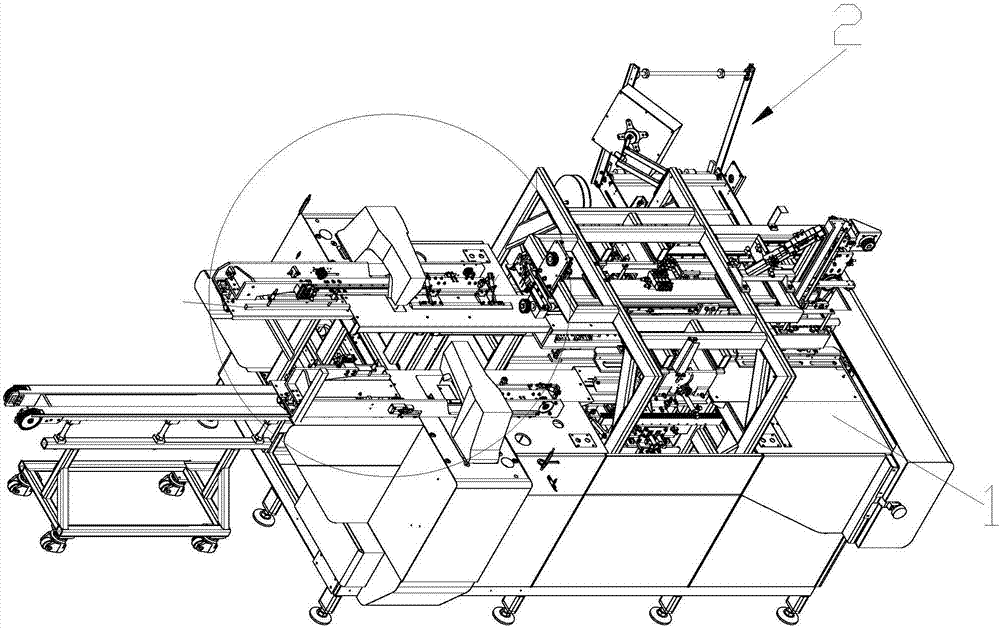

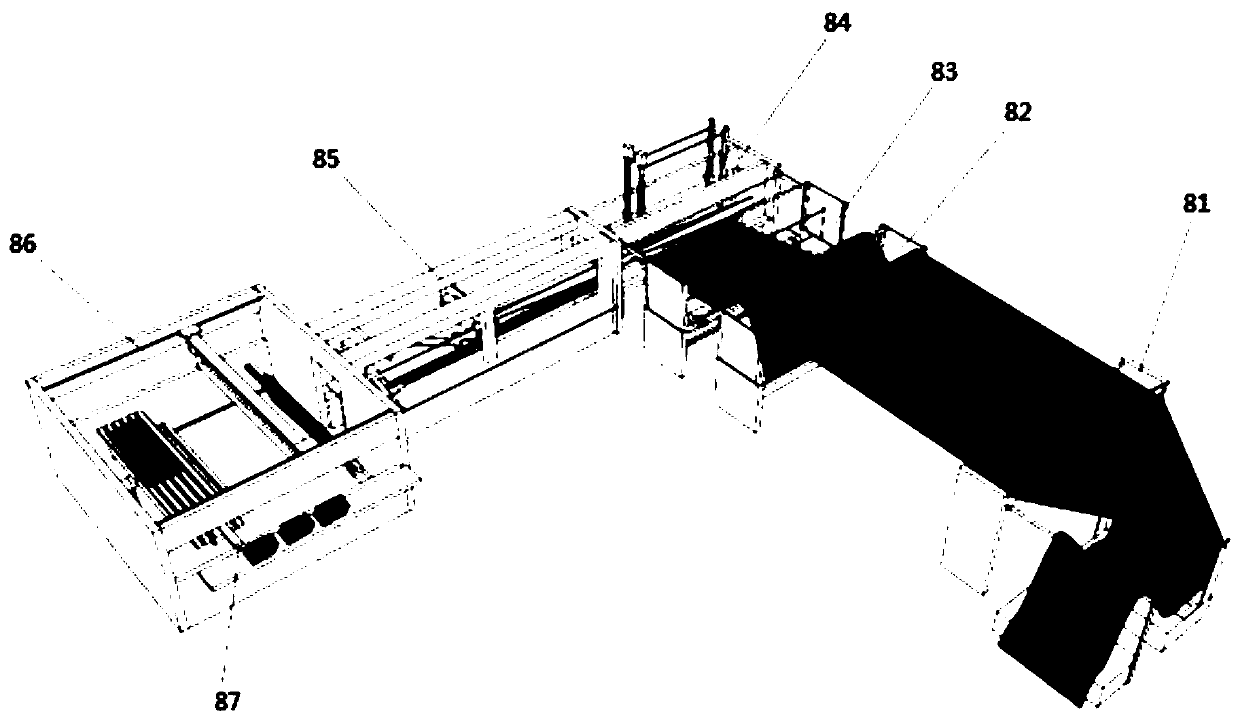

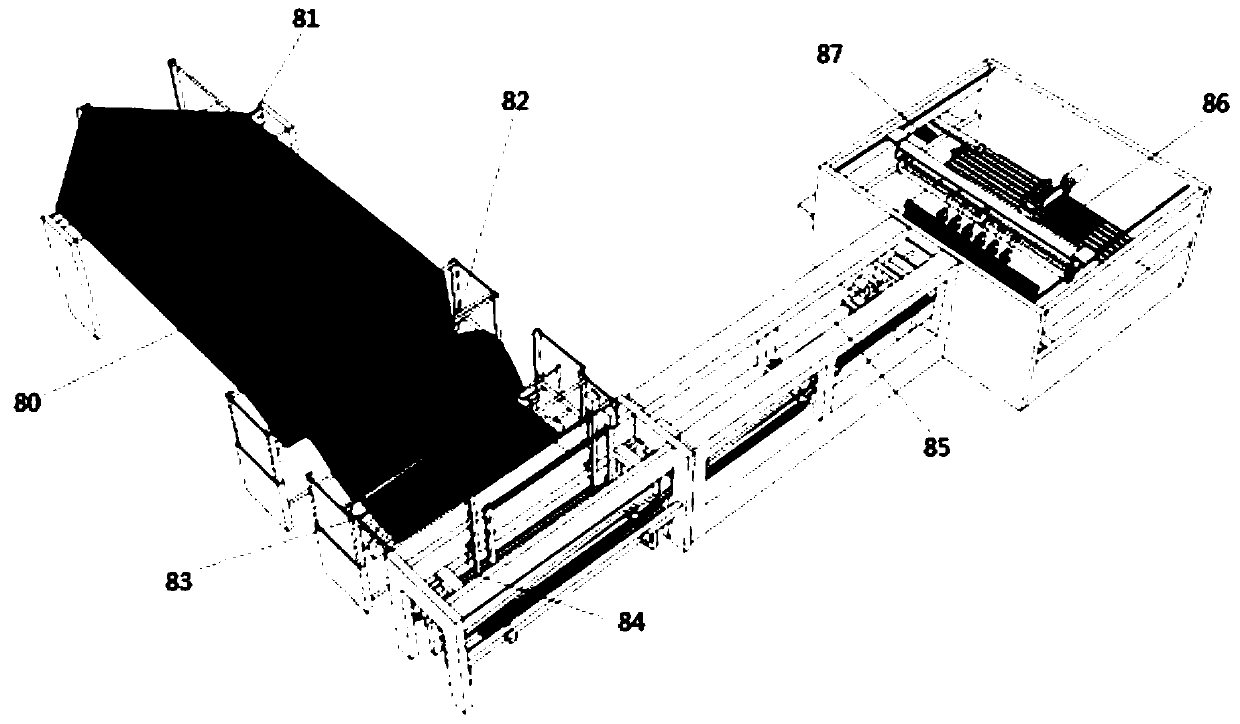

Full-automatic pillowcase machine

ActiveCN107435189AReasonable structure layoutMeet production and processing needsMechanical cleaningPressure cleaningEngineeringAssembly line

The invention relates to a full-automatic pillowcase machine. The machine comprises a feeding buffer area, a machine frame, a feeding component, a trimming device, an edge folding device, a sewing machine, a cloth slow storing mechanism, a correction device, a fixed-length cloth cutting-off mechanism, a label feeding device, a first binding-off device, a second binding-off device, a bag turning device and a collecting device, wherein the feeding component, the trimming device, the edge folding device, the sewing machine, the cloth slow storing mechanism, the correction device, the fixed-length cloth cutting-off mechanism, the label feeding device, the first binding-off device, the second binding-off device, the bag turning device and the receiving device are arranged on the machine frame; the feeding buffer area is located on one side of the machine frame; the feeding component, the trimming device, the edge folding device, the cloth slow storing mechanism, the correction device and the fixed-length cloth cutting-off mechanism are sequentially distributed on the machine frame; the label feeding device and the first binding-off device which are longitudinal distributed are arranged at the lower end of the fixed-length cloth cutting-off mechanism; the second binding-off device and the bag turning device are transversely distributed are arranged on one side of the lower end of the first binding-off device; the collecting device is arranged at the lower end of the bag turning device. The full-automatic pillowcase machine is reasonable in overall structural layout, assembly line processing of pillowcases can be automatically completed, the production efficiency is high, and the machine meets actual production and processing requirements.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Automatic material collecting device for sewing machine

InactiveCN105002671APrevent wrinkles, etc.Improve receiving efficiencyWork-collecting devicesEngineeringPack material

The invention provides an automatic material collecting device for a sewing machine. The automatic material collecting device comprises a conveying platform, wherein material absorbing mechanisms are symmetrically arranged on two sides of the conveying platform; each material absorbing mechanism comprises a connecting rod and an L-shaped frame; each L-shaped frame is perpendicularly connected to the corresponding connecting rod; one end of each first air cylinder is movably hinged to the inner side of the vertical beam of the corresponding L-shaped frame; the piston rod end of each first air cylinder is hinged onto a corresponding moving arm; one end of each moving arm is movably hinged to the end part of the vertical beam of the corresponding L-shaped frame; two groups of material fetching mechanisms are perpendicularly hinged onto each moving arm; each material fetching mechanism comprises a flat rod and a plurality of vacuum suction nozzles; a flattening mechanism comprises a flattening plate and a horizontal air cylinder. The automatic material collecting device has the benefits that the material absorbing mechanisms are utilized for collecting and storing sewed materials at a certain speed in a certain direction, so that a certain quantity of materials can be packed, and the material collecting efficiency is improved; the flattening device is arranged on a material receiving platform, so that all layers of the packed materials are prevented from being folded, and the operation is more convenient.

Owner:HAINING YUFANG WEAVING

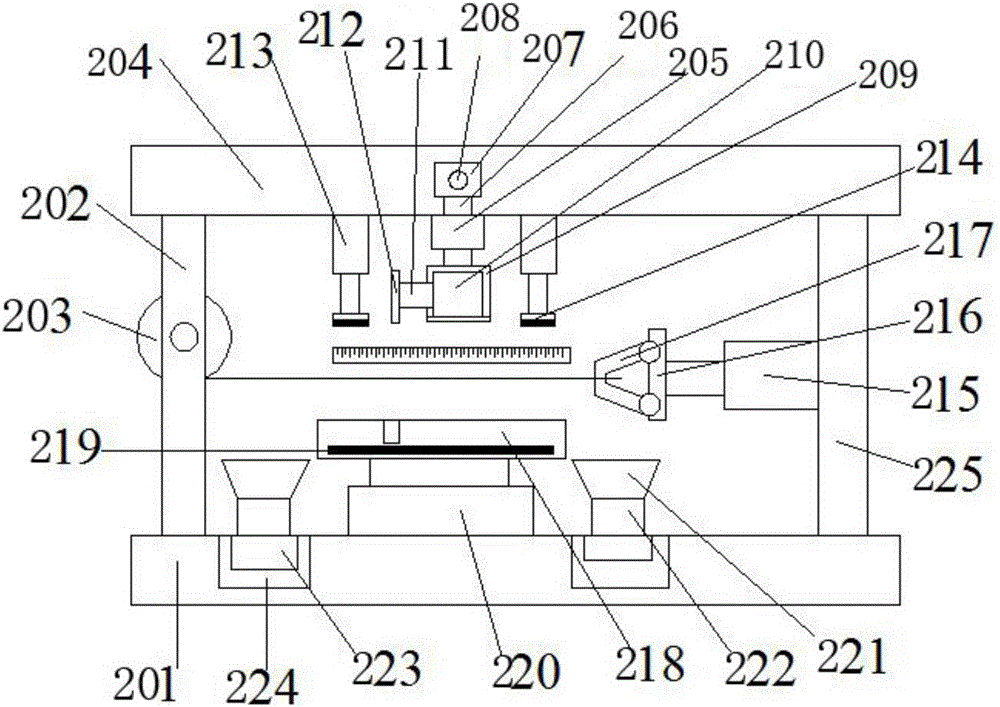

Sewing system capable of automatically adjusting size

ActiveCN105401343AImprove applicabilitySave human effortPressersWork-collecting devicesEngineeringSewing machine

The invention relates to a sewing system capable of automatically adjusting size. The system comprises a workbench, a material pressing mechanism, a size adjusting mechanism, a feeding mechanism, and a sewing machine mechanism. The sewing system capable of automatically adjusting size drives pressure plates to move through the size adjusting mechanism, so as to automatically adjust the distance among a plurality of pressure plates, so that the distance is matched with a to-be-processed sewing object. Thus, for sewing objects in different sizes, the pressure plates do not need to be changed. The system is good in applicability, and saves manpower, and is convenient in adjusting. The system is beneficial for improving production efficiency.

Owner:四方维控股有限公司

Automatic stitching, buttonholing and buttoning system and method

ActiveCN105019155AAutomate operationSave human effortWork-feeding meansWork-collecting devicesEngineeringAutomatic testing

The invention discloses an automatic stitching, buttonholing and buttoning system and method. The automatic stitching, buttonholing and buttoning system comprises a workbench, a stitching device, a feeding device, a positioning device, a buttonholing device, a buttoning device and a clamping device. The stitching device is arranged on the workbench for stitching cut pieces. The feeding device is provided with a bonding component for bonding the cut pieces and a feeding drive component for driving the bonding component to move. The positioning device is provided with a positioning table facet and a blowing component. The positioning table fact is arranged on the workbench. The blowing component is provided with a plurality of blowing nozzles. The blowing nozzles are fixed to the positioning table fact. The buttonholing device is arranged on the workbench and used for conducting buttonholing on the cut pieces. The buttoning device is arranged on the workbench and used for conducting buttoning on the cut pieces. The clamping device is arranged on the workbench and used for clamping the cut pieces to the buttonholing device and the buttoning device from the positioning table facet. By means of the automatic stitching, buttonholing and buttoning system, the production quality is guaranteed, and production efficiency is high.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Cloth continuous sewing device

ActiveCN106835516AReduce manual operationsIncrease the level of automationWork-feeding meansSewing-machine control devicesEngineeringTorsion spring

The invention discloses a cloth continuous sewing device. The device comprises a processing table, a processing plate, a power mechanism, multiple clamping parts and multiple sewing parts. A horizontal sliding groove is formed in the processing table, the processing plate is movably installed on the sliding groove, the power mechanism is used for driving the processing plate to move in the length direction of the sliding groove, and the clamping parts are evenly distributed in the length direction of the sliding groove at equal intervals; each clamping part comprises a supporting plate, a torsion spring component, a connection rod and a pressing plate, wherein the supporting plate is installed on the processing plate, the connection rod is connected with the supporting plate through the torsion spring component, the pressing plate is arranged over the supporting plate, one end of the pressing plate is connected with the connection rod, the other end of the pressing plate extends to the direction away from the connection rod, and the pressing plate is provided with a forming hole penetrating through the upper surface and the lower surface of the pressing plate; the sewing parts are evenly distributed in the length direction of the sliding groove at equal intervals; each sewing part comprises a sewing machine head and a driving unit, wherein the sewing machine head is arranged above the corresponding supporting plate, and the driving unit is used for driving the sewing machine head to move in the vertical direction.

Owner:SHENZHOU KNITTING ANHUI CO LTD

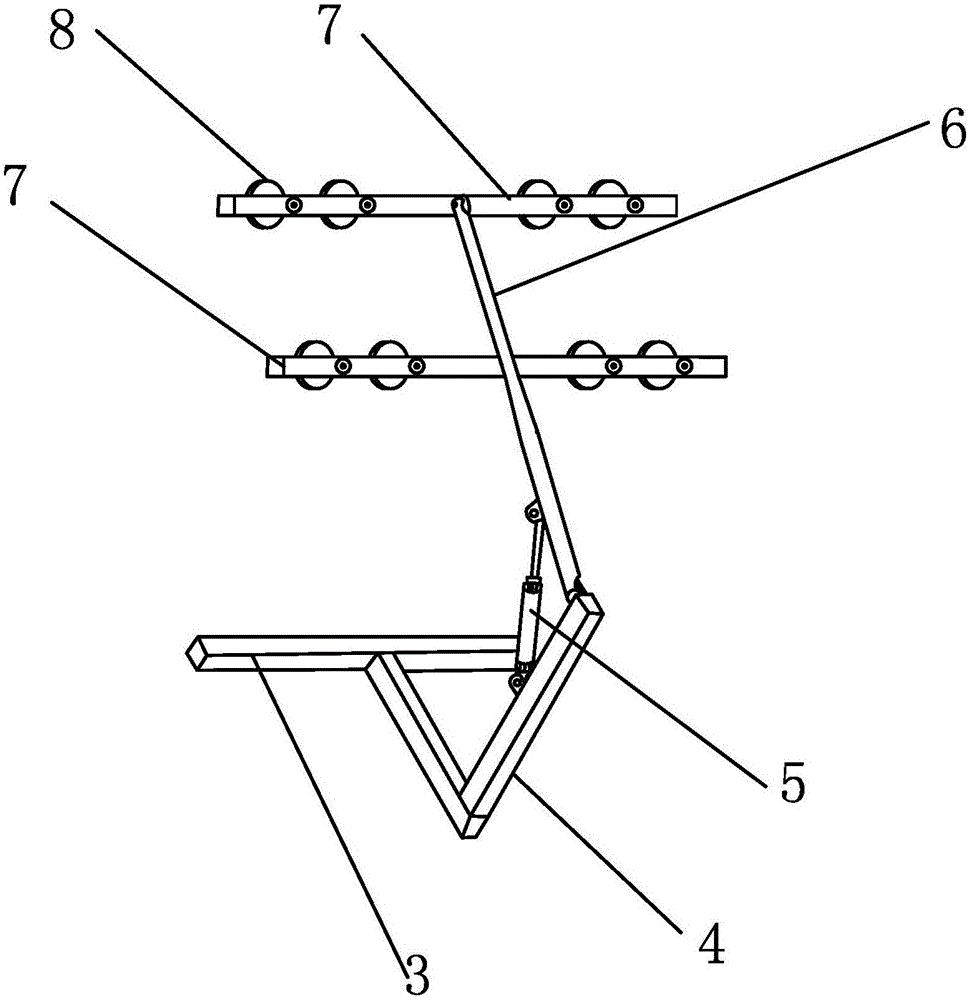

Continuous fabric strap sewing and edge-covering device

InactiveCN102587045AIncrease productivityImprove product qualityWork-feeding meansWork-collecting devicesSewing needle

A continuous fabric strap sewing and edge-covering device is used for sewing two continuous fabric straps in an edge aligning manner and covering edges of the two continuous fabric straps and comprises a framework, a sewing machine, a fabric strap carrying roll, an upper press roll, a lower press roll, a conveying mechanism and an edge covering strap folding guide part. The sewing machine and the knitting strap carrying roll are arranged on the framework, the upper press roll and the lower press roll are arranged on the framework on an input side of the sewing machine, the conveying mechanism is arranged on the framework and used for conveying fabric straps to the sewing machine continuously and comprises a plurality of guide rolls, a conveying roll, a cloth winding roll, a keeping mechanism and a first motor, and the edge covering strap folding guide part is arranged on the front side of a sewing needle of the sewing machine. The guide rolls are arranged on the framework, the conveying roll is arranged on the framework on an output side of the sewing machine, the cloth winding roll capable of moving relative to the conveying roll is arranged on the framework and parallel to the conveying roll, the keeping mechanism arranged on the framework is used for keeping fabrics on the cloth winding roll contacting with the conveying roll, and the first motor is connected with the conveying roll and drives the same to rotate. By the continuous fabric strap sewing and edge-covering device, sewing and edge covering efficiency of continuous fabric straps can be effectively improved, cost is saved and quality is improved.

Owner:冠达星股份有限公司

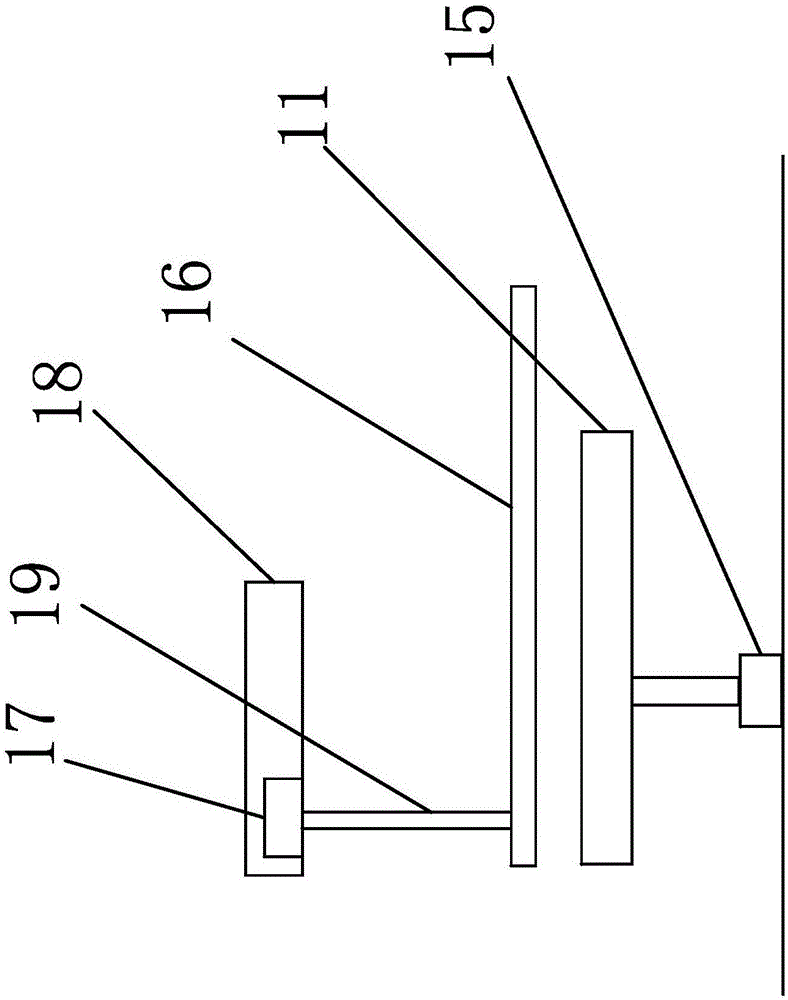

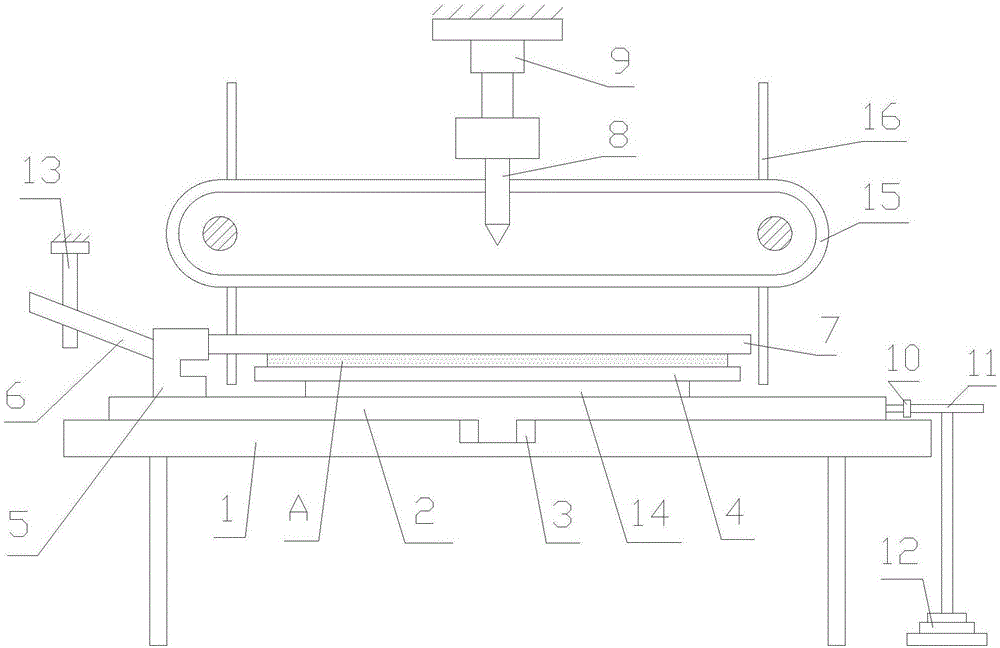

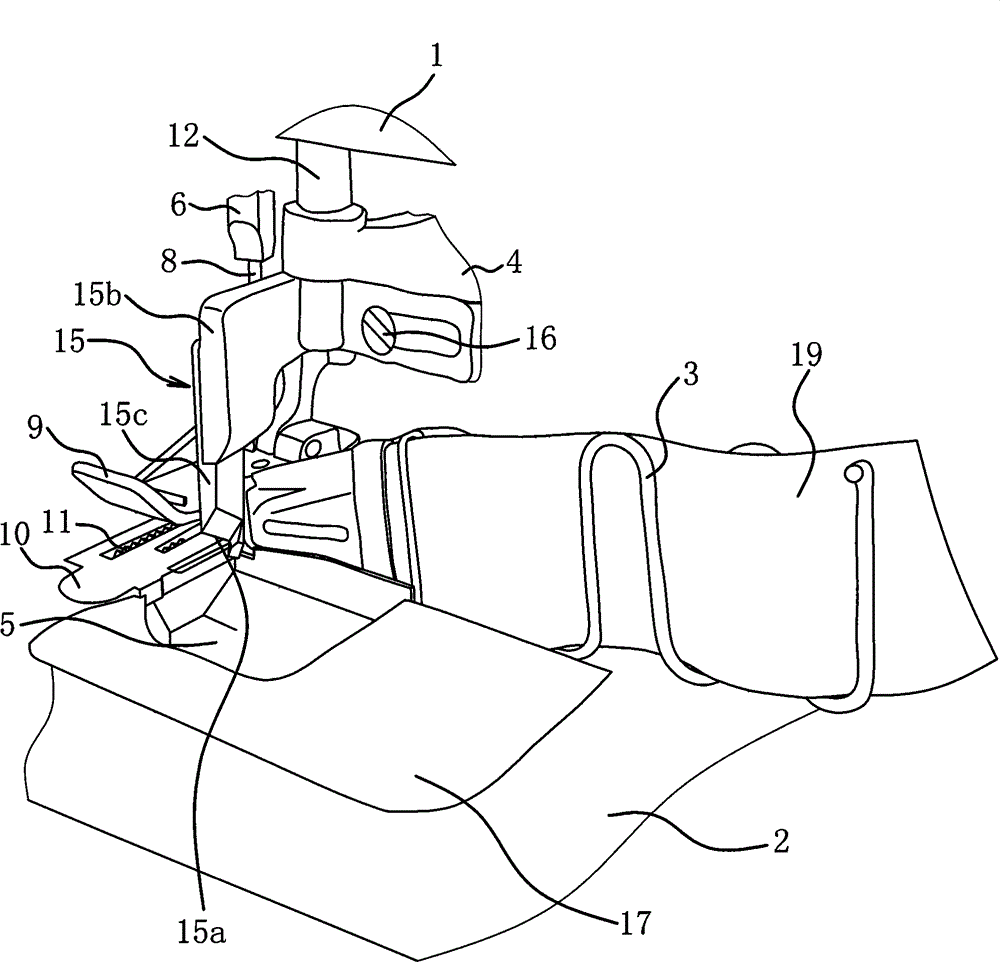

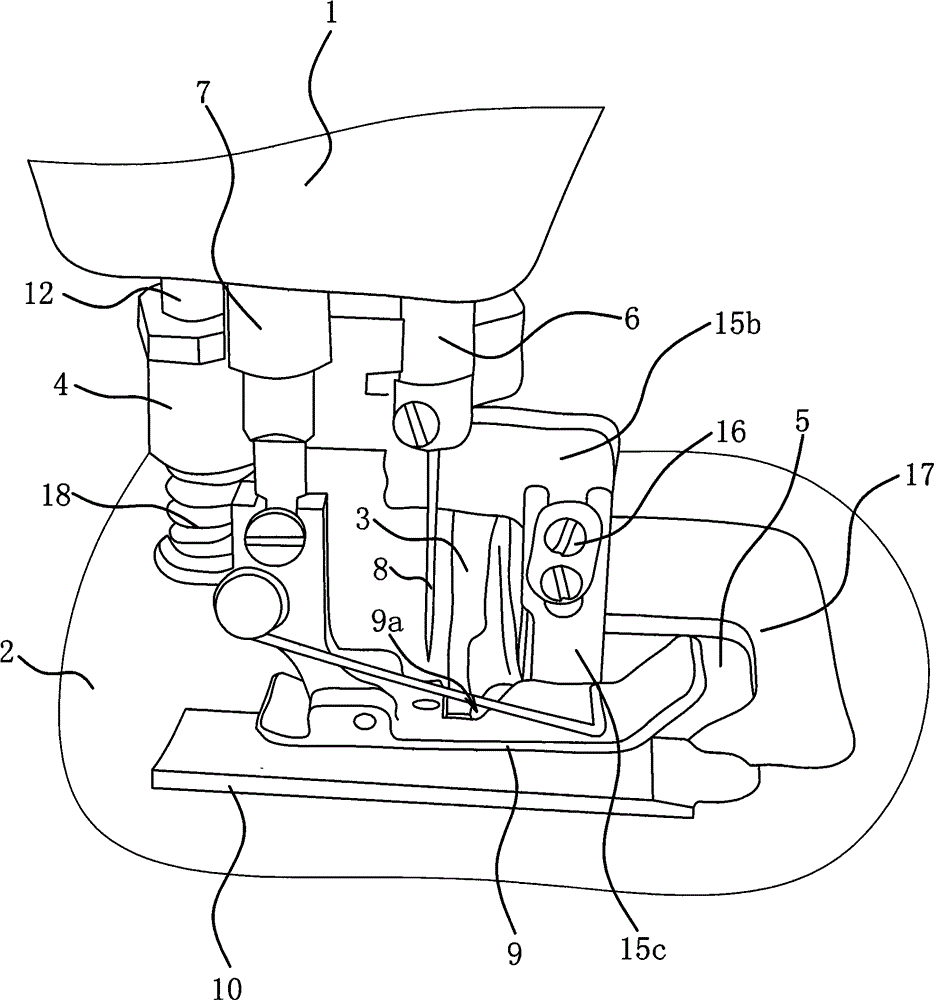

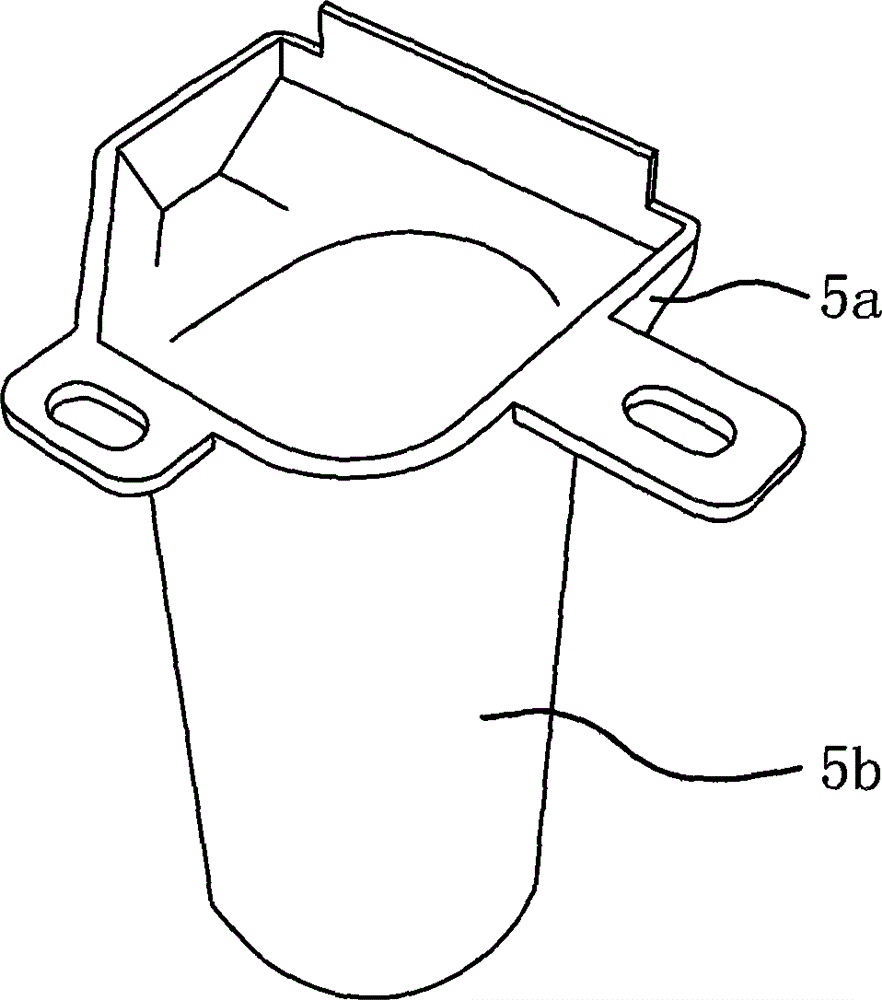

Sewing machine cloth collecting device

InactiveCN103015059ASimple processIncrease productivityWork-collecting devicesEngineeringSewing machine

The invention discloses a sewing machine cloth collecting device. The device comprises a placing bench (7), a deflector rod (6) and a driving device, wherein the placing bench (7) is used for placing a sewed fabric; the deflector rod (6) is arranged between the placing bench (7) and a sewing machine body (1) and turning the sewed fabric onto the placing bench (7); and the driving device is arranged between the sewing machine body (1) and the deflector rod (6) and is used for moving the deflector rod (6) by accepting a fabric sewing direction position signal. Two fabrics are sewed only by aligning the fabrics by an operator and placing the fabrics onto the sewing machine body (1) to form a sewing line. The sewed fabric is transferred onto the placing bench (7) from the workbench of the sewing machine body (1), so that the primary procedure of finishing the formed fabric is simplified, and the production efficiency is improved.

Owner:张兴年

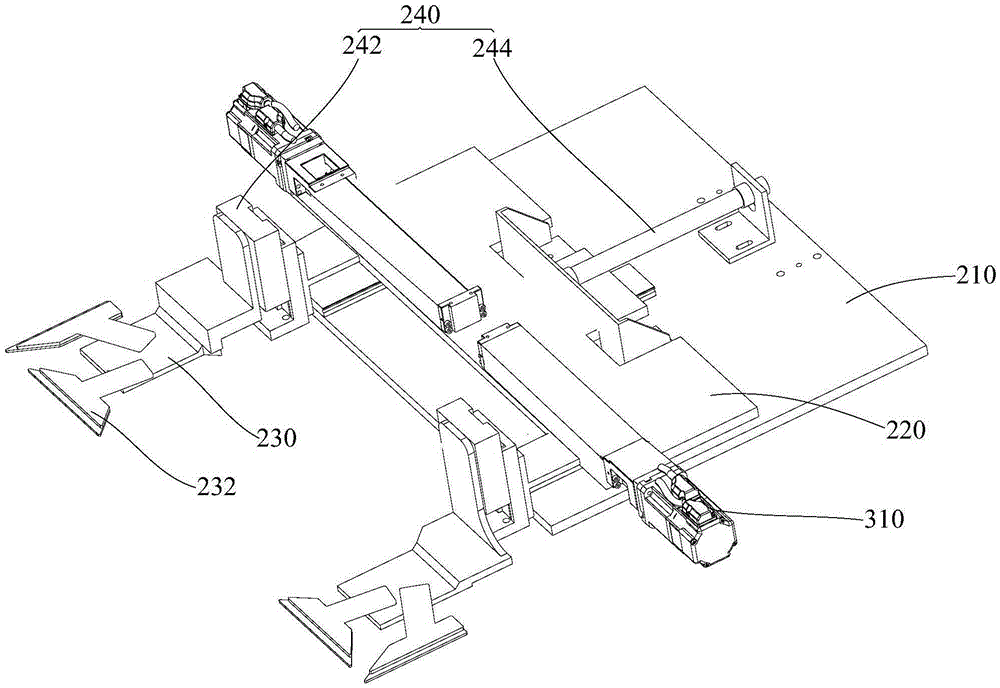

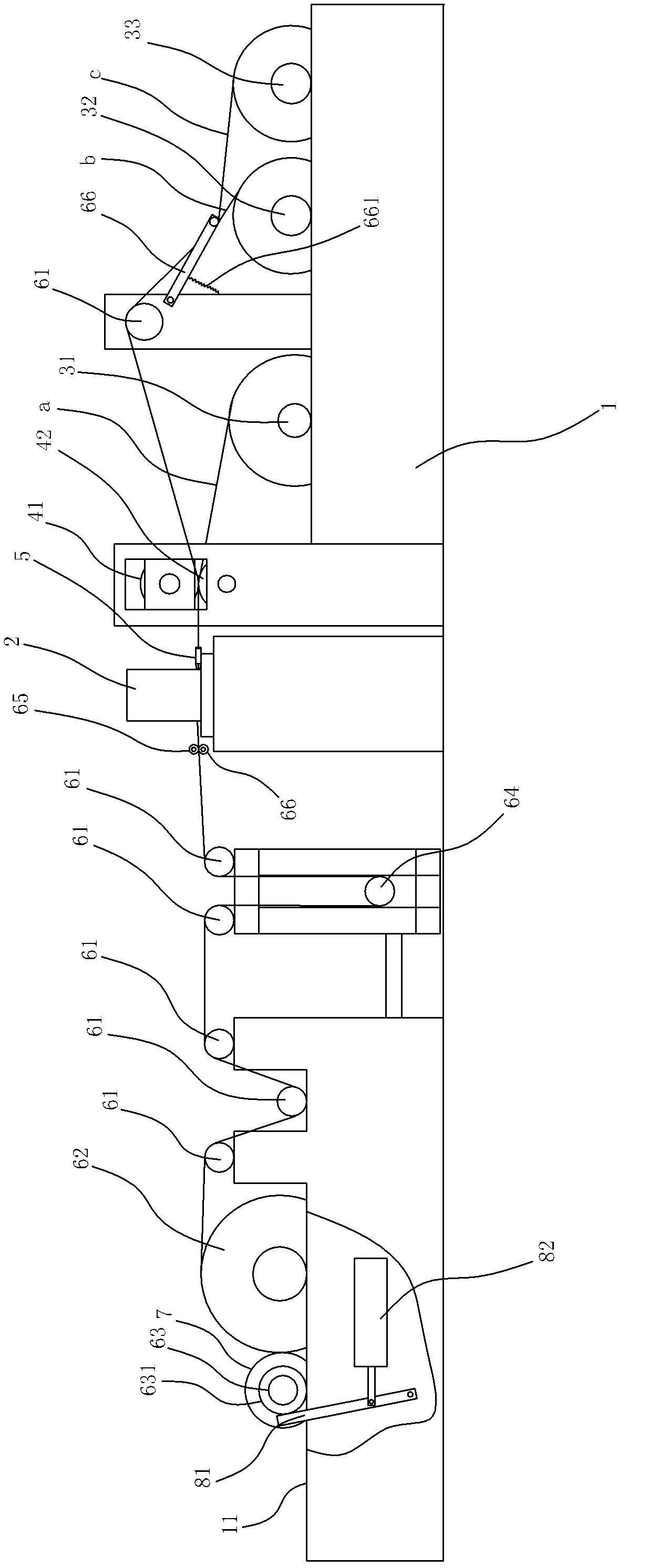

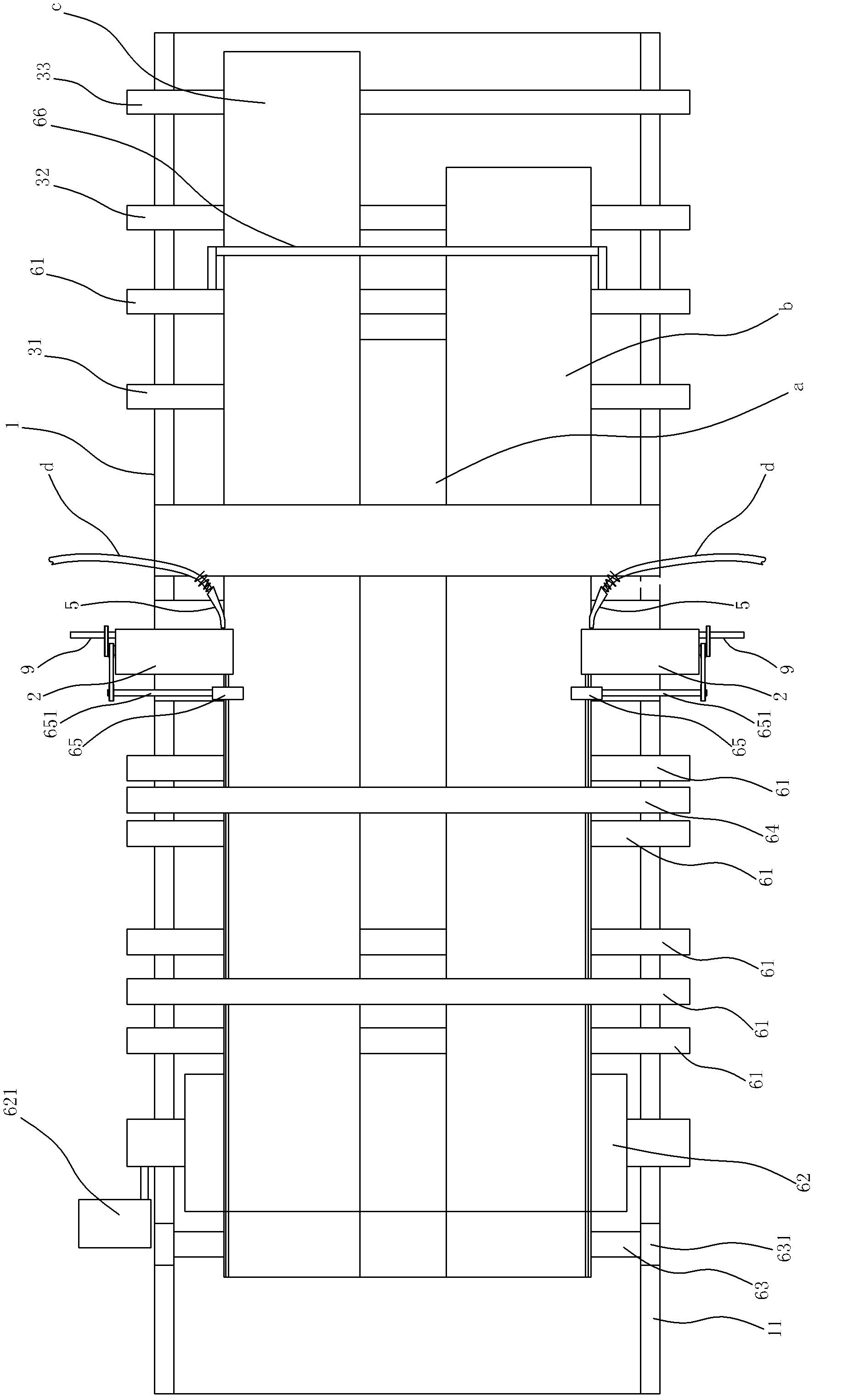

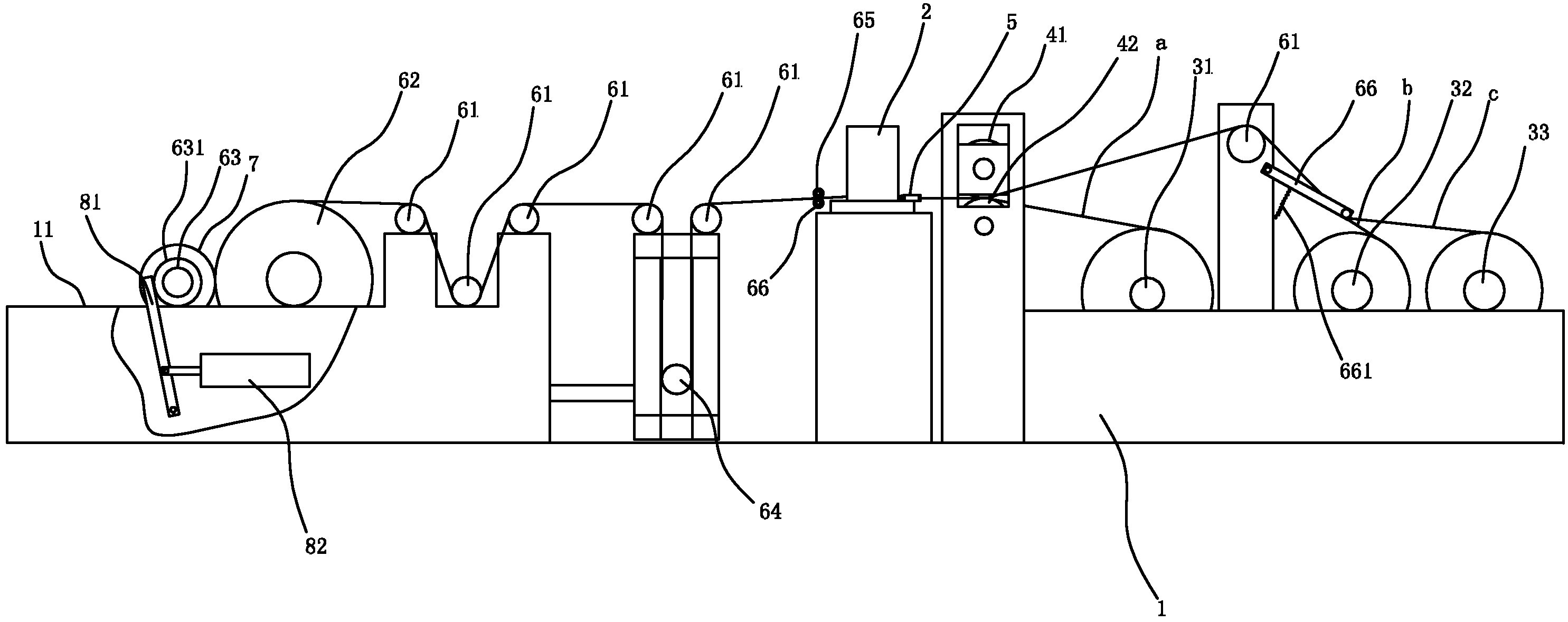

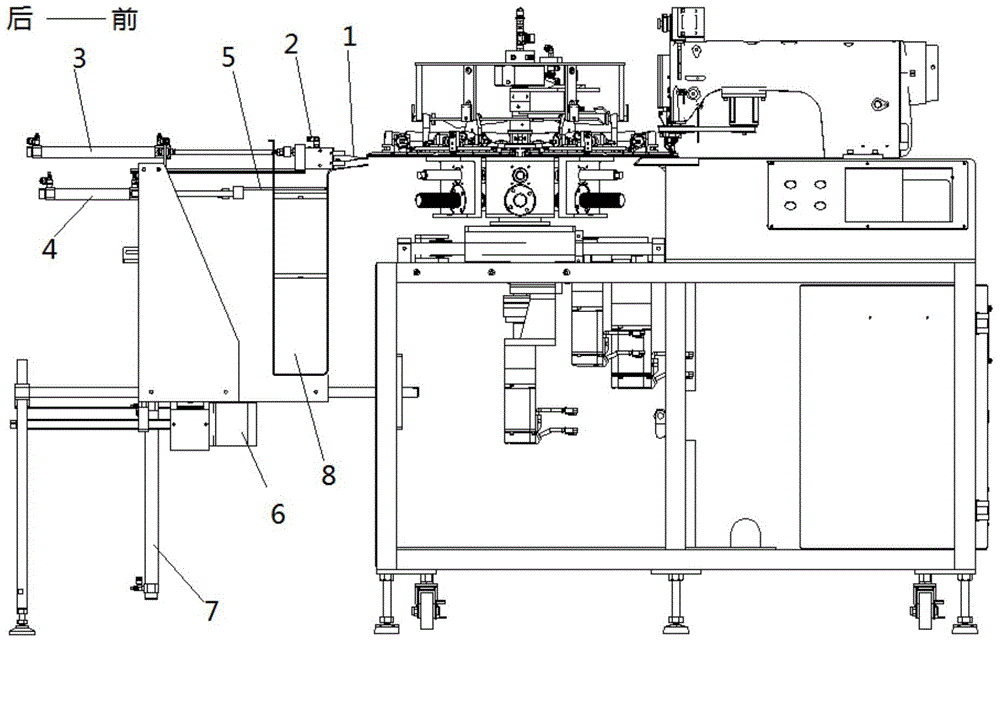

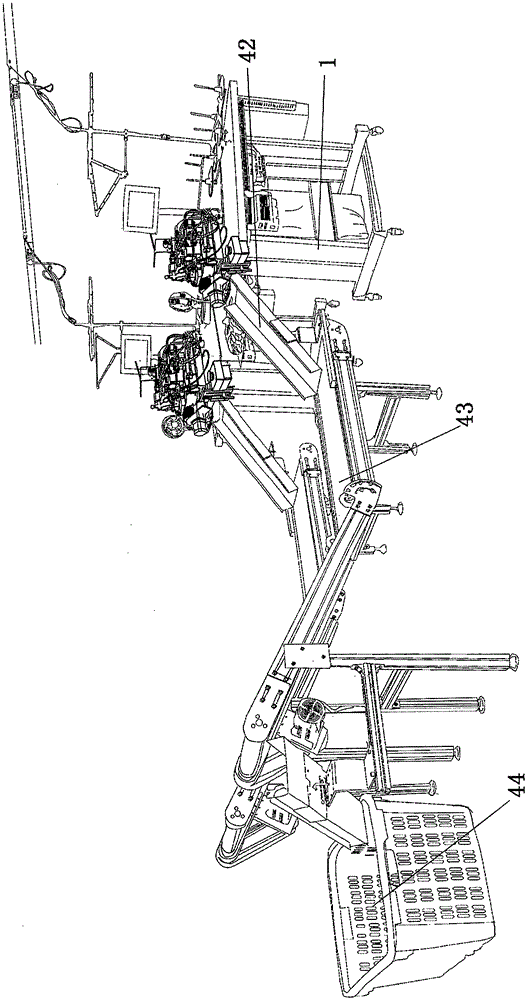

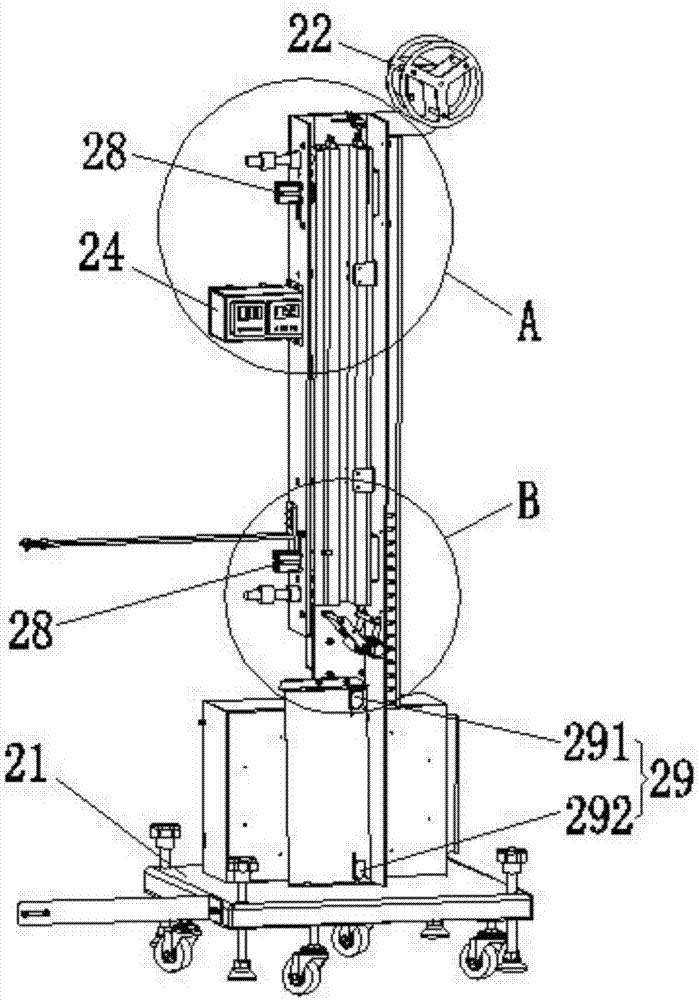

Full-automatic material distribution machine capable of achieving longitudinal sewing

PendingCN107164882AMeet development needsCompact structureWorkpiece carriersWork-feeding meansCardingEngineering

The invention relates to a full-automatic material distribution machine capable of achieving longitudinal sewing. A material feeding component is arranged on one side of a machine frame, and a material feeding deviation rectifying device is arranged in the material feeding component; a left and right deviation rectifying device is arranged on one side of the material feeding component; an edge trimming device, a hemming device, a sewing machine and a main material dragging device are sequentially arranged on the left and right deviation rectifying device; a material receiving mechanism is arranged on one side of the main material dragging device. After entering from the from the material feeding component through the main material dragging device, a fabric is first subjected to material feeding deviation rectification through the material feeding deviation rectifying device and then enters the left and right deviation rectifying device, and the fabric is subjected to left and right deviation rectification through the mutual cooperation of pile loop detection components and a deviation rectifying component; next, the fabric passes through the edge trimming device and the hemming device in sequence, excessive parts at the edge of the fabric are subjected to trimming and hemming, then the fabric is sewn through the sewing machine, and finally, the sewn towels is subjected to stacked carding and finishing. Be means of the full-automatic material distribution machine, operation is convenient and saves labor, the longitudinal sewing of the fabric can be automatically achieved, the overall process is fully automatic, and development requirements of enterprises are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Edge cutting, edge binding and sewing three-in-one sewing machine

InactiveCN104562466AExtended service lifeGuaranteed service lifeWorkpiece carriersWork-feeding meansBlade plateInstability

The invention provides an edge cutting, edge binding and sewing three-in-one sewing machine and belongs to the field of sewing technology. The edge cutting, edge binding and sewing three-in-one sewing machine solves the problems of structural instability of the cutter module and position unclearness of the discharging port in an existing sewing machine. The edge cutting, edge binding and sewing three-in-one sewing machine comprises a machine head, a bottom plate, a beader and a cutter seat. A machine needle bar and a pressing foot bar which are connected with a transmission module penetrates the acting end of the machine head; the lower end of the pressing foot bar is provided with a pressing foot; a needle plate is arranged under the pressing foot and fixed onto the bottom plate; the upper edge of one side of the needle plate is provided with a static cutting blade; the cutter seat is connected with the acting end of the machine head through a guide structure; the cutter seat is connected with the transmission module; the cutter seat is fixedly provided with a cutter; the cutter is provided with a movable cutting blade matched in pair with the static cutting blade, and the movable cutting blade is inclined relative to the bottom plate. According to the edge cutting, edge binding and sewing three-in-one sewing machine, the static cutting blade is made of tungsten steel and has the advantage of being long in service life; a cutter plate is replaceable to ensure that the movable cutting blade is sharp and further to ensure action effectiveness and regularity of edge cutting.

Owner:曹卫明

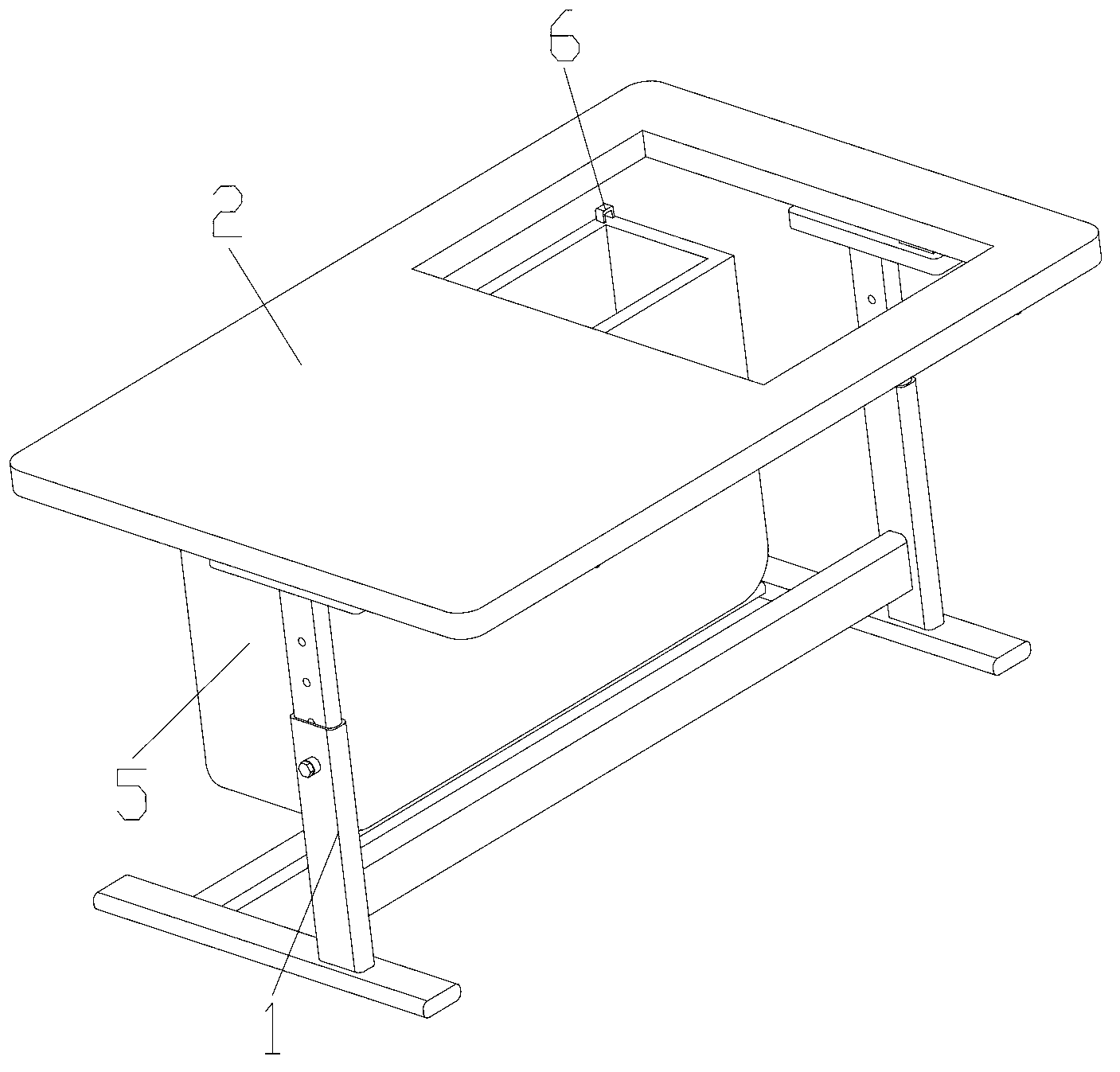

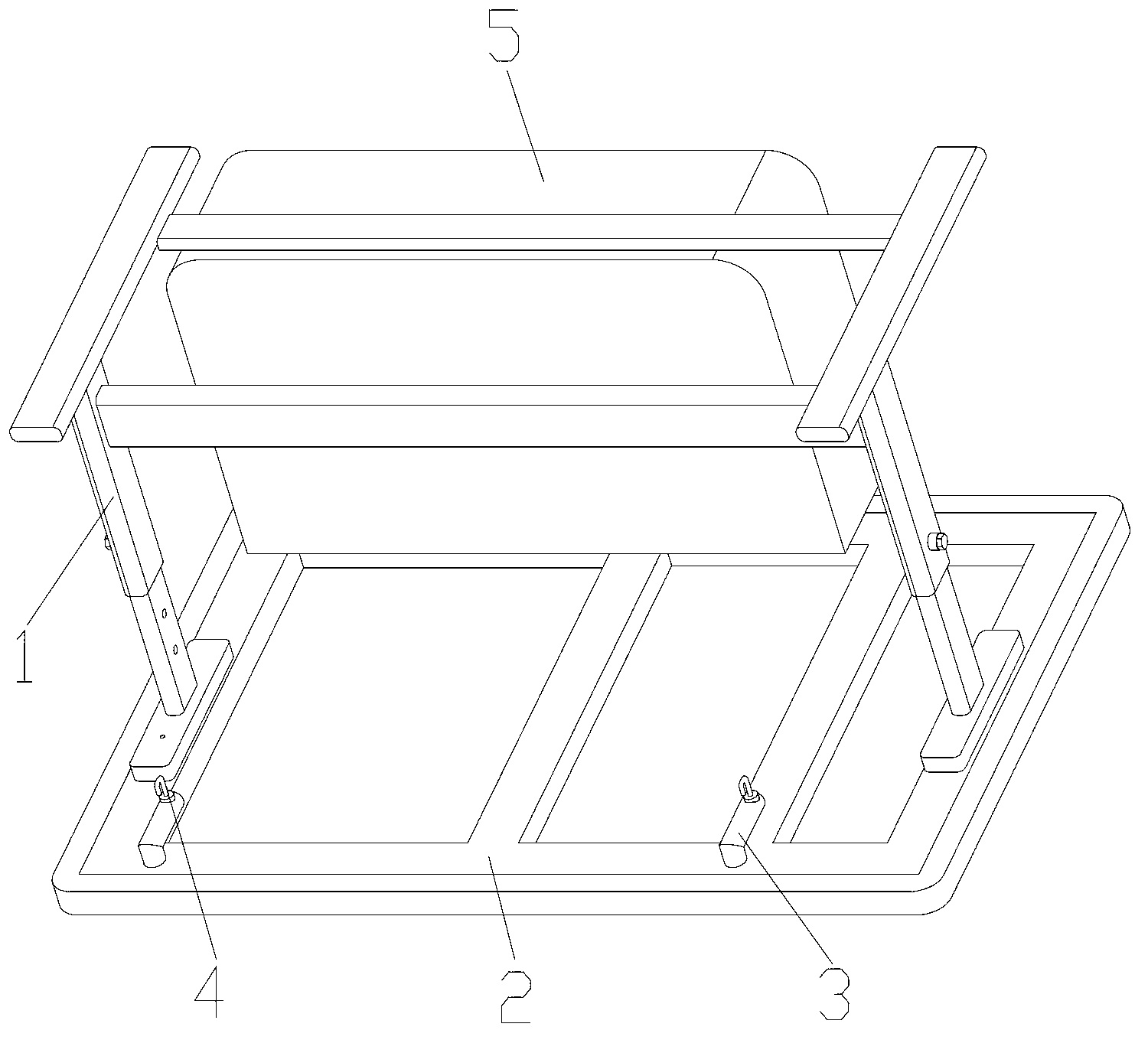

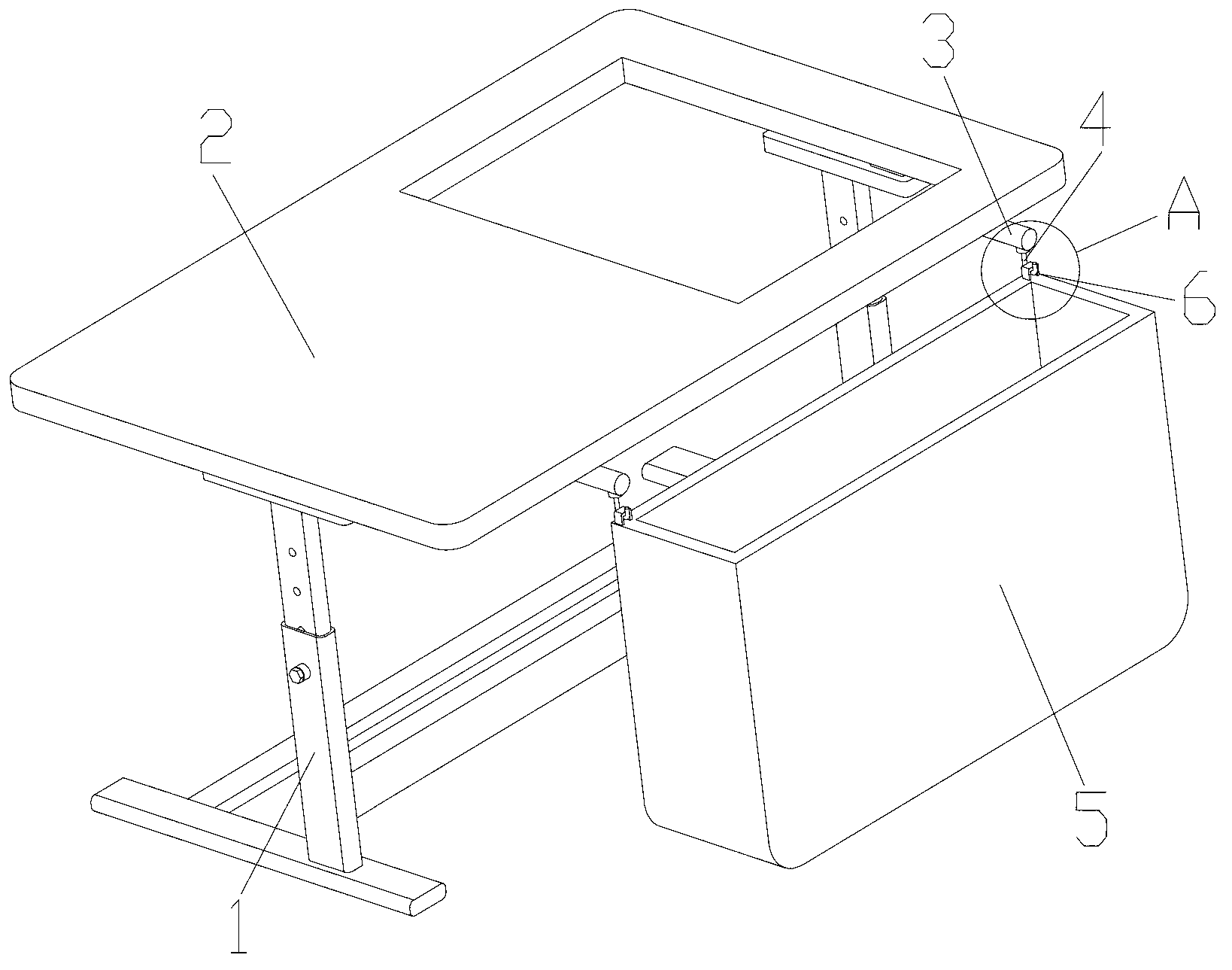

Bed for sewing machine

InactiveCN103306066AEasy to collectSave operating timeWork-collecting devicesOperation timeSewing machine

The invention discloses a bed for a sewing machine. The bed comprises a bracket and a bedplate, which are fixedly connected, as well as two rotating shafts, lifting hooks, a collection case and connecting parts, wherein the two rotating shafts below the bedplate can rotate around the bedplate, and are provided with the lifting hooks; and the collection case is arranged on the bracket and are respectively provided with the connecting parts, which are U-shaped blocks, at two ends. According to the bed, with the additional rotating shafts, the lifting hooks, the U-shaped blocks and the collection case, the collection case is connected with the bedplate through the U-shaped blocks and the lifting hooks; when an operator works with the sewing machine, completed workpieces automatically fall into the collection case, which facilitates the collecting of the workpieces completed through sewing, and as a result, the operation time is saved, the production efficiency is improved at lower cost, and therefore, the bed provided by the invention is suitable for large-scale application.

Owner:SUZHOU JUKANG SEWING ROBOT

Automatic woven tape processing device

ActiveCN105780316AEasy to operateSave non-value-added processesWorkpiece carriersWork-feeding meansEngineeringMechanical engineering

The invention discloses an automatic woven tape processing device which comprises a rack, a material pulling mechanism, a cutting mechanism and a collecting mechanism. The cutting mechanism and the material pulling mechanism are sequentially arranged along the moving direction of woven tape cutting pieces, and the collecting mechanism is arranged on one side of the cutting mechanism and the material pulling mechanism; the material pulling mechanism is used for pulling the woven tape cutting pieces, the cutting mechanism is used for cutting off two adjacent sewn woven tapes, and the collecting mechanism is used for collecting the sewn and cut woven tapes. According to the automatic woven tape processing device, the material pulling mechanism, the cutting mechanism and the collecting mechanism are arranged, the woven tape cutting pieces in sewing are automatically pulled, the sewn woven tape cutting pieces are automatically cut off and collected, therefore, sewing operation is easy, two procedures are merged into one procedure, non-value adding procedures are reduced, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

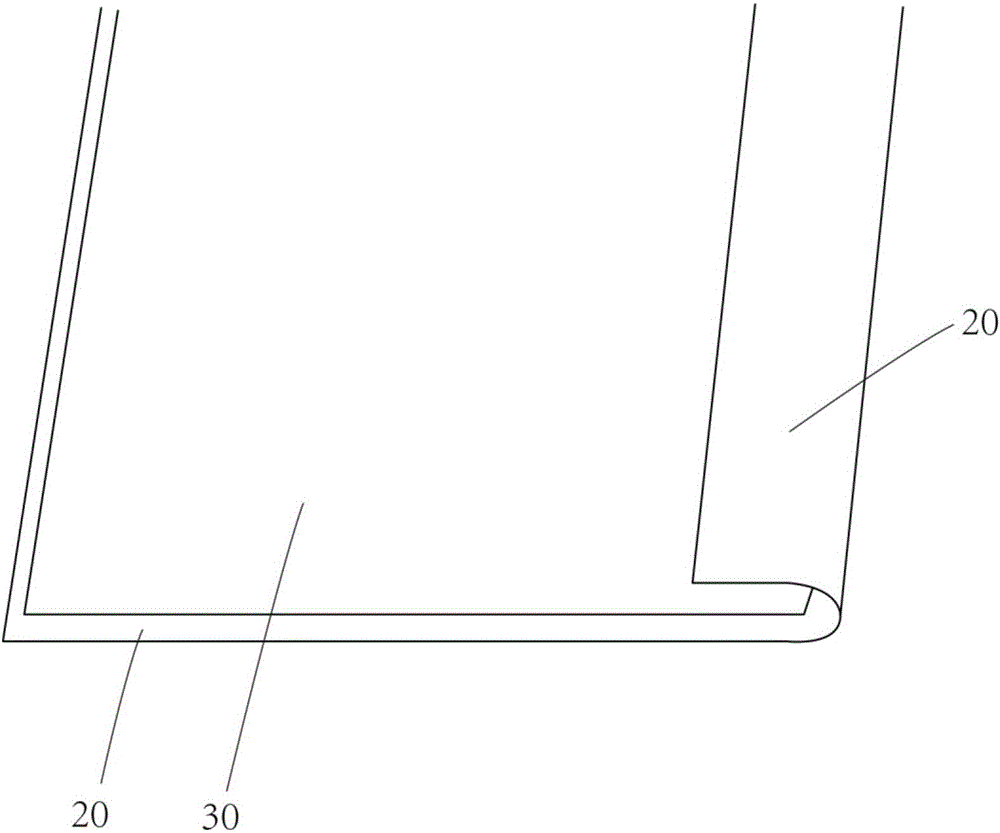

Covering machine

ActiveCN106436035ASave human effortImprove work efficiencyWork-feeding meansSewing-machine control devicesEngineeringMechanical engineering

The invention discloses a covering machine, including a machine body, a margin-wrapping device and a sewing device. The margin-wrapping device is provided with a folding board, which is arranged on the machine body; one side of the folding board curves as an arch from an end to the opposite end to form a folding part. A first off-cut and a second off-cut are placed on a binder in an overlapping way, and a side of the first off-cut can encase the second off-cut in an overlapping way through the folding part. The sewing device is arranged on the machine body; the sewing device is used for sewing the first off-cut and the second off-cut bound by the binder to form a bound off-cut. The covering machine improves work efficiency and the stability of products.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

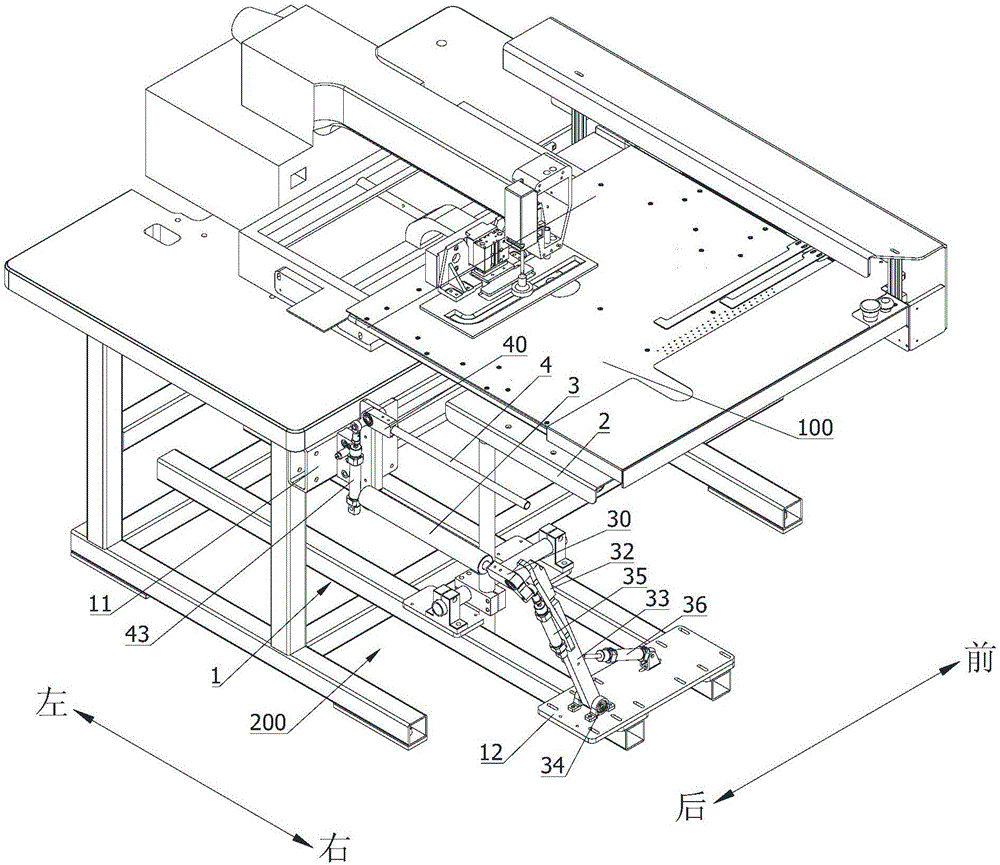

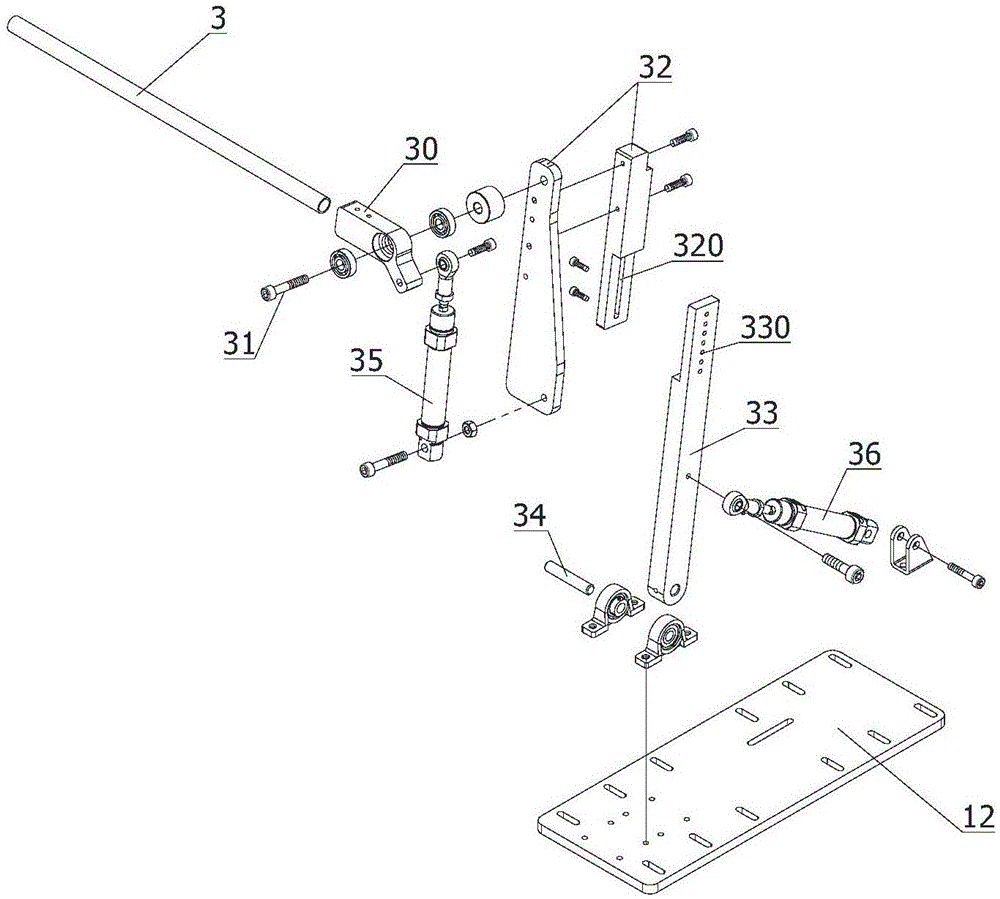

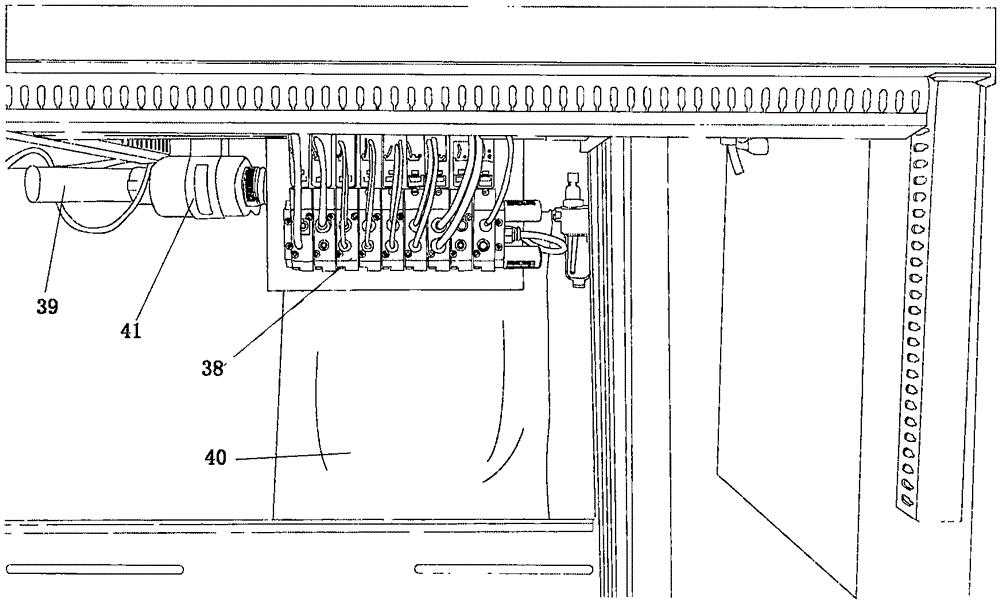

Material receiving system of automatic sewing machine

ActiveCN104652051AFully automatedStable receptionWork-collecting devicesElectric machineryEngineering

The invention relates to a material receiving system of an automatic sewing machine. The material receiving system is driven to be matched with the size of a variable mold of a material carrying rotary table by a servo motor, so as to move back and forth in a linked mode; a material receiving clamp is arranged corresponding to a discharging station of the material carrying rotary table, a sewn product is clamped by the material receiving clamp under the action of a first air cylinder and is retracted backward to be above a discharging frame under the action of a second air cylinder, at the time, the material receiving clamp is extended under the action of the first air cylinder, and the product falls onto a material receiving fork; the material receiving fork moves downward to the detection position of a material receiving frame sensor under the action of a third air cylinder and then exits backward from a material receiving frame under the action of a fourth air cylinder, so that the product falls into the material receiving frame; the material receiving fork returns upward under the action of the third air cylinder and then extends forward to return under the action of the fourth air cylinder, so as to perform the next material receiving motion. The invention provides the three-dimensional material receiving system which is matched with the telescopic variable mold of the variable rotary table; through the four air cylinders and under the action of a plurality of sensors, material receiving and discharging automation is realized.

Owner:SHANGHAI WEISHI MACHINERY

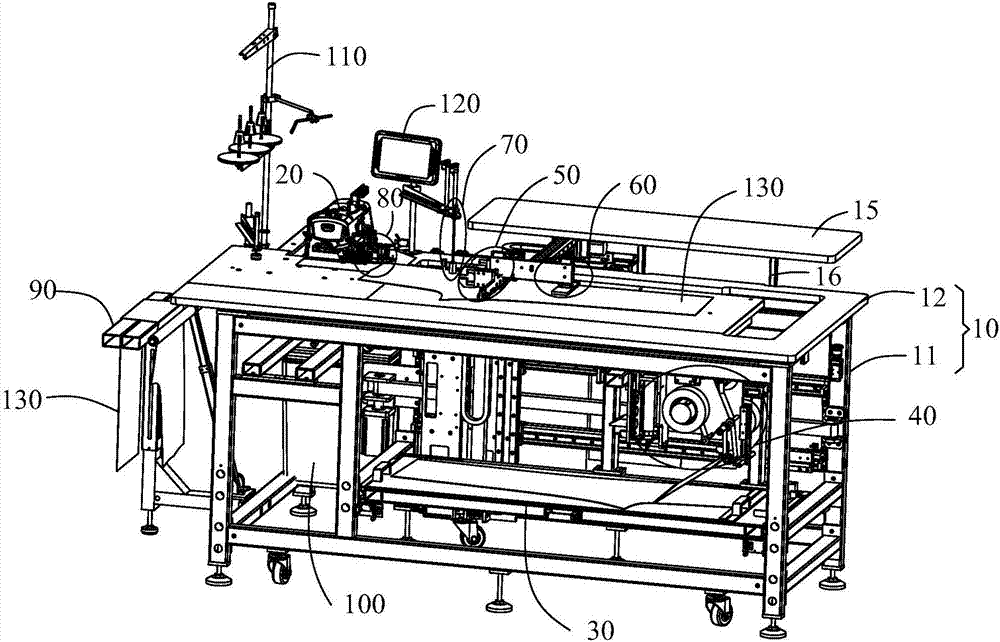

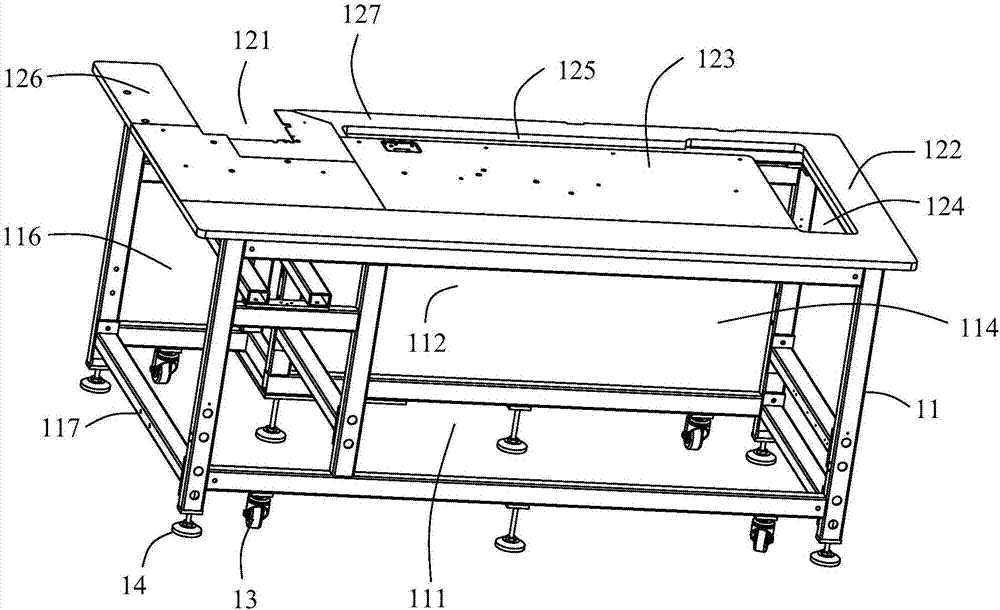

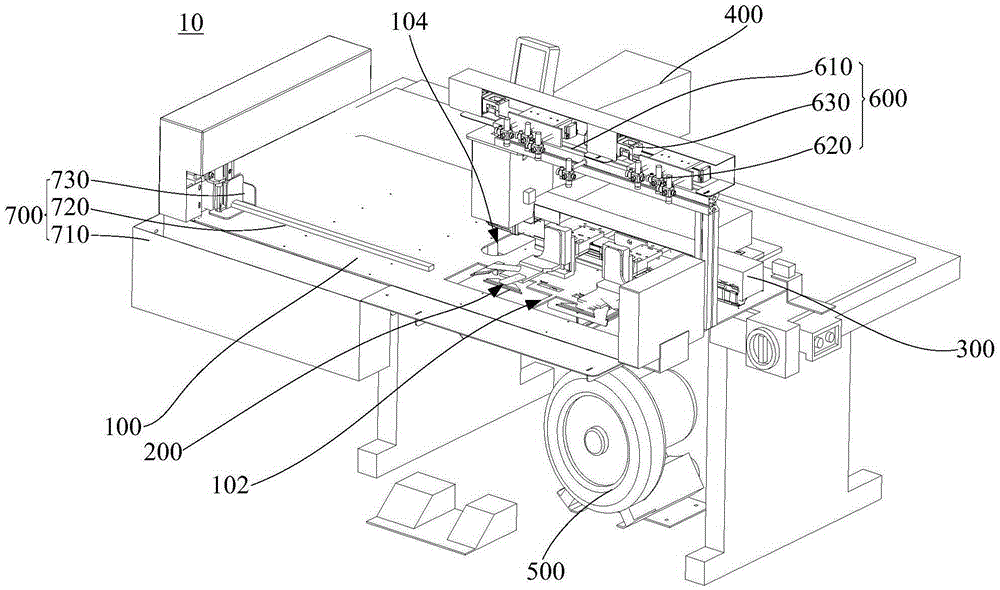

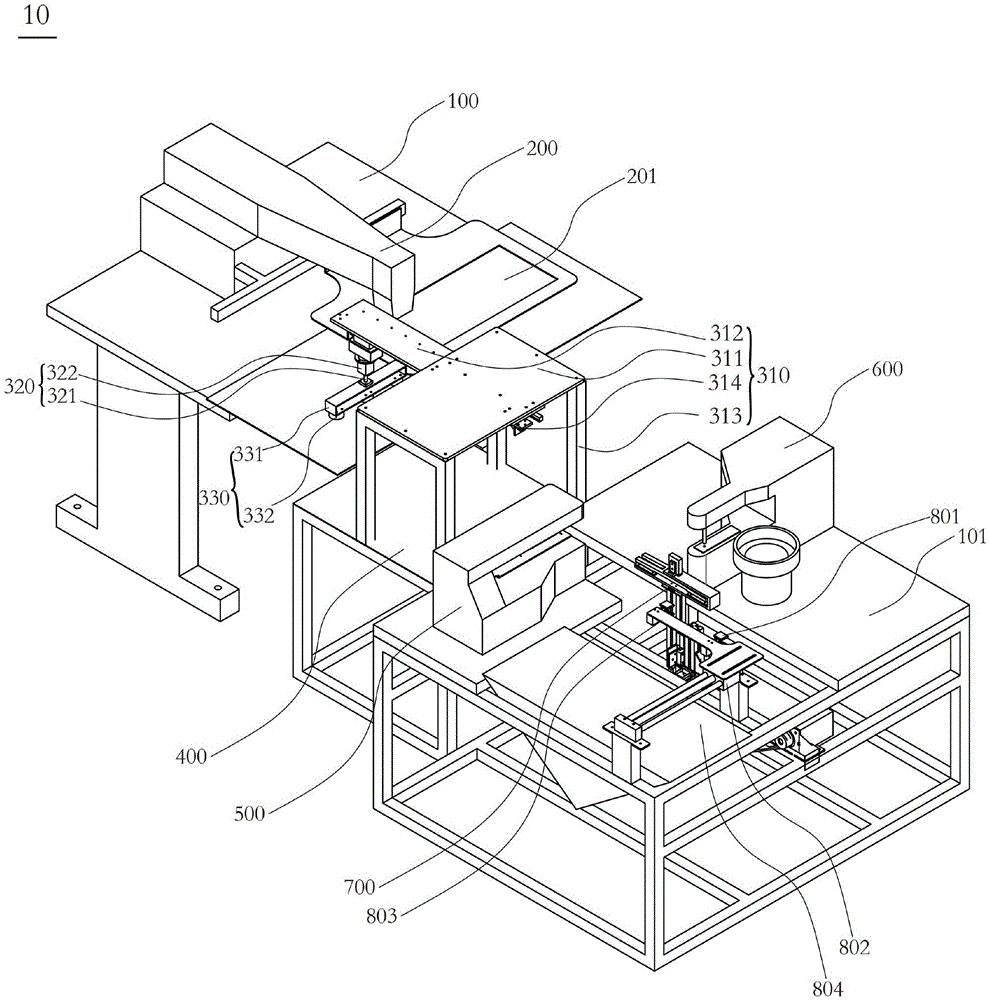

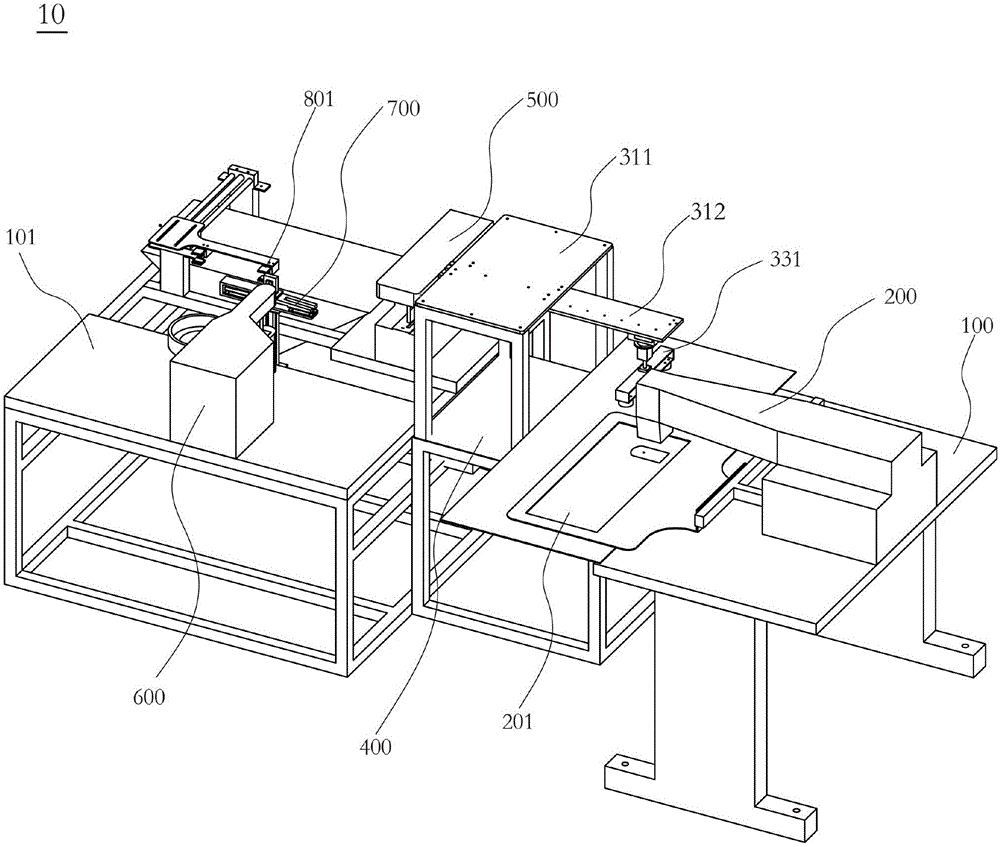

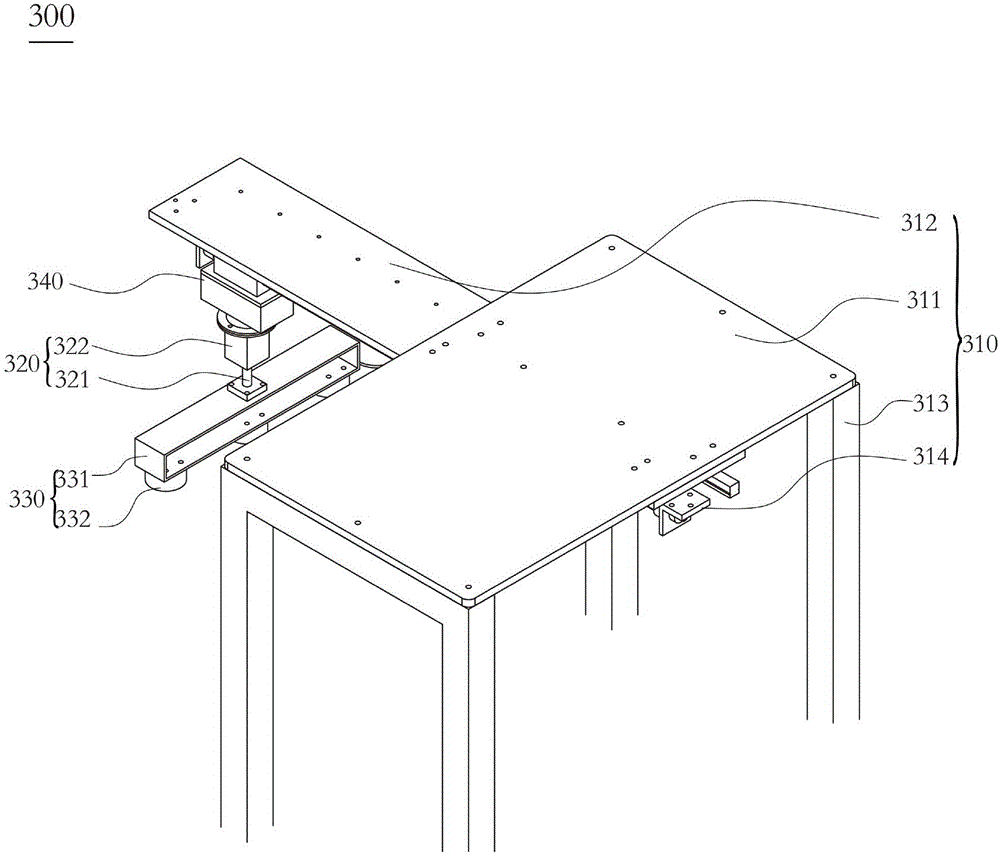

Sewing apparatus and automatic collection device thereof

ActiveCN106436067AImprove the effect of receiving materialsPressersWork-collecting devicesEngineeringMechanical engineering

Owner:SUZHOU HANDLEY ELECTROMECHANICAL TECH CO LTD

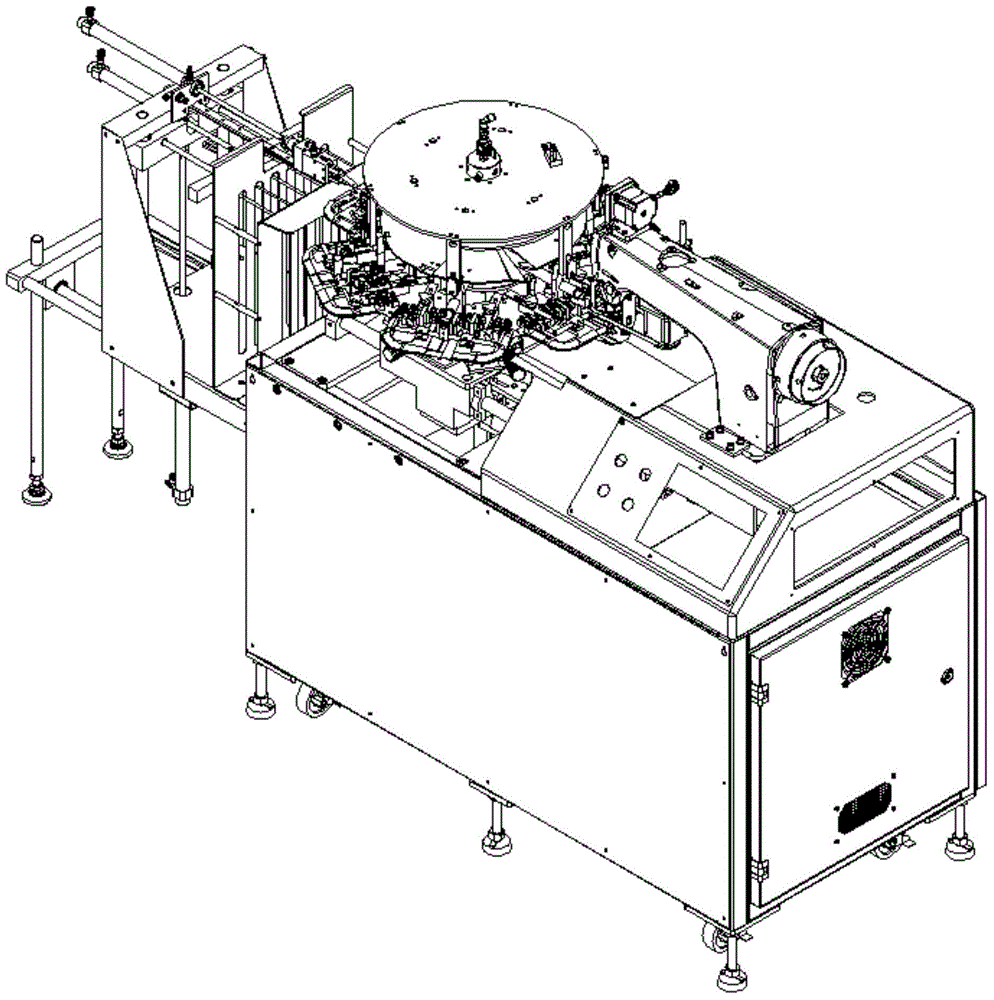

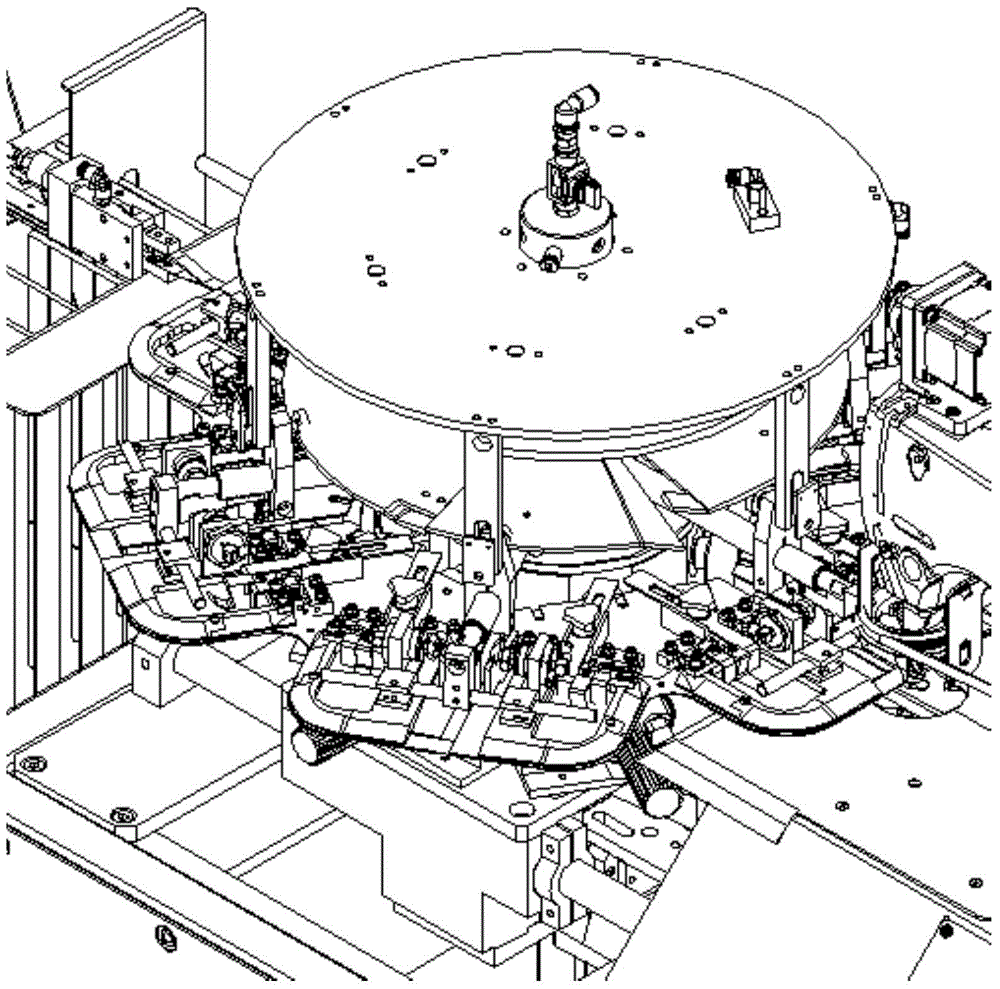

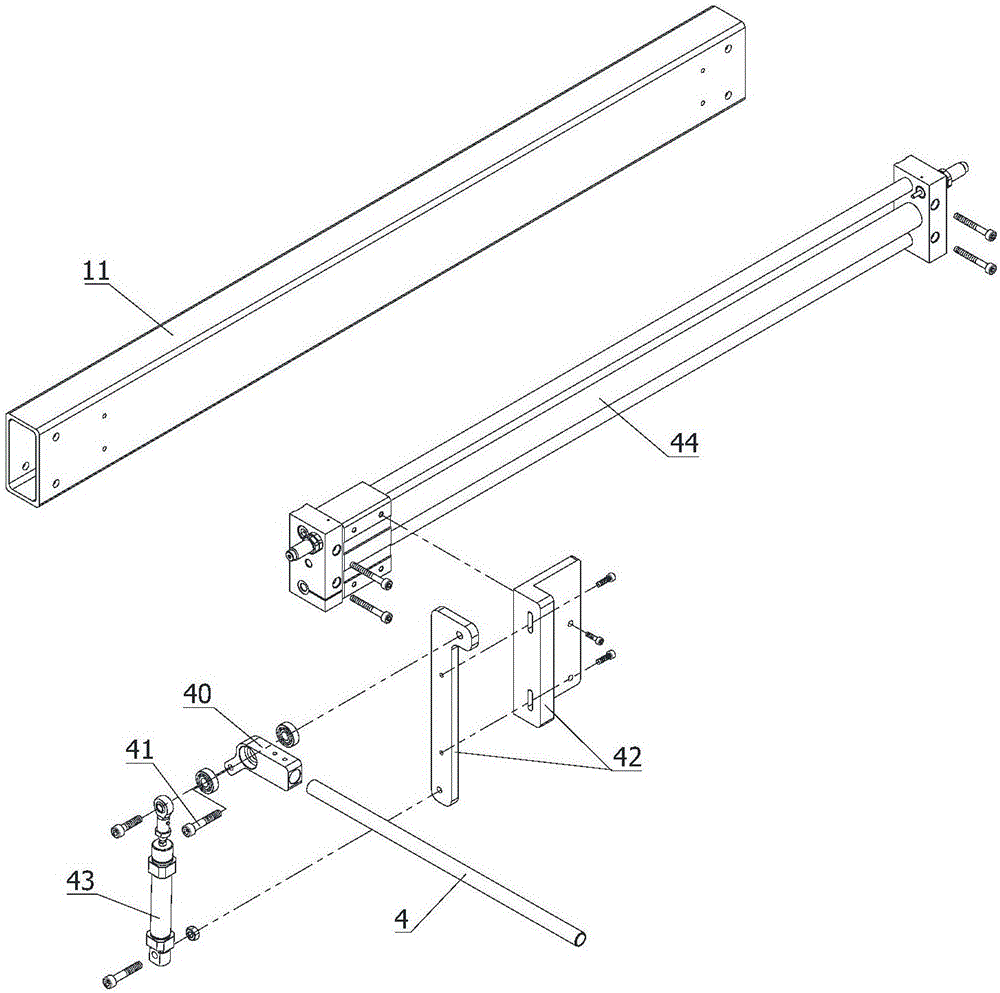

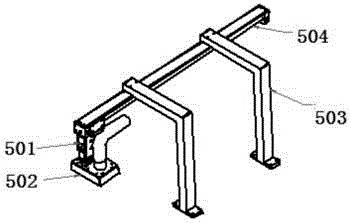

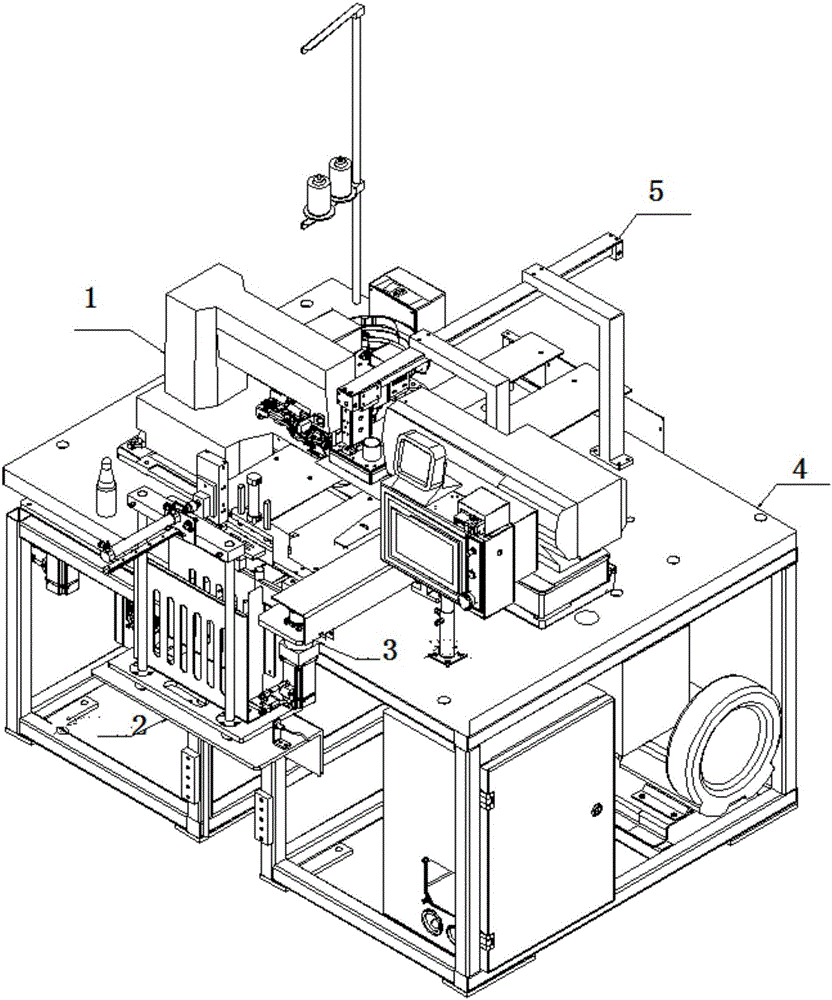

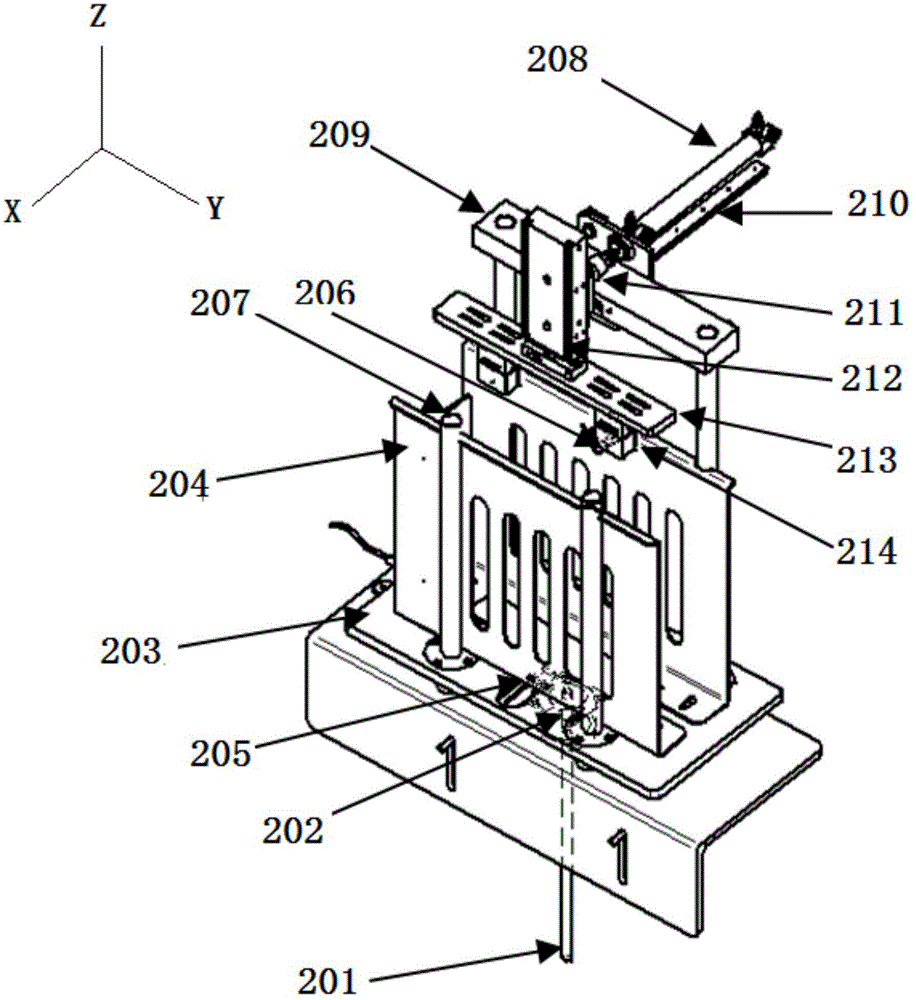

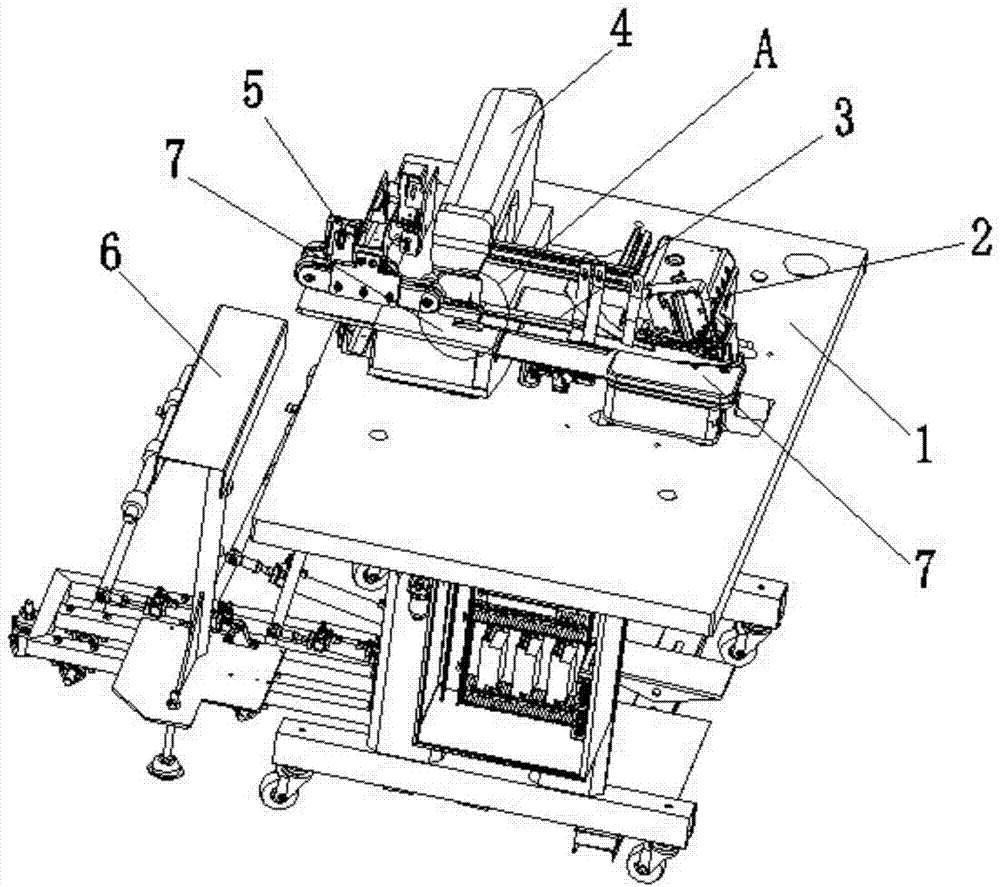

Automatic sleeve cuffs buttonholing and button attaching sewing machine

PendingCN107523942ARealize small movement in X directionImprove work efficiencyWork-feeding meansSewing-machine control devicesCuffIndustrial engineering

The invention relates to an automatic sleeve cuffs buttonholing and button attaching sewing machine. The automatic sleeve cuffs buttonholing button sewing machine comprises a grabbing feeding mechanism, a translation feeding mechanism, a button attaching machine and a buttonholing machine; a cloth detection switch detects cloth and then sends a signal to a control center, the control center sends an instruction to a jacking mechanism, and the jacking mechanism jacks a cloth putting base to the appointed position; a cloth taking air cylinder pushes a pneumatic gripper device downwards to the appointed position, and the pneumatic gripper device starts to grip the cloth; after cloth gripping is finished, the cloth taking air cylinder contracts upwards to the appointed position, an X-direction power mechanism is pushed out and conveys the cloth to the appointed position in the X direction, and the pneumatic gripper device loosens the cloth; the cloth continues to be conveyed by the translation feeding mechanism in the X direction and puts the cloth to the position between the button attaching machine and the buttonholing machine; the mechanism of the button attaching machine is fixed to an X-direction linear motion mechanism, the button attaching machine and the buttonholing machine do sewing work on the sleeve cuffs at the same time, and after the button attaching machine attaches one button, the X-direction linear motion mechanism drives the button attaching machine to move by a certain distance in the X direction to attach the next button.

Owner:SHANGHAI WEISHI MACHINERY

Intelligent glove hemming machine having display screen

ActiveCN105297298AAutomate operationAvoid quality problems such as empty edges, double sides, uneven edges, etc.Needle severing devicesPressersWire cuttingContinuous operation

The invention discloses an intelligent glove hemming machine having a display screen. The intelligent glove hemming machine comprises a frame, a table plate and a unit assembly and is characterized in that the table plate is fixed onto the frame; and the unit assembly is arranged on the table plate and comprises a wire-leading device, a machine head device, a rubber string feeding-in device, a wire-cutting device, a stripping device and a control device. The intelligent glove hemming machine having the display screen has following advantages: automated operation is achieved; quality problems such as margins, double sides and uneven sides are solved during manual operation are effectively avoided; automated continuous operation is achieved and production efficiency is enhanced; an operation process is simple and easily mastered; a user can operate two or multiple machines at the same time; and usage cost is decreased.

Owner:NANTONG HANSHUN MACHINERY TECH CO LTD

Top collar sewing method and top collar sewing system

The invention discloses a top collar sewing method and a top collar sewing system. The top collar sewing method comprises: positioning a collar sheet with two layers of cloth pieces on a worktable, sucking the air by virtue of an air suction device, and fixing the collar sheet onto the worktable; folding an upper layer of cloth piece of the collar sheet according to a preset size, and pressing a pressure bar of a pressing device onto the upper layer of cloth piece of the collar sheet; placing a neck part of a shirt sheet on a predetermined position on a lower layer of cloth piece of the collar sheet, respectively aligning two ends of the neck part of the shirt sheet to two end parts of the lower layer of cloth piece, and adjusting an overlapping position of the lower layer of sheet and the shirt sheet; resetting the pressure bar, resetting the upper layer of cloth piece, and arranging an overlapping position of the shirt sheet and the upper layer of cloth piece and the lower layer of cloth piece; pressing a material shifting device onto the collar sheet and the shirt sheet, and moving the collar sheet and the shirt sheet to a stitching device; and stitching the overlapped collar sheet and shirt sheet by virtue of the stitching device. The top collar sewing method is high in production efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Full-automatic cloth machine

PendingCN107217438AEasy to operateMeet production development needsWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention relates to a full-automatic cloth machine. A feeding mechanism, an ironing mechanism and a cloth grasping mechanism are sequentially distributed on a rack; a burr smoothing mechanism is arranged between the ironing mechanism and the cloth grasping mechanism; a cloth cutting mechanism is arranged on one side of the burr smoothing mechanism; a synchronous cloth moving mechanism which can move up and down is arranged between the burr smoothing mechanism and the cloth grasping mechanism; a length fixing mechanism is arranged between the cloth grasping mechanism and the burr smoothing mechanism, and the length fixing mechanism is positioned at one end of the synchronous cloth moving mechanism; edge folding mechanisms are respectively arranged on two sides of the synchronous cloth moving mechanism; a label mechanism is arranged at one edge folding mechanism; a labeling mechanism is arranged on one side of the label mechanism; and a sewing feeding mechanism, a sewing machine and a falling structure are sequentially arranged on one side of the edge folding mechanism. The full-automatic cloth machine provided by the invention is convenient and easy to operate, sewing of two transverse edges of cloth can be automatically completed, the whole processes are implemented automatically, the production efficiency is high, production development requirements of companies are met, and relatively high popularization values are made.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Peripheral seam automatic sewing machine

ActiveCN107164888AEnsure sewing efficiencyReduced sewing efficiencyWork-feeding meansWork-collecting devicesEngineeringPeripheral

The invention provides a peripheral seam automatic sewing machine, and belongs to the technical field of sewing machines. The sewing machine solves the problems that an existing sewing machine is low in working efficiency and the like. The peripheral seam automatic sewing machine comprises a table board, wherein an auxiliary feeding mechanism and a sewing mechanism used for sewing are arranged on the table board, the auxiliary feeding mechanism can press a sewing material on the table board and drive the sewing material to move on the table board, and a material collecting assembly is further arranged on the table board; the material collecting assembly comprises a material discharging plate, a material falling hole is formed in the table board, the discharging plate seals or opens the material falling hole, and the auxiliary feeding mechanism can convey the sewing material to the material falling hole. The sewing machine has the advantages that the material collecting speed is high and the work efficiency is high.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Intelligent sewing line pressing machine

PendingCN107313181AEasy to operateImprove processing efficiencyWork-feeding meansNeedle severing devicesMechanical engineeringEngineering

The invention discloses an intelligent sewing line pressing machine. The machine comprises a rack, a binding-off device, a feeding device, a flat-seaming device, an automatic trimming device, and a collecting device which are arranged on the rack in sequence from front to back; after two pieces of a fabric are bond by the binding-off device, the right edges of the fabric are aligned and front folded, the fabric is sent to the flat-seaming device for line pressing through the feeding device; when the fabric passes through the feeding device, the two pieces of the folded fabric are unfolded, a guide rod is clamped in a seam and used for guiding the advancing direction of the fabric; when the line-pressed fabric passes through the automatic trimming device, the connecting line at the tail part of the fabric is cut off; finally the process finished fabric is stacked and collected piece by piece by the collecting device. The intelligent sewing line pressing machine has the advantages of simple operation, the garment processing efficiency can be effectively improved, and the manpower resources are greatly saved.

Owner:FAR EAST CLOTHES SUZHOU CO LTD

Intelligent rope end knotting machine

InactiveCN107354594ASafe and quick headReduce processing timeWorkpiece carriersWork-feeding meansStructural engineeringMechanical engineering

The invention discloses an intelligent rope end knotting machine. The machine comprises a rack, a rope belt ironing mechanism arranged at one side of the rack, a rope feeding mechanism and a rope winding mechanism, wherein the rope feeding mechanism and the rope winding mechanism are mounted on the rack; the rope feeding mechanism comprises a length measuring device, a cutting device and a pushing device; after the rope belt ironing mechanism irons up a rope belt to be processed, the rope belt remains flat and is conveyed to penetrate through the cutting device through an electronic feeding rack. The cutting device cuts the rope belt of which the length is calculated out by the length measuring mechanism, and then, the rope belt is sent to the rope winding mechanism through the pushing mechanism to wind ropes. The intelligent rope end knotting machine can be used for rapidly and safely knotting and sealing belt ends such as rope belts and is suitable for promotion, and the practicability is high.

Owner:浙江凌志智能科技有限公司

Multifunctional integrated sewing machine

InactiveCN106192224AEasy to adjust speedFacilitate actual abnormal maintenanceProgramme-controlled sewing machinesWorkpiece carriersEngineeringSewing machine

The invention relates to a multifunctional integrated sewing machine, and belongs to the field of textile machinery. The multifunctional integrated sewing machine comprises a sewing machine head, a sewing machine base, a cloth dragging device and a cutting device; the sewing machine head is fixed on the sewing machine base, a PLC electric cabinet is arranged on one side of the sewing machine base, a fixed base is installed on the sewing machine base, and a rotating board corresponding to the sewing machine head is connected to the fixed base; the cloth dragging device comprises a front cloth dragging device body and a rear cloth dragging device body, and the rear cloth dragging device body and the cutting device are installed on the rotating board; the front cloth dragging device body is arranged on the sewing machine, and an ironing device flattening fabric is arranged on the rear portion of the cloth dragging device; an air blowing material receiving device is installed on the rear side of the sewing machine base. According to the multifunctional integrated sewing machine, the actual production efficiency is greatly improved, the product quality is improved, part of the sewing processes can be removed, the labor cost is reduced, and the production cycle is shortened.

Owner:SUZHOU AUTOMAZIONE AUTOMATIC SEWING EQUIP

Multi-handpiece pocket pasting machine

ActiveCN107881661AImprove sewing efficiencyWork-feeding meansCombination sewing machinesMechanical engineeringCotton material

The invention discloses a multi-handpiece pocket pasting machine. The machine is high in efficiency, and multiple pieces of thread with different colors can be sewed on a pocket. The machine comprisesa rack and two or more handpieces which are arranged on the rack in the front and back direction at intervals, each handpiece comprises a machine needle which is used for sewing a thread on the pocket, and the machine further comprises first material conveying devices which are arranged among two or more handpieces and used for conveying cloth from a front handpiece to a back mechanism; each first material conveying device comprises a first material conveying plate which can slide relative to the rack in the front and back direction, the rack has a working surface which is used for bearing the cloth, and the first material conveying plates are located above the working surface; the machine has a material conveying state, and in the material conveying state, the first material conveying plates are located at the lowest position to drive the cloth between the first material conveying plates and the working surface to move.

Owner:SUZHOU HANDLEY ELECTROMECHANICAL TECH CO LTD

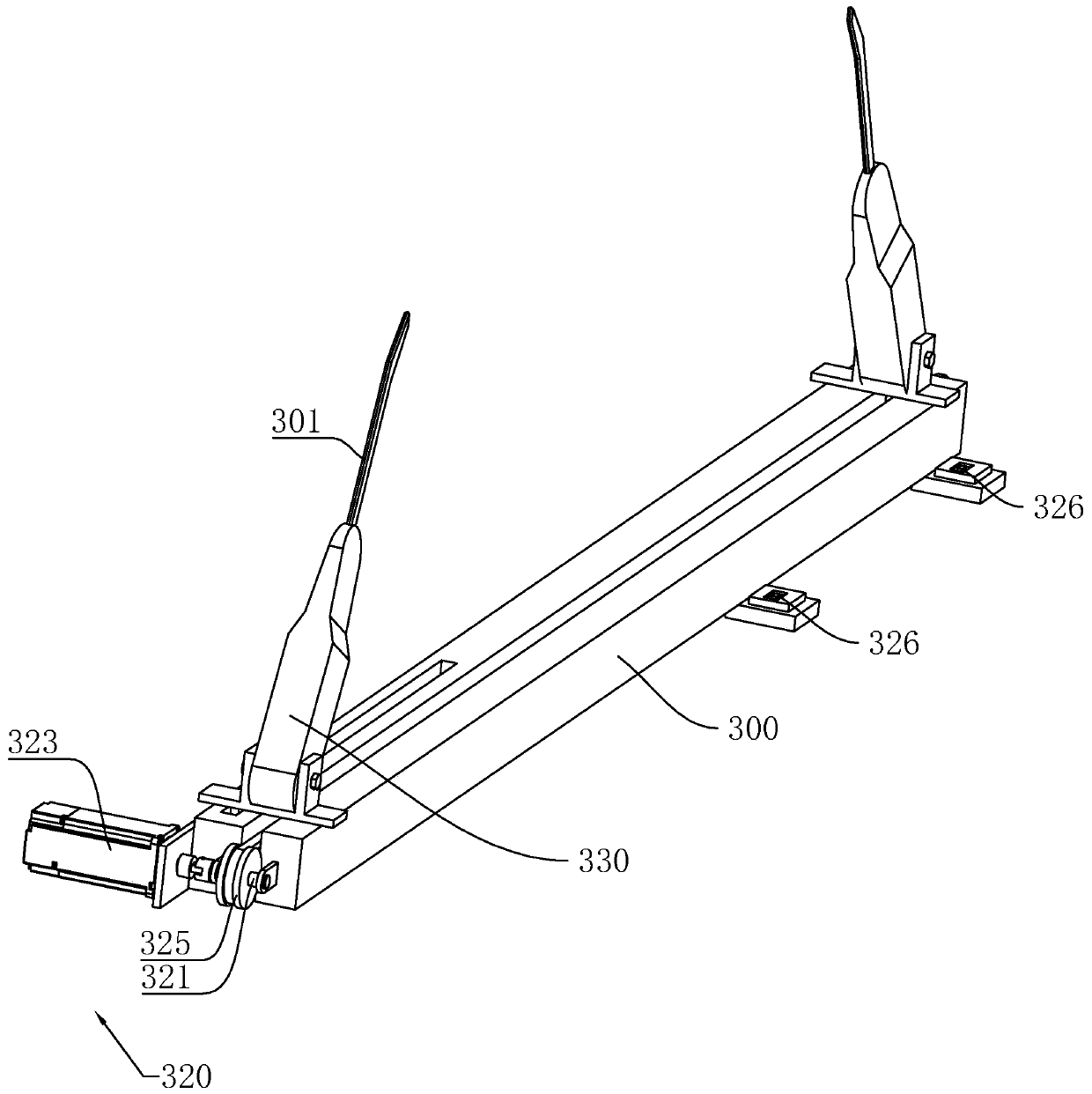

Pillow sleeve edge cutting turning production line

ActiveCN109778445AImprove work efficiencySave human effortMechanical cleaningPressure cleaningProduction lineEngineering

The invention discloses a pillow sleeve edge cutting turning production line, belongs to the technical field of pillow sleeve production equipment, and aims at providing the pillow sleeve edge cuttingturning production line. The production line is characterized by comprising a pillow sleeve edge cutting device, a pillow sleeve turning accommodation device and a control box, and the pillow sleeveturning accommodation device is located on the next working position of the pillow sleeve edge cutting device; the pillow sleeve edge cutting device comprises an edge cutting supporting frame, the edge cutting supporting frame is provided with an obliquely arranged working panel, the working panel is provided with two cutting grooves which are formed in the same line, the cutting grooves are formed in the direction perpendicular to the proceeding direction of the pillow sleeve, an edge cutting sliding rail which is arranged in the length direction of the cutting grooves is arranged on the edgecutting supporting frame, cutters are arranged on the two sides of the edge cutting sliding rails and driving mechanisms which are used for performing reciprocating sliding in the cutting grooves arearranged on the two sides of the edge cutting sliding rails. By arranging various kinds of sensors, automatic pillow sleeve accommodating is achieved, manual operation is reduced, and the automationlevel is higher.

Owner:无锡市维娅娜纺织品有限公司

Full-automatic fabric production equipment

PendingCN110938945AImprove work efficiencyImprove product qualityWorkpiece carriersWork-feeding meansMaterial resourcesIndustrial engineering

The invention relates to full-automatic fabric production equipment. The full-automatic fabric production equipment comprises a double-folded fabric continuous unfolding mechanism for completely unfolding the half-folded fabric; a drum-type belting machine for conveying the fabric in a decelerated manner; a fabric transverse edge cutting and trimming machine for performing rough selvedge tailoring, hemming and stitching on the fabric in a transverse width; a fabric longitudinal space reduction cutting machine for conveying the fabric to a fabric longitudinal edge trimming machine after the fabric is cut in the least length of a floor space; the fabric longitudinal edge trimming machine for performing hem-stitching after the fabric is inwardly rolled from two longitudinal edges; a fabric automatic folding machine for folding the fabric; and a fabric storage mechanism for storing processed fabric materials. Through the production equipment disclosed by the invention, the unfolding, the automatic hem-stitching at longitudinal and transverse directions, the automatic folding and the storage of the finished fabric product can be automatically accomplished in order, the whole process isautomatic in the whole course, the labor and the material resource are economized, and the working efficiency of the fabric product and the production quality of the product are improved.

Owner:SUZHOU TRANSPARENT TECH CO LTD

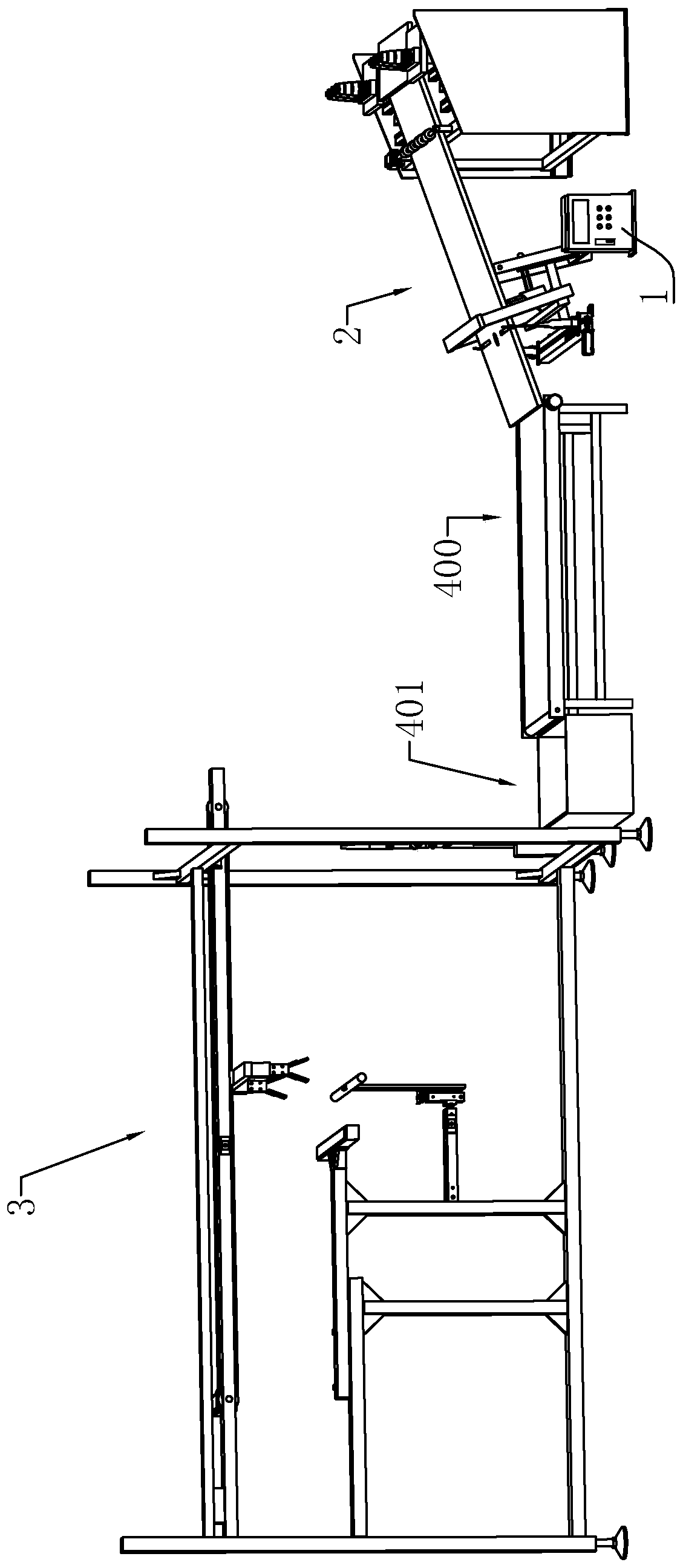

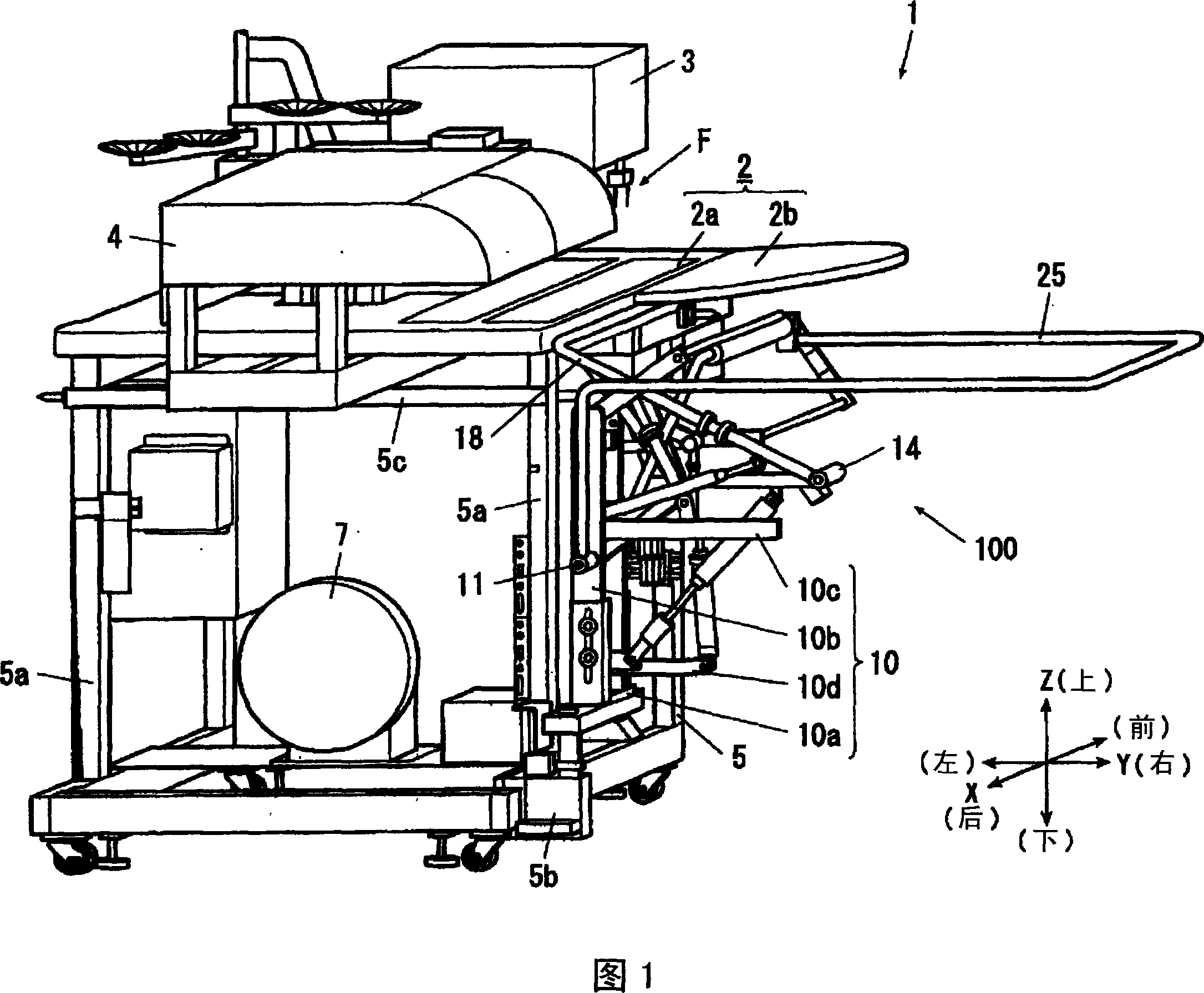

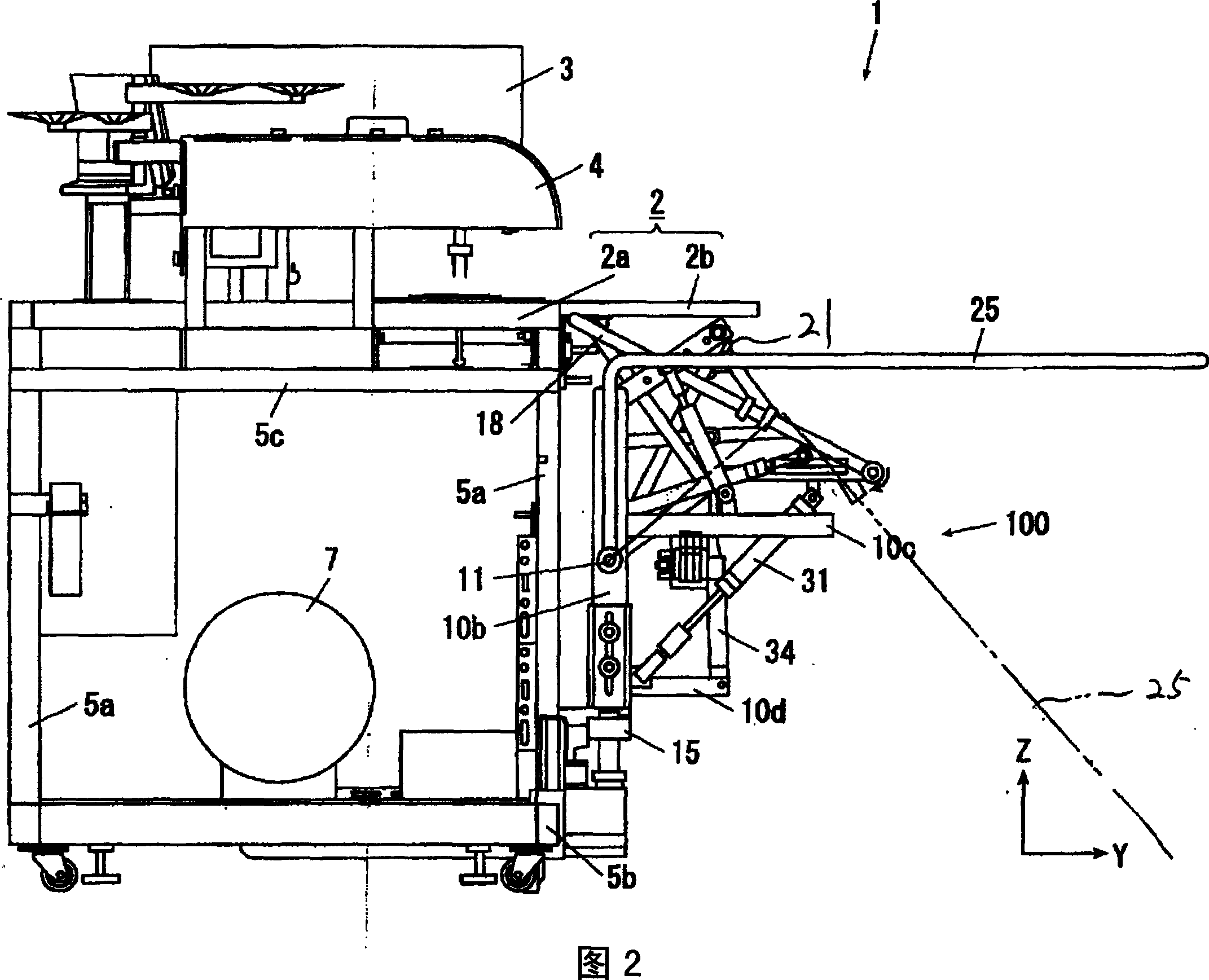

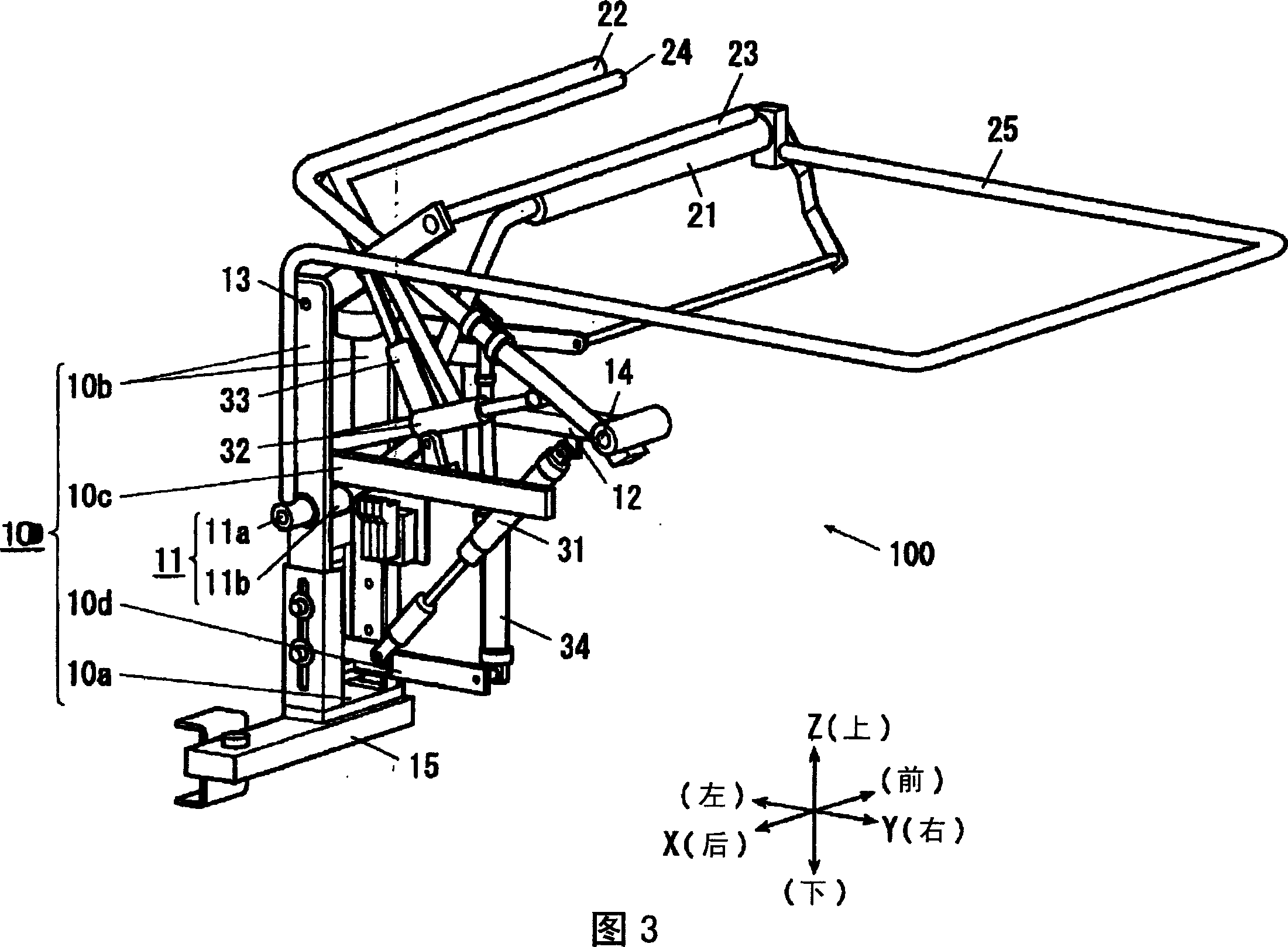

Stacking device of sewing machine

The present invention provides a stacker device (100) comprising: a mounting lever (21) for mounting cloth after the end of sewing by the sewing machine (1); a cloth driving bar (22) for guiding the cloth to the mounting bar (21) by being moved back and forth between the vicinity of the end edge of a main table (2a) and above the mounting bar (21); a first clamp bar (23) and a second clamp bar (24) for clamping the cloth after the end of sewing, which is mounted on the mounting bar (21), by cooperating with the mounting bar (21); a frame (10) for supporting the mounting bar (21), the cloth driving bar (22), the first clamp bar (23) and the second clamp bar (24); and a safety bar (25) for preventing contact with an operator when the respective bars (21, 22, 23 and 24) perform a stacking operation. Then, the distal end side of the safety bar (25) is lowered in linkage with the lowering of the mounting bar (21). Thus, a sewn object after the end of sewing, which is mounted on the mounting bar (21), is taken out more easily than before.

Owner:JUKI CORP

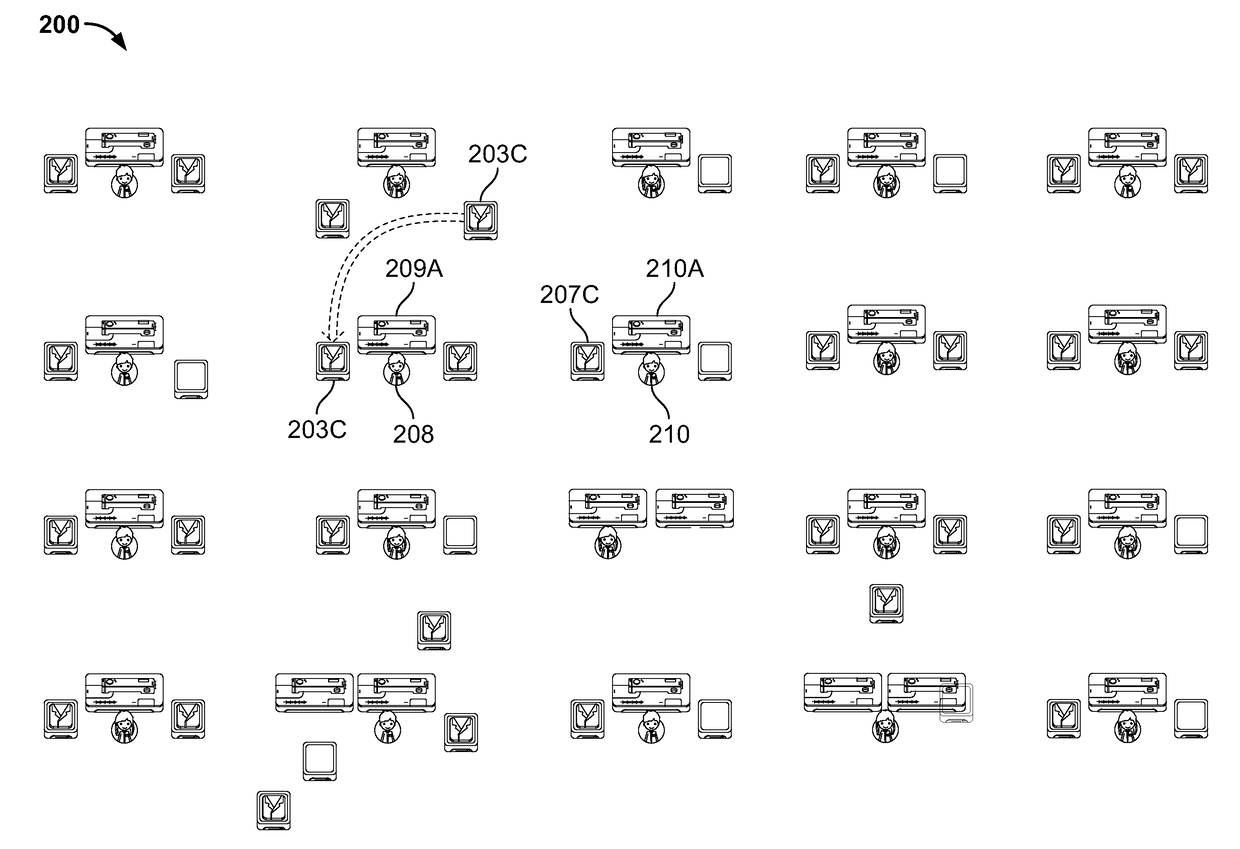

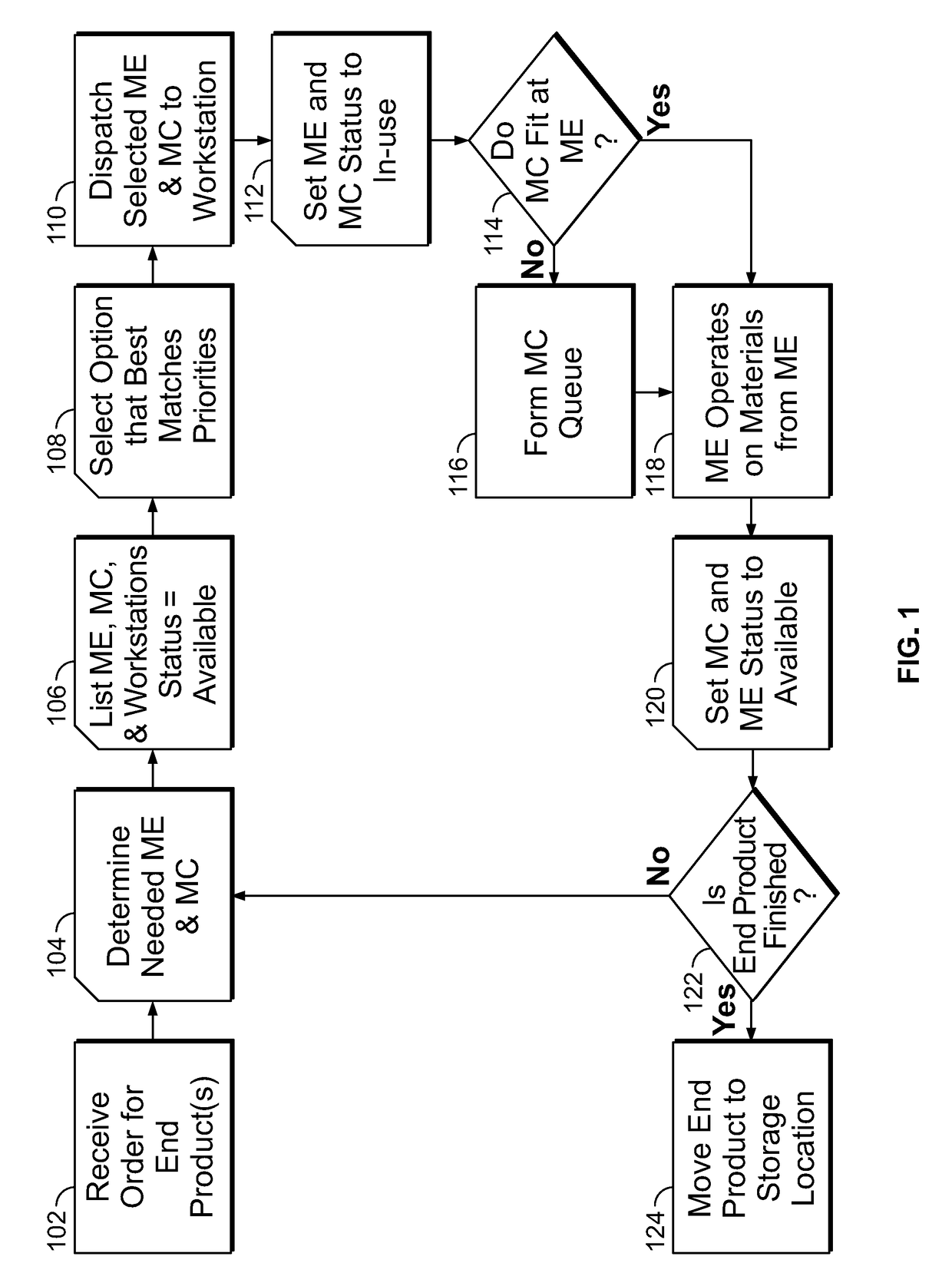

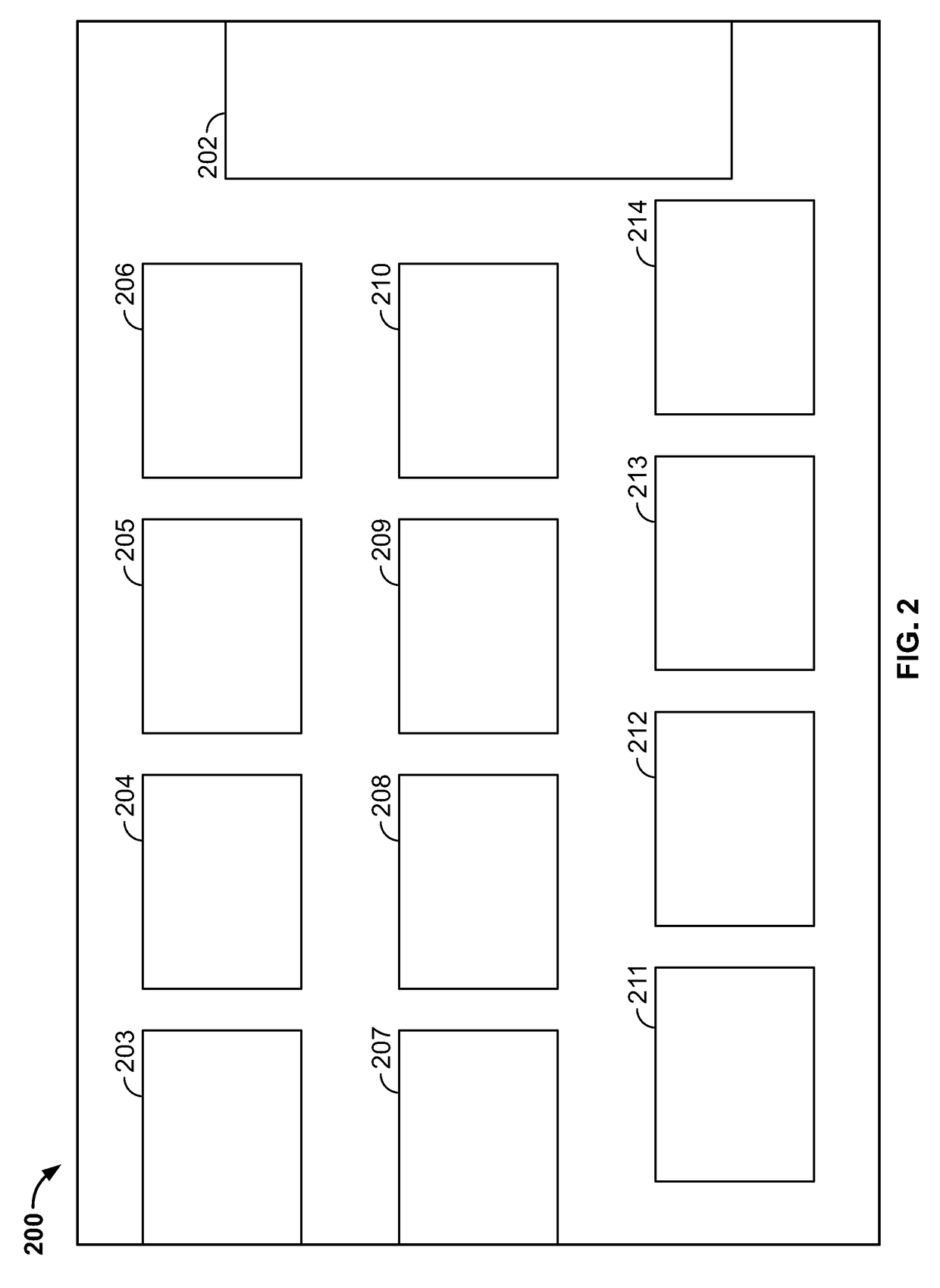

Parallel manufacturing systems and methods

ActiveUS20180024518A1Programme controlData processing applicationsHybrid approachManufacturing management

The invention provides methods, equipment and apparatuses for a highly flexible assembly system. The system may include at least one item of mobile equipment, at least one mobile container and at least one manufacturing management system (MMS). Because it is so flexible, the system may allow for efficient simultaneous processing of multiple dissimilar products. The system may also accommodate manufacturing processes requiring hybrid methods.

Owner:LERIDGE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com