Automatic sleeve cuffs buttonholing and button attaching sewing machine

A technology of button sewing machine and sleeve cloth, which is applied to sewing machine components, control devices for sewing machines, sewing equipment and other directions, can solve the problems of cloth transfer, difficulty in turning, low buttonhole buttoning efficiency, etc., so as to improve production efficiency and improve production efficiency. Product quality, compact structure, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

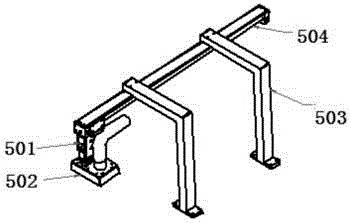

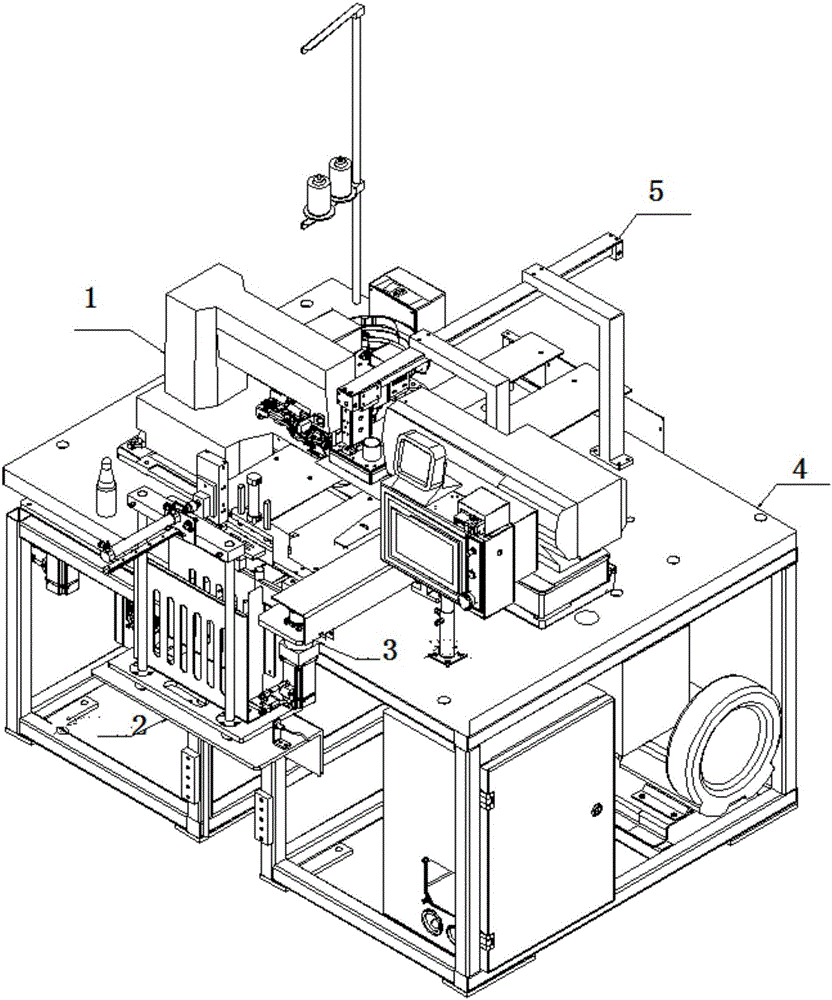

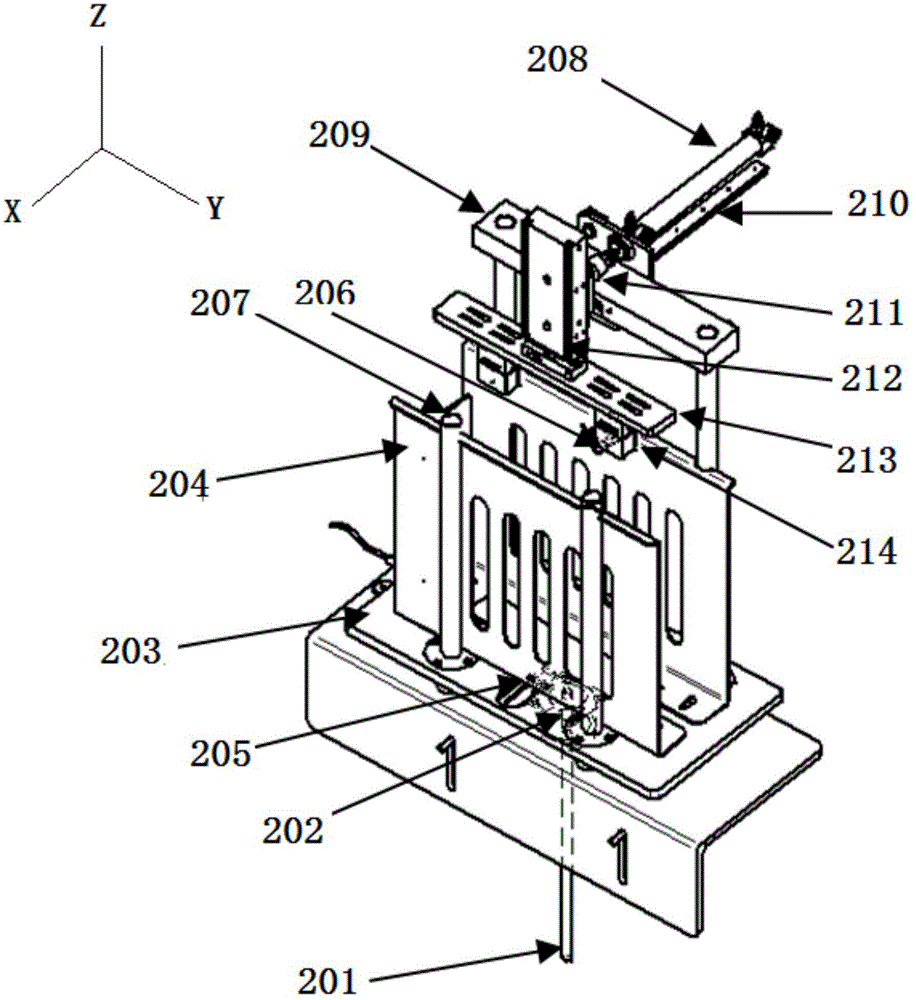

[0024] see Figure 1-5 , an automatic buttonhole buttonhole sewing machine, comprising a grasping and feeding mechanism 2, a translational feeding mechanism 3, a buttonhole machine 1, and a buttonhole machine 4; the horizontal conveying direction of cloth is the X direction, and the vertical upward direction is the Z direction; The grasping and feeding mechanism 2 includes a Z-direction power mechanism 201, and the Z-direction power mechanism 201 is connected to the discharge seat 203 through the connection mechanism 2. A pair of fence panels 204 arranged on both sides of the sleeve kuff cloth are installed on the discharge seat 203. A feeding support plate 209 is fixedly arranged on the fence board 204, and an X-direction power mechanism 208 is fixedly arranged on the described material feeding support plate 209, and one end of the X-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com