Full-automatic fabric production equipment

A kind of production equipment, fully automatic technology, applied in the direction of textiles and papermaking, cloth feeding mechanism, cloth pressing mechanism, etc., can solve the problems of high labor intensity for workers to operate equipment, limited improvement of production efficiency, limited production efficiency, etc., to achieve high practicality value, improve work efficiency, and meet processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

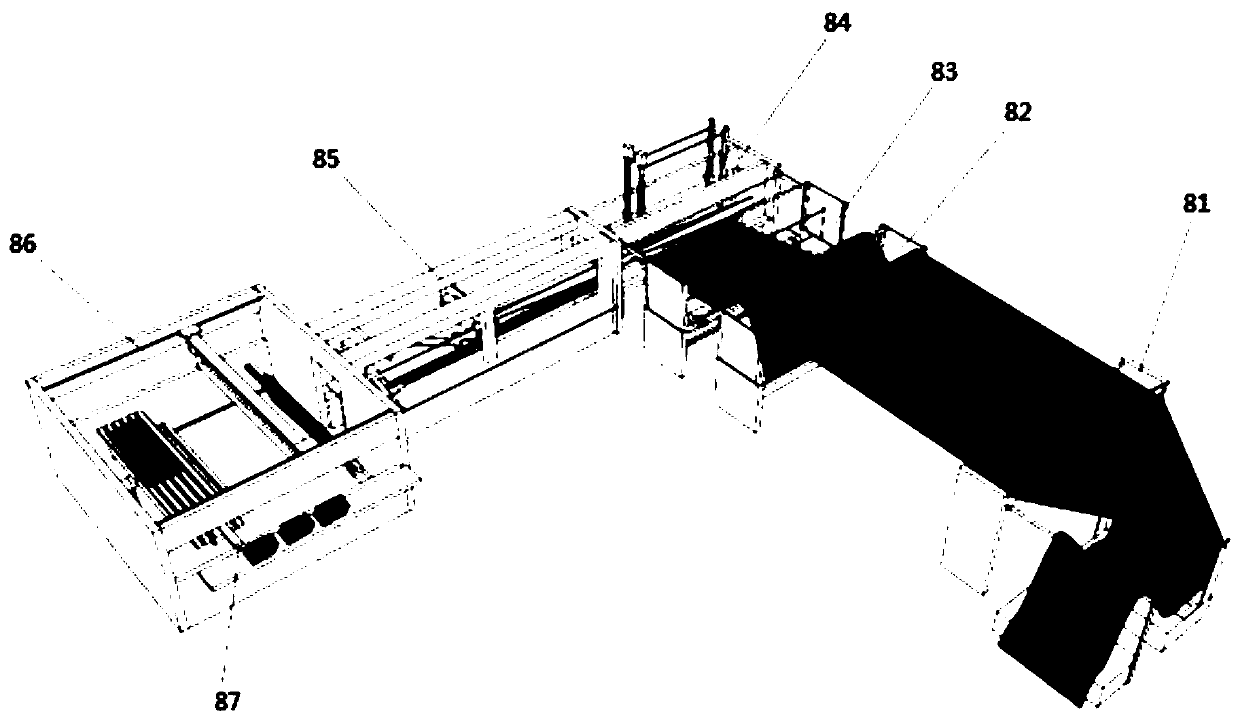

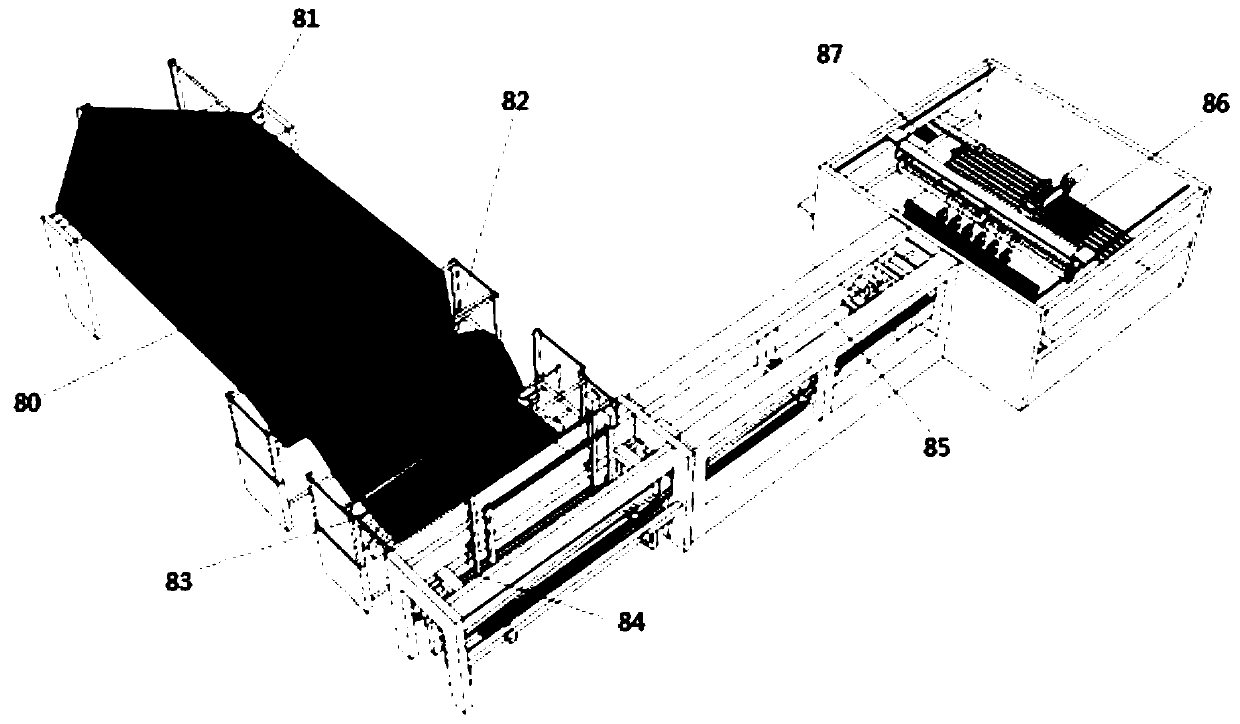

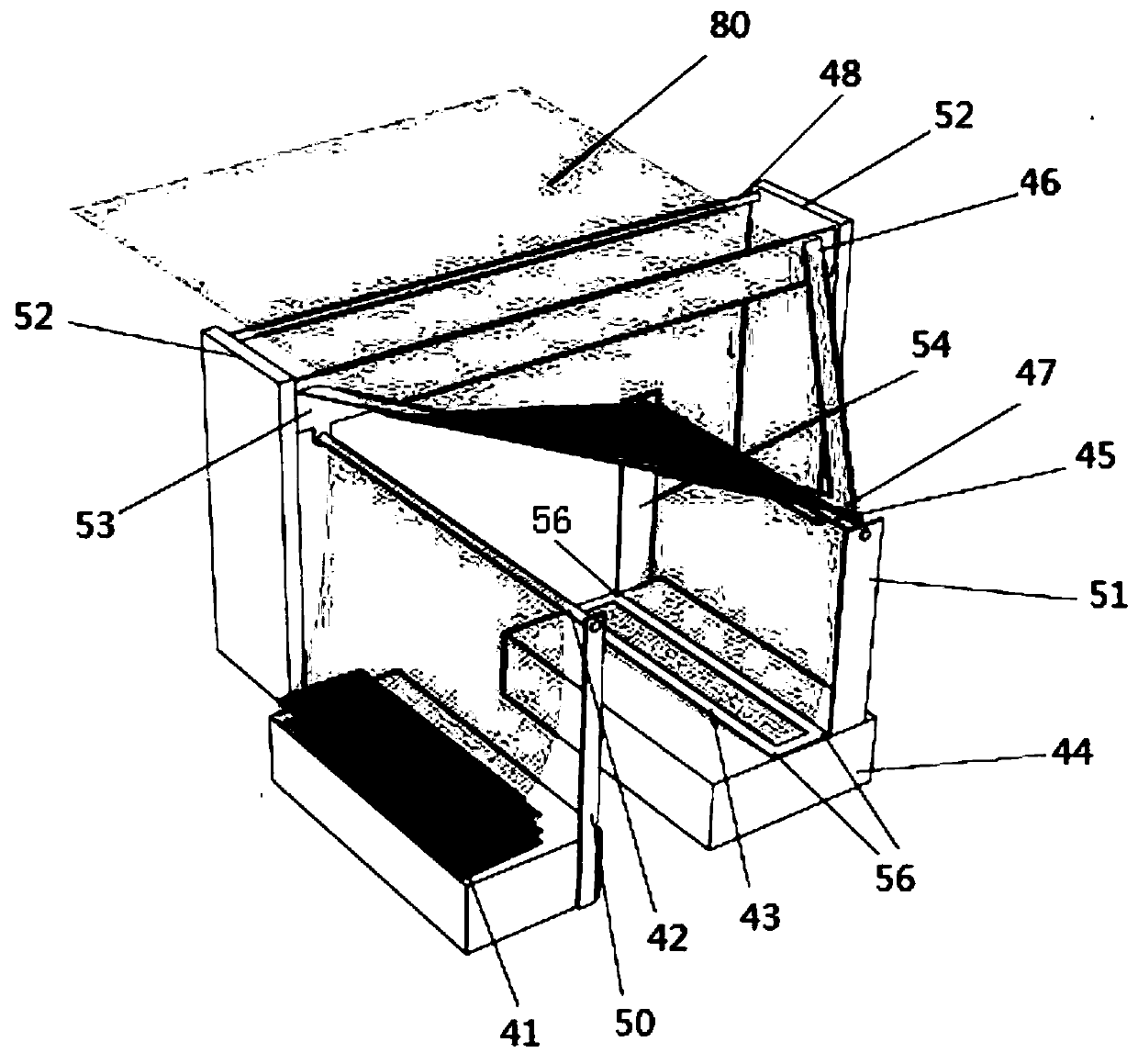

[0045] Please refer to the attached Figure 1-2 , a kind of fully automatic fabric production equipment described in one embodiment of the present invention, comprises the bi-fold fabric continuous unfolding mechanism 81 that is arranged successively, drum type belt fabric machine 82, fabric transverse edge cutting and seaming machine 83, fabric longitudinal Space narrowing cutting machine 84, fabric longitudinal edge seaming machine 85, fabric automatic folding mechanism 86 and fabric storage mechanism 87; During work, first double-folding fabric continuous unfolding mechanism 81 fully unfolds the fabric after half-folding, and conveys to drum type In the tape cloth machine 82, the drum type tape cloth machine 82 is provided with rollers to slow down the forward speed of the fabric, and the fabric lateral edge cutting and seaming mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com