Intelligent sewing line pressing machine

A thread crimping machine, intelligent technology, applied to the mechanism of cutting the thread in the sewing machine, sewing unit, sewing machine components, etc., can solve the problem of manpower consumption, achieve the effect of improving processing efficiency, simple operation, and reducing human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described below in conjunction with accompanying drawing.

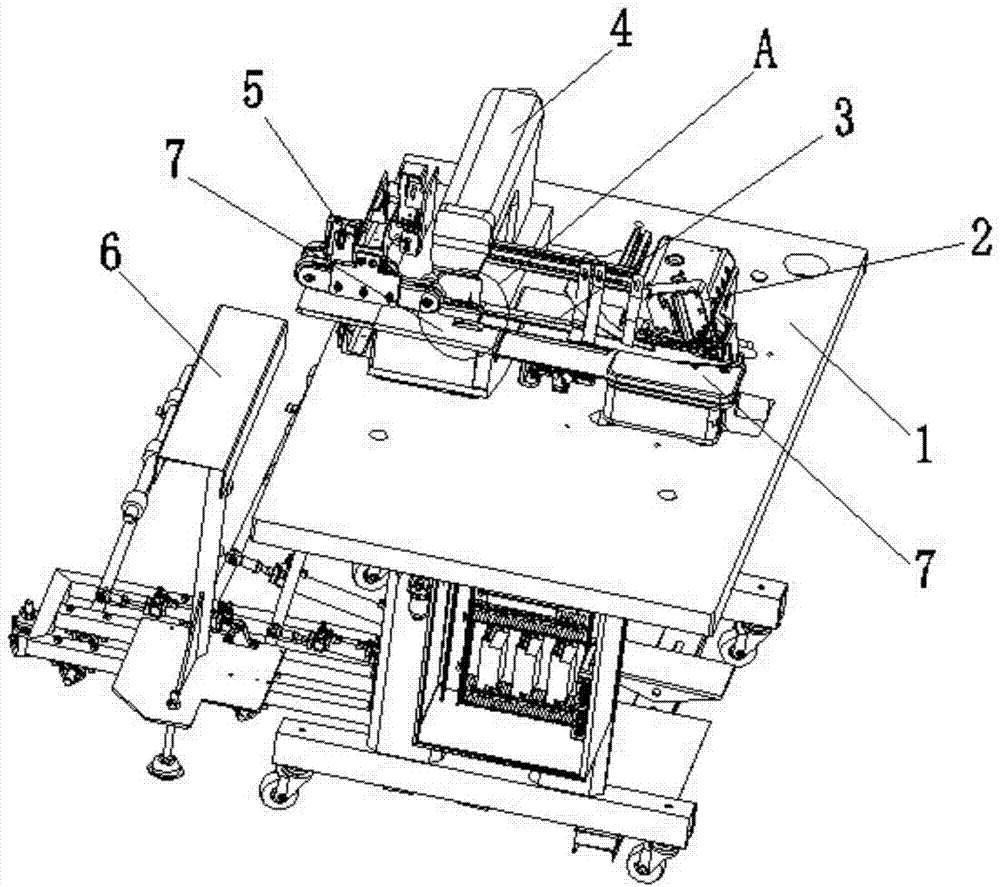

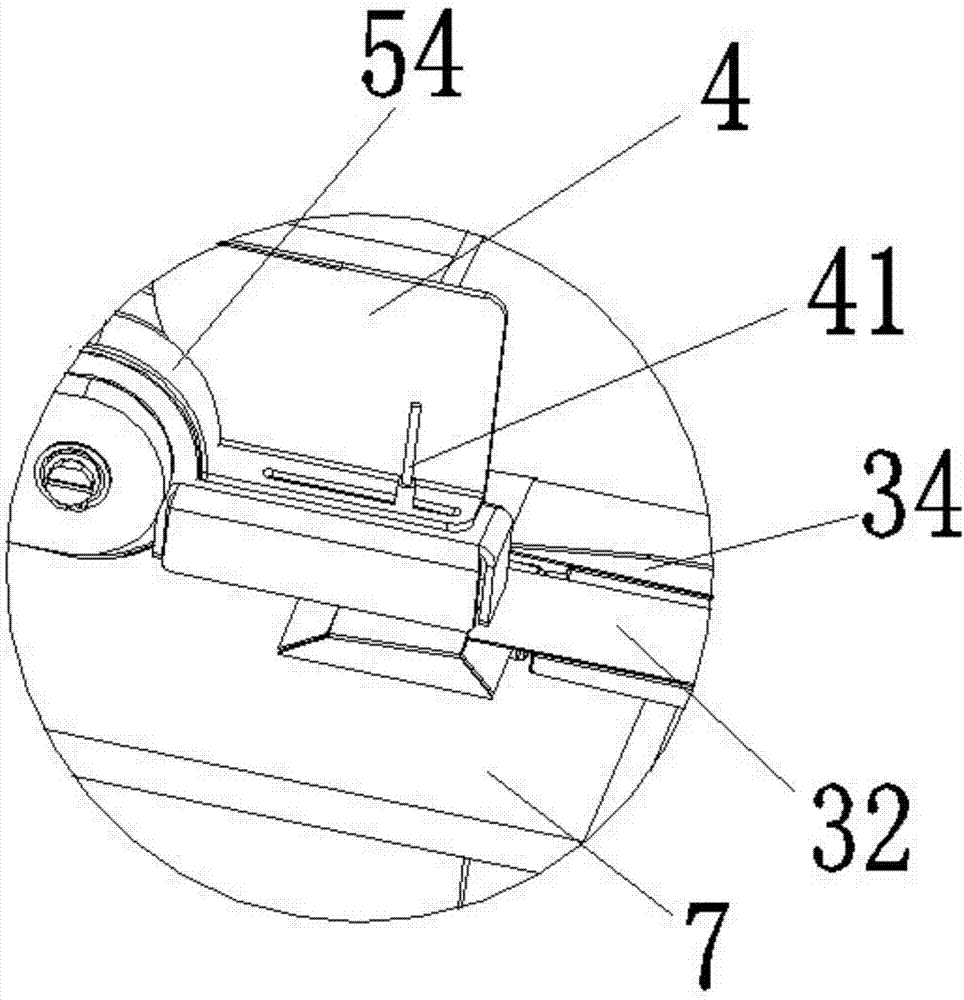

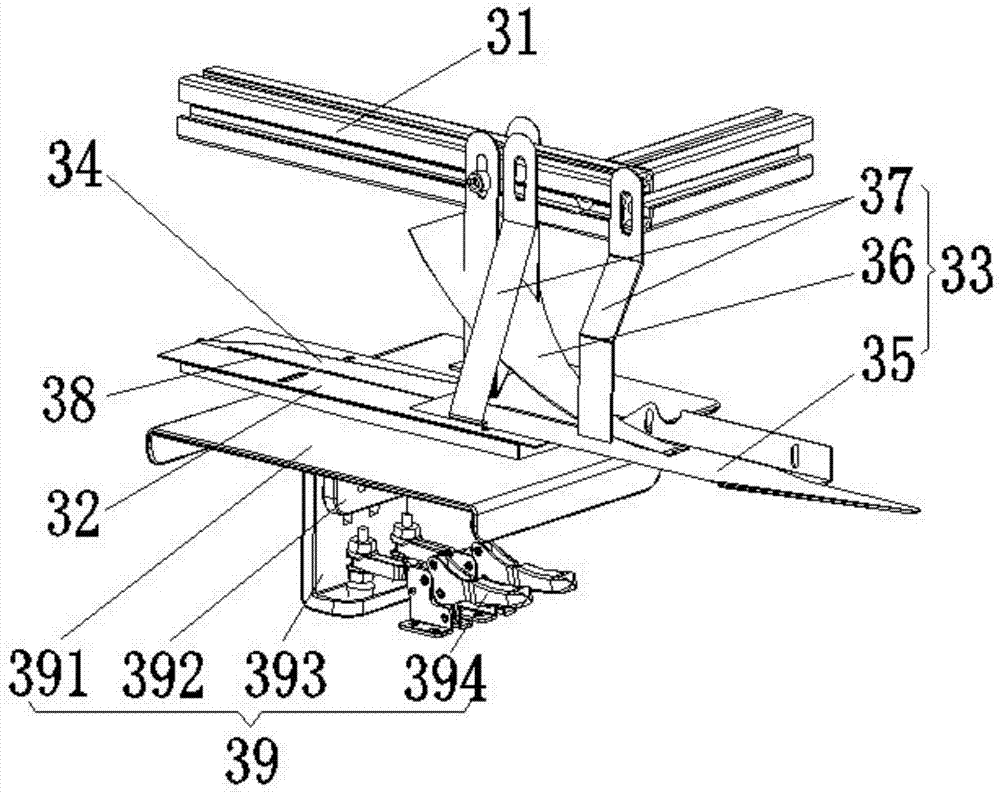

[0024] Intelligent suture crimping machine of the present invention, as attached Figure 1-5 As shown, it includes a frame 1, an overlay device 2, a feeding device 3, an interlock sewing device 4, an automatic thread trimmer 5 and a material receiving device 6; Afterwards, it is installed on the frame 1 in turn; the left side of the hemming device 2 and the interlock device 3 is provided with a workbench 7; the feeding device 3 includes a support frame 31, a guide plate 32, a cloth turning tool 33 and a guide Rod 34; the front and rear ends of the support frame 31 are respectively fixed on the hemming device 2 and the stretch seam device 4; the cloth turning tool 33 and the guide rod 34 are all fixed on the support frame 31; the front and rear ends of the guide plate 32 Ends are respectively connected to 2 and the workbench 7 of the interlock seam device 4; the cloth turning tool 33 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com