Continuous fabric strap sewing and edge-covering device

A technology of hemming device and fabric belt, applied in the direction of garment collecting device, sewing equipment, sewing machine components, etc., can solve the problems of low production efficiency, large labor amount, inconsistent production quality, etc., achieve convenient operation, reduce labor amount, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

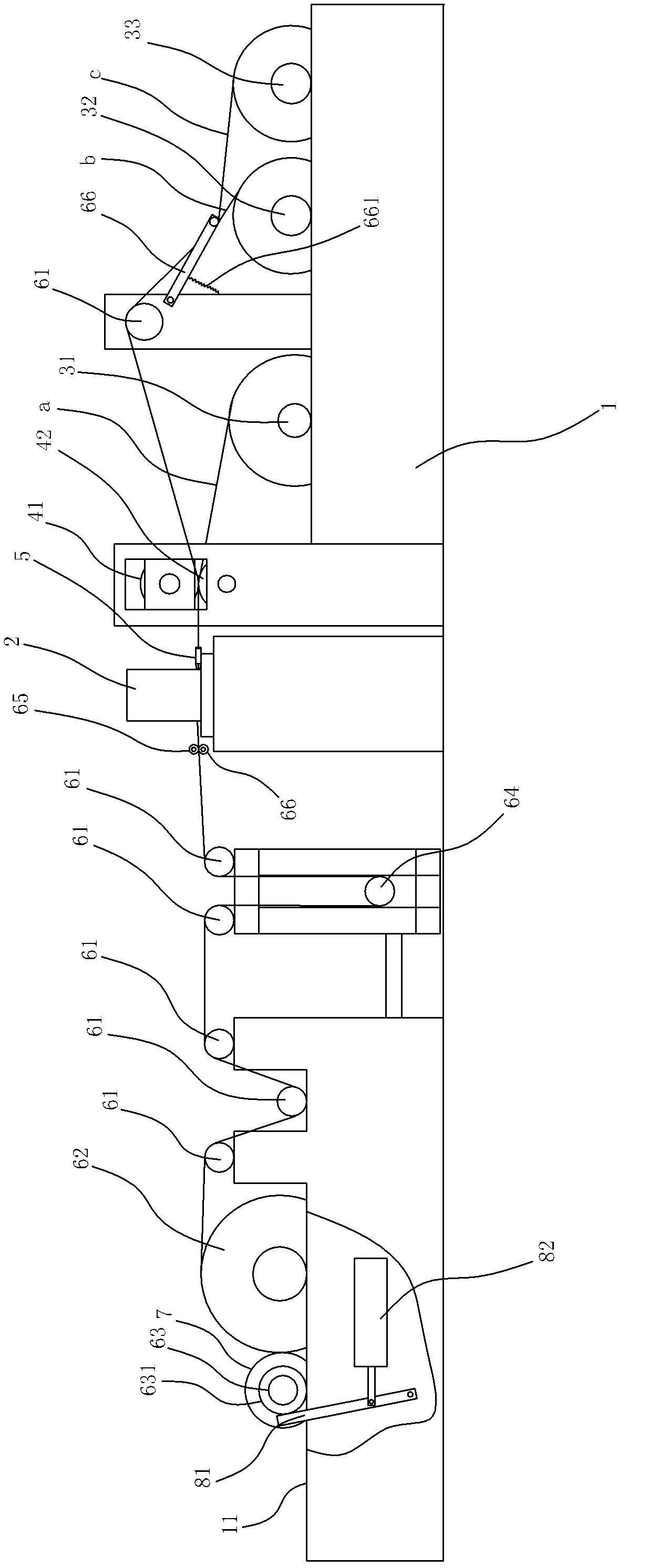

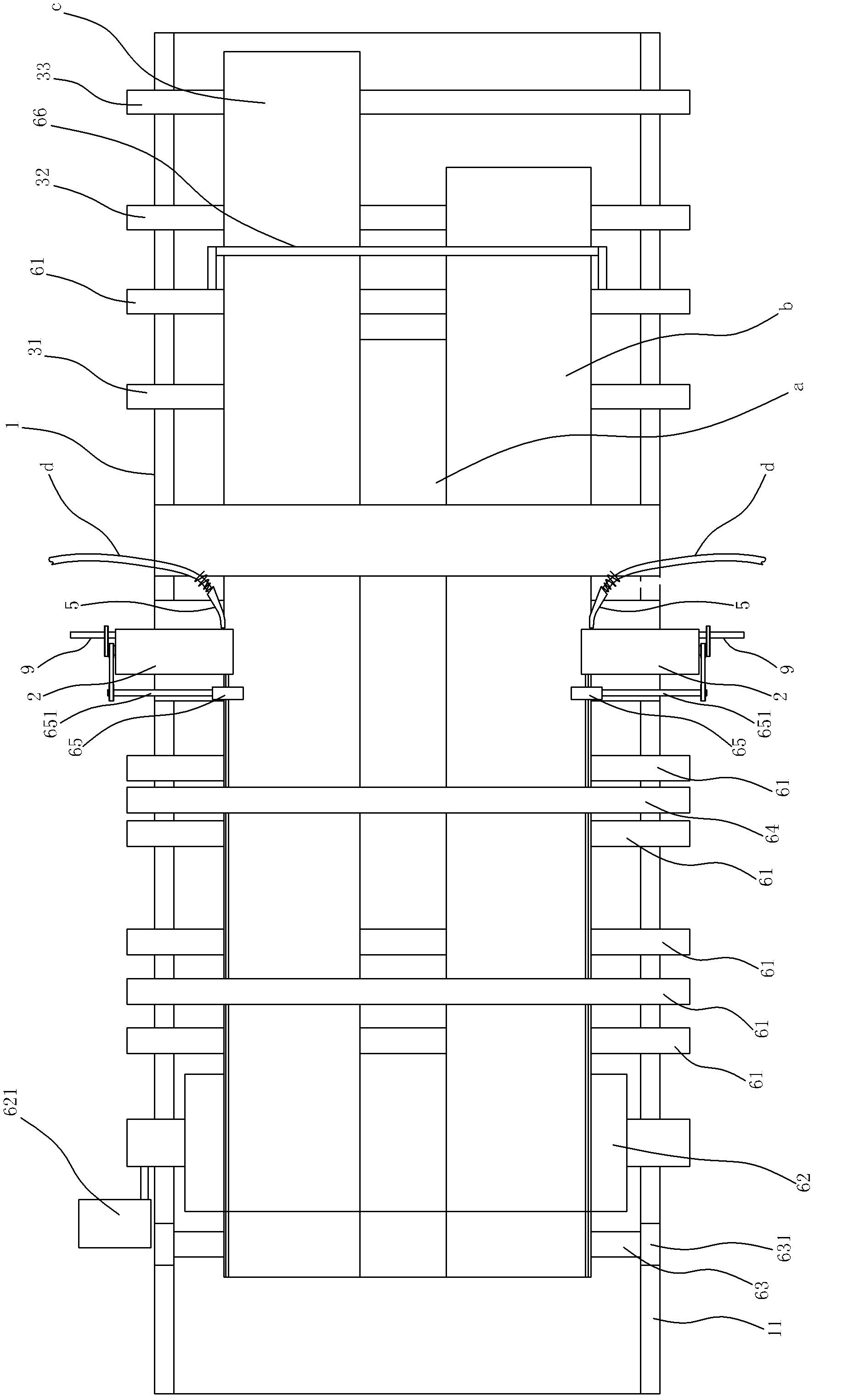

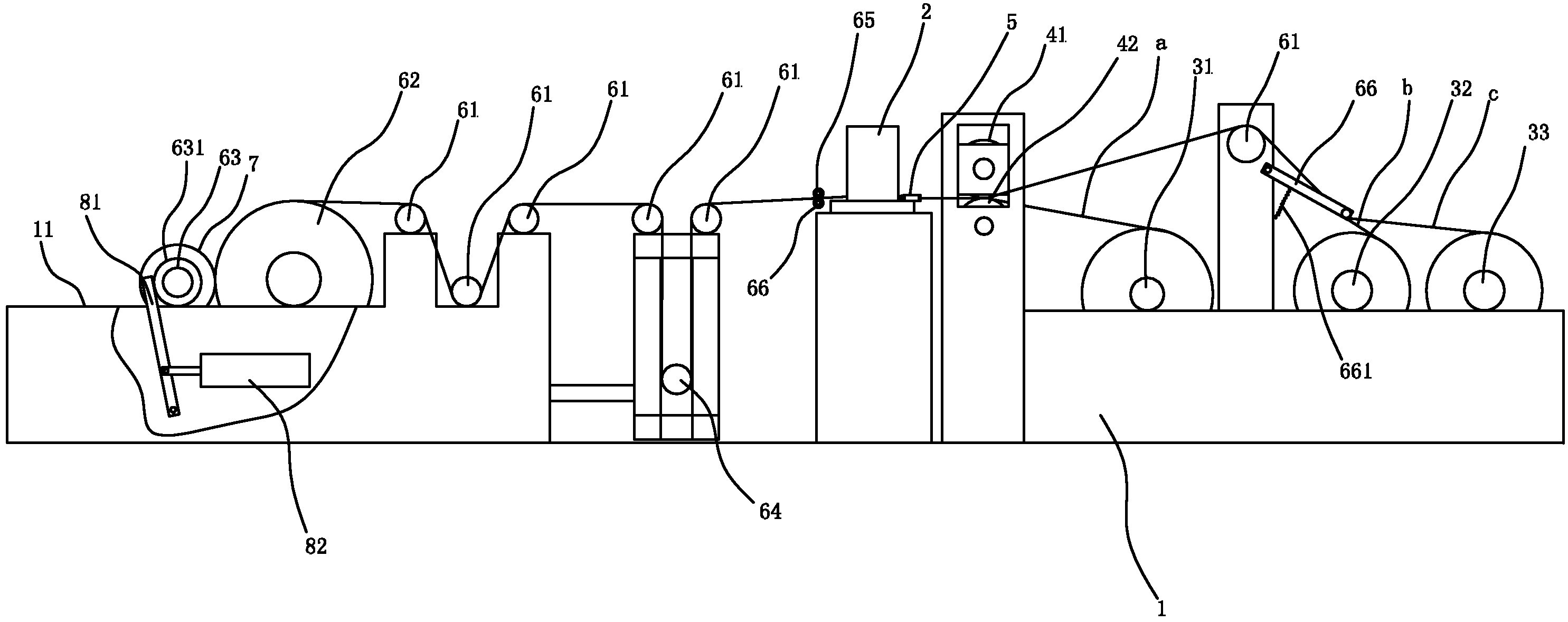

[0016] refer to figure 1 and figure 2 As shown, a sewing and hemming device for a continuous fabric belt includes a frame 1, two sewing machines 2 symmetrically arranged on both sides of the frame 1, and a belt for carrying the fabric belts a, b, and c arranged on the frame 1. Carrying rollers 31, 32, 33, upper and lower pressure rollers 41, 42 arranged on the frame 1 on the input side of the sewing machine 2, arranged on the frame 1 for continuously conveying the fabric belts a, b, c to the sewing machine 2 Conveyor mechanism, and the hemming tape hemming guide 5 that is arranged on the front side of the sewing machine 2 sewing needles,

[0017] The frame 1 is provided with a synchronous shaft 9 and a second motor (not shown) connected to drive the synchronous shaft 9 to rotate.

[0018] The conveying mechanism includes several guide rollers 61 arranged on the frame 1, conveying rollers 62 arranged on the output side frame of the sewing machine 2, a roll that is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com