Edge cutting, edge binding and sewing three-in-one sewing machine

A three-in-one, sewing machine technology, applied in the field of sewing, to achieve the effect of effective trimming, quality assurance, and neat trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

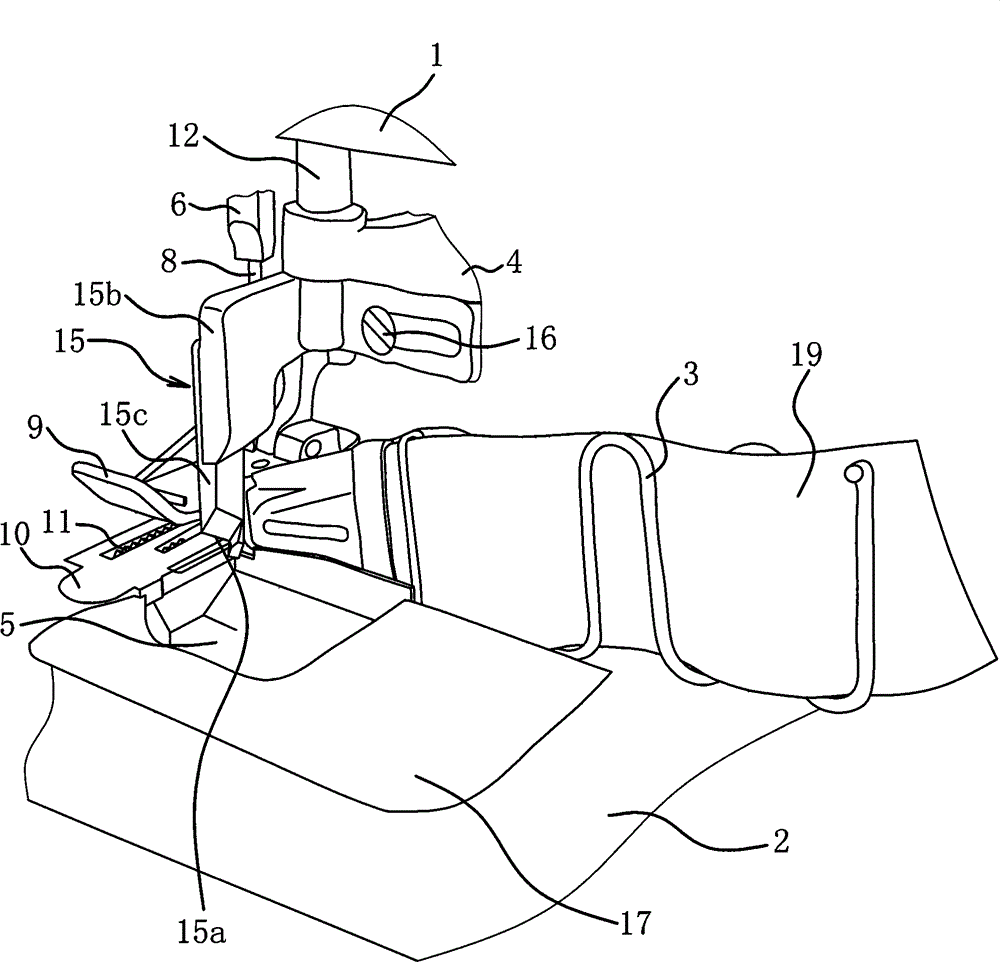

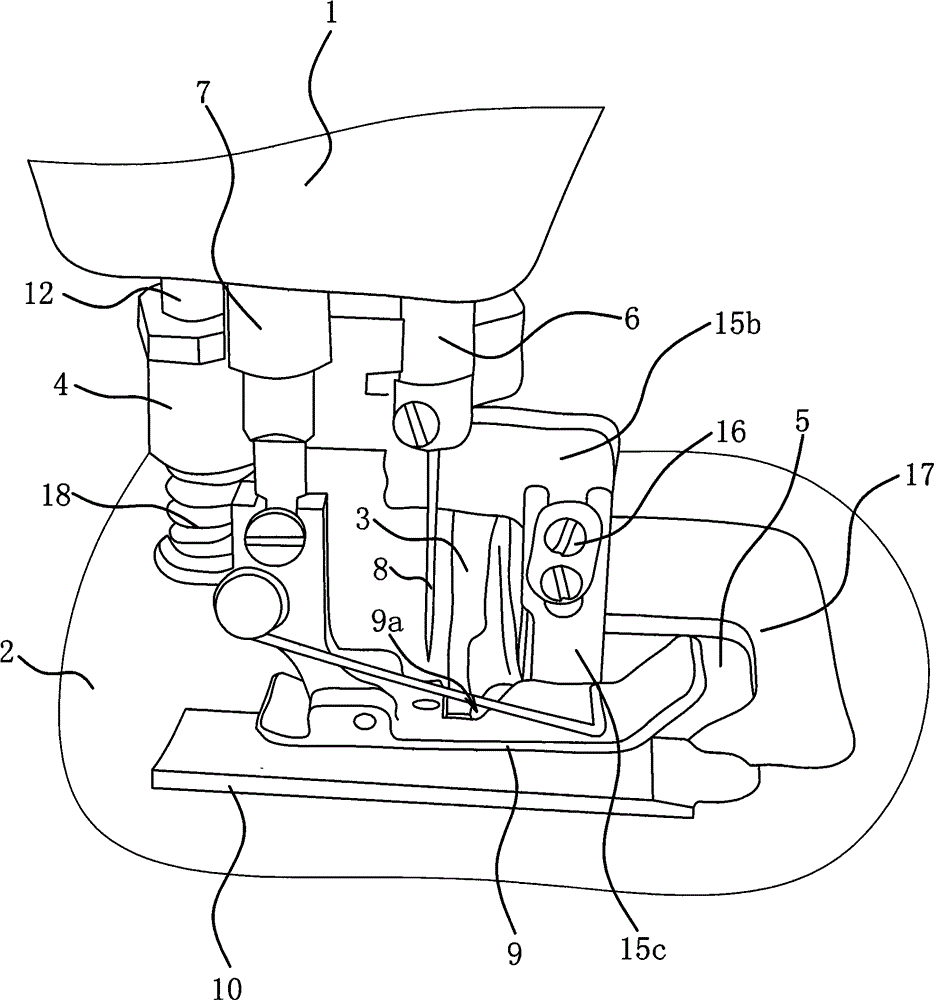

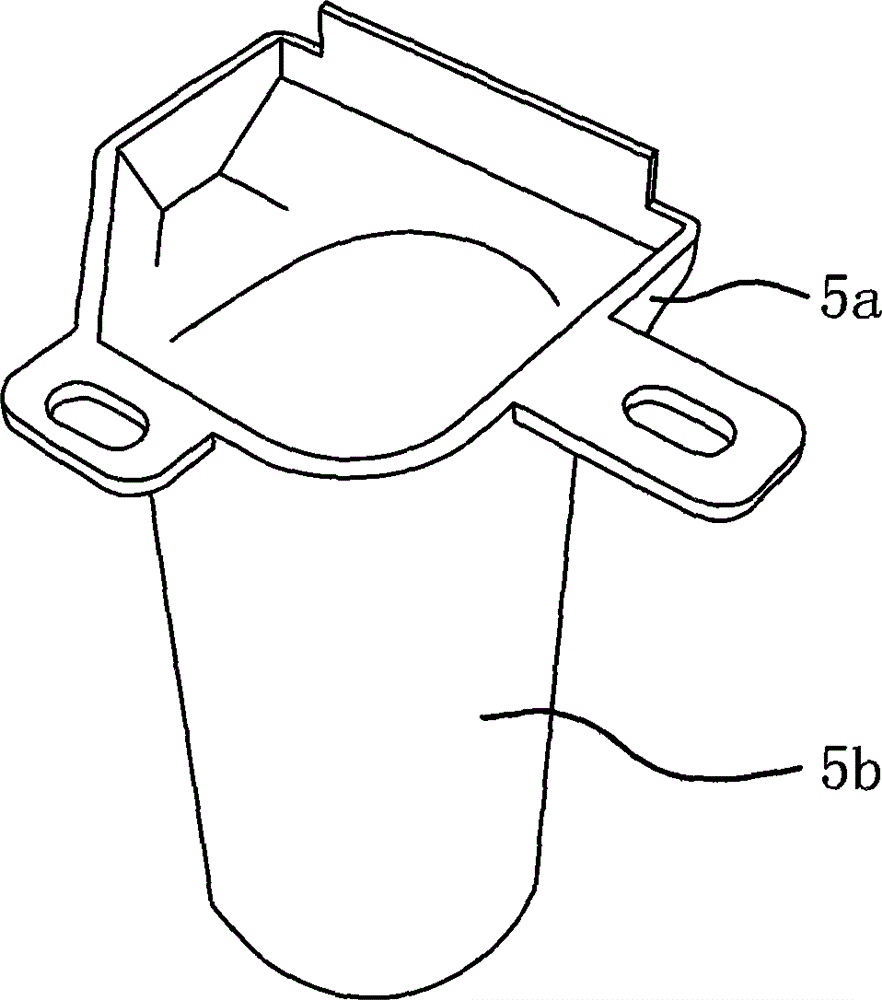

[0028] Such as Figure 1 to Figure 4 As shown, the trimming, hemming and sewing three-in-one sewing machine includes a machine head 1, a bottom plate 2, an edge curler 3, a cutter seat 4, a blanking joint 5 and a transmission assembly.

[0029] The action end of machine head 1 is worn with machine needle bar 6 and presser foot bar 7, and machine needle bar 6 and presser foot bar 7 are vertically arranged. The transmission assembly is located in the machine head 1, and the transmission assembly includes components such as a transmission shaft and a cam, and the transmission shaft is connected with the motor. The machine needle bar 6 and the presser foot bar 7 are all connected with the transmission assembly, that is, the rotation of the motor main shaft drives the machine needle bar 6 and the presser foot bar 7 to reciprocate up and down. The lower end of the machine needle bar 6 is fixed with an organic needle 8, and the lower end of the presser foot bar 7 is connected with a...

Embodiment 2

[0042] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the lower end of the transmission rod is connected with the cutter seat 4 by a clutch, and a spring 18 is set on the transmission rod, and the spring 18 makes the clutch in During the separated state, the knife plate 15c is separated from the needle plate 10, and the trimming process is cancelled. Only transmission rod moves up and down during this state, parts such as cutter seat 4 and cutter 15 do not move, and then reduce the load of motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com