Full-automatic material distribution machine capable of achieving longitudinal sewing

A fully automatic, cloth machine technology, applied in the direction of sewing machine, cloth feeding mechanism, sewing machine components, etc., can solve the problems of high labor intensity, restricting the development of enterprises, and high rate of defective towels, and achieves convenient and labor-saving operation, compact overall structure, The effect of meeting the needs of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

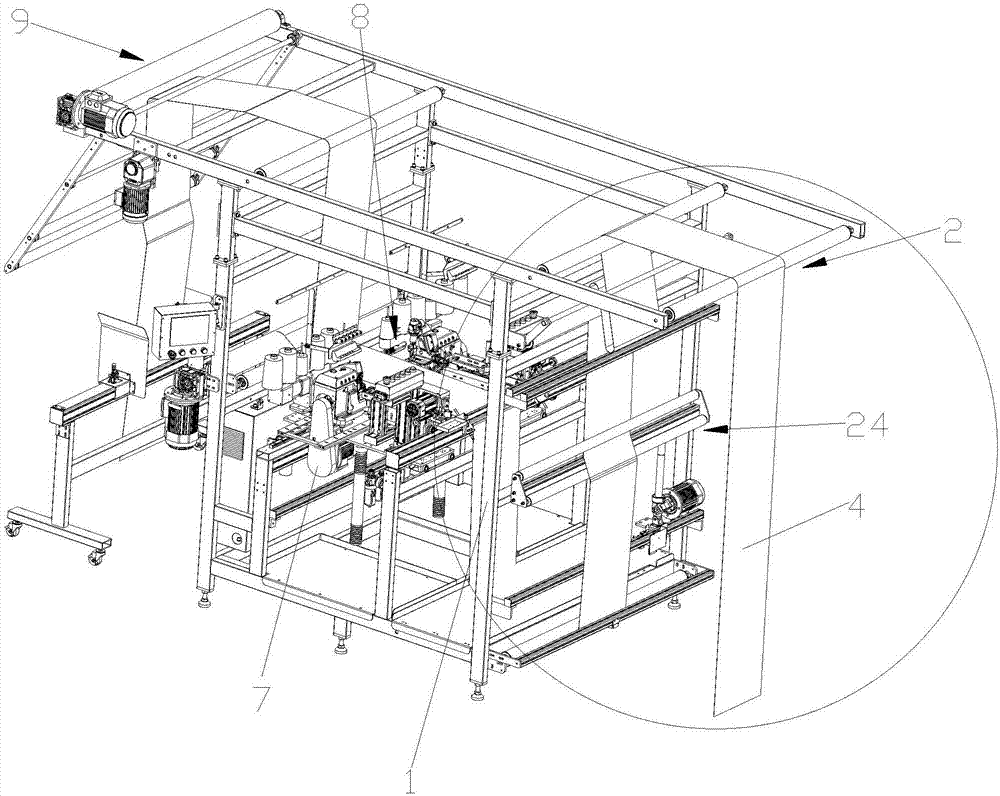

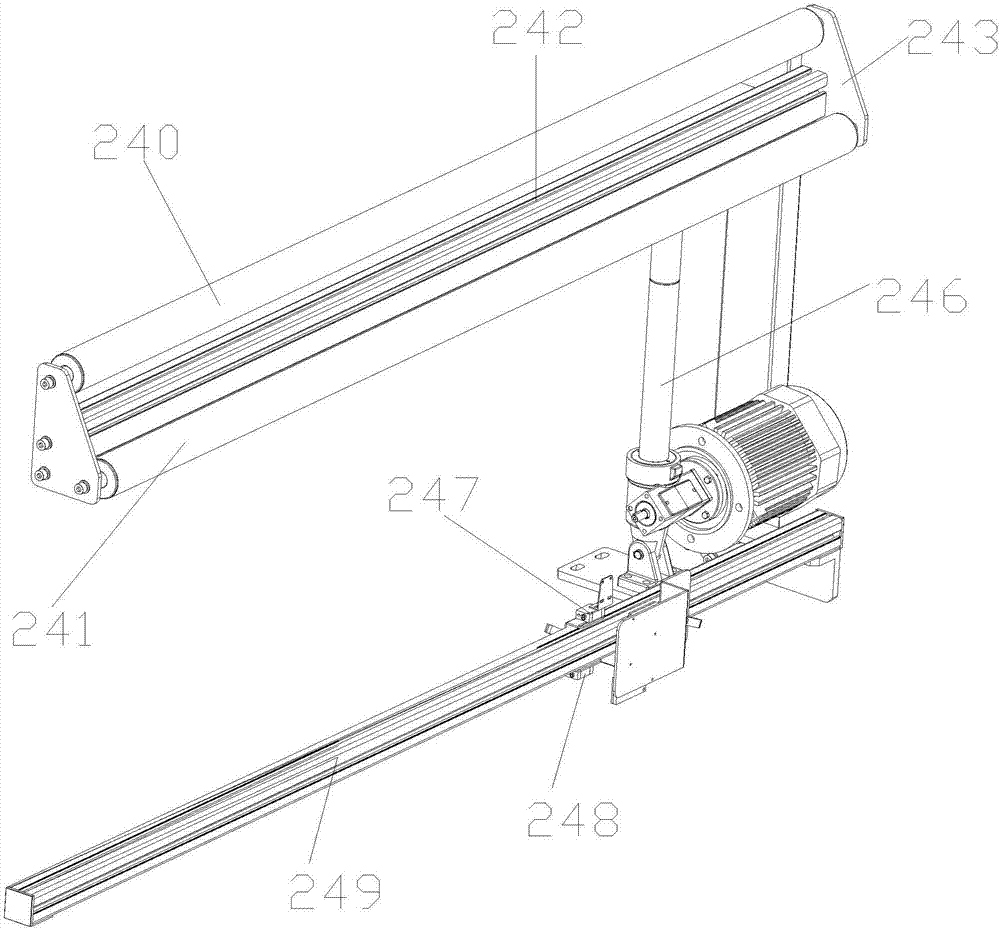

[0038] as attached figure 1 , a kind of longitudinal stitching full-automatic distributing machine of the present invention shown in 2, 5, comprises frame 1, and the feed assembly 2 that is arranged on frame 1, feeding correction device 24, left and right deviation correction device 3 , trimming device 5, curling device 6, sewing machine 7, main dragging device 8 and material receiving mechanism 9; described feeding assembly 2 is arranged on frame 1 side, and also is provided with feeding in feeding assembly 2 A deviation correction device 24; the left and right deviation correction devices 3 are provided on one side of the feeding assembly 2; the left and right deviation correction devices are successively provided with a trimming device 5, a curling device 6, a sewing machine 7 and a main drag device 8; One side of the dragging dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com