Urethane foam reinforcing material

A technology for foaming polyurethane and reinforcing materials, applied in textiles and papermaking, textiles, fabrics, etc., can solve the problems of lack of productivity, processability, mold deviation, and incorrect sewing of reinforcing materials, and achieve mold punching properties. Excellent, high productivity, effect of suppressing fricative noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

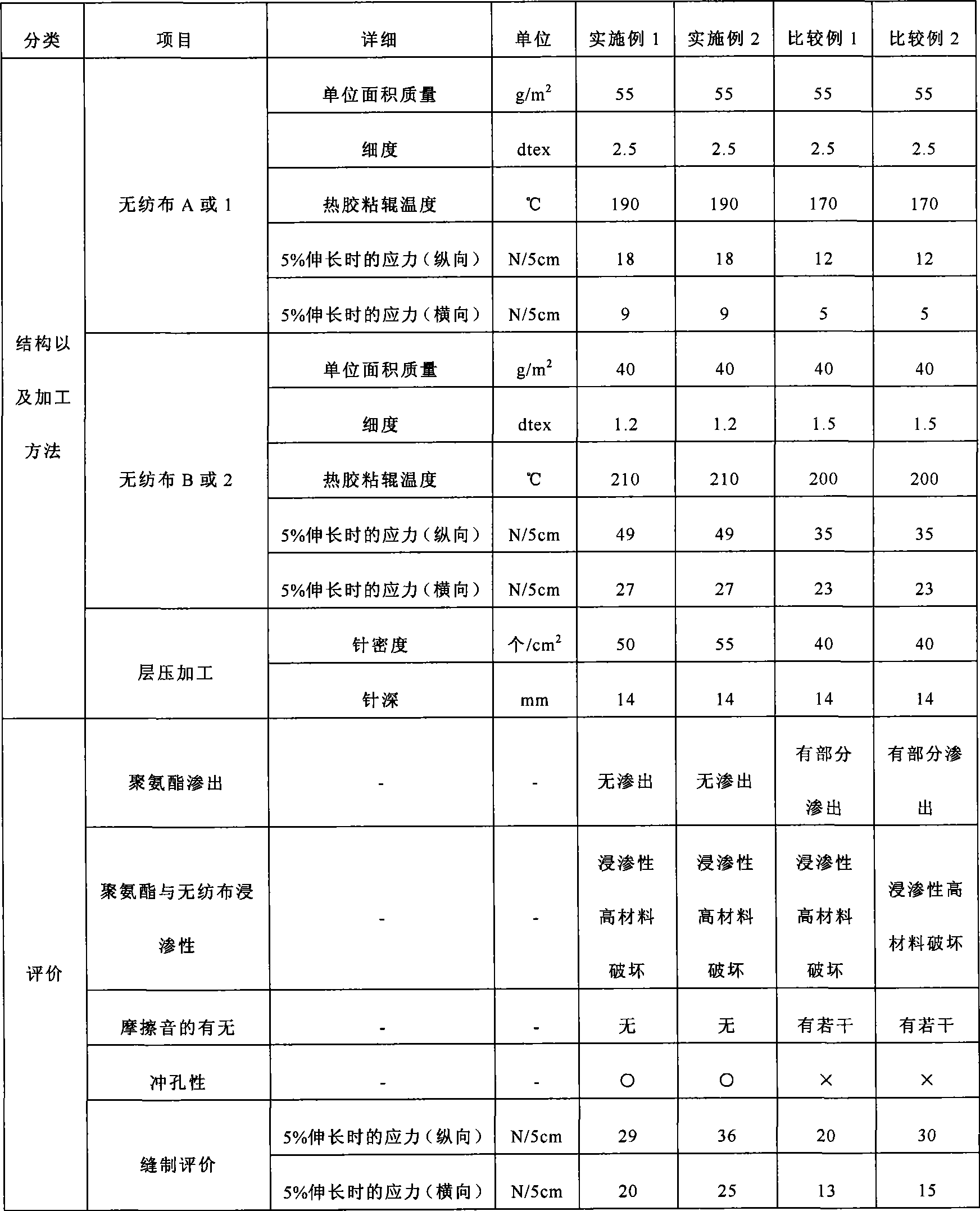

Embodiment 1

[0039] The weight per unit area of the random ring structure formed by the polyethylene terephthalate fiber of 2.5dtex manufactured according to the spunbond method is 55g / m 2 The cotton web is temporarily thermally bonded by calendering with a hot roller at 170°C to obtain a non-woven fabric A. The same spunbond method is made of polyethylene terephthalate containing 2% carbon black and made of 1.2dtex polyethylene terephthalate. The mass per unit area of the random rings formed by alcohol ester fibers is 40g / m 2 The cotton web was thermally bonded by calendering with a hot roll at 200°C to obtain a nonwoven fabric B, and the thus obtained nonwoven fabric A and nonwoven fabric B were laminated using a FPD1-40S needle manufactured by Organ. , with a needle density of 50 / cm2 and a needle depth of 14 mm for needle punching to obtain a nonwoven fabric with a two-layer laminated structure. The stress at 5% elongation of nonwoven fabric A is: longitudinal=15N / 5cm, transverse=8...

Embodiment 2

[0041] In Example 1, non-woven fabric A is laminated on both sides of non-woven fabric B, using FPD1-40S needles manufactured by Organ Company, with a needle density of 50 / cm 2 1. Needle punching with a needle depth of 14 mm to obtain a non-woven fabric with a three-layer laminated structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fineness modulus | aaaaa | aaaaa |

| fineness modulus | aaaaa | aaaaa |

| fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com