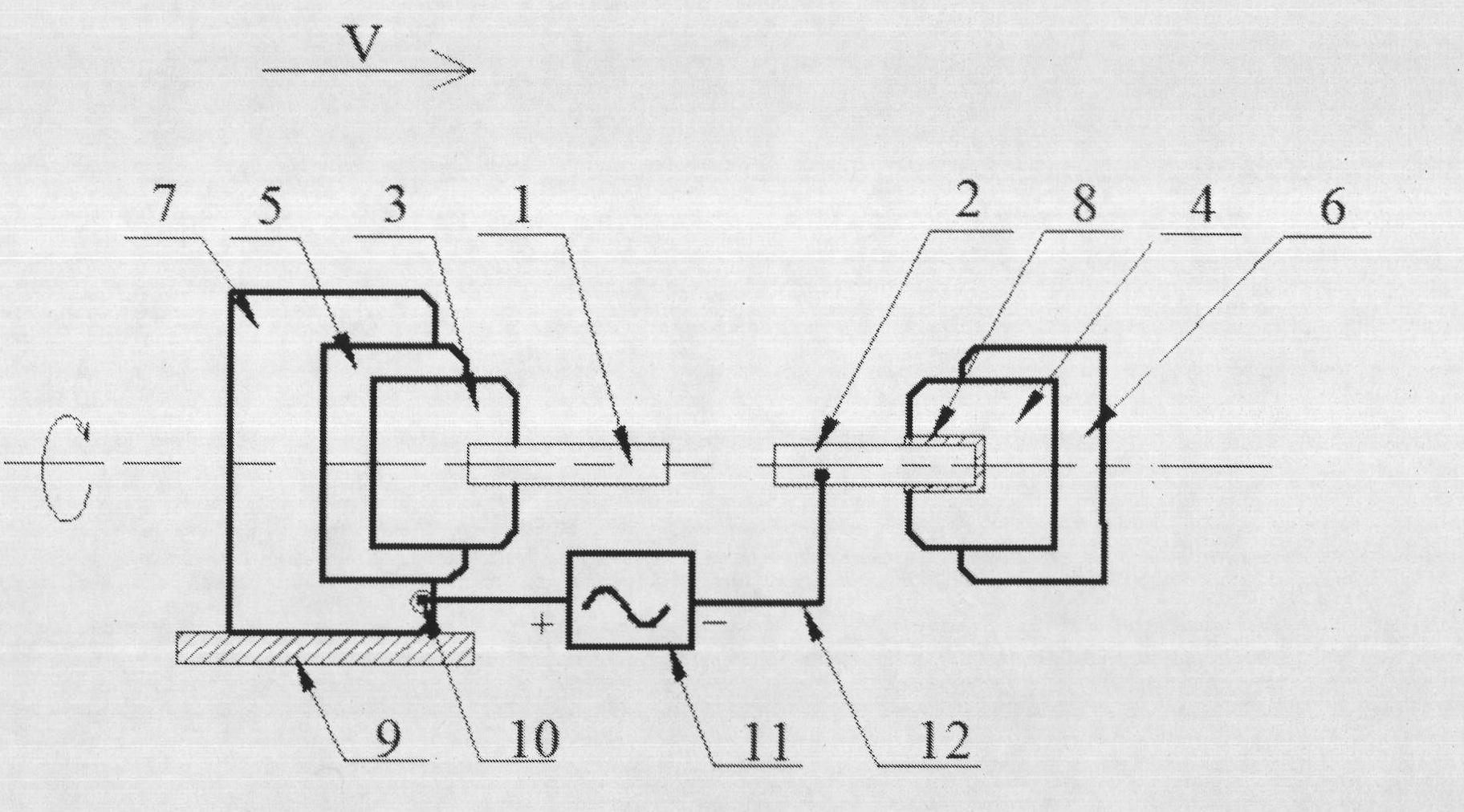

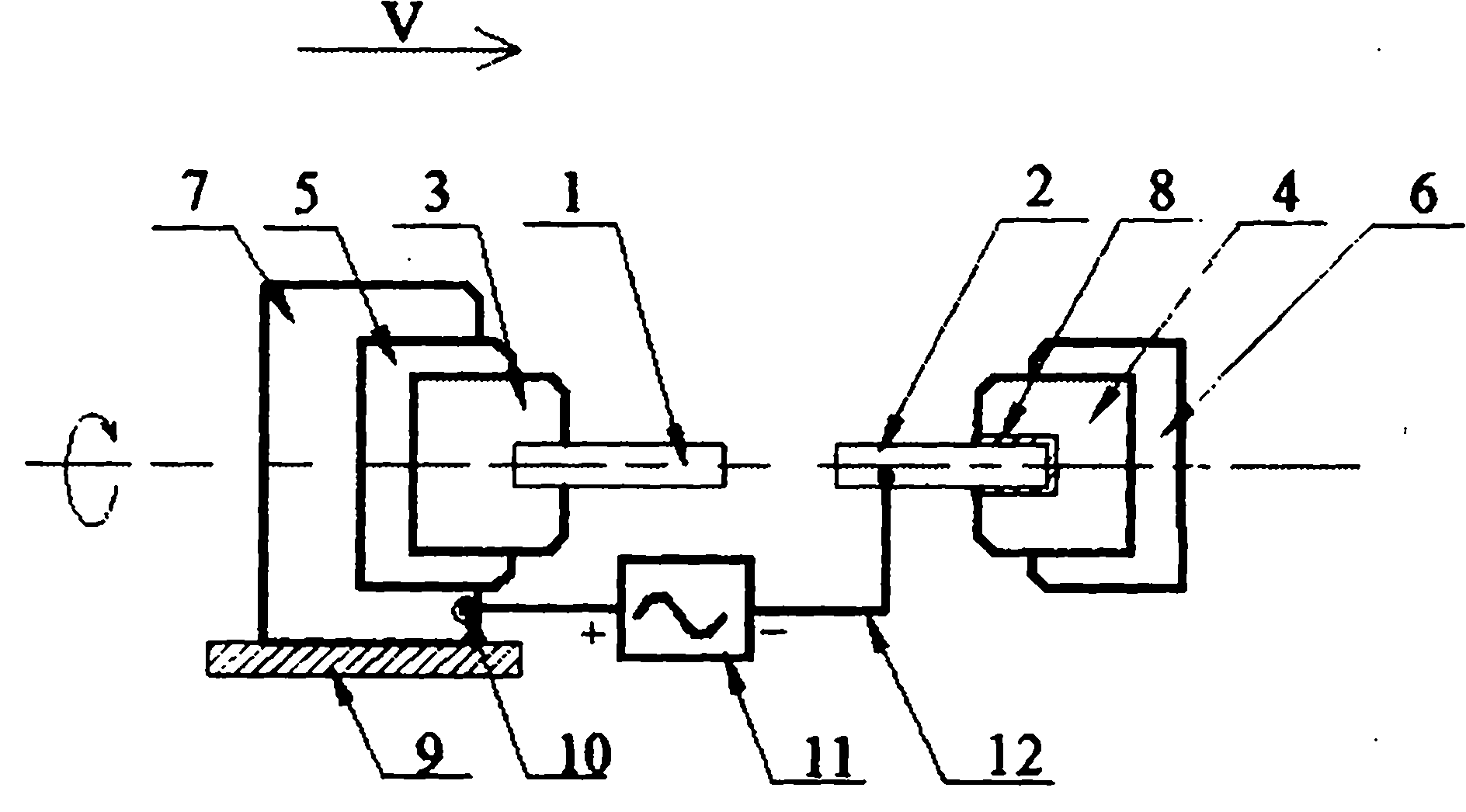

Current-carrying inertial axial friction composite welding method and equipment thereof

A hybrid welding and friction welding technology, used in welding equipment, non-electric welding equipment, resistance welding equipment, etc., can solve the problems of poor welding effect, insufficient friction heat, and unsafe use process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

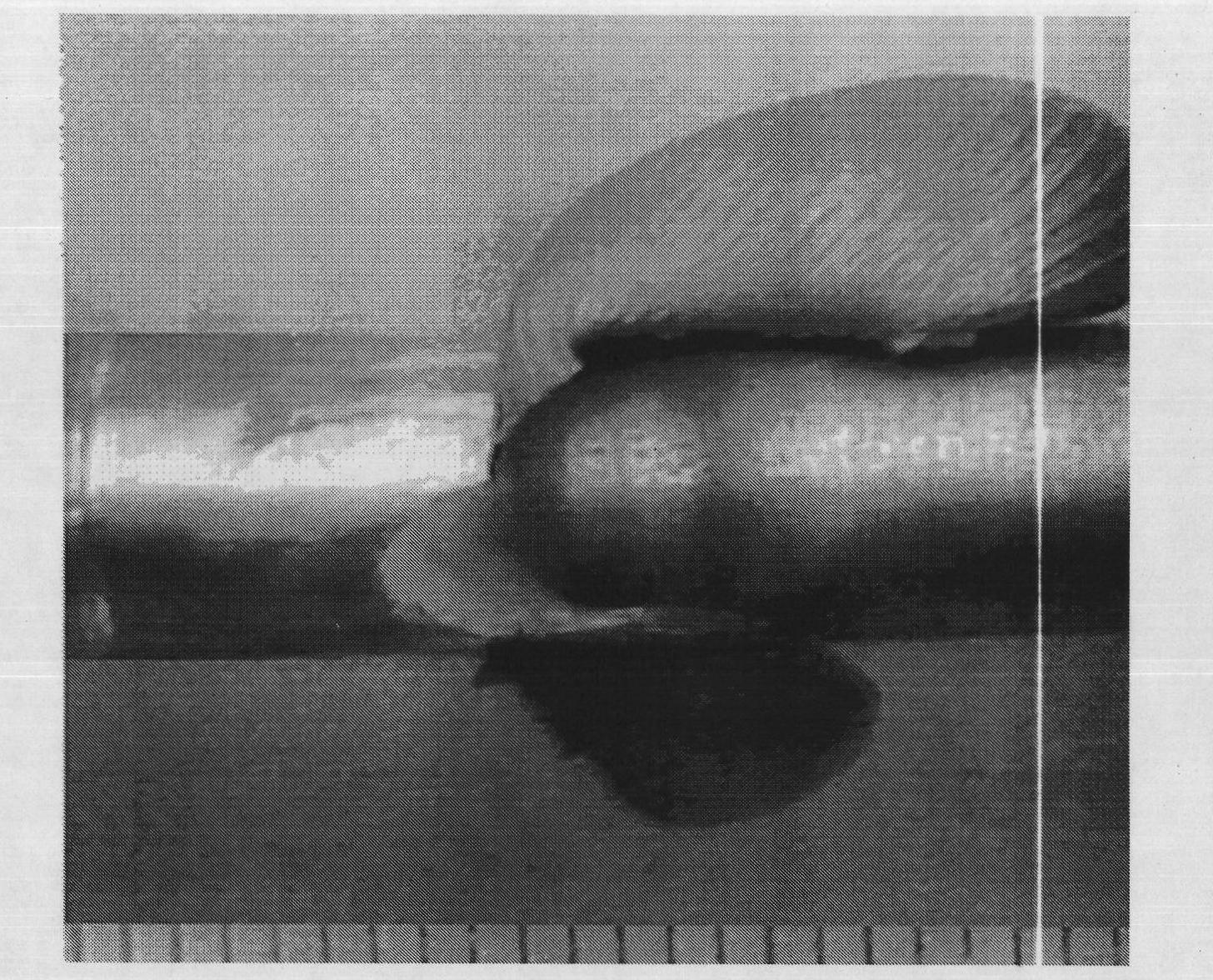

[0040] Welding dissimilar materials are K418 high-temperature alloy steel and 45CrMo steel, rod-shaped samples with a diameter of 6mm and a length of 200mm. The current-carrying inertial axial friction composite welding method and its equipment are used for welding, and the friction spindle speed is 3000-5000rpm. The friction pressure is 20-40Mpa, the upsetting pressure is 100-180Mpa, the digital inverter arc welding power supply is used as the external power supply, the external current provided is 200-500A, and the insulating sheet is insulating rubber to obtain a welded joint with good performance ,Such as figure 2 Exterior photos shown.

Embodiment 2

[0042] The welding material is 45CrMo steel, with a diameter of 4mm and a length of 300mm. The rod-shaped sample is welded by the current-carrying continuous drive axial friction composite welding method and its equipment. The friction spindle speed is 1800r / min, and the friction pressure is 20Mpa. The pressure is 100Mpa, the digital inverter resistance welding power supply is used as the external power supply, the external current is 280A, the current frequency is 50Hz, the duty cycle is 80%, the welding time is 3 minutes, the insulating sheet is insulating rubber, and the insulating block is Dry the wood to obtain a welded joint with good properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com