Intermediate frequency induction heat treatment device for steel tubes, and heat treatment method of the same

A technology of induction heat treatment and steel pipes, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., to achieve the effects of small grain size, fast heating speed, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

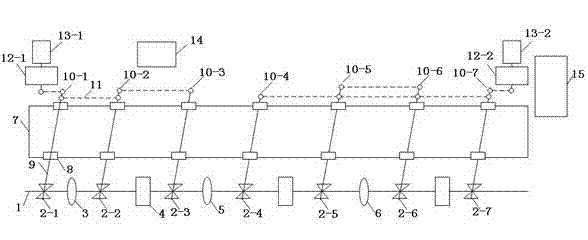

[0042] Start the motor to rotate the double-cone roller, and transport the steel pipe to the preheating furnace at a running speed of 0.5cm / s to preheat to 200°C;

[0043] Then the steel pipe enters the heating furnace and is heated to 750°C, and the temperature is measured by a portable infrared thermometer. By controlling the output frequency of the intermediate frequency induction power supply to 18kHz, the temperature error of the steel pipe in the furnace is within the range of ±10°C;

[0044] After that, the steel pipe enters the cooling box and is cooled to 20°C;

[0045] The cooled steel pipe enters the tempering furnace and is kept at 200°C;

[0046] Finally, the steel pipe enters the cooling box for water cooling.

Embodiment 2

[0048] Start the motor to rotate the double-cone roller, and send the steel pipe to the preheating furnace at a running speed of 4cm / s to preheat to 400°C;

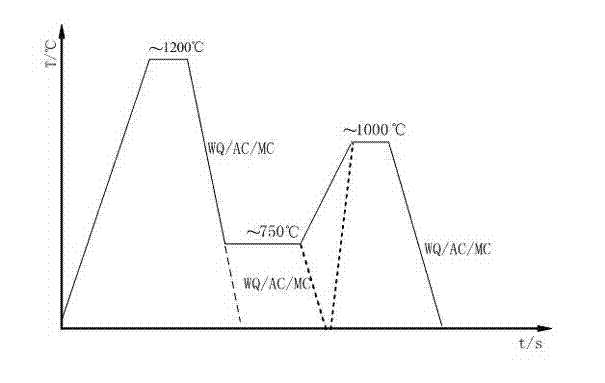

[0049] Then the steel pipe enters the heating furnace and is heated to 1200°C, using a portable infrared thermometer to measure the temperature, and controlling the output frequency of the intermediate frequency induction power supply to 30kHz, so that the temperature error of the steel pipe in the furnace is within the range of ±10°C;

[0050] The steel pipe enters the cooling box and is air-cooled to 450°C;

[0051] The cooled steel pipe is sent to the tempering furnace and kept at 600°C;

[0052] Finally, the steel pipe enters the cooling box for air cooling.

Embodiment 3

[0054] Start the motor to rotate the double-cone roller, and transport the steel pipe to the preheating furnace at a running speed of 2cm / s to preheat to 300°C;

[0055] Then the steel pipe enters the heating furnace and is heated to 1000°C, and the temperature is measured by a portable infrared thermometer. By controlling the output frequency of the intermediate frequency induction power supply to 28kHz, the temperature error of the steel pipe in the furnace is within the range of ±10°C;

[0056] The steel pipe enters the cooling box and is cooled to 300°C by water mist;

[0057] The cooled steel pipe enters the tempering furnace and is kept at 400°C;

[0058] Finally, the steel pipe enters the cooling box for water mist cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com