Pressurization trace quantity helix powder feeding equipment

A screw and powder feeding technology, applied in the directions of loading/unloading, packaging, gear transmission, etc., can solve the problems of aggravated bearing and screw shaft wear, material accumulation and unsmooth feeding, pulverized coal escaping, etc., to avoid accumulation. , Smooth powder output, ensure the effect of normal rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

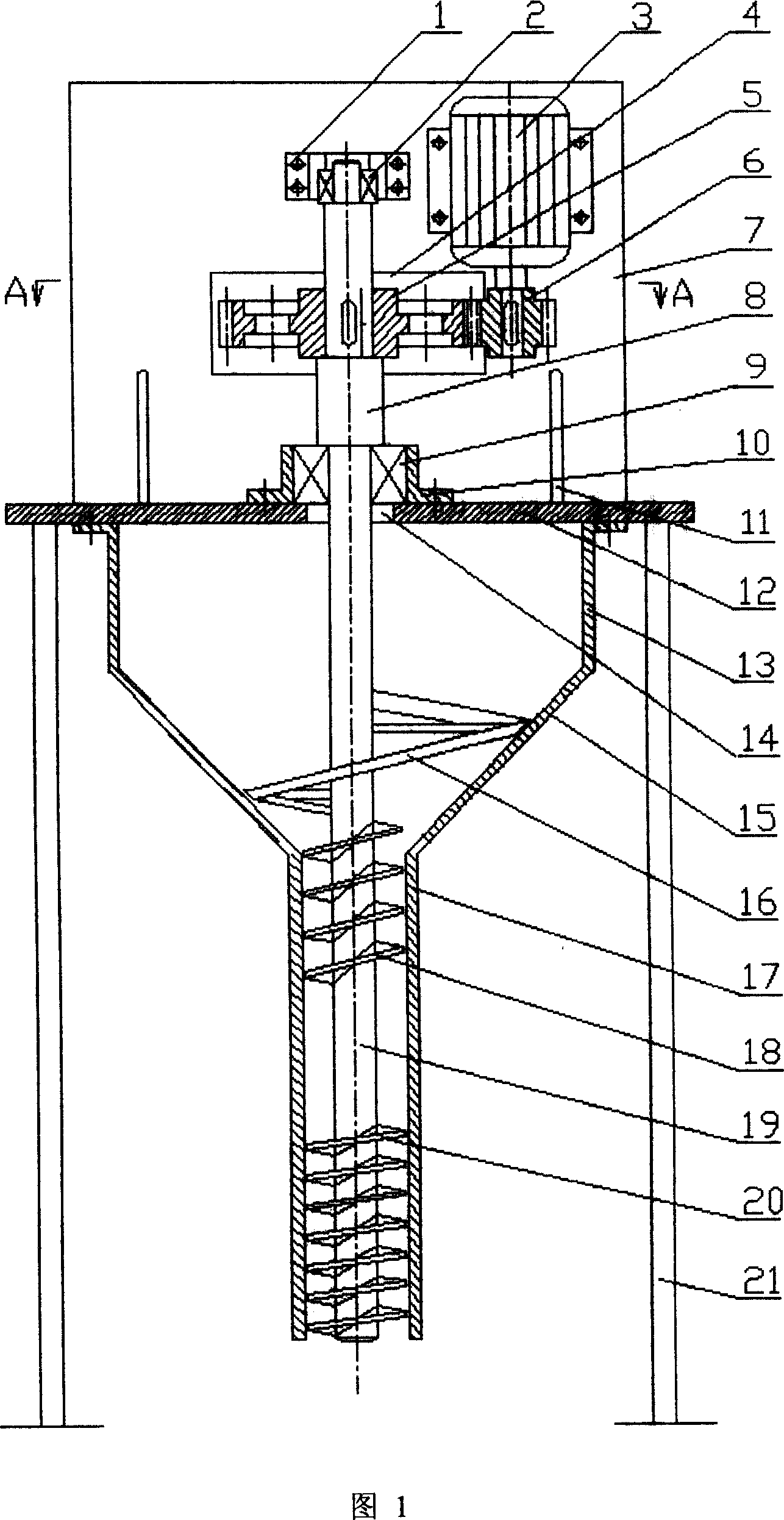

[0018] The specific implementation of the present invention using a pressurized micro-volume screw powder feeder will be further described below in conjunction with the accompanying drawings.

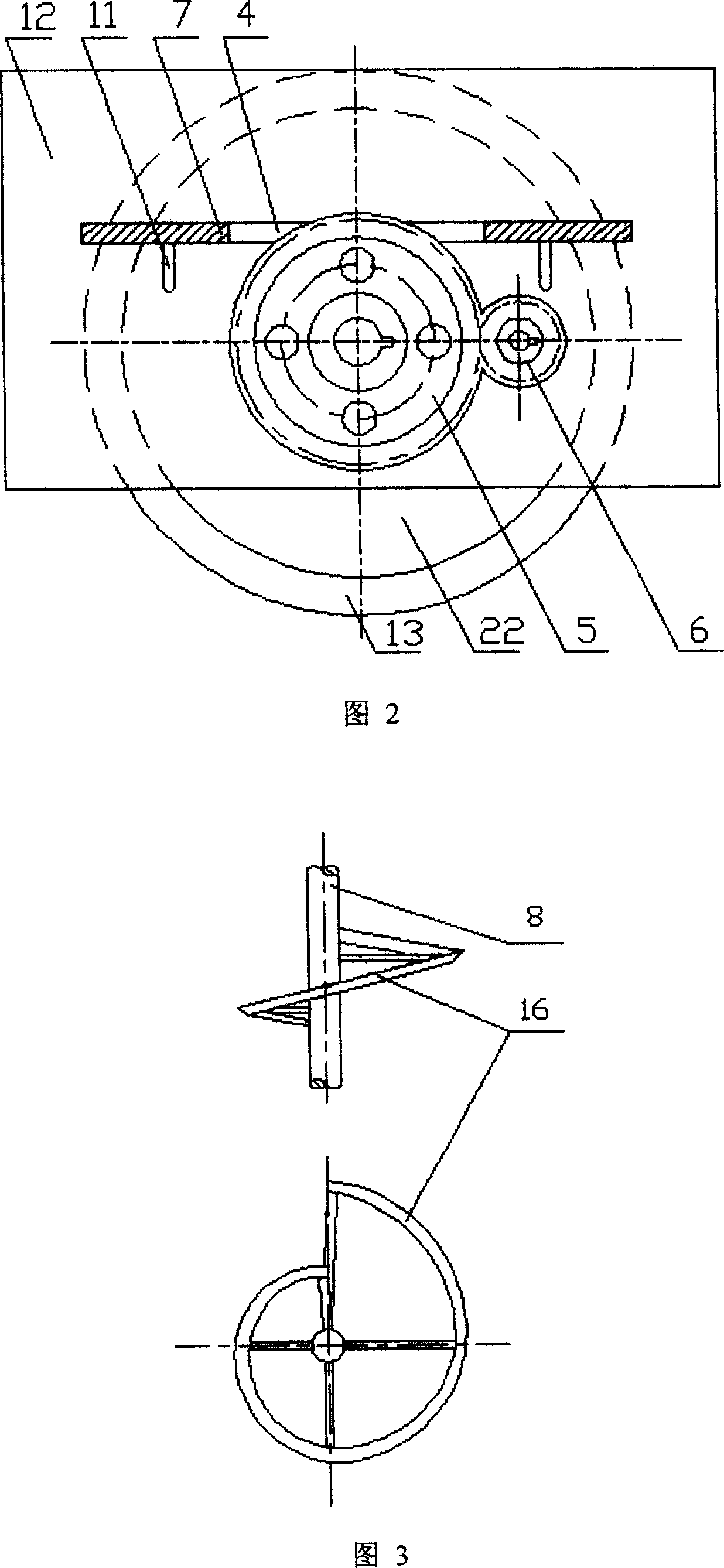

[0019] The pressurized micro screw powder feeder of this embodiment includes a motor 3, a large gear 5 and a pinion 6 meshing with each other, a screw shaft 8, an agitator 16, an upper helical blade 18 and a lower helical blade 20, a cylindrical section hopper 13 and a cone Section hopper 15, discharge pipe 17, support table 12. The whole machine is placed vertically.

[0020] Fig. 1 shows a schematic structural view of a pressurized micro-volume spiral powder feeder, Fig. 2 is a sectional view of A-A of Fig. 1, and Fig. 3 is a schematic structural view of a gradually expanding ribbon agitator 16.

[0021] The vertical plate 7 is vertically fixed on the support table 12, and the two ends of the two inclined support rods 11 are respectively welded on the vertical plate 7 and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com