Compound optical reflecting film and preparation method thereof

一种光学反射、反射膜的技术,应用在光学、光学元件、光学元件等方向,能够解决反射率低、易变形等问题,达到提高反射率、易于操作、优异尺寸稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a composite optical reflective film includes the following steps:

[0033] (1) After crystallization and drying, the polyester base material, white masterbatch and foaming masterbatch are melted and plasticized in a single-screw extruder or twin-screw extruder; after passing through a melt pipeline filter, The hanger-type long slot die is cast to the quench roll, and the polyester melt is quickly cooled to below its glass transition temperature on the quench roll that rotates at a constant speed to form a glassy cast sheet with uniform thickness;

[0034] (2) The cast sheet prepared in step (1) is stretched longitudinally with a longitudinal stretcher under heating, with a stretch ratio of 3-4; then it enters the horizontal stretch oven to stretch it in the width direction. Stretching, the ratio is consistent with the longitudinal stretching ratio;

[0035] (3) The stretched film prepared in step (2) is subjected to corona treatment during drawing to ac...

Embodiment 1

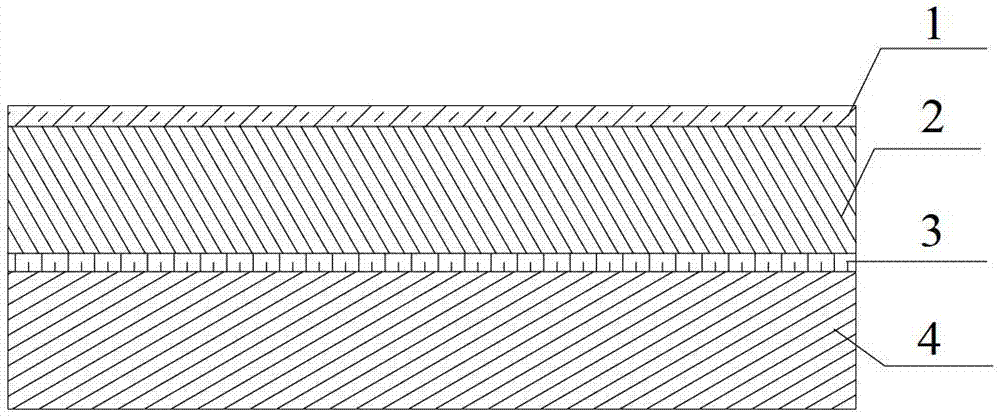

[0044] A composite optical reflective film, comprising a bottom transparent film, one side of the bottom transparent film is provided with a white reflective film, one side of the white reflective film is coated with an anti-ultraviolet high-reflection coating, and the other side is glued The mixture is compounded with the bottom transparent film, and the adhesive forms an adhesive layer.

[0045] The material of the bottom transparent diaphragm is high-viscosity PET (that is, PET high-viscosity material), with a thickness of 120μm, and the thickness of the reflective diaphragm is 100μm; the adhesive is a high-orthogonal thermosetting phenolic resin, inorganic zirconium borosilicate Powder (zirconium powder, boron powder, silicon powder mixed according to the weight ratio of 3:1:1) and ethanol solvent compound, the weight ratio is 100:120:60; the anti-ultraviolet high reflection coating is silane cross-linked The compound of polyolefin, titanium dioxide and zinc oxide, the conten...

Embodiment 2

[0047] A composite optical reflective film, comprising a bottom transparent film, one side of the bottom transparent film is provided with a white reflective film, one side of the white reflective film is coated with an anti-ultraviolet high-reflection coating, and the other side is glued The mixture is compounded with the bottom transparent film, and the adhesive forms an adhesive layer.

[0048] The material of the bottom transparent diaphragm is PC with a thickness of 170 μm, and the thickness of the reflective diaphragm is 120 μm; the adhesive is a high-position thermosetting phenolic resin, inorganic zirconium borosilicate powder (zirconium powder, boron powder, silicon The powder is mixed according to the weight ratio of 3:1:1) and the compound of ethyl acetate solvent, the weight ratio of which is 100:80:40; the anti-ultraviolet high-reflection coating is silane crosslinked polyolefin with titanium dioxide and zinc oxide The content of titanium dioxide and zinc oxide is 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com