Three-dimensional forming equipment capable of preparing soft-hard compound polyurethane product

A three-dimensional molding, soft and hard composite technology, applied in the direction of additive processing, can solve the problems of difficult to meet the use requirements, poor bonding performance, obvious interface, etc., and achieve the effect of reducing the risk of operating equipment, protecting safety and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

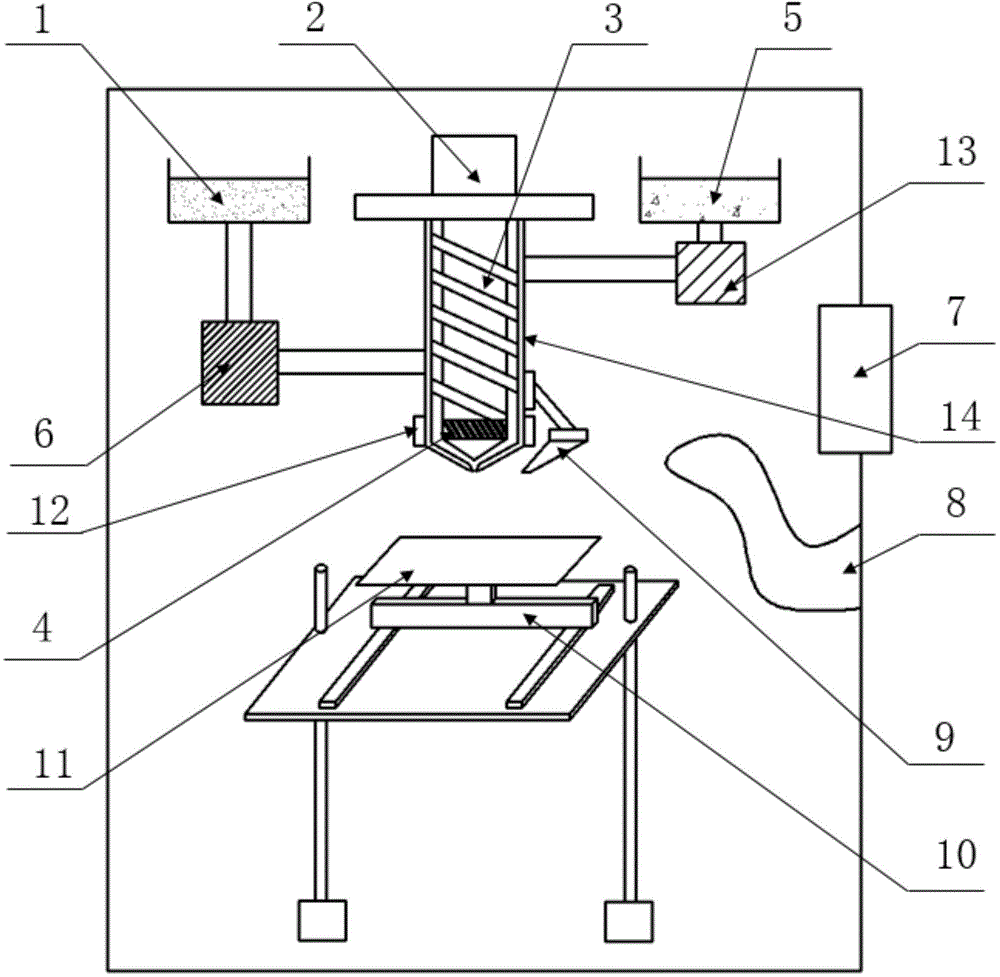

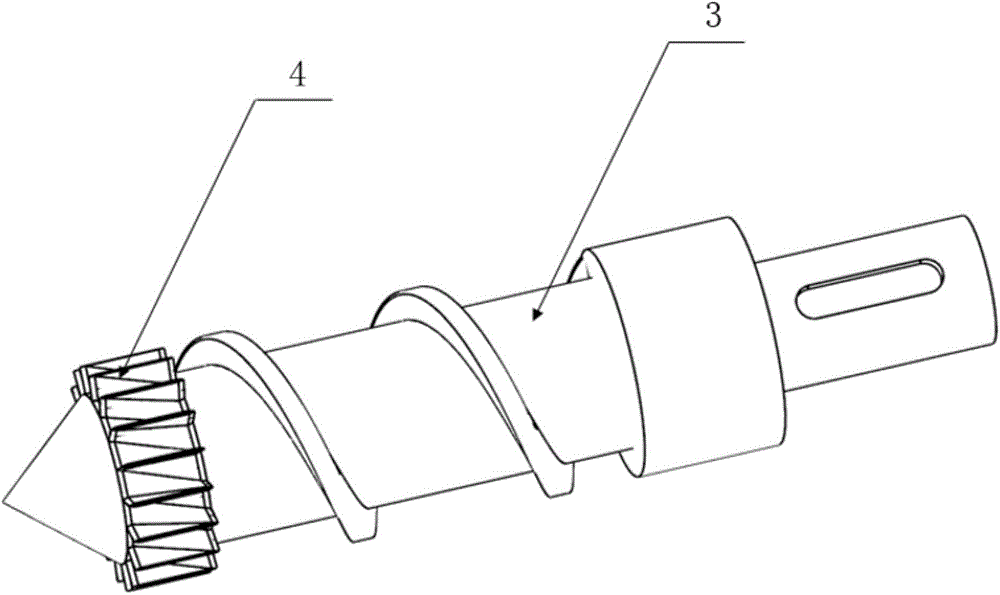

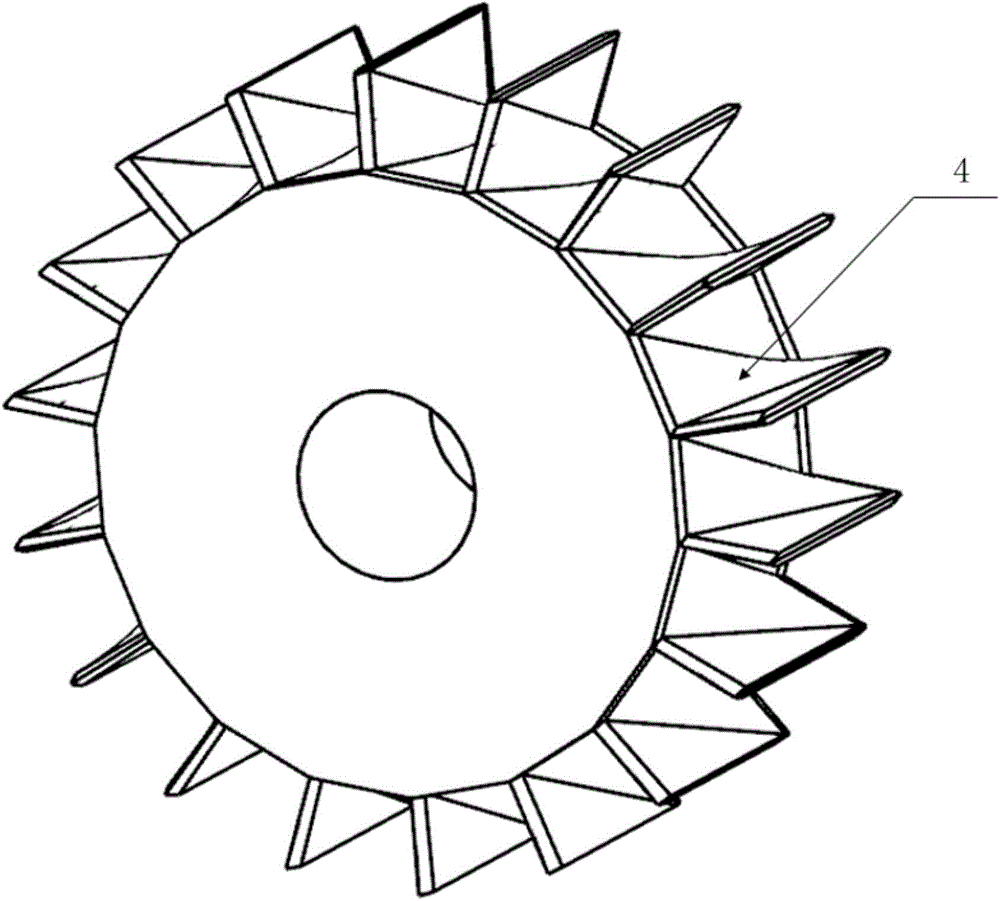

[0014] The invention provides a three-dimensional molding equipment for preparing soft and hard composite polyurethane products, which is composed of a screw extrusion unit, a material conveying unit, a three-dimensional molding platform unit and a safety equipment unit; wherein the screw extrusion unit includes a heat insulation sleeve 1, a step Inlet motor 2, screw conveying section 3, screw stirring section 4, fan 9, resistance heater 12; wherein the material conveying unit includes variable pumps 6 and 13, polyol raw material 1, isocyanate mixture raw material 15; wherein the three-dimensional forming platform unit includes balls The three-dimensional moving part 10 of the screw pair and the three-dimensional forming platform 11; wherein the safety equipment unit includes an exhaust fan 7 and a rubber glove 8.

[0015] In a three-dimensional molding equipment capable of preparing soft and hard composite polyurethane products of the present invention, the variable storage pumps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com