Drying method of high moisture material and dryer set thereof

A drying unit and drying method technology, applied in the direction of dryer combination, dryer, drying solid materials, etc., can solve the problems of energy waste and materials not getting out of the dryer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

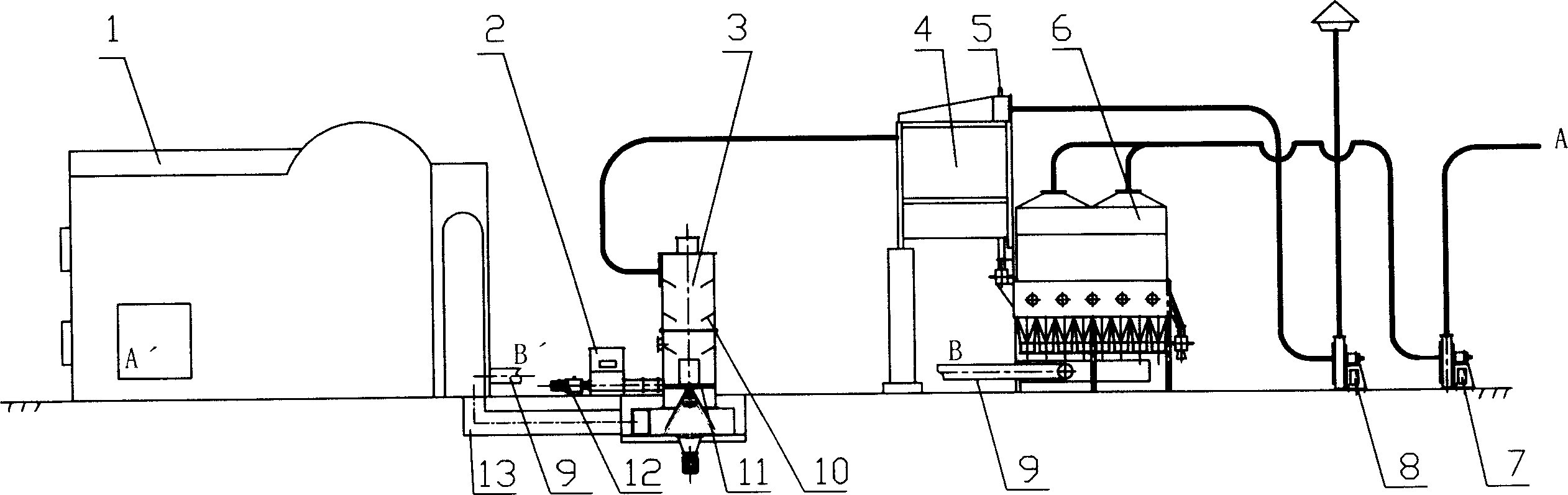

[0016] The drying method of the high-humidity material involved in the present invention is to quickly dry the high-humidity material in a rotary airflow dryer to reduce its moisture content to 25% to 35%, and then dry the material particles leaving the airflow dryer with the airflow. The gas is separated, and then the material enters the fluidized bed dryer to continue drying to reduce the moisture content to below 17%.

[0017] As shown in the accompanying drawings, the high-humidity material drying unit applying the above-mentioned drying method includes a hot blast stove 1, a rotary airflow dryer 3, a fluidized bed dryer 6 and a feeder 2 driven by a speed-regulating motor 12. It also includes Cyclone separator 4, induced draft fan 8 and blower 7. The air inlet of the rotary airflow dryer 3 is connected to the outlet of the flue gas pipe 13 of the hot blast stove, the outlet of the rotary airflow dryer 3 is connected to the inlet of the cyclone separator 4, and the outlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com