Phenolic resin activated carbon microballon and rapid preparation method thereof

A kind of technology of activated carbon microspheres and phenolic resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

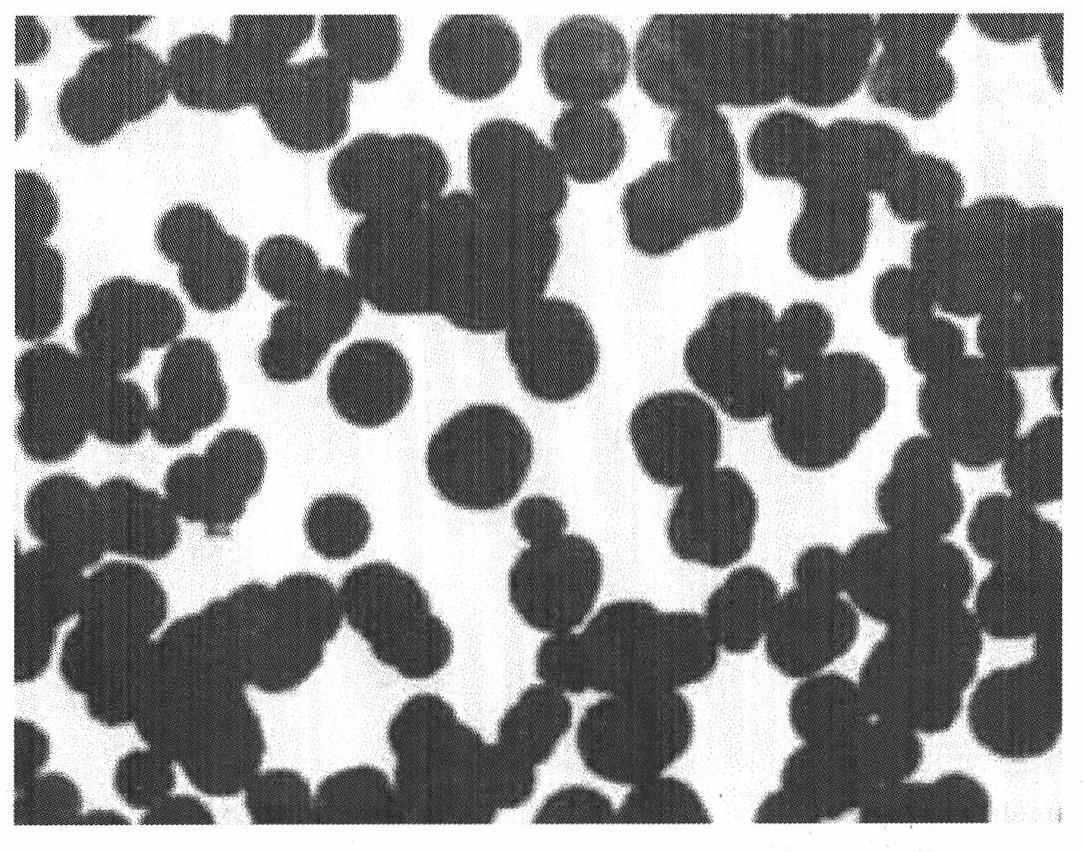

Image

Examples

Embodiment 1

[0033] (1) Preparation of resole phenolic resin: phenol: formaldehyde: NaOH molar ratio = 1: 2.2: 0.5, first add phenol in a reaction kettle with a temperature of 45 ° C, and add 40% wt of NaOH solution, fully stir for 10 min, add Formaldehyde, control the temperature at 75-80°C to react for 40 minutes, raise the temperature to 95°C, keep the heat for 2 hours, cool to below 35°C and discharge the material to obtain the aqueous solution of resole phenolic resin. The weight percentage concentration of resole phenolic resin is 45%, and the viscosity is: 20°C, 15-100s when coating -4 cups.

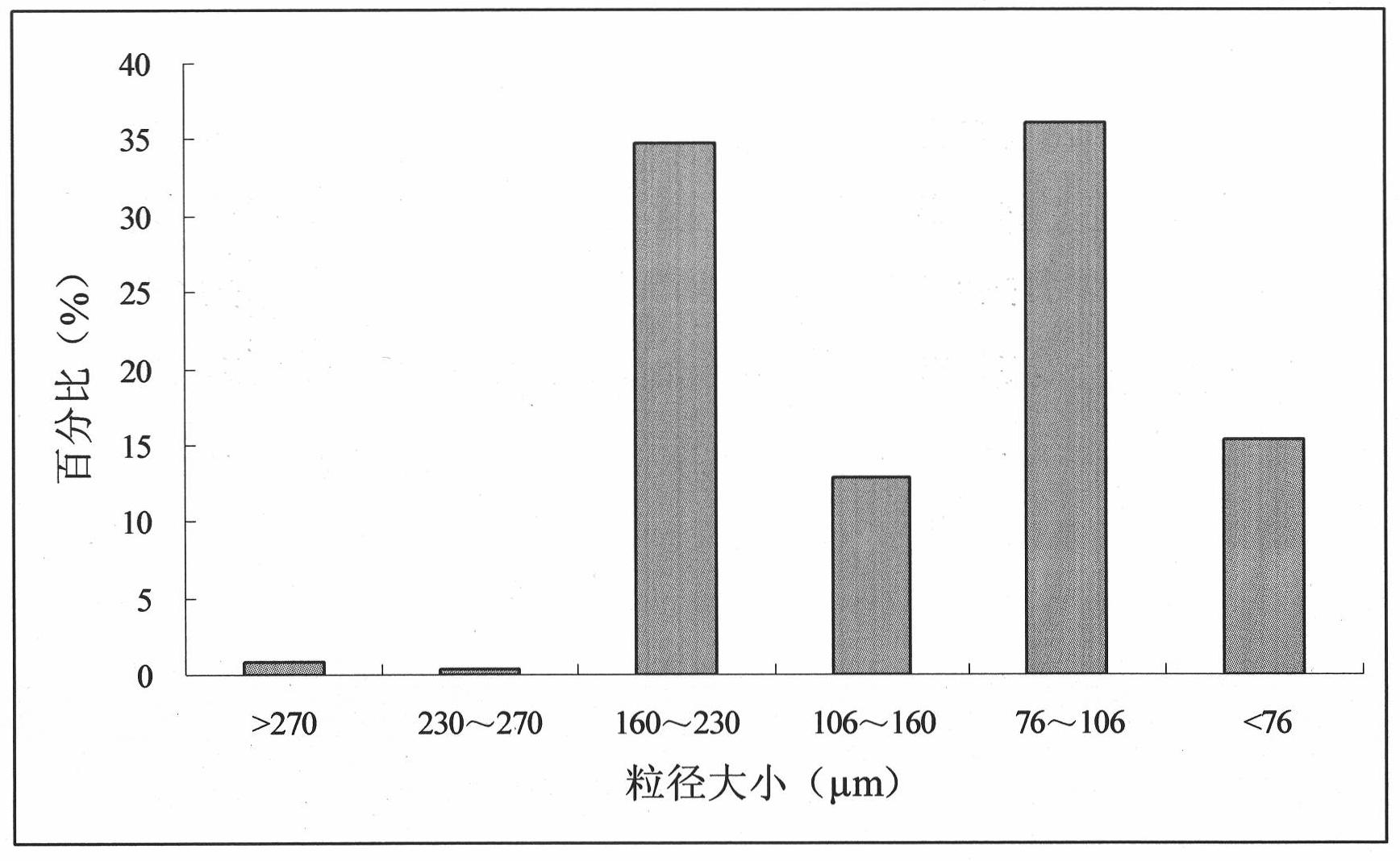

[0034] (2) Spray drying of resole phenolic resin: Spray drying is carried out under the conditions of inlet temperature 225±5℃, outlet temperature 90℃, feed rate 50mL / min, spray disc rotation speed 12000r / min, and the particle size is 50-350um , Brown phenolic resin microspheres with a volatile content of 5.2%.

[0035] (3) Thermal curing of microspheres: curing the resin microspheres obtaine...

Embodiment 2

[0038] (1) Preparation of resole phenolic resin: phenol: formaldehyde: NaOH molar ratio = 1: 2.2: 0.8, first add phenol in a reaction kettle with a temperature of 45 ° C, and add 40% wt of NaOH solution, fully stir for 10 min, add Formaldehyde, control the temperature at 75-80°C to react for 40 minutes, raise the temperature to 95°C, keep the heat for 2.5 hours, cool to below 35°C and discharge the material to obtain an aqueous solution of resole phenolic resin. The weight percentage concentration of resole phenolic resin is 65%, and the viscosity is : 20°C, 15-100s when coating -4 cups.

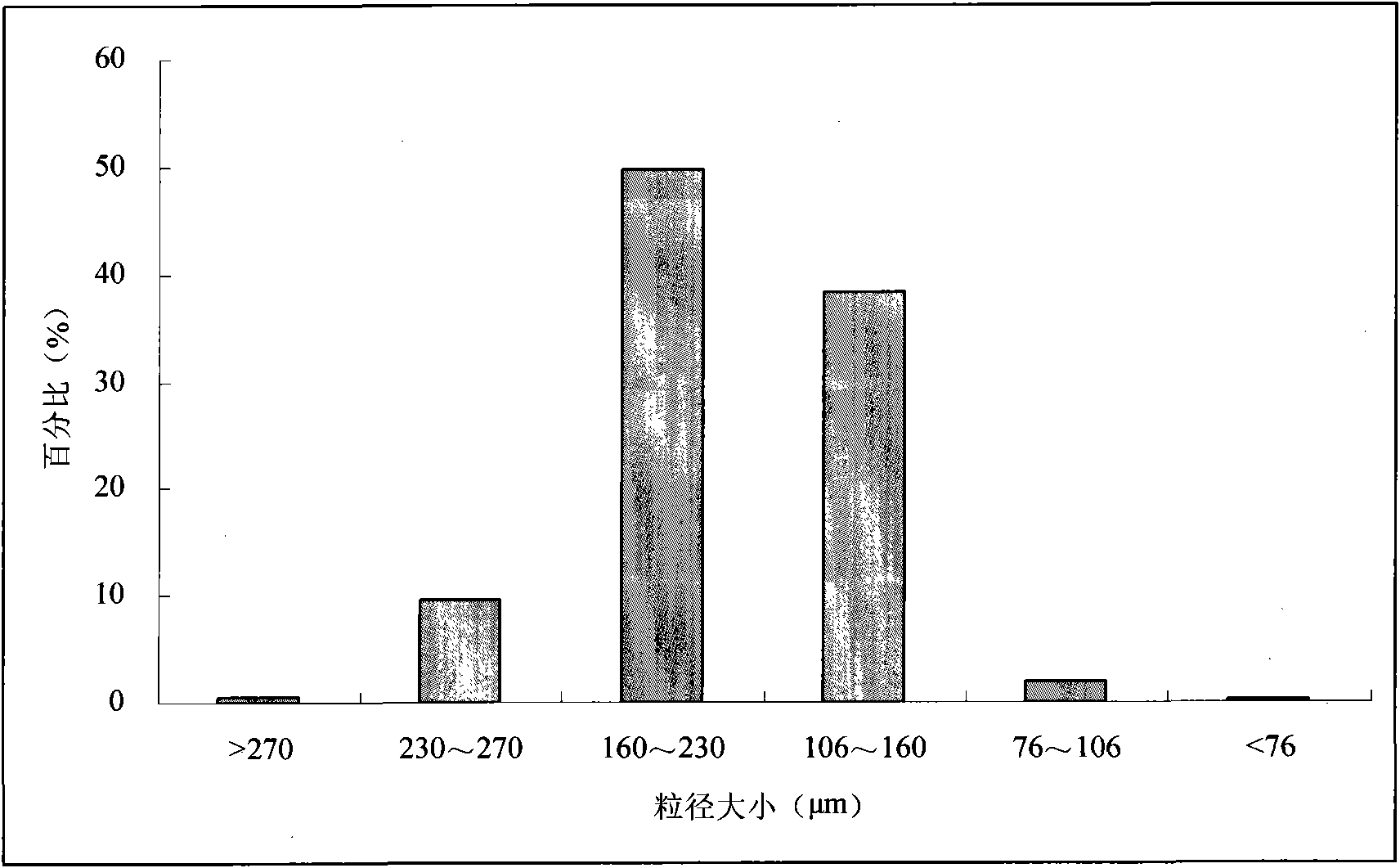

[0039] (2) Spray drying of resole phenolic resin: spray drying under the conditions of inlet temperature 235±5°C, outlet temperature 90±2°C, feed rate 50mL / min, spray disc speed 10000r / min, and the particle size is 80 ~350μm brown phenolic resin microspheres with a volatile content of 3.2%.

[0040] (3) Thermal curing of microspheres: curing the resin microspheres obtained in step (2) at 20...

Embodiment 3

[0043] (1) Preparation of resole phenolic resin: phenol: formaldehyde: KOH molar ratio = 1: 2.2: 0.6, first add phenol in a reaction kettle with a temperature of 45 ° C, and add 40% KOH solution, stir for 10 minutes, add formaldehyde , Control the temperature at 75-80°C to react for 40 minutes, raise the temperature to 95°C, keep the heat for 2 hours, cool to below 35°C and discharge the material, and then the aqueous solution of resole phenolic resin is obtained. The weight percentage concentration of resole phenolic resin is 90%, viscosity: 20 ℃, 15-100s when coating -4 cups.

[0044] (2) Fluidized bed drying of resole phenolic resin: drying under the conditions of bed temperature 225±5°C, fluidization gas velocity 0.5m / s, and spray feed rate 50mL / min, to obtain a particle size of 70-350um , Brown phenolic resin microspheres with a volatile content of 5.8 wt%.

[0045] (3) Thermal curing of microspheres: curing the resin microspheres obtained in step (2) at 200° C. for 1 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Adsorption value of methylene blue | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com