Method for producing fresh-keeping instant rice

A production method and rice technology, which are applied in the fields of food preservation, food preparation, food science, etc., can solve the problems of starch aging, affecting product quality and shelf life, etc., and achieve good taste, solve the effect of reducing taste and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

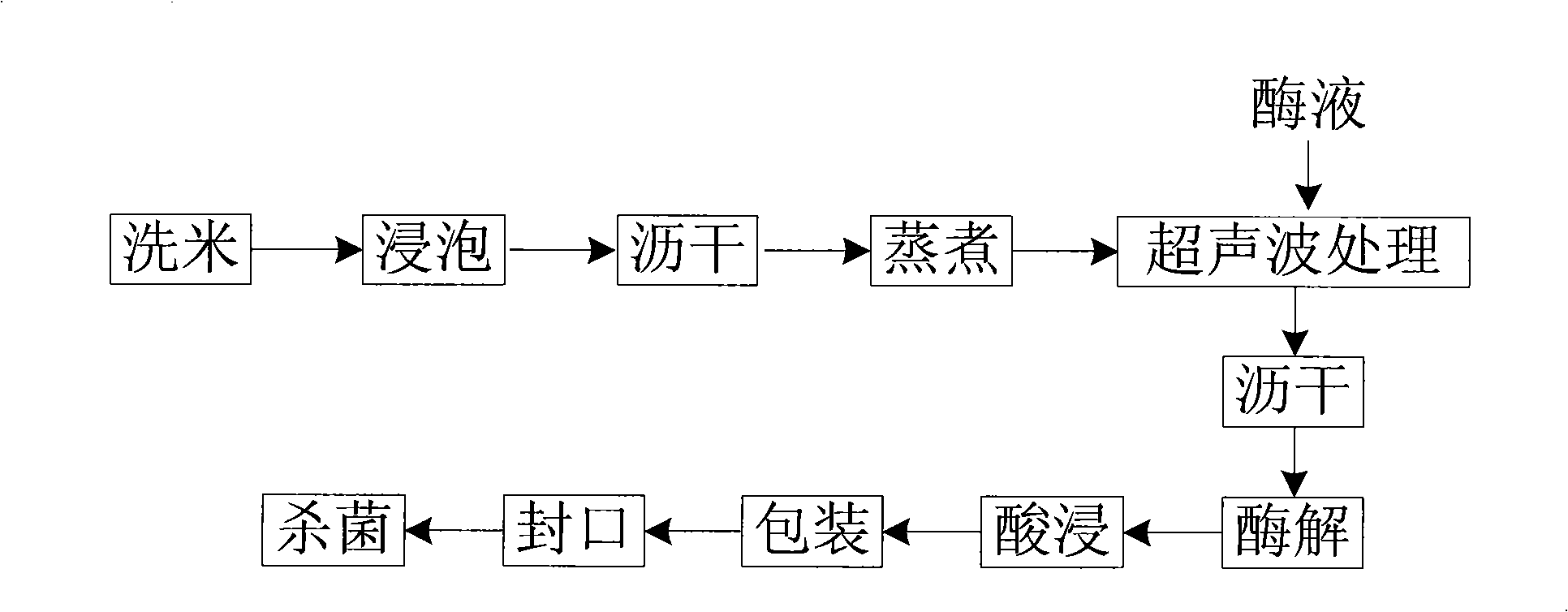

Method used

Image

Examples

Embodiment 1

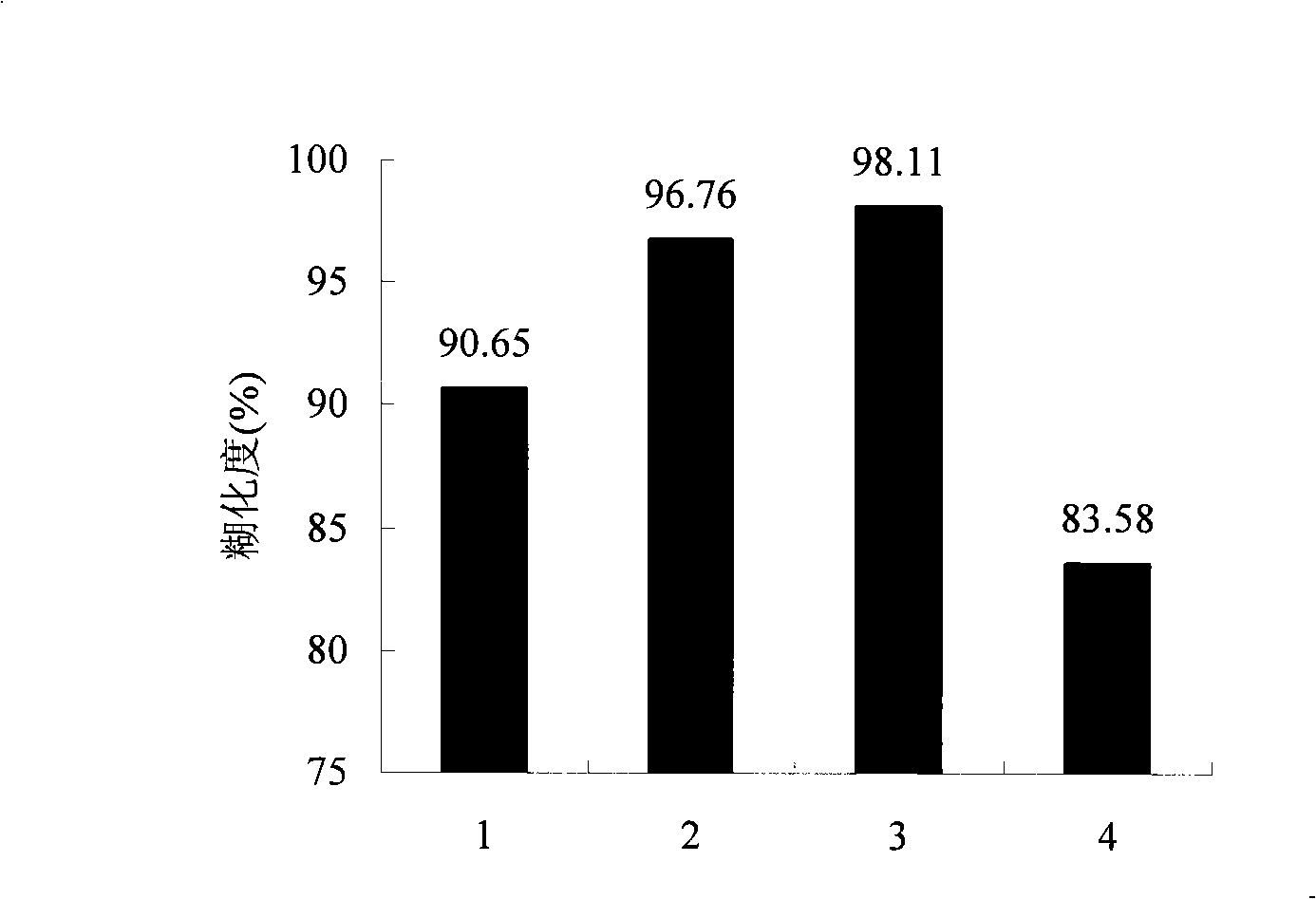

[0033] Example 1: According to the production process of fresh-keeping instant rice in the instructions, take 500 g of pre-cooked rice, add 1000 mL of 200 mg / L α-amylase and xylanase mixed enzyme, β-amylase and xylan respectively Enzyme mixed enzyme, maltose amylase and xylanase mixed enzyme (mass ratio of amylase to xylanase: 9:1) aqueous solution, soaked for 20 minutes, drained, and enzymatically hydrolyzed at 55°C for 1 hour. After the samples were prepared, they were refrigerated at 4°C for 14 days and then measured for their degree of gelatinization. The higher the degree of gelatinization, the smaller the degree of aging. For specific results, see figure 2

Embodiment 2

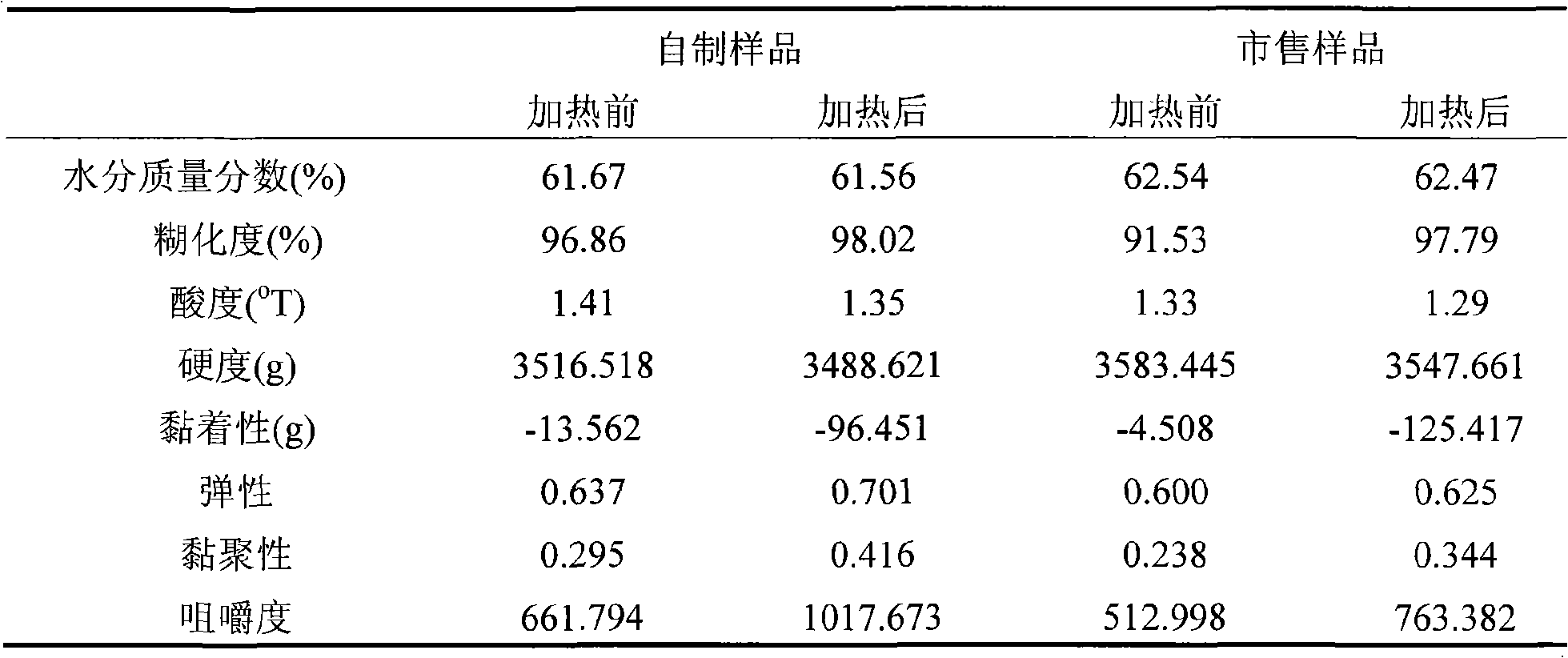

[0034] Embodiment 2: according to the production process of fresh-keeping instant rice in the instruction manual, get pre-cooked rice 500g, add 1000mL 50mg / L maltose amylase and xylanase mixed enzyme (mass ratio of maltose amylase and xylanase 9:1), ultrasonic treatment, ultrasonic power 400w, action time 25min, drained, enzymatic hydrolysis for 30, 60, 90 and 120min respectively, after the samples were prepared, they were refrigerated at 4°C for 21 days to measure their gelatinization degree and Texture, the specific results are shown in Table 2

[0035] Table 2 Effect of enzymatic hydrolysis time on gelatinization degree and texture of fresh-keeping instant rice

[0036]

Embodiment 3

[0037]Embodiment 3: according to the production process of fresh-keeping ready-to-eat rice in the instruction manual, get pre-cooked rice 500g, add 1000mL 50mg / L of maltogenic amylase and xylanase mixed enzyme (mass ratio of maltogenic amylase and xylanase 9:1), ultrasonic treatment was carried out, the ultrasonic power was 200w, 400w, 600w, 800w respectively, the action time was 25min, drained, and enzymolysis was carried out for 60min. and texture, the specific results are shown in Table 3

[0038] Table 3 Effect of ultrasonic power on gelatinization degree and texture of fresh-keeping instant rice

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com