Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

427results about How to "Avoid large quantities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

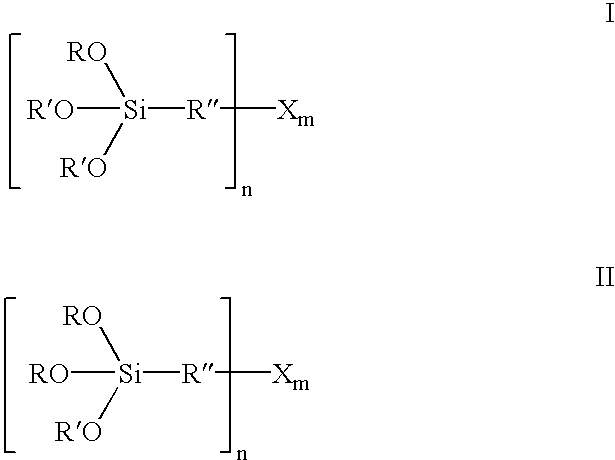

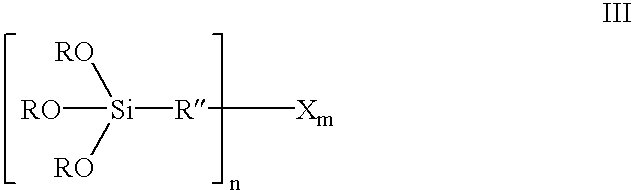

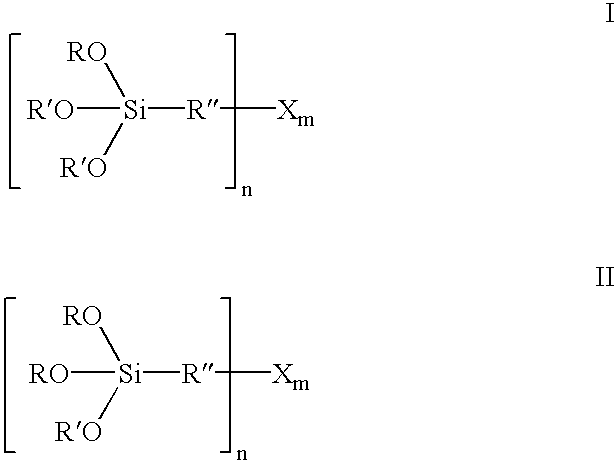

Organosilicon compounds

InactiveUS6849754B2Improve bindingAvoid large quantitiesSilicon organic compoundsOrganic chemistry methodsAlcoholSilanes

Organosilicon compounds of the general formula I and / or II are produced by reacting silanes of the general formula III with alcohols of the general formula R′—OH, with elimination of R—OH, wherein R—OH may be continuously separated from the reaction mixture by distillation. The organosilicon compounds may be used in rubber mixtures. Compounds, such as rubbers, produced using such organosilicon compounds.

Owner:EVONIK DEGUSSA GMBH

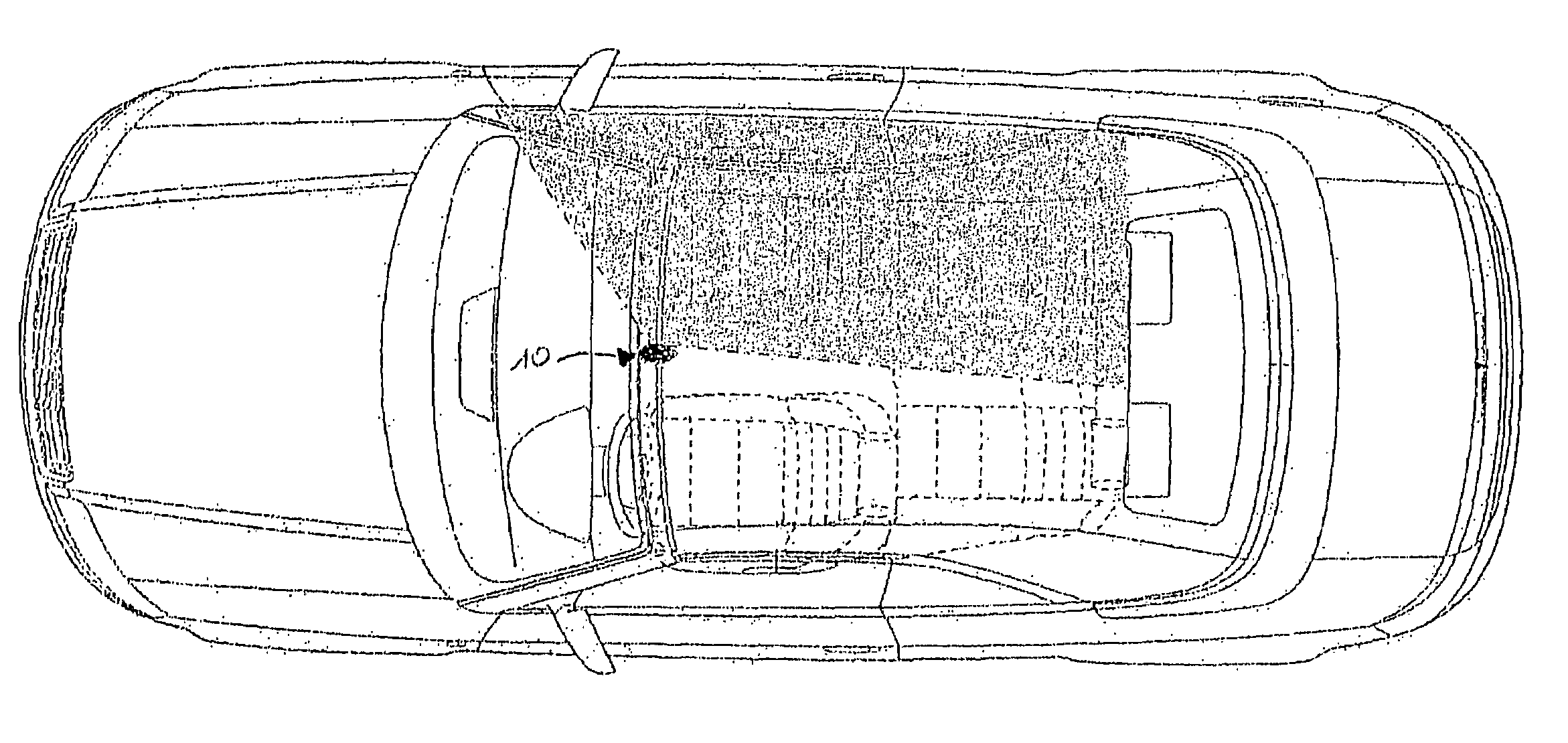

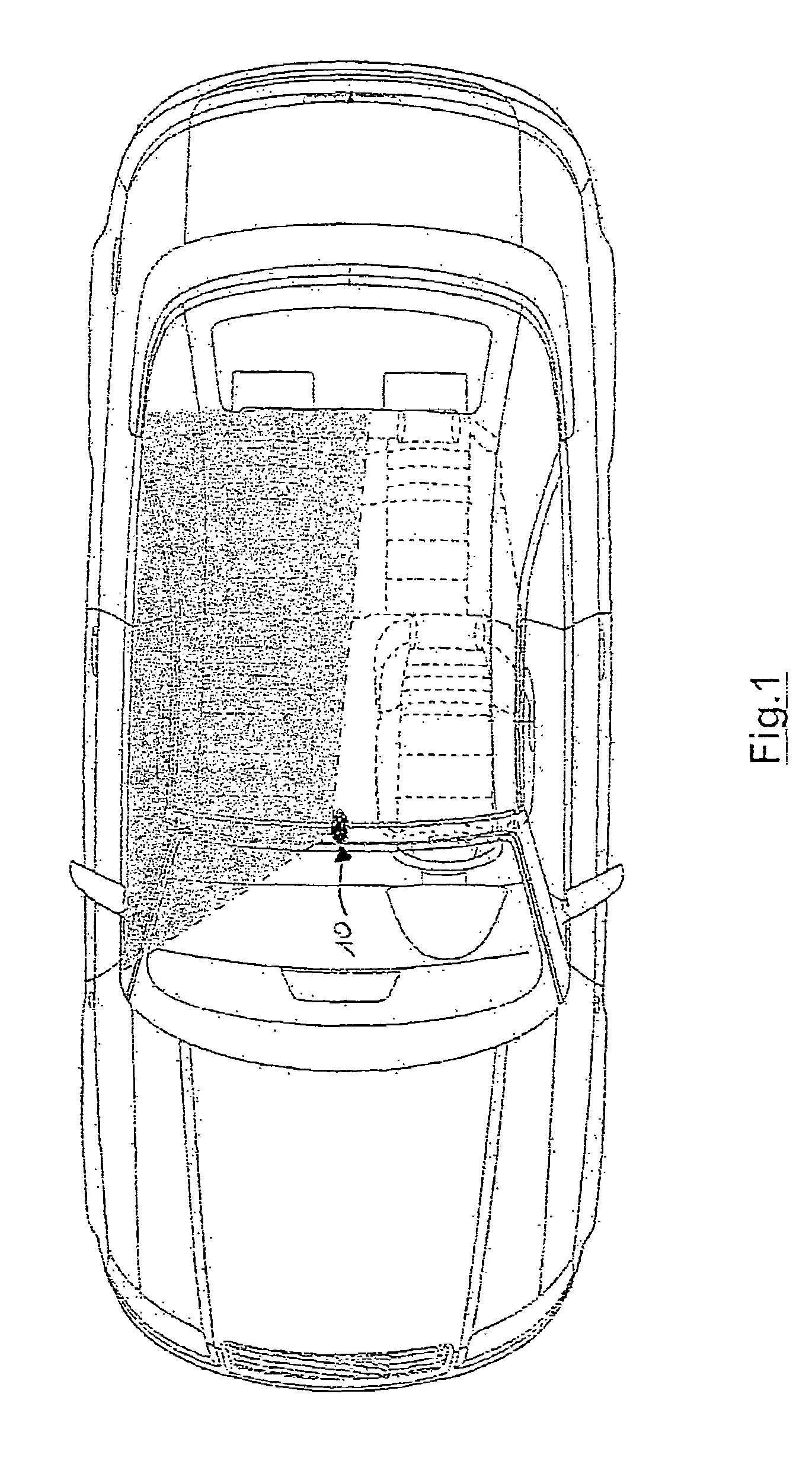

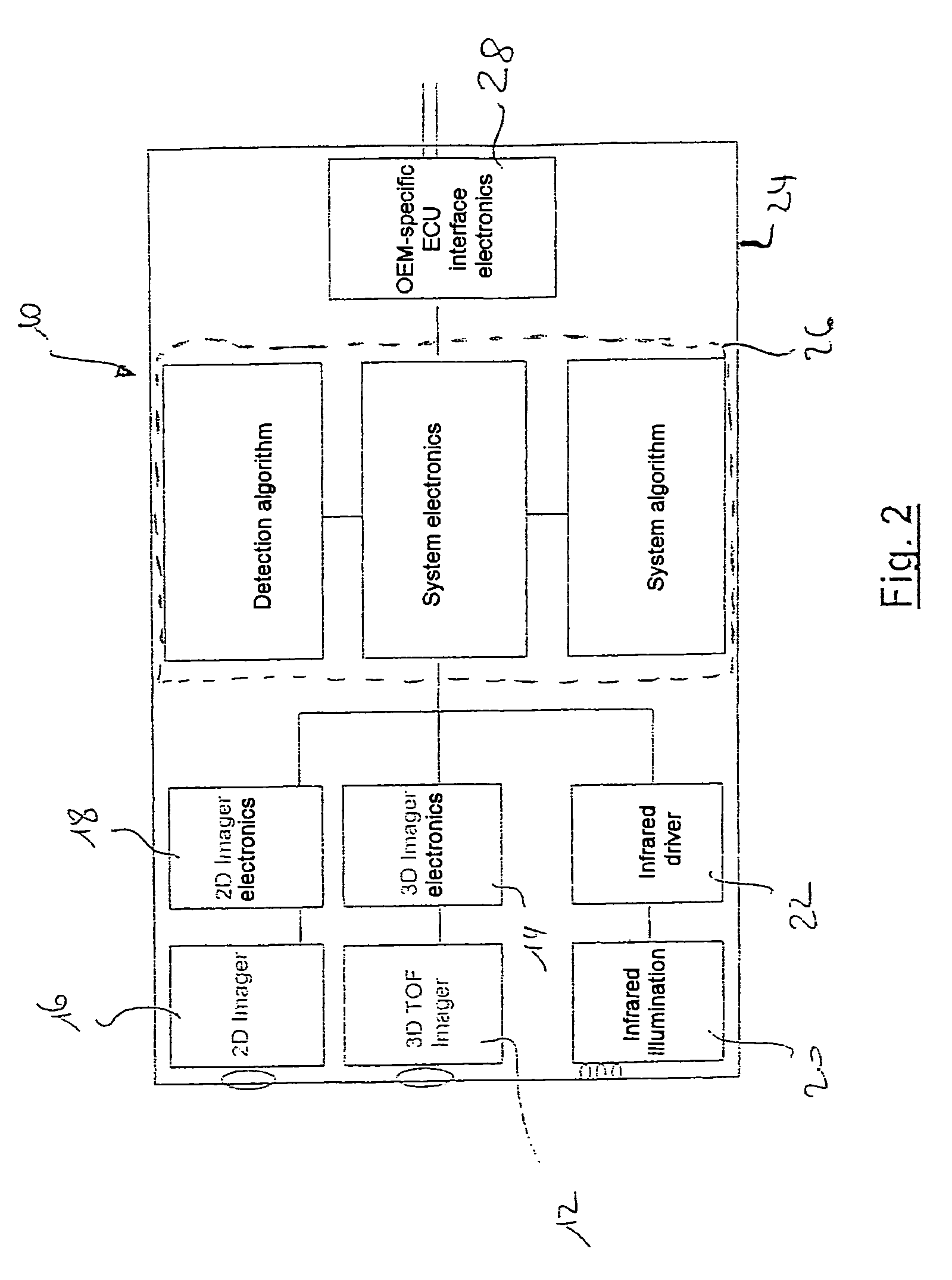

Safety device for a vehicle

ActiveUS7607509B2Low imageObject detectionBelt control systemsPedestrian/occupant safety arrangement3d cameraObject detection

Owner:IEE INT ELECTRONICS & ENG SA

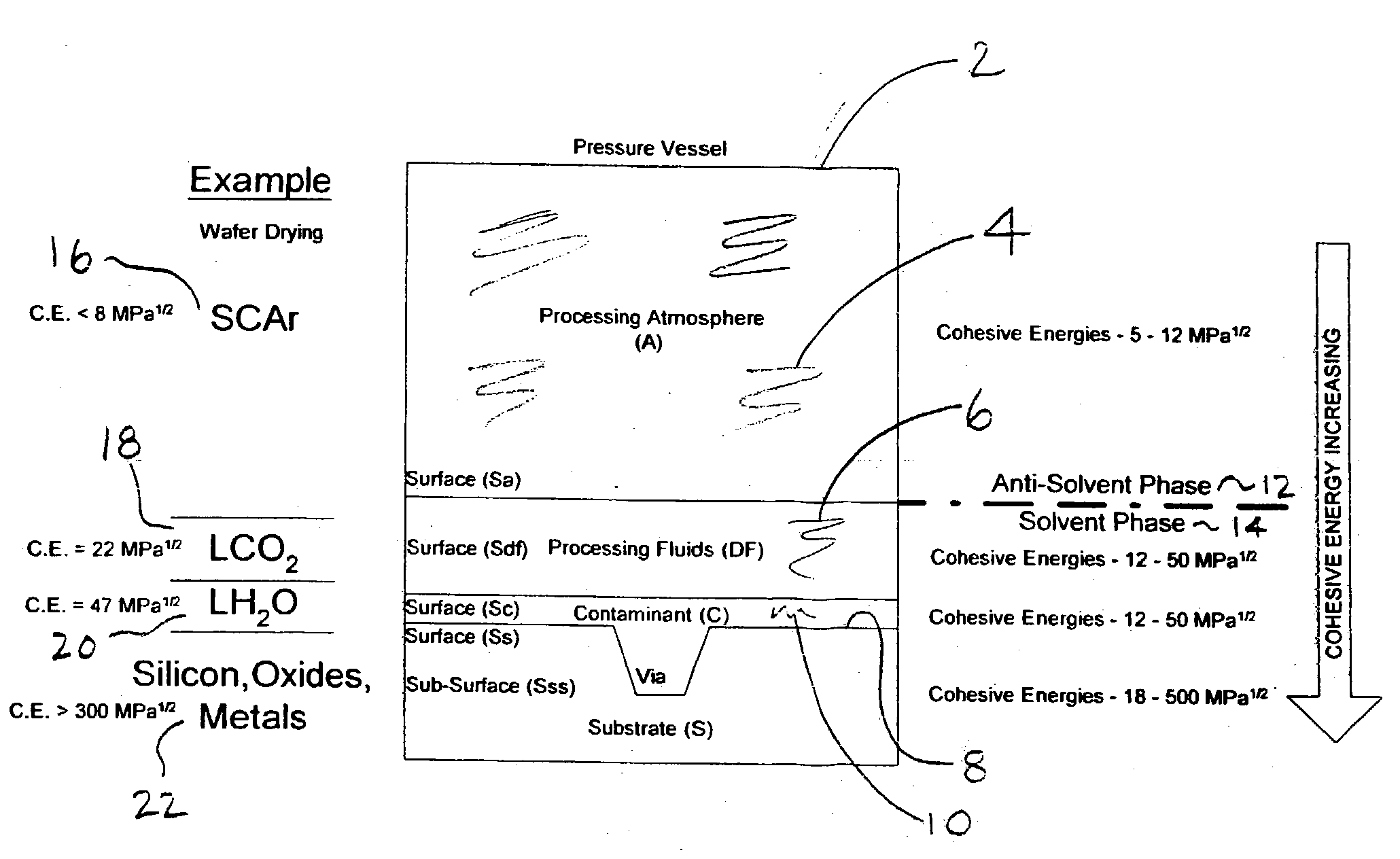

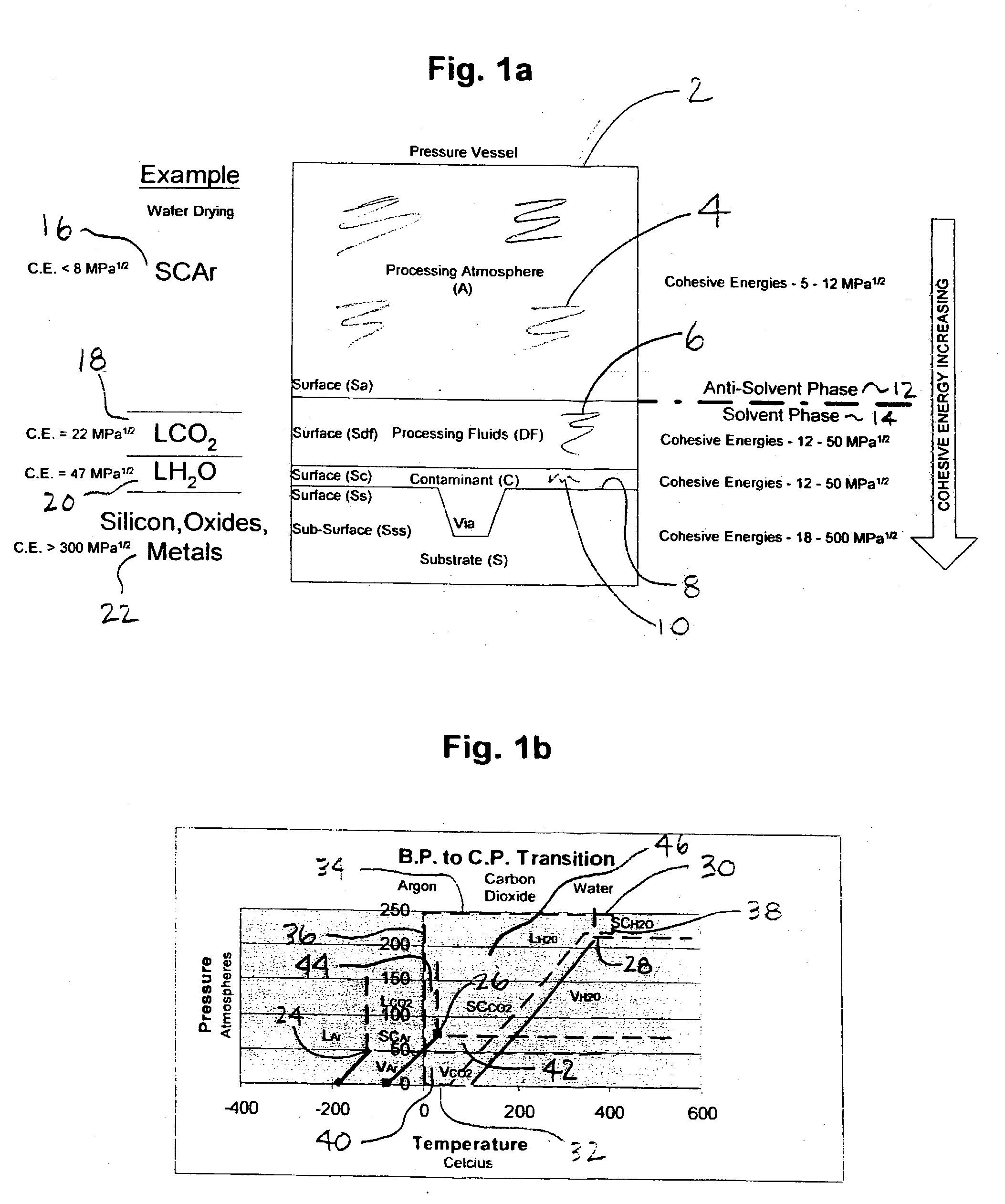

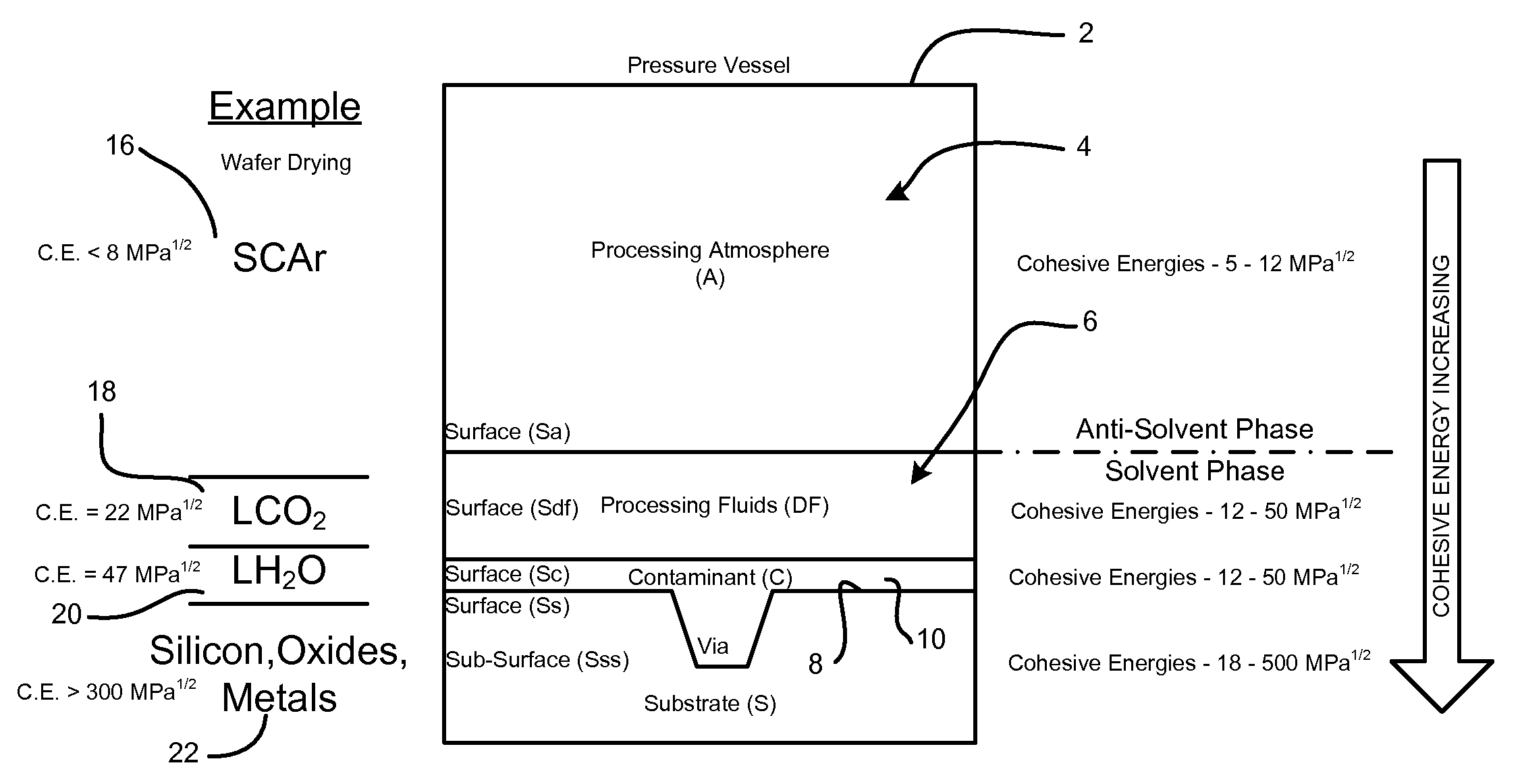

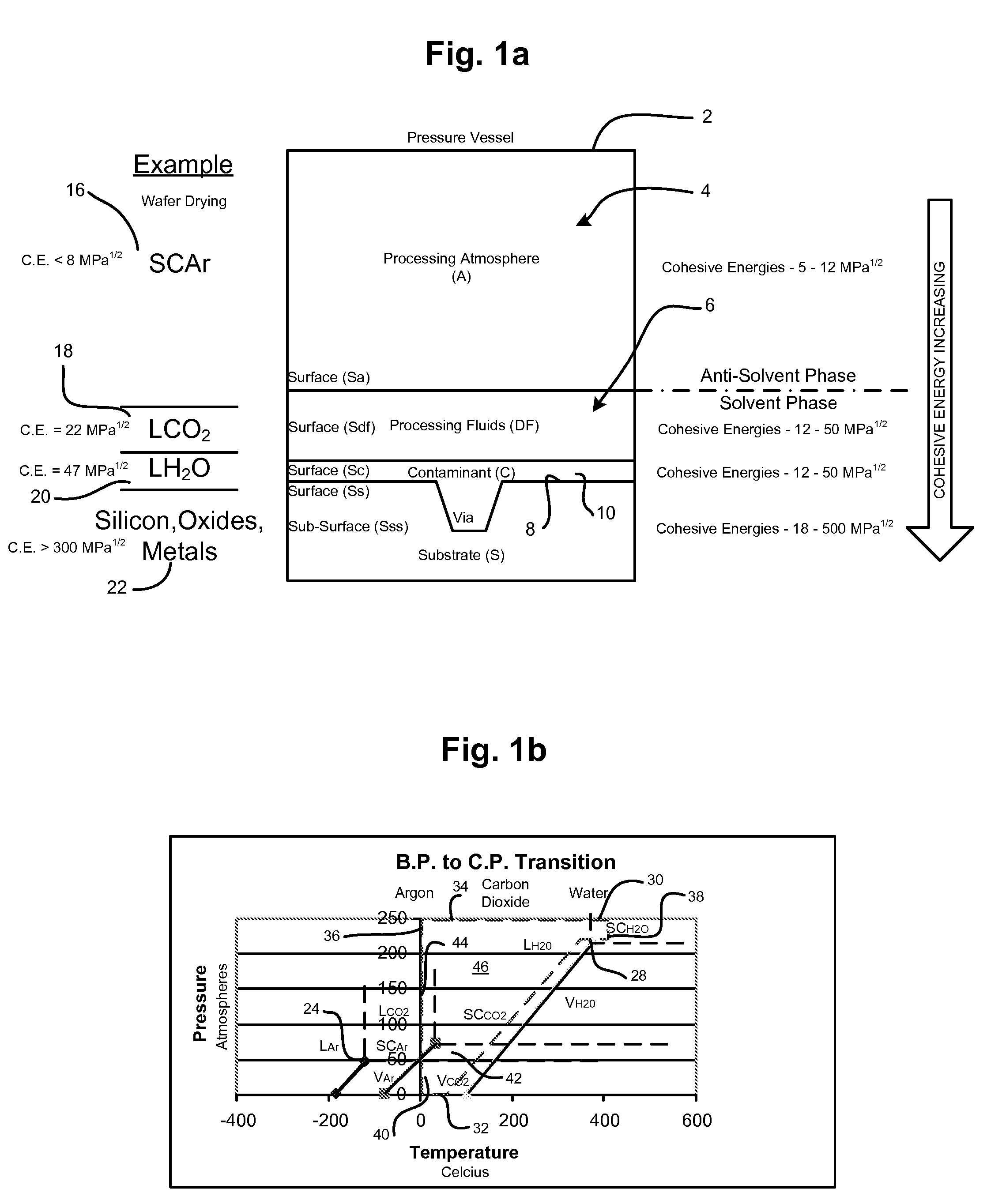

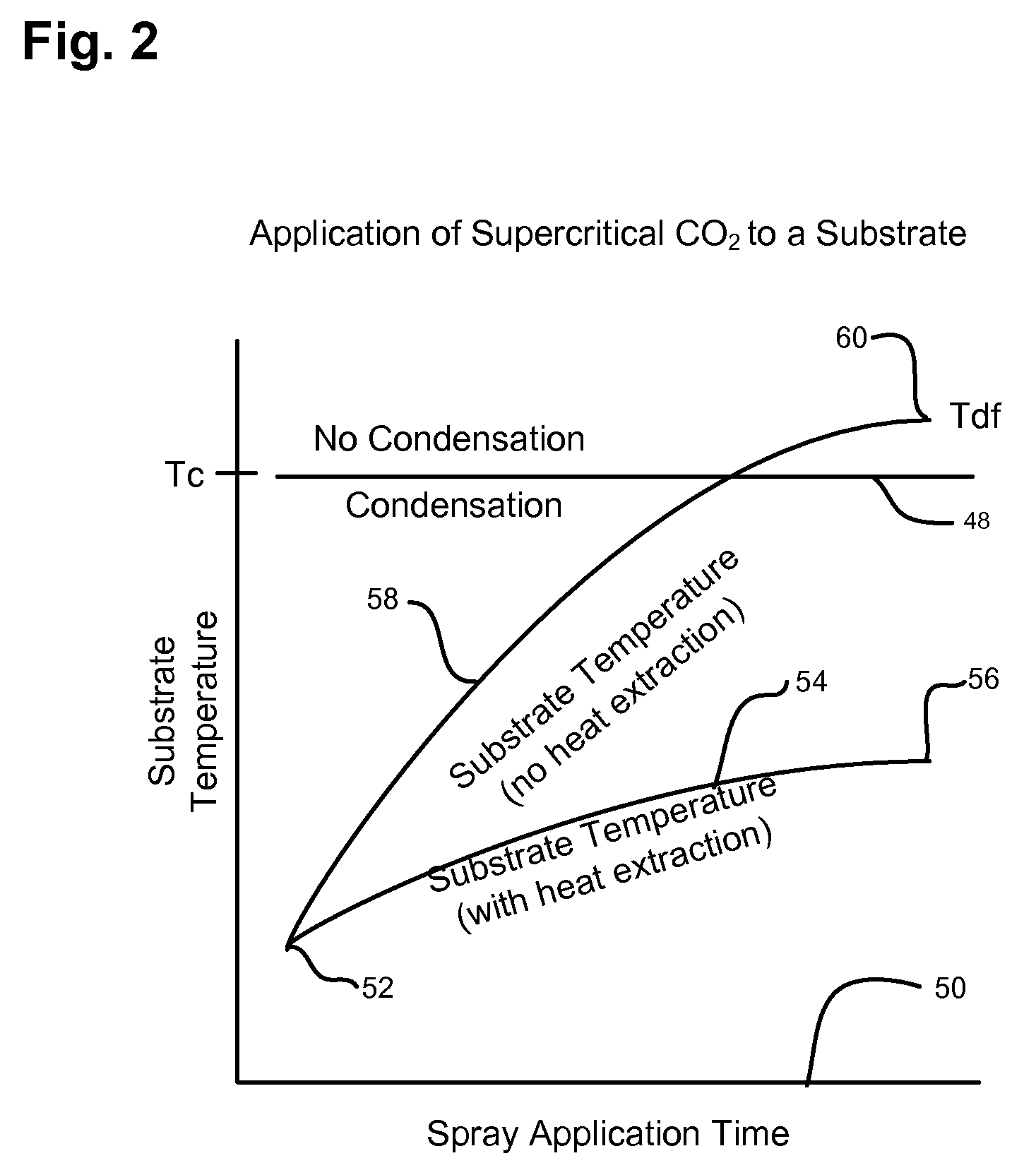

Precision surface treatments using dense fluids and a plasma

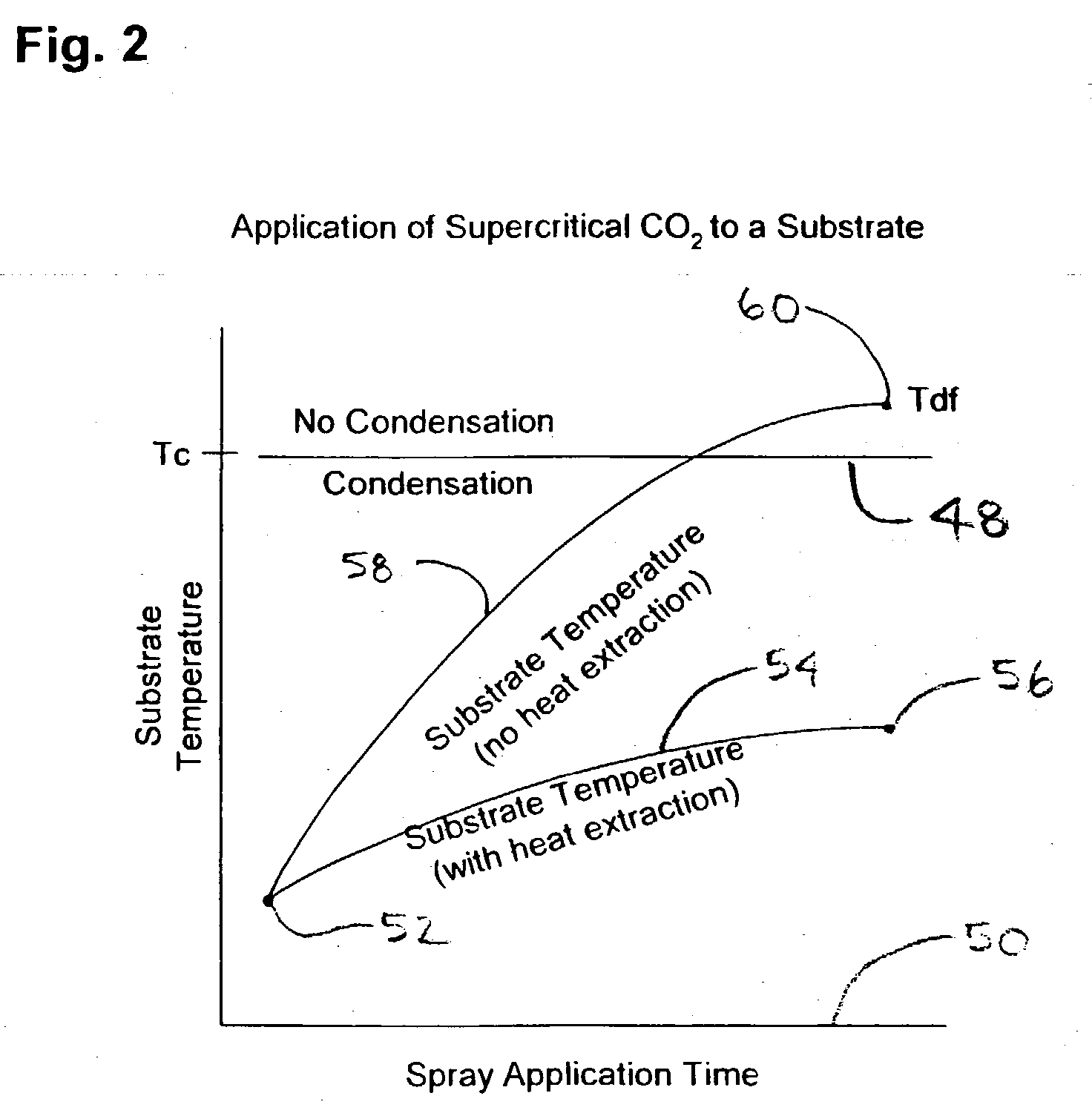

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

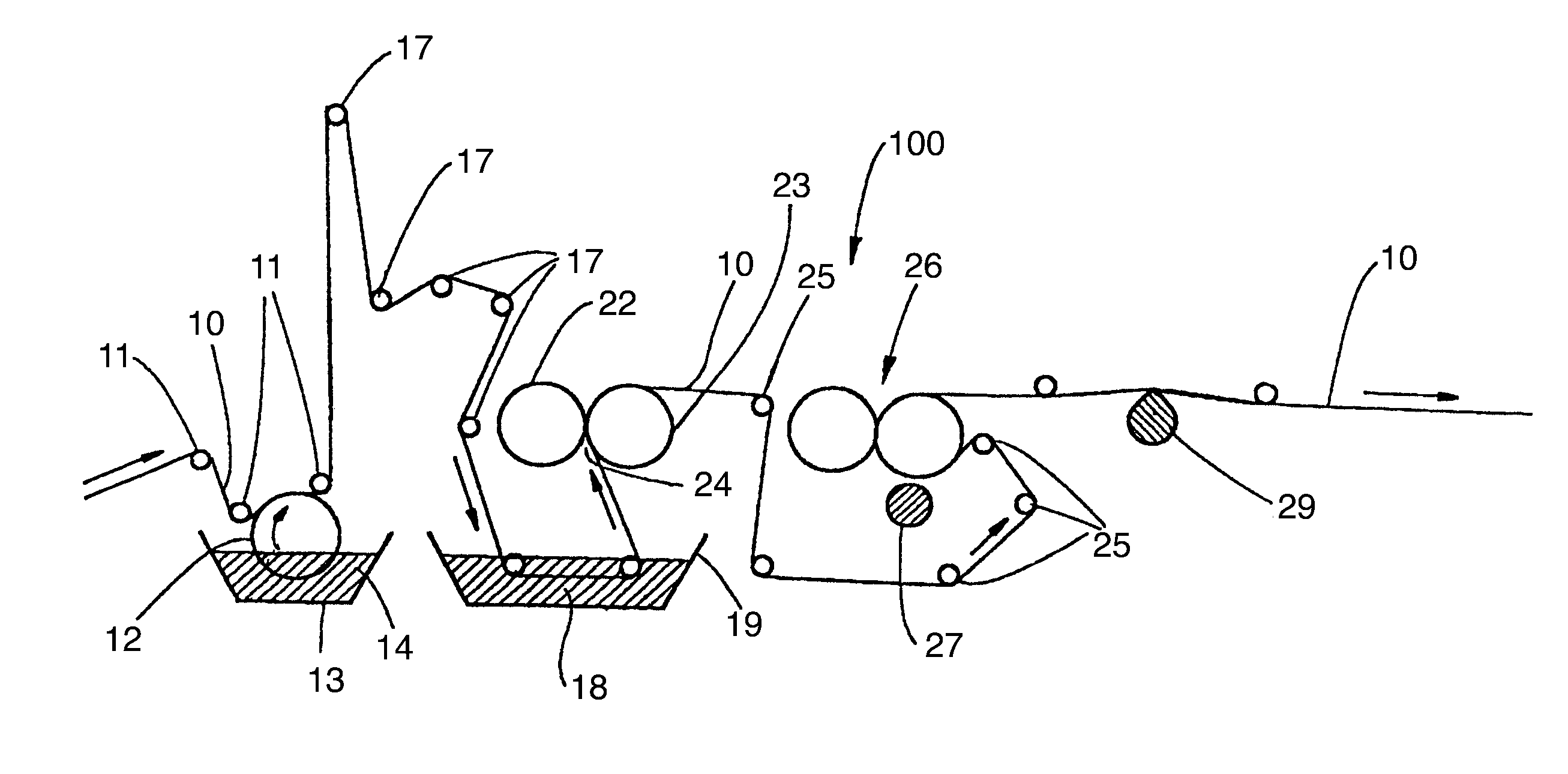

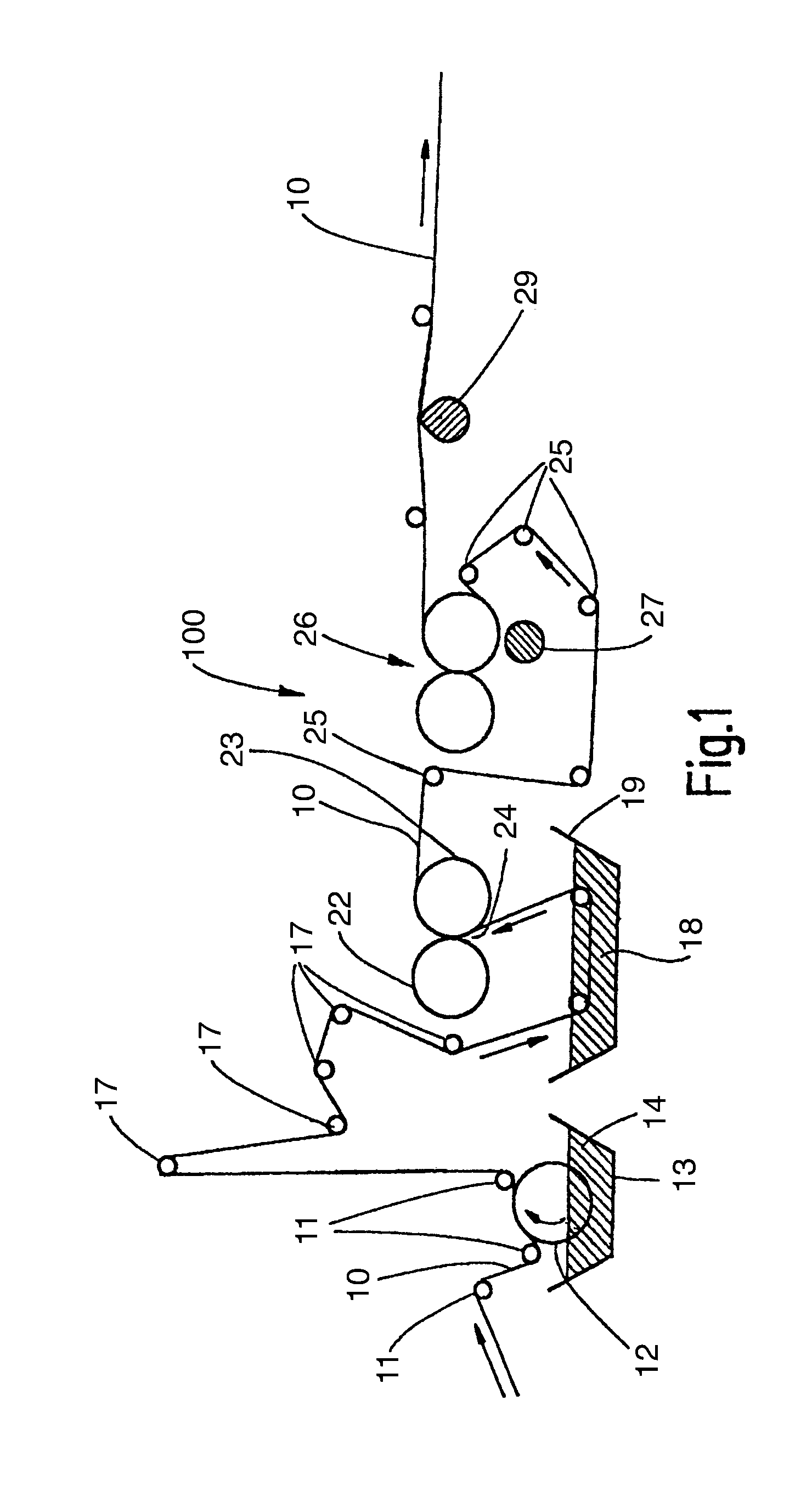

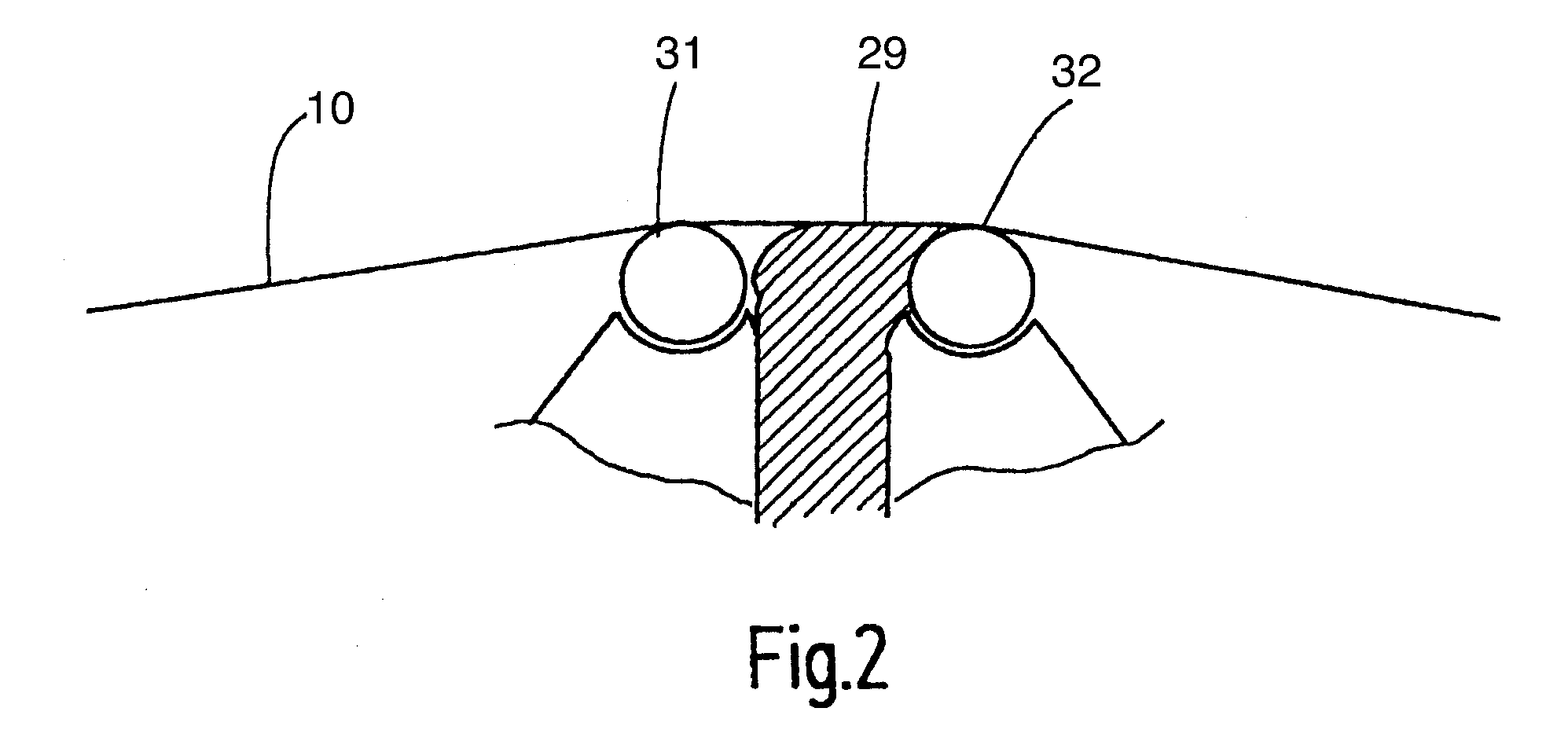

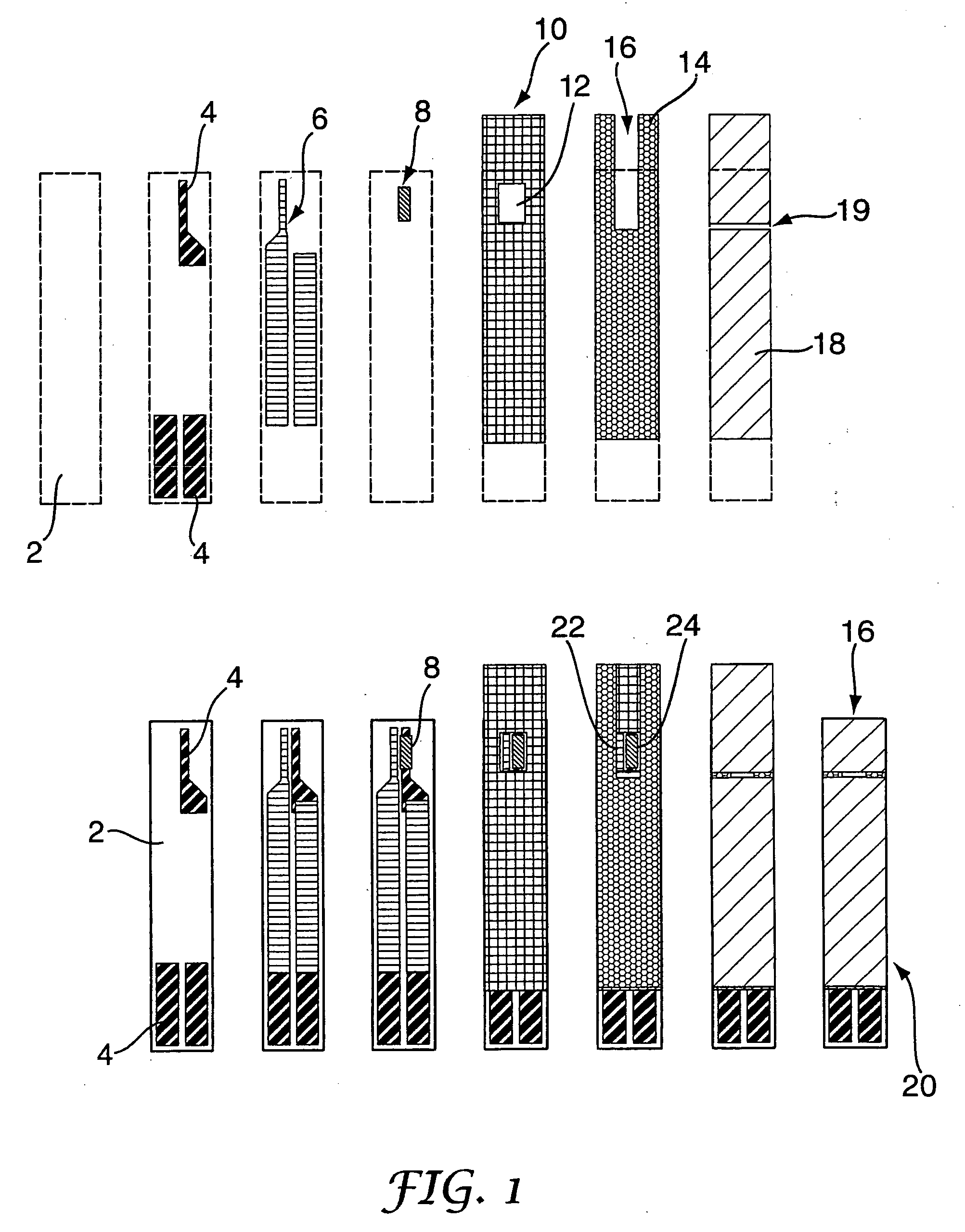

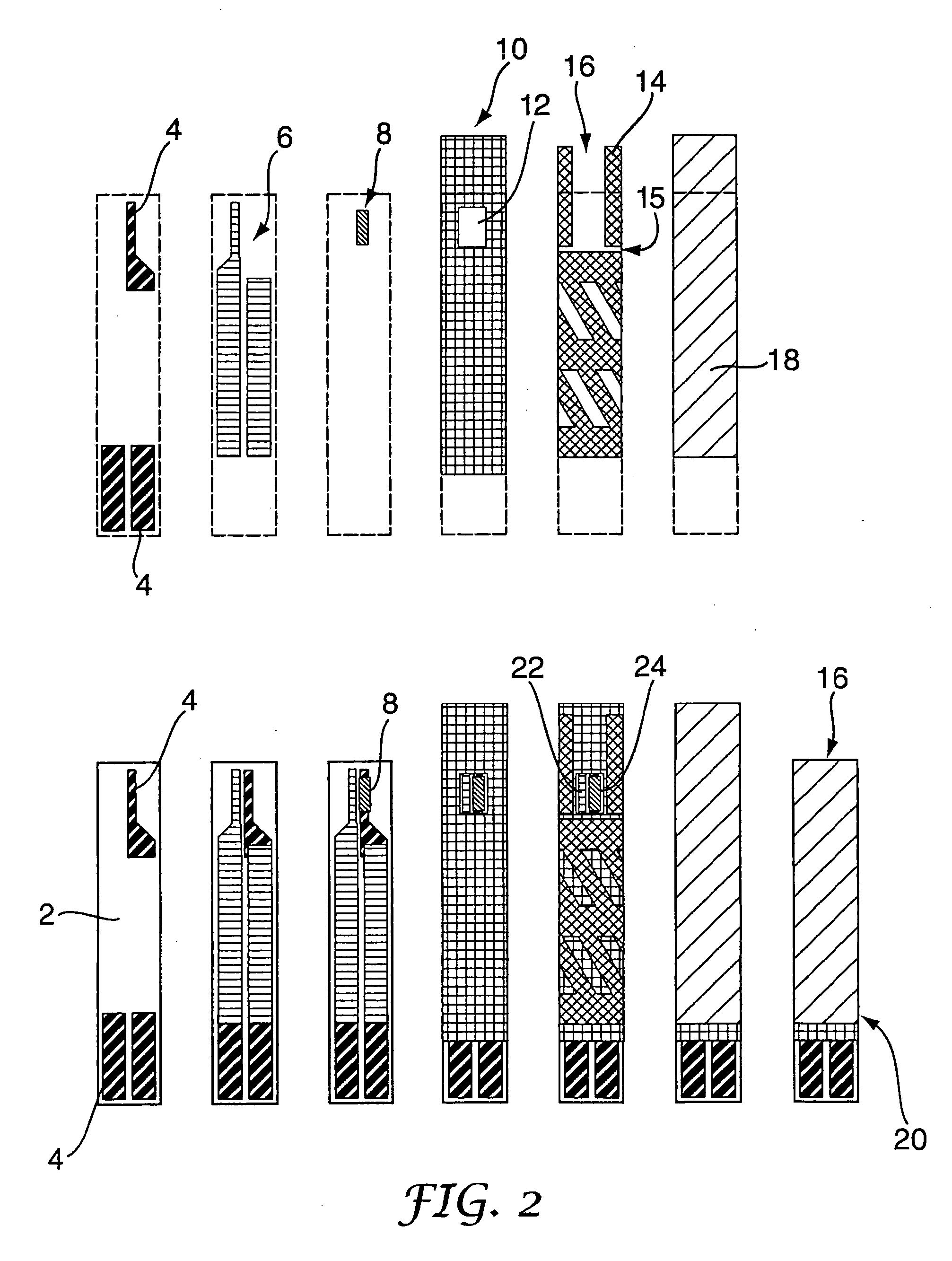

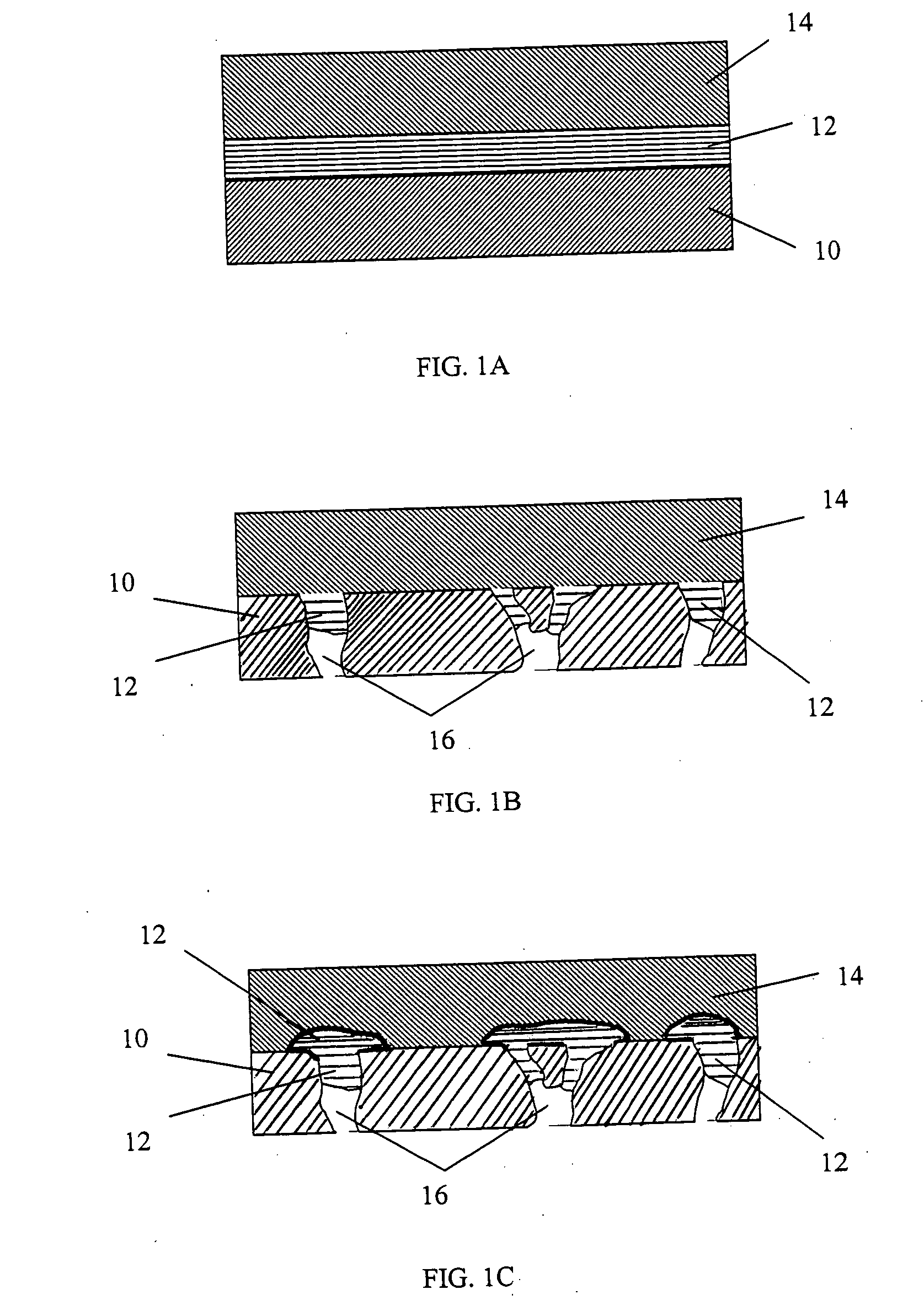

Method for the production of a chafe resistant overlay

InactiveUS20090208646A1Avoid large quantitiesSpecial paperSpecial ornamental structuresBiochemical engineeringCorundum

The invention relates to a method (100) for the production of an overlay, in particular for laminates. For this, firstly an overlay base paper (10) is impregnated in the usual manner and is coated on one side with a resin / coarse corundum application. In order to endow the overlay with additional characteristics, such as for example chafe resistance on the surface, in a further wet-in-wet application step a coating substance (29) is applied on the opposite side and is dosaged by a wiper (31).

Owner:DEKOR KUNSTE

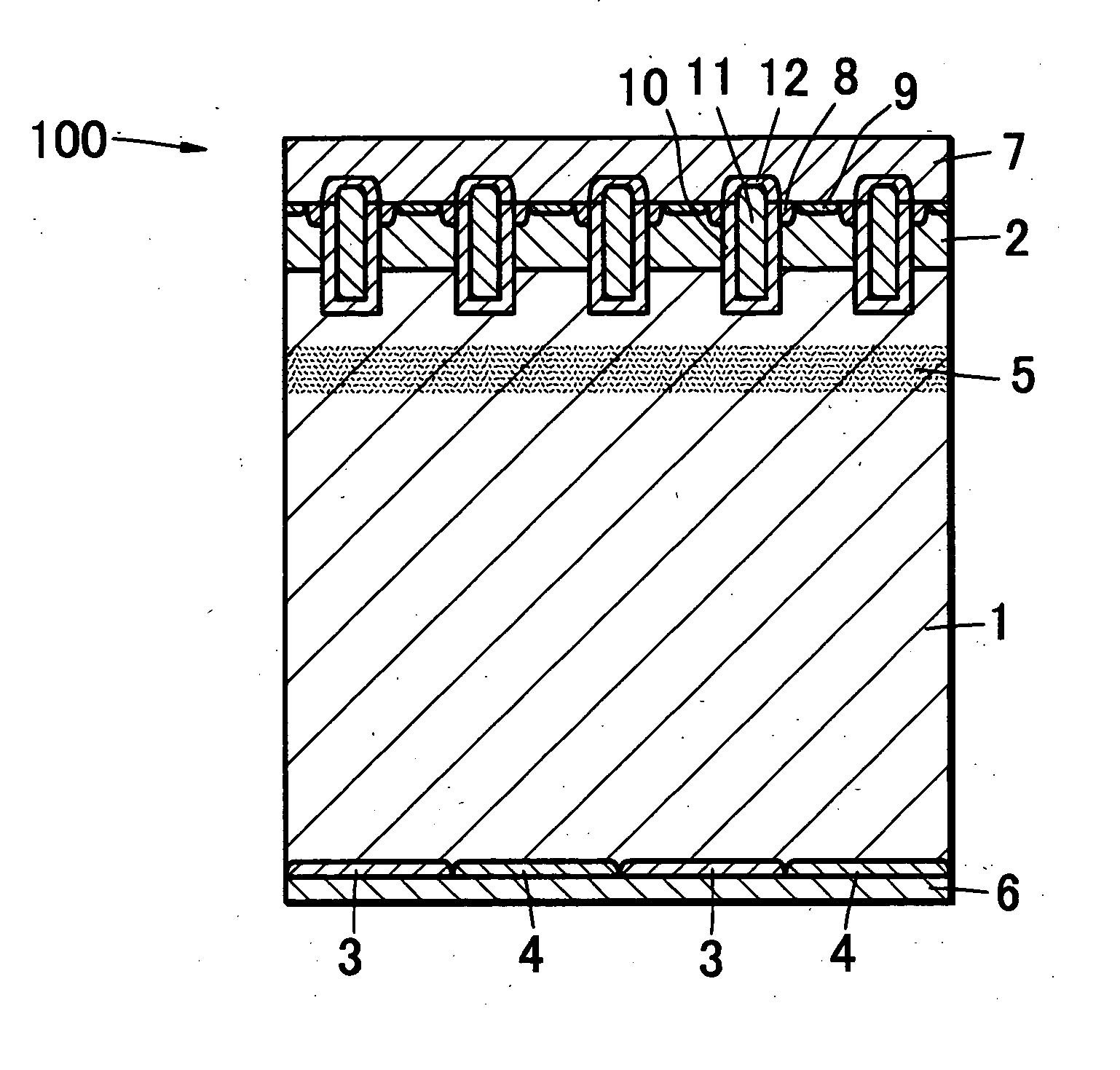

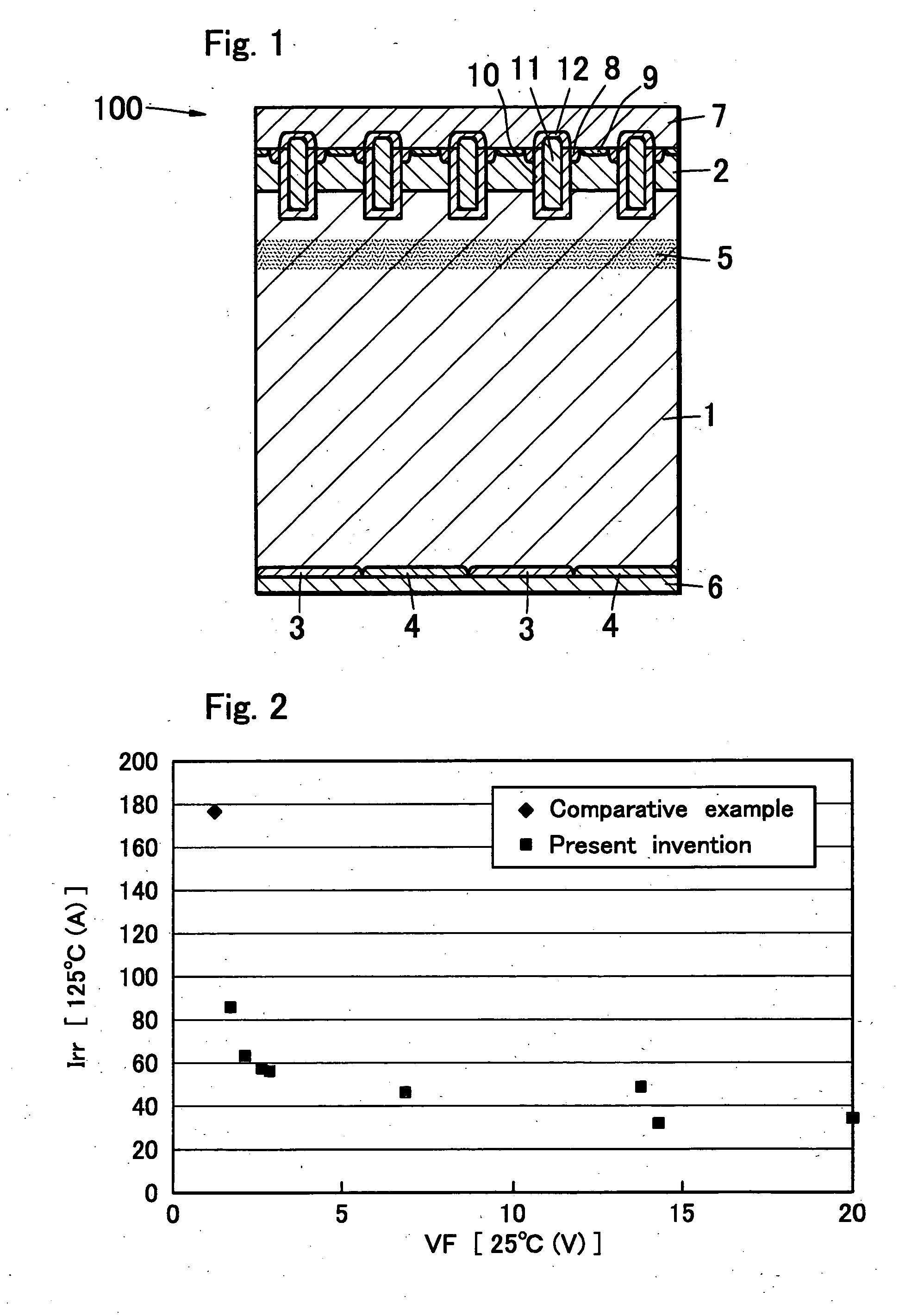

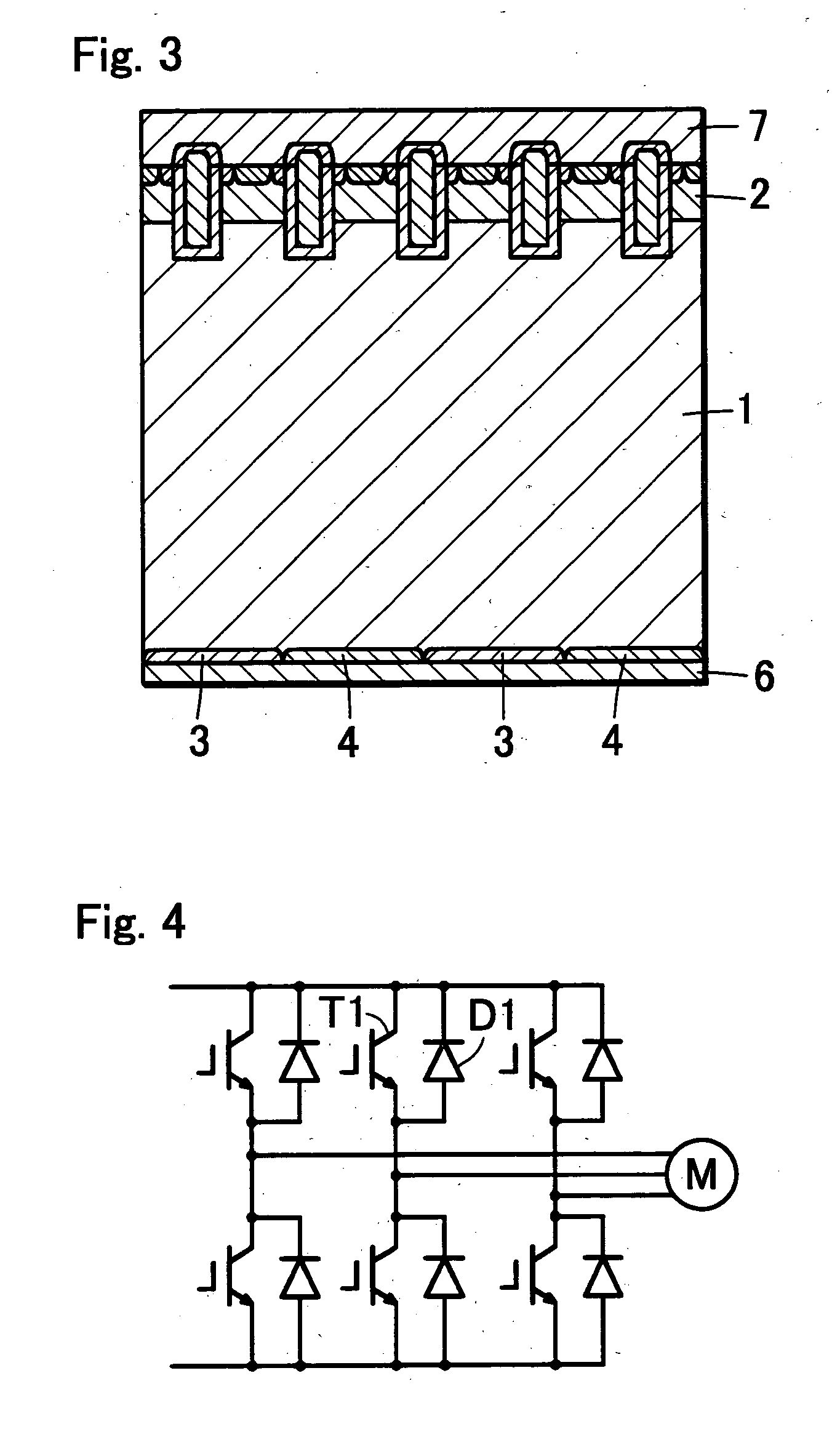

Reverse conducting semiconductor device and a fabrication method thereof

ActiveUS20050258493A1Reverse recovery is improvedAvoid large quantitiesTransistorSolid-state devicesDevice materialEngineering

To provide a reverse conducting semiconductor device in which an insulated gate bipolar transistor and a free wheeling diode excellent in recovery characteristic are monolithically formed on a substrate, the free wheeling diode including; a second conductive type base layer to constitute the insulated gate bipolar transistor; a first conductive type base layer for constituting the insulated gate bipolar transistor, an anode electrode which is an emitter electrode covering a first conductive type emitter layer and the second conductive type base layer, a cathode electrode which is a collector electrode covering the first conductive type base layer and a second conductive type collector layer formed on the part of the first conductive type base layer, wherein a short lifetime region is formed on a part of the first conductive type base layer.

Owner:MITSUBISHI ELECTRIC CORP

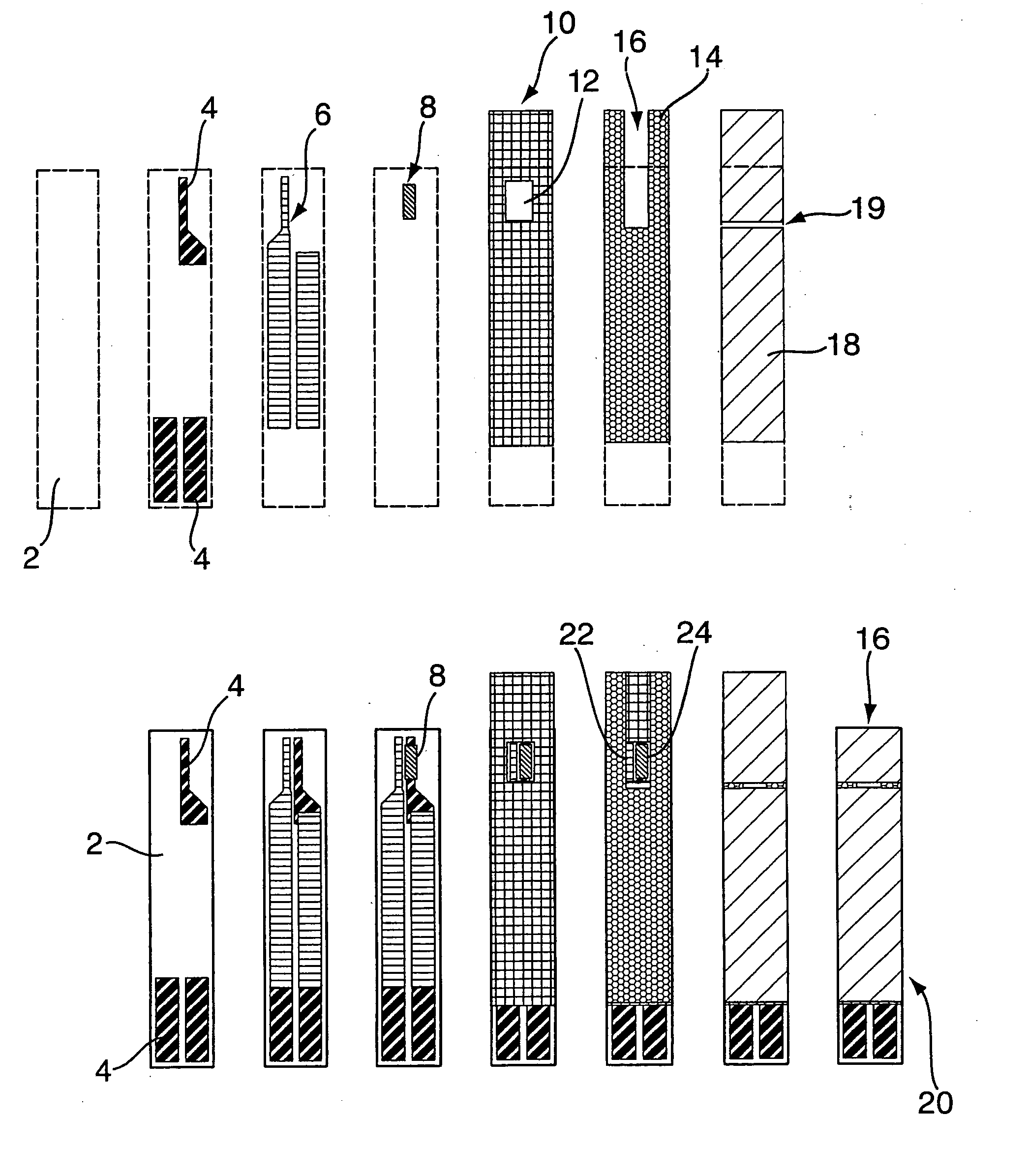

Biosensor and method of manufacture

InactiveUS20050150763A1Reduce volumeFacilitate adjustmentImmobilised enzymesBioreactor/fermenter combinationsChemistryElectrically conductive

A non-mediated biosensor for indicating amperometrically the catalytic activity of an oxidoreductase enzyme in the presence of a fluid containing a substance acted upon by said enzyme, the biosensor comprising: (a) a first substrate; (b) a working electrode and a counter electrode on the first substrate; (c) conductive tracks connected to said electrodes for making electrical connections with a test meter apparatus; (d) a second substrate overlying at least a part of the first substrate; and (e) a spacer layer having a channel therein and disposed between the first substrate and the second substrate, the spacer layer channel co-operating with adjacent surfaces to define a capillary flow path which does not contain a mesh and which extends from an edge of at least one of said substrates to said electrodes; wherein the working electrode includes: (f) an electrically-conductive base layer comprising particles of finely divided platinum-group metal or platinum-group metal oxide bonded together by a resin; (g) a top layer on the base layer, said top layer comprising a buffer; and (h) a catalytically-active quantity of said oxidoreductase enzyme in at least one of said base layer and said top layer.

Owner:HYPOGUARD (UK) LTD

Portable hydration system

InactiveUS6558537B1Enhanced efficiencyEasy to carryGeneral water supply conservationSeawater treatmentEmbedded systemOxidizing agent

A portable hydration system comprising water disinfection, filtration and pump features. The system comprises an electrolytic oxidant generating cell which utilizes a salt to create oxidants for disinfecting liquids such as water.

Owner:MIOX CORP

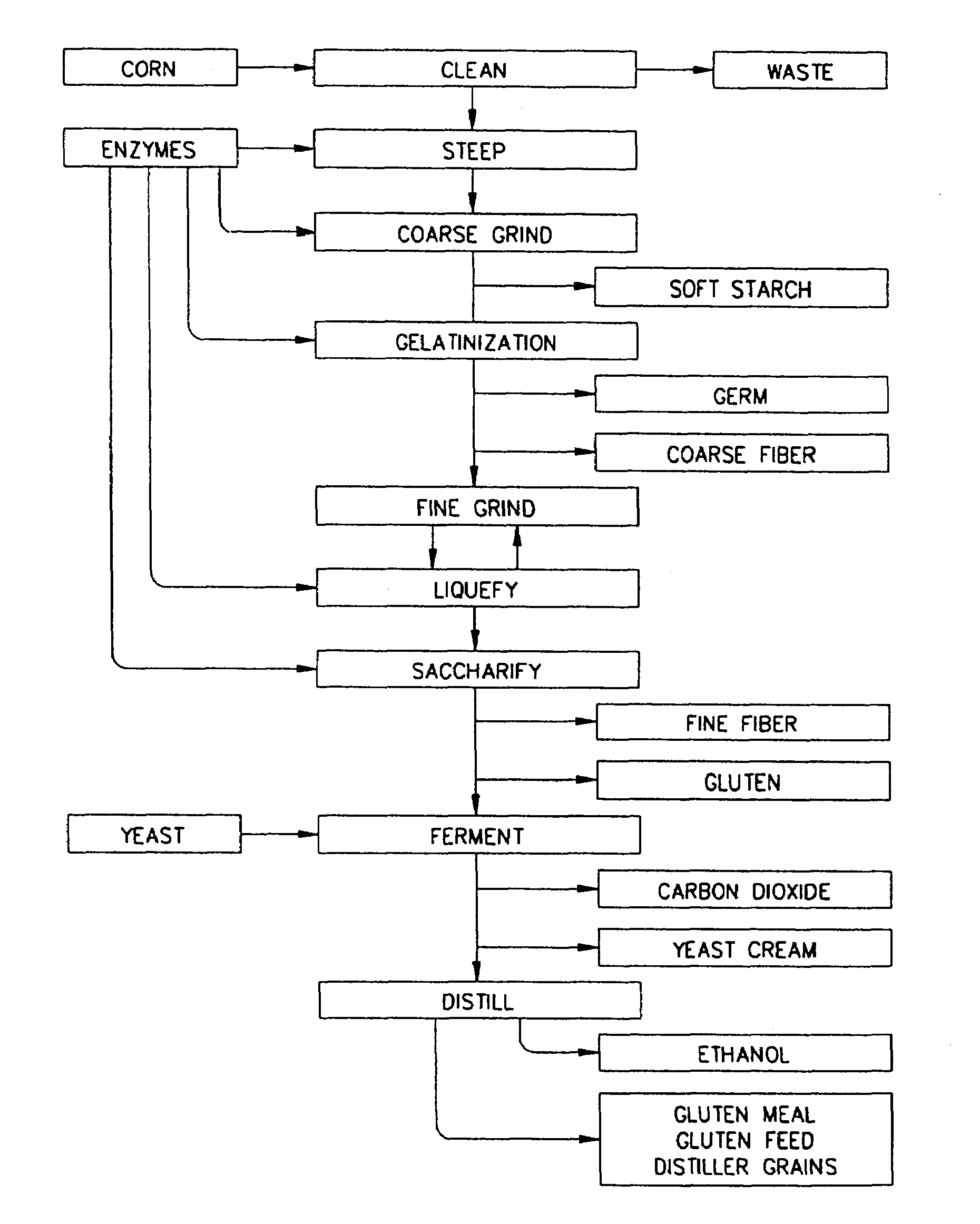

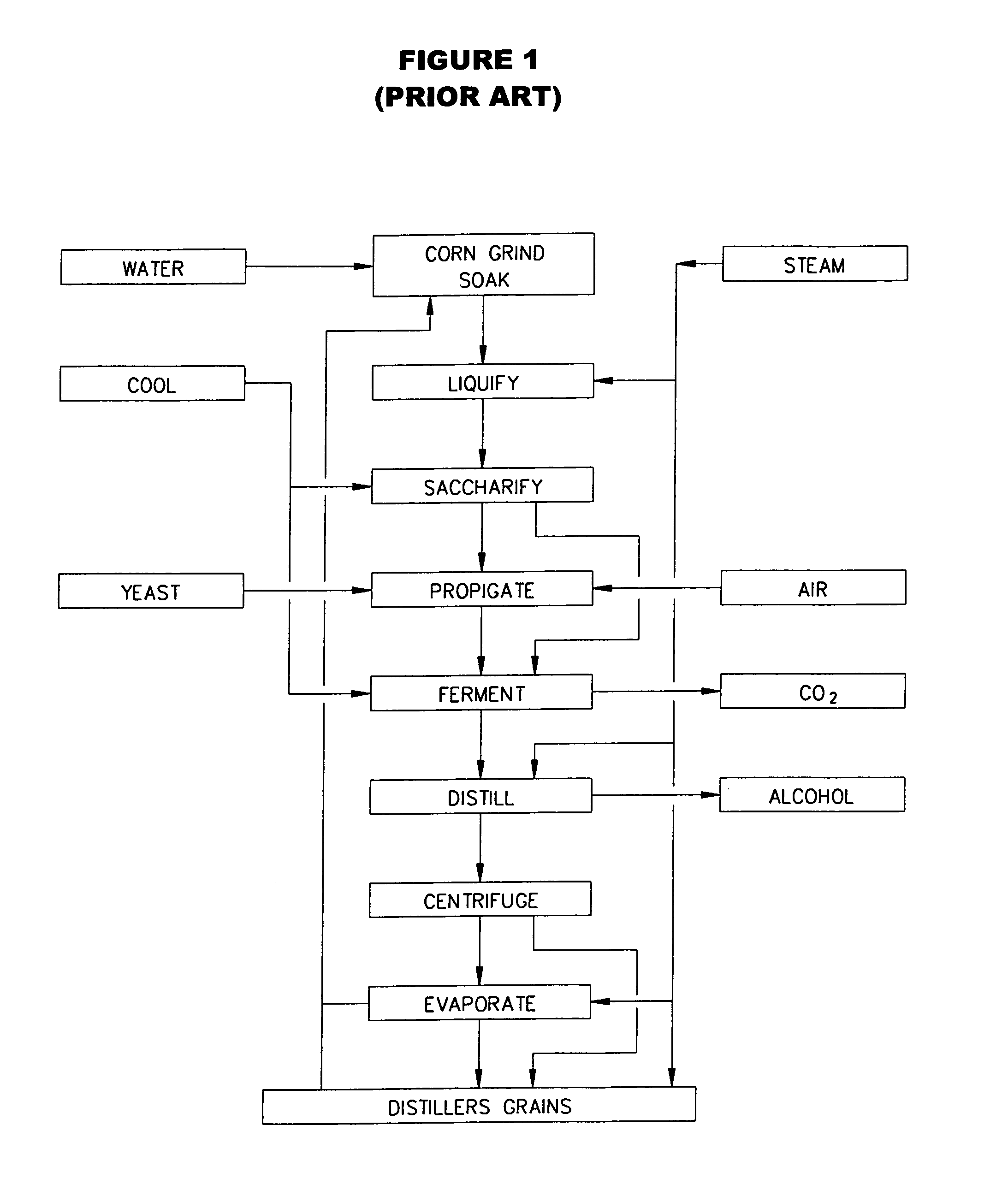

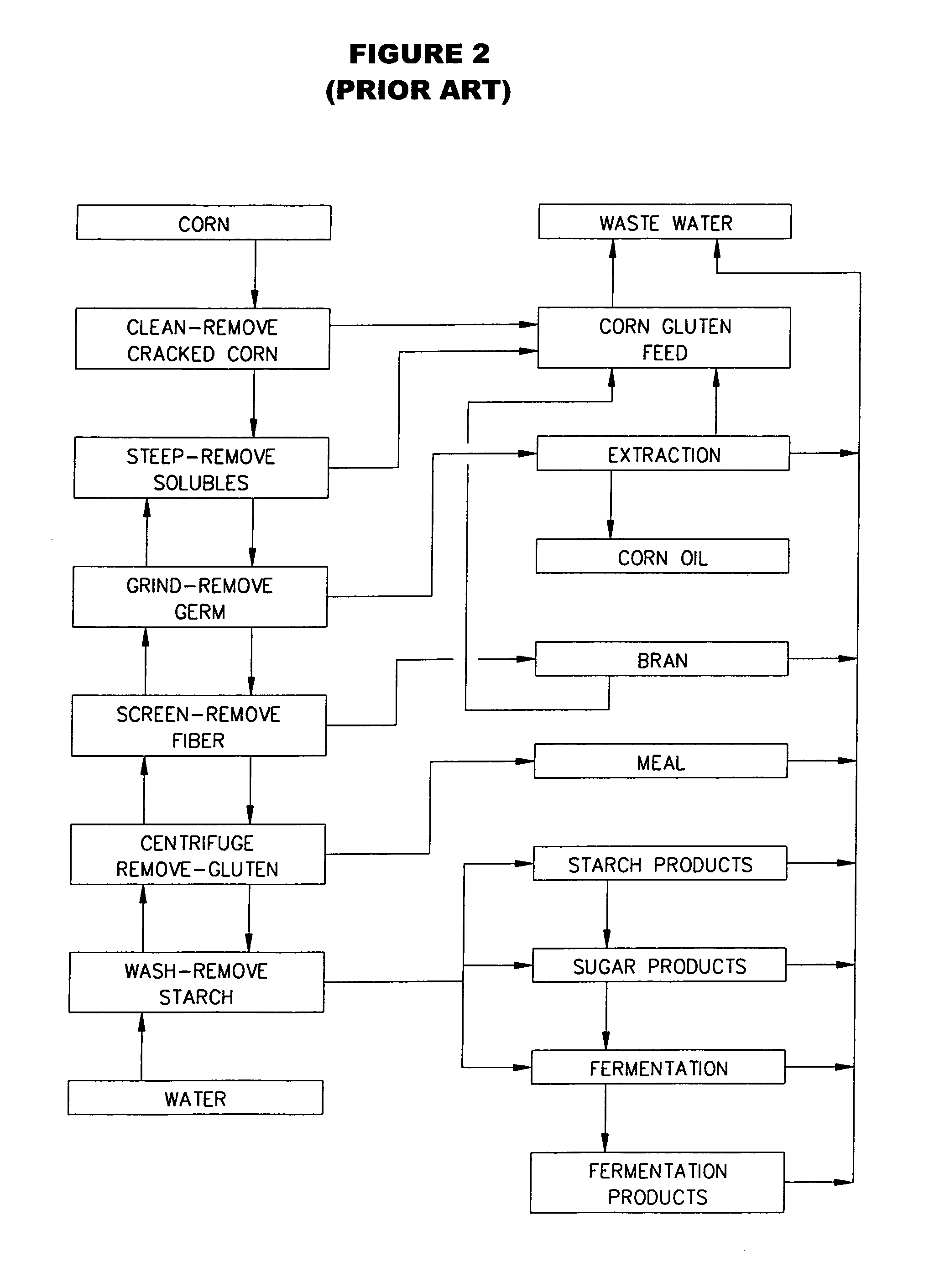

Corn refining process

InactiveUS7452425B1Quickly and efficiently producedAvoid large quantitiesJuice extractionBiofuelsSteepingSlurry

A grain containing starch, such as corn, is refined. The grain is steeped in water at a temperature of about 125 to 160° F., which water is essentially free of sulfurous acid and contains recycled enzymes from downstream processes, in a counter-current steeping reactor for about 10 to 20 hours to produce an aqueous slurry of steeped grain having a moisture content of about 40 to 50 percent. The various components of the grain are then separated and the starch is converted to ethanol.

Owner:LANGHAUSER ASSOC

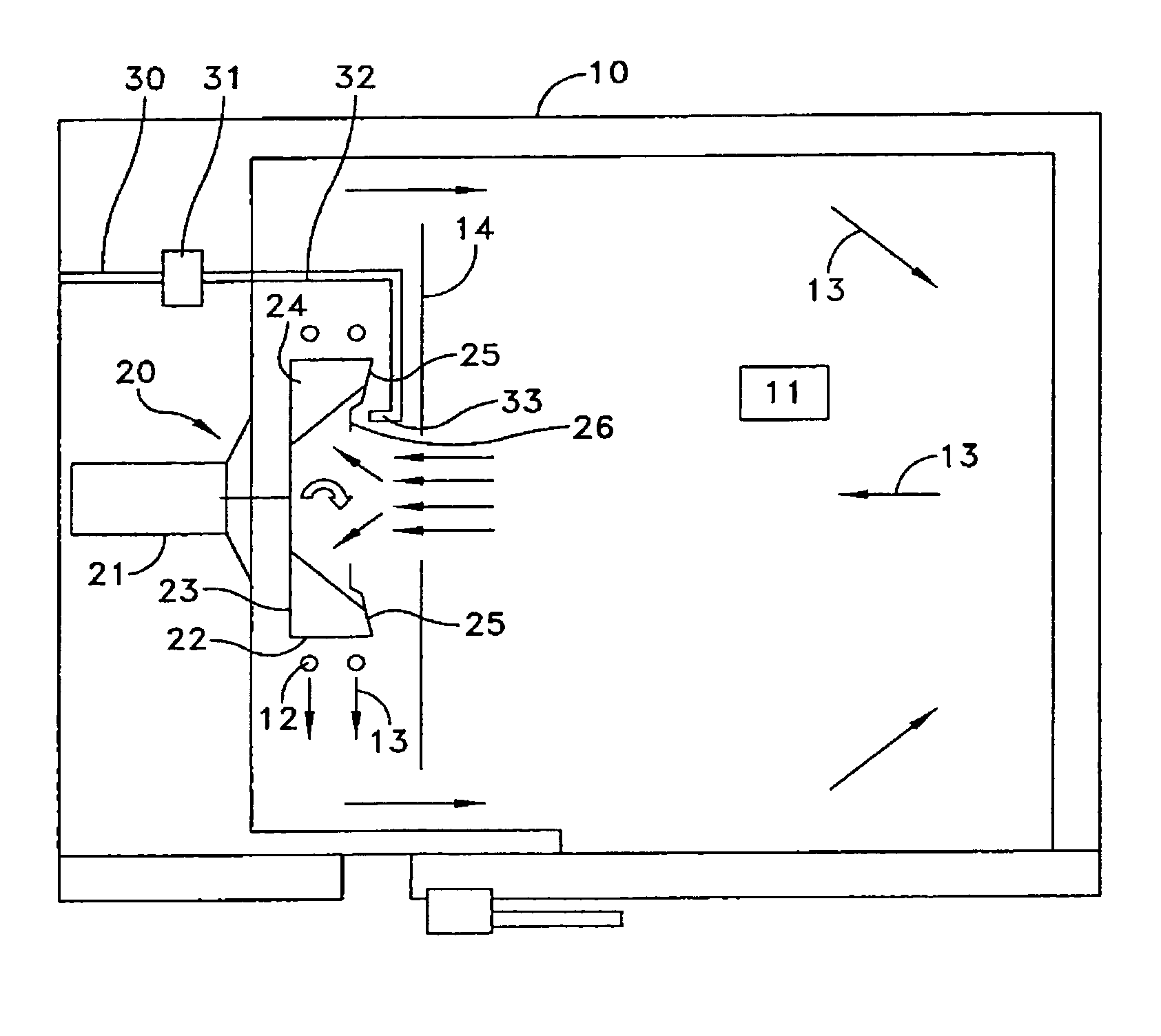

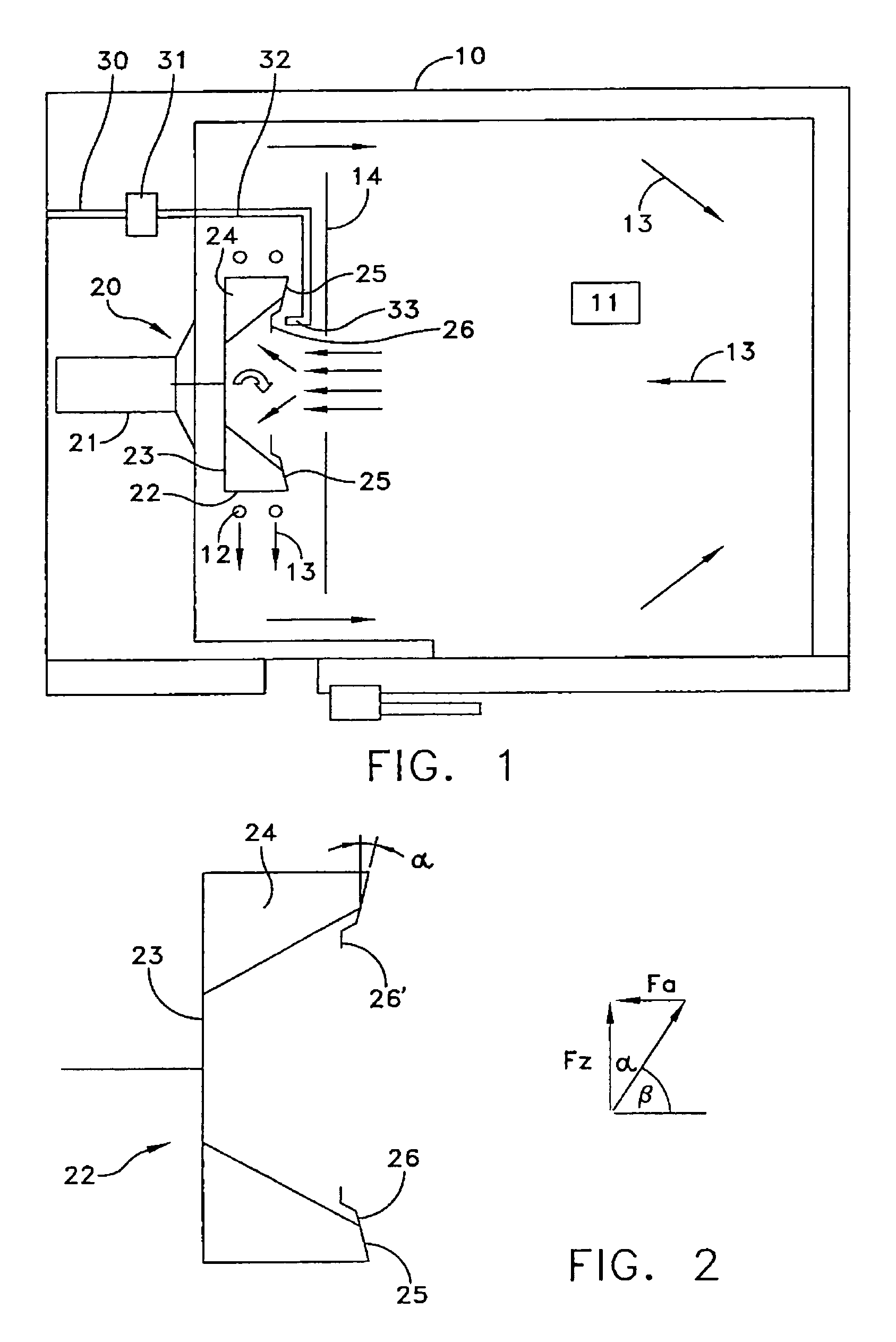

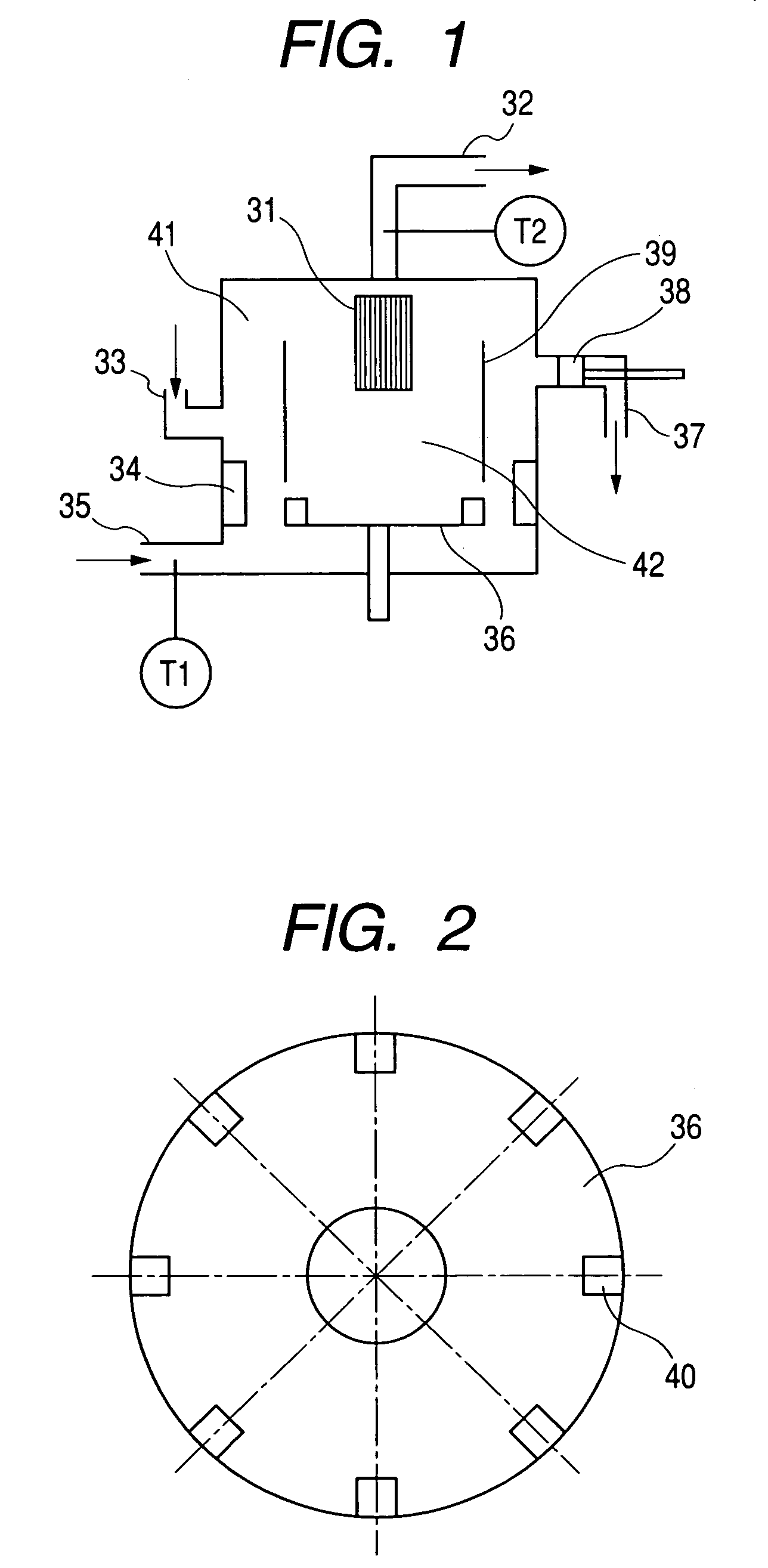

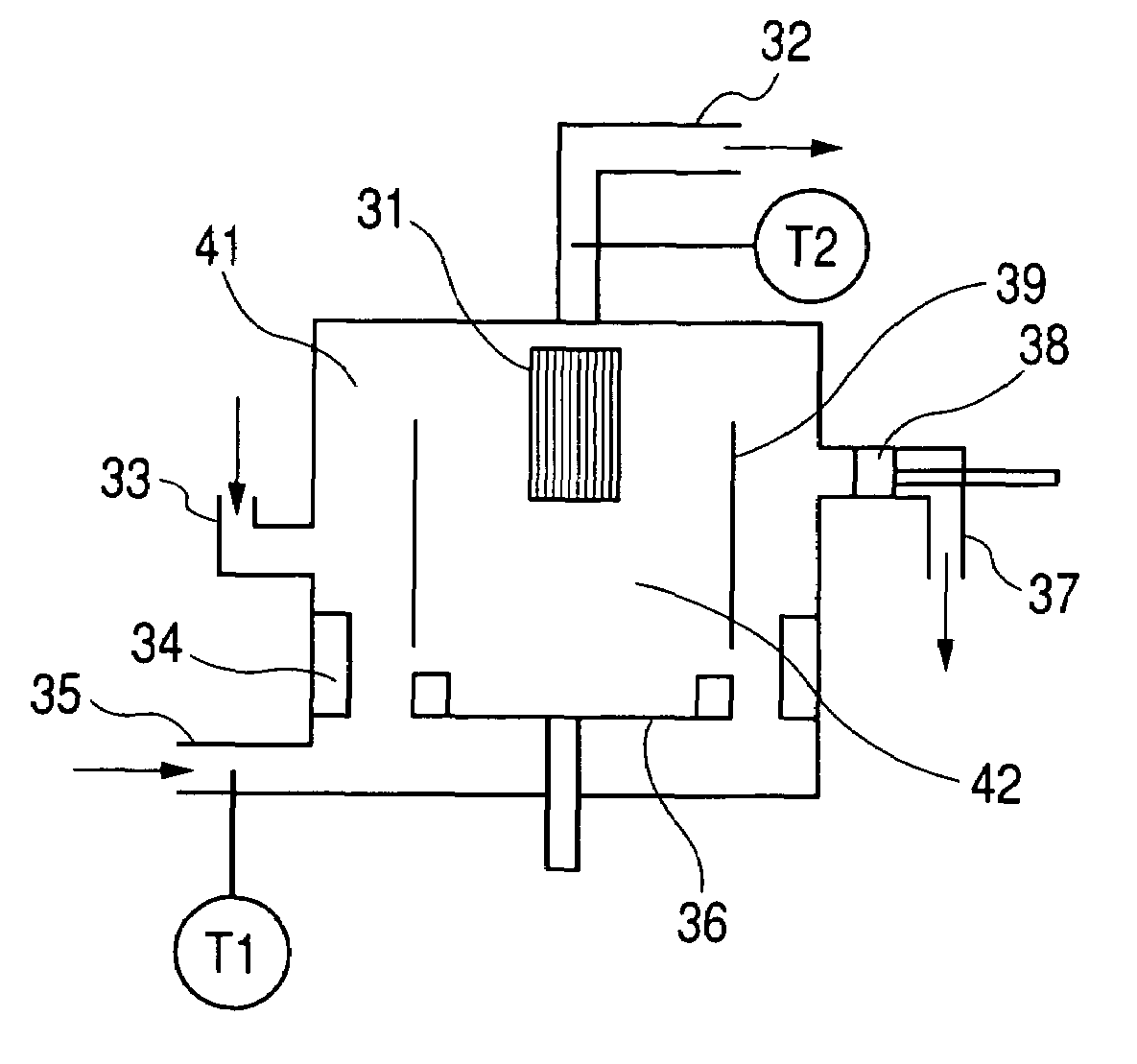

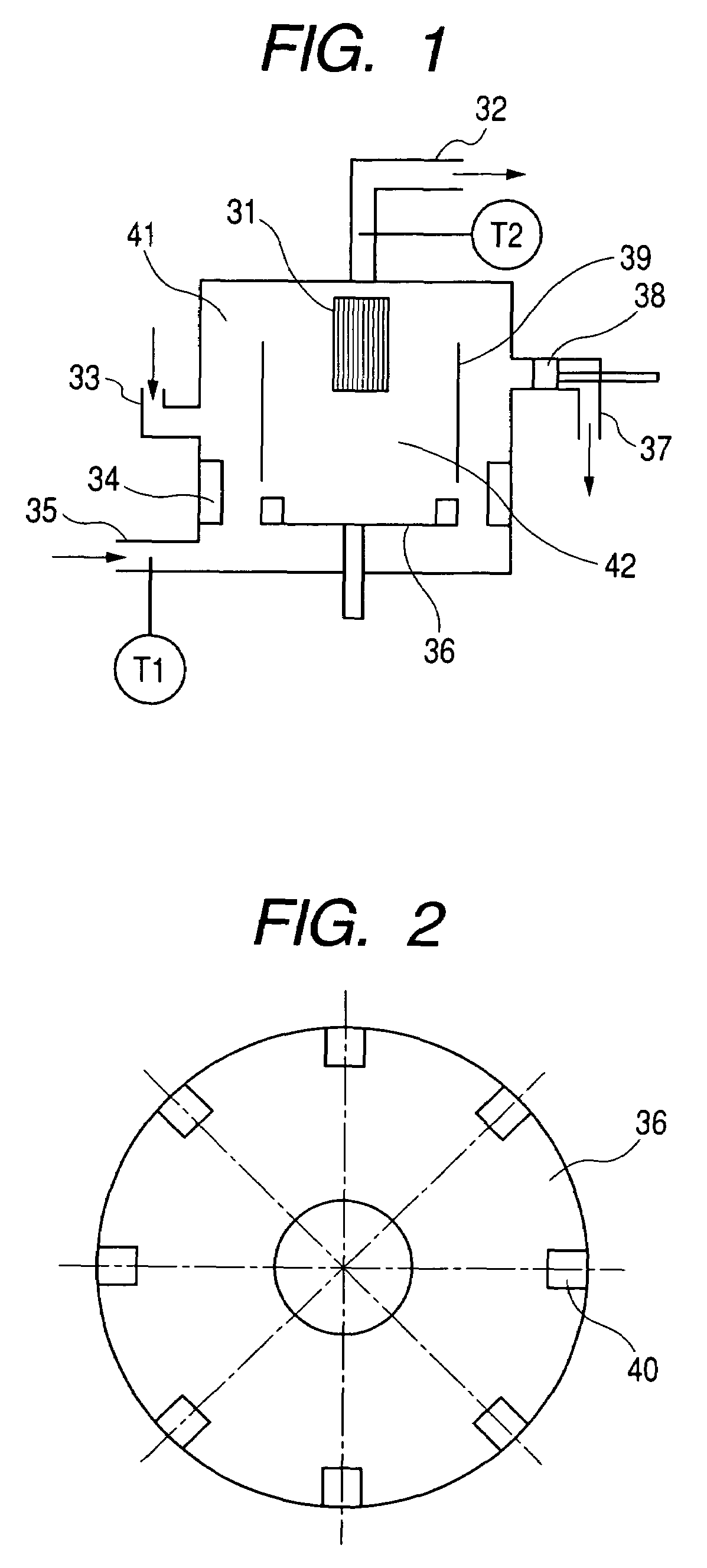

Cooking device with a fan and a water supply

InactiveUS7325481B2Maximum speedLarge radiusAir-treating devicesDomestic stoves or rangesImpellerEvaporation

A cooking device comprises a cooking chamber (11) and one or more heating elements (12). Furthermore, a blower (20) is provided, which comprises a radial blower impeller (22) and an atomisation element rotating with the radial blower impeller (22). A water supply (30) comprises at least one water outlet (33), which supplies water onto the atomisation element (25). An evaporation of the water and thus a humid cooking chamber air is achieved. The atomising element is a discoidal, axially-symmetrical element, the outer radius of which is the same as, or larger than the inner radius of the blade region of the radial blower impeller (22). The atomisation element is arranged adjacent to the radial blower impeller in the axial direction and the water outlet (33) is arranged adjacent to the atomisation element (25), outside the radial blower impeller (22).

Owner:MKN MASCHFAB KURT NEUBAUER

Method and apparatus for treating a substrate with dense fluid and plasma

ActiveUS20060278254A1High densityDivergent cohesion energyElectric discharge tubesElectric arc lampsSolid phasesWet cleaning

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid anti-solvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:HITACHI HIGH-TECH CORP

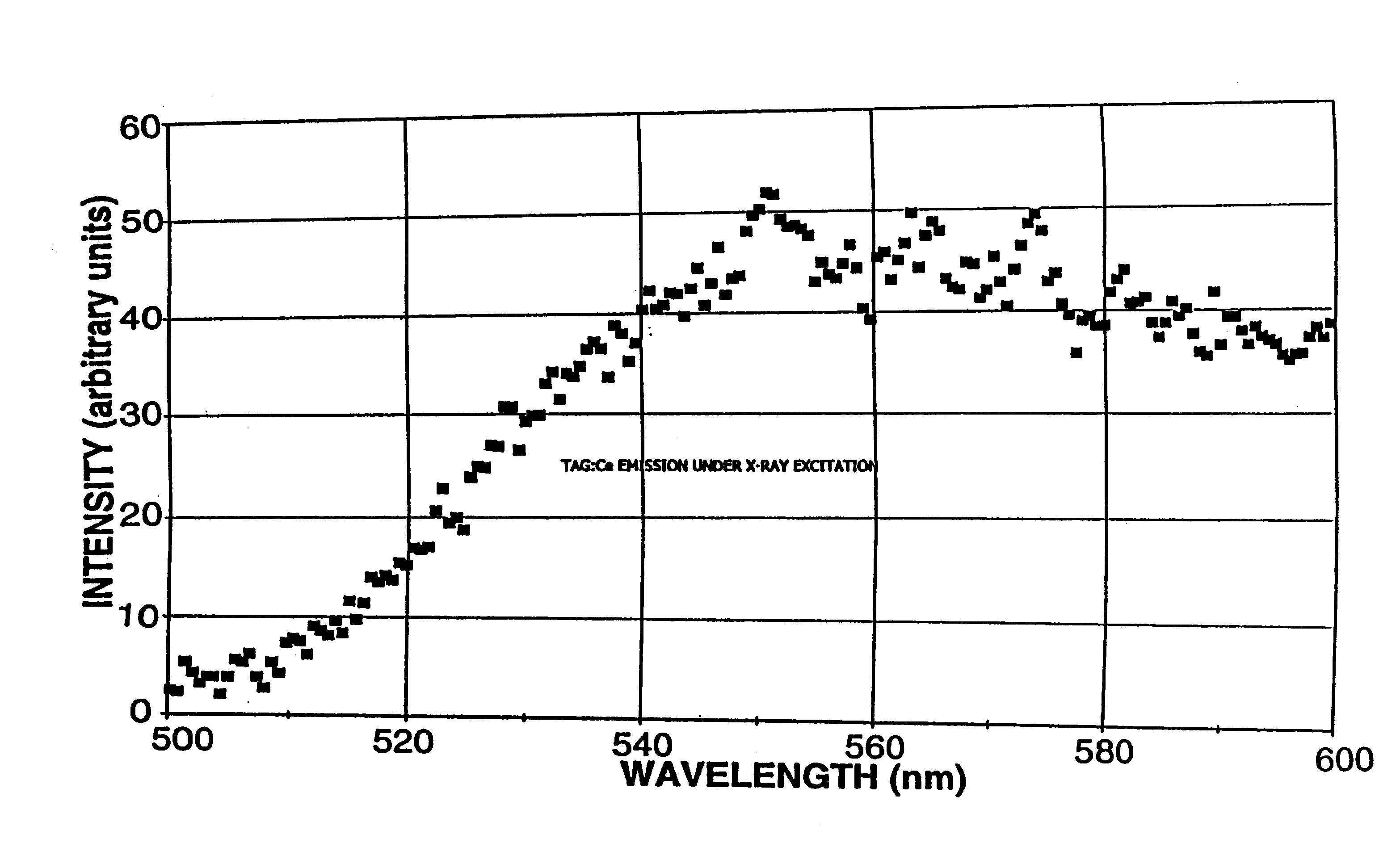

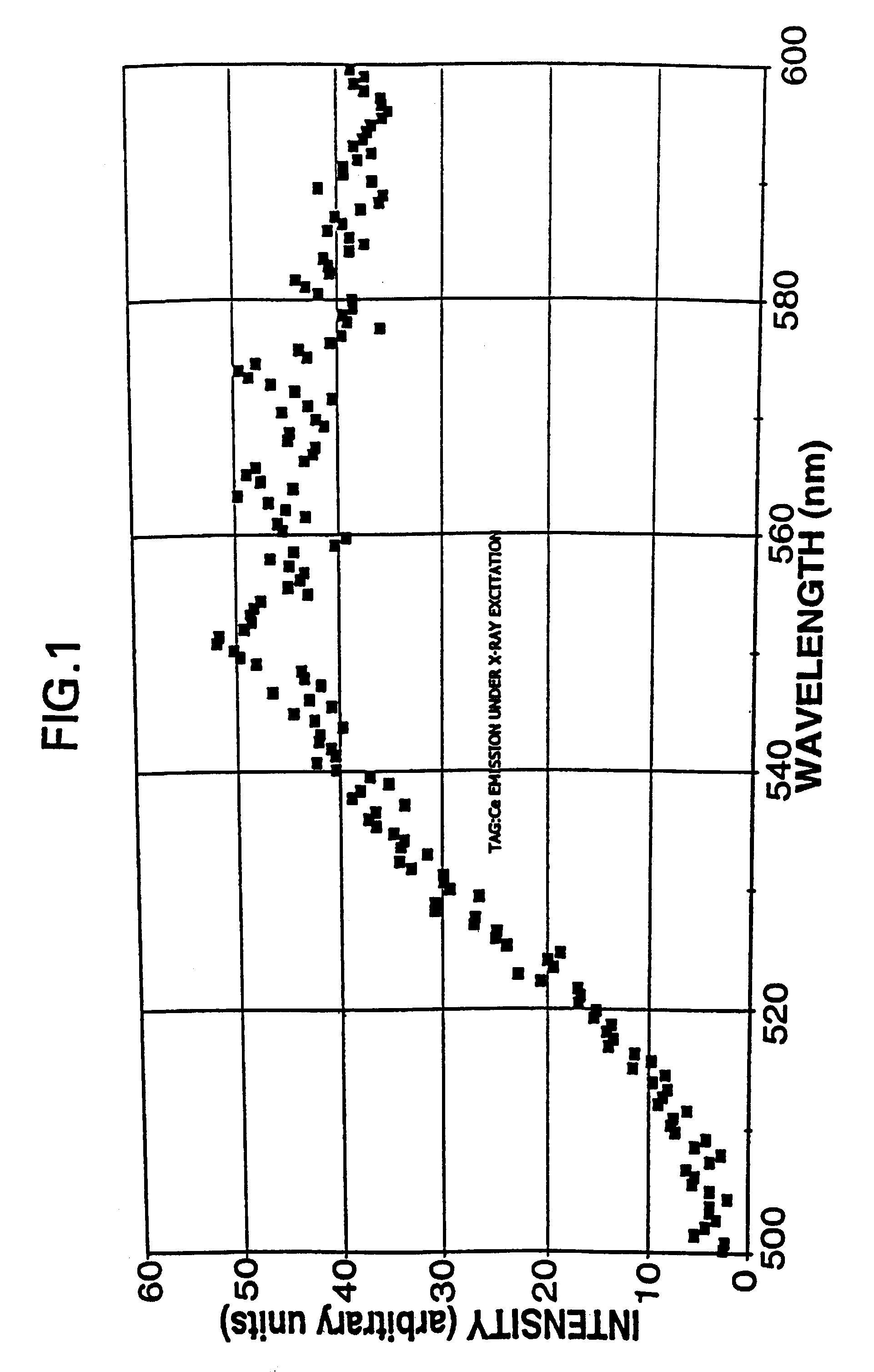

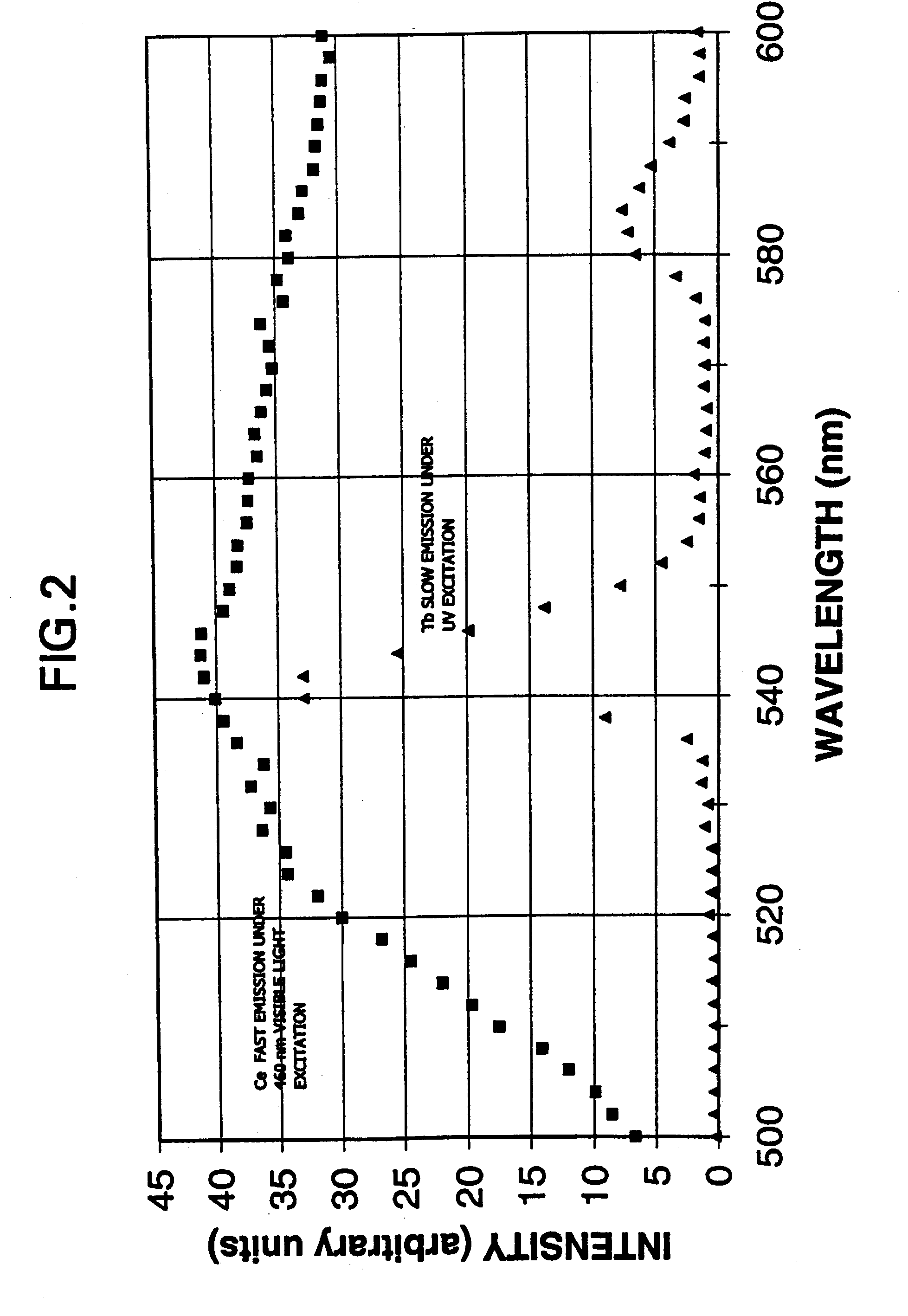

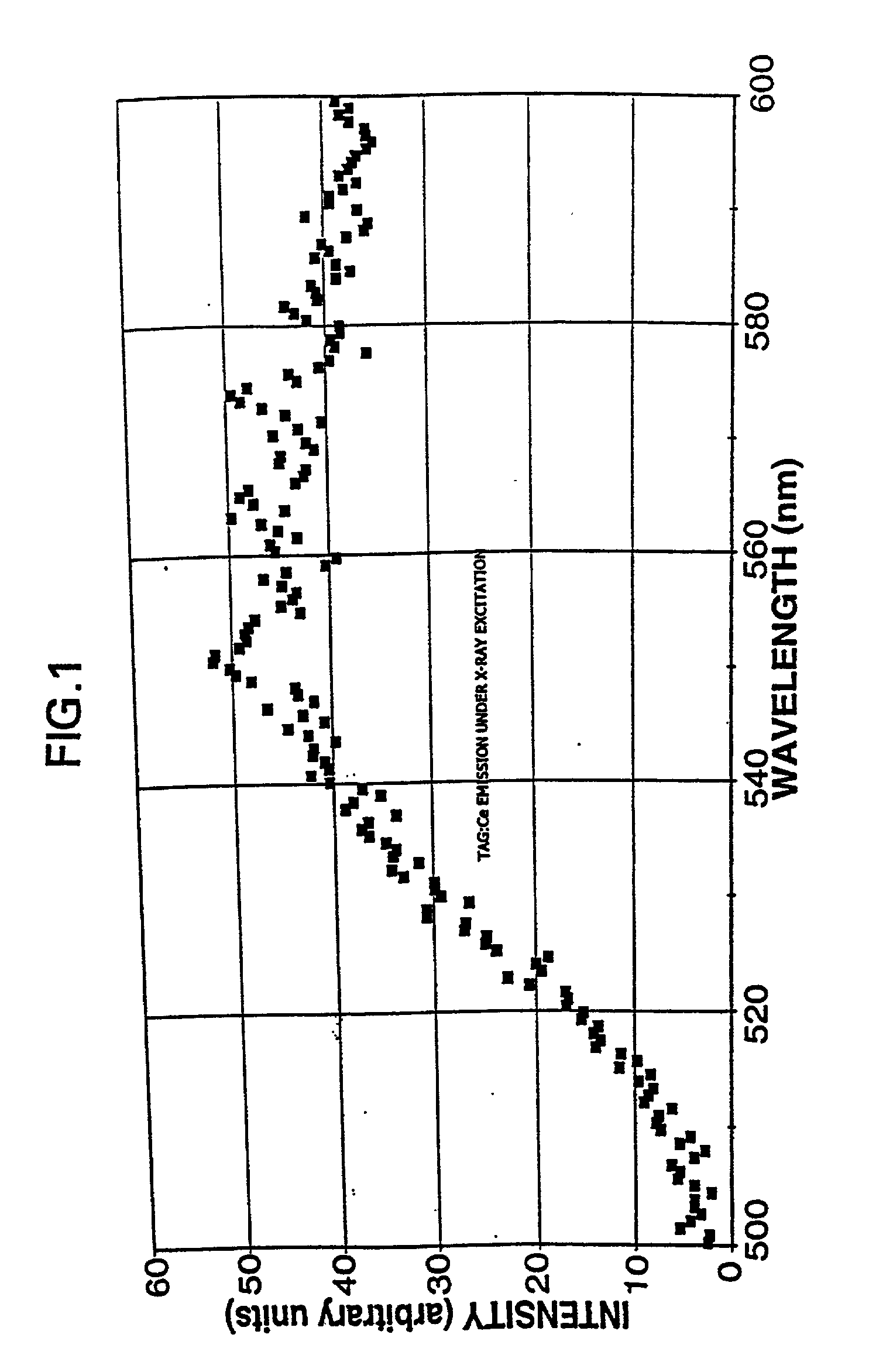

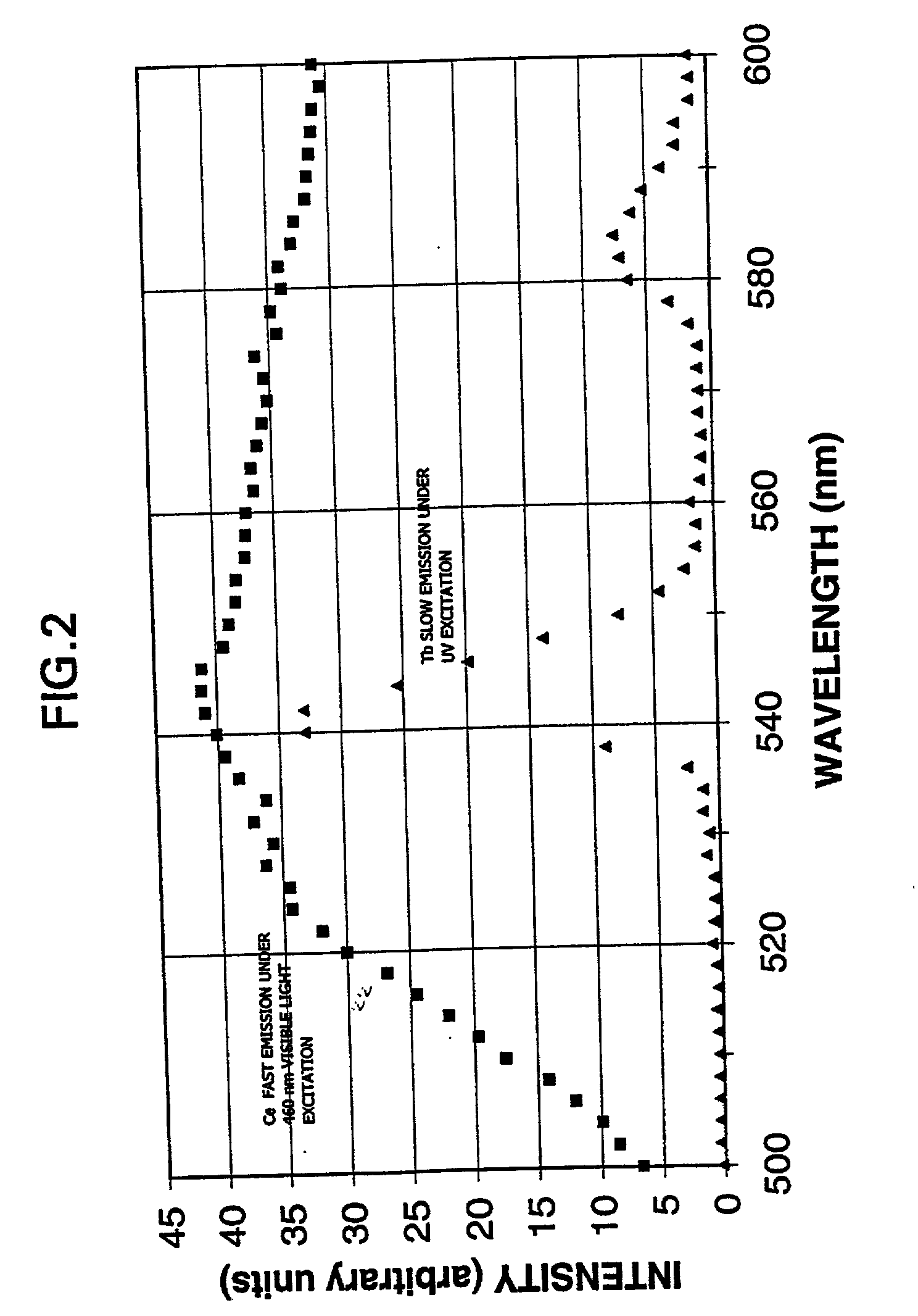

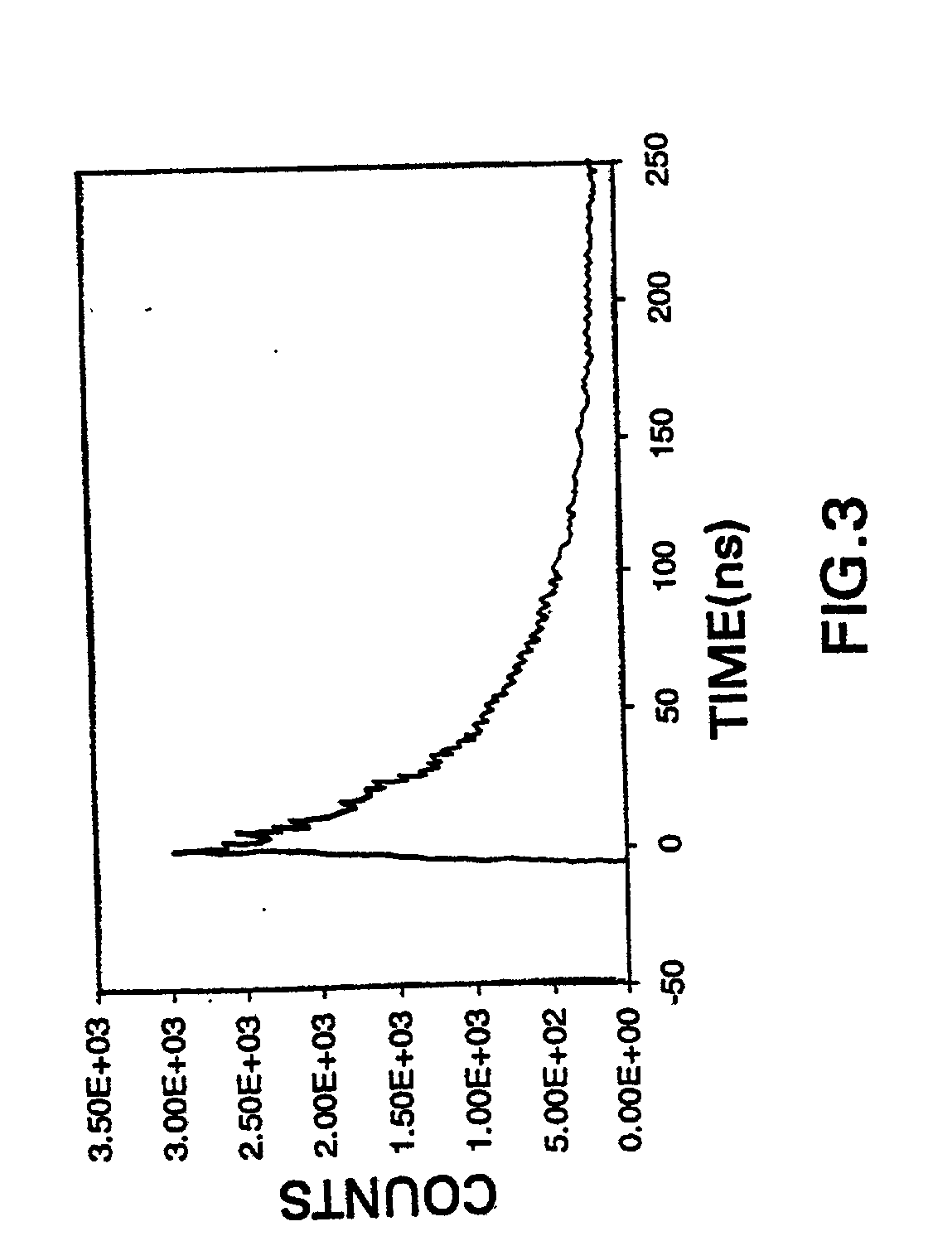

Terbium- or lutetium - containing garnet phosphors and scintillators for detection of high-energy radiation

InactiveUS6630077B2Improve light outputShort decay timePolycrystalline material growthMaterial analysis using wave/particle radiationLutetiumHigh energy

Owner:GENERAL ELECTRIC CO

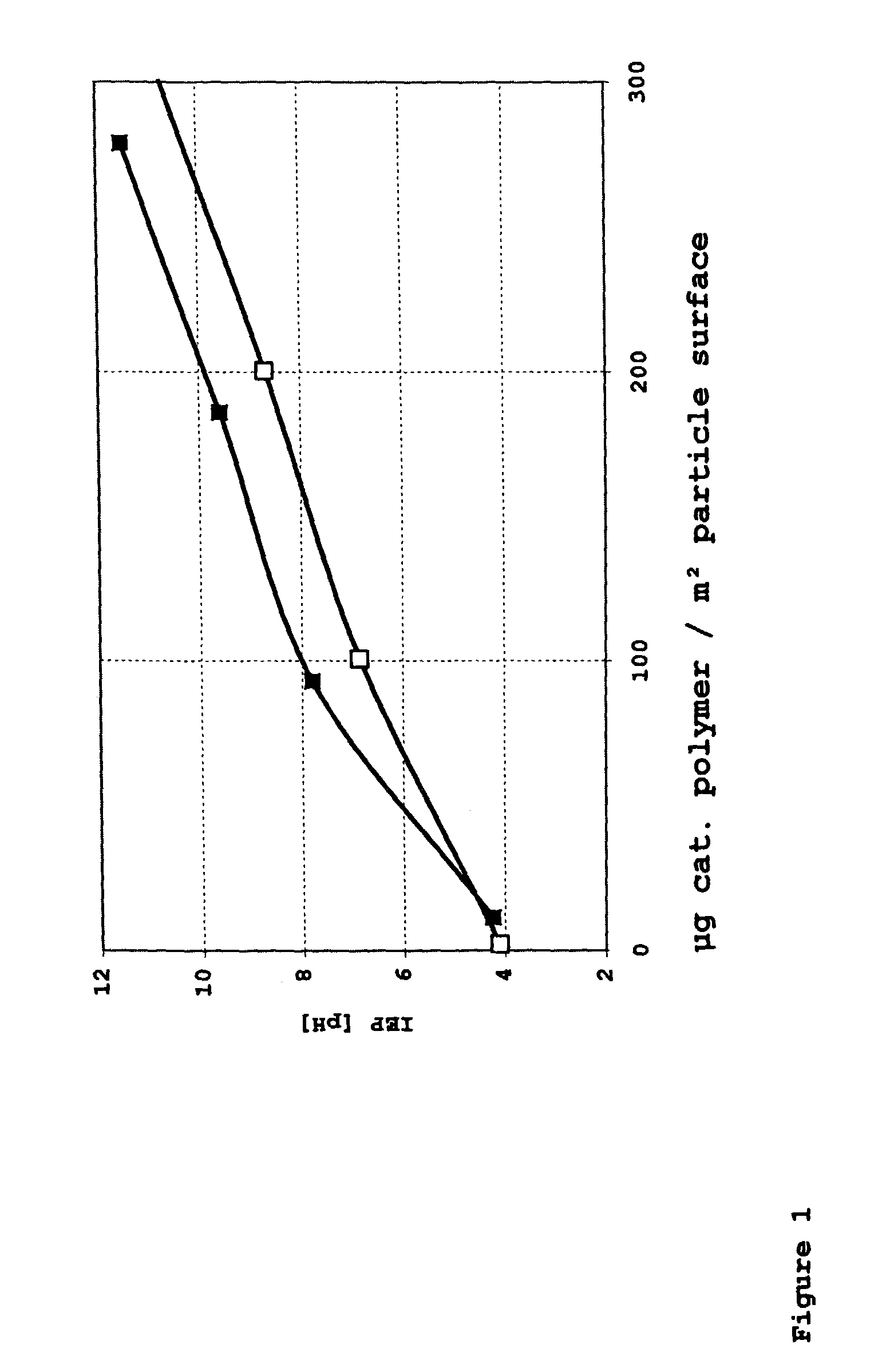

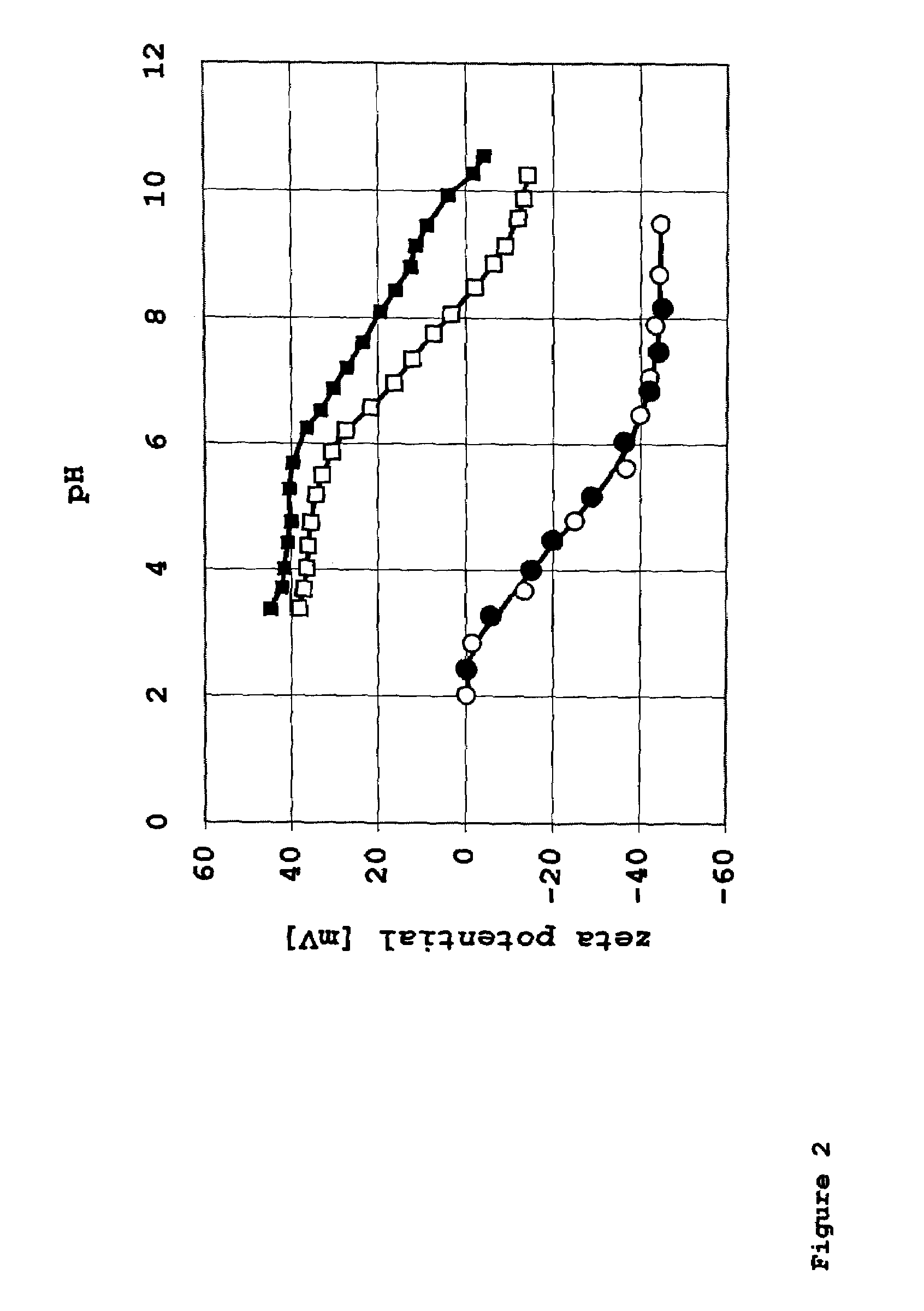

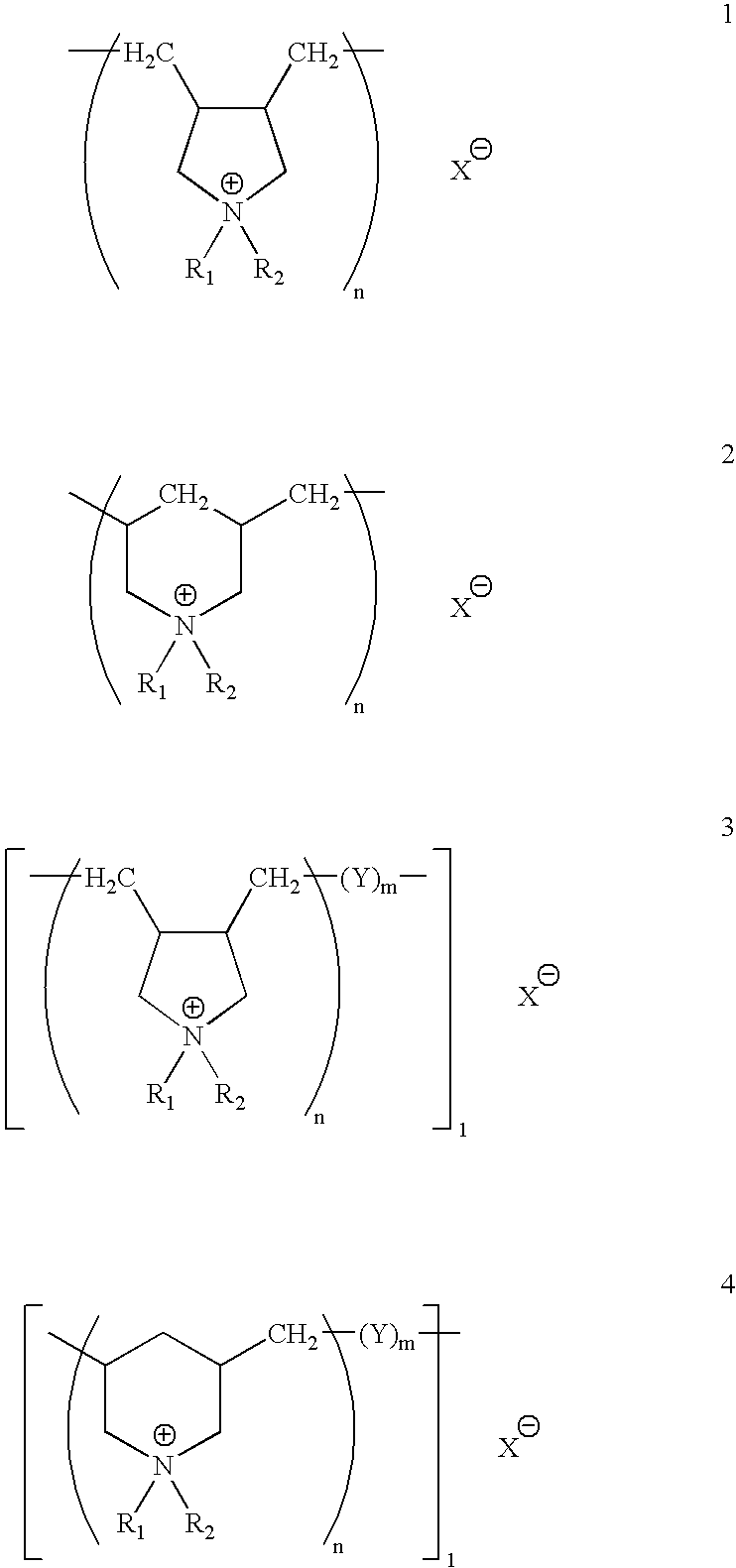

Cationic mixed-oxide dispersion, coating pigment and ink-absorbing medium

InactiveUS7015270B2Avoid large quantitiesHigh glossCoatings with pigmentsInorganic pigment treatmentZeta potentialMixed oxide

A stable, aqueous dispersion, which includes:silicon dioxide mixed-oxide particles dispersed in at least one water-soluble cationic polymer having a mass average molar mass of less than 100,000 g / mol, said mixed-oxide including aluminum oxide or titanium dioxide,wherein said particles are produced by flame hydrolysis,wherein said particles have a BET specific surface area of 5 to 600 m2 / g and a negative zeta potential,and wherein the dispersion has a positive zeta potential.

Owner:EVONIK DEGUSSA GMBH

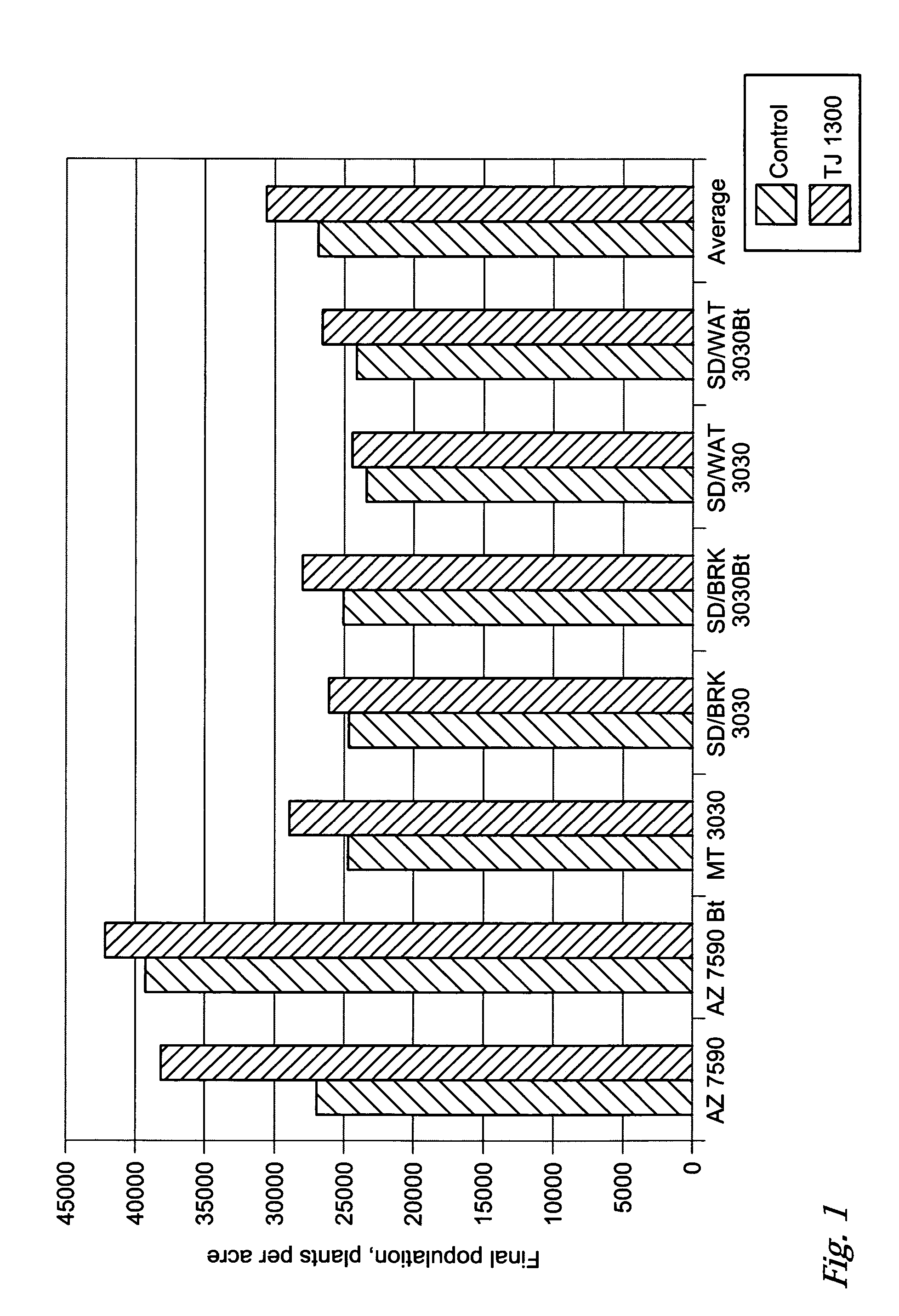

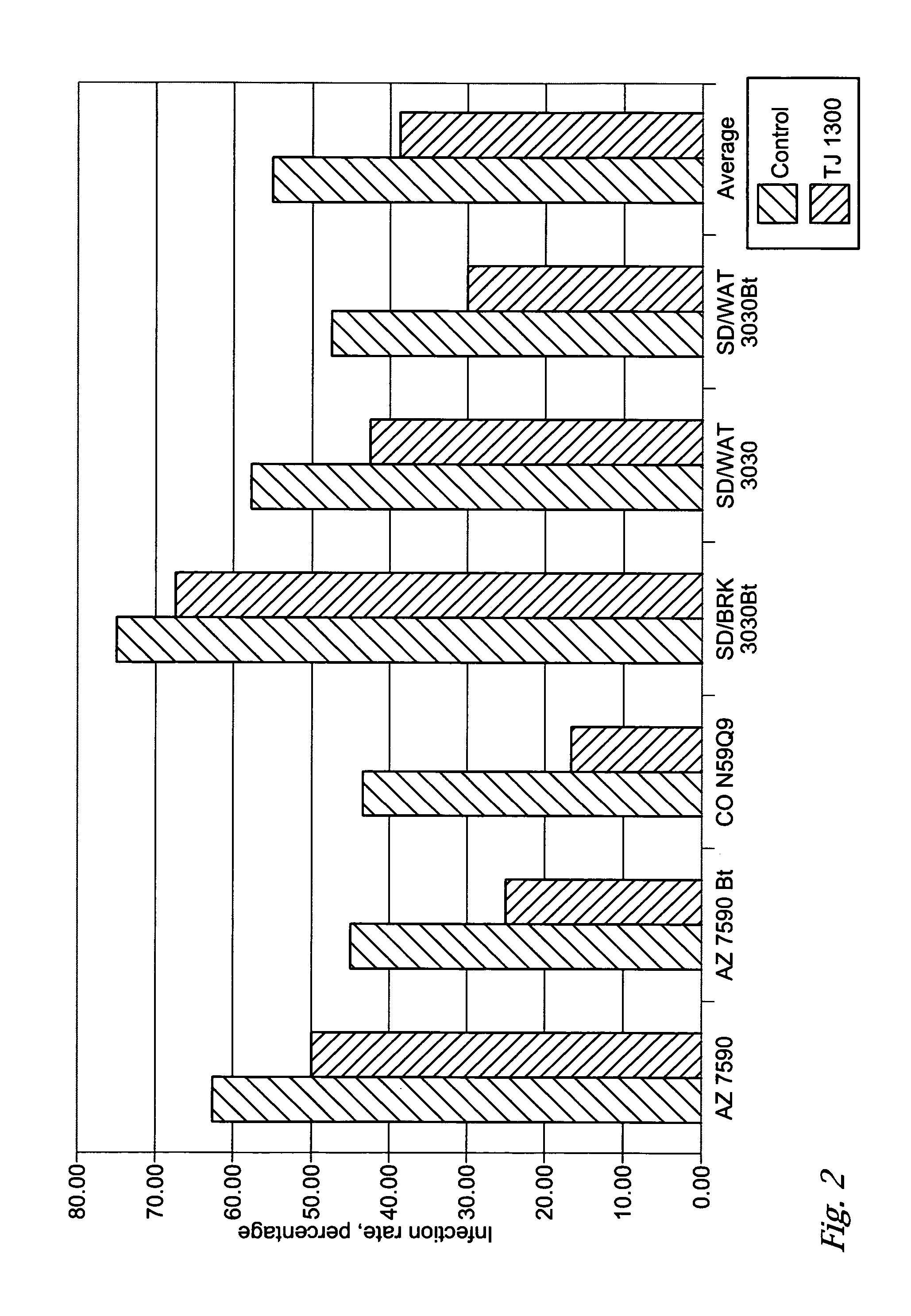

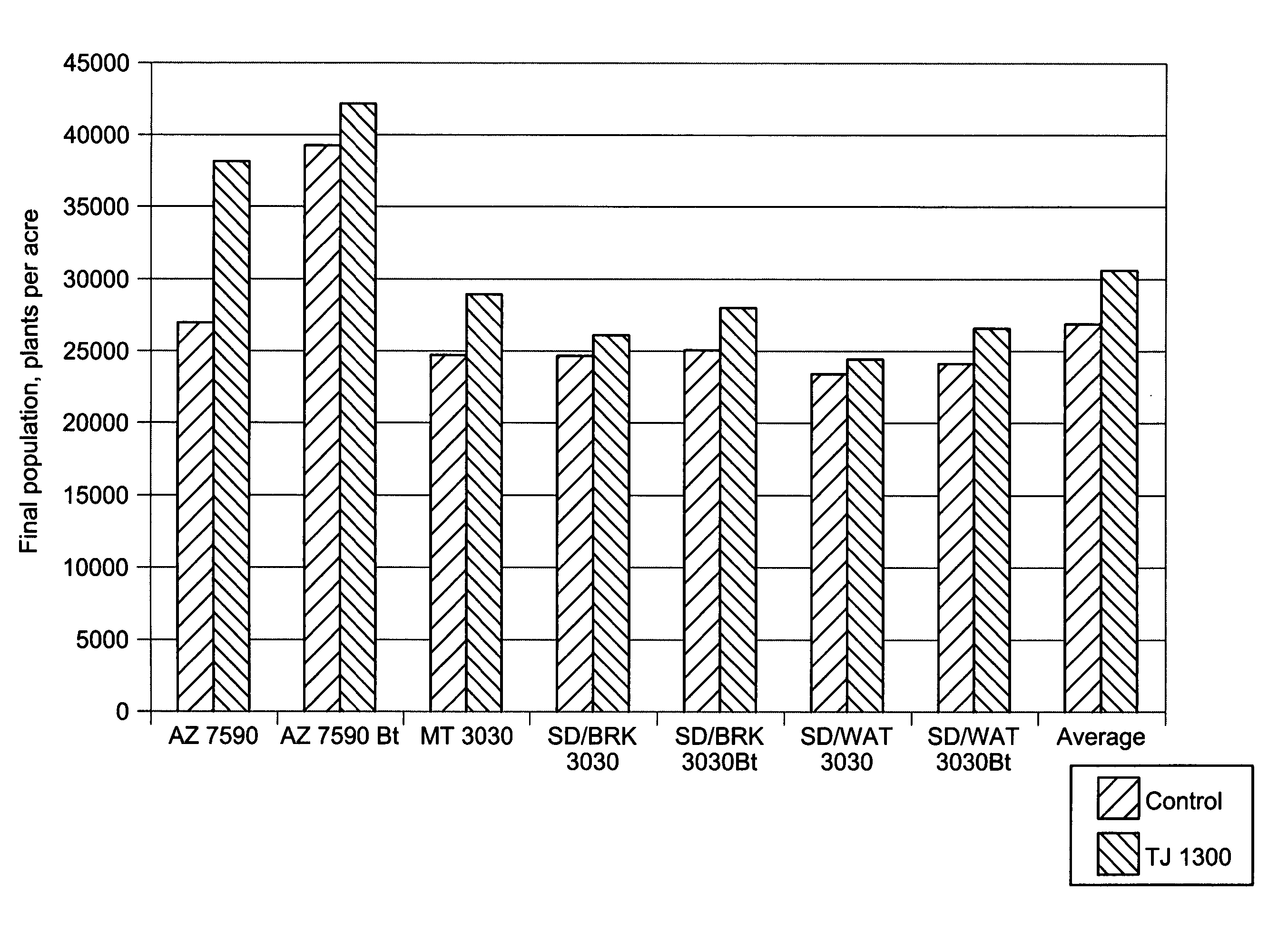

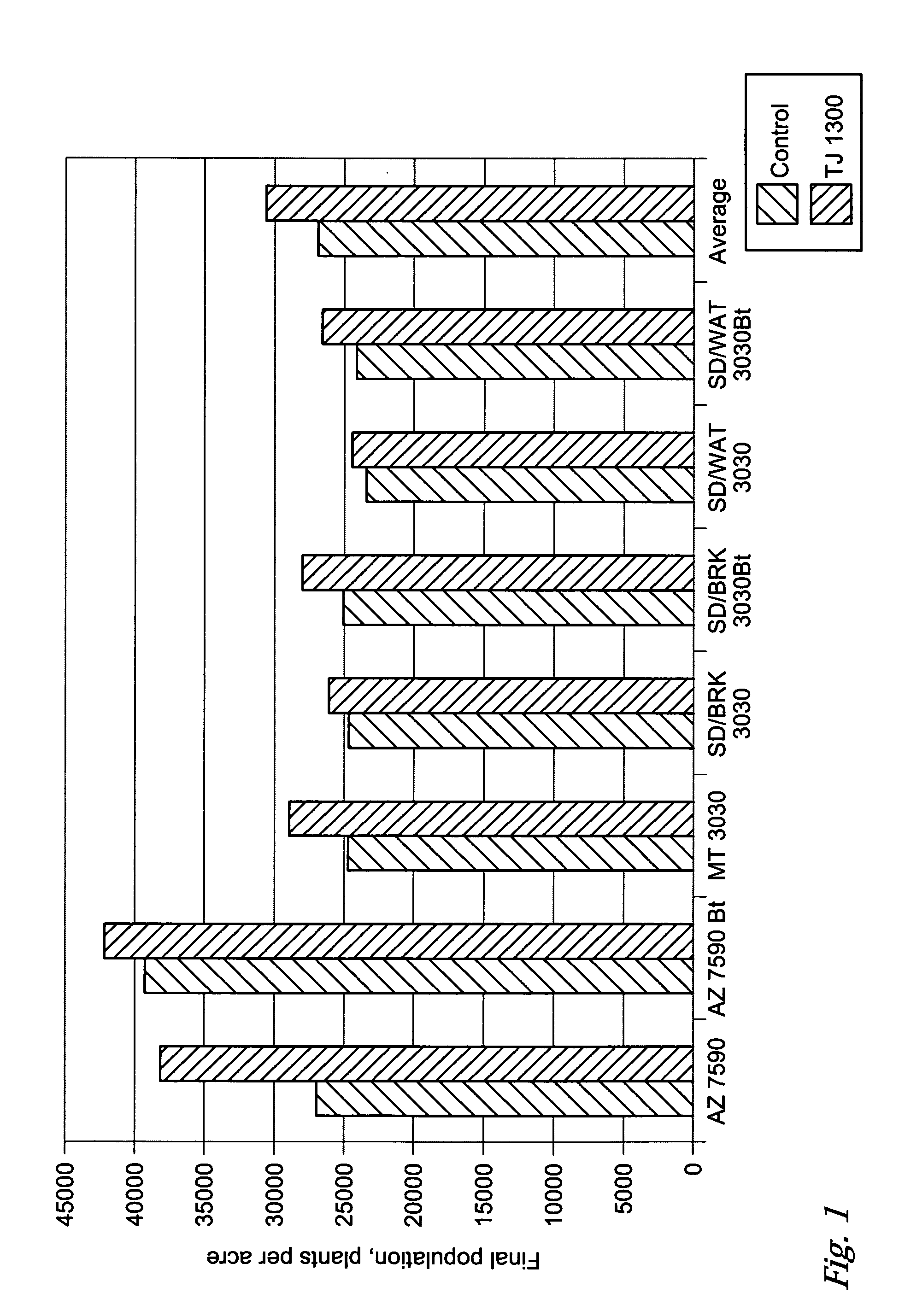

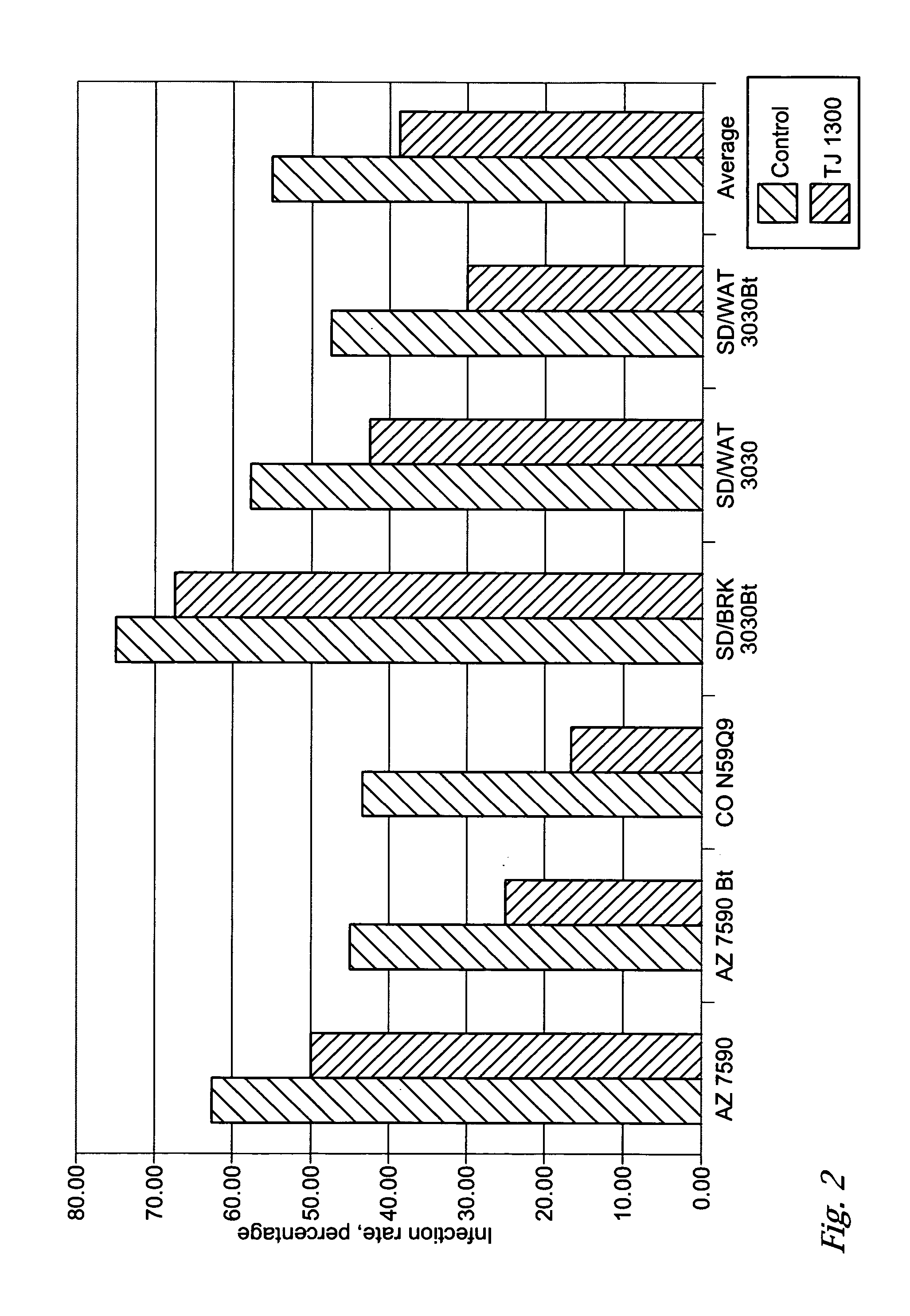

Controlling plant pathogens with bacterial/fungal antagonist combinations

Fungal / bacterial antagonist combinations, a seed coated with one of the combinations and a plant protected from plant pathogens by one of the combinations. The invention is also a fungal / bacterial antagonist combination comprising a Trichoderma virens fungal antagonist and a Bacillus subtilis var. amyloliquefaciens (Bacillus amyloliquefaciens) bacterial antagonist and its use for controlling plant pathogens as a biocontrol agent, bio-pesticide or bio-fungicide. The invention also finds utility as a fungal / bacterial antagonist combination applied to the seed, stalk or leaf that results in an increase in plant yield. Control of early and late season stalk and root rot caused by fungi such as Fusarium, Phythium, Phytophthora and Penicillium in tomatoes, peppers, turf grass, soybeans, sunflower, wheat and corn is achieved.

Owner:NOVOZYMES BIOAG AS

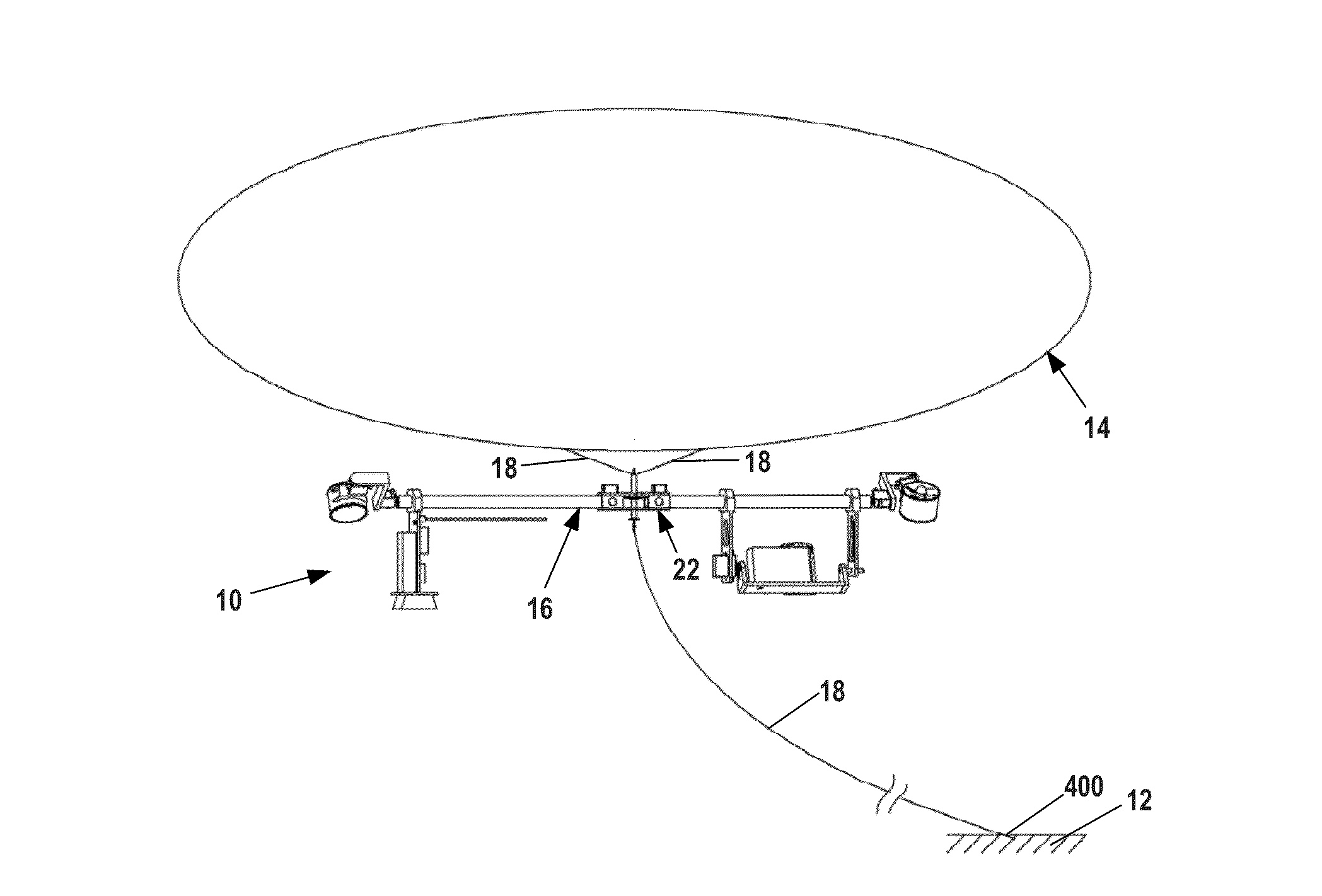

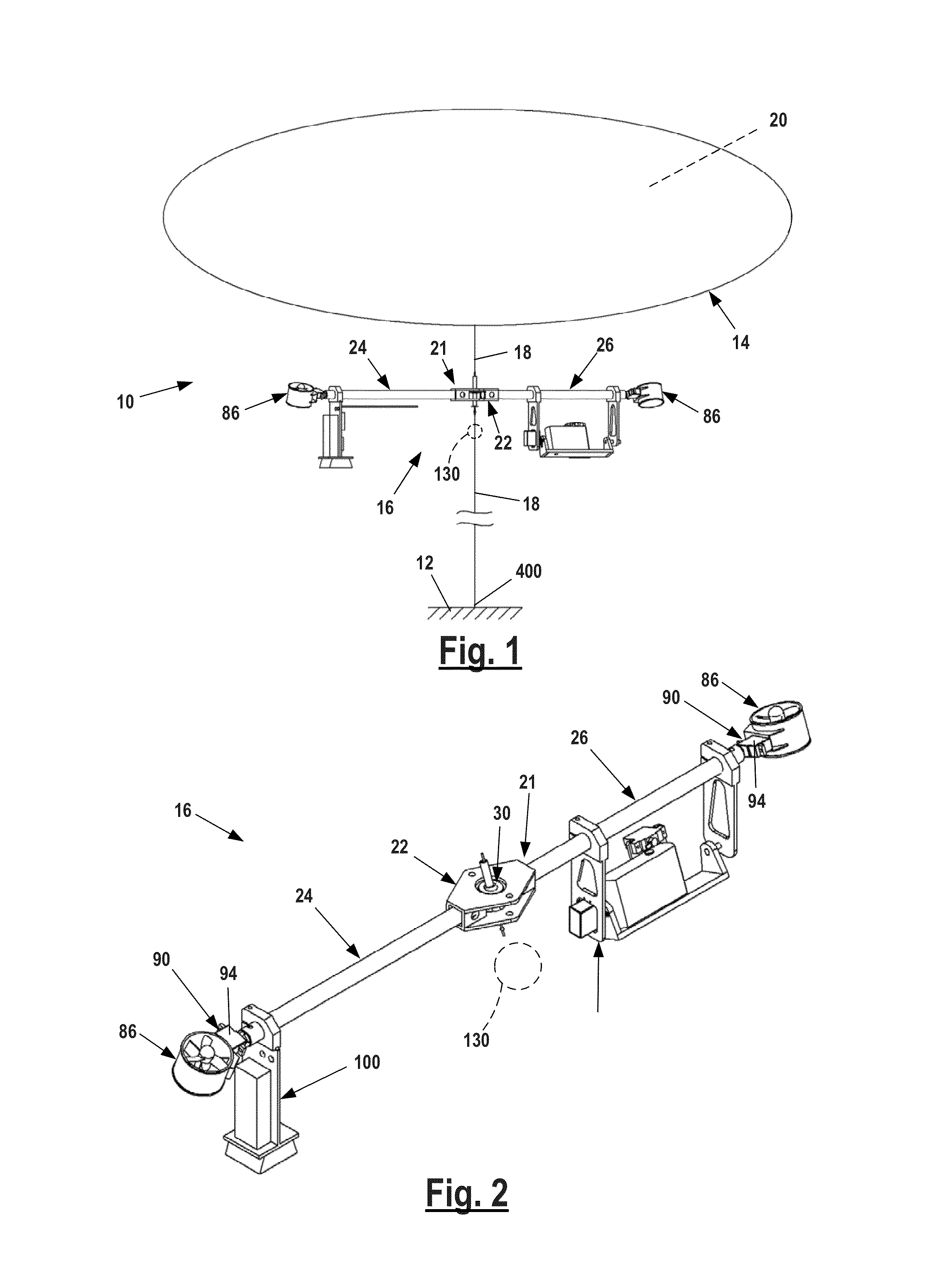

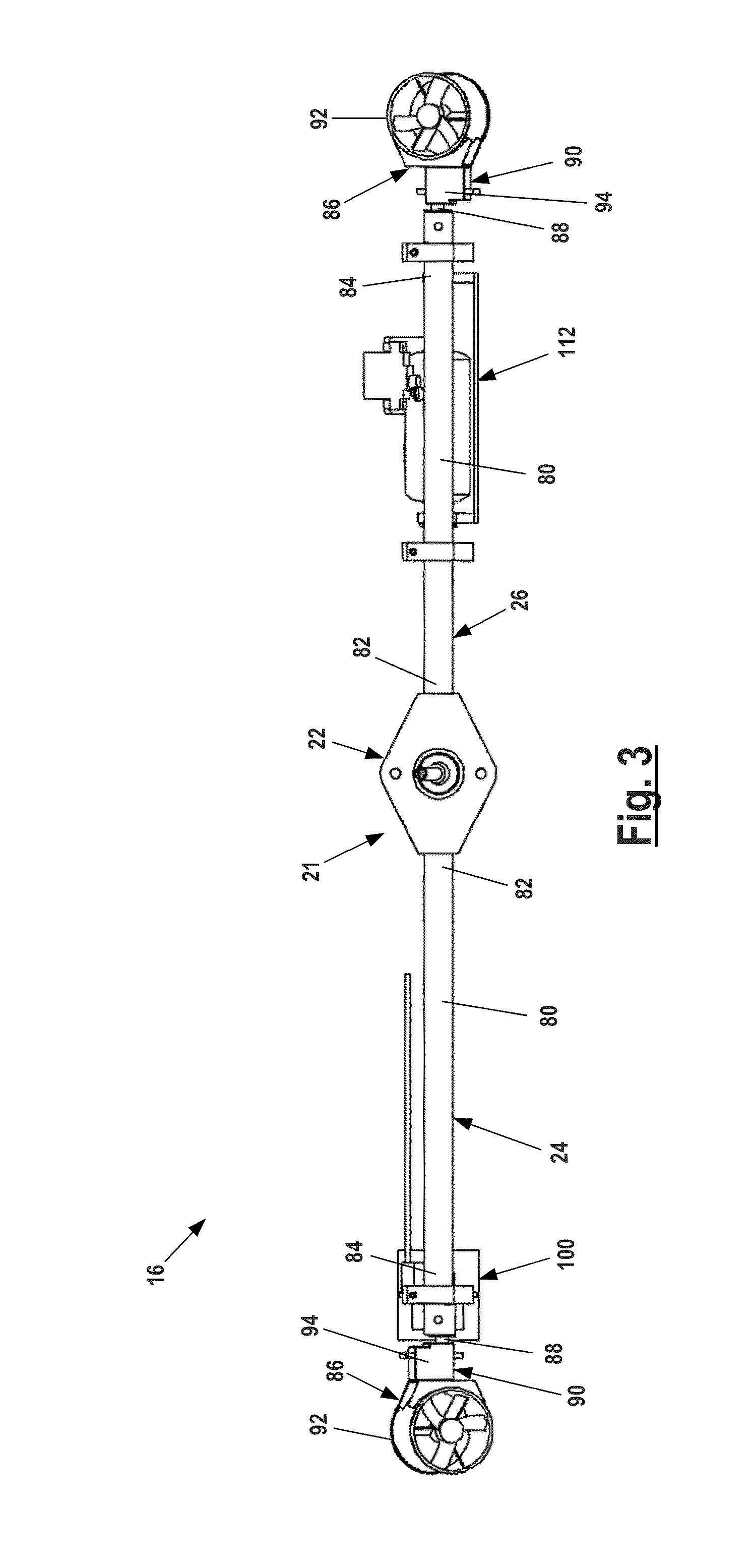

Aerostat assembly

InactiveUS8544788B1Easy to transportMinimal vibrationUnmanned aerial vehiclesRemote controlled aircraftEngineeringAerial photography

An aerostat assembly, specifically an aerostat assembly including one or more cameras for aerial photography and surveillance. The aerostat assembly includes a frame assembly having a pivot assembly joined to a balloon tether line. Thrusters on the frame allow an operator to maneuver the assembly to desired positions as well as rotate the frame assembly about the pivot assembly.

Owner:CAPTURES

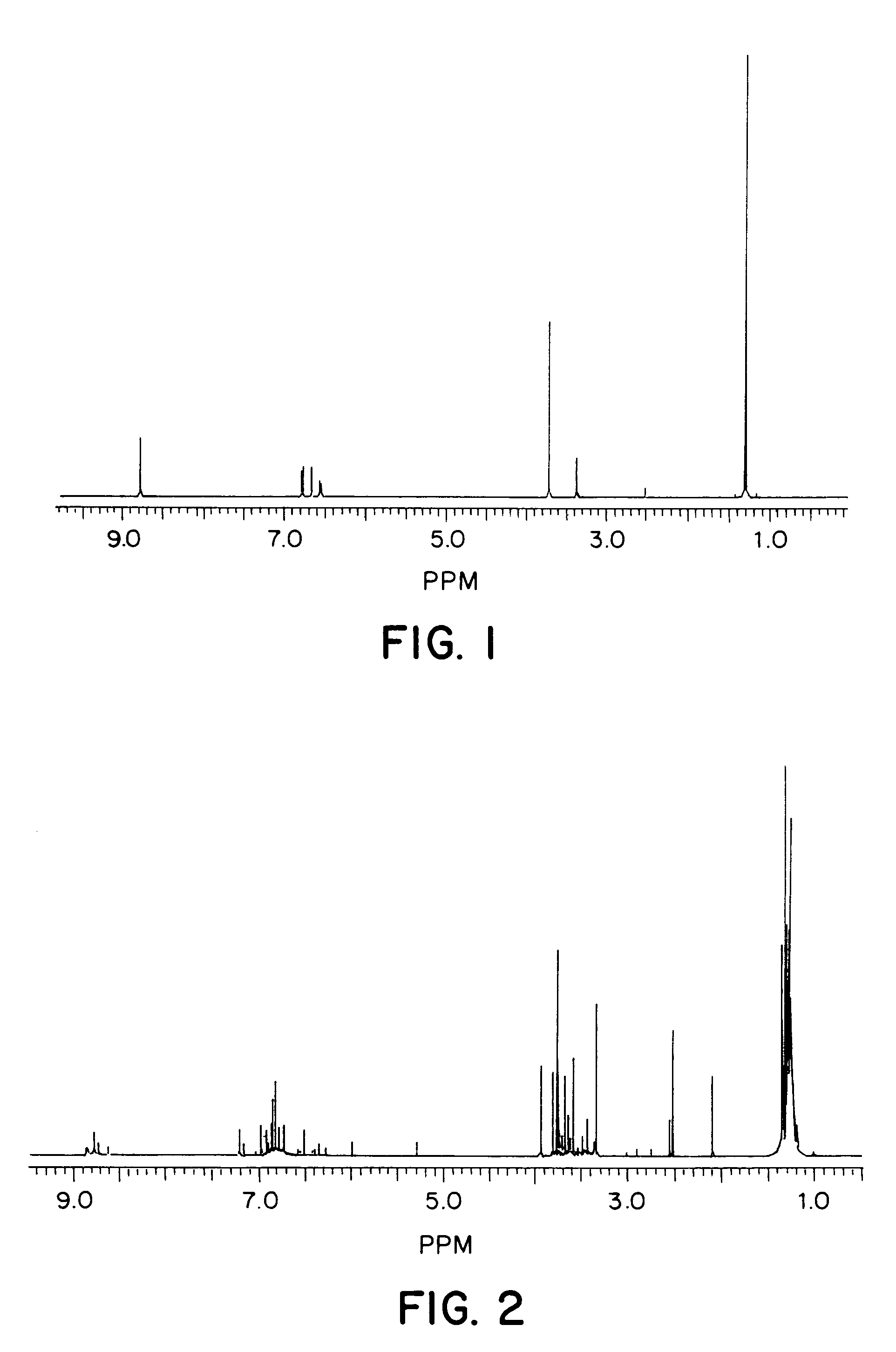

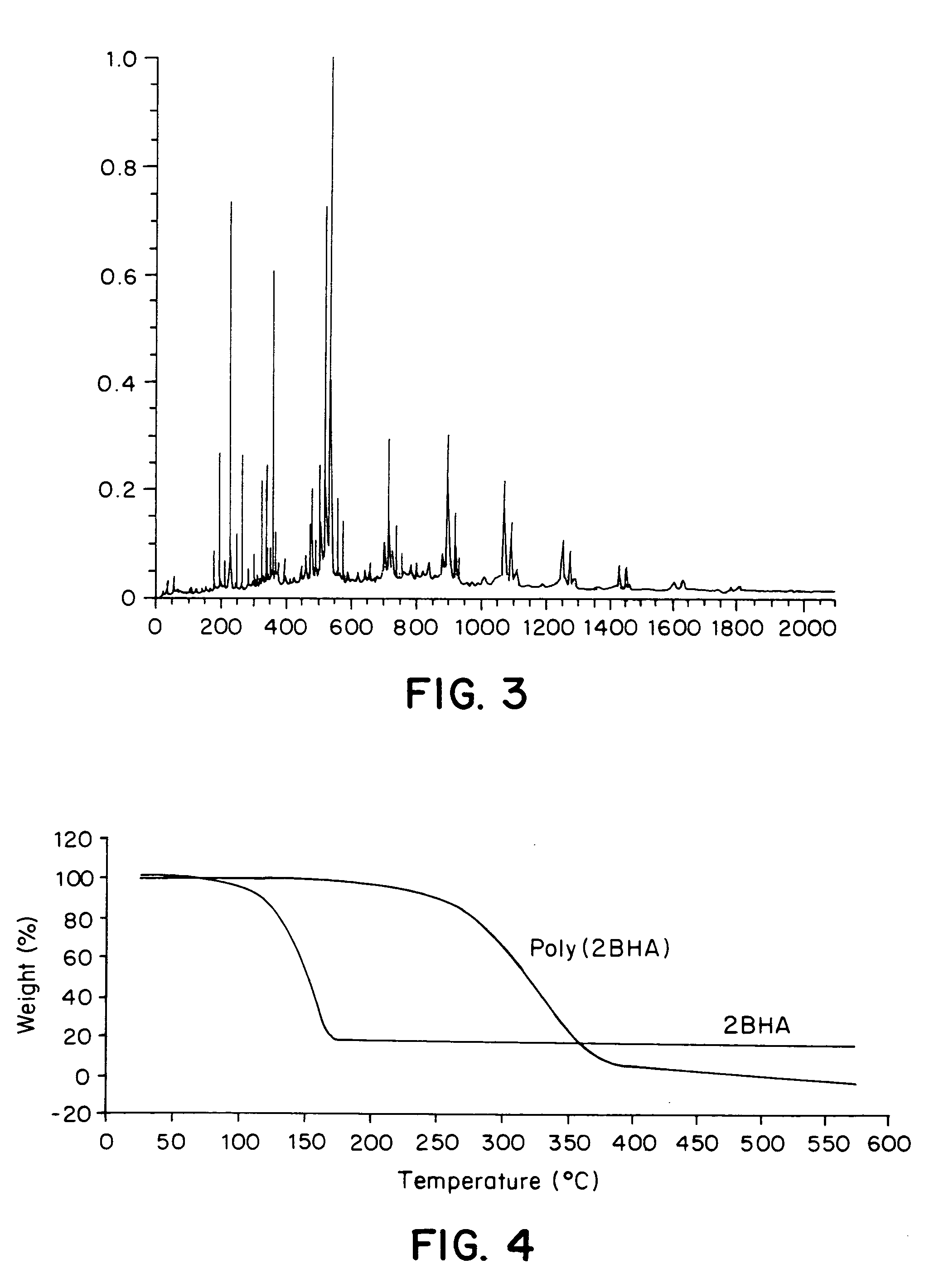

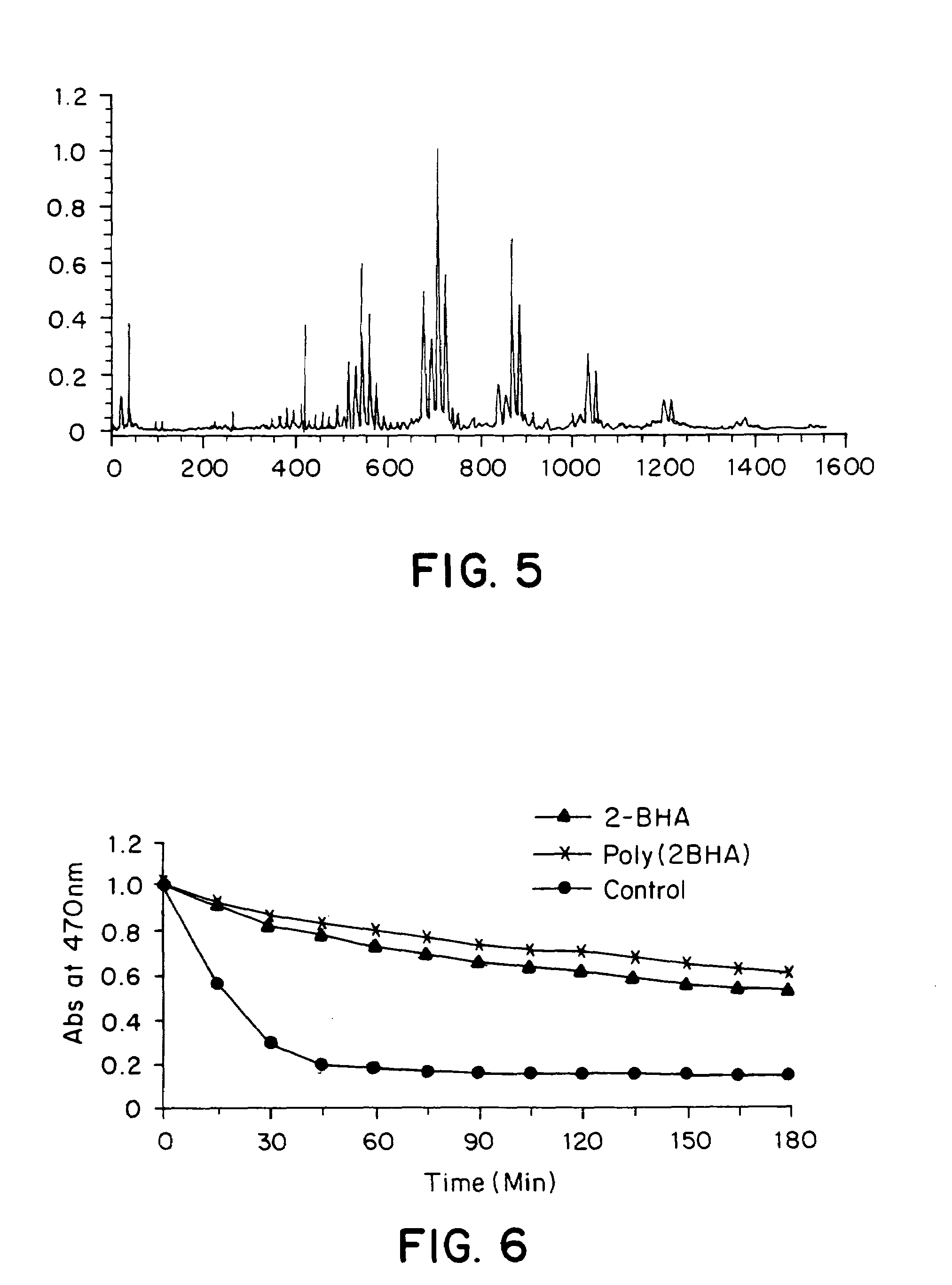

Polymeric antioxidants

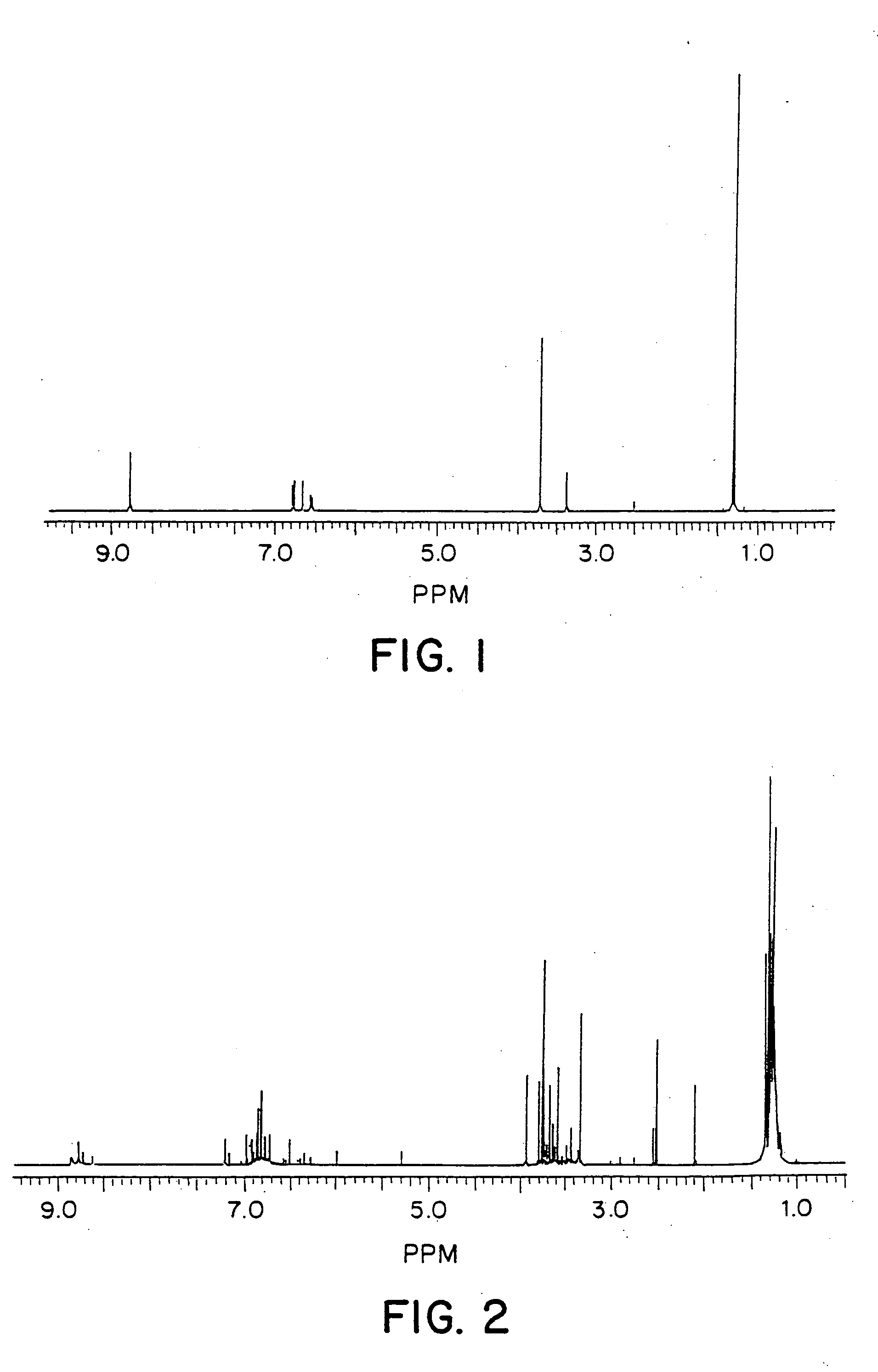

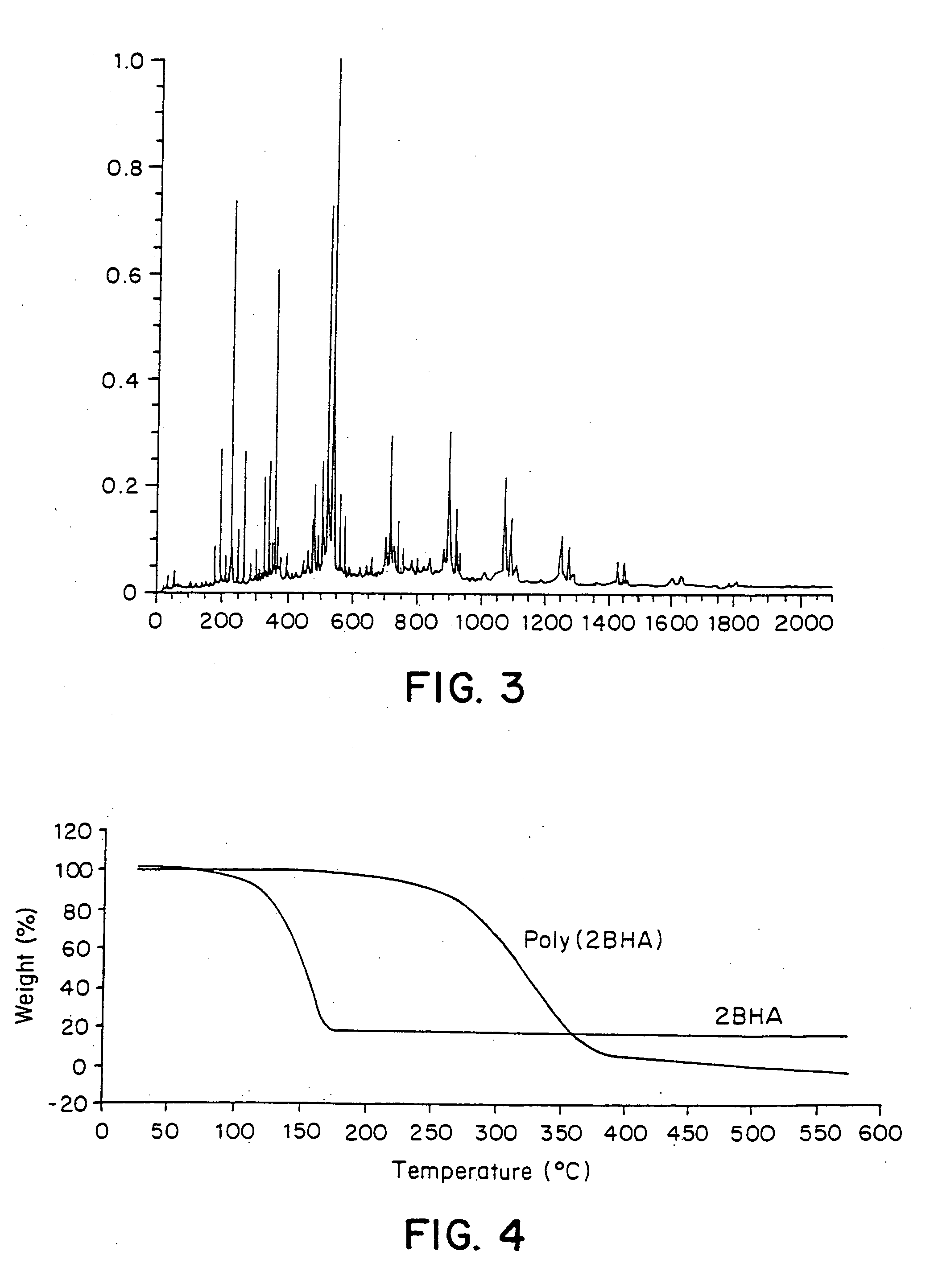

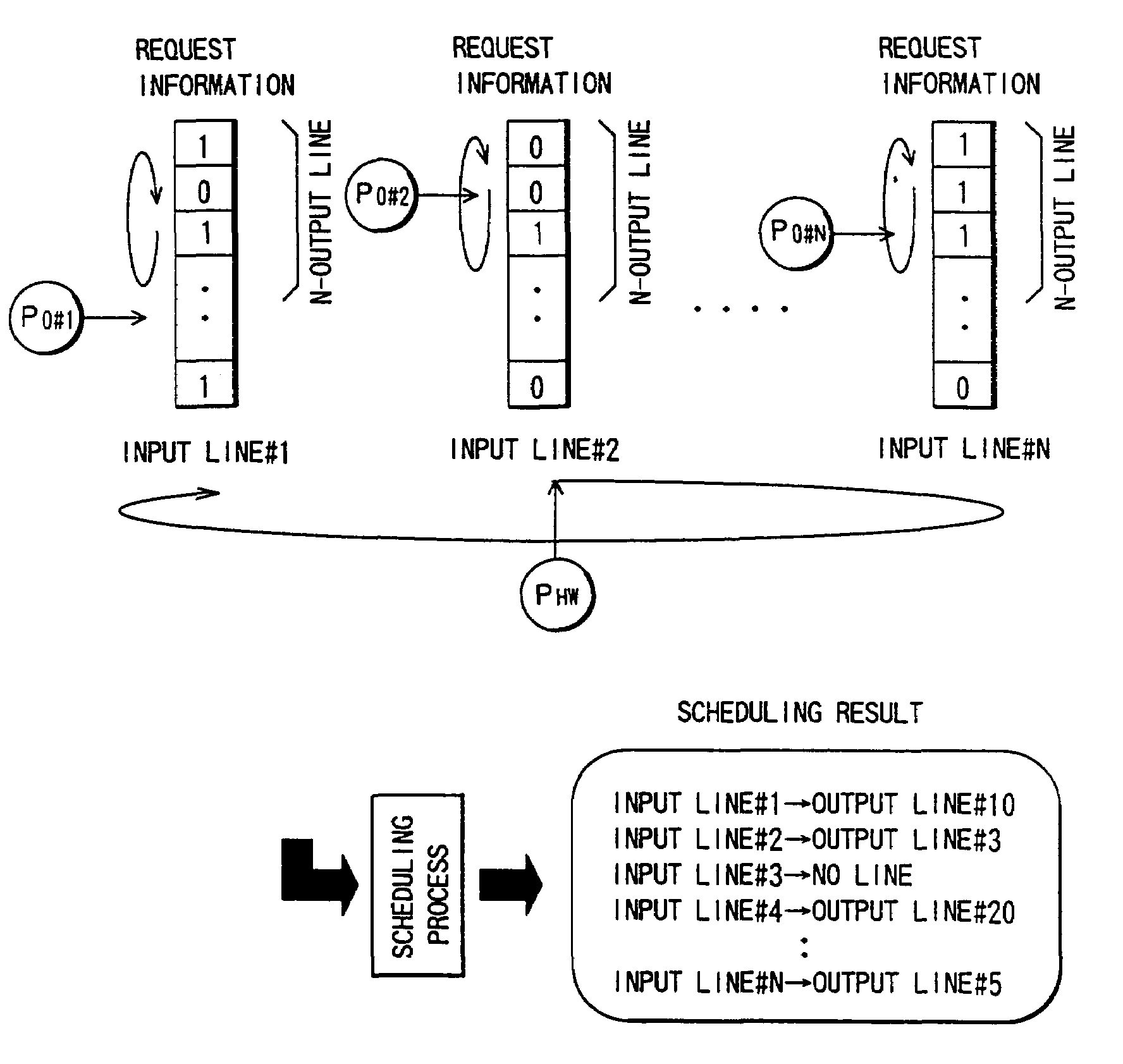

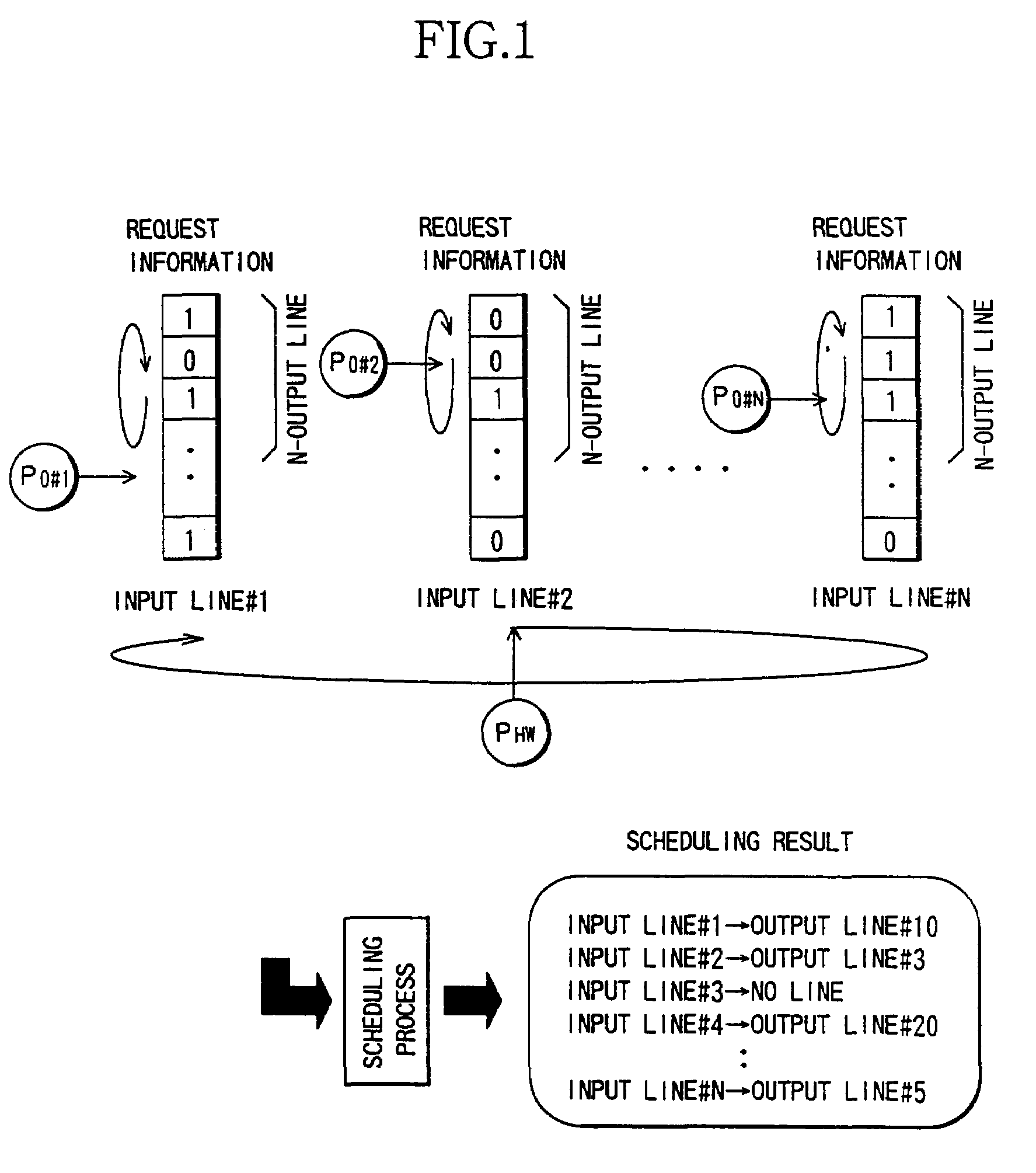

InactiveUS7223432B2Toxic reductionImprove thermal stabilityFatty substance preservation using additivesFood preservationArylPolymer science

Antioxidant polymers of the present invention comprise repeat units that include one or both of Structural Formulas (I) and (II):wherein:R is —H or a substituted or unsubstituted alkyl, acyl or aryl group;Ring A is substituted with at least one tert-butyl group or substituted or unsubstituted n-alkoxycarbonyl group;Ring B is substituted with at least one —H and at least one tert-butyl group or substituted or unsubstituted n-alkoxycarbonyl group;Rings A and B are each optionally substituted with one or more groups selected from the group consisting of —OH, —NH, —SH, a substituted or unsubstituted alkyl or aryl group, and a substituted or unsubstituted alkoxycarbonyl group;n is an integer equal to or greater than 2; andp is an integer equal to or greater than 0.The invention also includes methods of using and preparing these polymers.

Owner:UNIVERSITY OF MASSACHUSETTS LOWELL +1

Composite gas separation modules having a layer of particles with a uniform binder metal distribution

InactiveUS20060016332A1Reduce pore sizeSimplifies manufactureLiquid surface applicatorsMolten spray coatingCeramic particleGas separation

A composite gas separation module includes a porous substrate; an intermediate layer at the porous substrate that includes particles and a binder metal, wherein the binder metal is uniformly distributed throughout the intermediate layer; and a dense gas-selective membrane, wherein the dense gas-selective membrane overlies the intermediate layer. In one embodiment, the intermediate layer includes a gradient of particle size from a surface of the intermediate layer proximate to the porous substrate to a surface of the intermediate layer distal to the porous substrate. The particles of the intermediate layer can include particles selected from the group consisting of metal particles, metal oxide particles, ceramic particles, zeolite particles, and combinations thereof.

Owner:WORCESTER POLYTECHNIC INSTITUTE

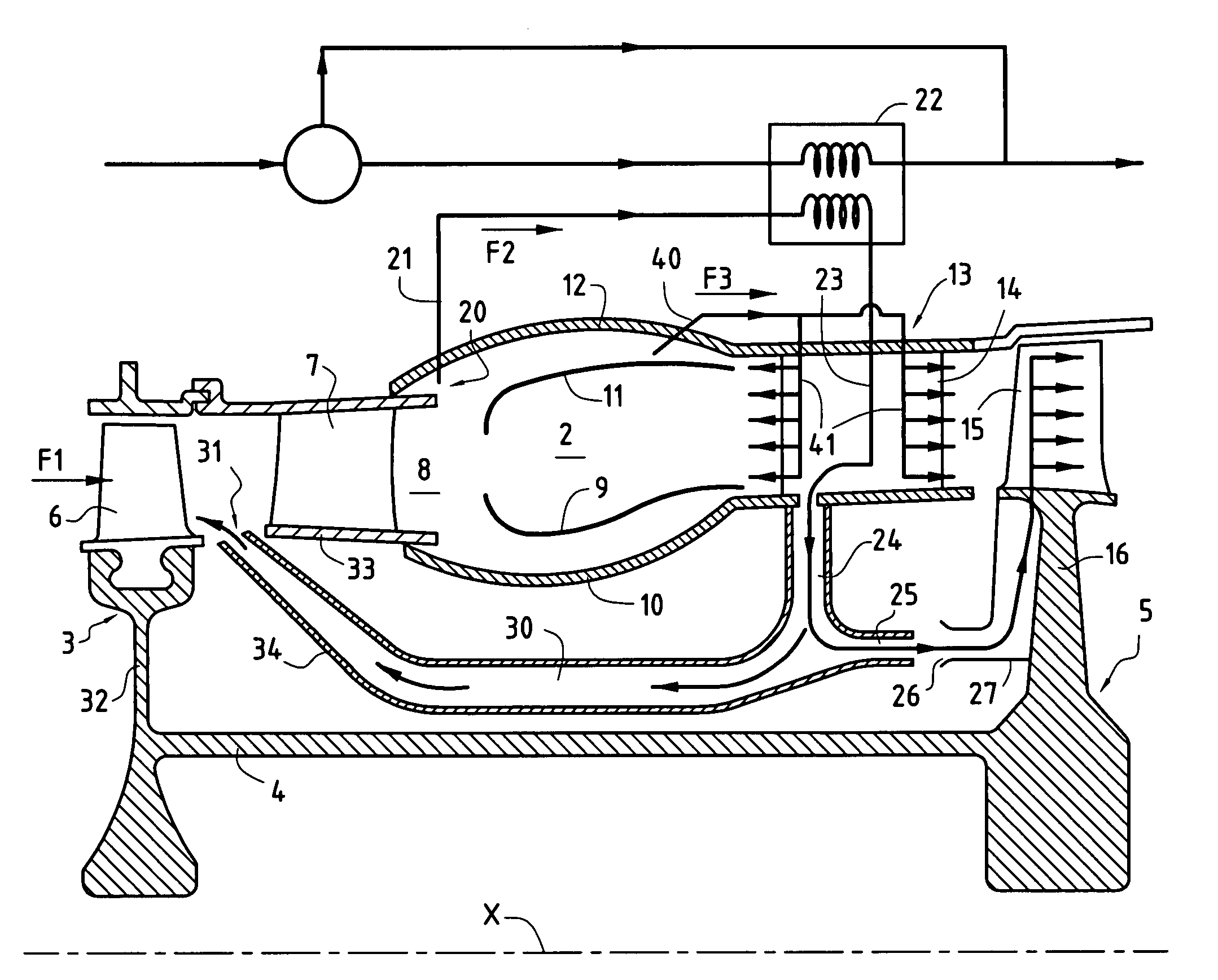

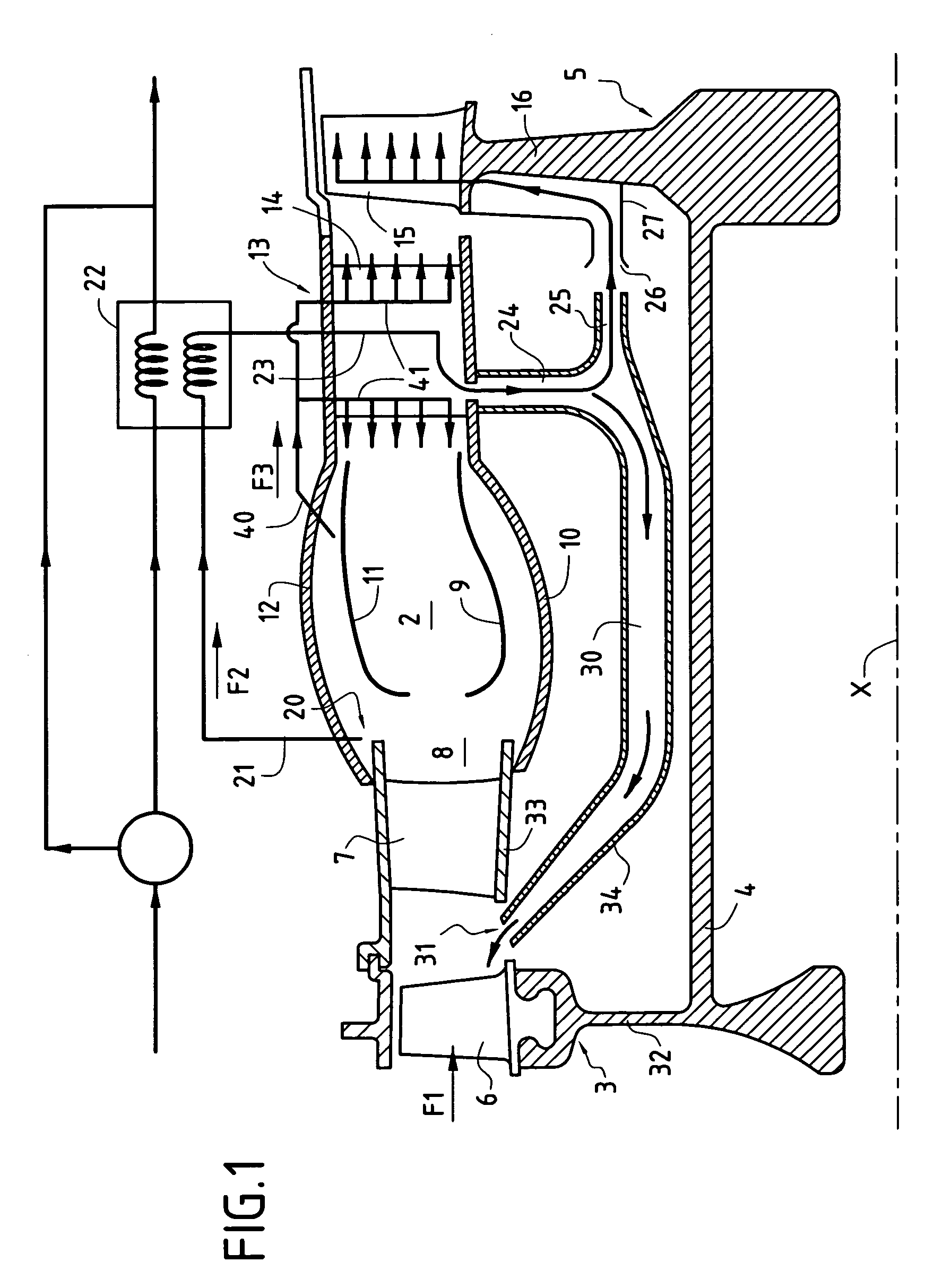

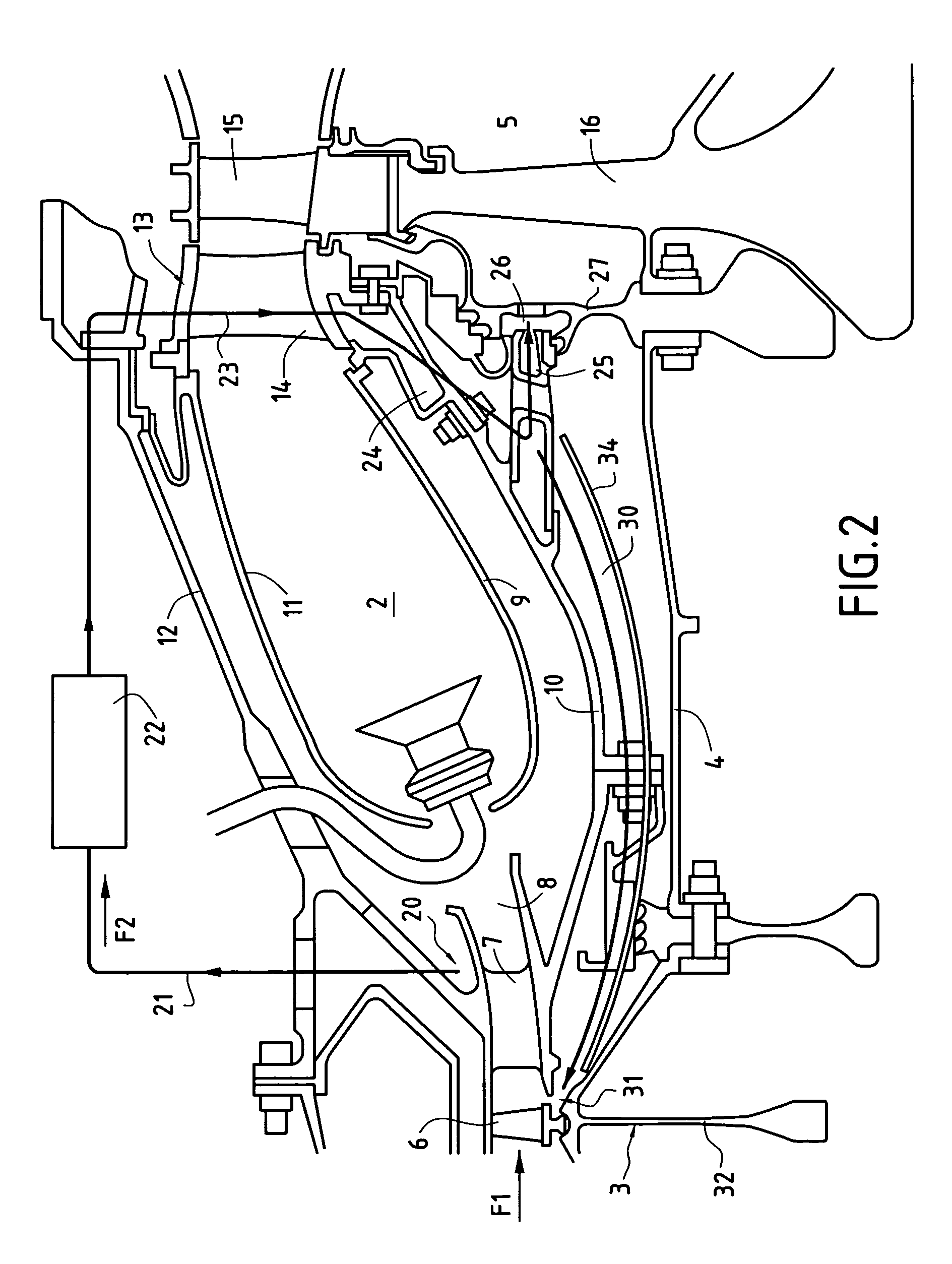

Heat exchanger on a turbine cooling circuit

ActiveUS7000404B2Avoid cloggingAvoid large quantitiesPump componentsEngine fuctionsCombustion chamberPlate heat exchanger

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Polymeric antioxidants

InactiveUS20060029706A1Toxic reductionImprove thermal stabilityFatty substance preservation using additivesFood preservationArylAntioxidant

Antioxidant polymers of the present invention comprise repeat units that include one or both of Structural Formulas (I) and (II): wherein: R is —H or a substituted or unsubstituted alkyl, acyl or aryl group; Ring A is substituted with at least one tert-butyl group or substituted or unsubstituted n-alkoxycarbonyl group; Ring B is substituted with at least one —H and at least one tert-butyl group or substituted or unsubstituted n-alkoxycarbonyl group; Rings A and B are each optionally substituted with one or more groups selected from the group consisting of —OH, —NH, —SH, a substituted or unsubstituted alkyl or aryl group, and a substituted or unsubstituted alkoxycarbonyl group; n is an integer equal to or greater than 2; and p is an integer equal to or greater than 0. The invention also includes methods of using and preparing these polymers.

Owner:UNIVERSITY OF MASSACHUSETTS LOWELL +1

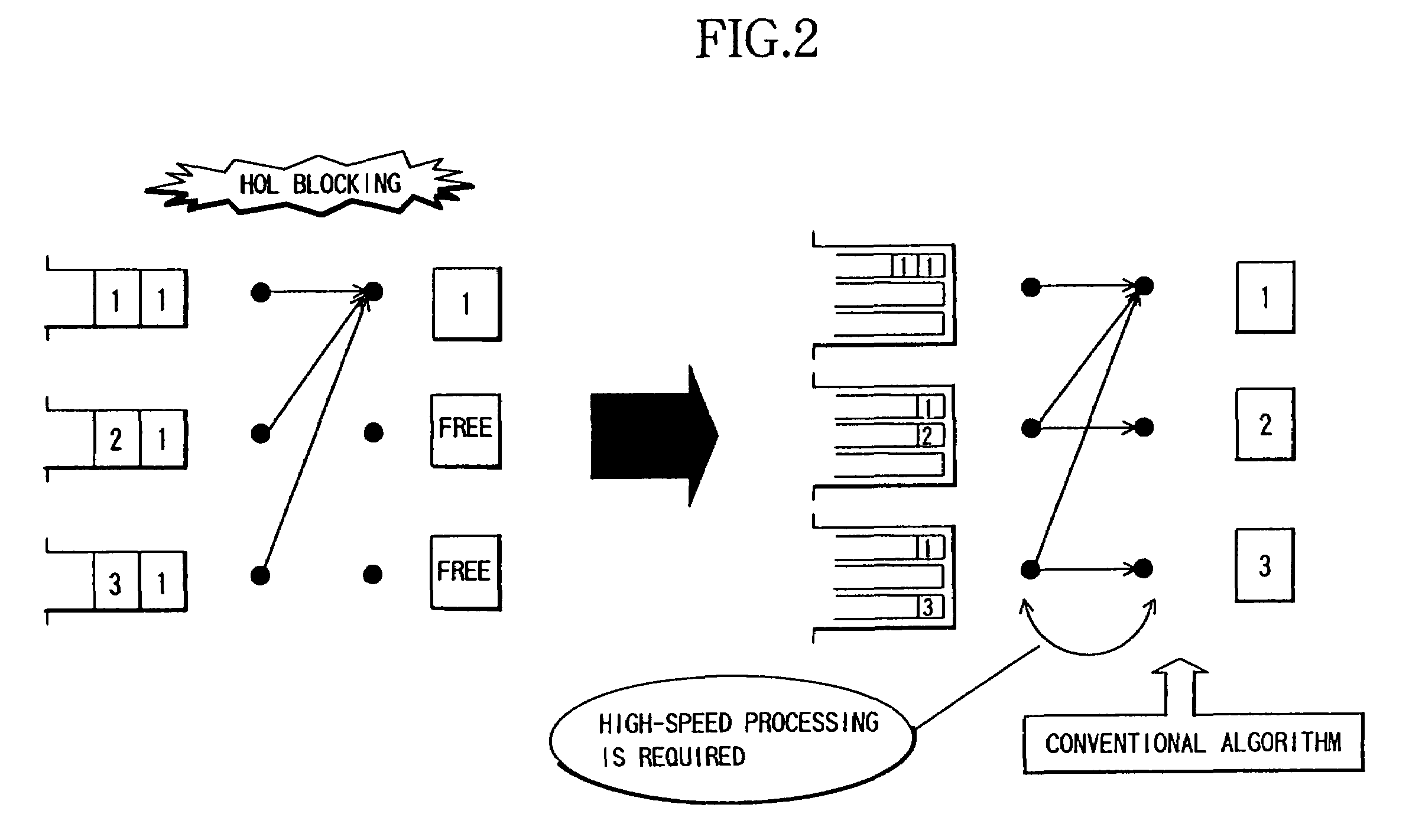

Scheduling control system and switch

InactiveUS7046685B1Shorten the timeCutting synchronizationMultiplex communicationDigital computer detailsControl systemClockwise

A scheduling system is capable of causing no deterioration of characteristics even under equal and unequal loads, eliminating the necessity for high-speed repetitive scheduling and complicated arithmetic processes, simplifying its architecture and having its processing speed which does not depend upon a device capability. For attaining this system, an inter-highway pointer is updated to an adjacent line (rightward) when the scheduling for all the lines are finished. If the inter-highway pointer is updated N-times in the same direction (clockwise), the same pointer is updated to an adjacent line in a reverse direction (counterclockwise) in next N-processes of scheduling.

Owner:FUJITSU LTD

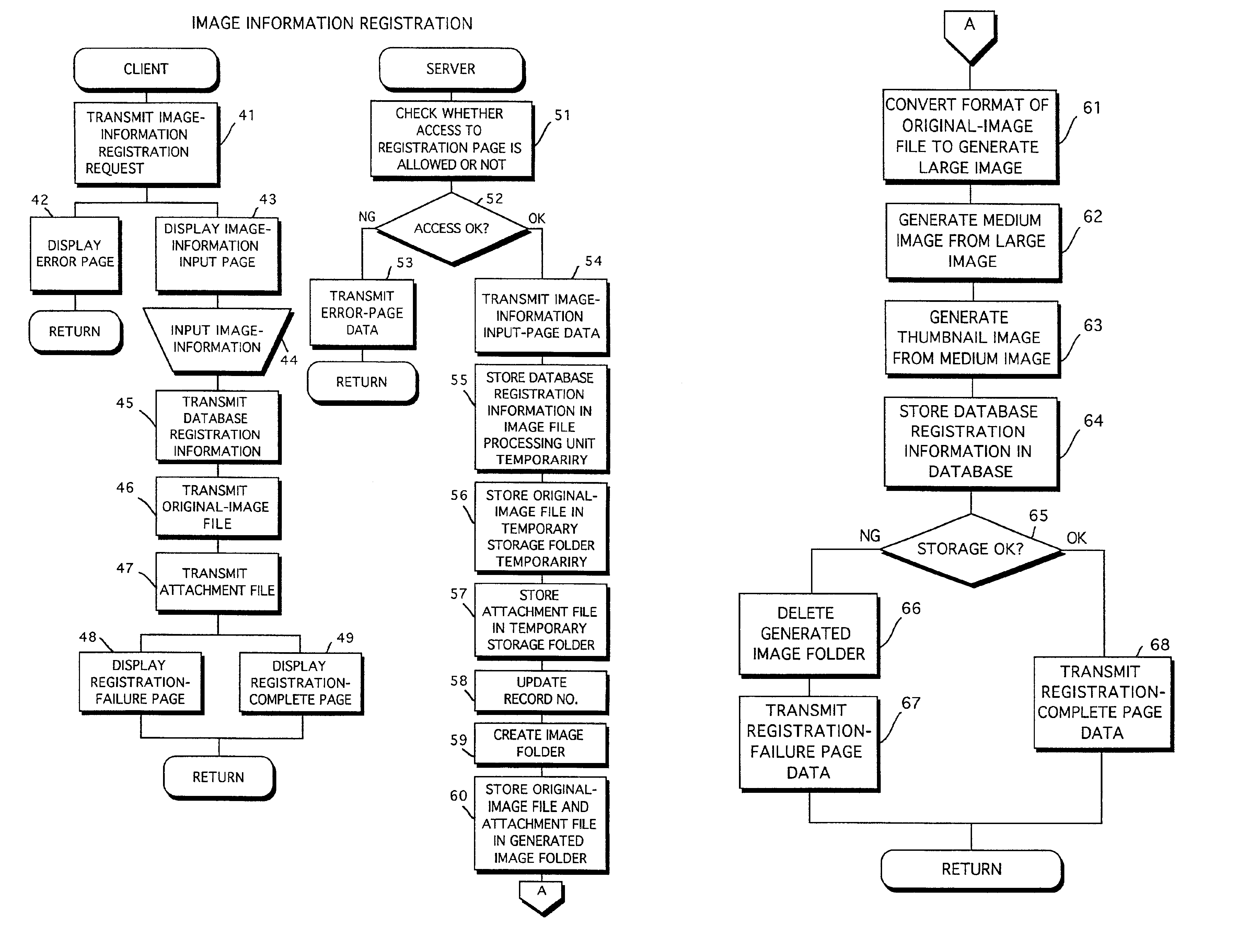

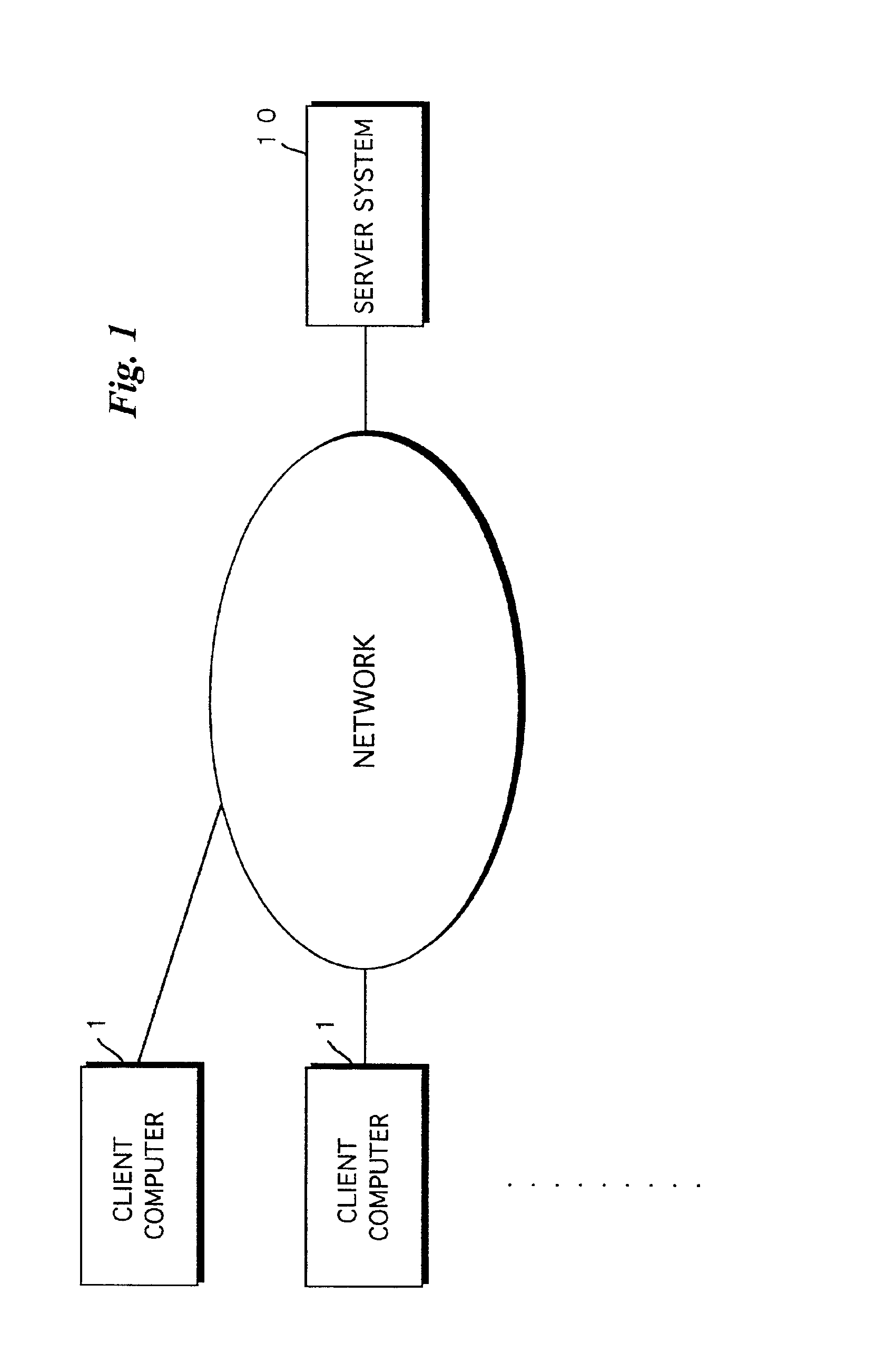

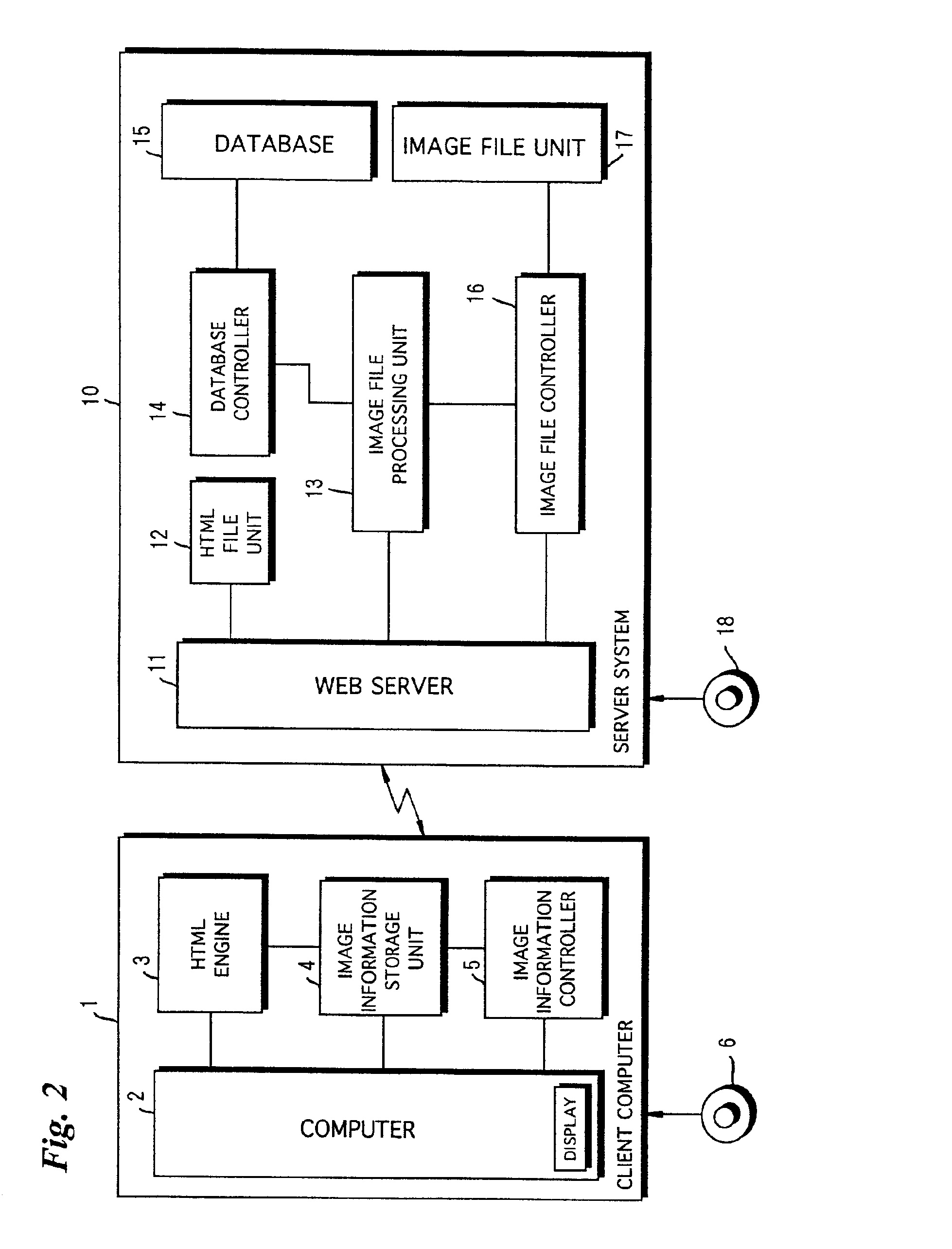

Image data communication system, server system, method of controlling operation of same, and recording medium storing program for control of server system

InactiveUS6856414B1Easy to seeImprove image qualityData processing applicationsStill image data indexingCommunications systemClient-side

Original images, large images, medium images and thumbnail images are registered with a server system. An original-image file is transmitted from a client computer to the server system. The server system converts the format of the original-image file to generate a large-image file, generates a medium-image file, in which the quantity of data is less than that of the large-image file, from the large-image file, and generates a thumbnail-image file, in which the quantity of data is less than that of the medium-image file, from the medium-image file. The original-image file, large-image file, medium-image file and thumbnail-image file are placed on one folder and stored in an image file unit. After the folder containing the original-image file, etc., has been stored in the image file unit, the user of a client computer having access privileges is capable of accessing files such as the large-image file.

Owner:META PLATFORMS INC

Heat-conductive silicone composition and cured product thereof

ActiveUS20080057325A1Minimal increaseGood flexibilityLayered productsAdhesivesPliabilityElectronic component

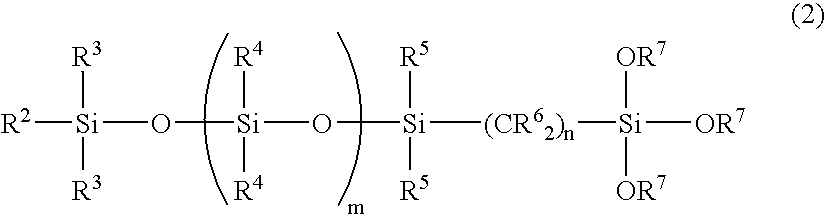

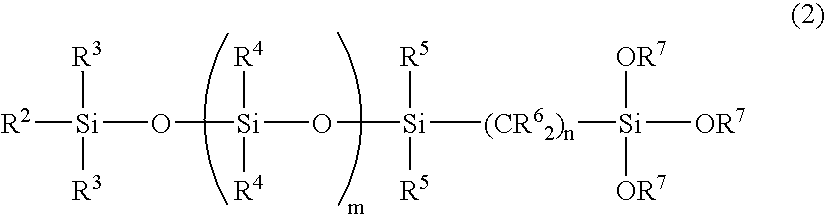

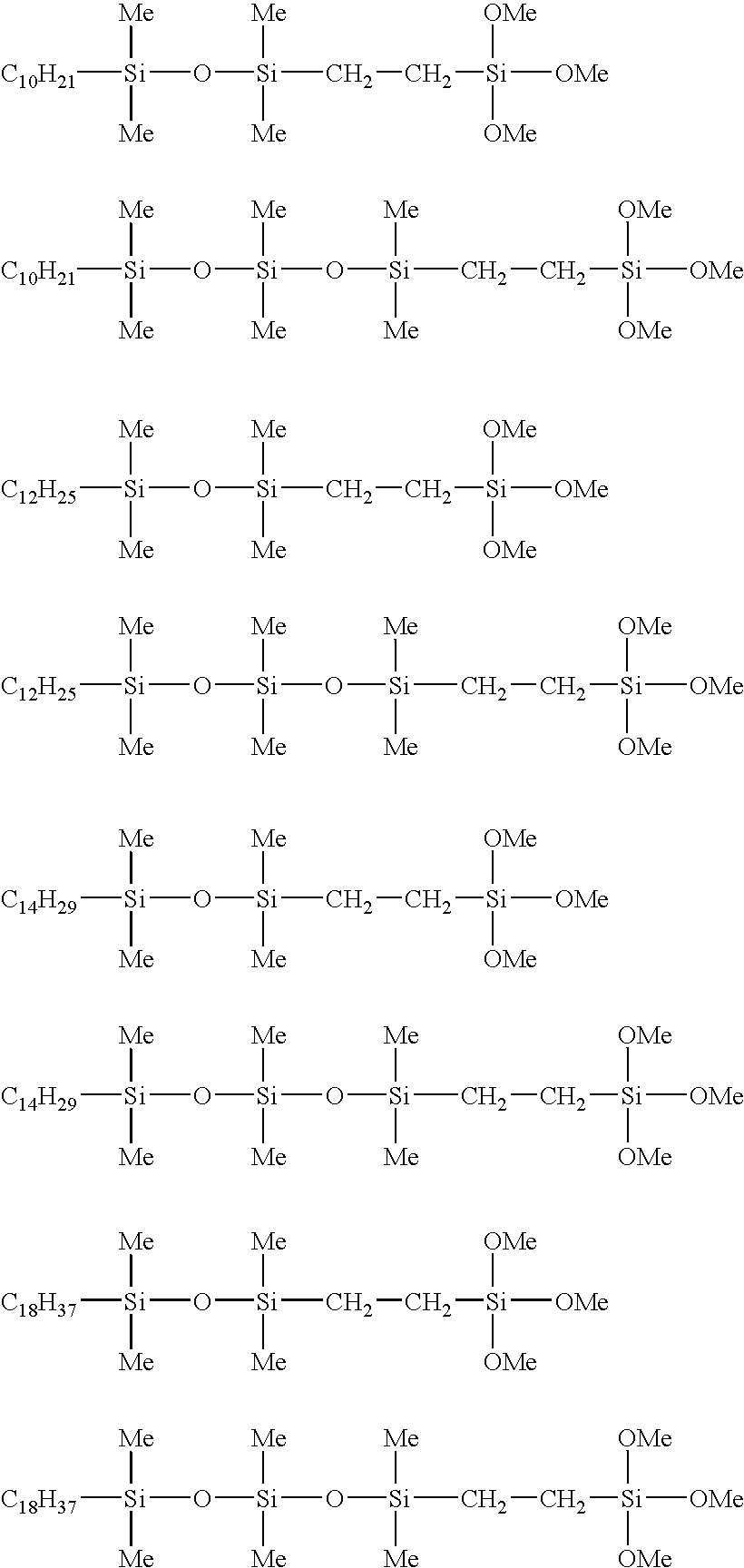

Provided is a heat-conductive silicone composition, including: (A) 100 parts by volume of an organopolysiloxane having a specific structure, (B) 0.1 to 50 parts by volume of an organosilicon compound that functions as a wetter and contains a triorganooxysilyl group bonded to one terminal via an alkylene group that may be branched, (C) 100 to 2,500 parts by volume of a heat-conductive filler, and (D) an effective quantity of a curing agent. Also provided is a heat-conductive silicone cured product obtained by curing this composition. The heat-conductive silicone composition, even when filled with a large quantity of a heat-conductive filler in order to provide superior thermal conductivity, exhibits a minimal increase in viscosity or plasticity, and retains favorable handling properties and moldability. The heat-conductive silicone cured product exhibits excellent flexibility even when filled with a large quantity of a heat-conductive filler. Heat generated by a heat-generating electronic component can be dissipated into a heat-radiating component by sandwiching the cured product between the heat-generating electronic component and the heat-radiating component.

Owner:SHIN ETSU CHEM IND CO LTD

Toner

ActiveUS7273686B2Less overall consumptionAvoid large quantitiesScanning probe techniquesDevelopersSurface roughnessEngineering

In a toner comprising toner particles which comprise toner base particles containing at least a binder resin and a magnetic material, and inorganic fine particles, the toner base particles have been obtained through a pulverization step; and, the toner base particles having a circle-equivalent diameter of from 3 μm or more to 400 μm or less as measured with a flow type particle image analyzer have an average circularity of from 0.935 or more to less than 0.970; and the toner base particles have an average surface roughness of from 5.0 nm or more to less than 35.0 nm as measured with a scanning probe microscope. The toner can enjoy less toner consumption per sheet of images, can achieve a long lifetime in a smaller quantity of toner, and has superior developing performance in any environment.

Owner:CANON KK

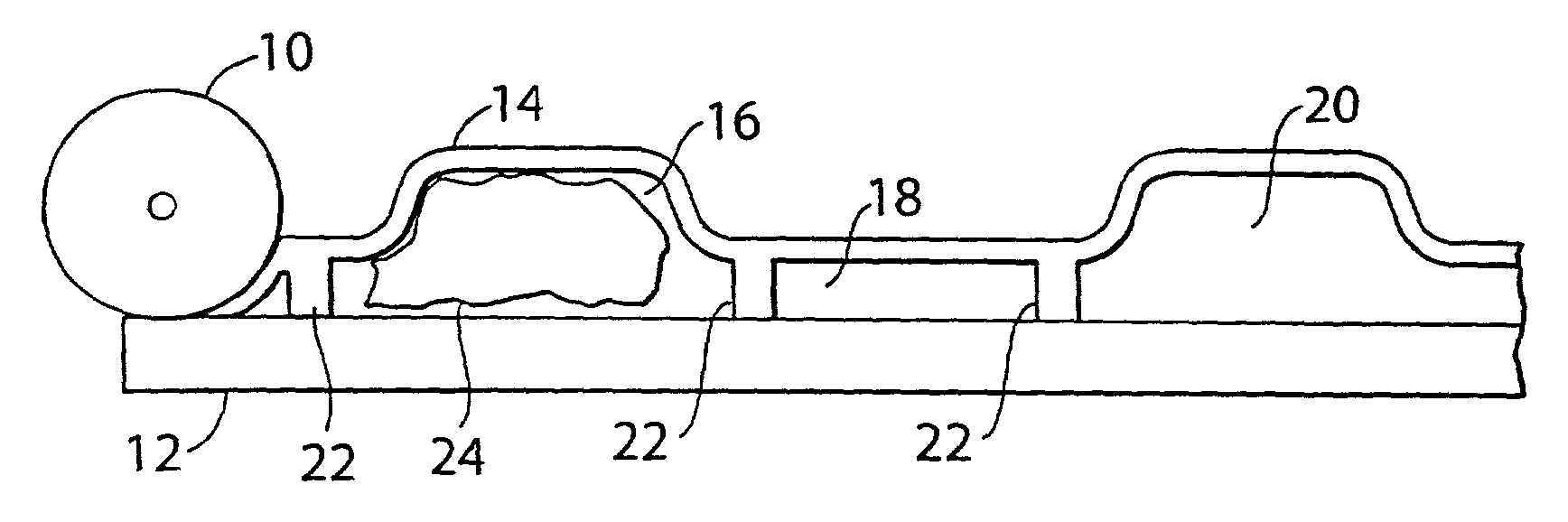

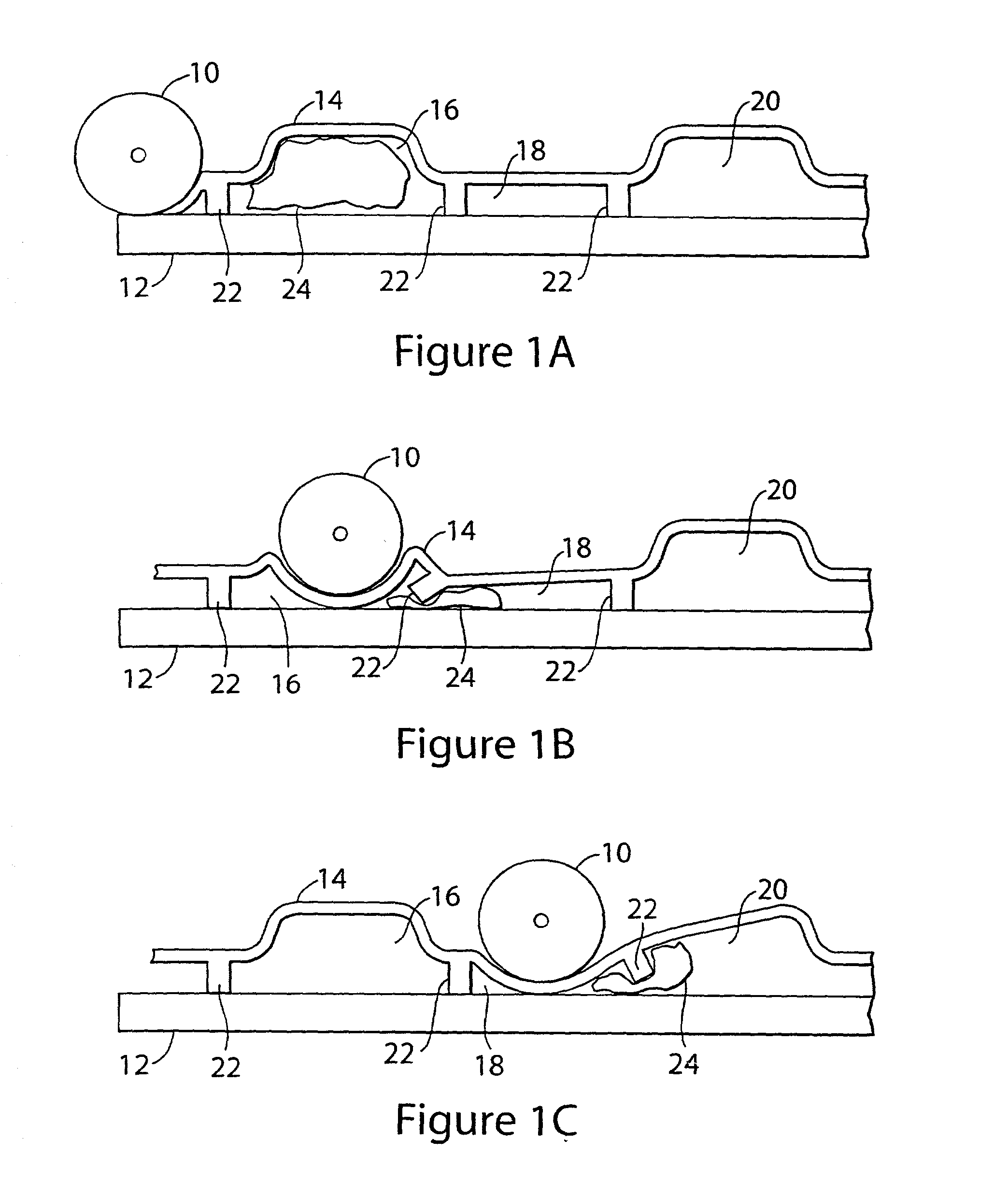

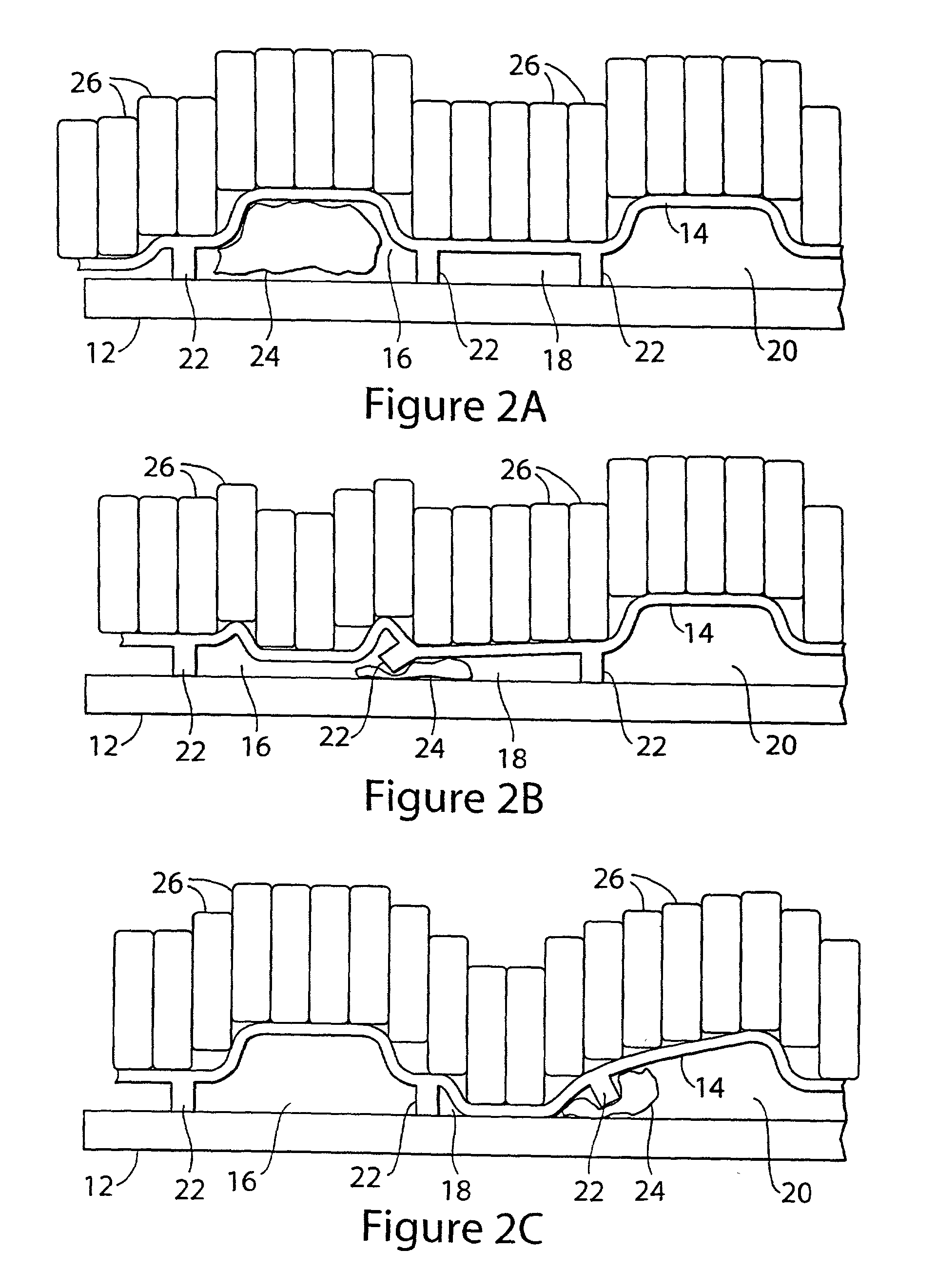

Fluidically isolated pumping and metered fluid delivery system and methods

InactiveUS20030143754A1Avoid damageMinimize electric power consumptionBioreactor/fermenter combinationsFunctional valve typesBall bearingBiological fluids

An apparatus and method for pumping and optionally mixing of small quantities of biological fluid wherein the pumping mechanism is segregated from the biological fluid being pumped. The micro-pump pushes the biological fluid by compressing a cartridge housing the blood and reagents with collapsible walls with a roller or ball bearing, synchronized perpendicular plungers, or an acutely-angled member to push the biological fluid by collapsing the walls of the cartridge in the direction of flow.

Owner:AGILENT TECH INC

Fluidically isolated pumping and metered fluid delivery system and methods

InactiveUS7056475B2Minimize electric power consumptionMinimal overheadBioreactor/fermenter combinationsBiological substance pretreatmentsBall bearingEngineering

Owner:AGILENT TECH INC

Controlling plant pathogens with bacterial/fungal antagonist combinations

InactiveUS20050096225A1Extended shelf lifeEffective controlBiocideClimate change adaptationPhytophthora sp.Trichoderma sp.

Fungal / bacterial antagonist combinations, a seed coated with one of the combinations and a plant protected from plant pathogens by one of the combinations. The invention is also a fungal / bacterial antagonist combination comprising a Trichoderma virens fungal antagonist and a Bacillus subtilis var. amyloliquefaciens (Bacillus amyloliquefaciens) bacterial antagonist and its use for controlling plant pathogens as a biocontrol agent, bio-pesticide or bio-fungicide. The invention also finds utility as a fungal / bacterial antagonist combination applied to the seed, stalk or leaf that results in an increase in plant yield. Control of early and late season stalk and root rot caused by fungi such as Fusarium, Phythium, Phytophthora and Penicillium in tomatoes, peppers, turf grass, soybeans, sunflower, wheat and corn is achieved.

Owner:NOVOZYMES BIOAG AS

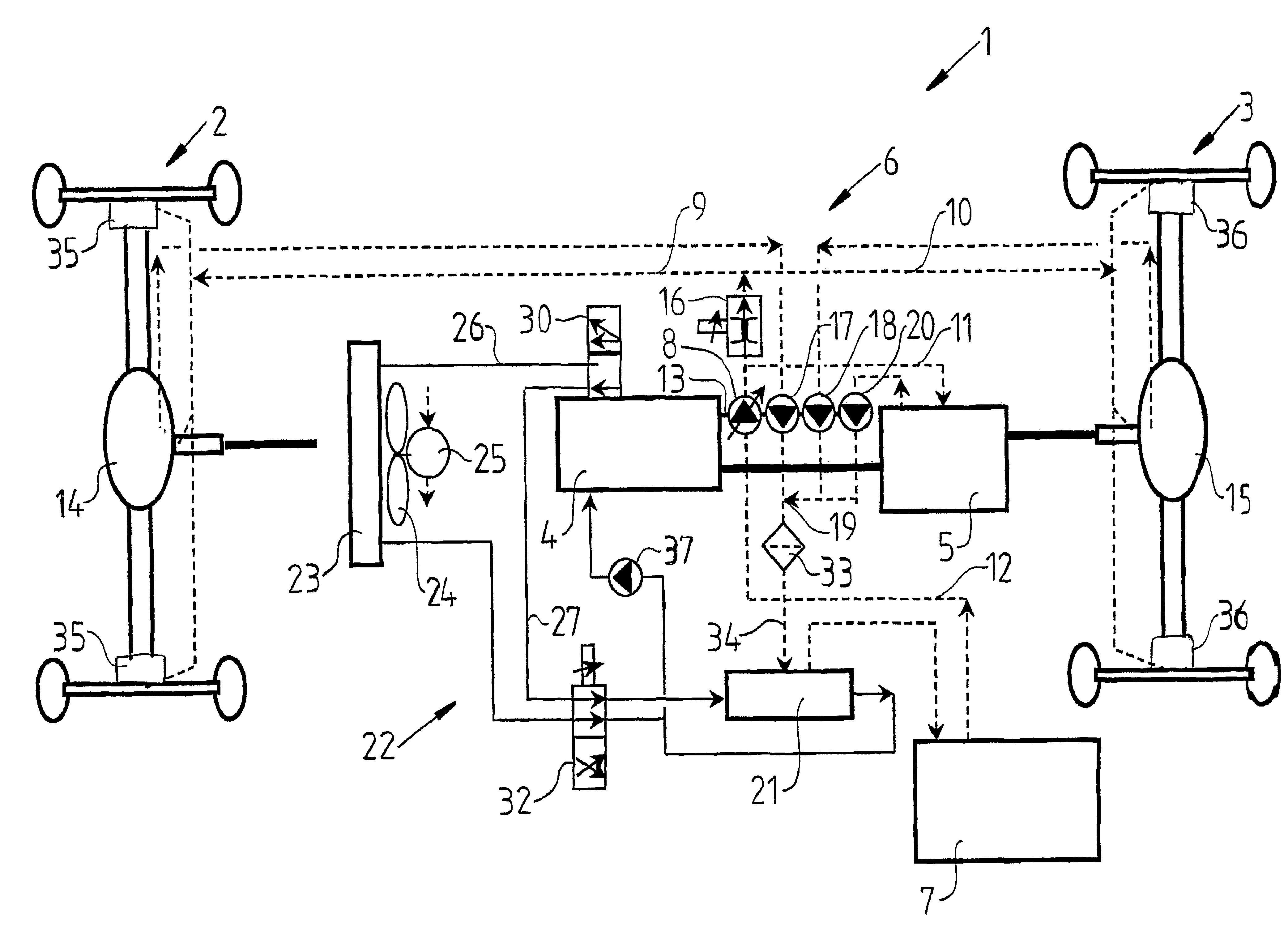

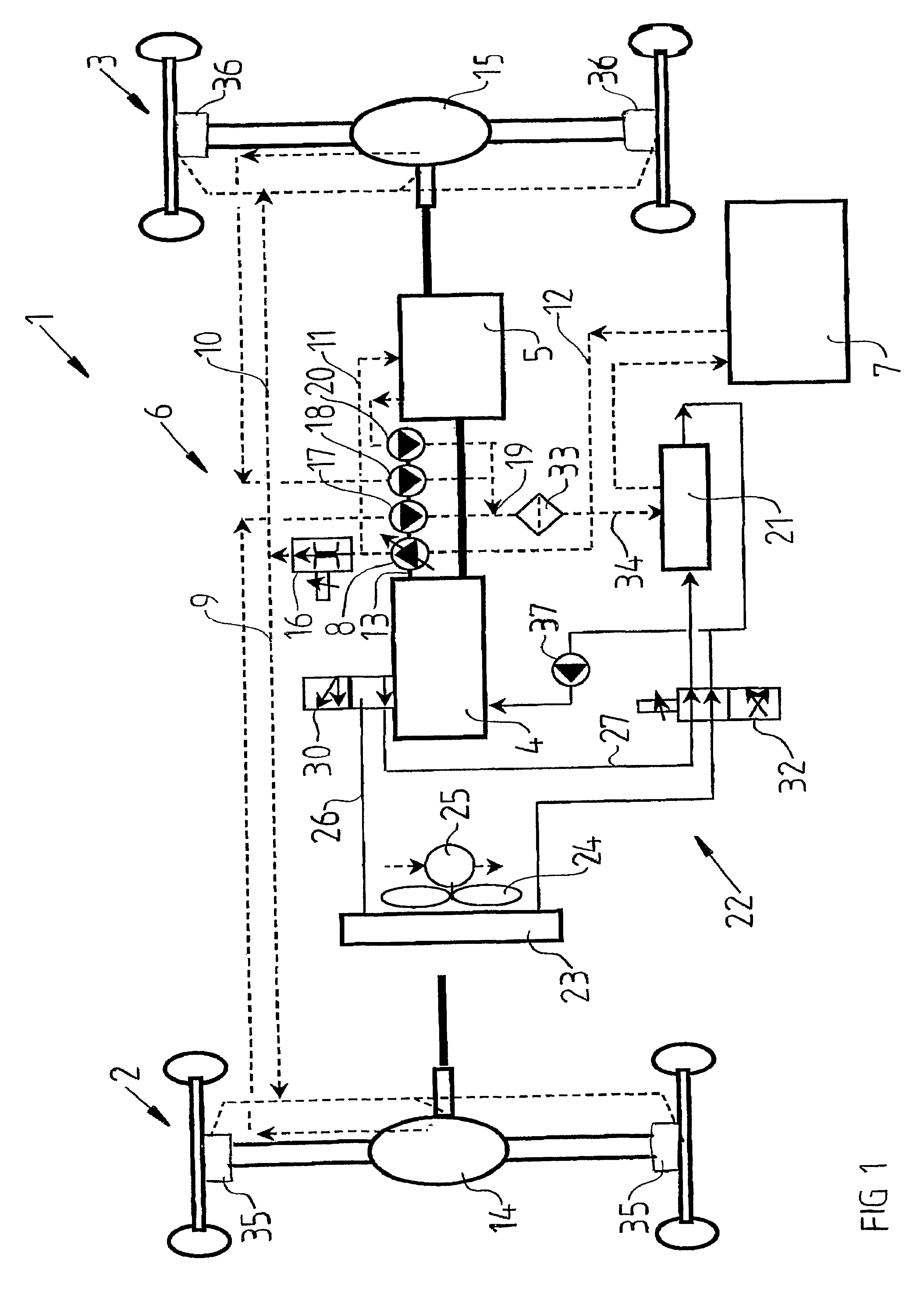

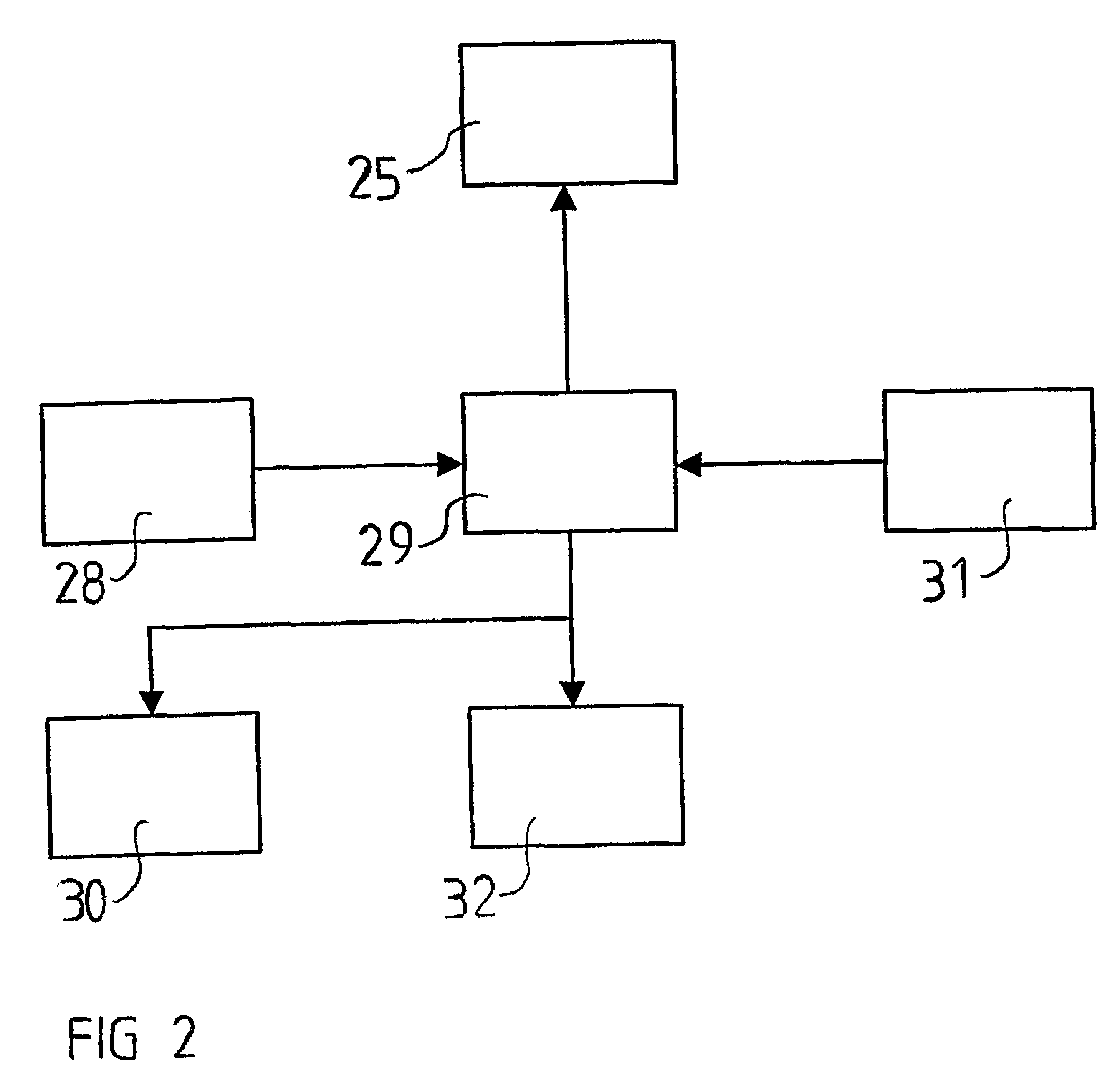

Temperature regulating system

InactiveUS6899074B1Guaranteed uptimeReduce wearAir coolingGear lubrication/coolingHeat exchangerAutomotive engineering

Method and arrangement for providing a temperature regulating system (1) in a vehicle. The system includes an hydraulic arrangement (6) that is adapted to provide components intended for rotation belonging to a gearbox (5) of the vehicle and at least one of the axles (2, 3) of the vehicle with hydraulic oil from the same container (7). The system also has an arrangement (22) for regulating the temperature of the oil in the hydraulic arrangement (6) via a heat exchanger unit (21). The temperature regulating arrangement (22) is also adapted to cool the engine (4) of the vehicle.

Owner:VOLVO CONSTR EQUIP COMPONENTS AB

Terbium- or lutetium - containing garnet phosphors and scintillators for detection of high-energy radiation

InactiveUS20030075706A1Improve light outputShort decay timePolycrystalline material growthMaterial analysis using wave/particle radiationLutetiumHigh energy

Scintillator compositions having a garnet crystal structure useful for the detection of high-energy radiation, such as X, beta, and gamma radiation, contain (1) at least one of terbium and lutetium; (2) at least one rare earth metal; and (3) at least one of Al, Ga, and In. Terbium or lutetium may be partially substituted with Y, La, Gd, and Yb. In particular, the scintillator composition contains both terbium and lutetium. The scintillators are characterized by high light output, reduced afterglow, short decay time, and high X-ray stopping power.

Owner:GENERAL ELECTRIC CO

Toner

ActiveUS7288354B2Less overall consumptionAvoid large quantitiesDevelopersSurface roughnessEngineering

A toner is composed of toner particles including toner base particles containing at least a binder resin and a colorant, and inorganic fine particles. The toner base particles having a specific circle-equivalent diameter as measured with a flow type particle image analyzer have a specific average circularity. The toner base particles have a specific surface roughness as measured with a scanning probe microscope. The binder resin contains at least a vinyl resin having as partial structure a linkage formed by the reaction of a carboxyl group with an epoxy group.

Owner:CANON KK

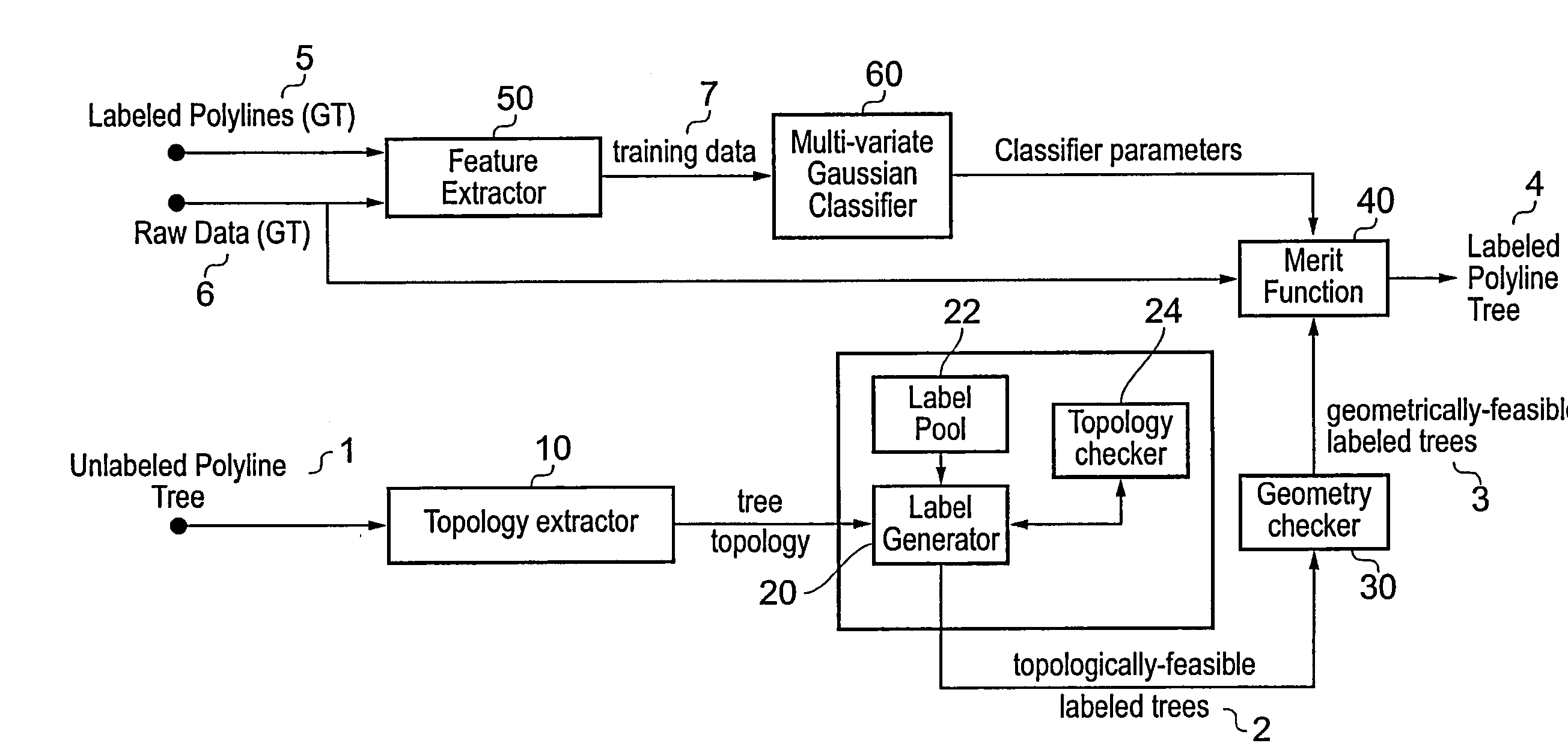

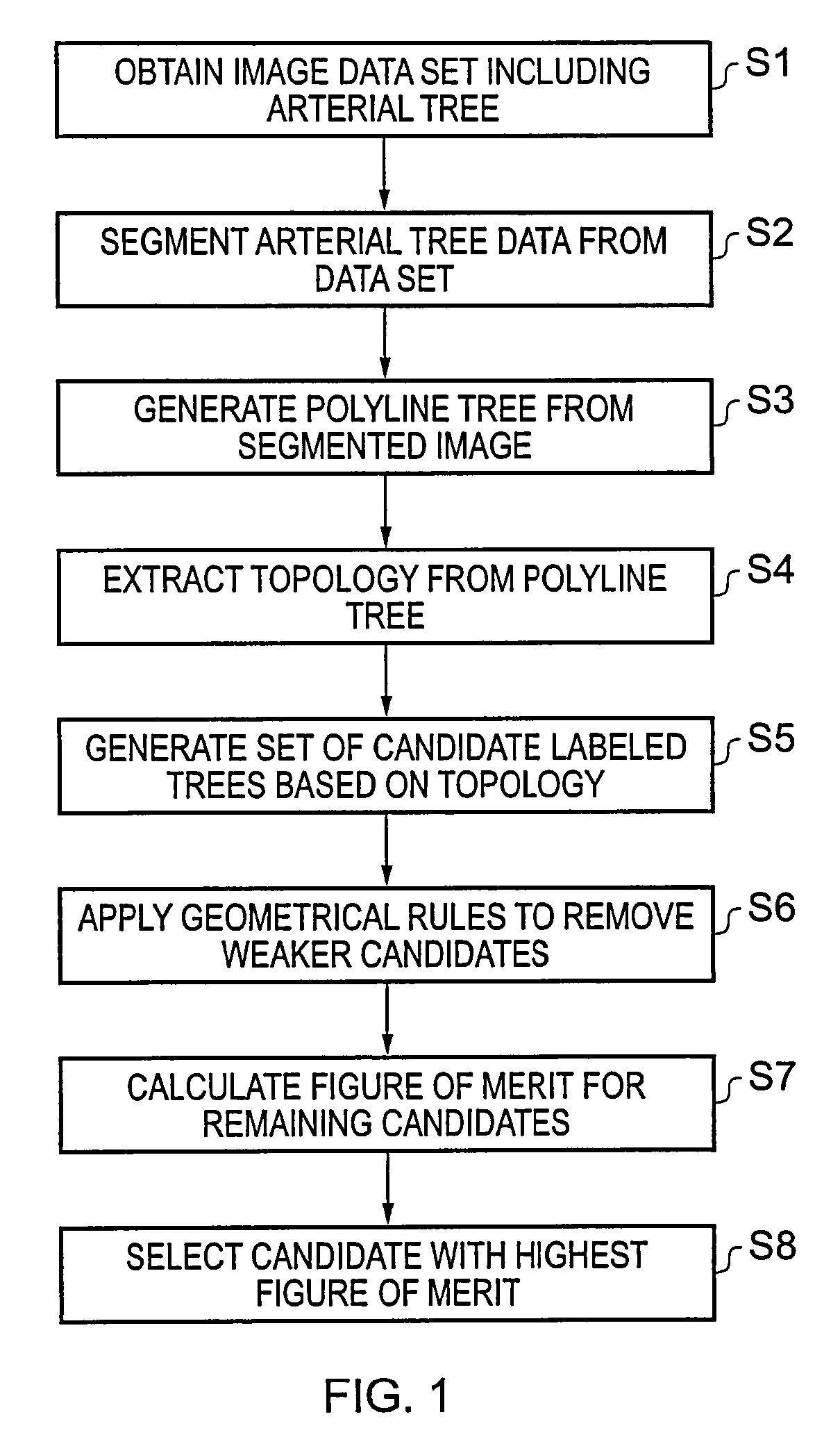

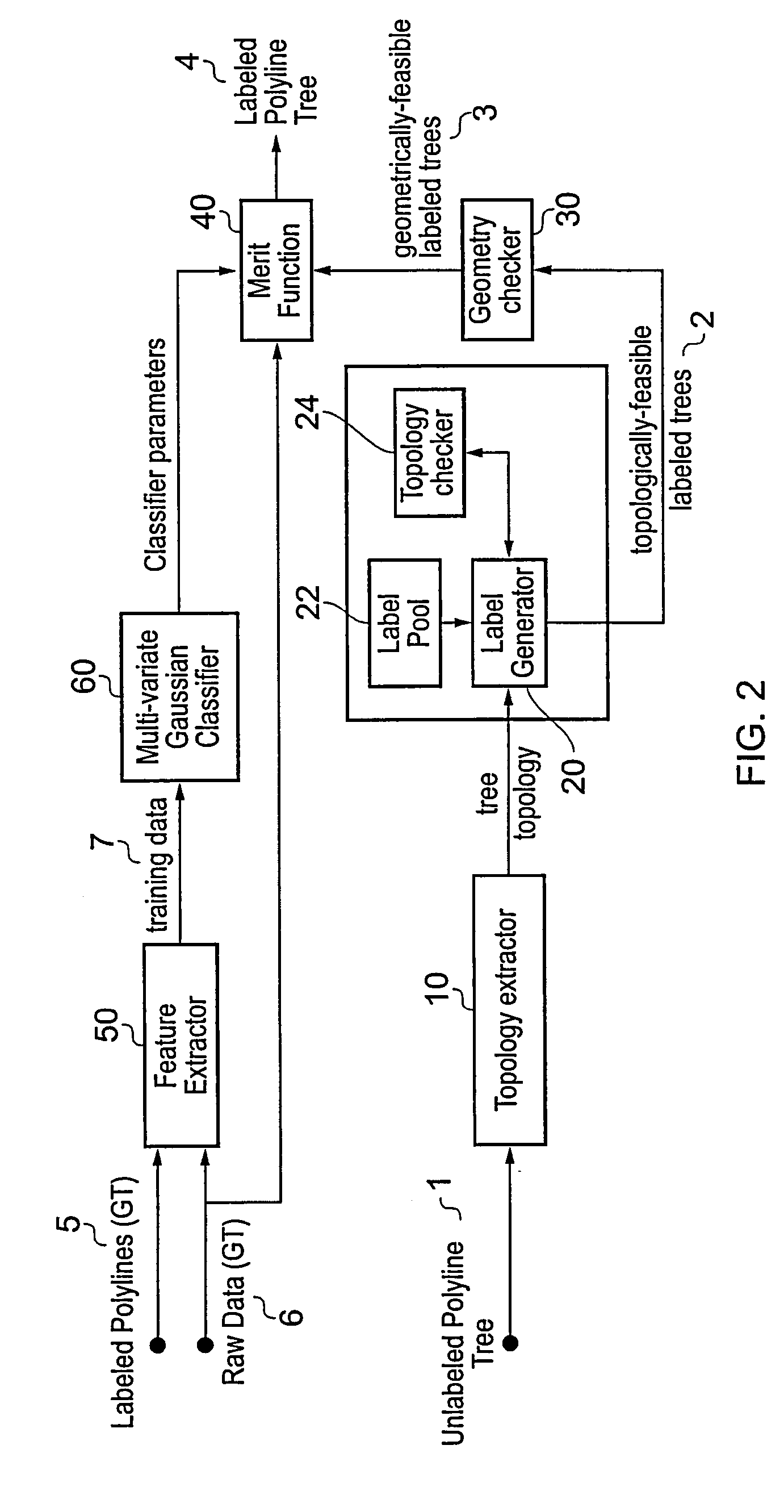

Method and apparatus for classification of coronary artery image data

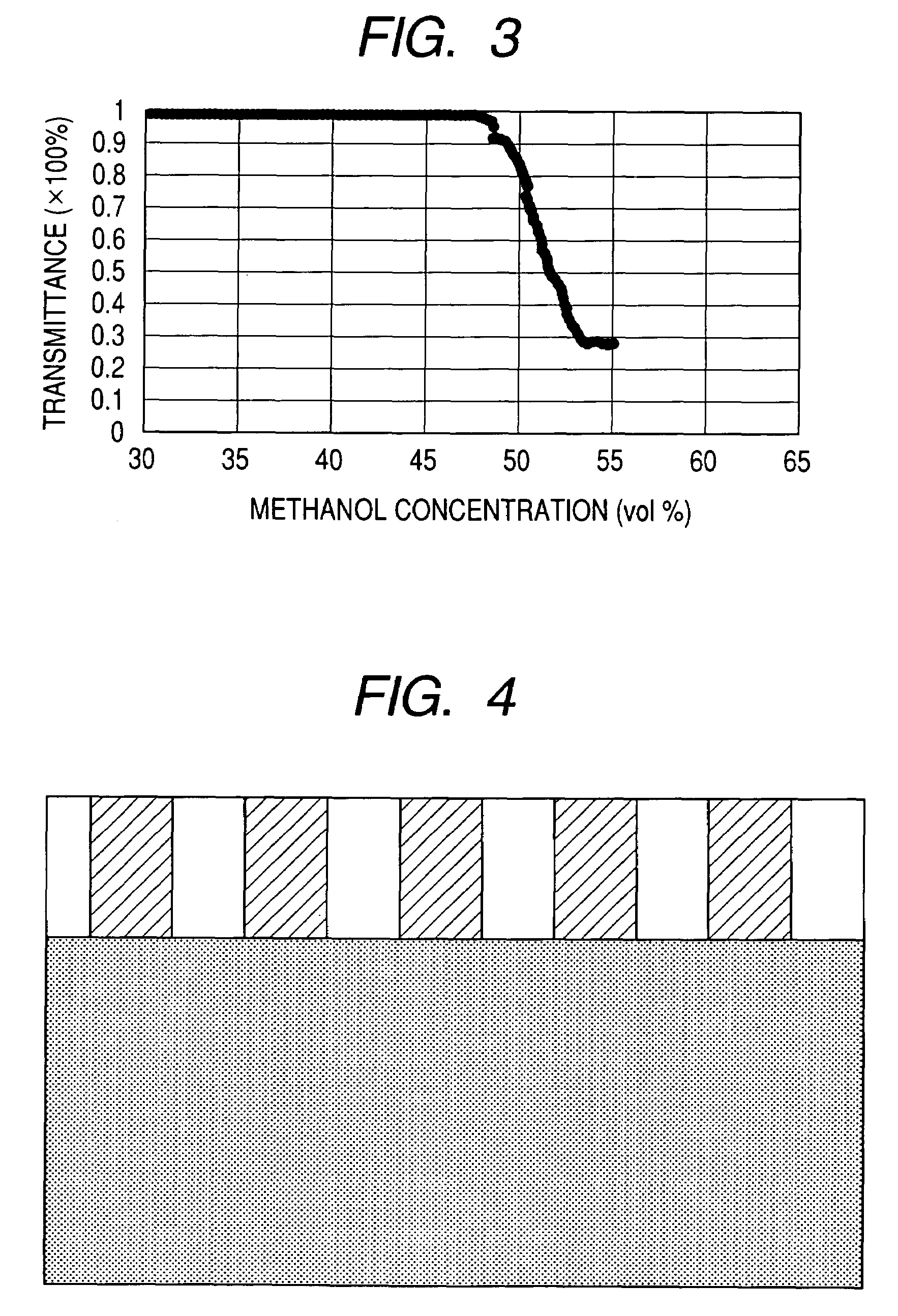

InactiveUS20100082692A1Accurate and computationally efficient techniqueIncrease speedImage enhancementMedical data miningCoronary arterial treeBlood vessel feature

A polyline tree representation of a coronary artery tree imaged in a volume data set is obtained, and its topology is extracted to give a topological representation indicating the relative positions of vessels in the tree. The topological representation is compared with a set of topological rules to find possible anatomical classifications for each vessel, and a set of candidate labeled polyline trees is generated by labeling the polyline tree with labels showing each combination of possible anatomical classifications. Each candidate labeled tree is filtered according to a set of geometric rules pertaining to spatial characteristics of vessels in arterial trees, and any labeled tree not satisfying the geometric rules is rejected A figure of merit is calculated for each remaining candidate by comparing features of the vessels measured from the polyline tree and from the volume data set with features of correctly classified vessels in other data sets to determine the probable correctness of the labeling of each candidate, and the candidate with the best figure of merit is selected as showing the proper classification of the vessels.

Owner:TOSHIBA MEDICAL VISUALIZATION SYST EURO

Universal non-contact dispense peripheral apparatus and method for a primary liquid handling device

InactiveUS20030072679A1Allocation is accurateAvoid large quantitiesSequential/parallel process reactionsMaterial analysis by optical meansComputer moduleMicrotiter plate

A removable secondary liquid dispensing module for use with an existing, automated liquid handling system that defines a work area having a plurality of discrete work stations. Each of the work stations of the automated liquid handling system includes a lab ware site and alignment structure enabling the removable securing standardized microtiter-plates at respective lab ware site. A plate positioning mechanism is configured to move and position the microtiter plates to and from the lab ware sites of the respective work stations thereof and into engagement with the respective carrier alignment structure thereof. Further, a primary liquid dispensing device is configured for selective contact-type dispensing of discrete quantities of fluid, in the range of about one (1) microliter to about ten (10) milliliters, into the test sites of the microtiter plates secured in the respective alignment structure of the respective work station. The removable secondary liquid dispensing module includes a base member dimensioned to fit substantially within a footprint of a work station, and mounting hardware adapted to removably secure the base member in the work station. A support platform is affixed to the base member, and is configured to support a microtiter-plate. An alignment mechanism is configured to removably receive and secure the a microtiter-plate therein by the plate positioning mechanism of the automated liquid handling system. The support platform and alignment mechanism cooperate to form and provide a lab ware site suitable for secured receipt of a microtiter-plate. The secondary liquid dispensing module further includes a secondary liquid dispensing device which is self-contained and operationally independent from the primary liquid dispensing device. The secondary dispensing device is further adapted for selective non-contact-type dispensing of discrete quantities of fluid, in the range of about one (1) nanoliter to about ten (10) microliters, into the test sites of the microtiter-plate.

Owner:BIONEX SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com