Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Large radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

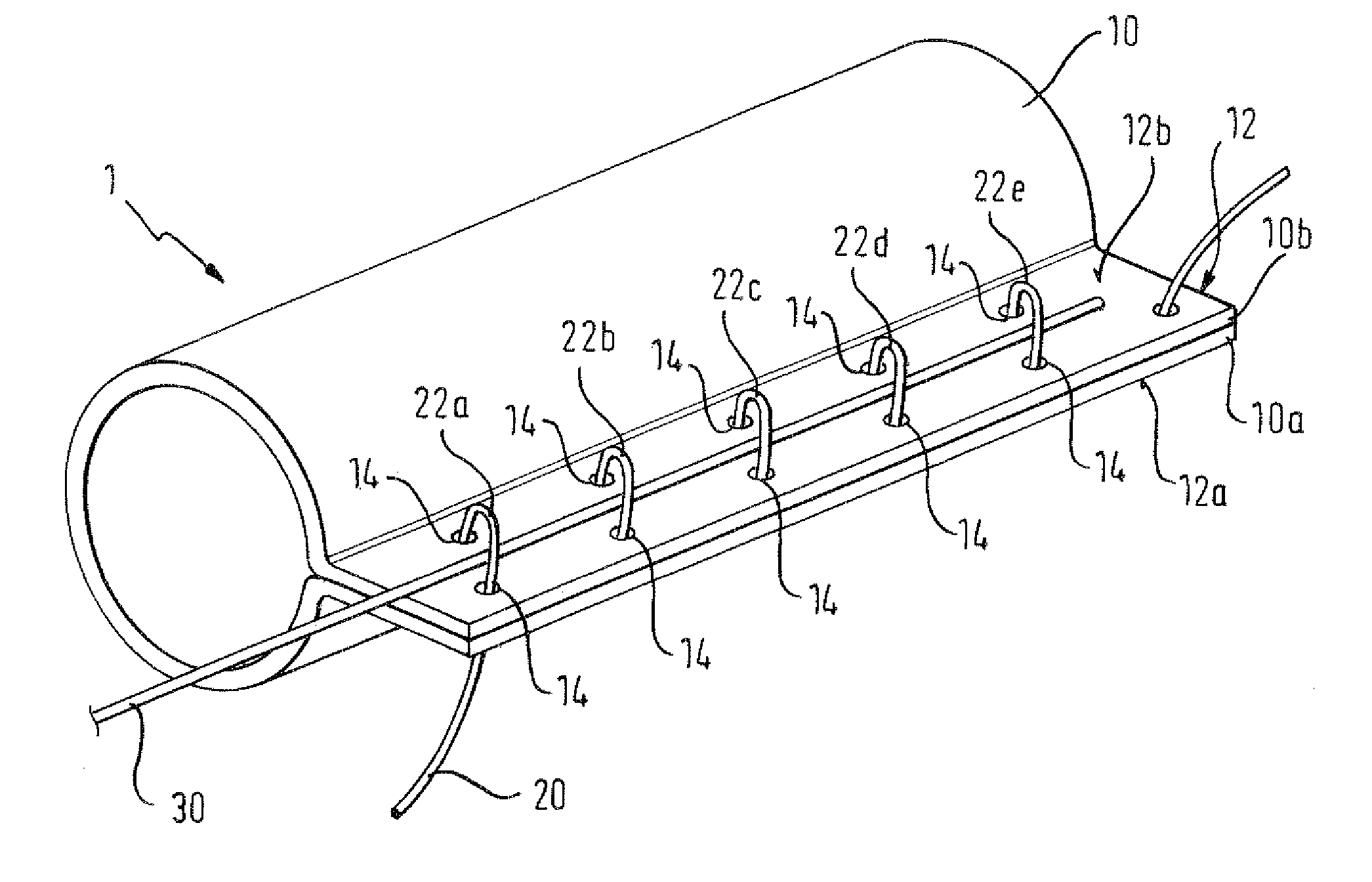

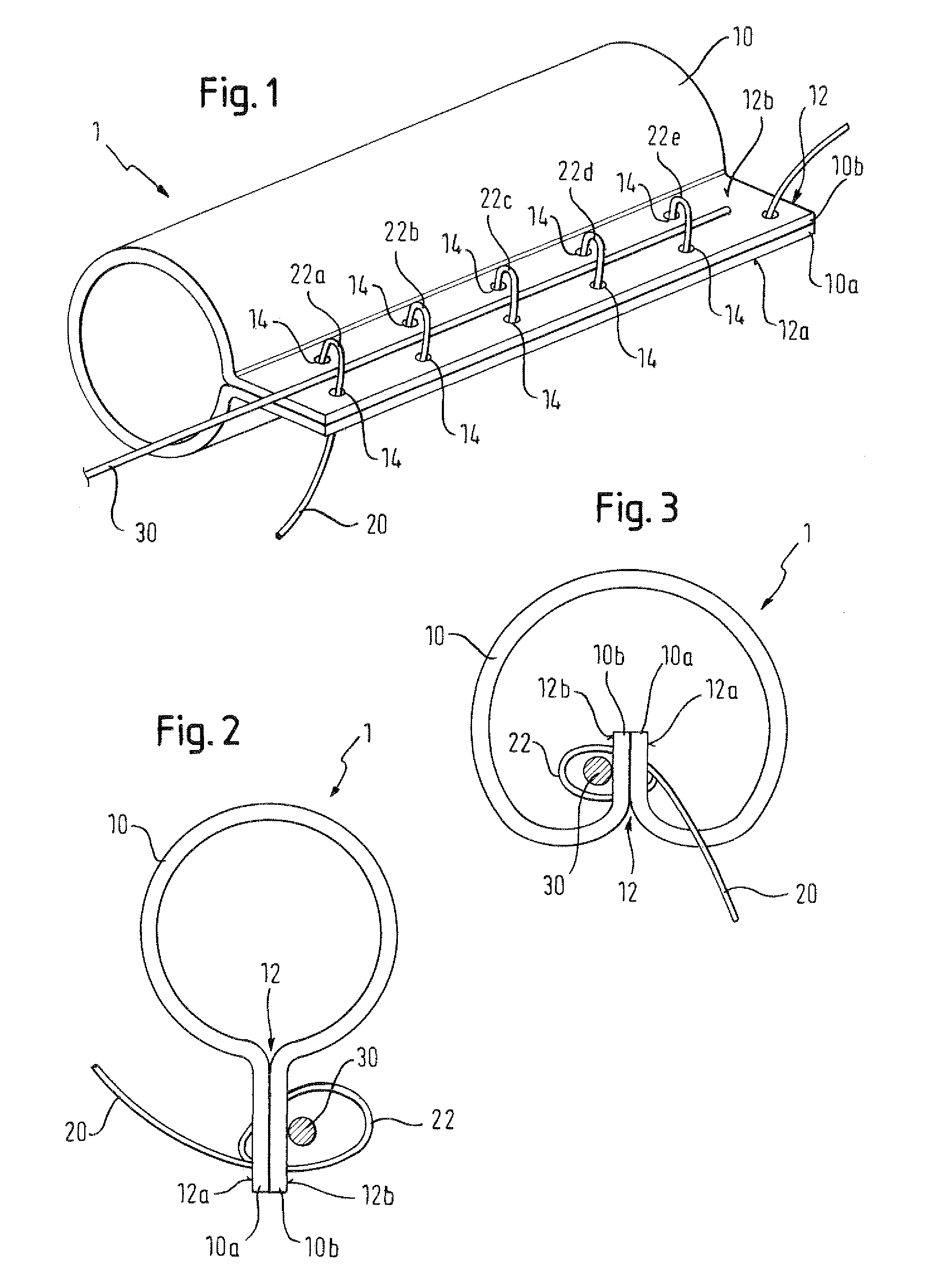

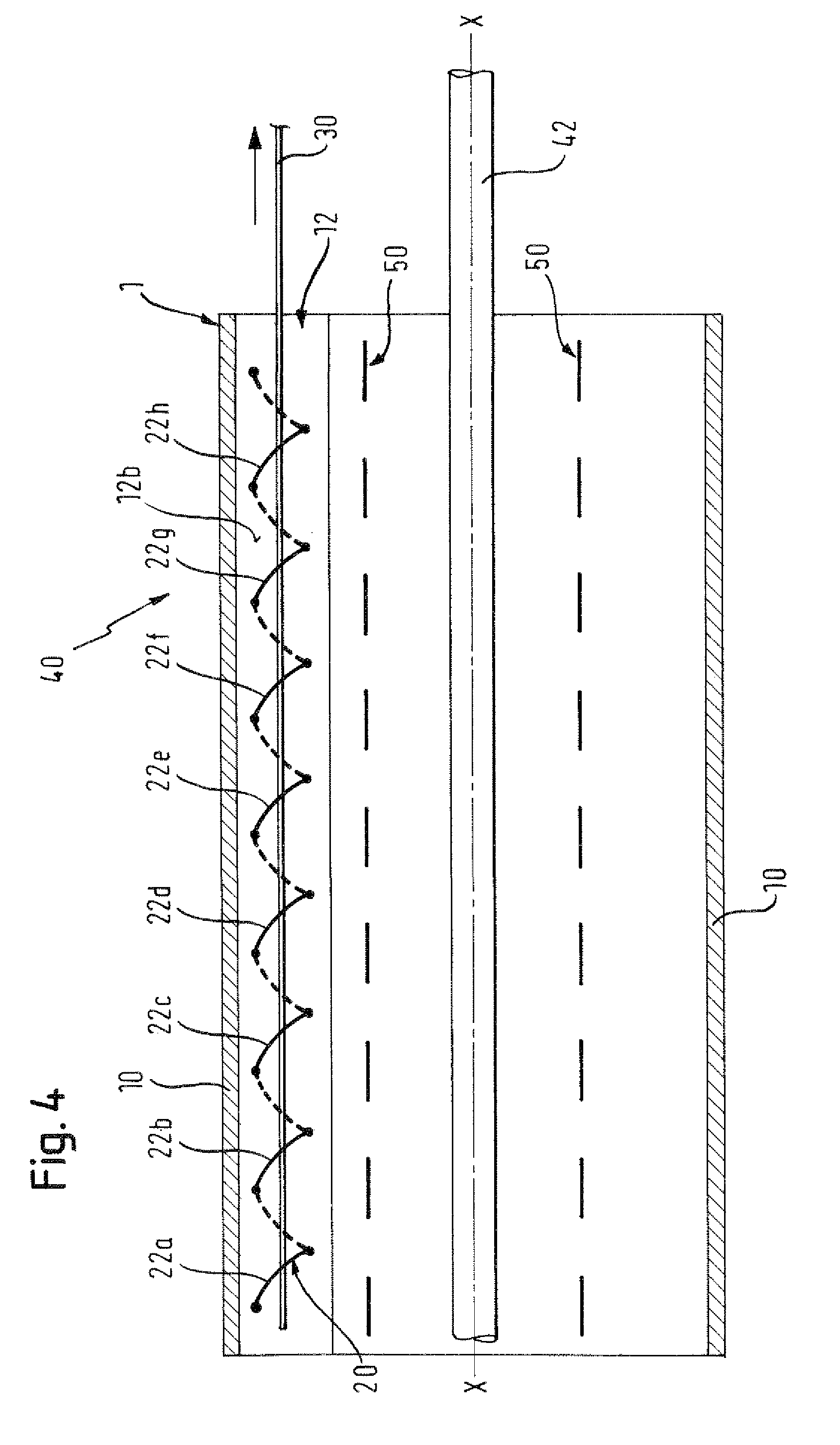

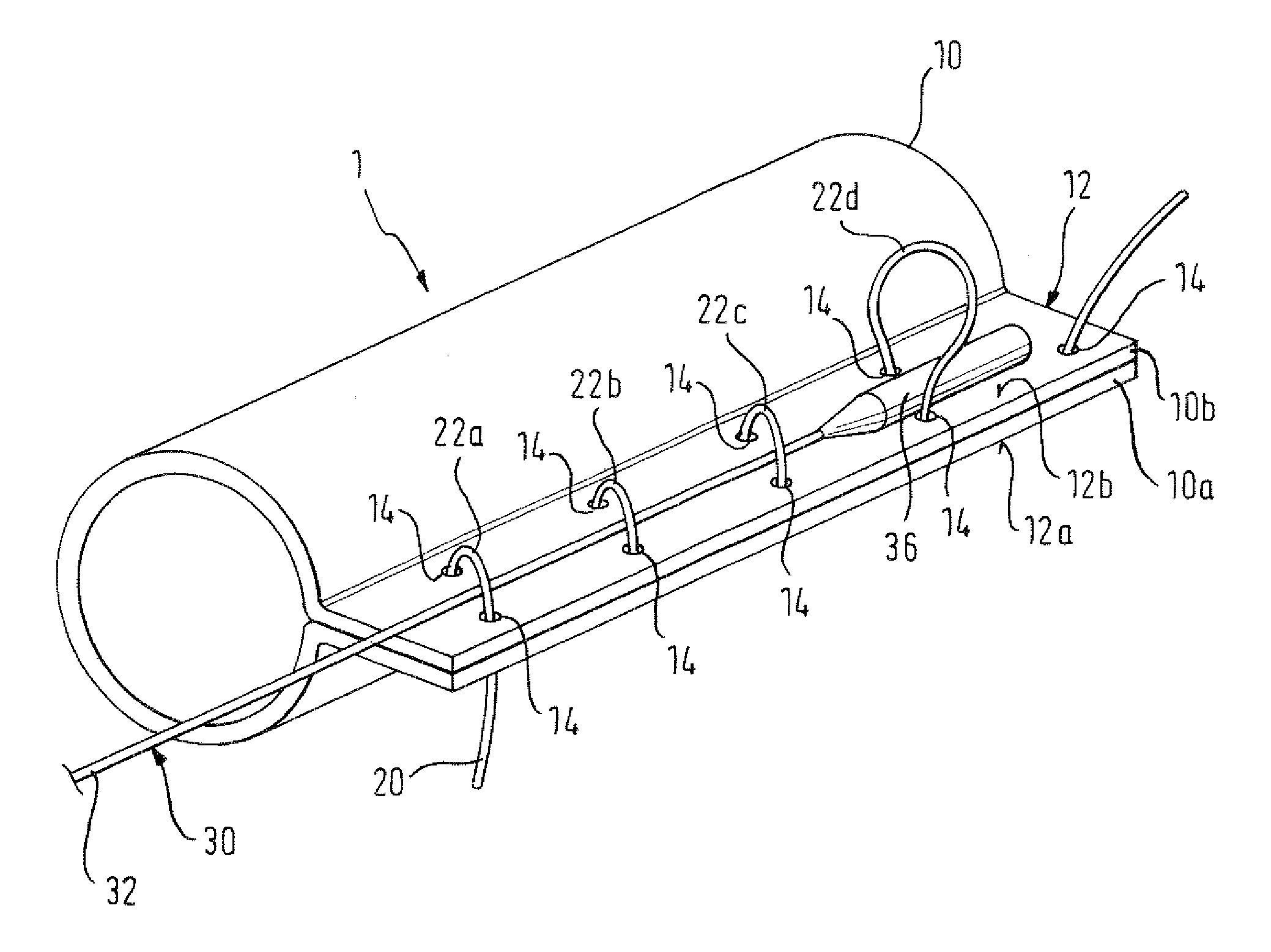

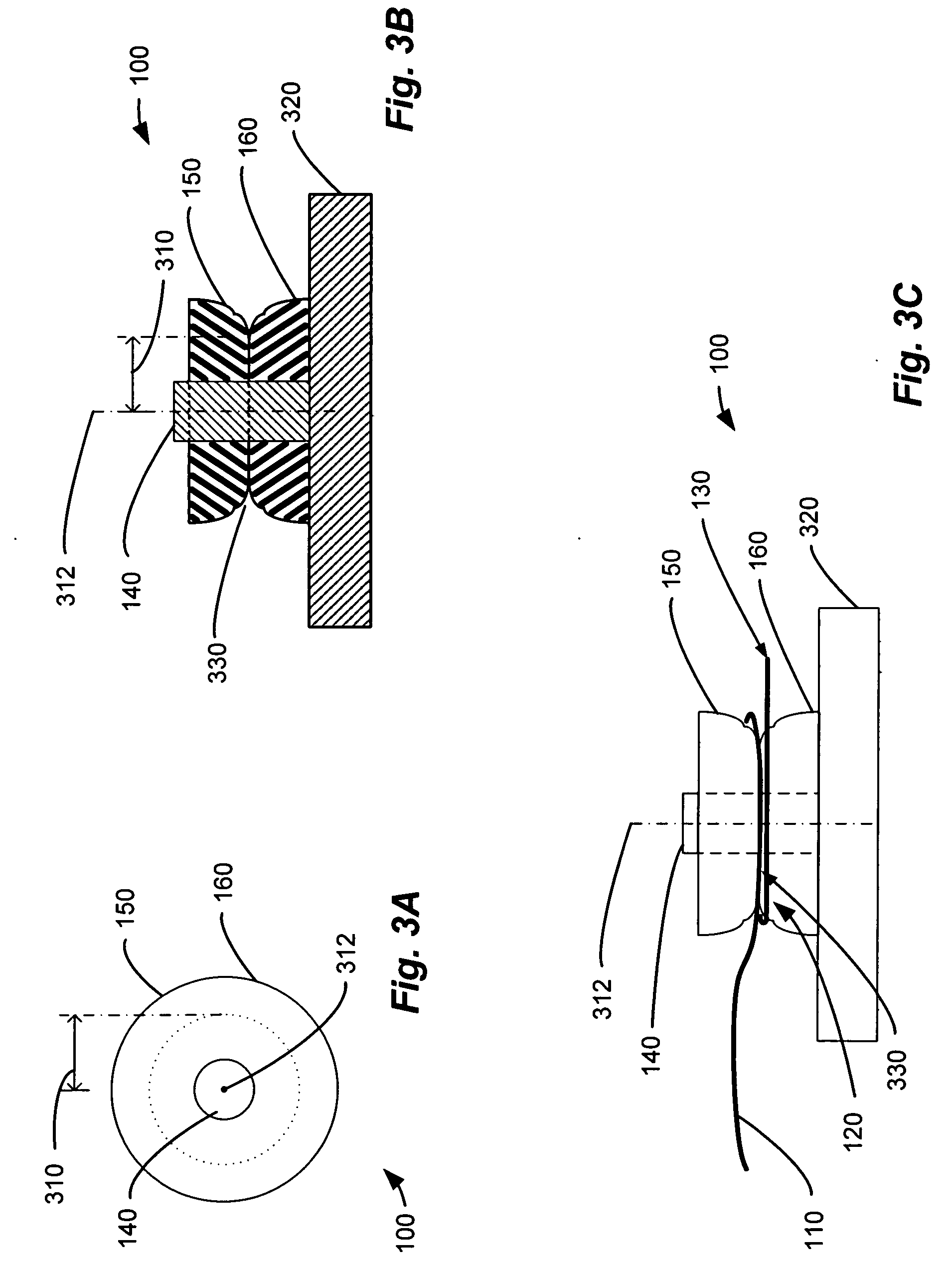

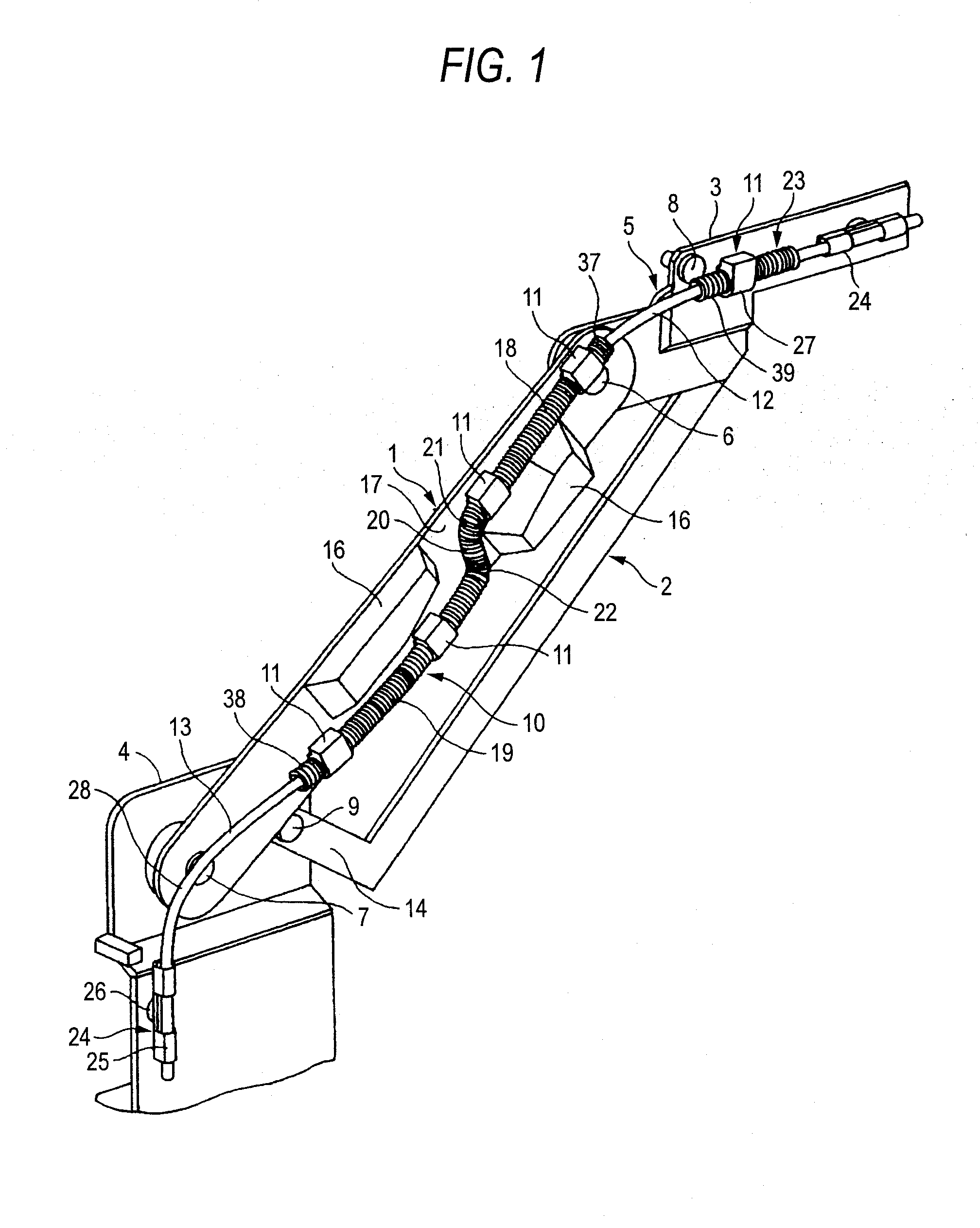

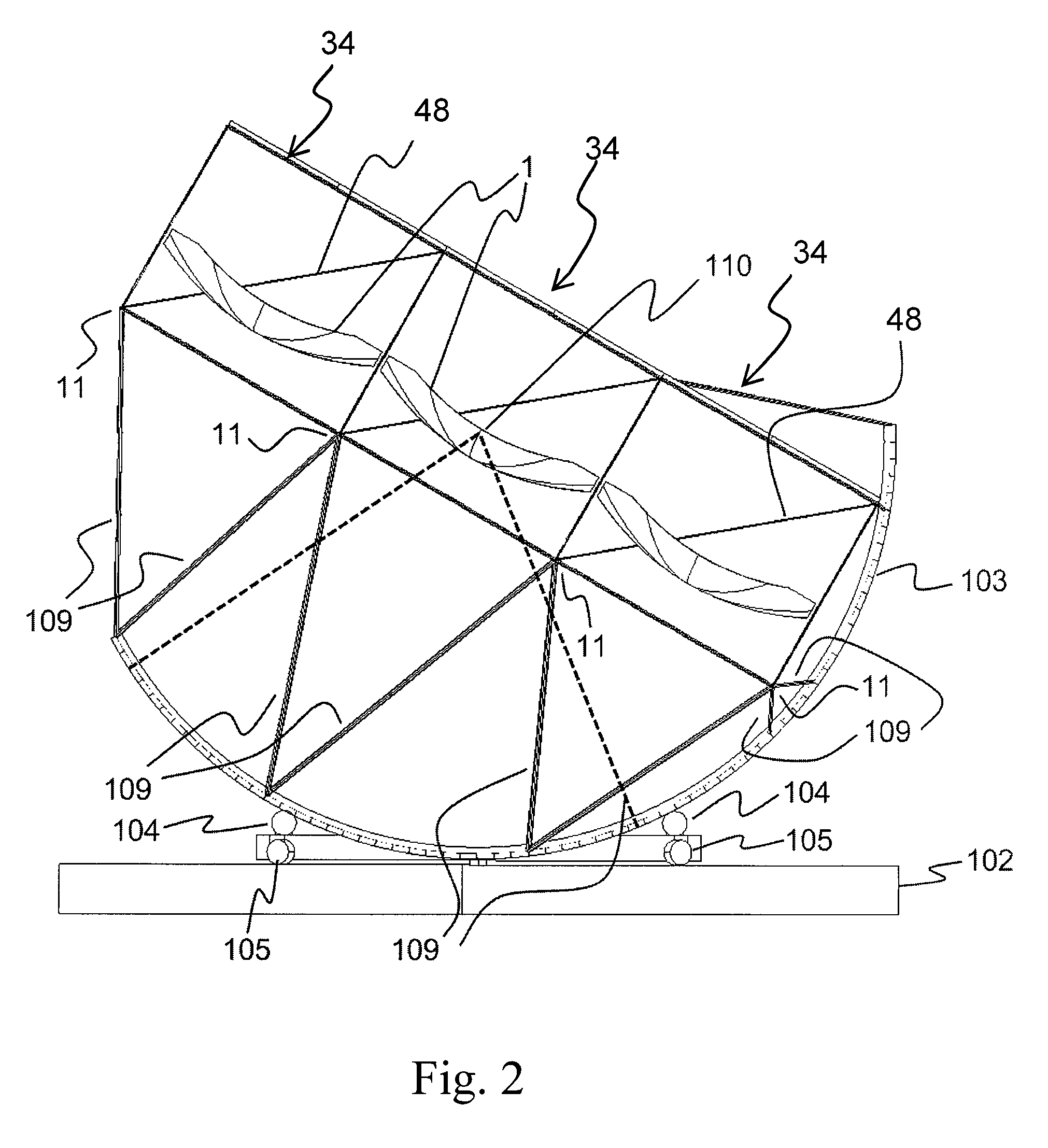

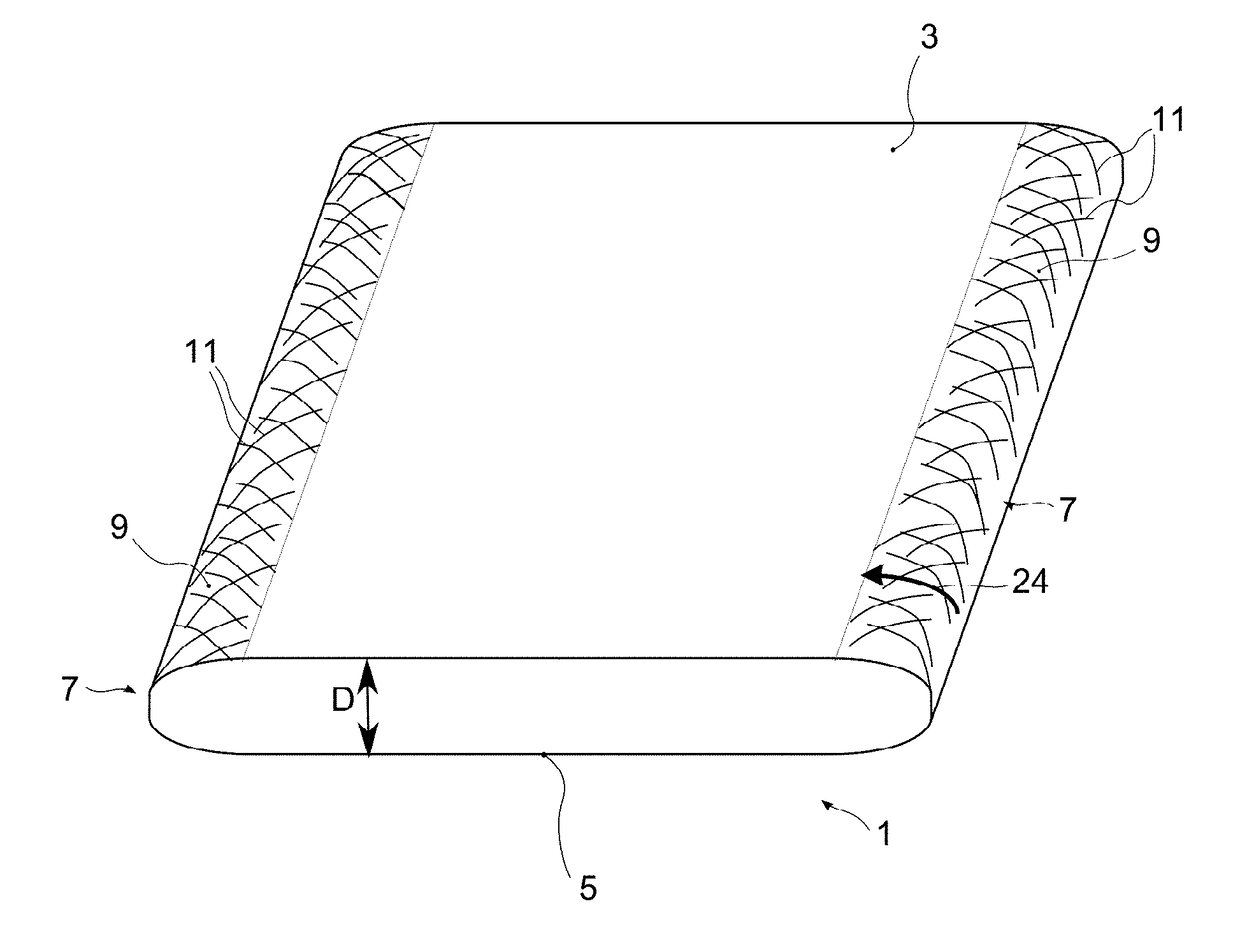

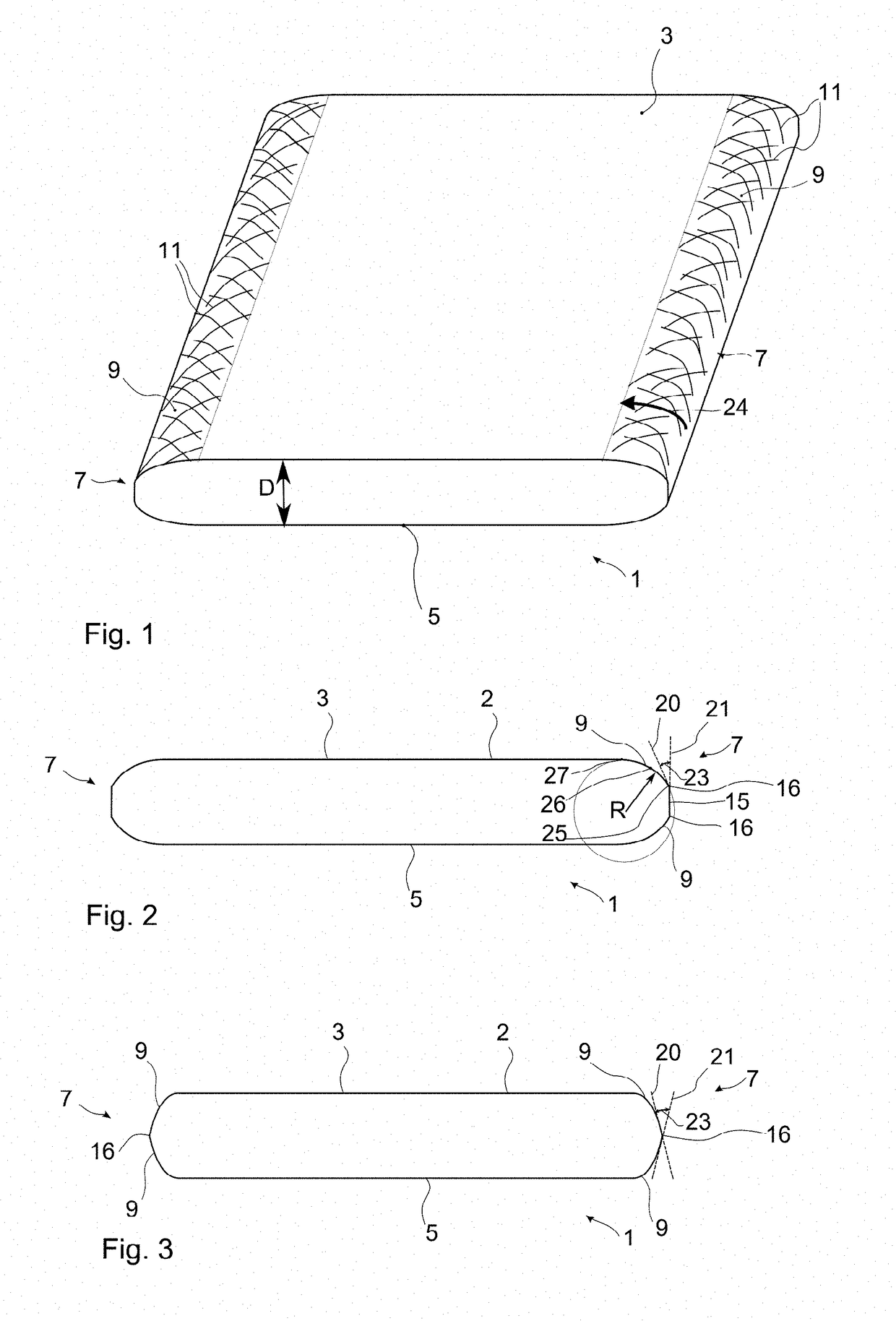

Catheter sheath for implant delivery

ActiveUS9060894B2Increase deflectionLarge radiusStentsBlood vesselsBiomedical engineeringCatheter sheath

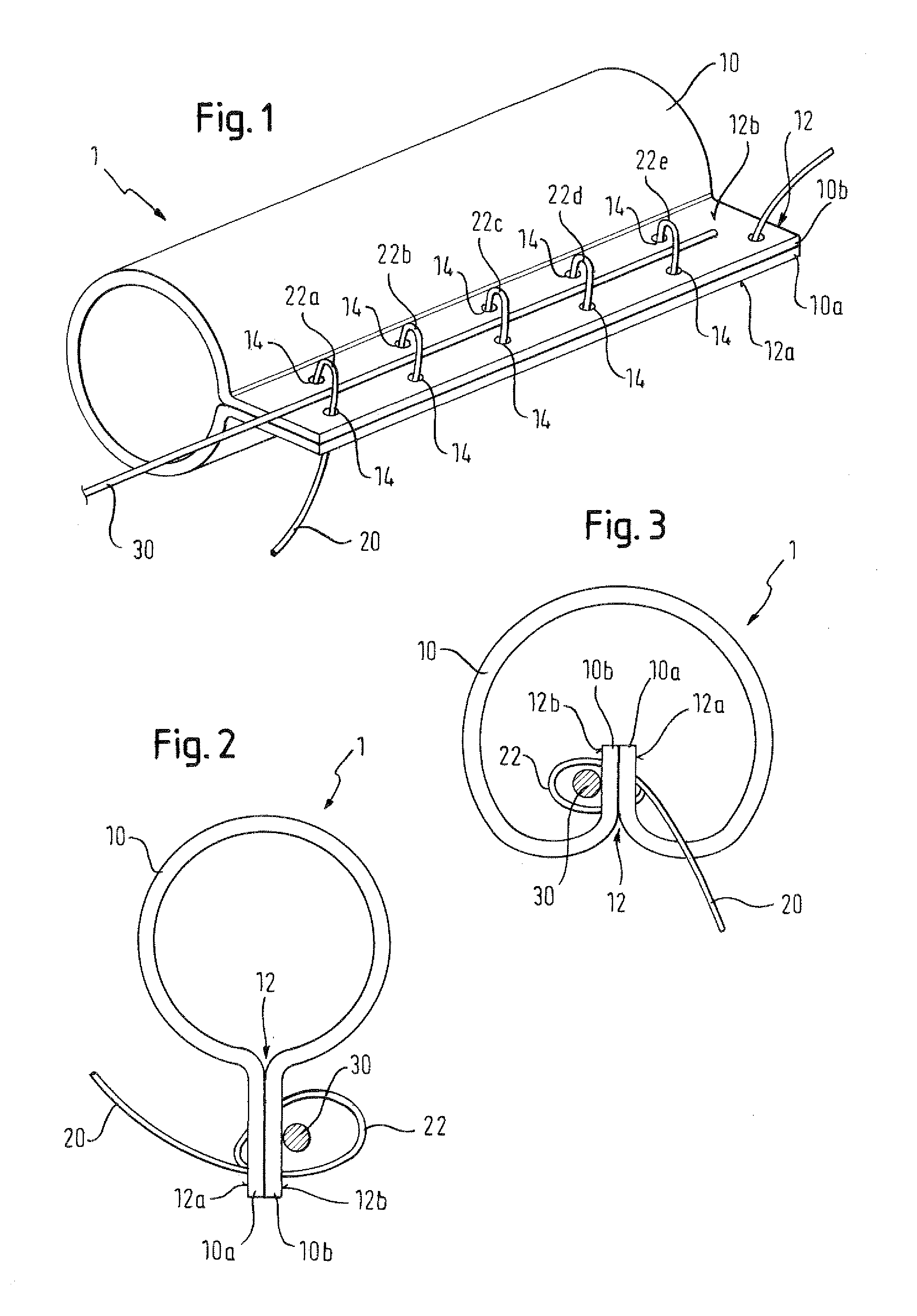

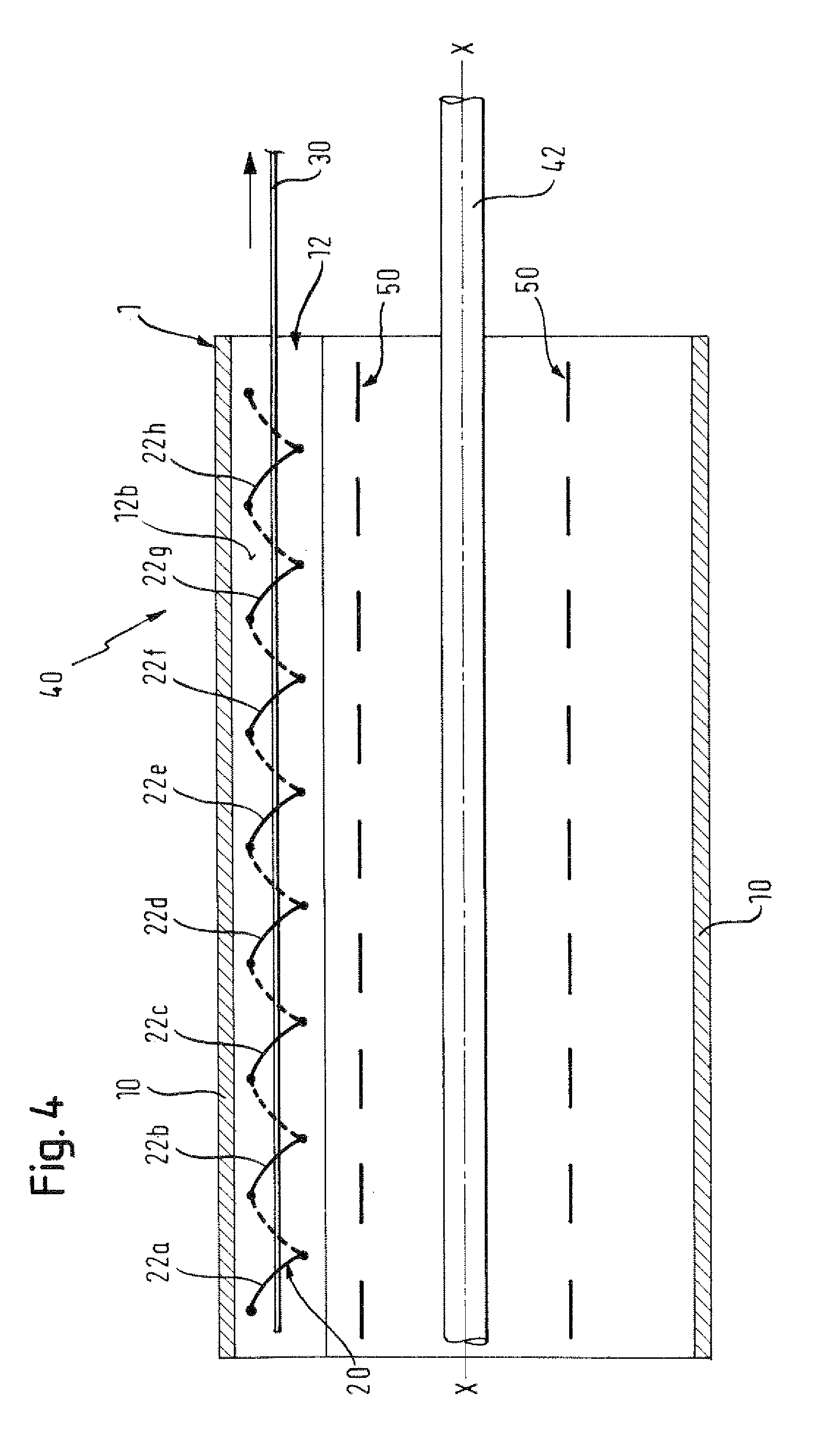

There is disclosed herein a tube of material (1) having a seam (12) extending between a proximal end and a distal end, two edges (10a, 10b) of the material meeting and at least partially overlapping along the seam (12) and being sewn together at the seam by stitches (21, 22, 24) of relatively flexible thread (20), the thread of one or more of the stitches (22, 24) passing from a first side (12a) of the overlapped edges (10a, 10b) of material, through both layers of overlapped material, crossing a relatively rigid member (30) which is disposed on a second, opposite side (12b) of the overlapped edges of material, and passing back to the first side (12a). There is further disclosed an implant delivery catheter (40) incorporating the tube of material (1), and associated methods for its manufacture.

Owner:CR BARD INC

Catheter sheath for implant delivery

ActiveUS20120022630A1Increase deflectionLarge radiusStentsLeather sewingBiomedical engineeringCatheter sheath

There is disclosed herein a tube of material (1) having a seam (12) extending between a proximal end and a distal end, two edges (10a, 10b) of the material meeting and at least partially overlapping along the seam (12) and being sewn together at the seam by stitches (21, 22, 24) of relatively flexible thread (20), the thread of one or more of the stitches (22, 24) passing from a first side (12a) of the overlapped edges (10a, 10b) of material, through both layers of overlapped material, crossing a relatively rigid member (30) which is disposed on a second, opposite side (12b) of the overlapped edges of material, and passing back to the first side (12a). There is further disclosed an implant delivery catheter (40) incorporating the tube of material (1), and associated methods for its manufacture.

Owner:CR BARD INC

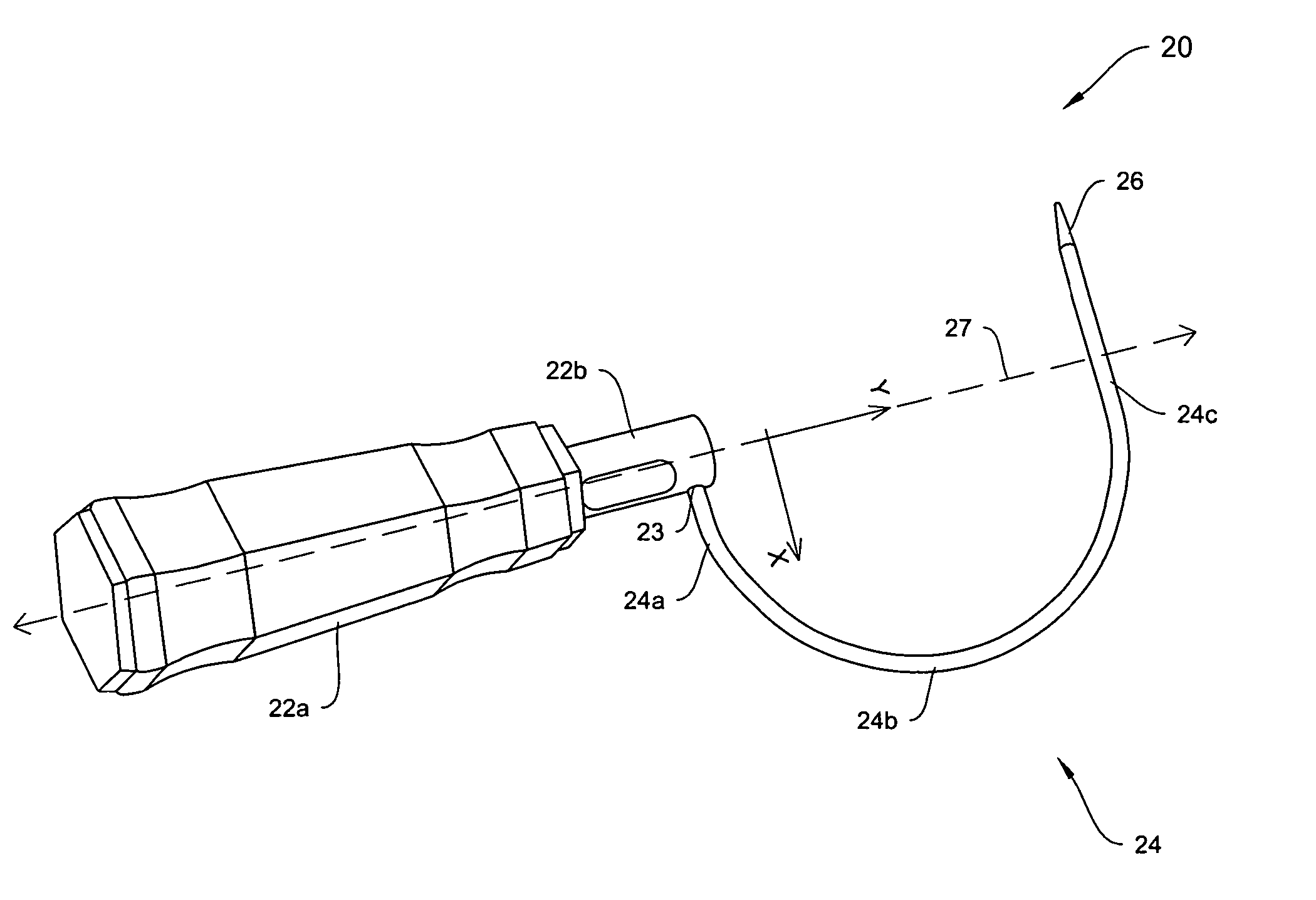

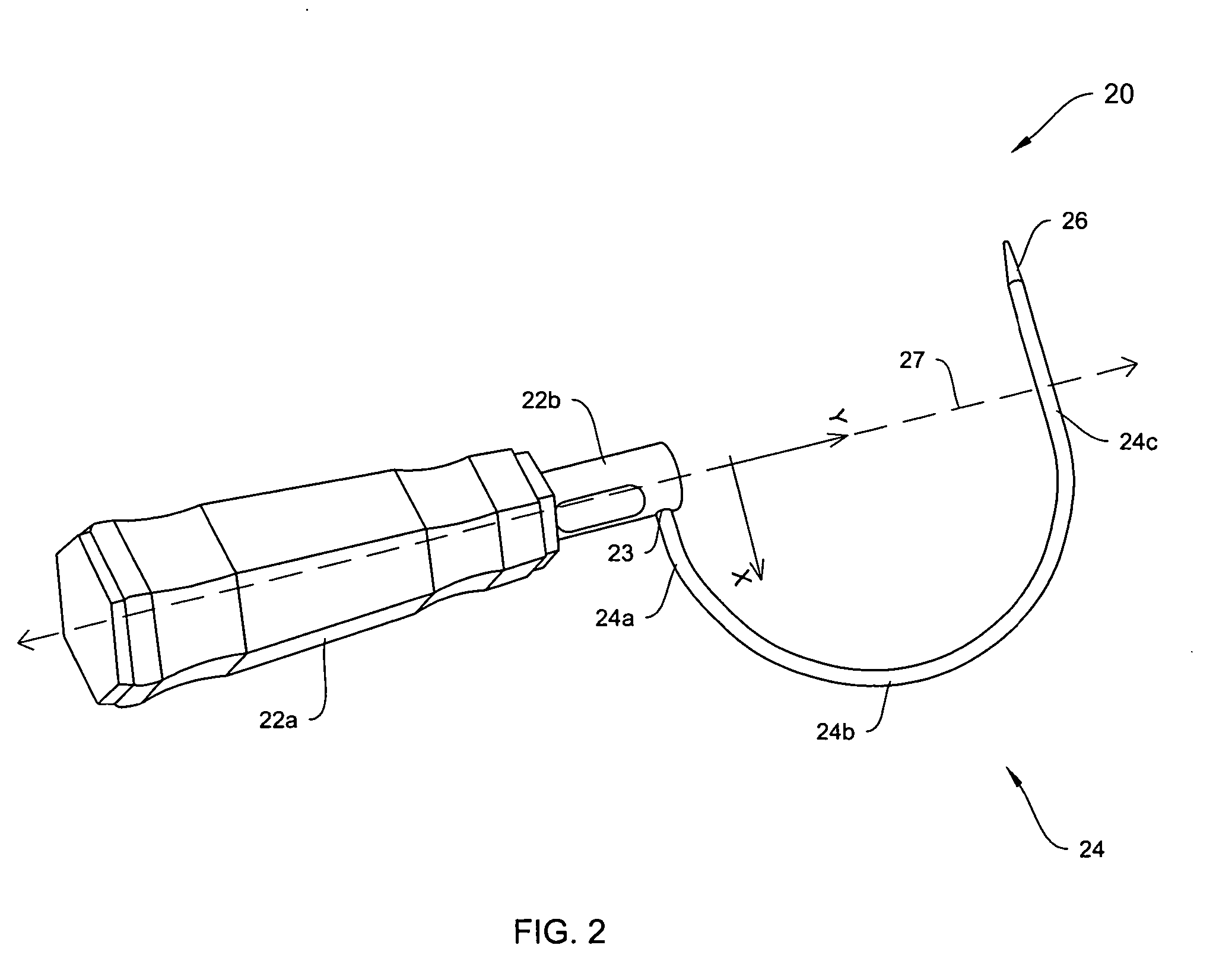

Systems and methods for delivering a medical implant to an anatomical location in a patient

ActiveUS20050075660A1Large radiusImprove usabilitySuture equipmentsAnti-incontinence devicesBiomedical engineeringAnatomical location

Owner:BOSTON SCI SCIMED INC

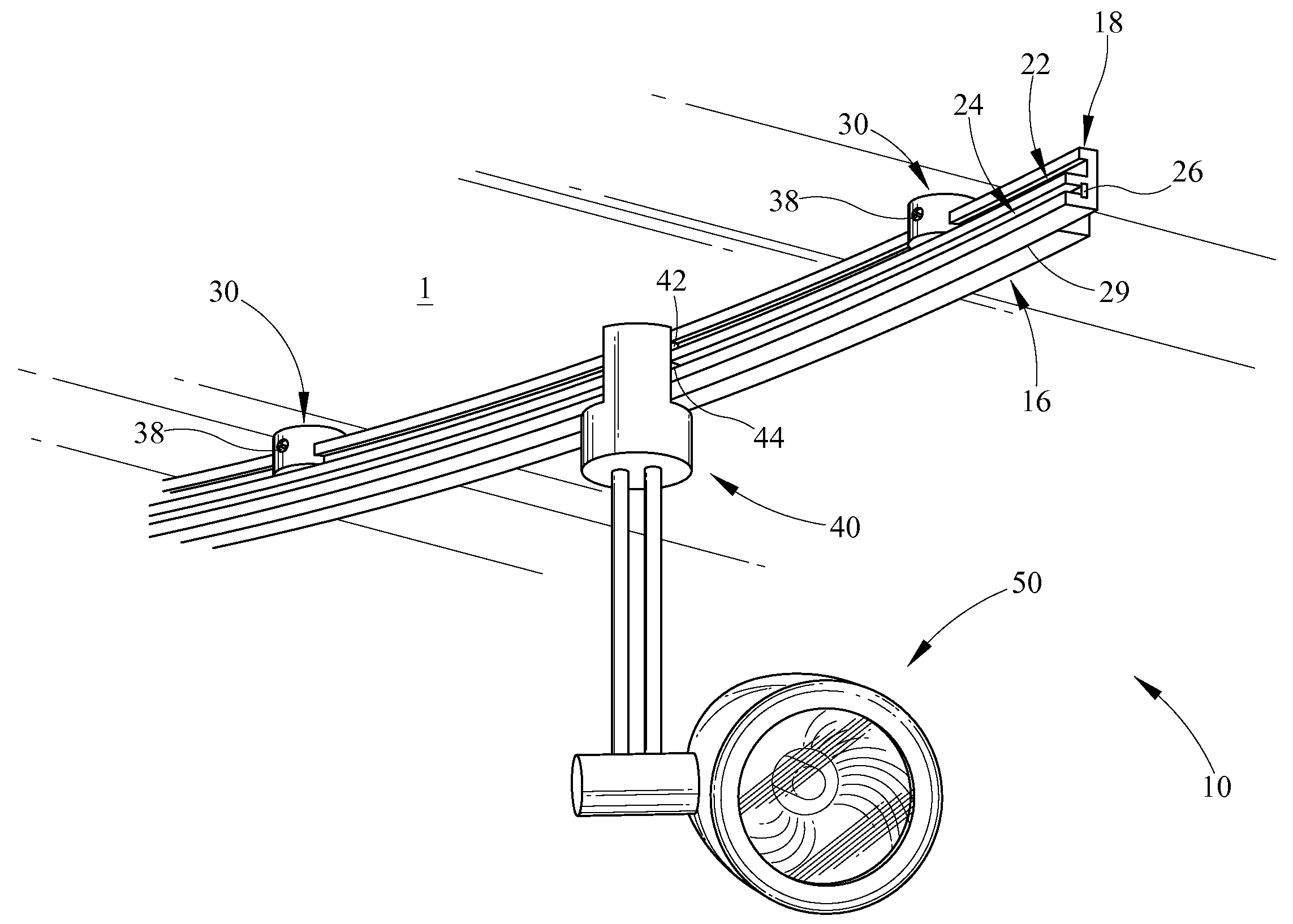

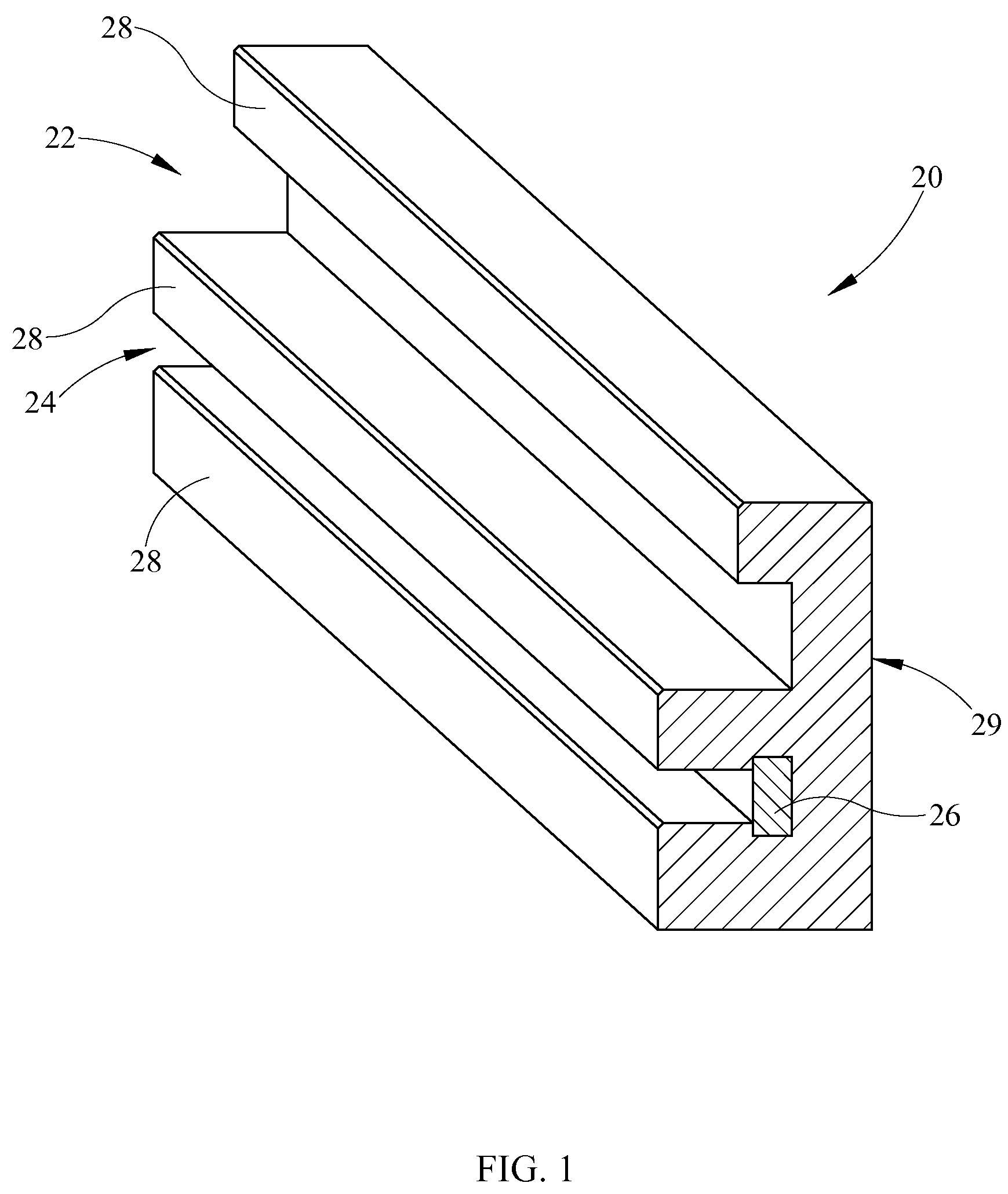

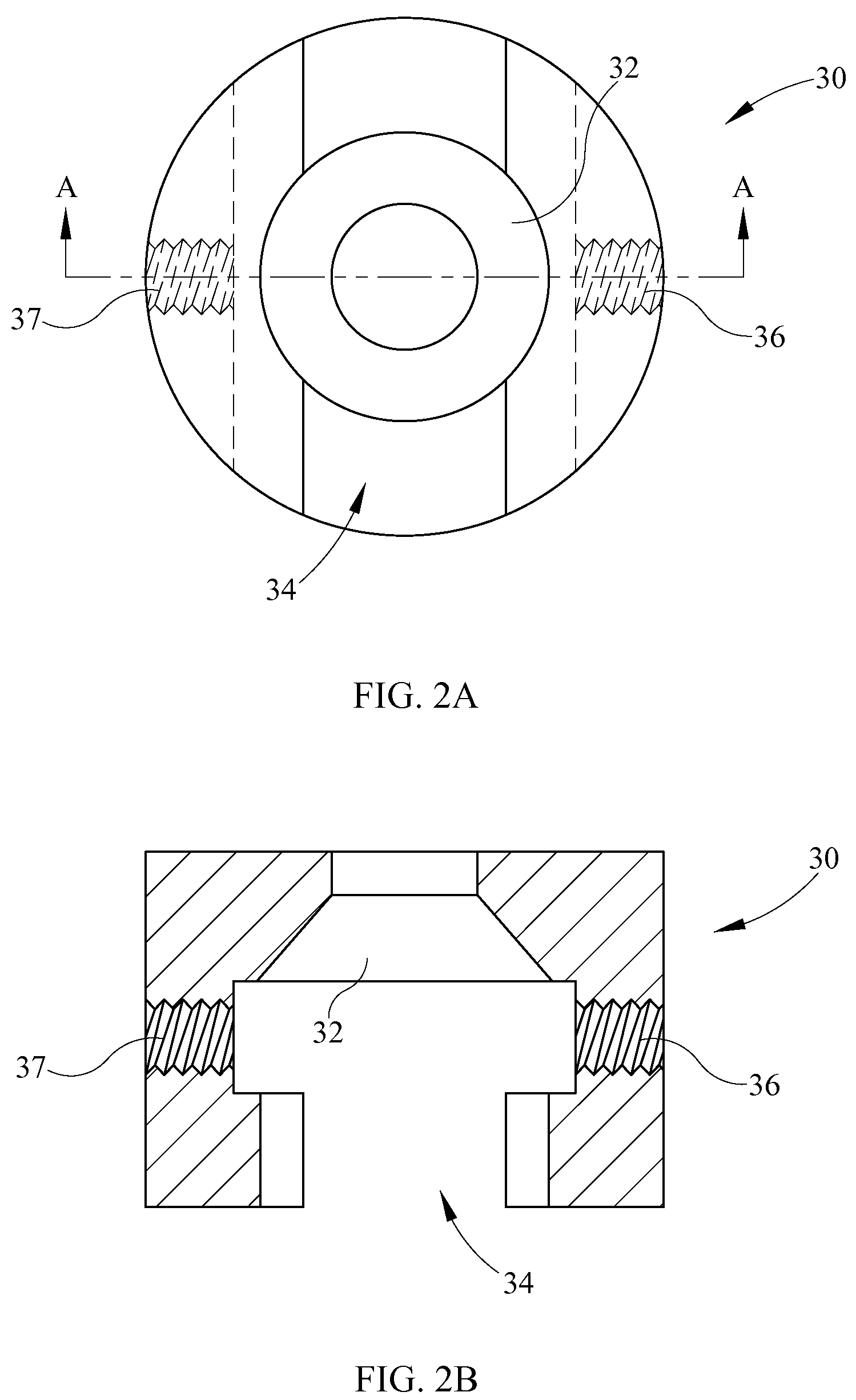

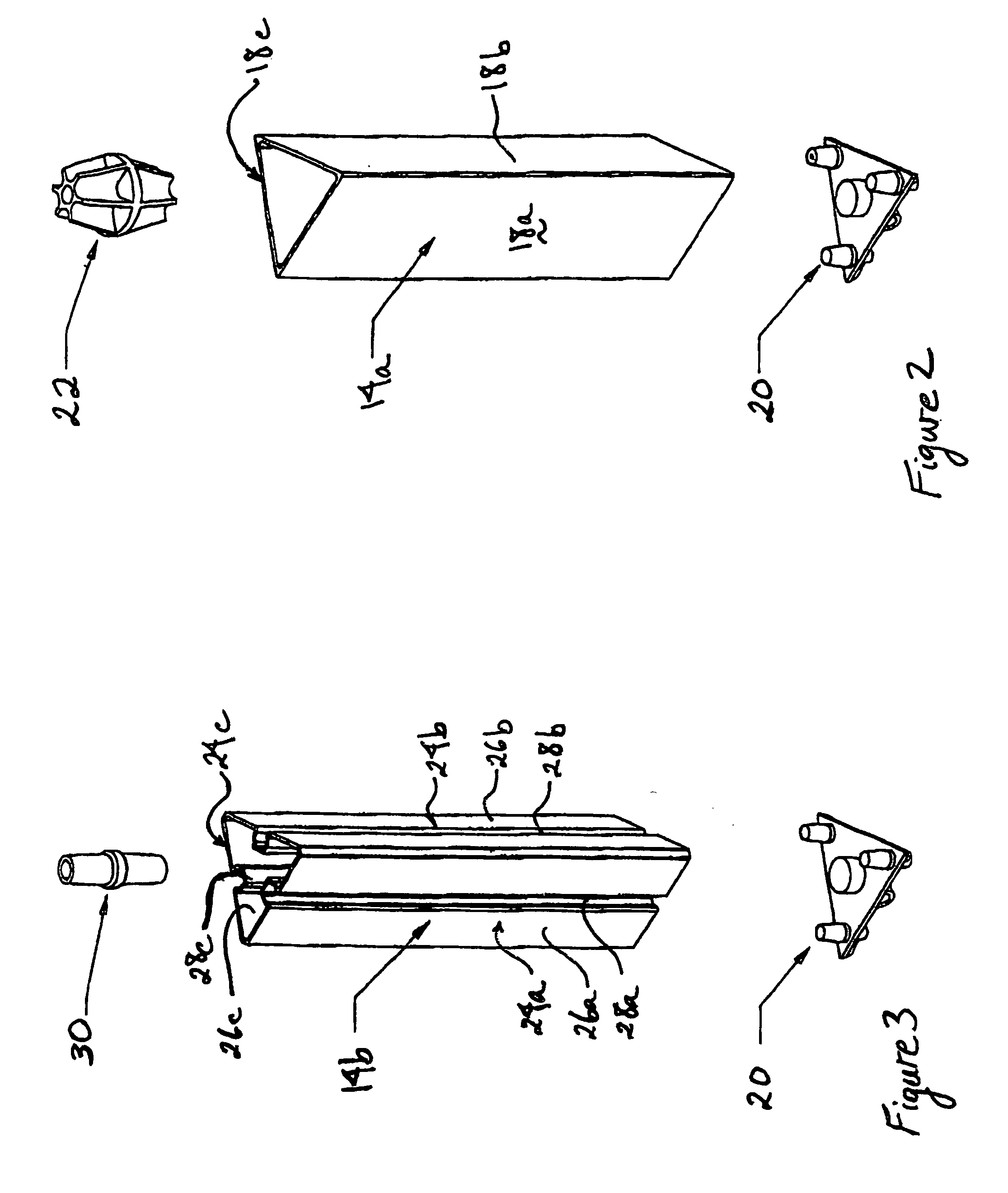

Sliding flexible track lighting

InactiveUS7507005B1Large radiusCoupling device connectionsLighting support devicesEngineeringLight fixture

A flexible track for use in a track lighting system which includes two elongated track members mounted back-to-back which can be manually set and secured into a desired curved configuration. The elongated flexible track members are parallel and adjacent to each other with conductors positioned in channels on the lateral faces of the flexible track, capable of engaging one or more light fixtures. Each track member can slide relative to the other creating a mechanism that allows for large or small diameter curves of the flexible track.

Owner:GENLYTE THOMAS GRP LLC

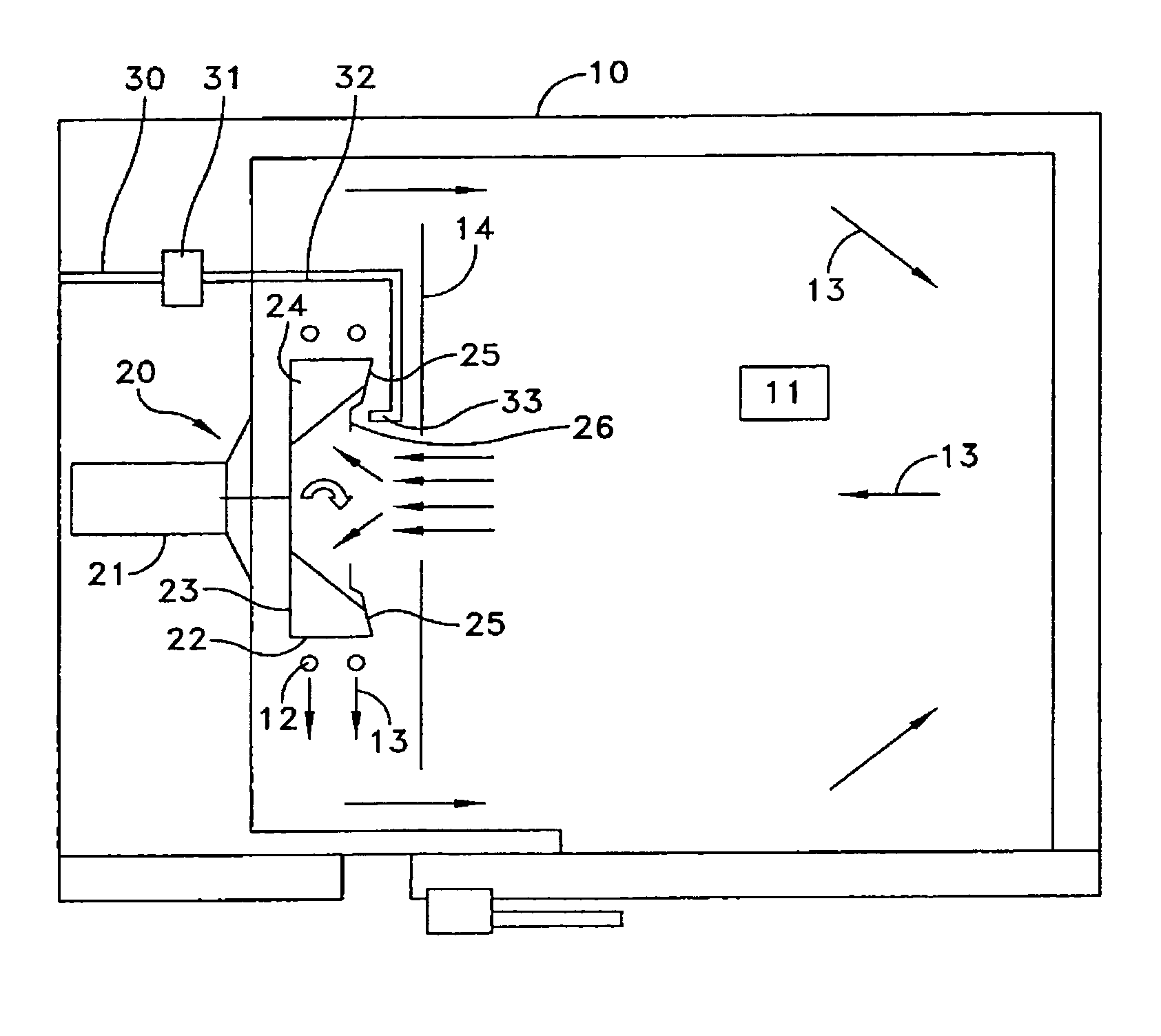

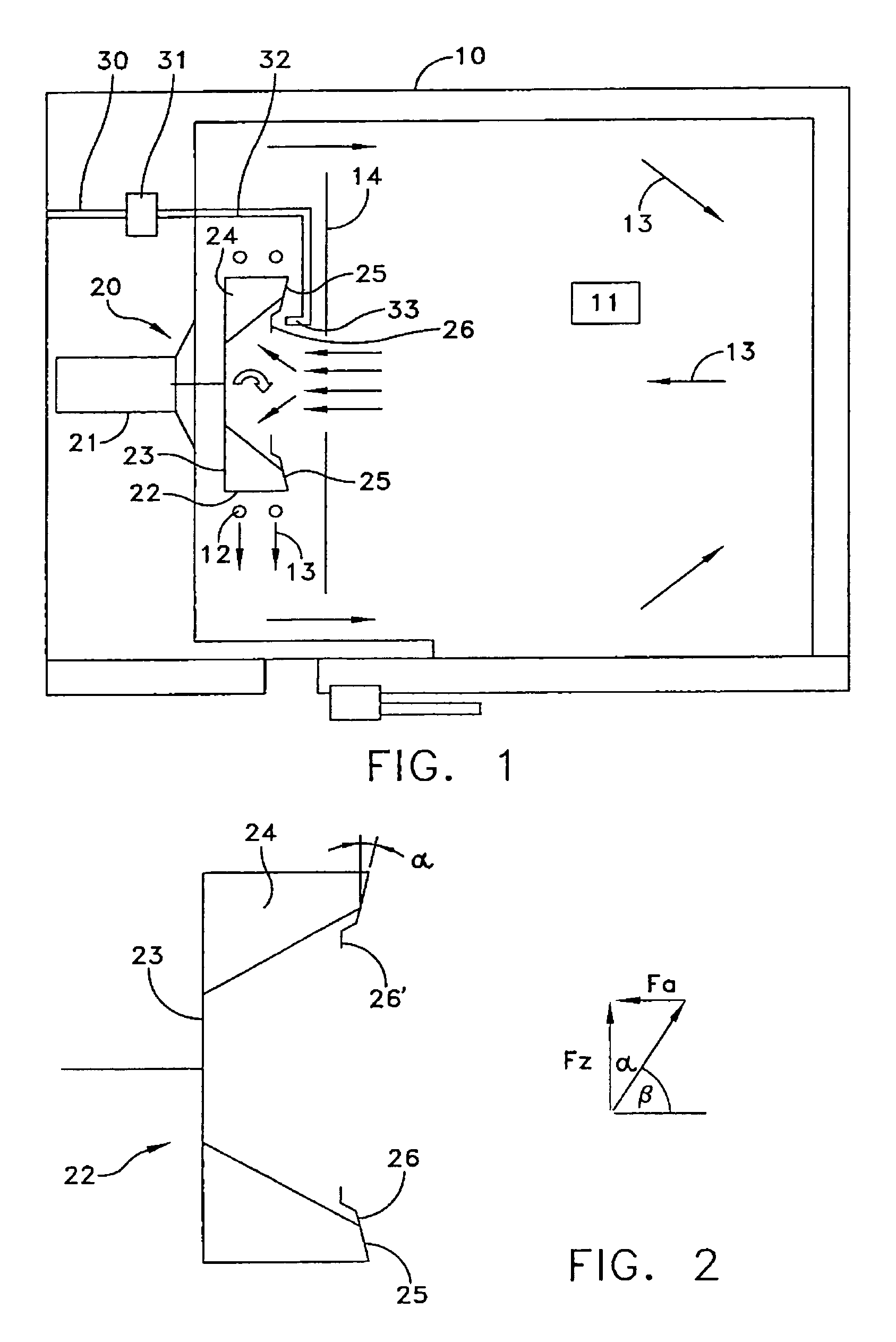

Cooking device with a fan and a water supply

InactiveUS7325481B2Maximum speedLarge radiusAir-treating devicesDomestic stoves or rangesImpellerEvaporation

A cooking device comprises a cooking chamber (11) and one or more heating elements (12). Furthermore, a blower (20) is provided, which comprises a radial blower impeller (22) and an atomisation element rotating with the radial blower impeller (22). A water supply (30) comprises at least one water outlet (33), which supplies water onto the atomisation element (25). An evaporation of the water and thus a humid cooking chamber air is achieved. The atomising element is a discoidal, axially-symmetrical element, the outer radius of which is the same as, or larger than the inner radius of the blade region of the radial blower impeller (22). The atomisation element is arranged adjacent to the radial blower impeller in the axial direction and the water outlet (33) is arranged adjacent to the atomisation element (25), outside the radial blower impeller (22).

Owner:MKN MASCHFAB KURT NEUBAUER

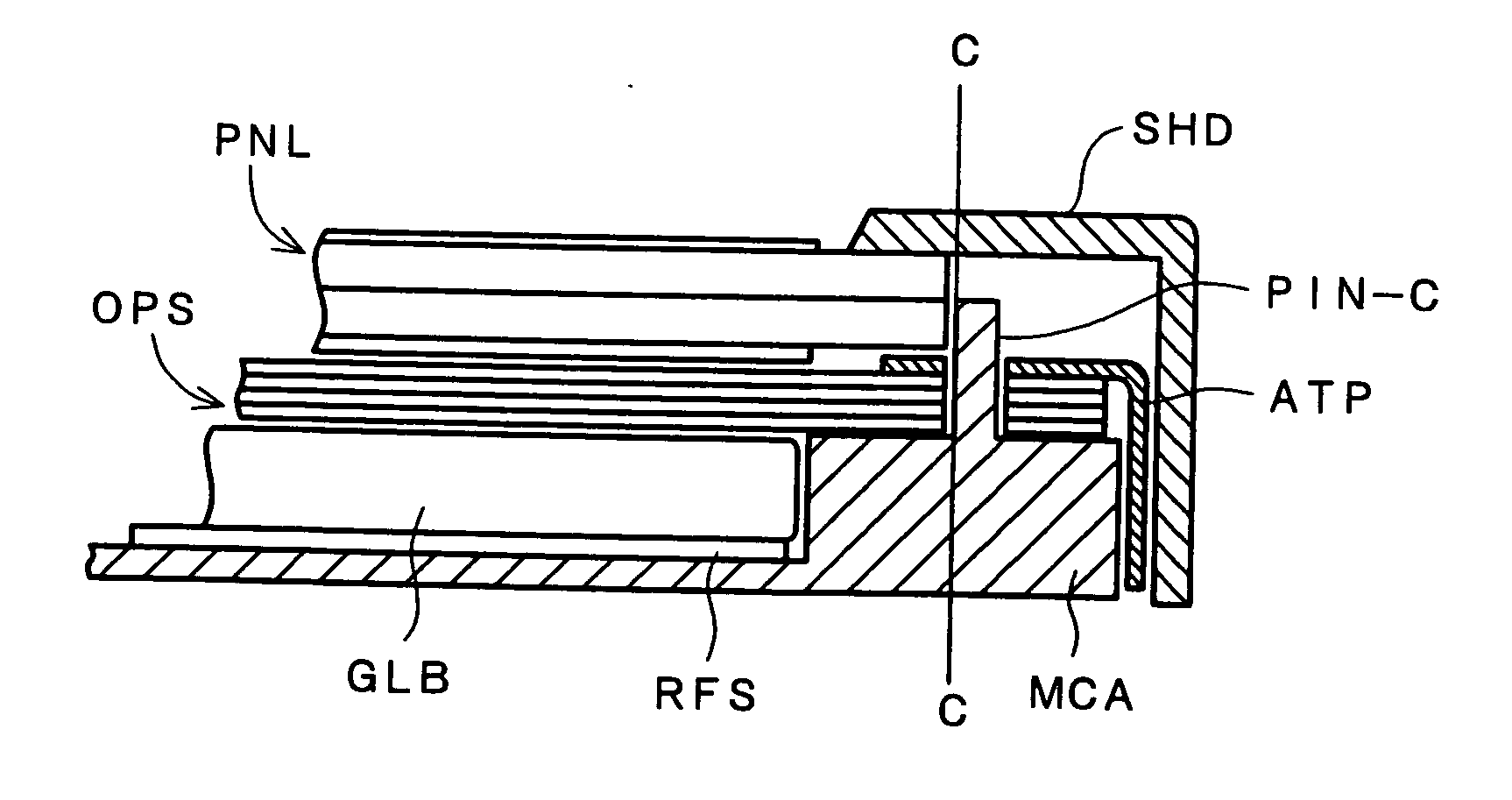

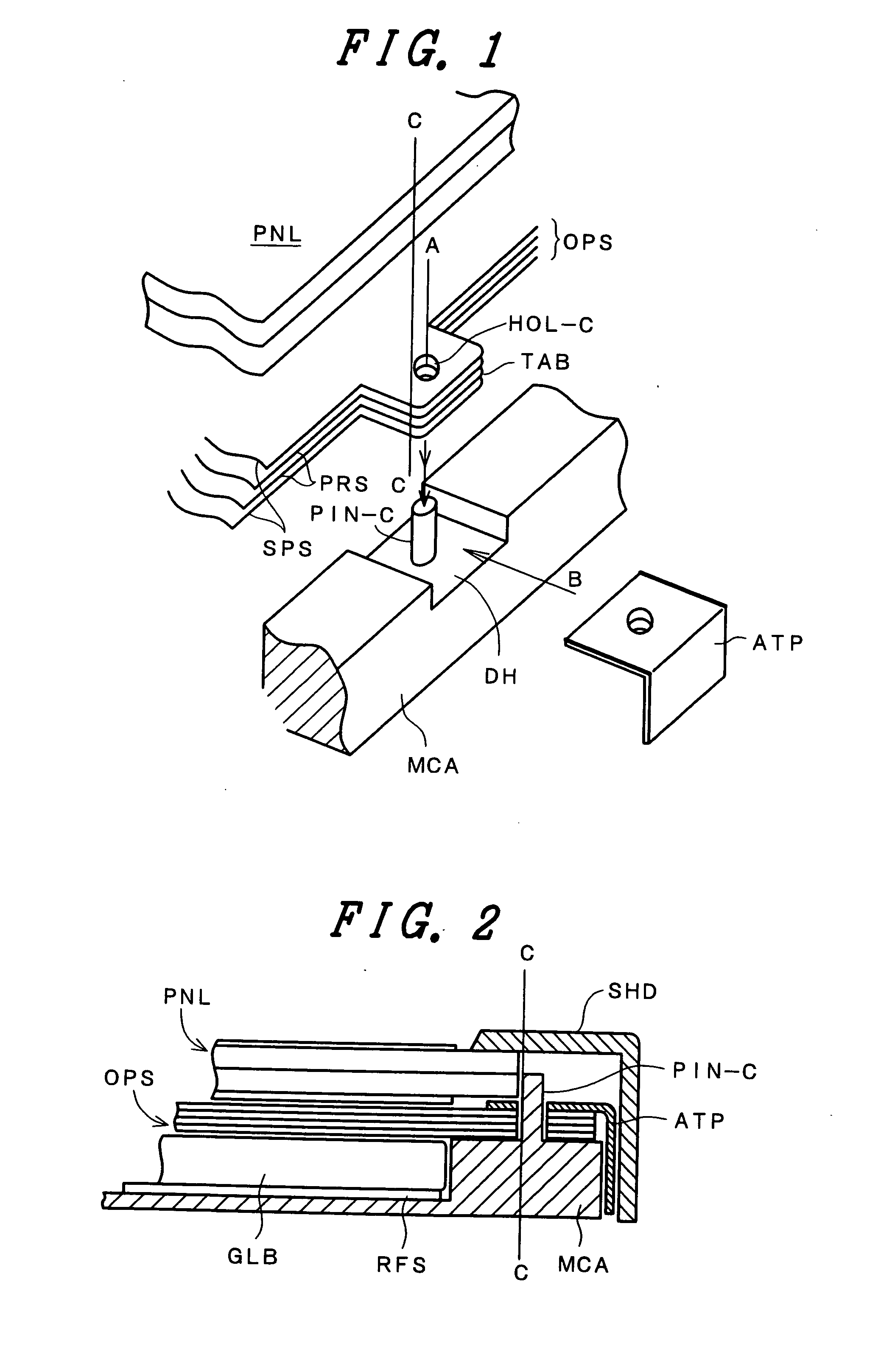

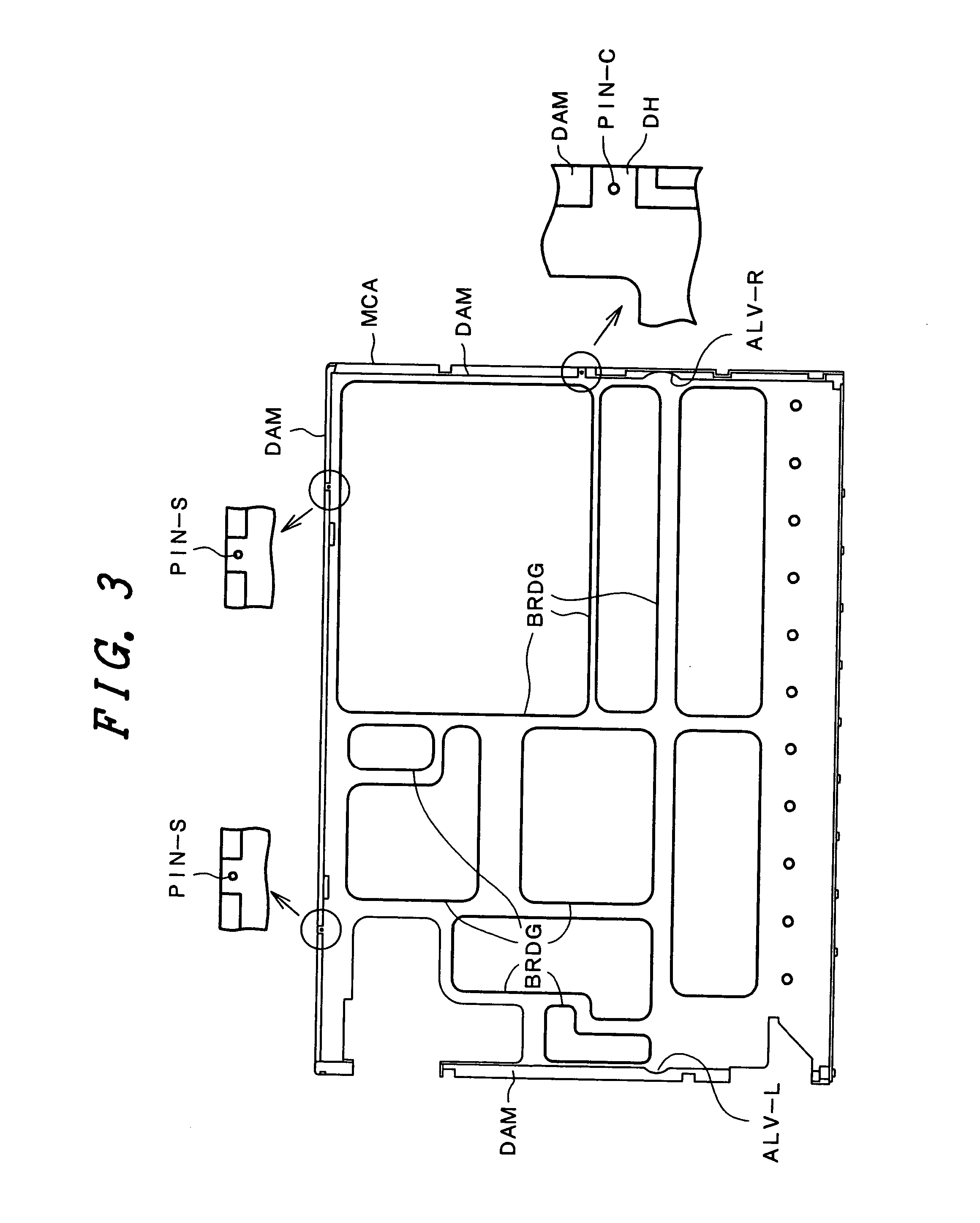

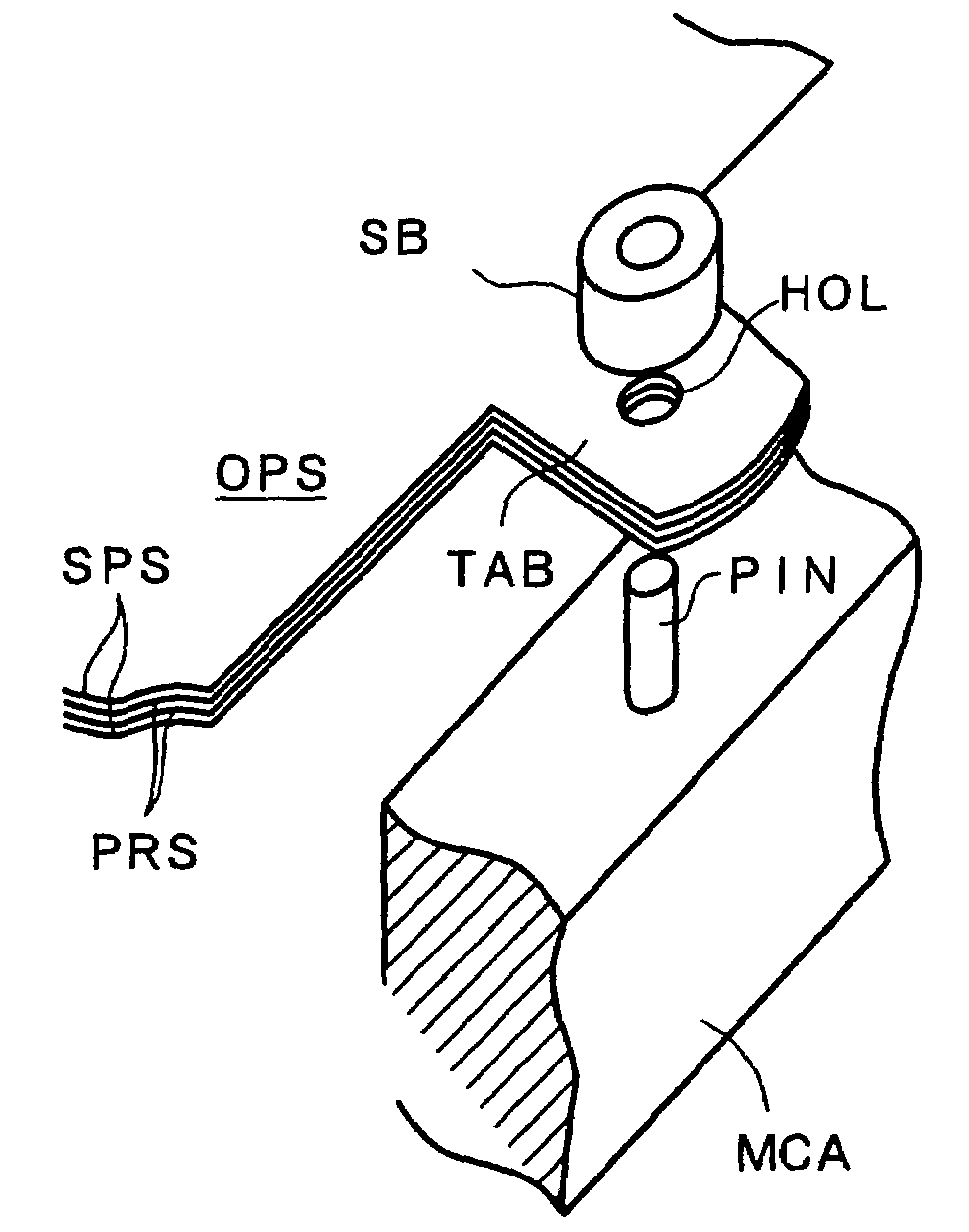

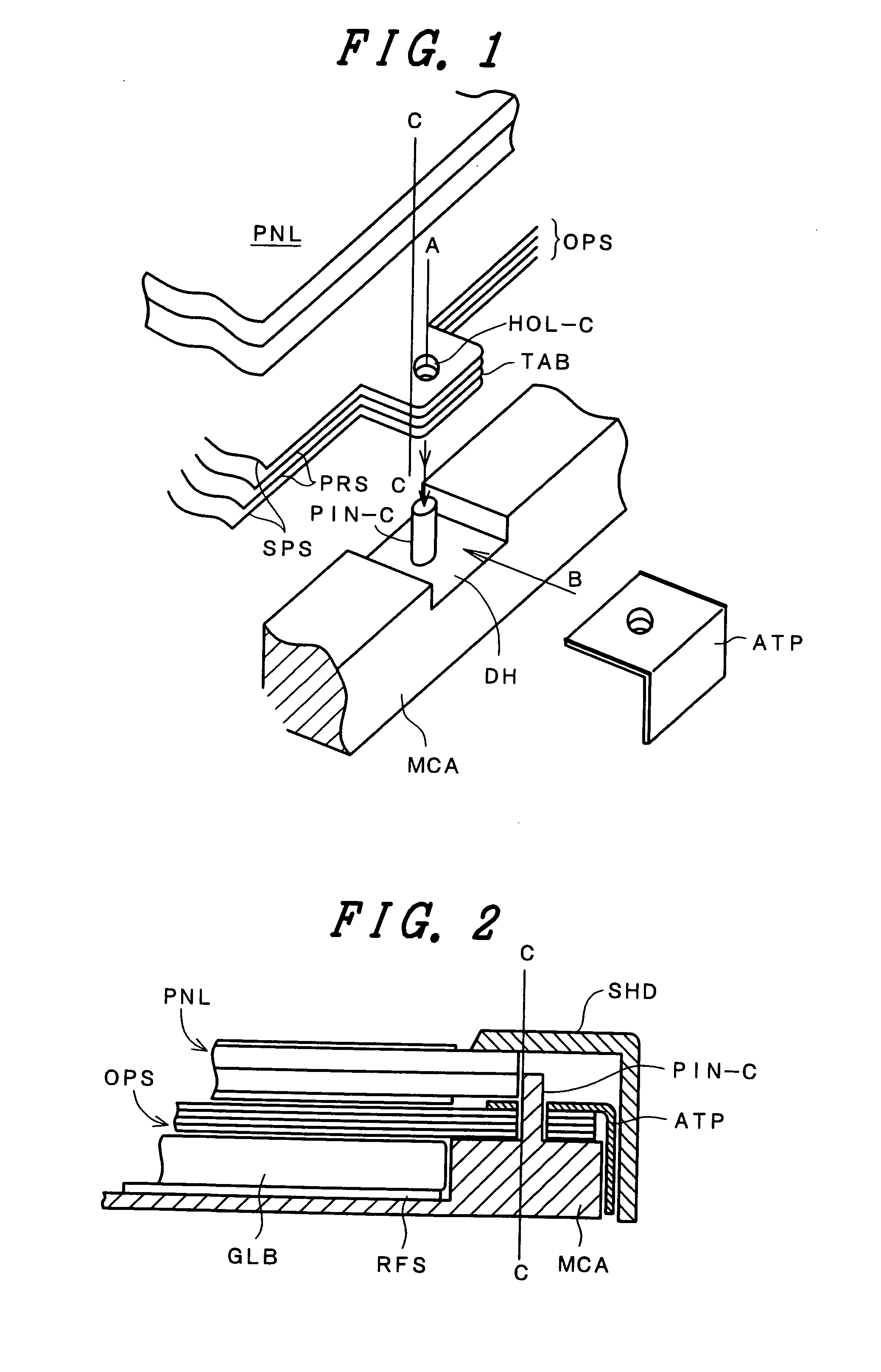

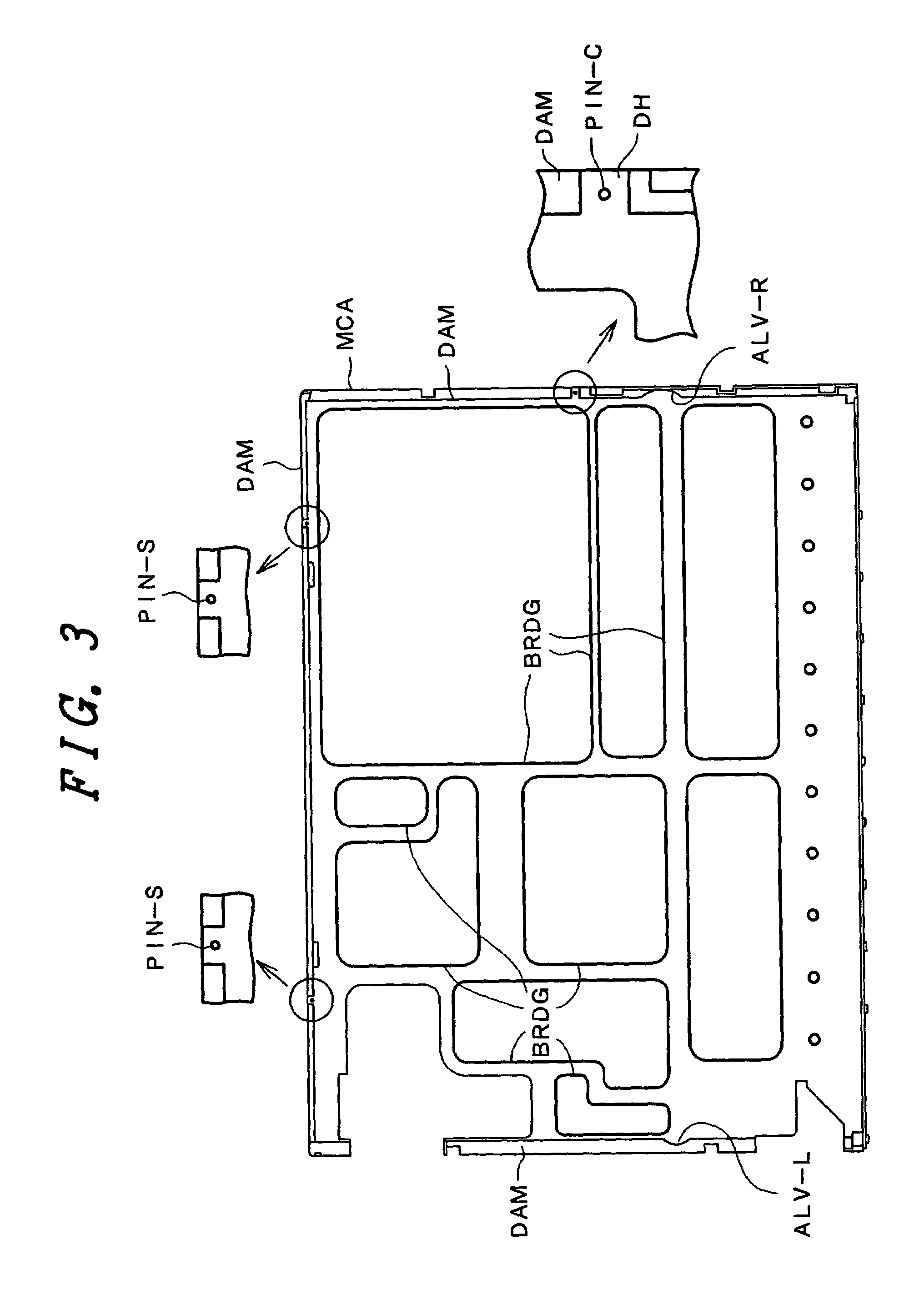

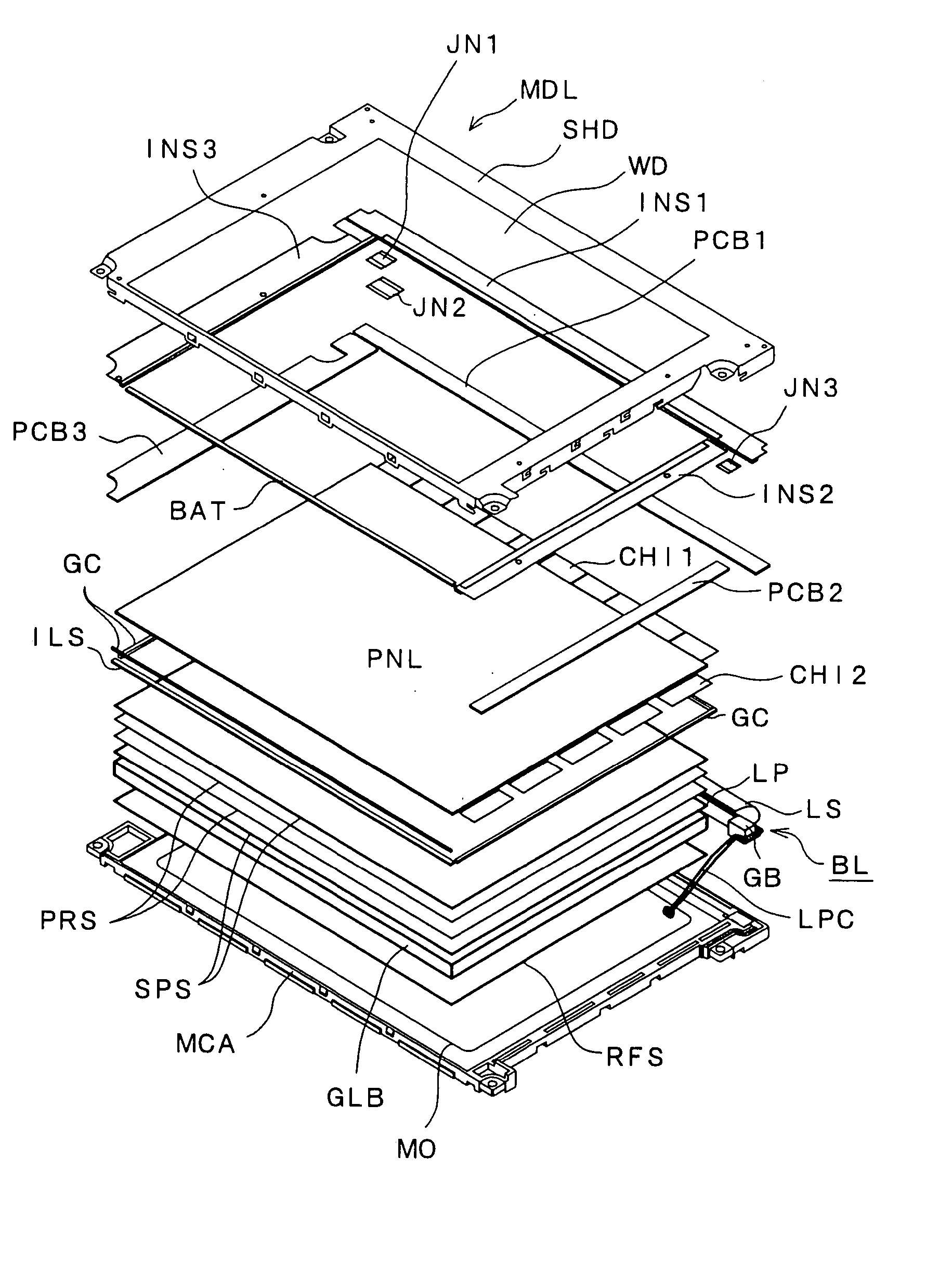

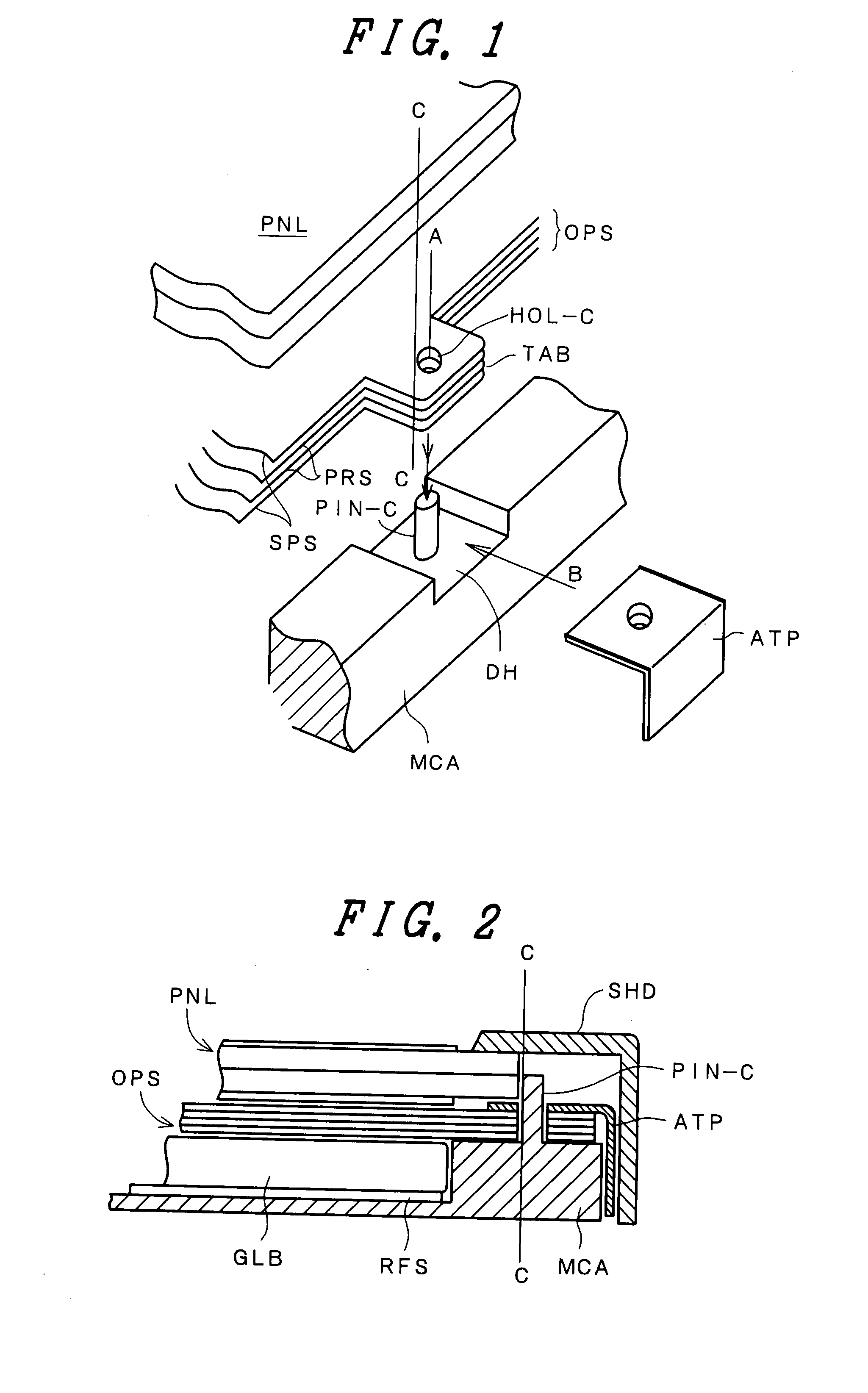

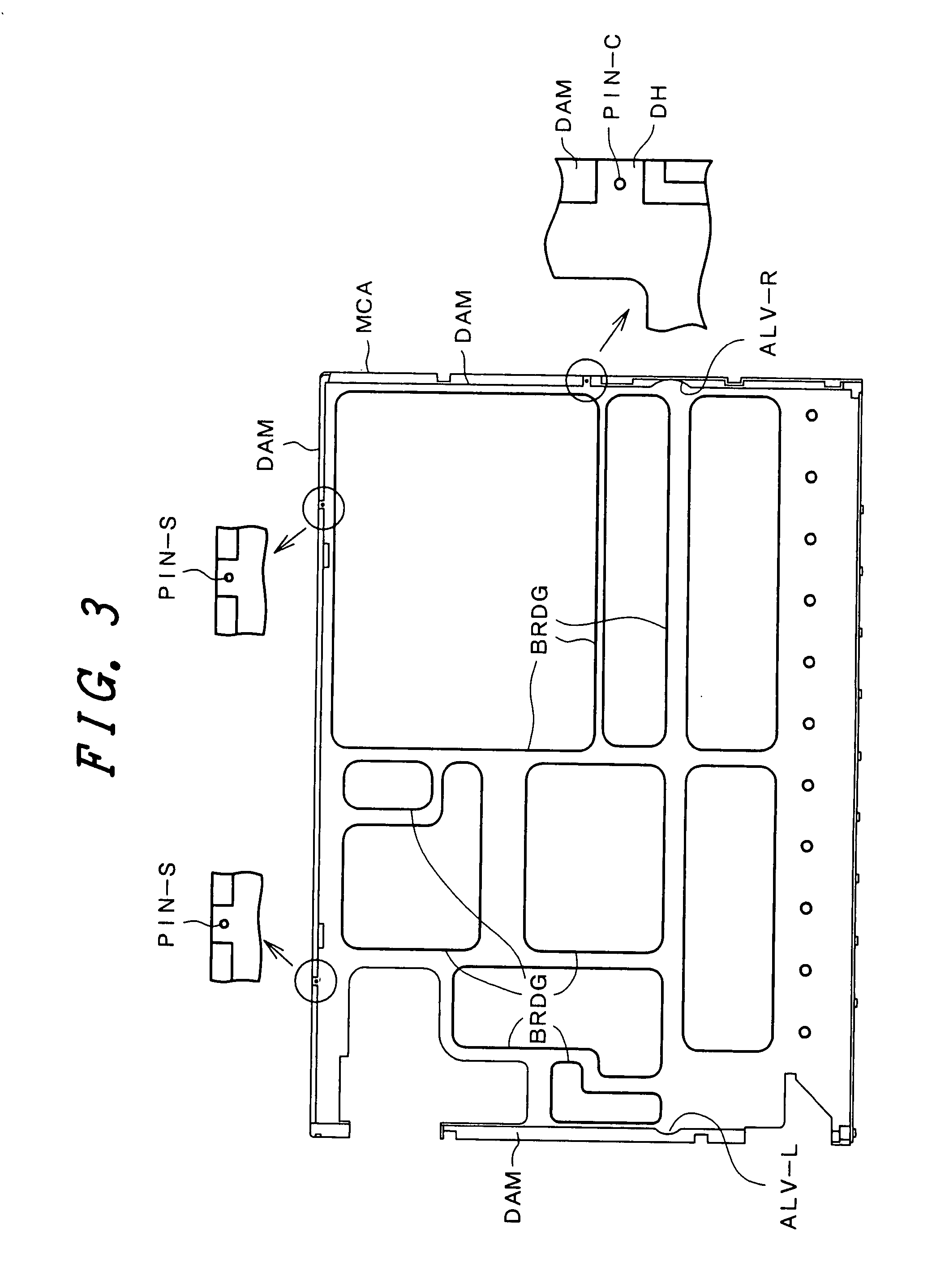

Liquid crystal display device

InactiveUS20050062902A1Precise positioningSuppressing removal and disengagementDetails for portable computersNon-linear opticsLiquid-crystal displayEngineering

In a liquid crystal display device, a recessed portion is formed in a portion of a periphery of a lower frame, a columnar member is provided to the recessed portion, the columnar member is allowed to pass through a hole formed in a projecting portion which is provided on an optical sheet, and a side surface of a liquid crystal panel is brought into contact with the columnar member. The columnar member provided on the lower frame not only determines the position of the liquid crystal panel with respect to the lower frame, but also determines the position of the optical sheet with respect to the lower frame and firmly holds the optical sheet onto the lower frame, thus preventing the disengagement of the optical sheet from the lower frame.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

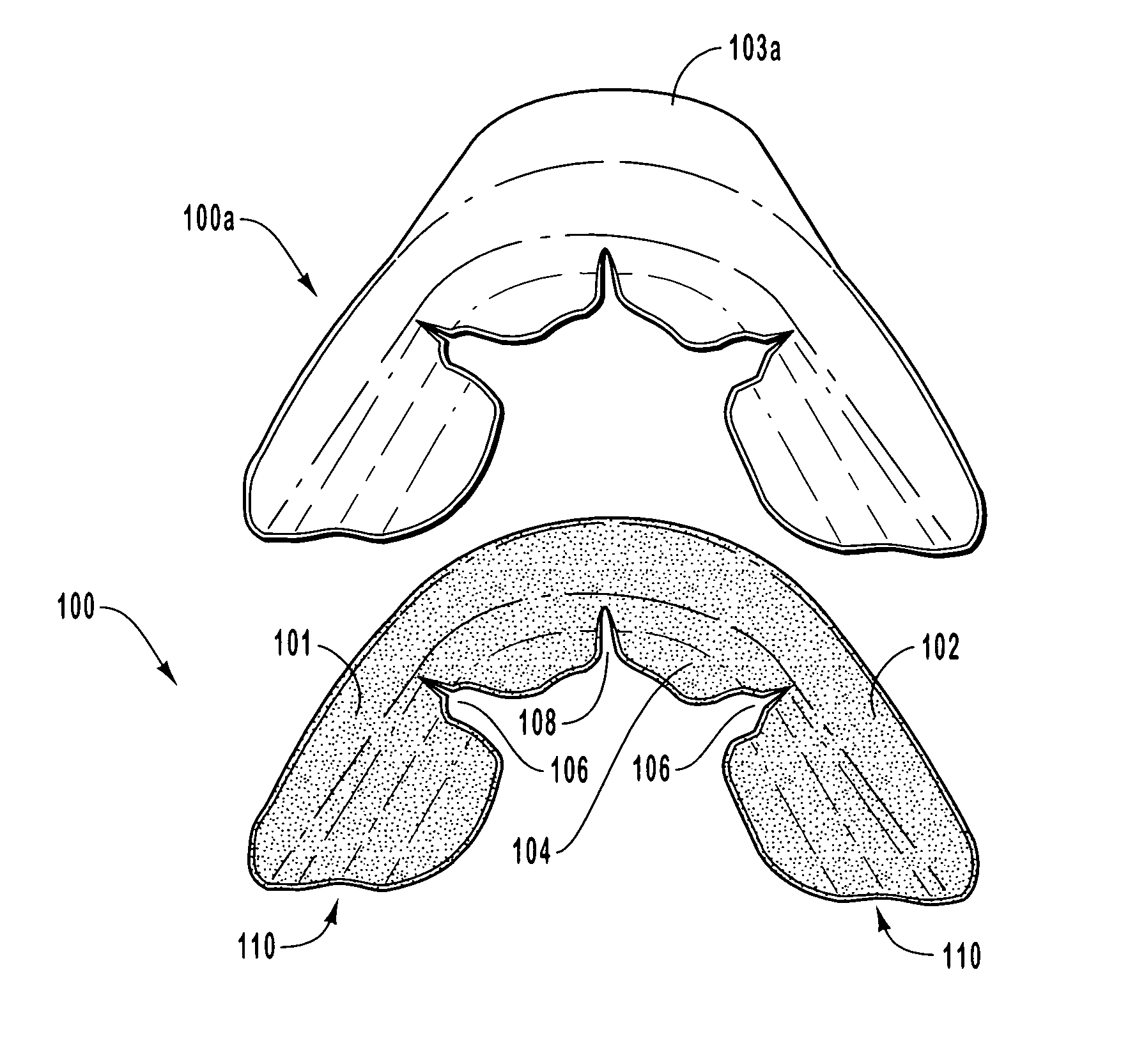

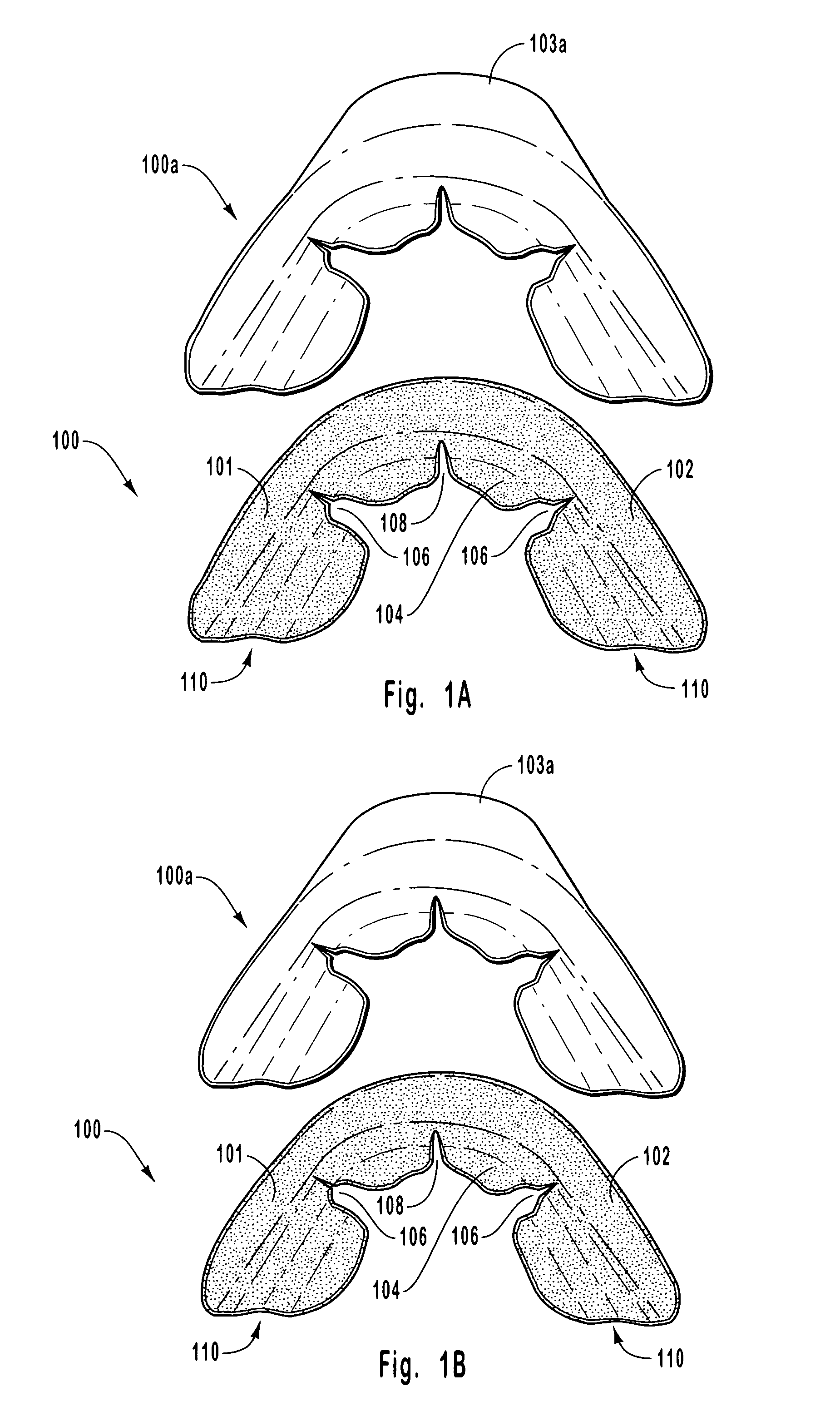

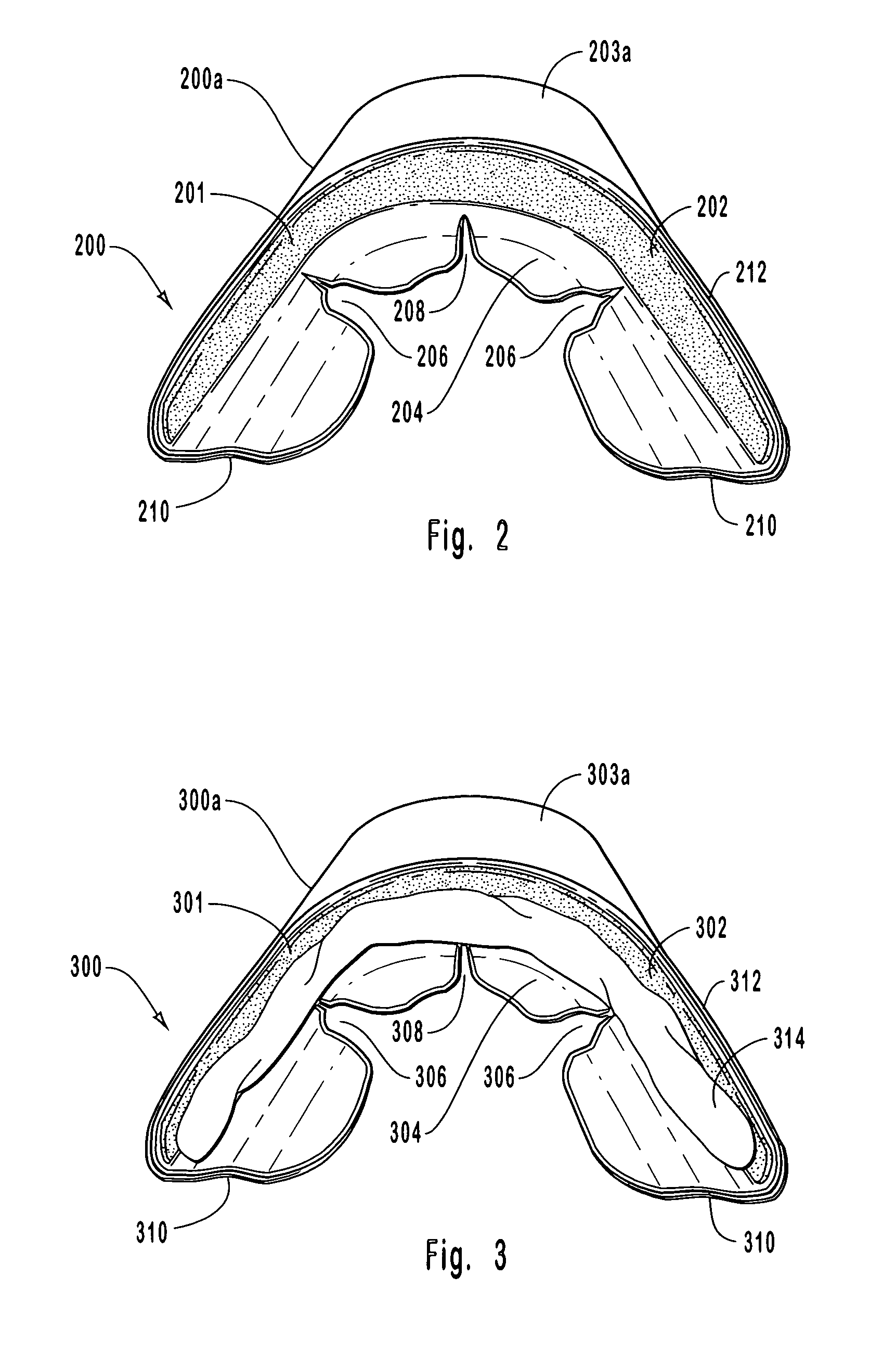

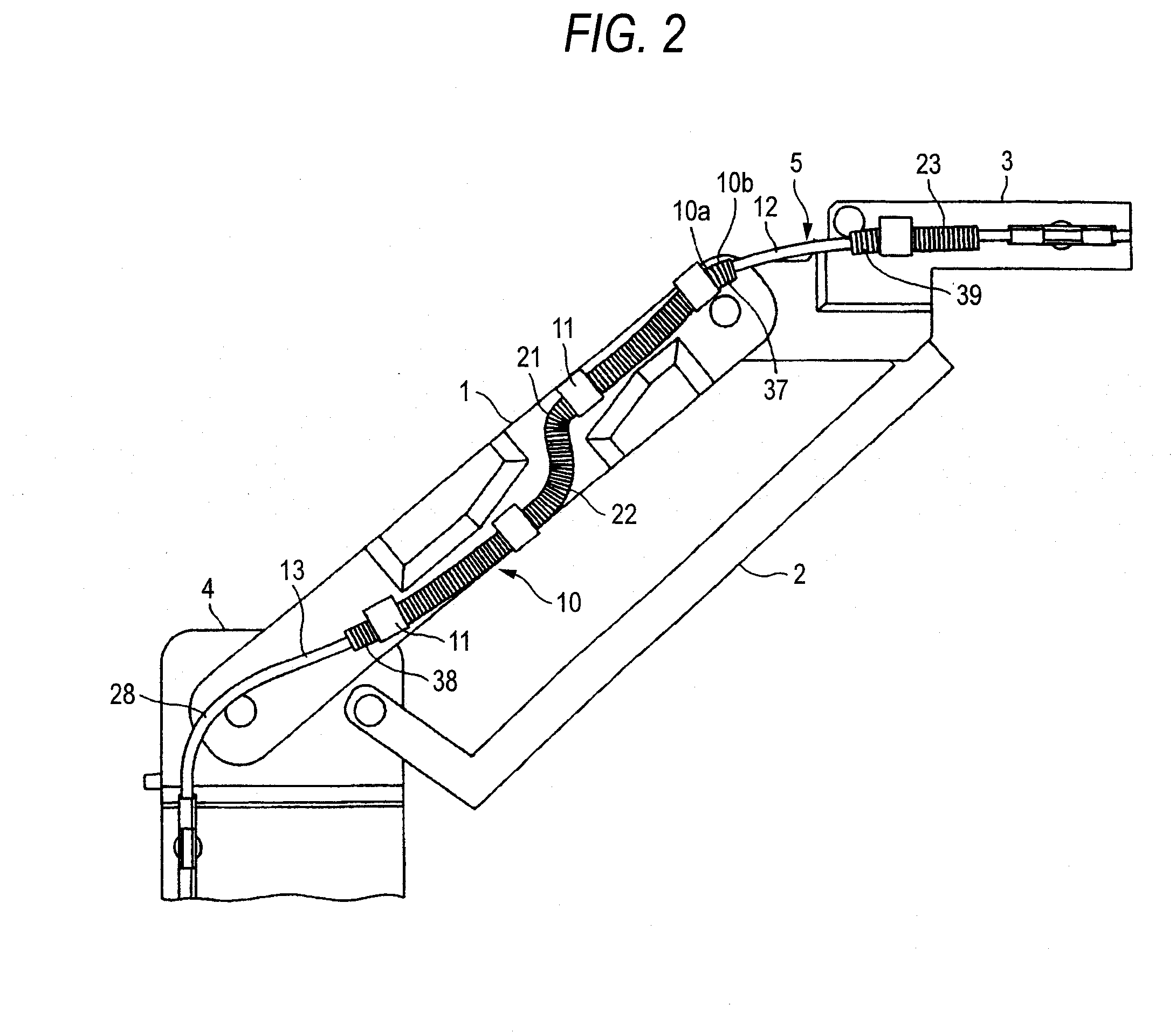

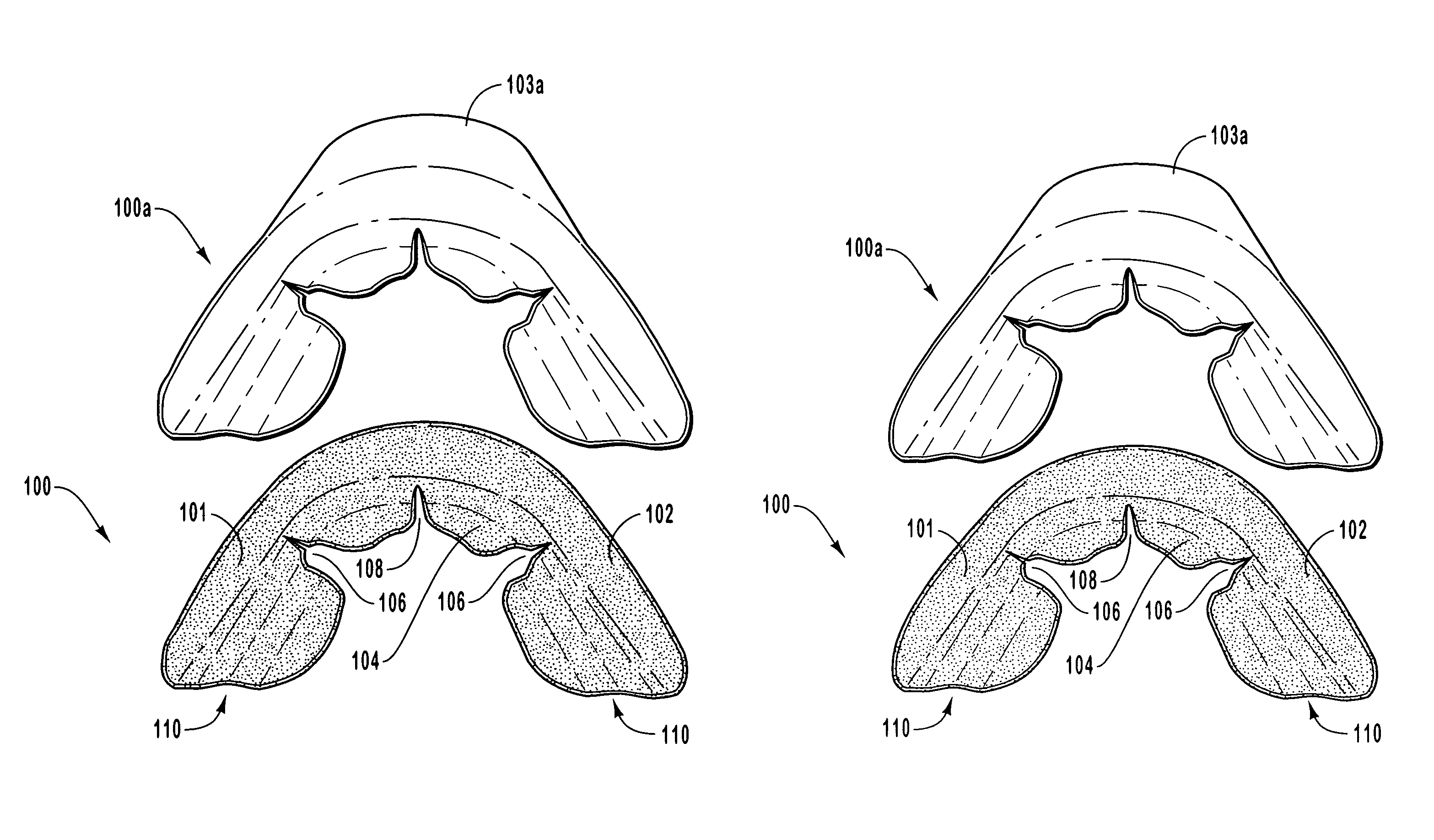

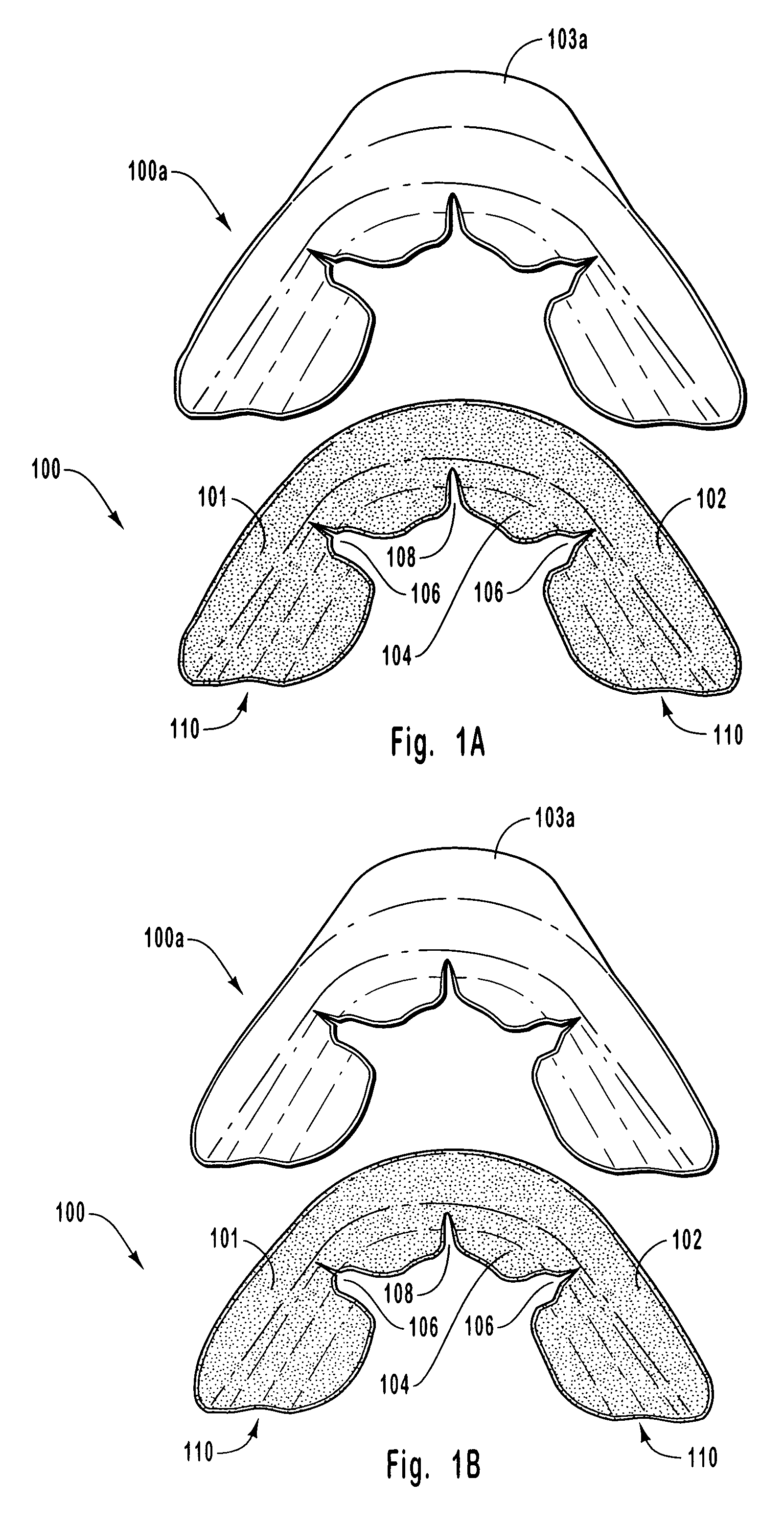

Universal tray design having anatomical features to enhance fit

ActiveUS20050186539A1Enhance anatomical fitBetter conformGum massageTeeth fillingEngineeringDental treatments

A tray-shaped dental treatment device includes a moisture-resistant barrier layer having a front side wall and a bottom wall, and a dental treatment composition. In addition, the tray-shaped dental treatment device includes at least one of the following anatomical features to enhance the fit of the device: (1) the bottom wall includes a plurality of cuts positioned to help the bottom wall better conform to abrupt changes in the diameters of a person's teeth where the bicuspids and canines meet, or (2) the bottom wall includes at least one V-shaped or U-shaped indentation configured to be inserted into the depression typically found along the top surfaces of a person's molars, or (3) the front side wall and bottom wall include radii of curvature that account for typical flaring of a patient's incisors.

Owner:ULTRADENT PROD INC

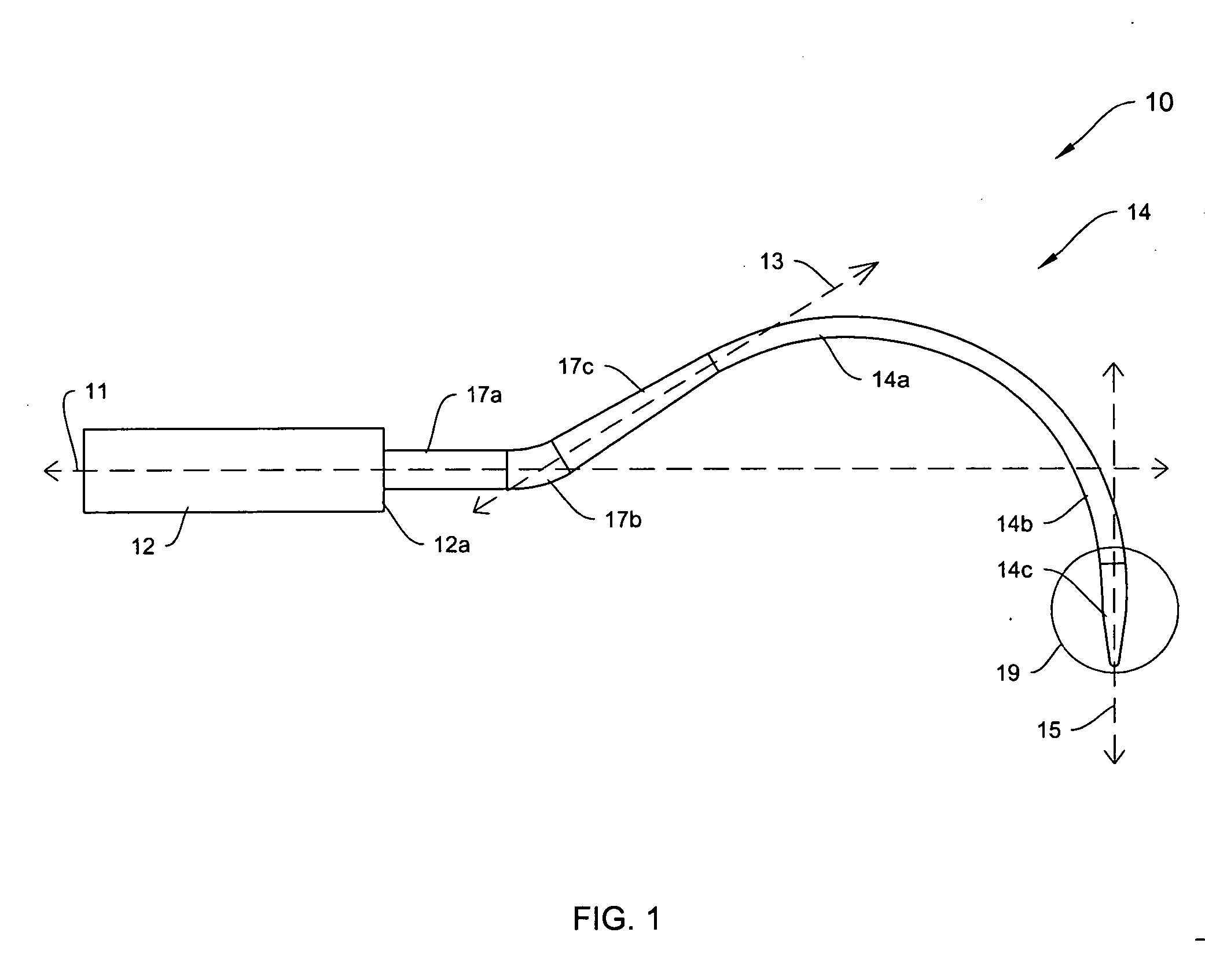

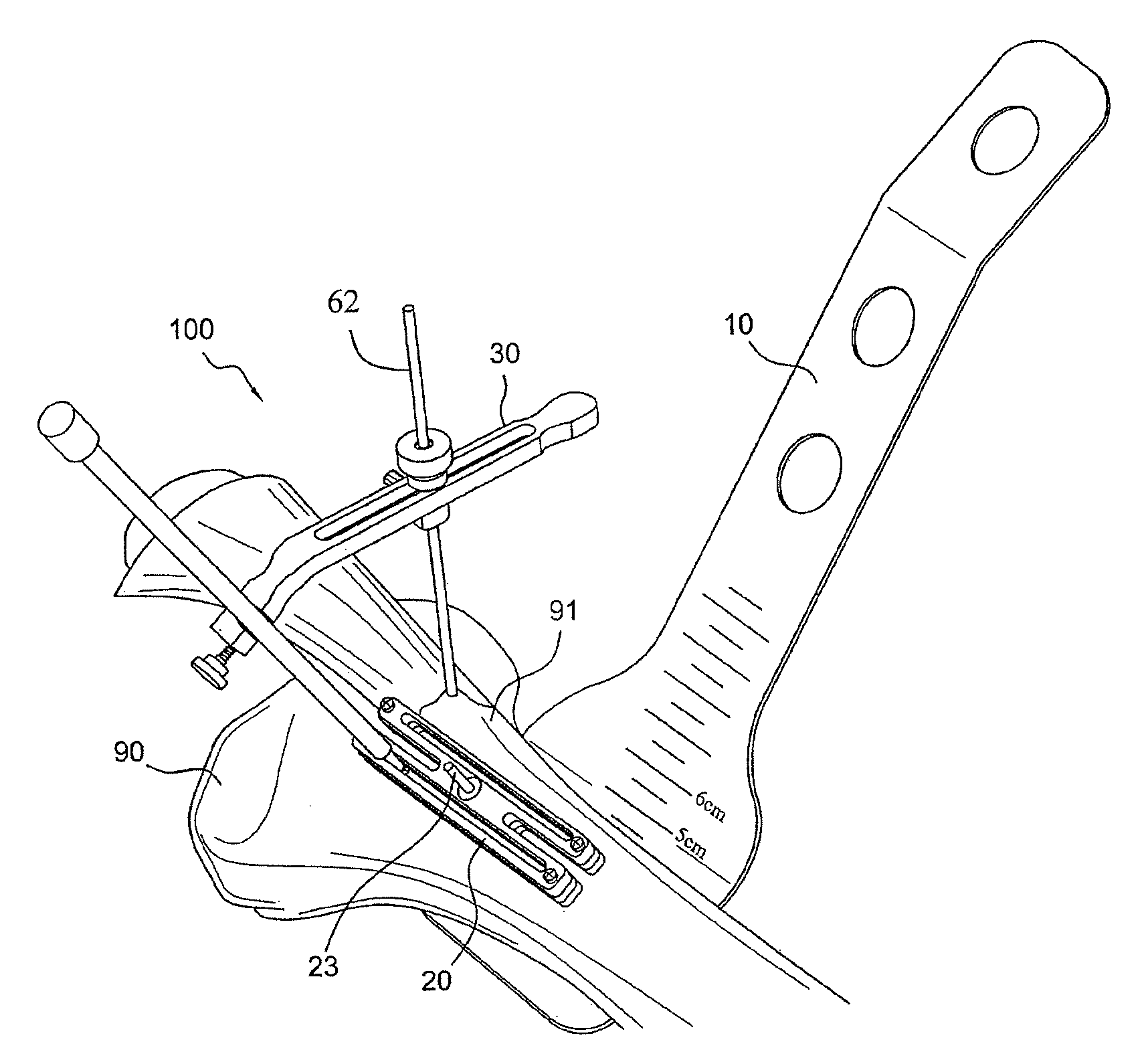

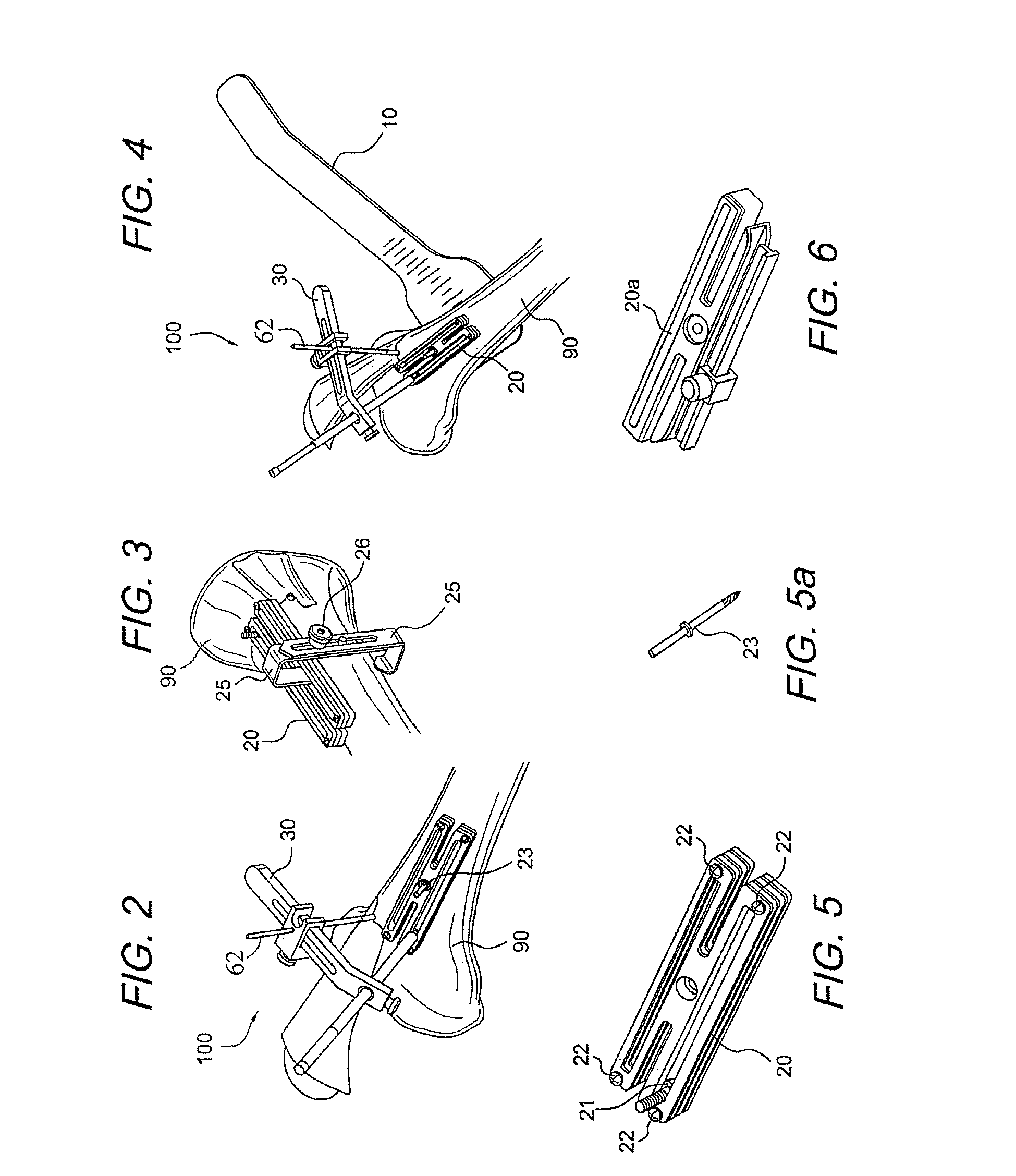

AMZ tibial tuberosity transfer system

ActiveUS8353915B2Large radiusSimple designNon-surgical orthopedic devicesSurgical sawsMedicineTransfer system

An AMZ tibial tuberosity transfer system and method of treatment of patellofemoral joints. The AMZ system includes 1) a retractor with a better conformation to anatomy and more curve (not just a bend), and also with a larger radius on the front of the retractor to allow for easier insertion; 2) a cutting block that can fully accept a collared pin; 3) a rod preferably formed of stainless steel; 4) a tuberosity pin guide; 5) an exit indicator that engages tightly the cutting block so there is no slope on exit indication; and 6) a horizontal bar provided with markings to measure the medial shift.

Owner:ARTHREX

Liquid crystal display device

InactiveUS7244966B2Precise positioningSuppressing removal and disengagementDetails for portable computersNon-linear opticsLiquid-crystal displayEngineering

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

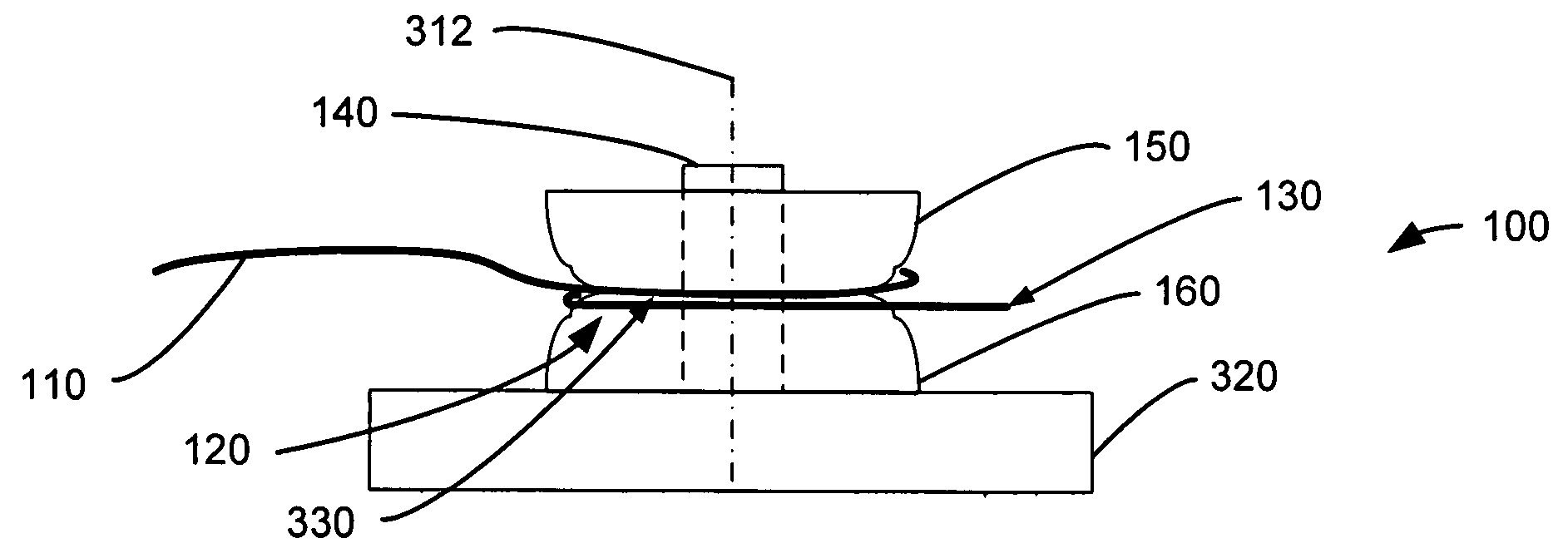

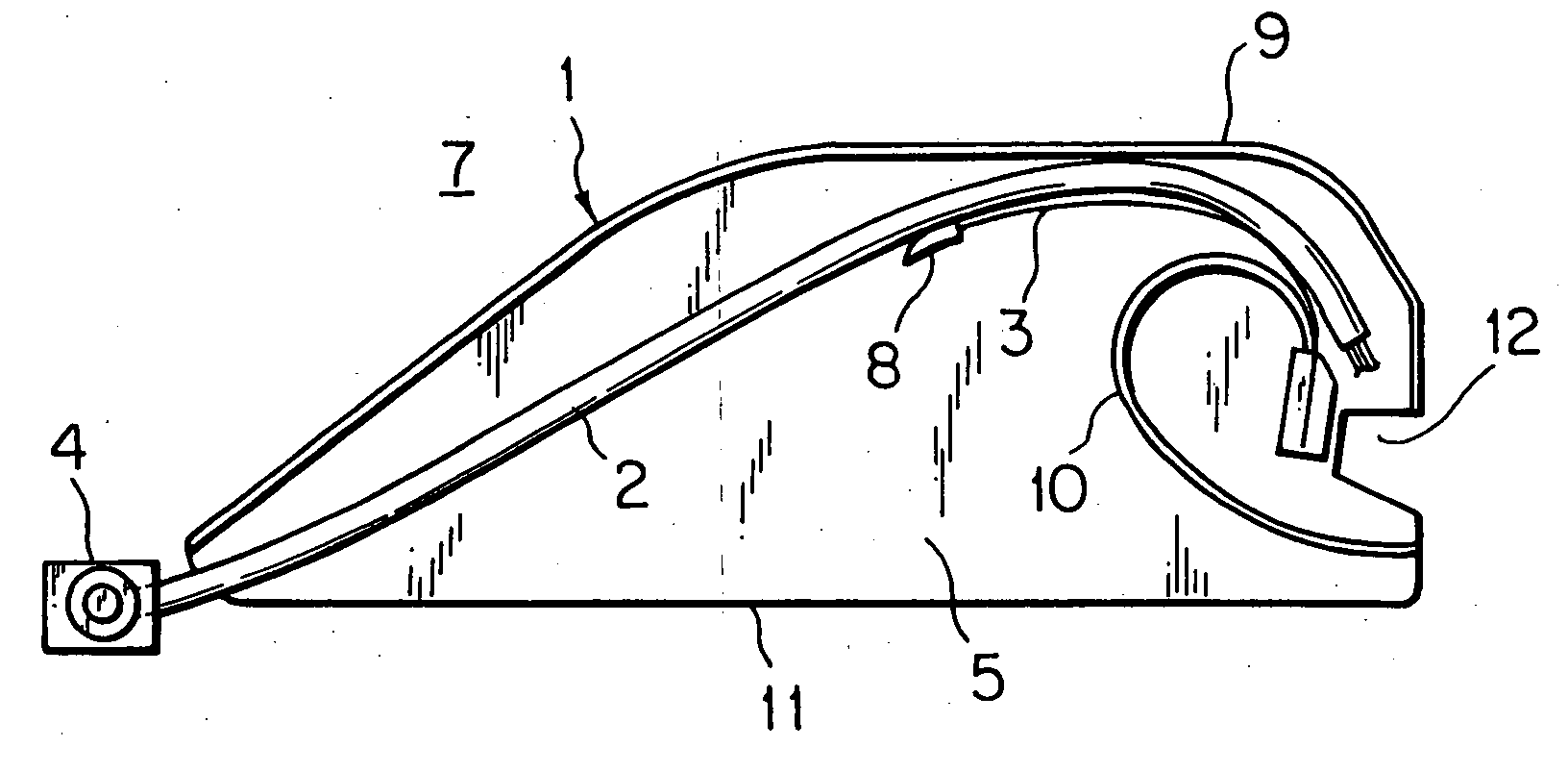

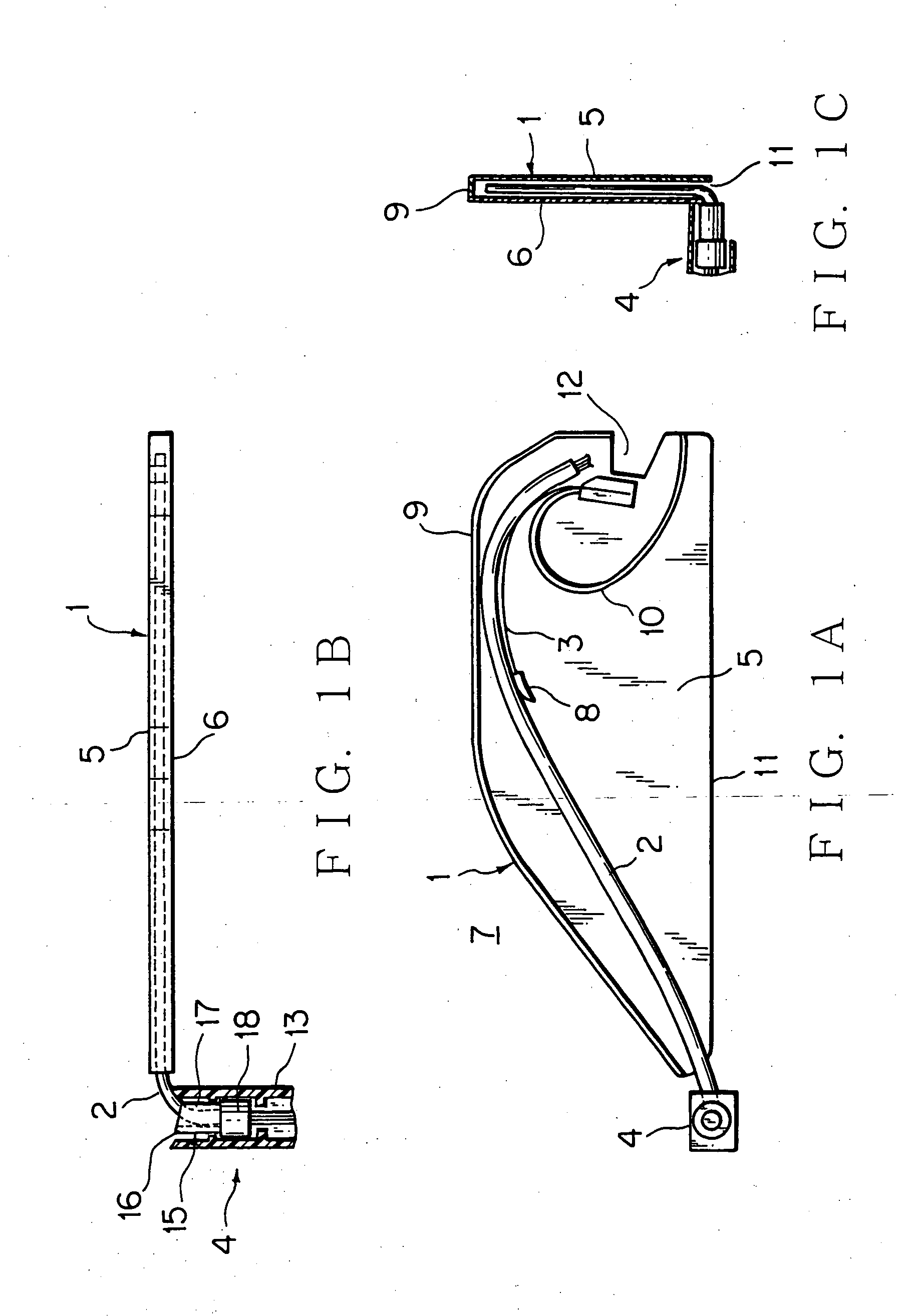

Reflection suppression for an optical fiber

ActiveUS20050053350A1Suppresses internal reflectionSuppresses back reflectionCoupling light guidesFibre mechanical structuresEngineeringReturn loss

Forming a plurality of loops in an optical fiber around a spool adjacent to an exposed end face can suppress internal reflections from the exposed end face. The radius of the loops can attenuate light that is propagating to and from the end face by causing light to leak out of the optical fiber's core and into its cladding. The radius can be selected to control physical stress in the optical fiber and promote reliability. The radius and the number of loops can be selected to meet a return loss specification. The loops can be formed by coiling the optical fiber around a spool that includes a slot for holding the optical fiber until it is put into service.

Owner:ARRIS SOLUTIONS

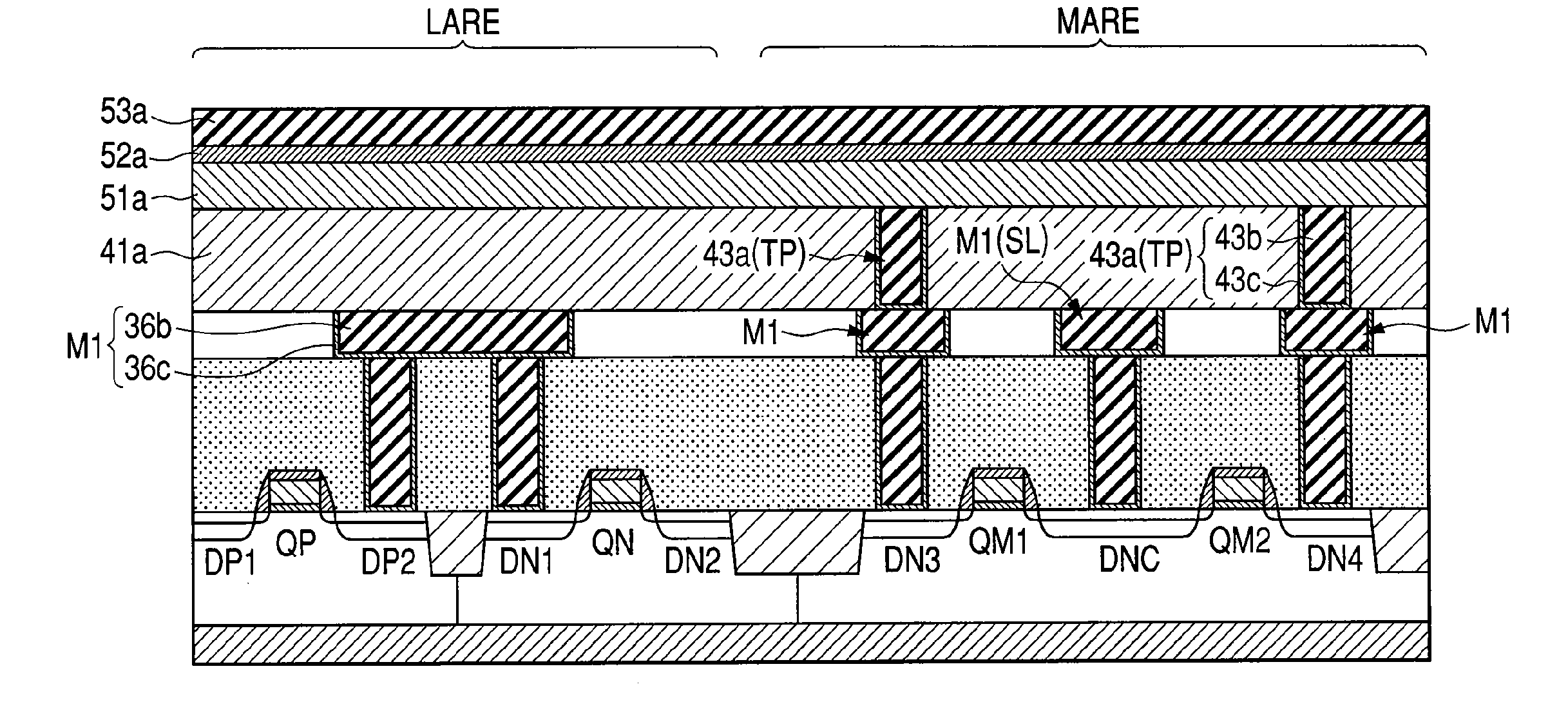

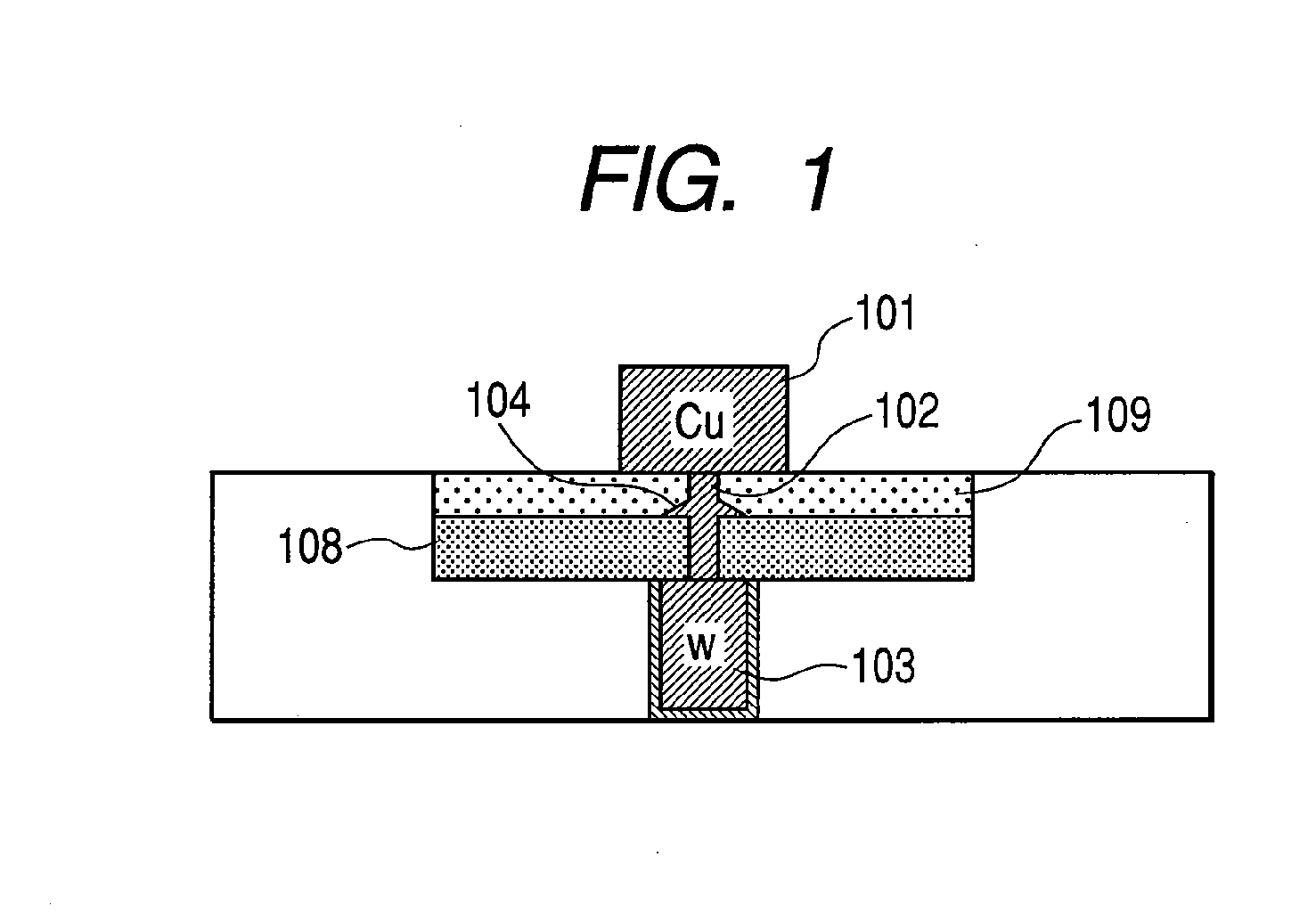

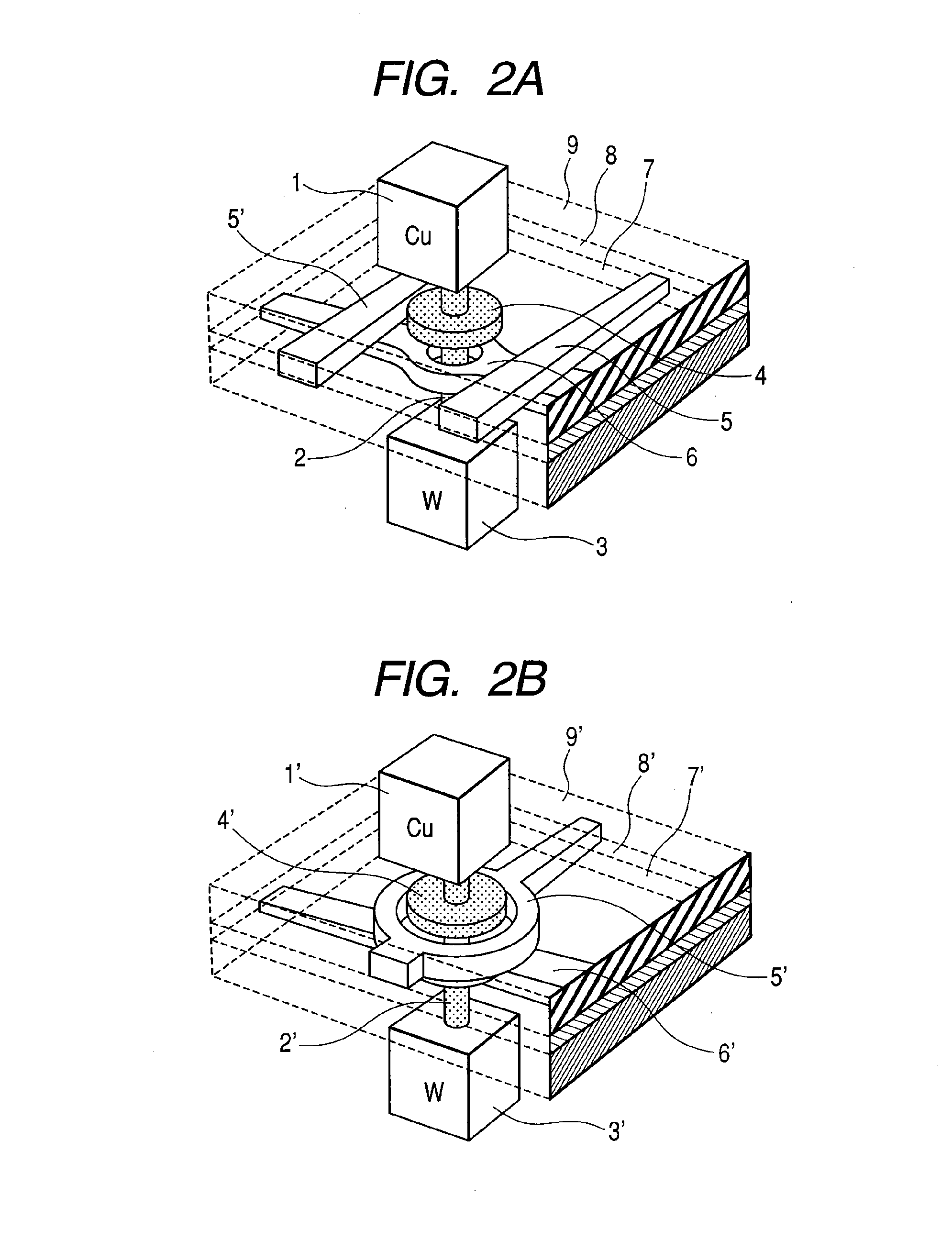

Semiconductor device

InactiveUS20090014770A1Rewriting endurance is thus more loweredFacilitate conductionSolid-state devicesDigital storageElectrical resistance and conductanceEngineering

A technique that can realize high integration even for multilayered three-dimensional structures at low costs by improving the performance of the semiconductor device having recording or switching functions by employing a device structure that enables high precision controlling of the movement of ions in the solid electrolyte. The semiconductor element of the device is formed as follows; two or more layers are deposited with different components respectively between a pair of electrodes disposed separately in the vertical (z-axis) direction, then a pulse voltage is applied between those electrodes to form a conductive path. The resistance value of the path changes according to an information signal. Furthermore, a region is formed at a middle part of the conductive path. The region is used to accumulate a component that improves the conductivity of the path, thereby enabling the resistance value (rate) to response currently to the information signal. More preferably, an electrode should also be formed at least in either the x-axis or y-axis direction to apply a control voltage to the electrode.

Owner:HITACHI LTD

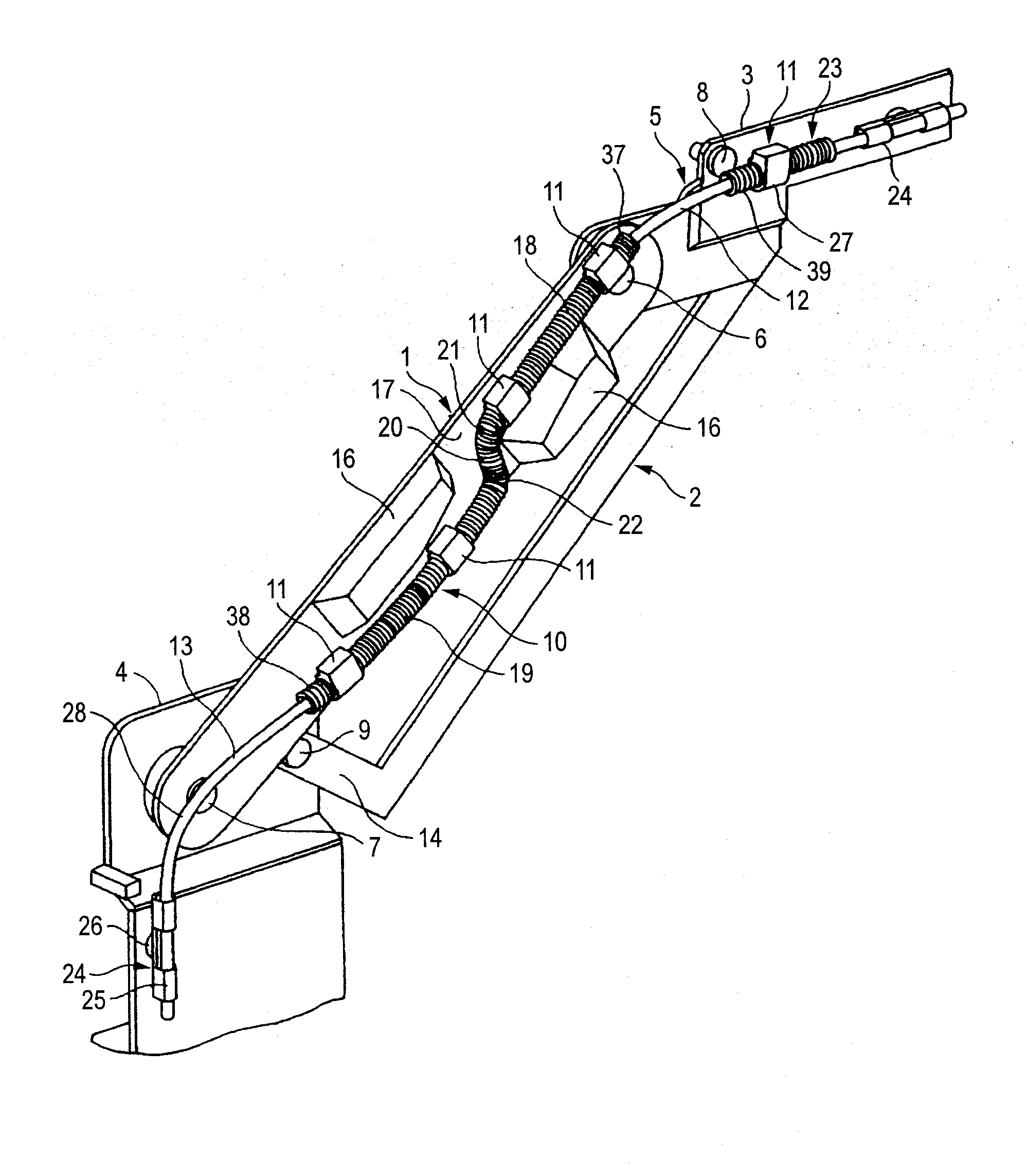

Installing structure of wire harness

ActiveUS20080035800A1Promote absorptionAvoid damagePipe supportsSemiconductor/solid-state device detailsEngineeringMechanical engineering

Owner:YAZAKI CORP

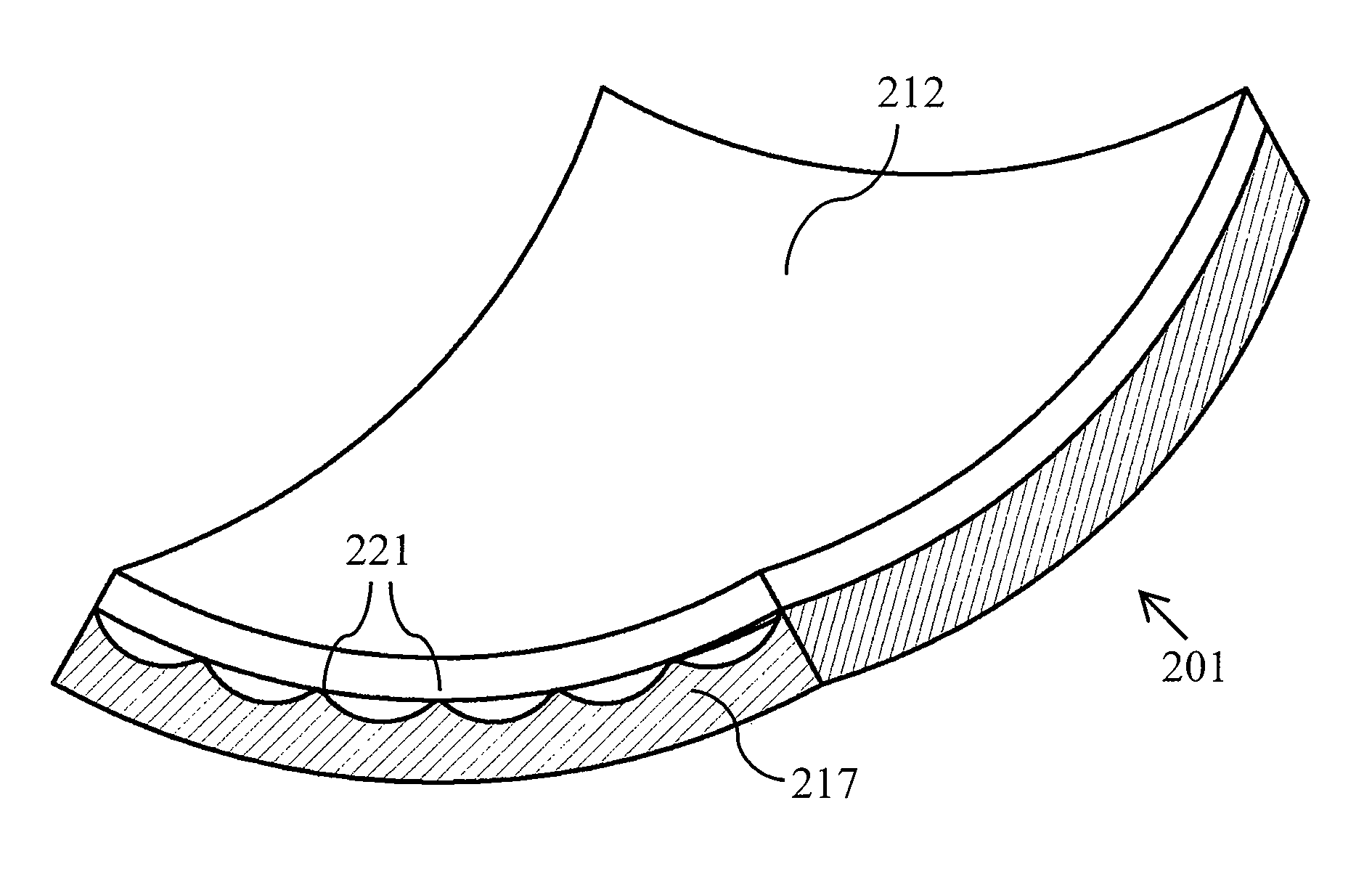

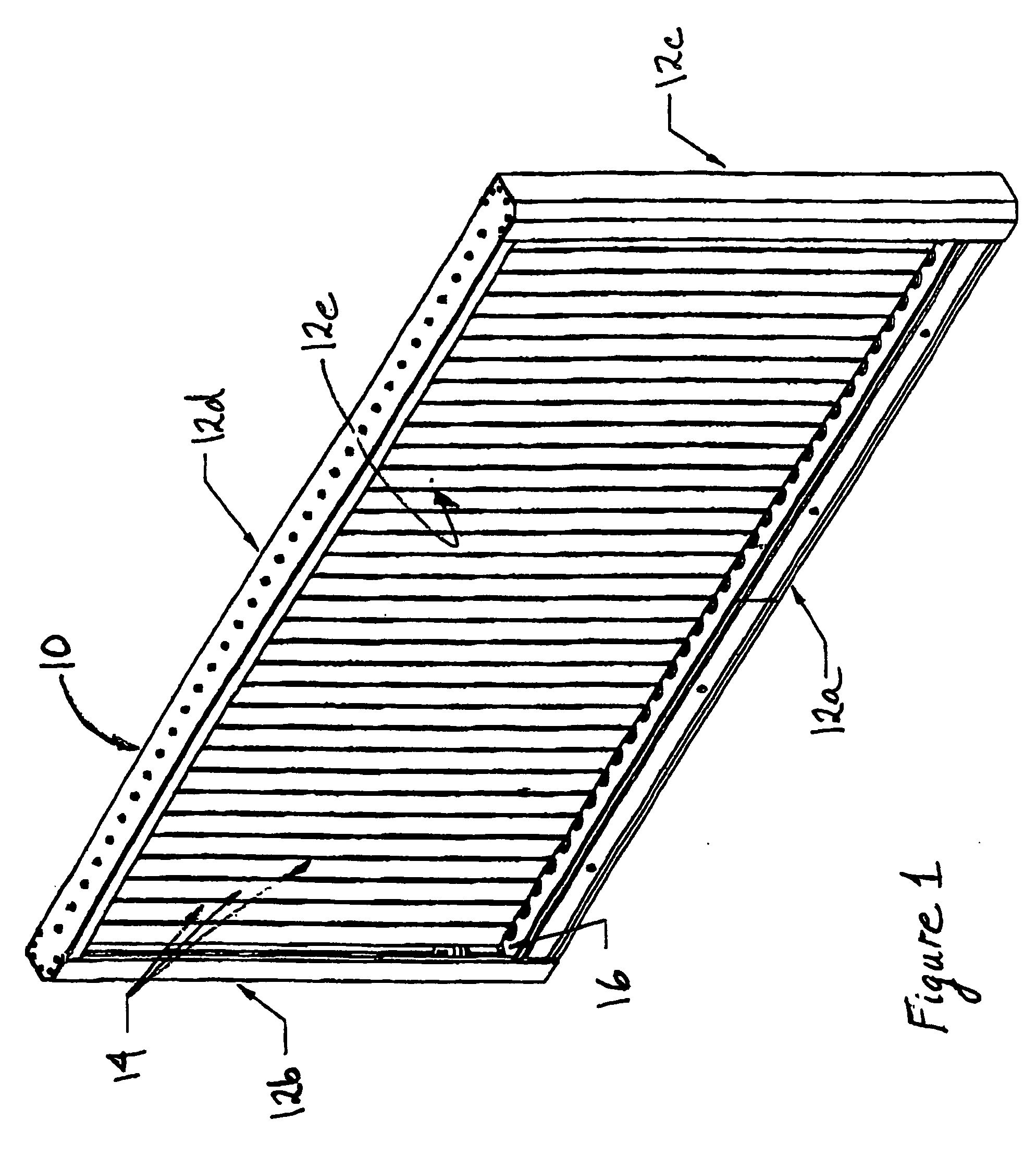

Method of manufacturing large dish reflectors for a solar concentrator apparatus

ActiveUS8082755B2Clean separationExtensive collectionSolar heating energySolar heat devicesProduction rateProduction line

A method of manufacturing monolithic glass reflectors for concentrating sunlight in a solar energy system is disclosed. The method of manufacturing allows large monolithic glass reflectors to be made from float glass in order to realize significant cost savings on the total system cost for a solar energy system. The method of manufacture includes steps of heating a sheet of float glass positioned over a concave mold until the sheet of glass sags and stretches to conform to the shape of the mold. The edges of the dish-shaped glass are rolled for structural stiffening around the periphery. The dish-shaped glass is then silvered to create a dish-shaped mirror that reflects solar radiation to a focus. The surface of the mold that contacts the float glass preferably has a grooved surface profile comprising a plurality of cusps and concave valleys. This grooved profile minimizes the contact area and marring of the specular glass surface, reduces parasitic heat transfer into the mold and increases mold lifetime. The disclosed method of manufacture is capable of high production rates sufficiently fast to accommodate the output of a conventional float glass production line so that monolithic glass reflectors can be produced as quickly as a float glass production can make sheets of float glass to be used in the process.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

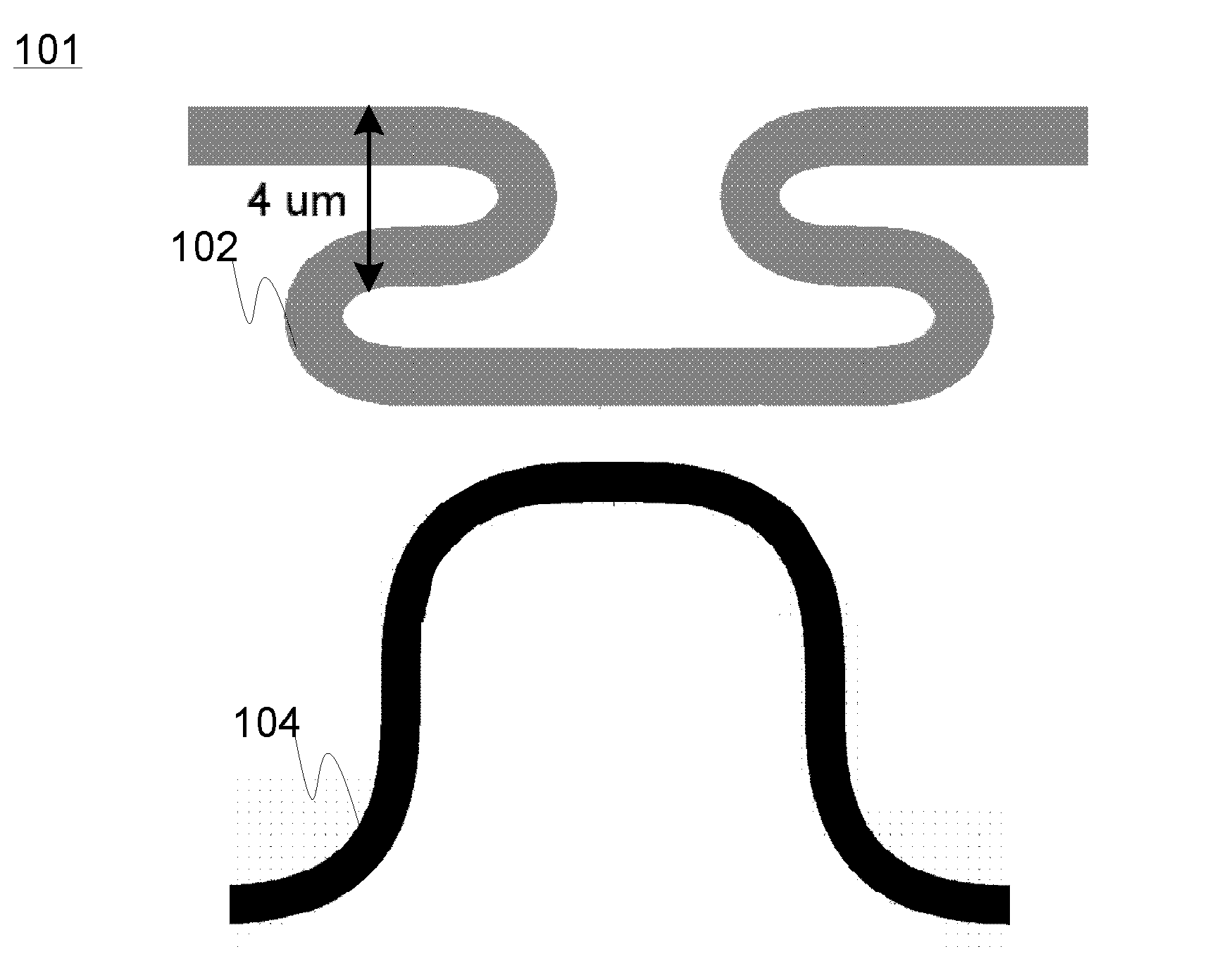

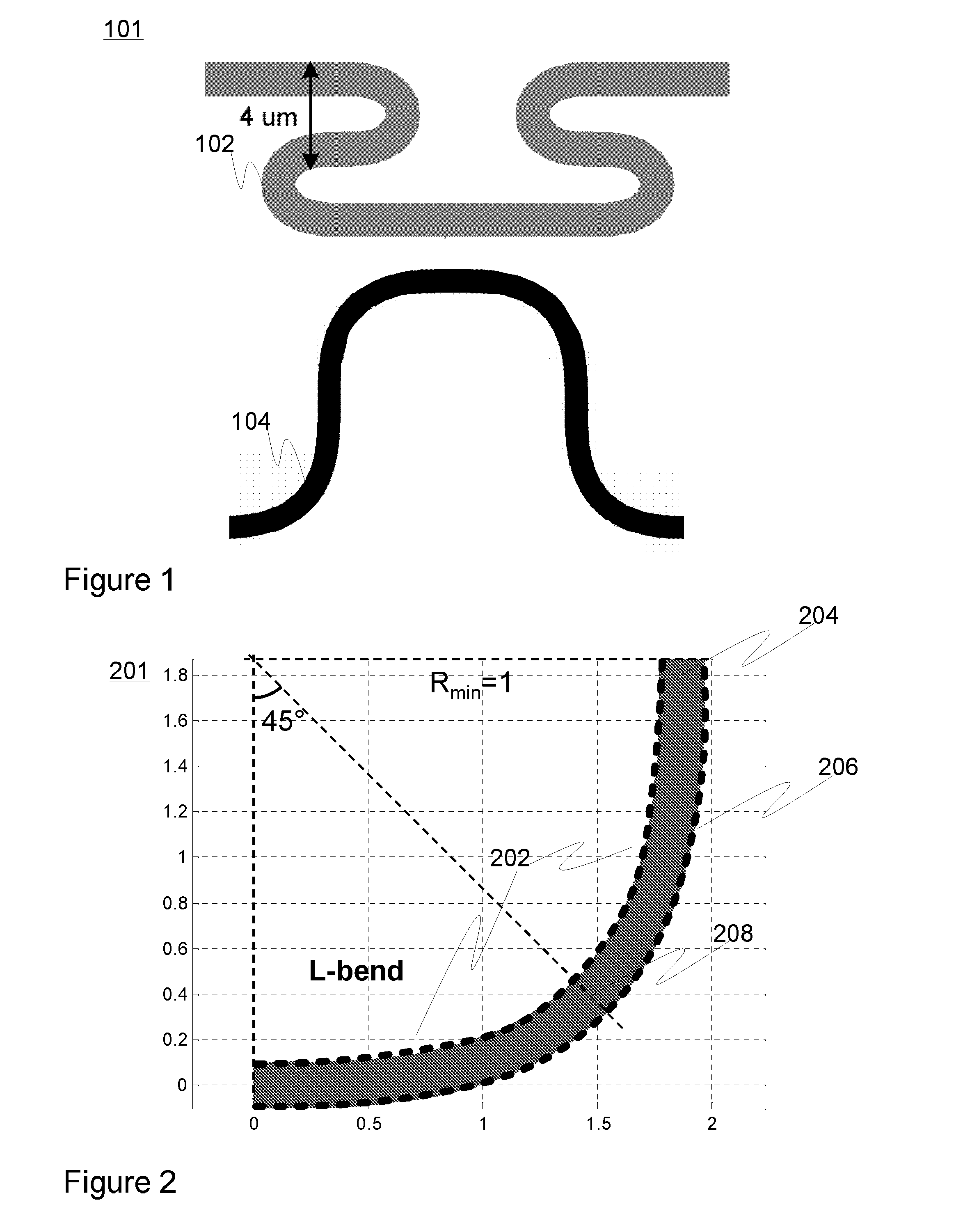

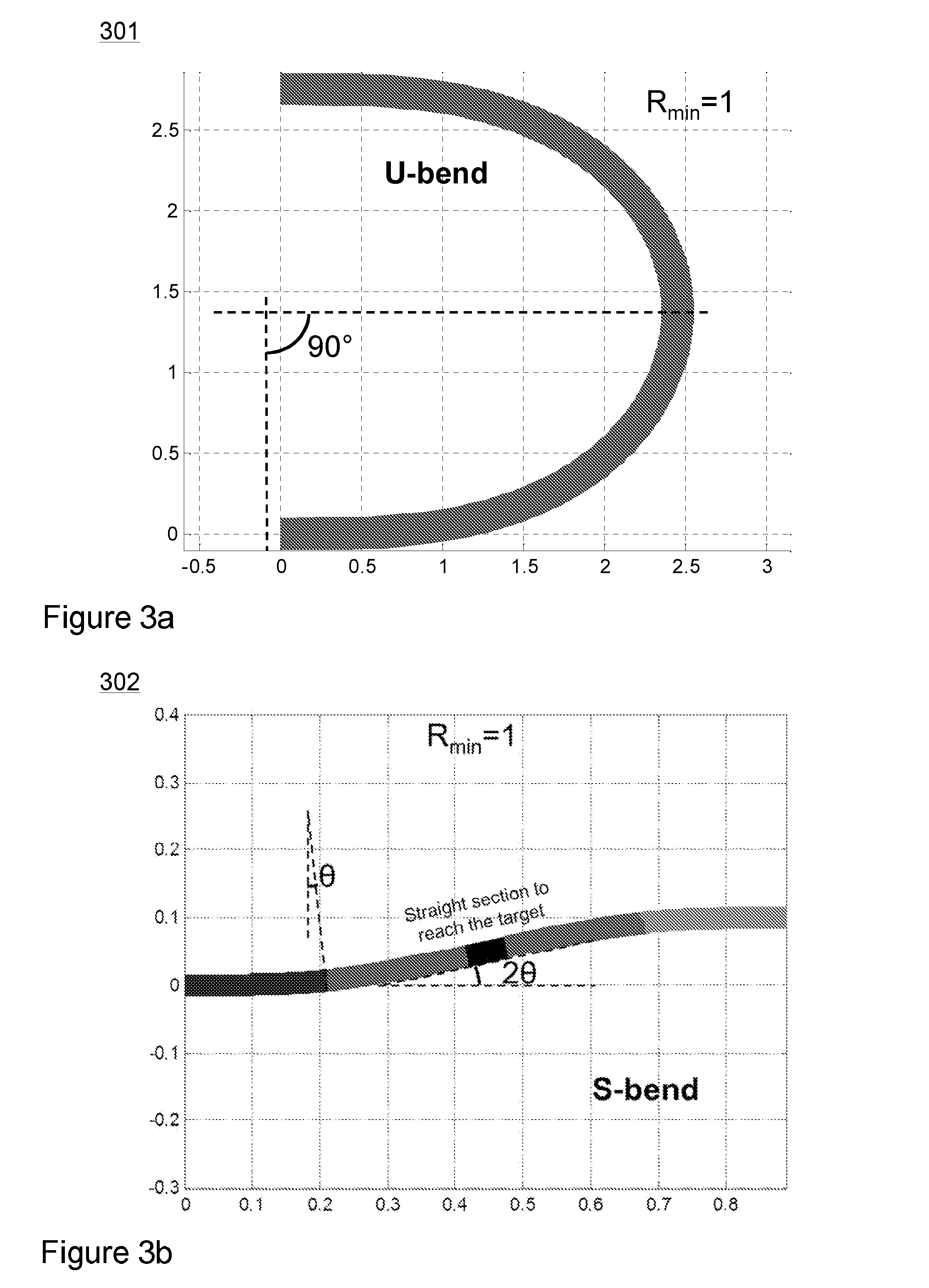

Bent optical waveguide

ActiveUS20150260916A1Improved and tight bend(s)Reduce lossCoupling light guidesDual mode fibreLight guideRefractive index

An optical multi-mode HIC (high index contrast) waveguide (102,104, 201, 301) for transporting electromagnetic radiation in the optical waveband, the waveguide comprising a guiding core portion (204) with higher refractive index, and cladding portion (206) with substantially lower refractive index configured to at least partially surround the light guiding core in the transverse direction to facilitate confining the propagating radiation within the core, the wave-guide being configured to support multiple optical modes of the propagating radiation, wherein the waveguide incorporates a bent waveguide section (202) having bend. curvature that is configured to at least gradually, preferably substantially continuously, increase towards a maximum curvature of said section from a section end.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

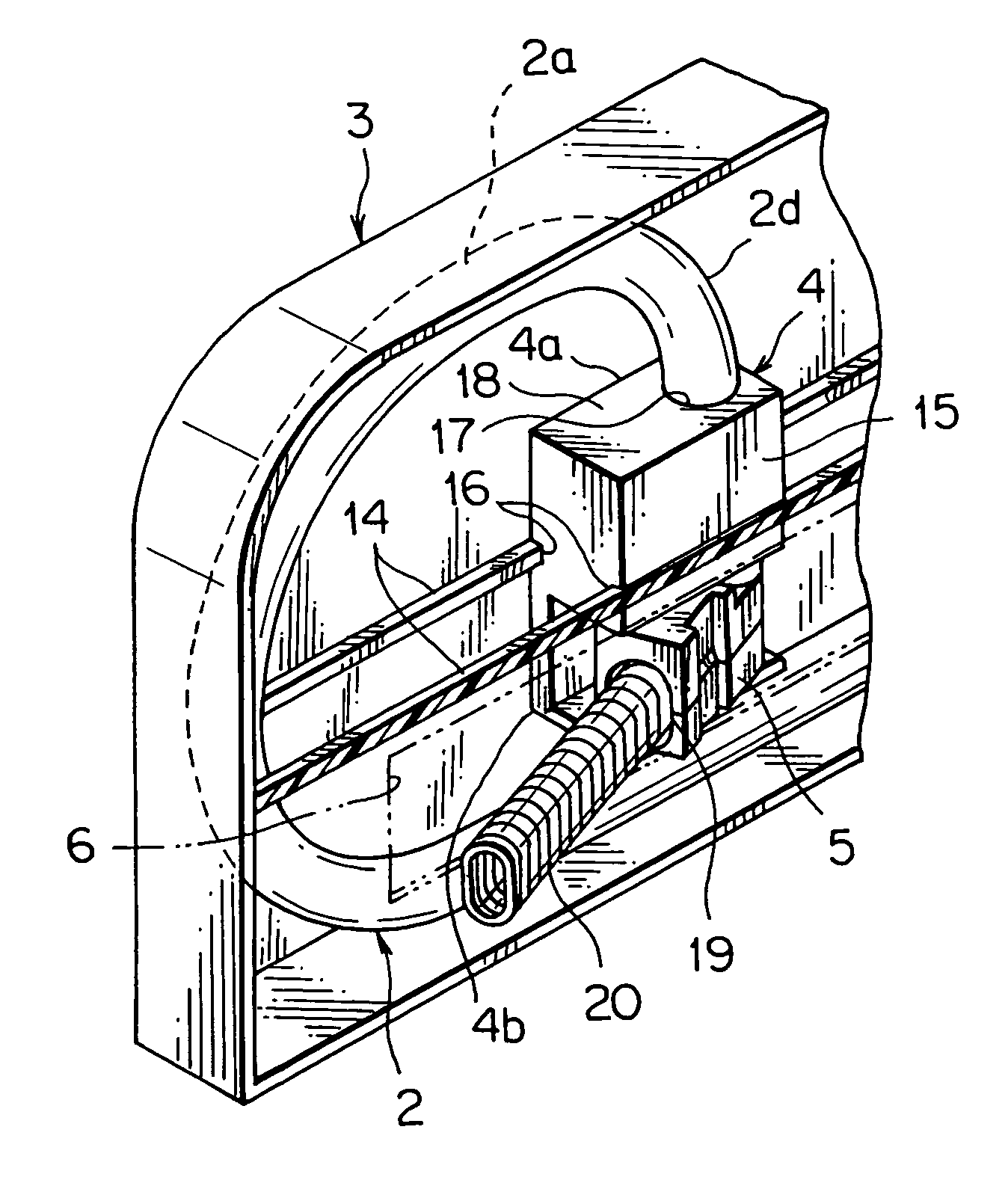

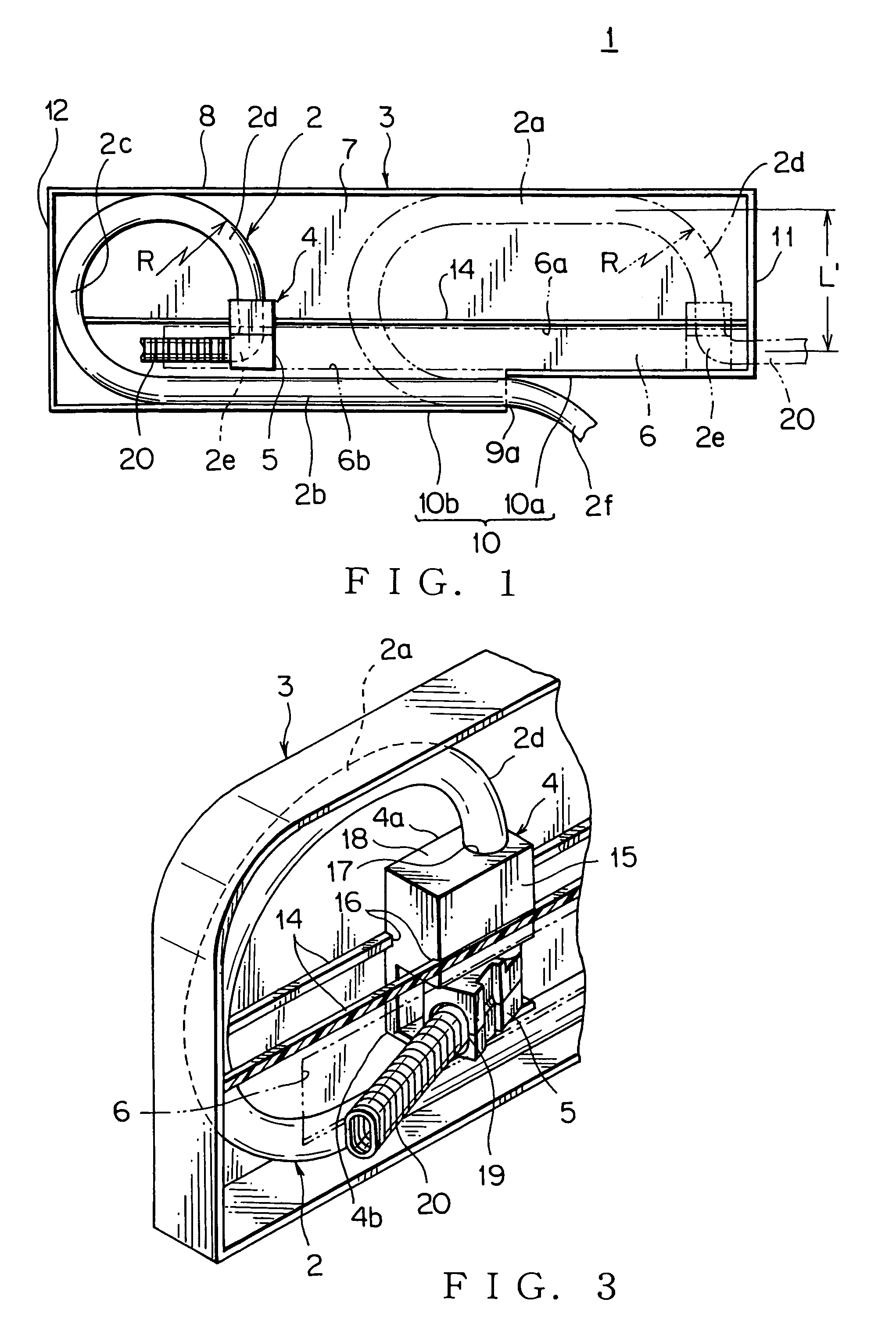

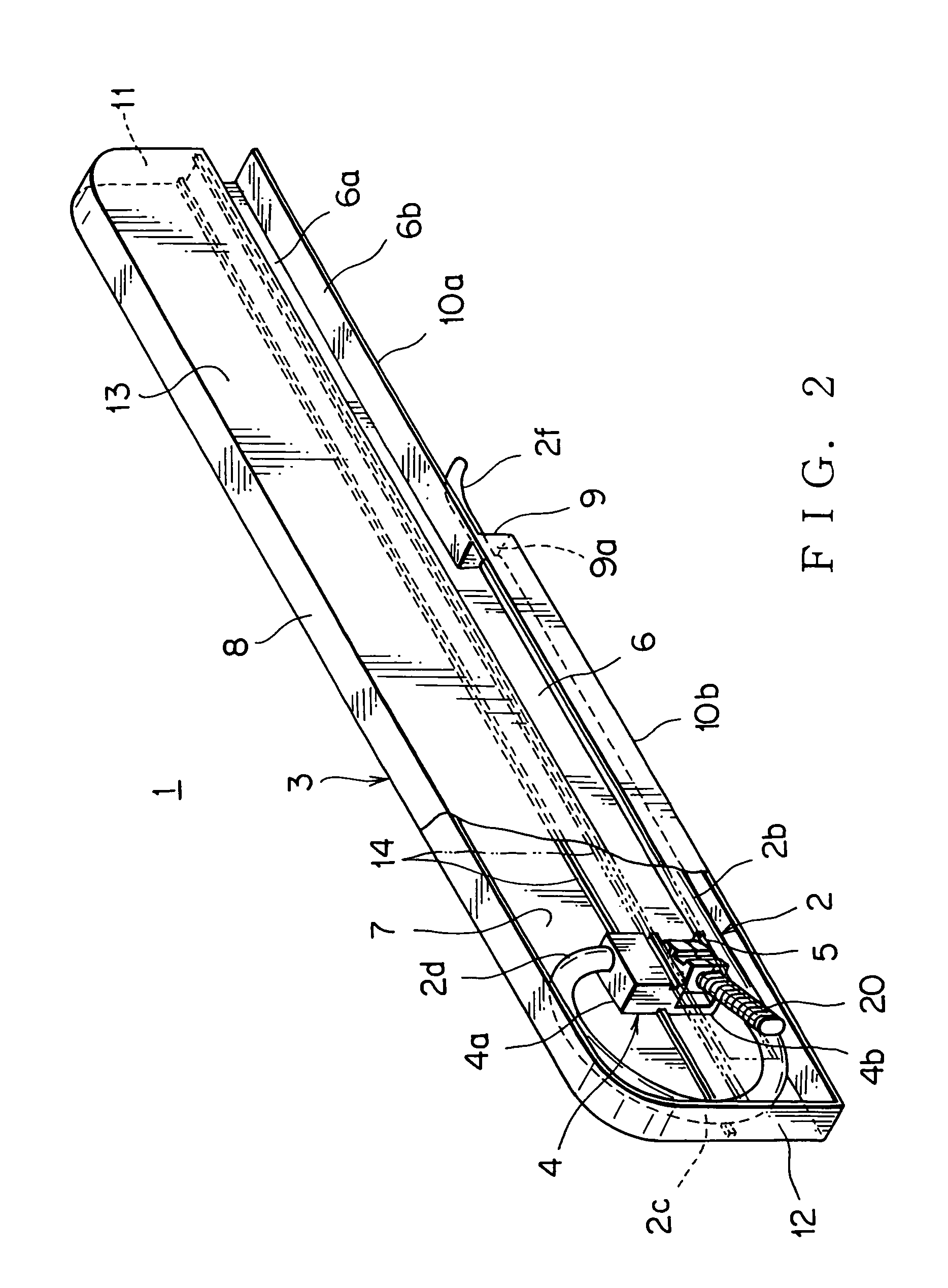

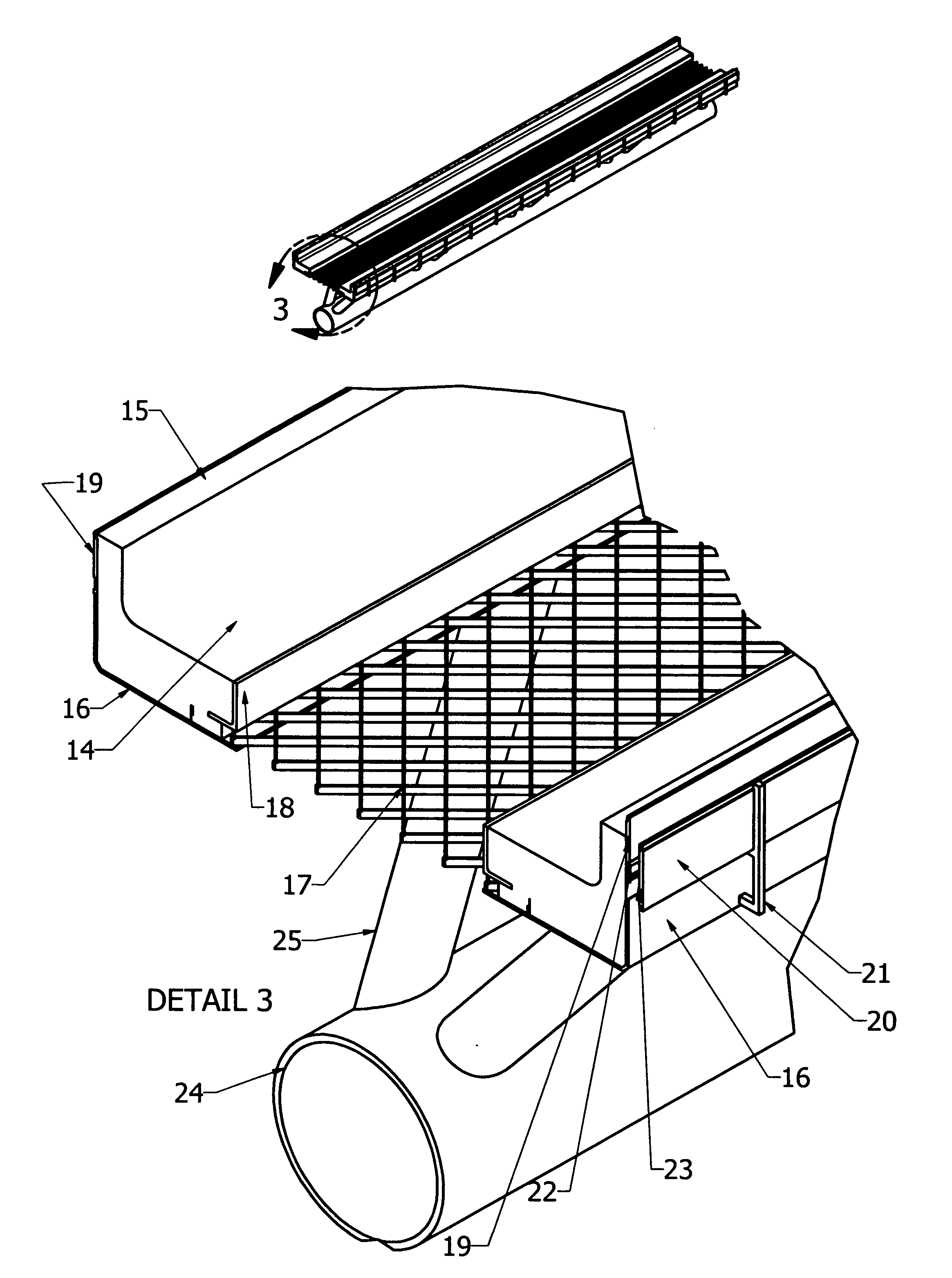

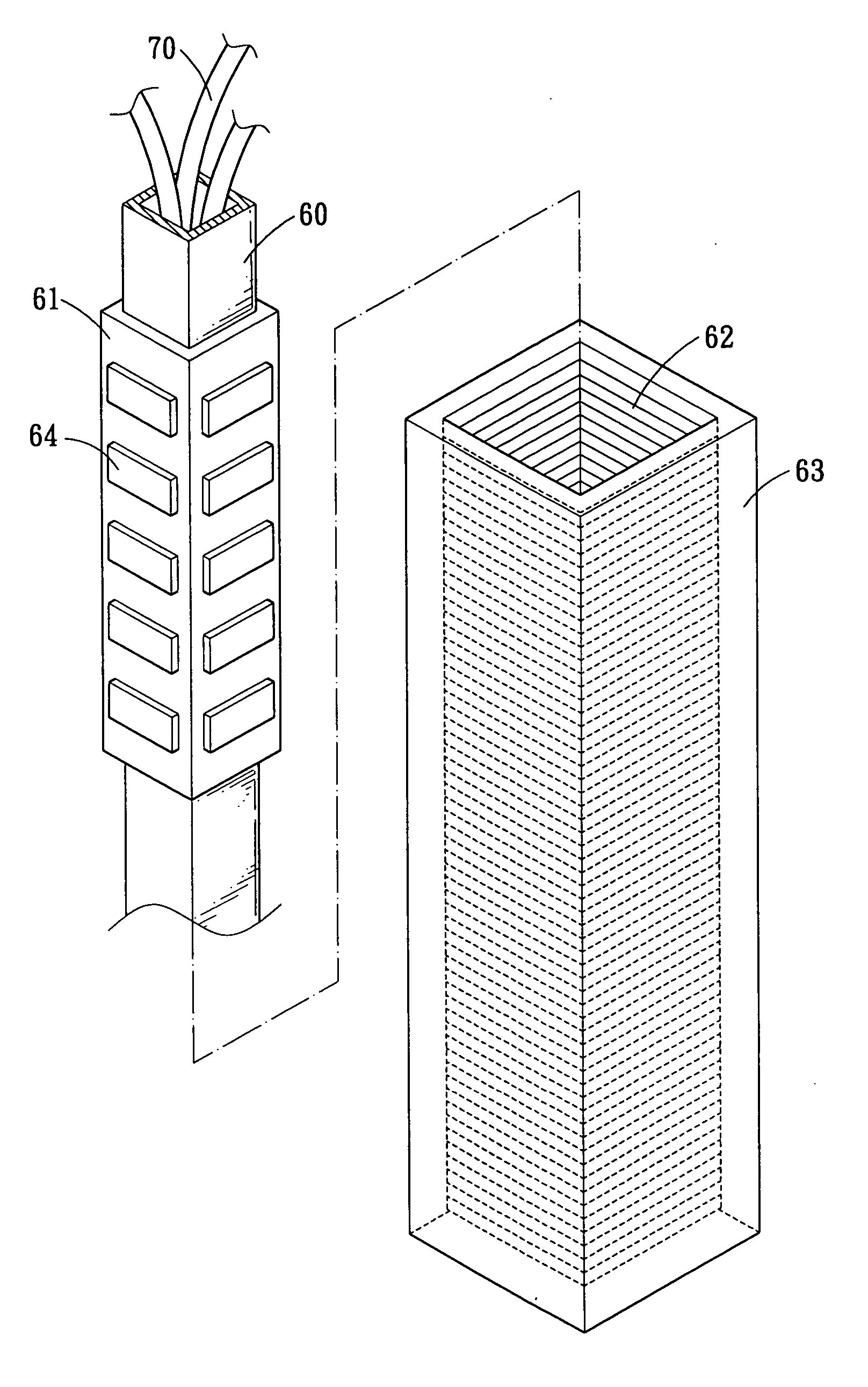

Electricity-feeding device

InactiveUS7053306B2Avoid interferenceReduce exerciseInsulated cablesElectric/fluid circuitElectricityEngineering

An electricity-feeding device includes: a case for accommodating a wire harness bent into a substantially U-shaped form; a slider slidable in the case, in which slider the wire harness is bent and through which the wire harness is led out swingably; and a horizontally long opening disposed between one and the other walls opposite to each other in the case. The slider slides along the opening. The wire harness is bent in traverse from the one wall to the other wall, then bent toward the one wall to be led into the slider, and then led out through the slider and the opening. A rail on which the slider is slidably guided is formed in the vicinity of the opening of the case. A swinging member is formed on the slider. The wire harness is bent and led out through the slider and the swinging member.

Owner:YAZAKI CORP

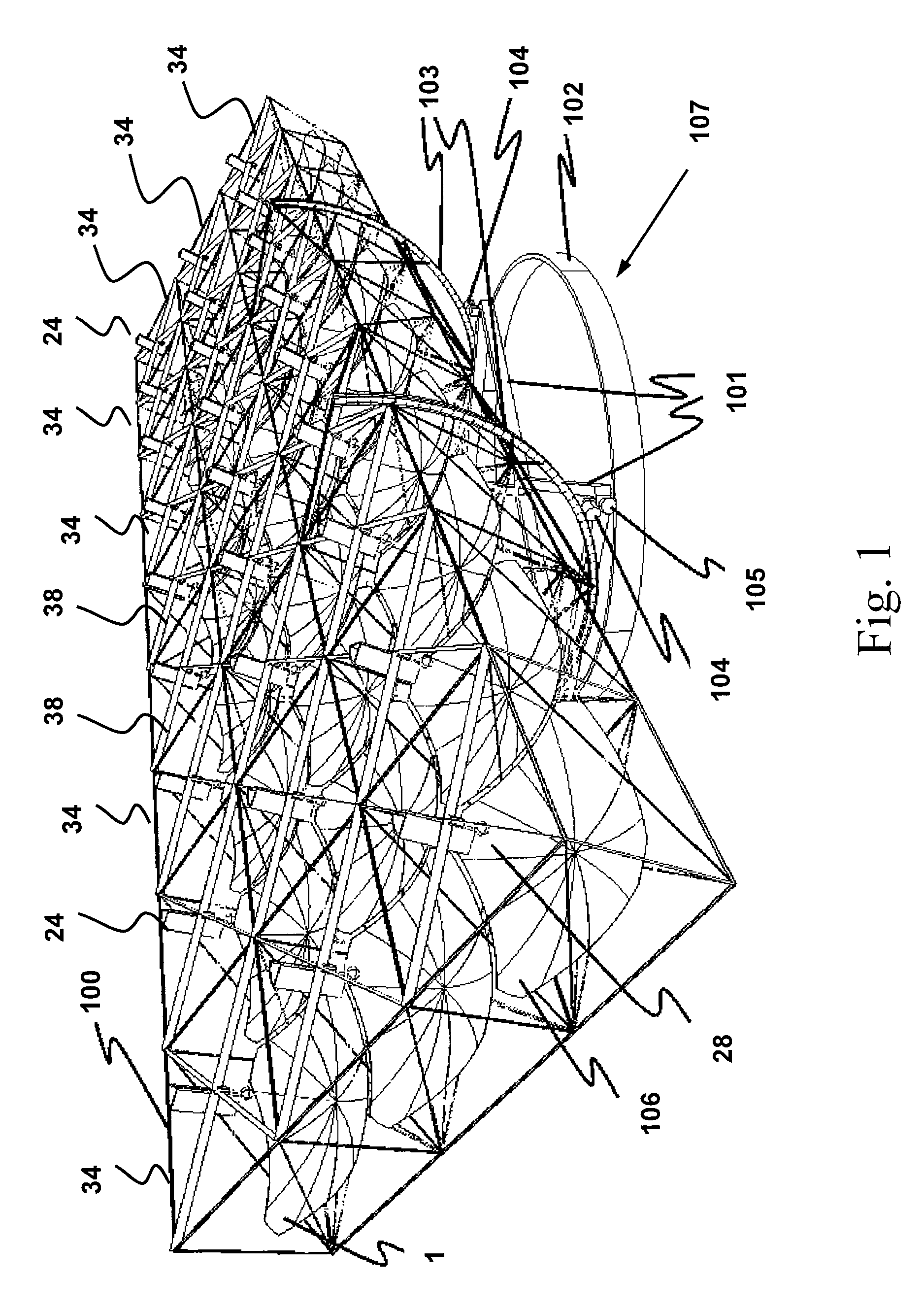

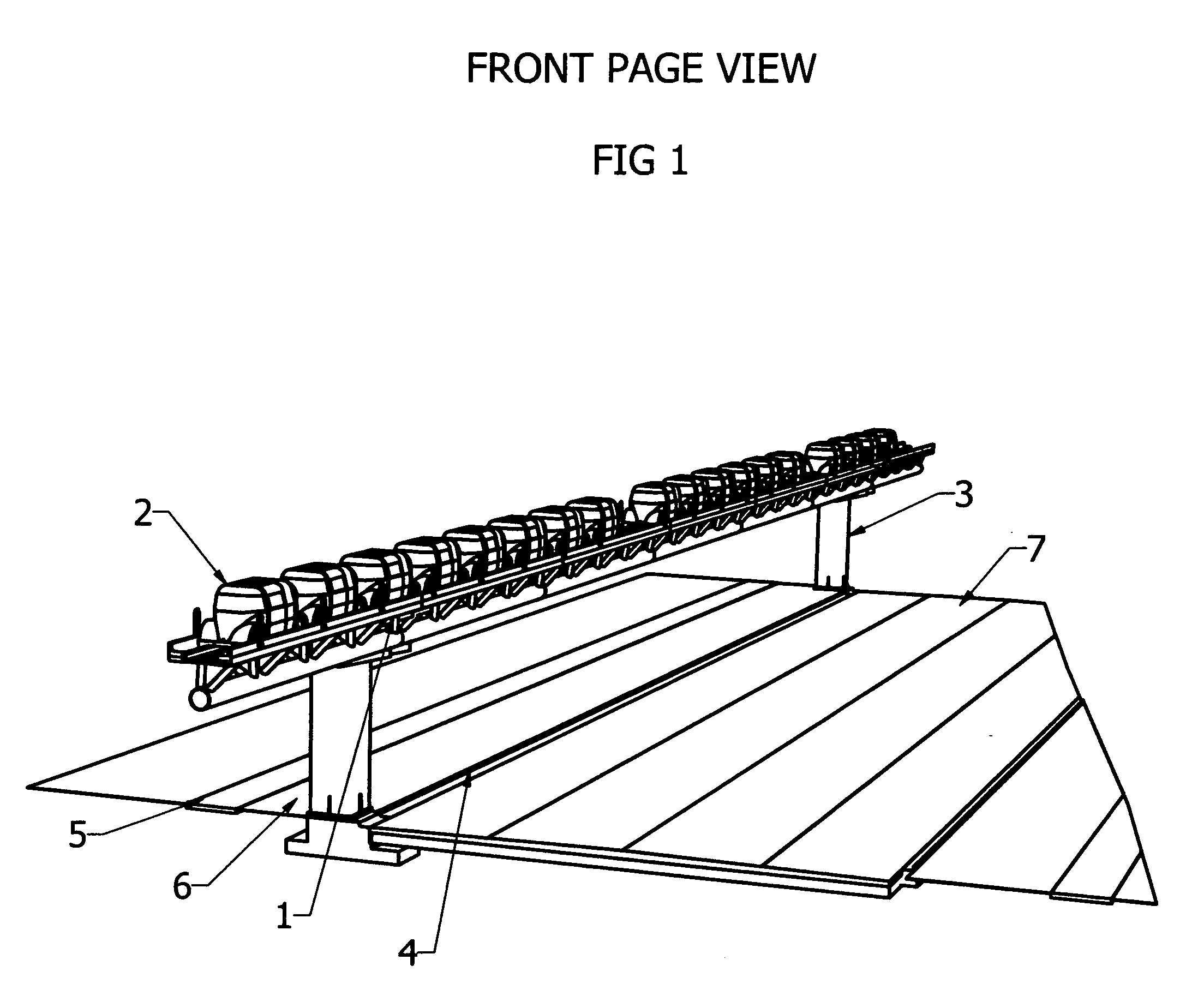

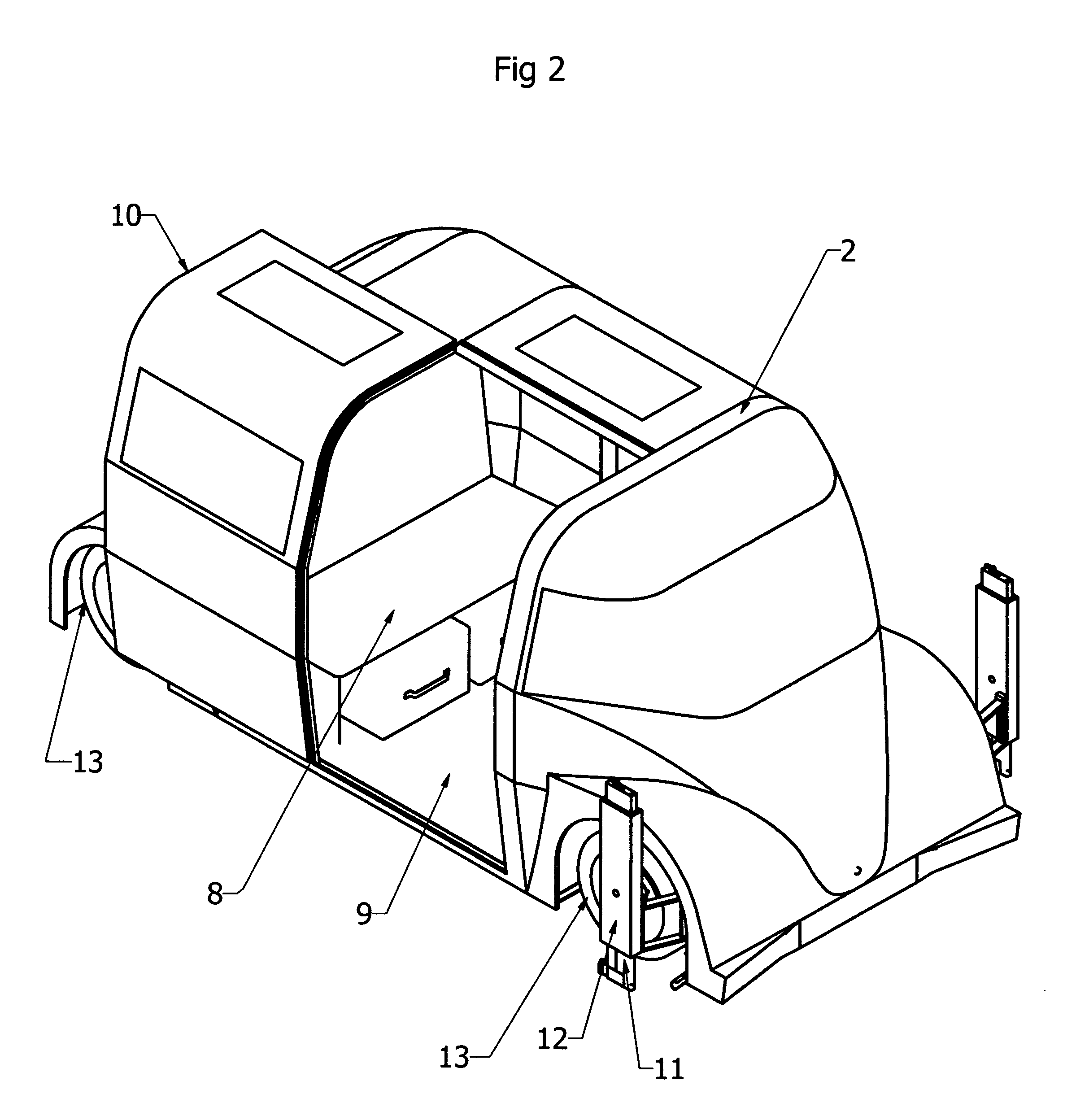

Patent for a personal transportation network-ptn

InactiveUS20110196561A1Maximize useNeed lessRail devicesRailway componentsElectricityPersonalization

This invention generally relates to an elevated transportation network run on electricity with personalized cars that can automatically transport passengers anywhere in a large city or densely populated metropolitan area served by the system without stopping on the way to the final destination. The cars travel on two continuous concrete ribbons with no bumps or cutouts crossing the tire path during switching or on the straight away. The travel path is a combination of central routing and individual car communications with car automatic steering and distance control. The personalized transportation concept can also apply to high speed intercity transportation allowing instant available transportation without intermediate time consuming stops.

Owner:JORGENSEN ARNE ROY

Harness holder and harness layout structure thereby

ActiveUS20050092511A1Relaxation stressLarge radiusPipe supportsInsulated cablesEngineeringMechanical engineering

Owner:YAZAKI CORP

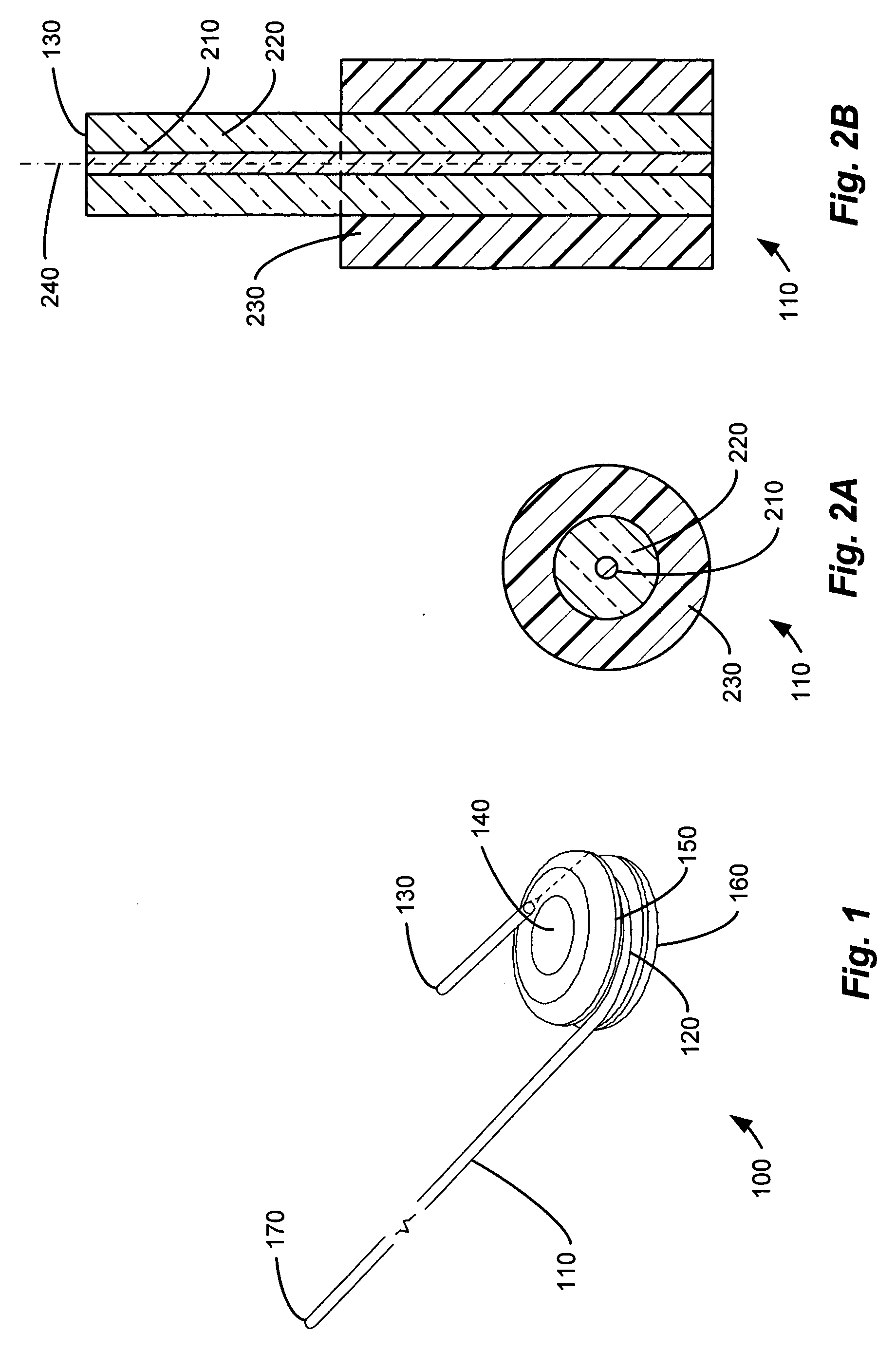

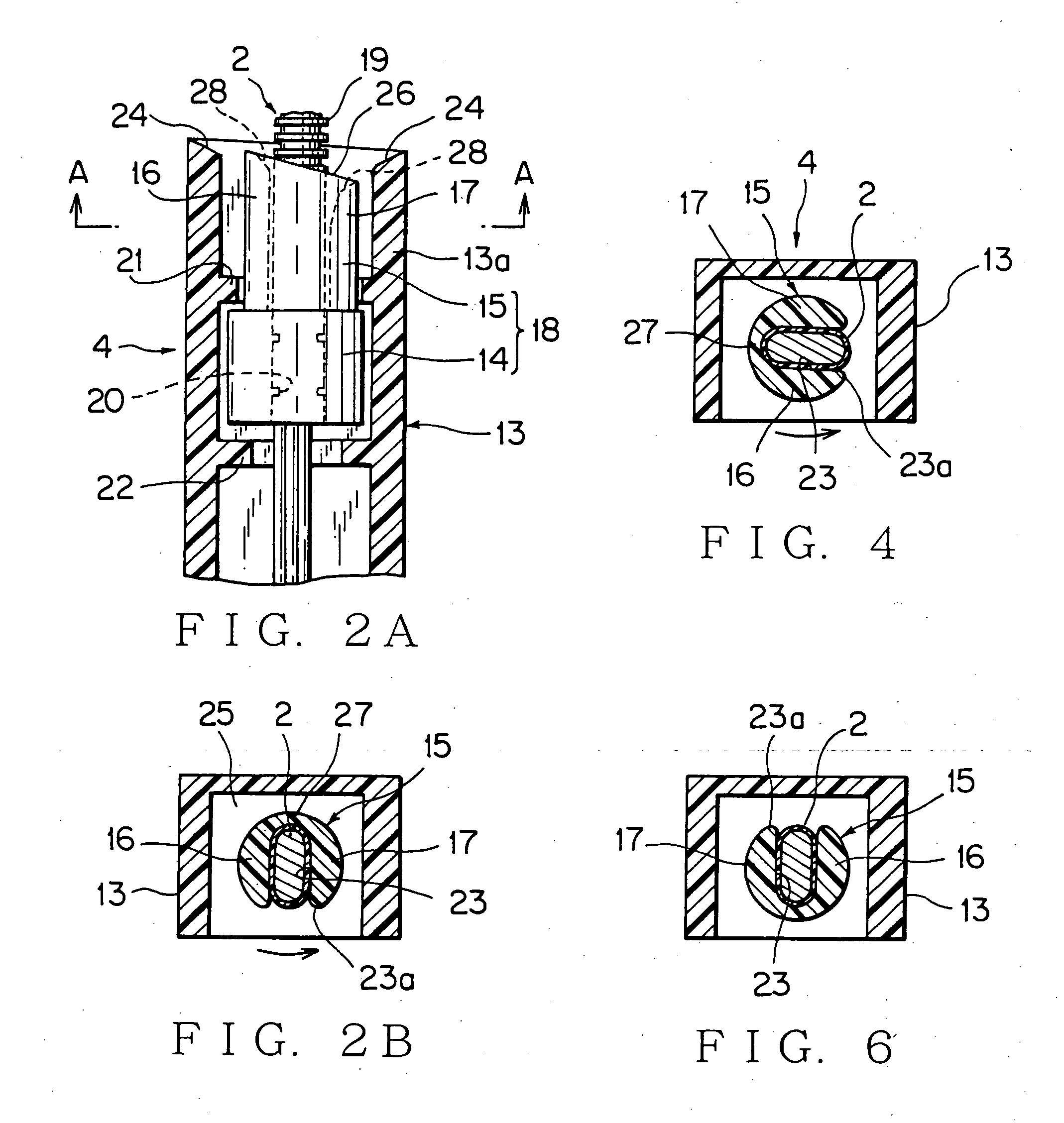

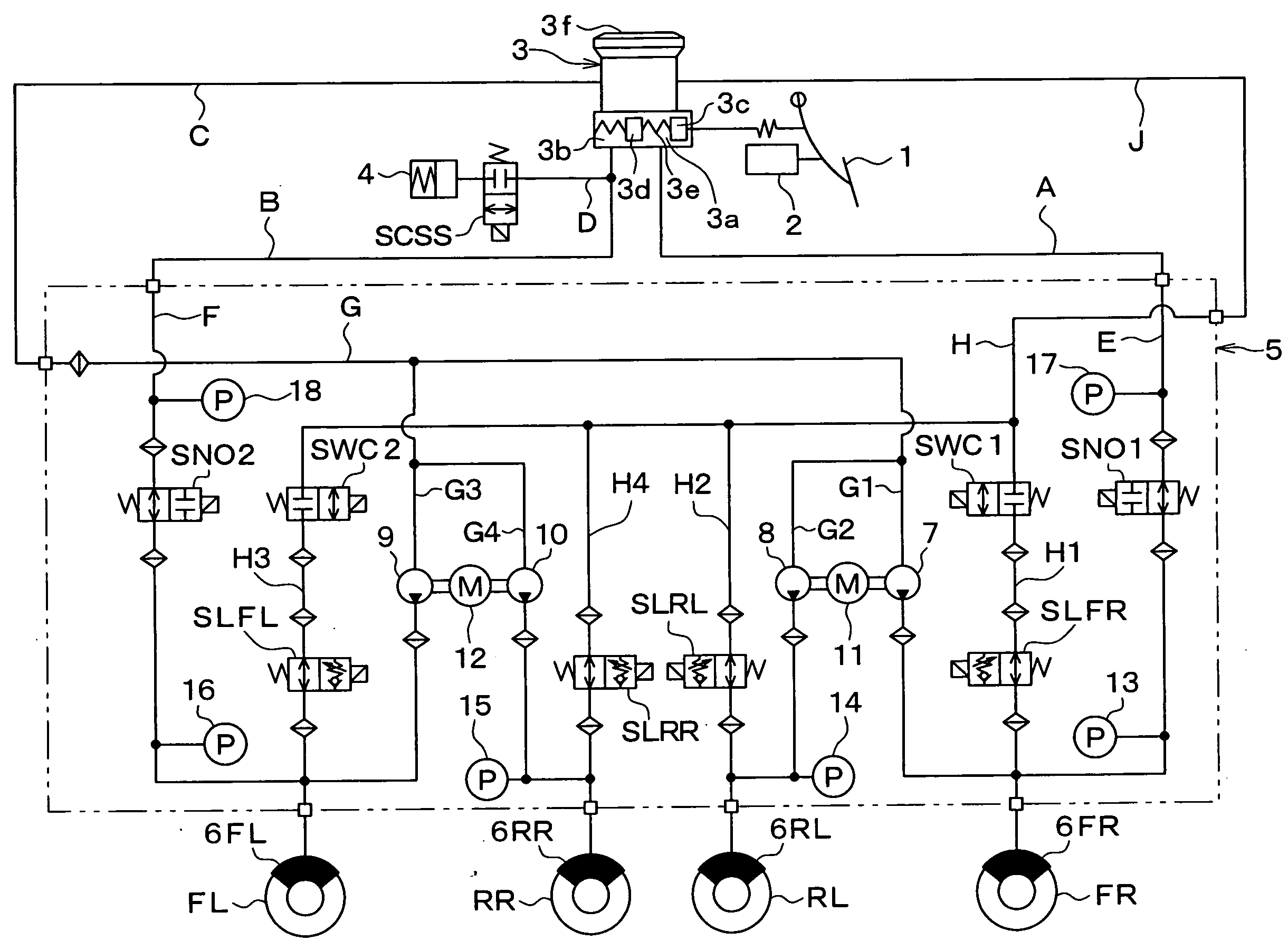

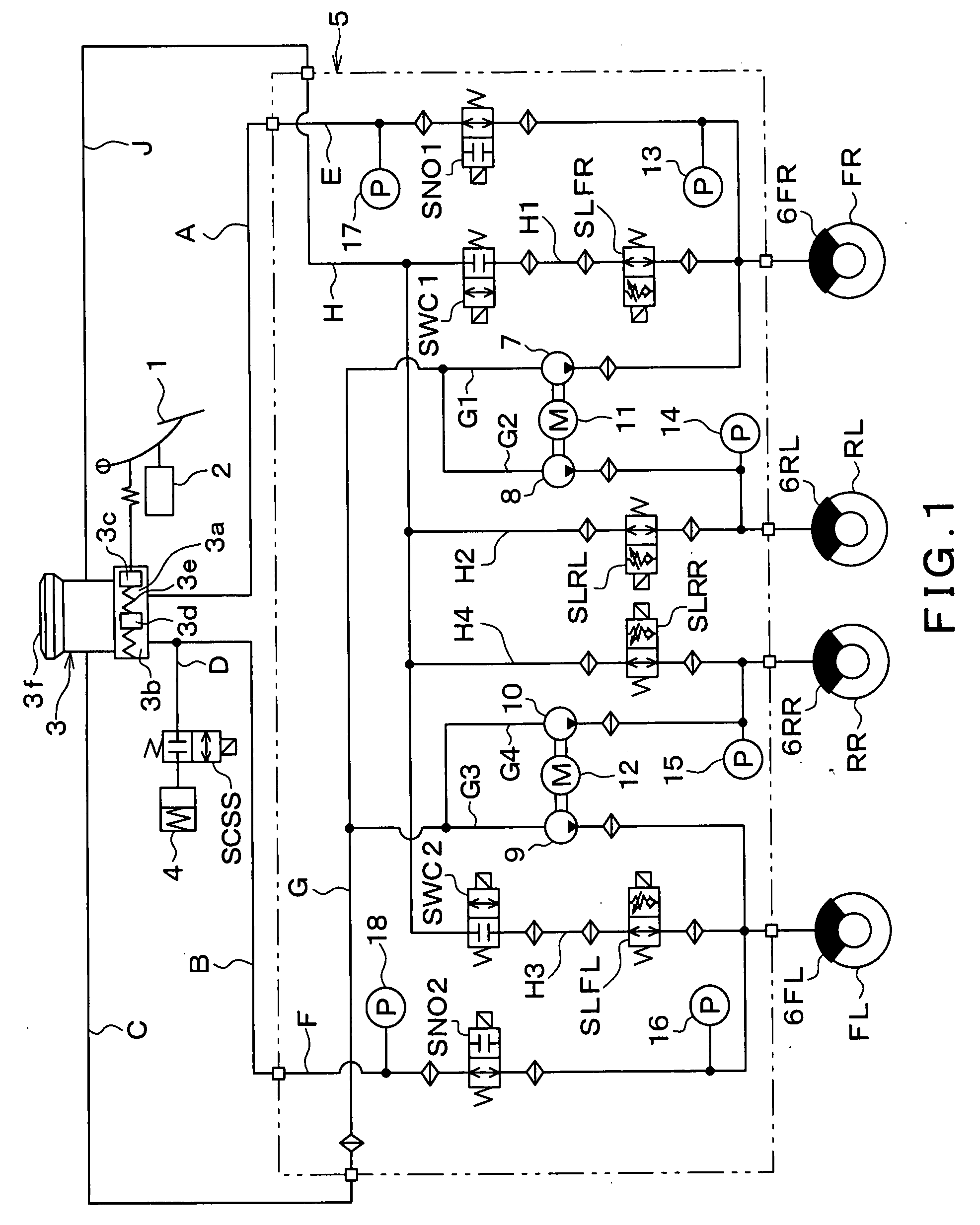

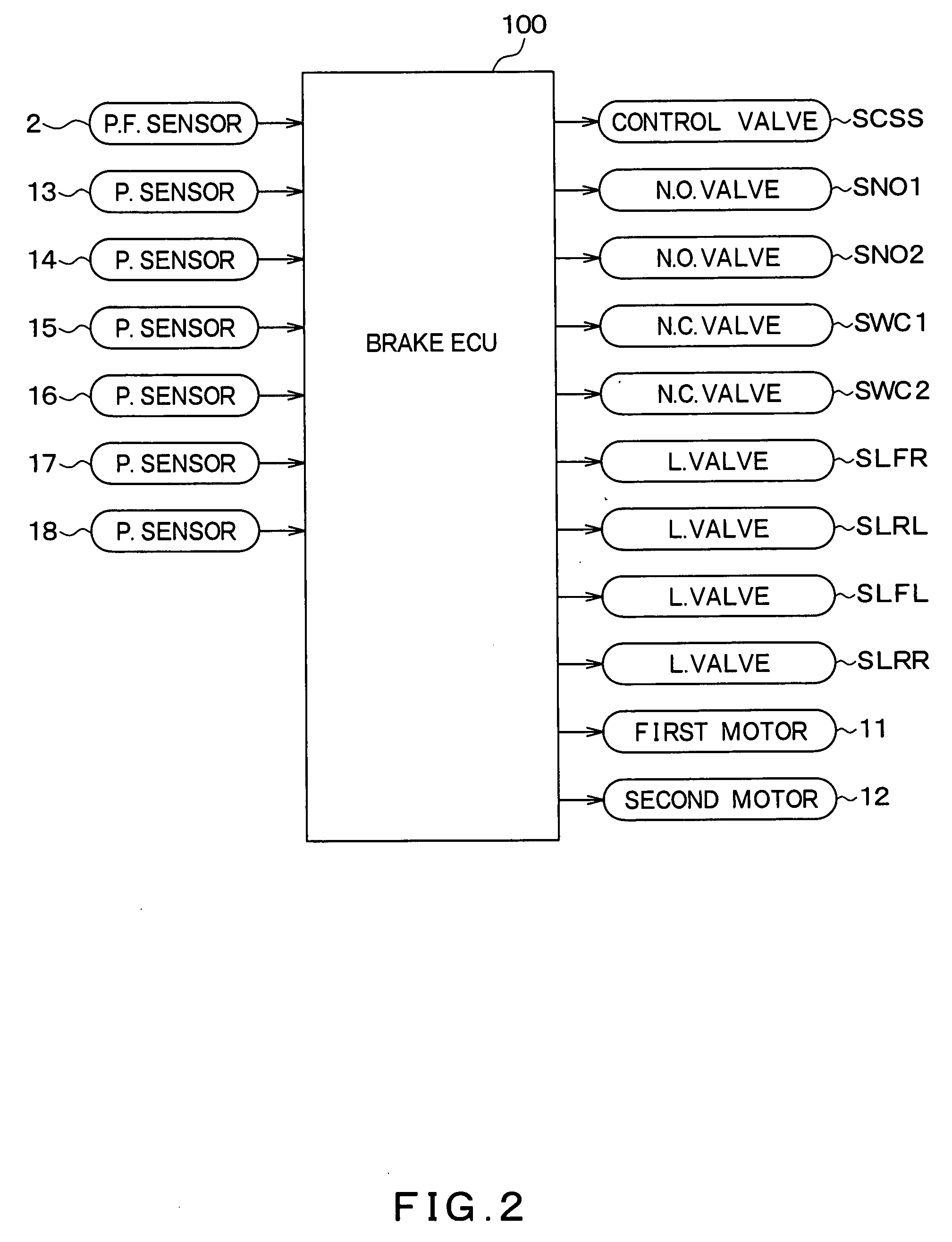

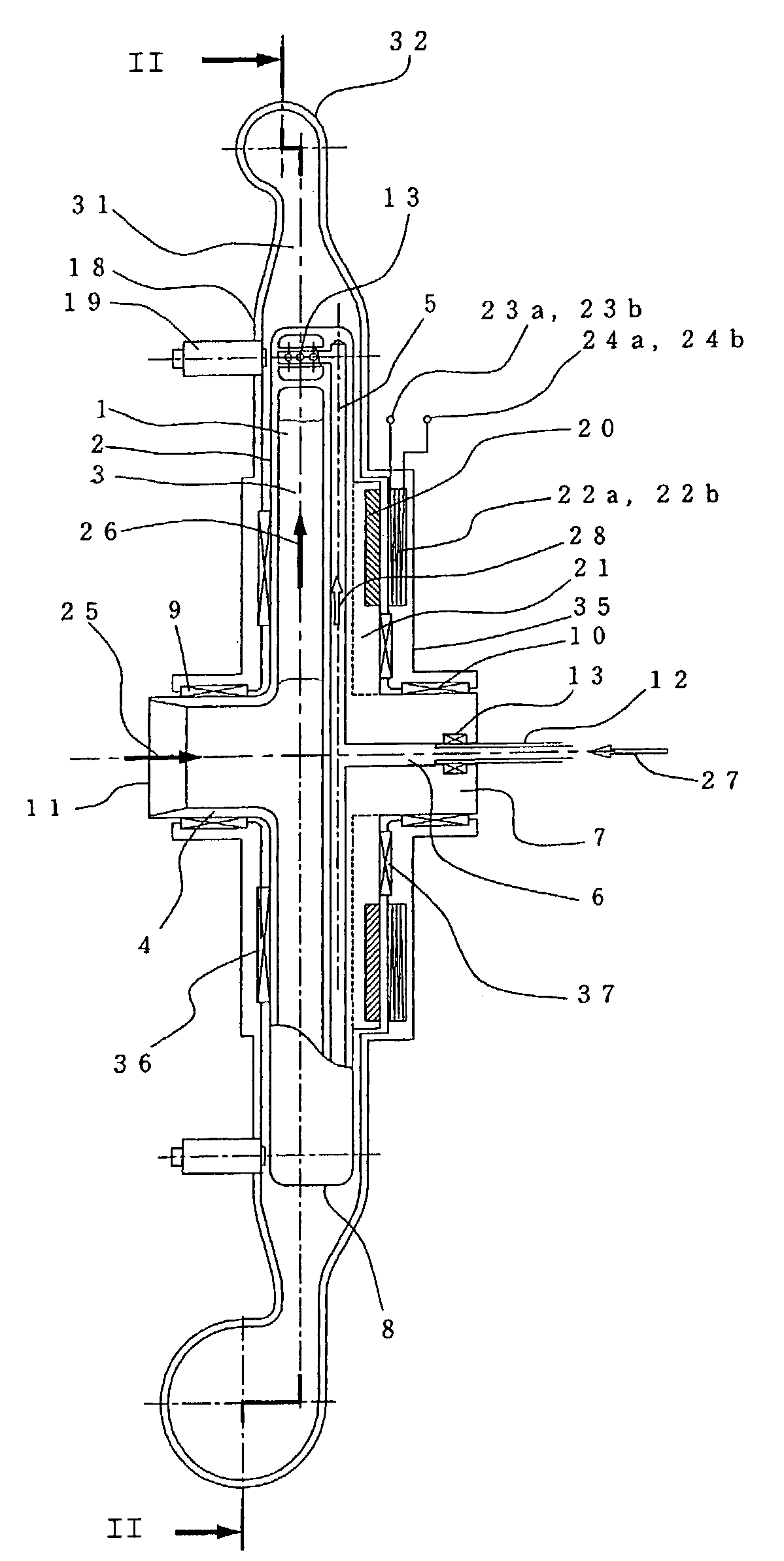

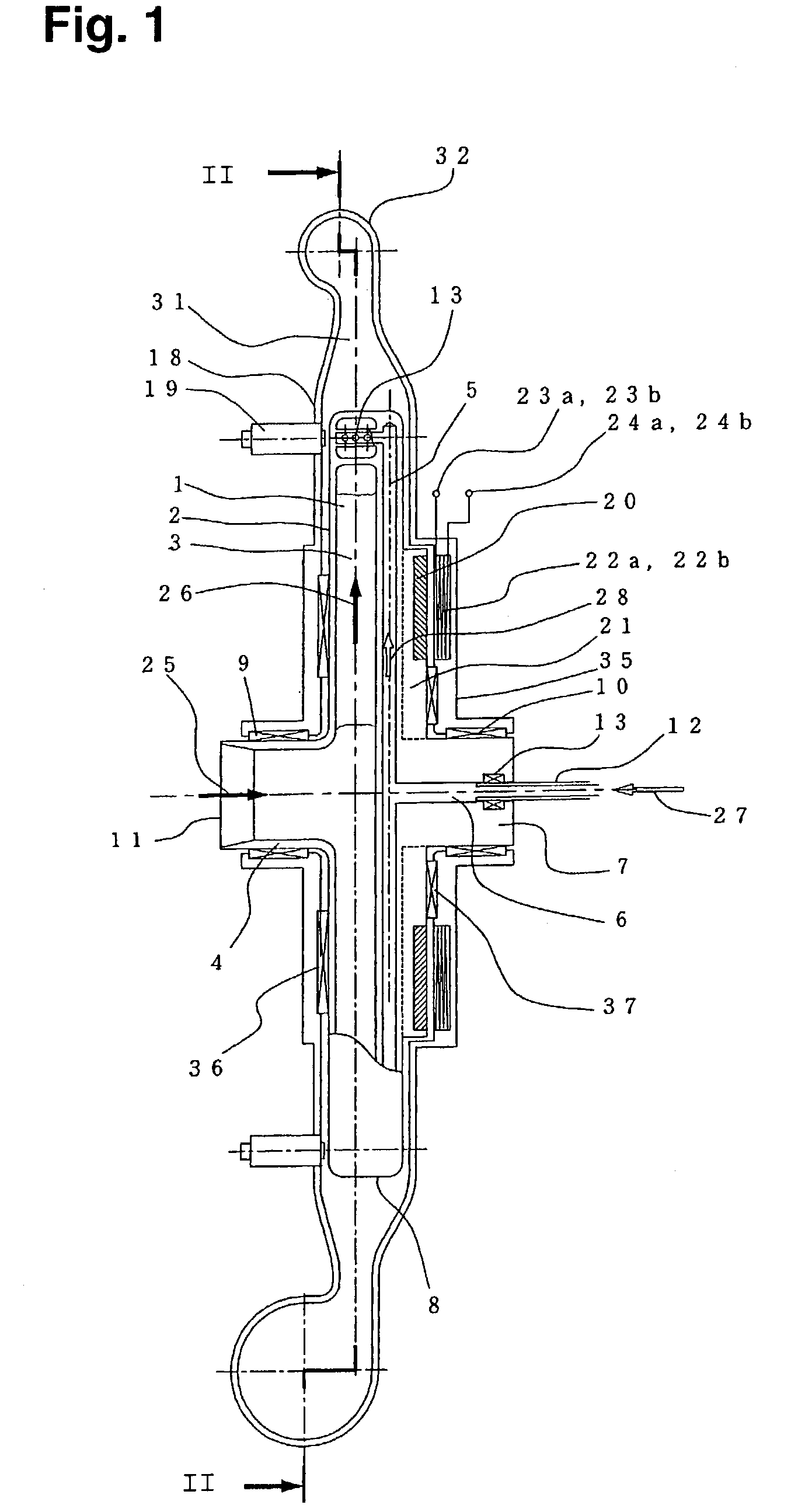

Actuator for controlling brake fluid pressure

InactiveUS20080048492A1Small sizeSuppress power consumptionPump controlApplication and release valvesEngineeringWheel cylinder

An actuator installed in a vehicle controls brake fluid pressures applied respectively to a first wheel cylinder for a front wheel and a second wheel cylinder for a rear wheel. The actuator includes a first pump for the front wheel, a second pump for the rear wheel, and a motor for driving the first pump and the second pump. The first pump sucks brake fluid and discharges the brake fluid to the first wheel cylinder. The second pump sucks brake fluid and discharges the brake fluid to the second wheel cylinder. In addition, a discharge volume of the first pump is larger than a discharge volume of the second pump.

Owner:ADVICS CO LTD

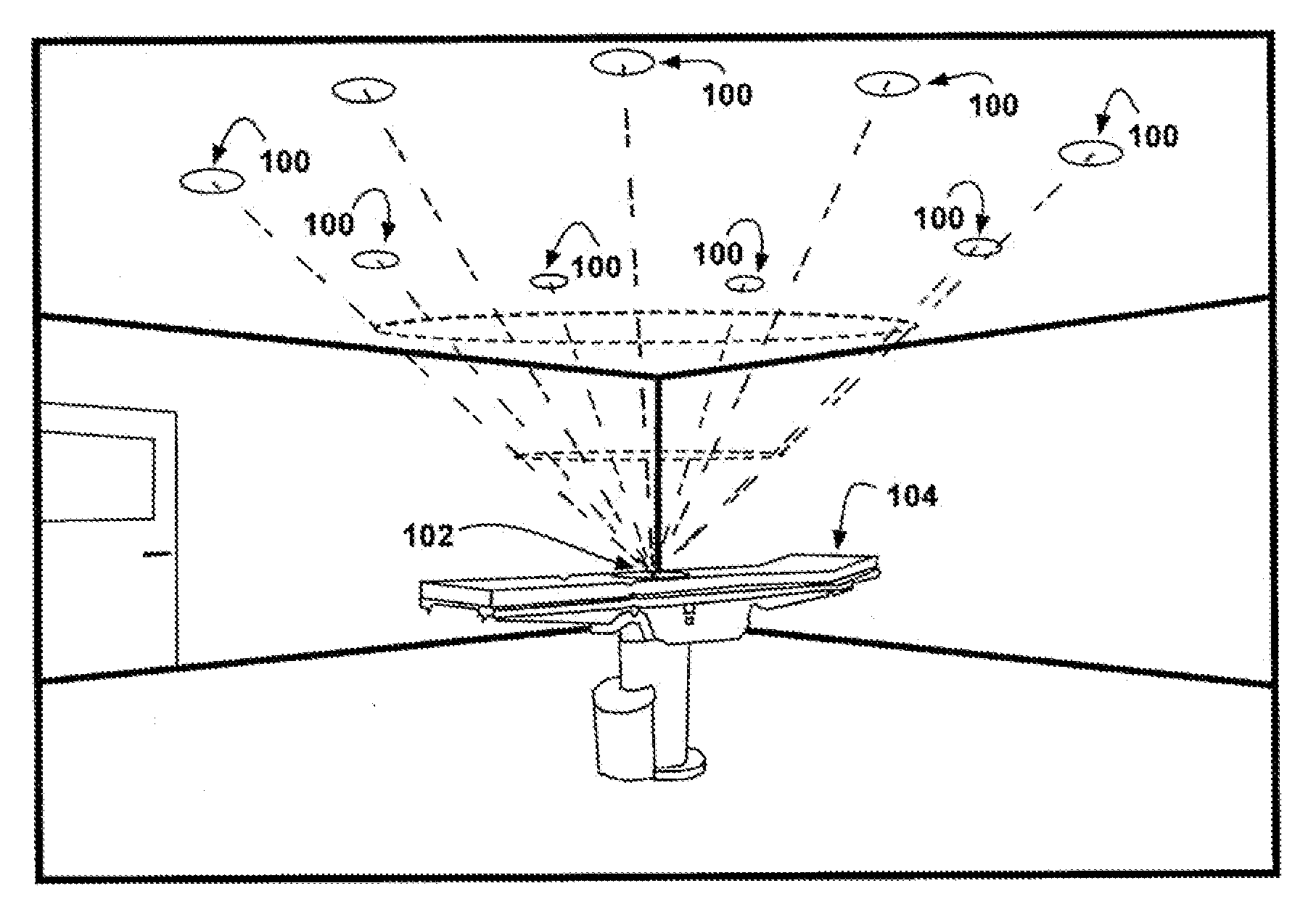

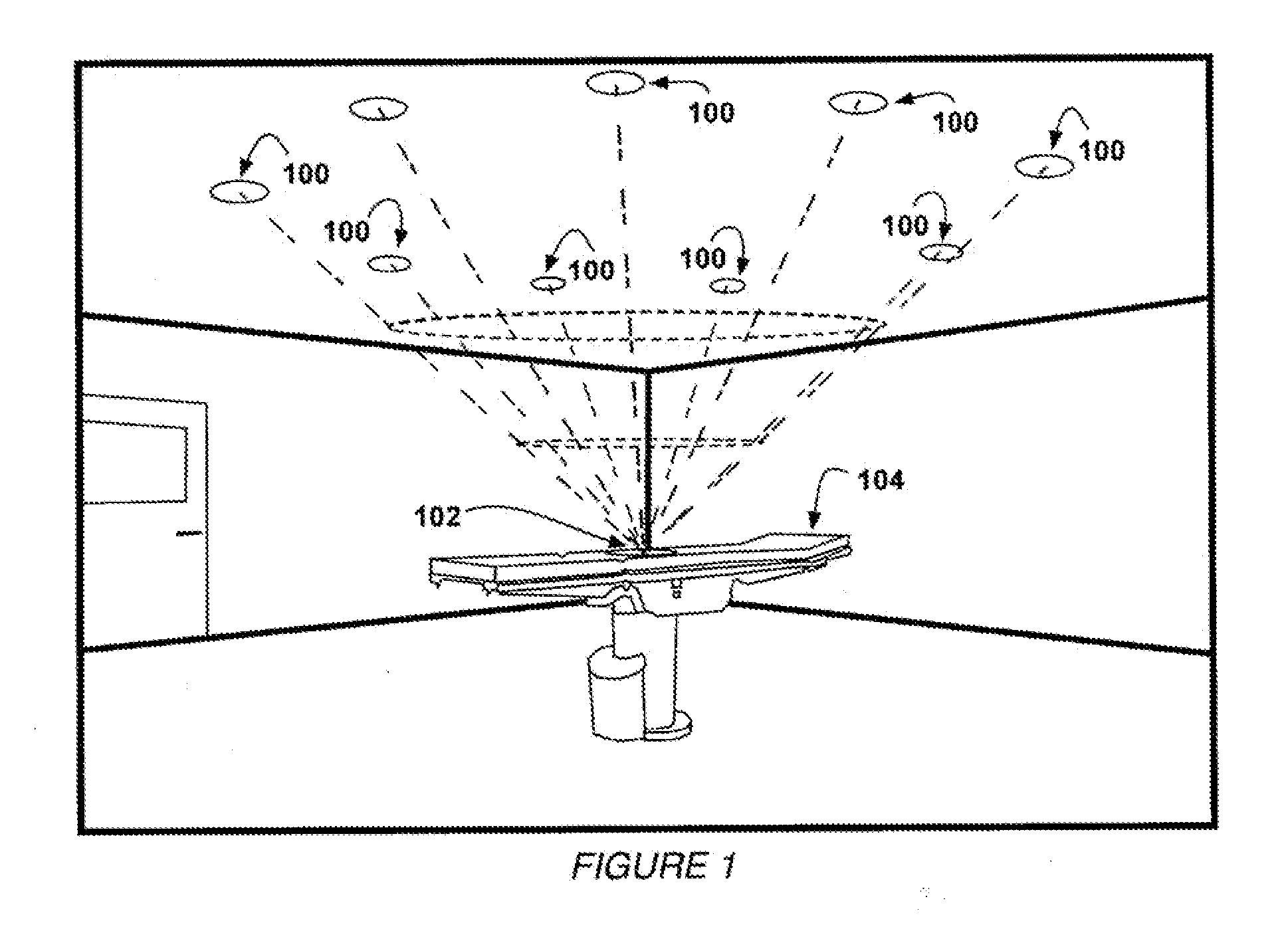

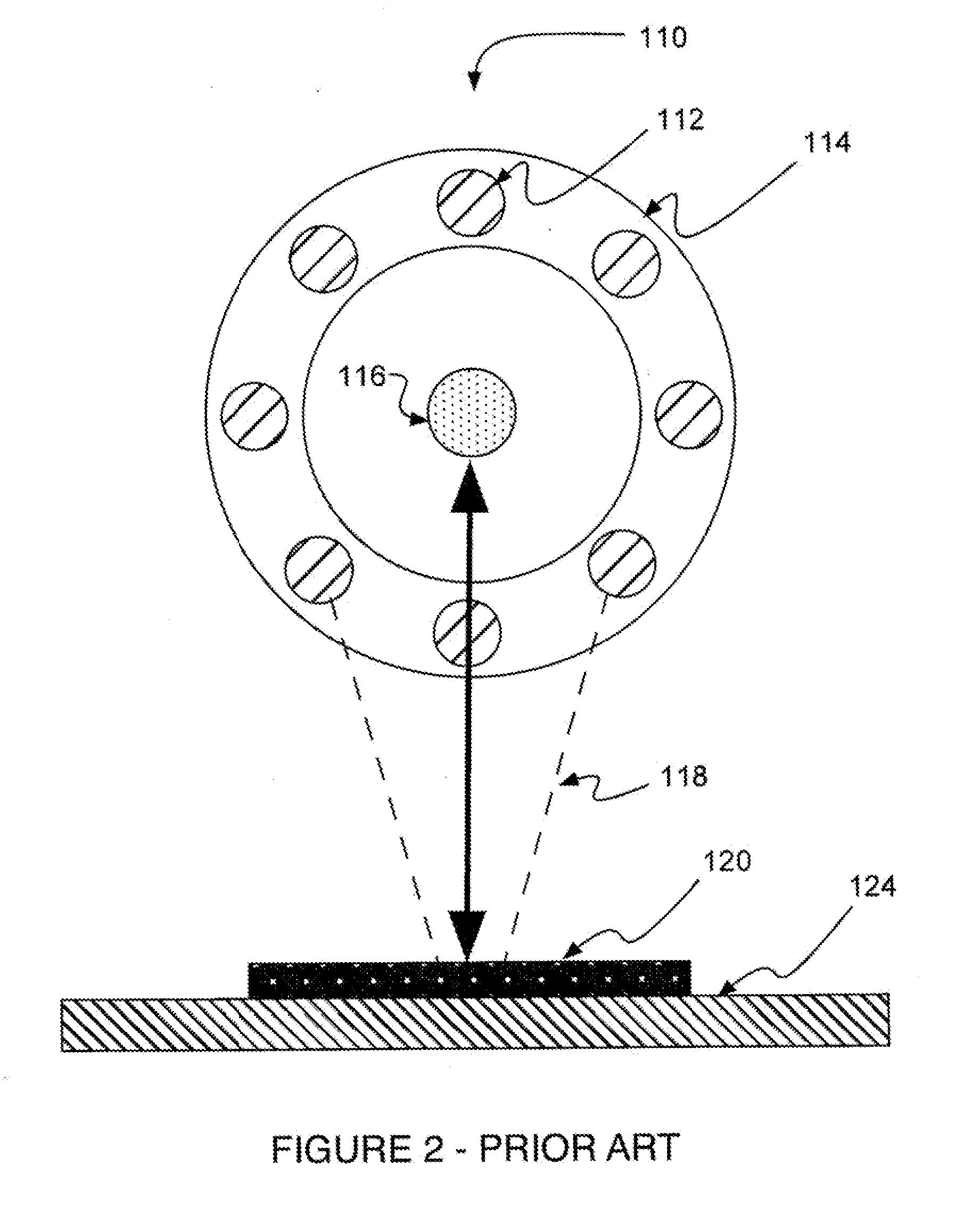

In-Ceiling Focus Located Surgical Lighting

InactiveUS20110015492A1Rapid and on-the-fly trackingMinimize shadowsCoupling device connectionsSurgical furnitureBiomedical engineeringSurgical lighting

The present disclosure provides a device for the automated illumination of a surgical sight and methods of use thereof.

Owner:OPTIMUS SERVICES

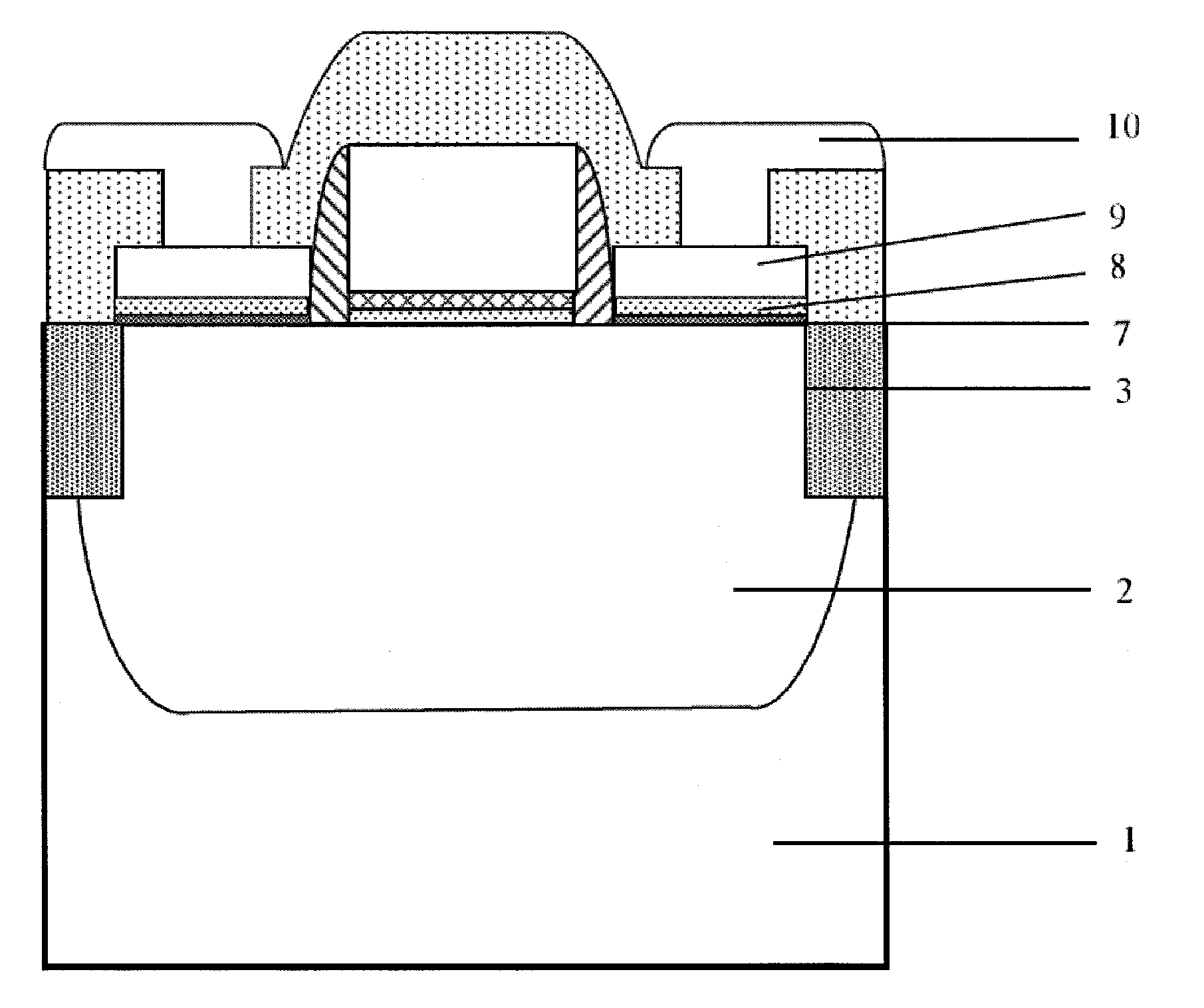

Ge-based nmos device and method for fabricating the same

ActiveUS20140117465A1Alleviate Fermi level pinning effectReduce electron barrierSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierDielectric layer

The embodiments of the present invention provide a Ge-based NMOS device structure and a method for fabricating the same. By using the method, double dielectric layers of germanium oxide (GeO2) and metal oxide are deposited between the source / drain region and the substrate. The present invention not only reduces the electron Schottky barrier height of metal / Ge contact, but also improves the current switching ratio of the Ge-based Schottky and therefore, it will improve the performance of the Ge-based Schottky NMOS transistor. In addition, the fabrication process is very easy and completely compatible with the silicon CMOS process. As compared with conventional fabrication method, the Ge-based NMOS device structure and the fabrication method in the present invention can easily and effectively improve the performance of the Ge-based Schottky NMOS transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

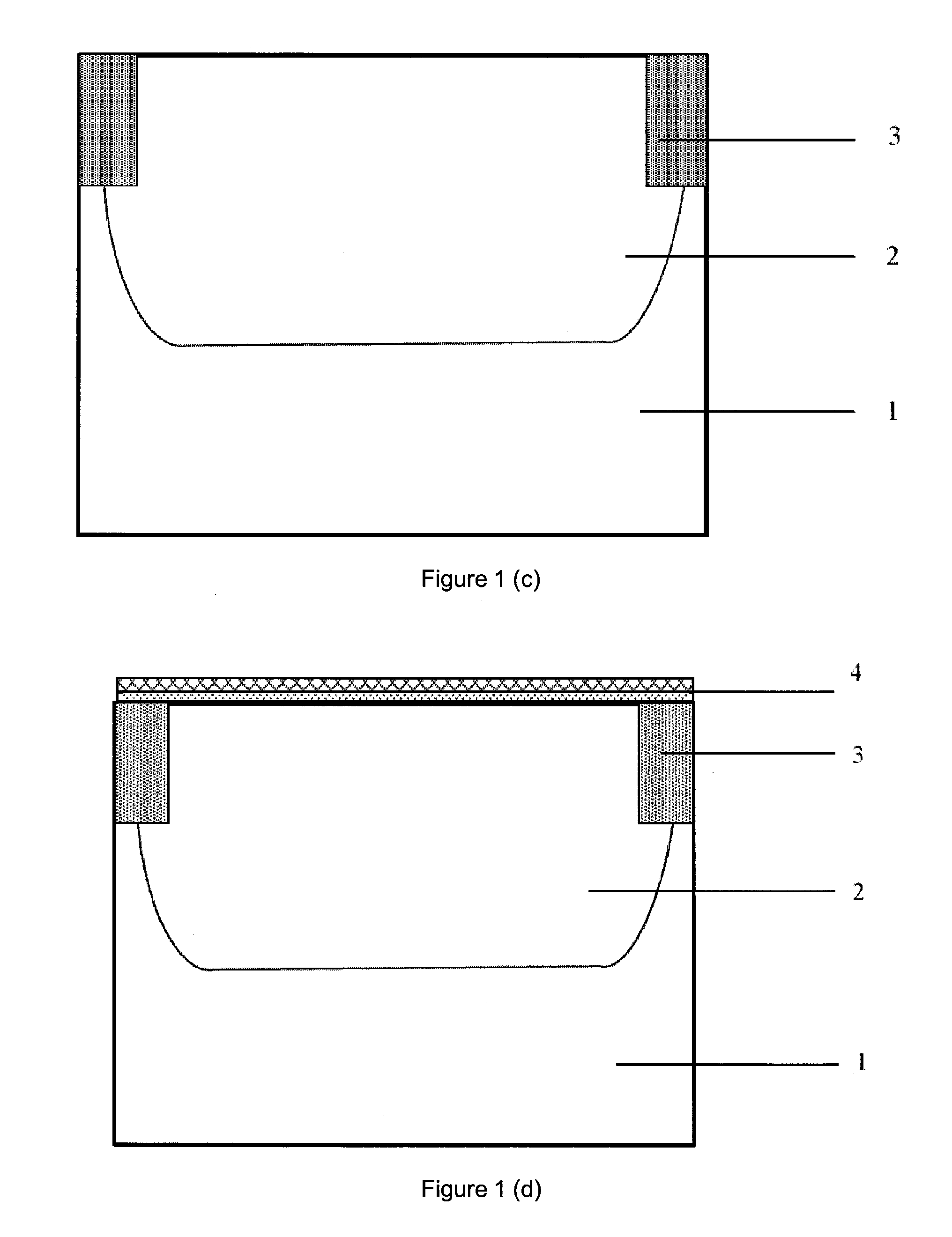

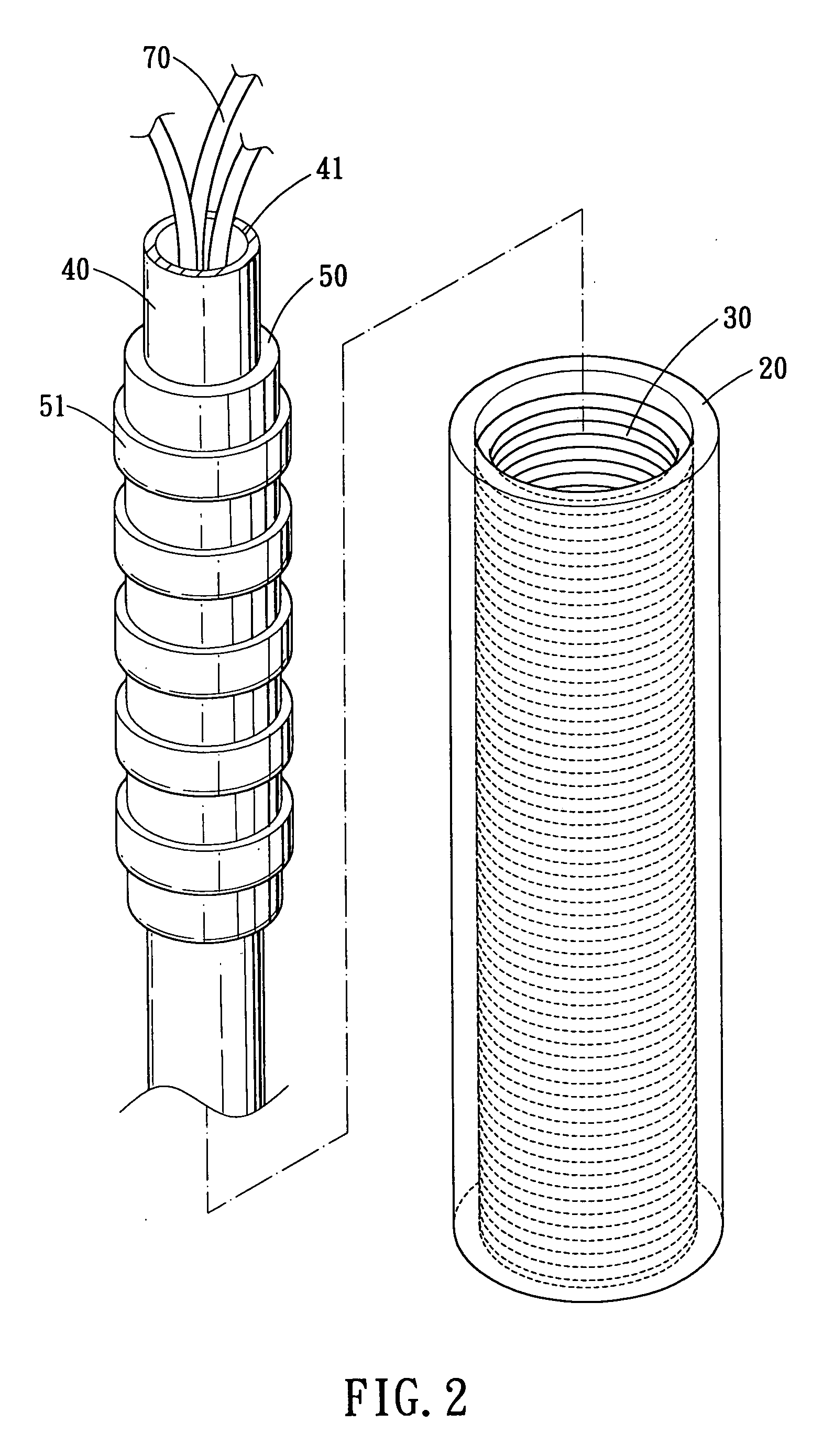

Tubular linear motor for electrical discharge machine

A tubular linear motor for electrical discharge machine generally comprises: a stator, a forcer, a set of coils and a hollow central shaft. The forcer is mounted onto the hollow central shaft, the forcer and the hollow central shaft are slidably disposed at the axial center of the stator, the set of coils is disposed in the stator (or in the forcer). After the coil is powered, the forcer will be driven to reciprocate along the central shaft by the electromagnetic force produced by the set of coils. The central shaft can be interiorly provided with wires, and thus, both the production cost and installation space of the linear motor of the present invention can be substantially reduced.

Owner:HIWIN MIKROSYST

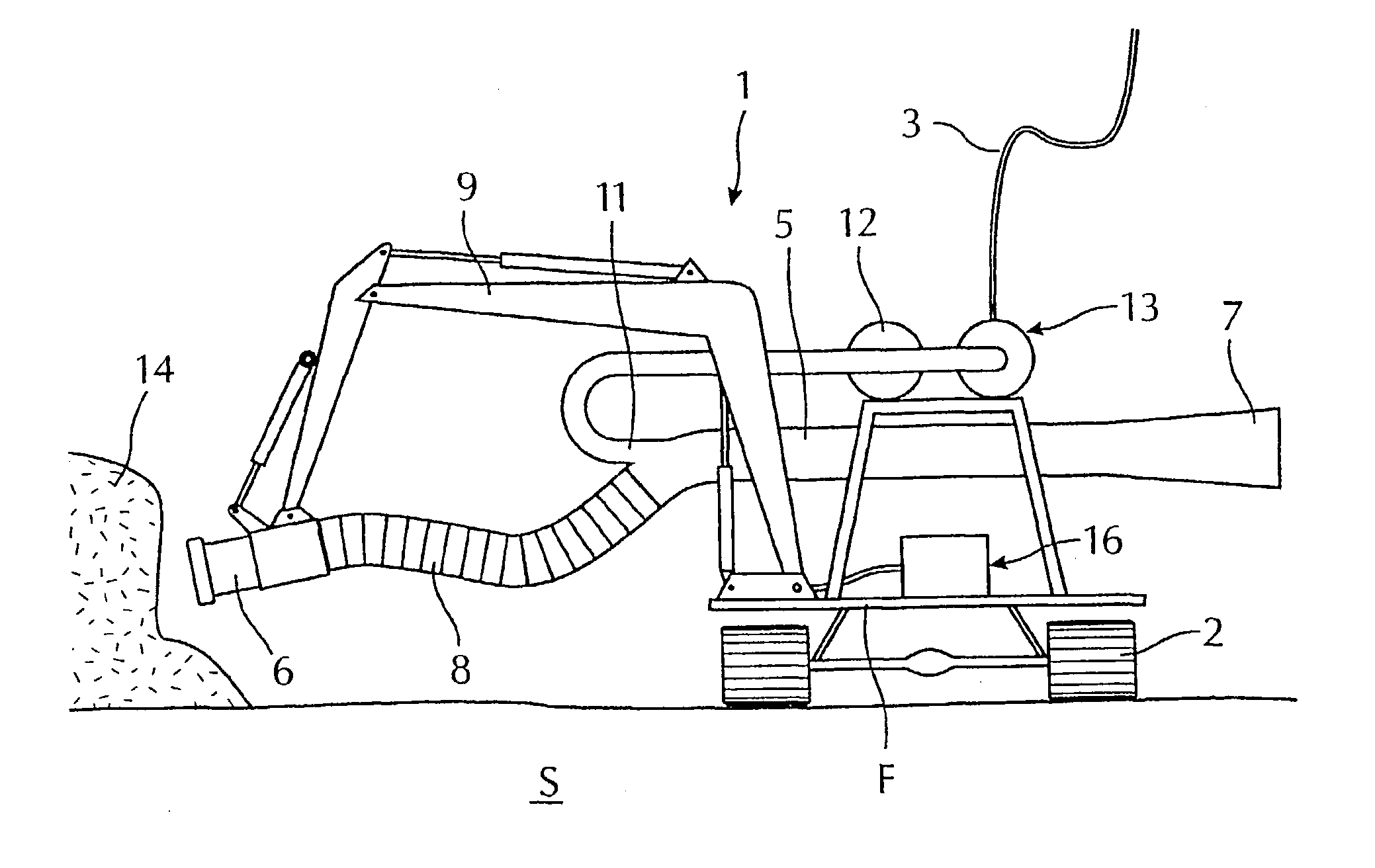

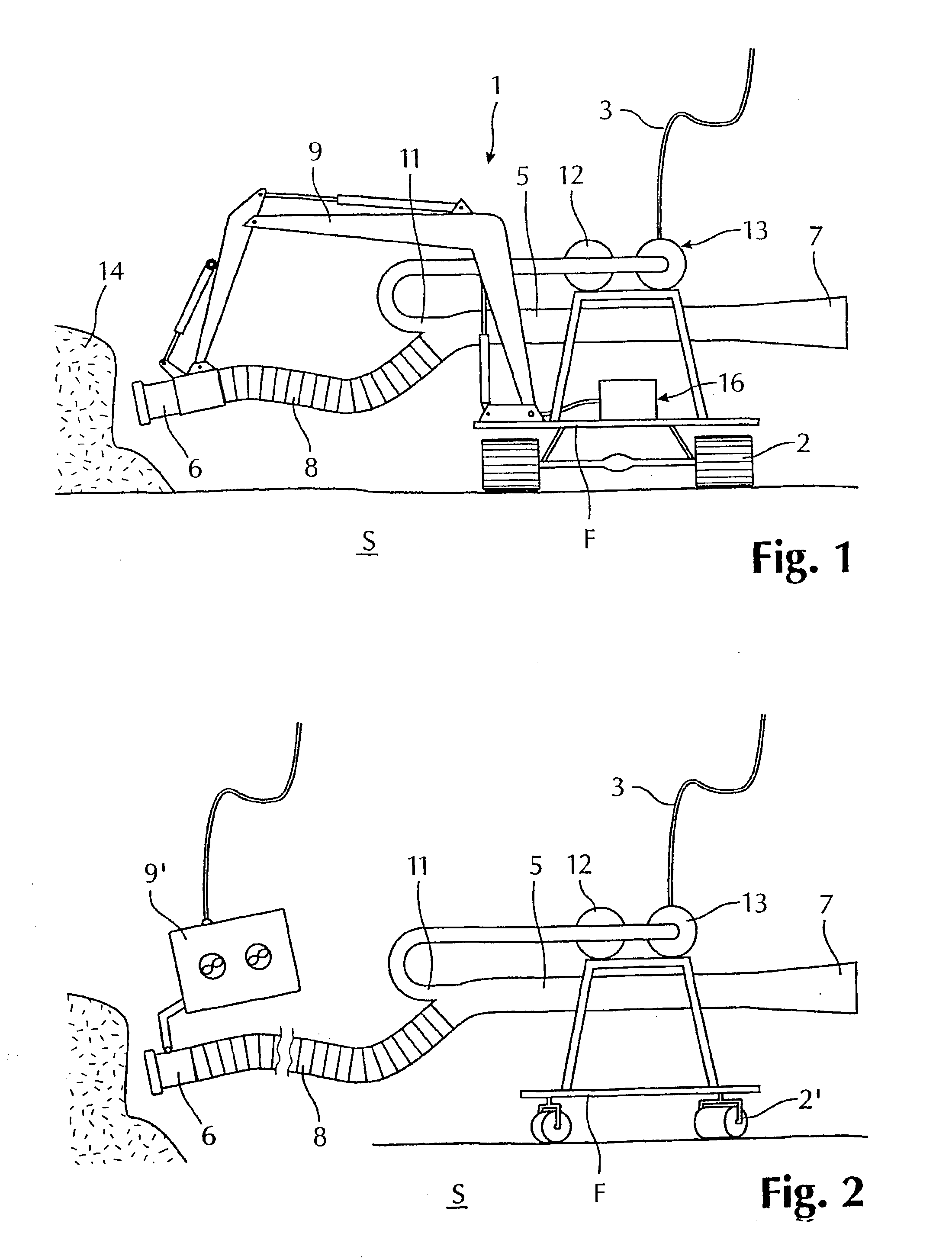

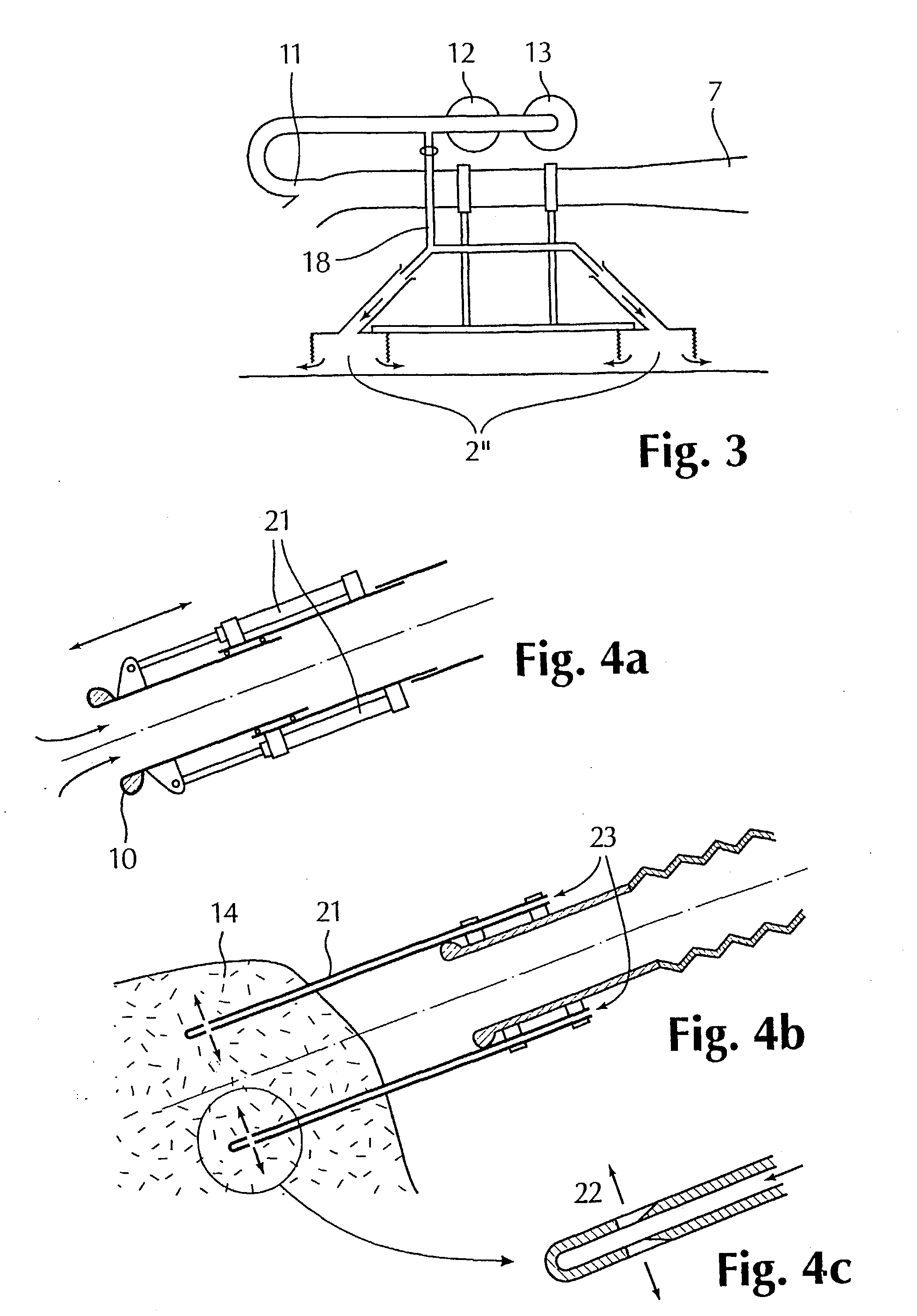

Method and device for subsea dredging

InactiveUS20030121182A1Large radiusAdd supportMachines/dredgers working methodsMechanical machines/dredgersEngineeringManipulator

Method and device for moving subsea rocks and sediments, also at significant depths, e.g. in connection with removal of protective rocks around subsea installations, where maintenance is to be conducted. The device comprises a rigid or at least partly flexible tubing (5) thorough which the masses (14) may be transported with the aid of a pressure gradient produced by an ejector nozzle (11) arranged externally in relation to said tubing. The nozzle (11) is fed with water from a water pump (12). The device further comprises a chassis (F) adapted to be transported along the (sea) bottom. The required power is arranged to be supplied through a cable (3) from the surface, while the tubing (5) preferably is arranged to be remotely controlled by a manipulator (9, 9'').

Owner:FOSSURA

Liquid crystal display device

InactiveUS20070242183A1Precise positioningSuppressing removal and disengagementDetails for portable computersNon-linear opticsLiquid-crystal displayEngineering

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

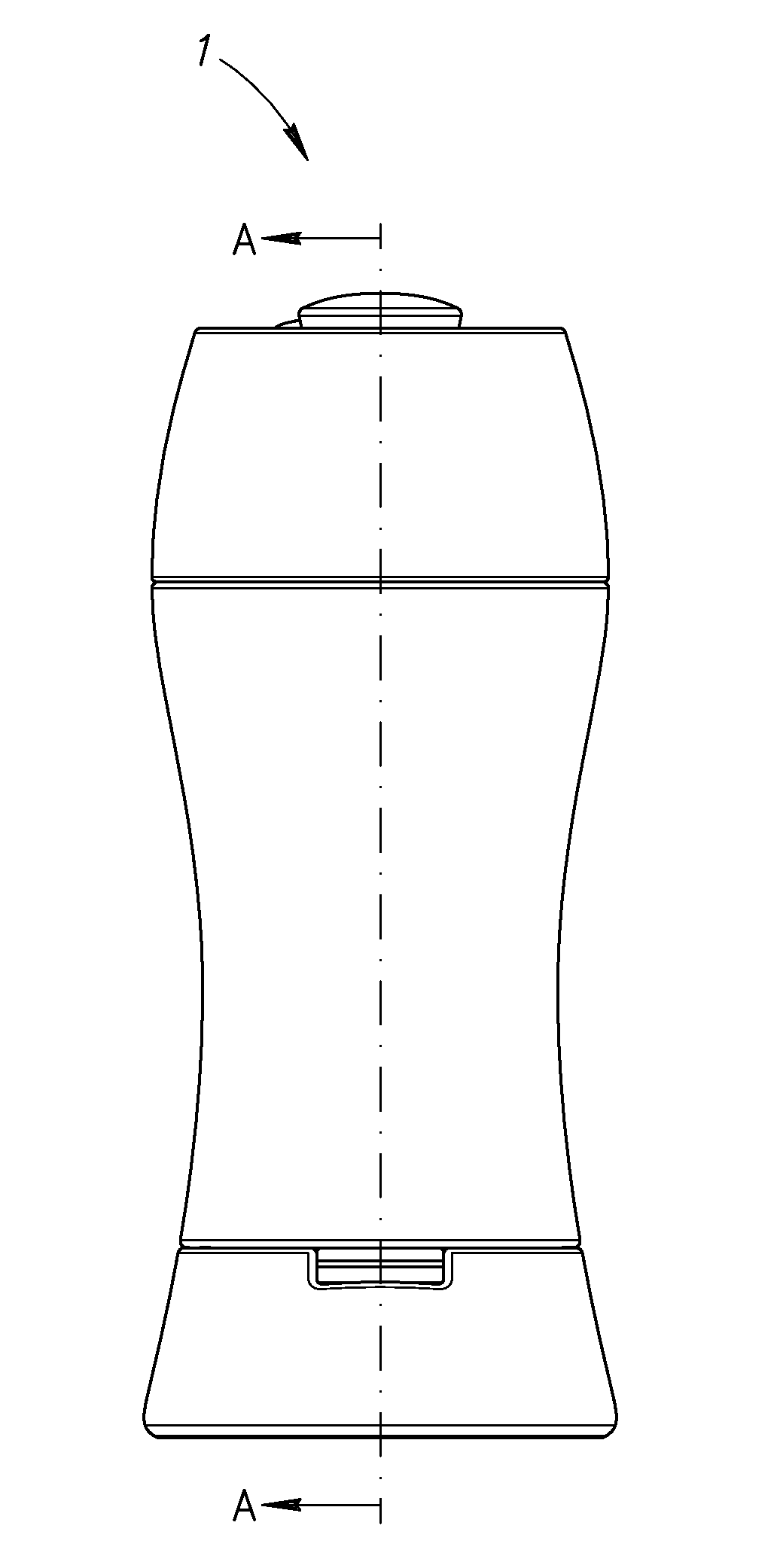

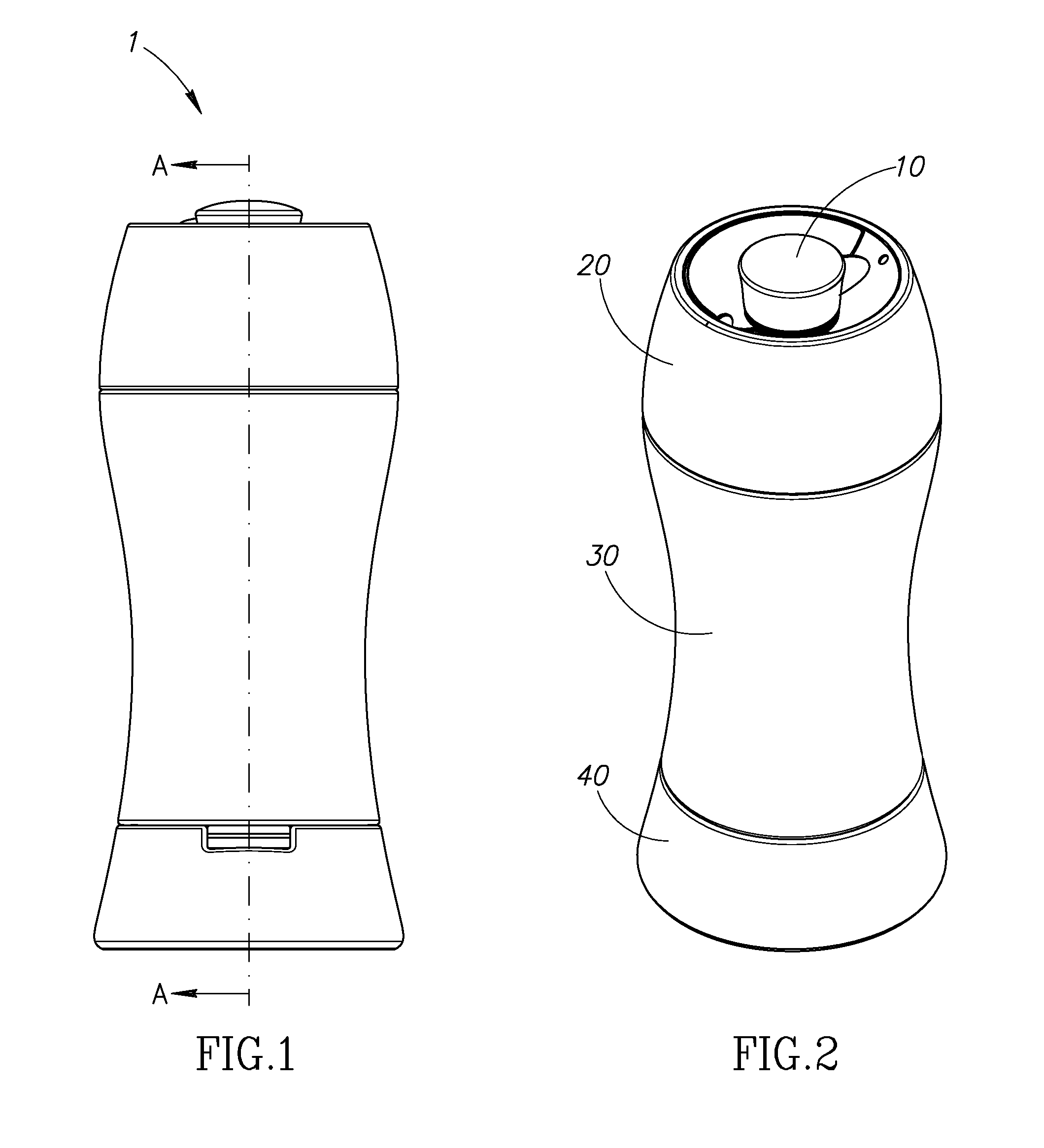

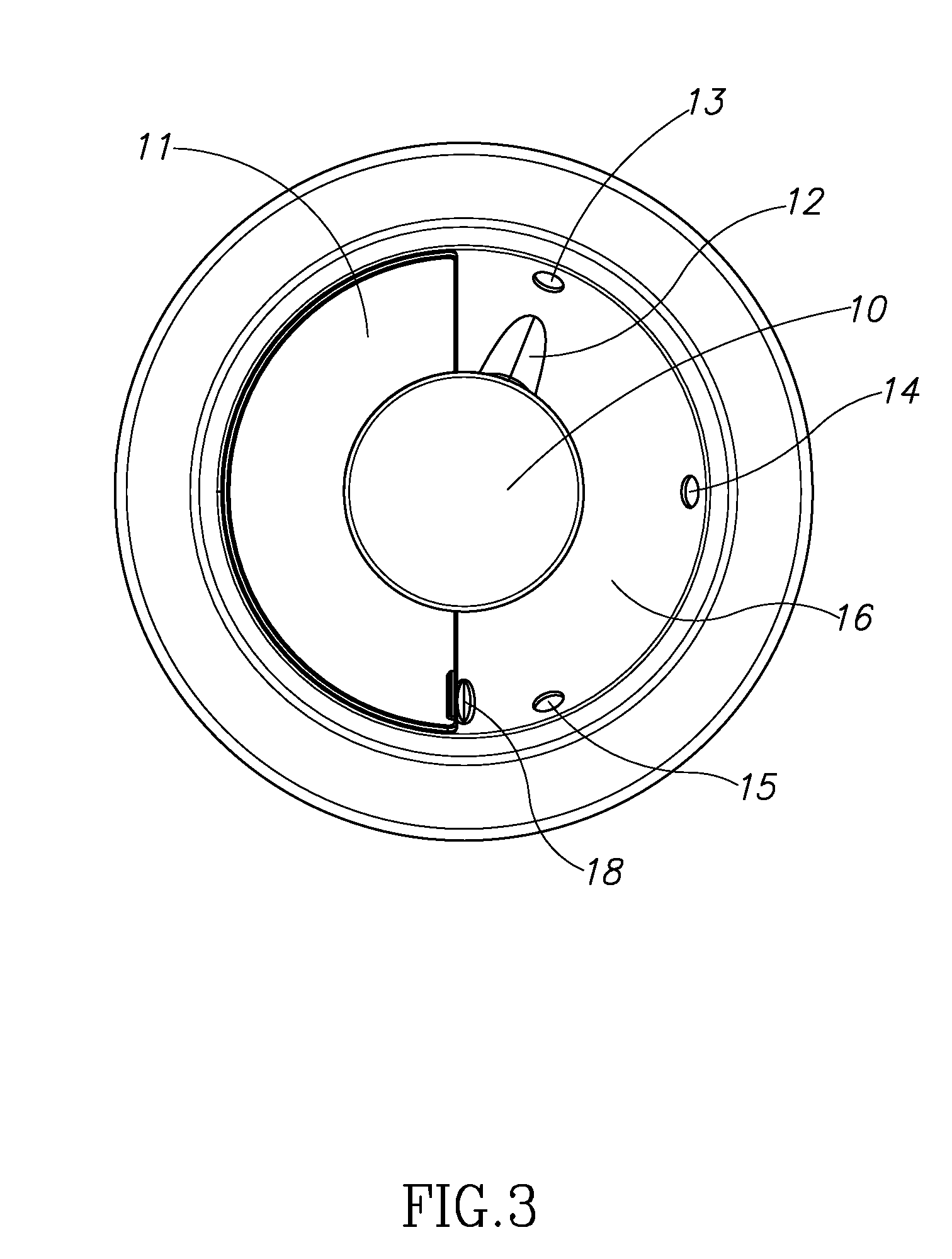

Spice mills and shakers

A grinder includes an improved mechanism for adjusting the coarseness of the grind by providing a grind selector knob centrally located at the top of a cap. In some versions of the invention, the mill includes a base with a cavity for collecting the salt, spice, or pepper that is ground so that it can be measured within the base before dispensing. Ideally, the collector base includes an inclined floor and measurement indicators to enable the grinding and measuring of a desired volume of spice.

Owner:PROGRESSIVE INT

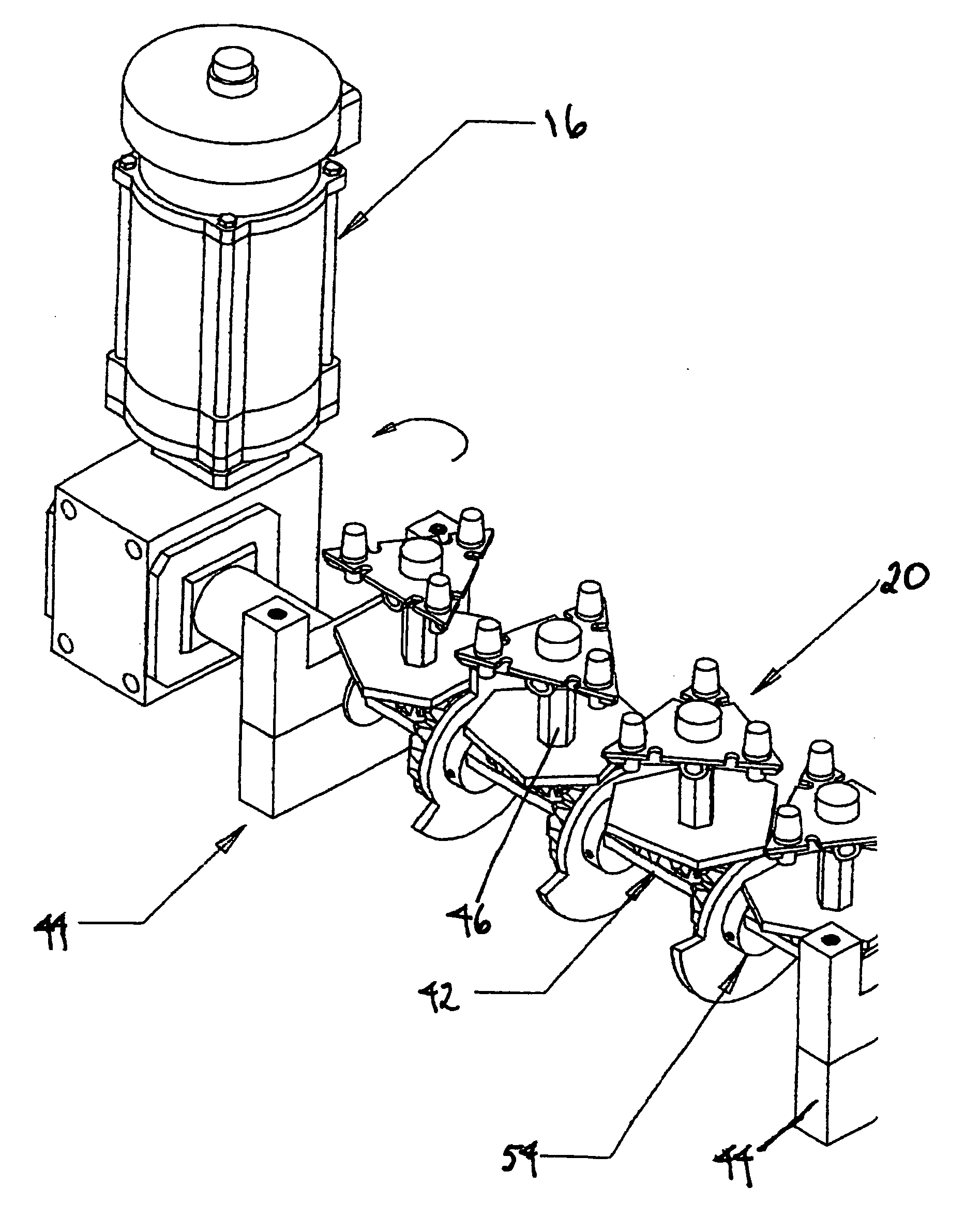

Gear alignment and slip assembly for drive transmission system of multi-faced signs and billboards

InactiveUS20070199216A1Durable and strongPrevent rotationBoardsIdentification meansGear wheelDrive shaft

A sign (10) includes a gear subassembly (50, 52) and a slip assembly (74, 80) operatively associated between the drive shaft (42) and the output shaft (46) of one of the display elements (14). During a portion of a rotation of the input gear element (50), the input gear teeth (72) engage the output gear teeth (78). During another portion, the input gear teeth (72) disengage. At least one partial gear tooth (82a, 82b) assists in periodically aligning the gear teeth. The slip subassembly comprises: an input slip element (74) defining a generally arcuate line about the axis of the input slip element; and an output slip element (80) defining a generally straight line that is non-intersecting with and extends perpendicular to the input slip axis. During a portion of a rotation of the input slip element (74), the arcuate line and the straight line of the slip elements (74, 80) are in slipping contact to prevent the output slip element (80) from rotating. During another portion of the rotation, the output slip (80) can be rotated. The slip subassembly has a radius at least a large as the radius of the gear teeth (72, 78).

Owner:ACTION GRAPHIX

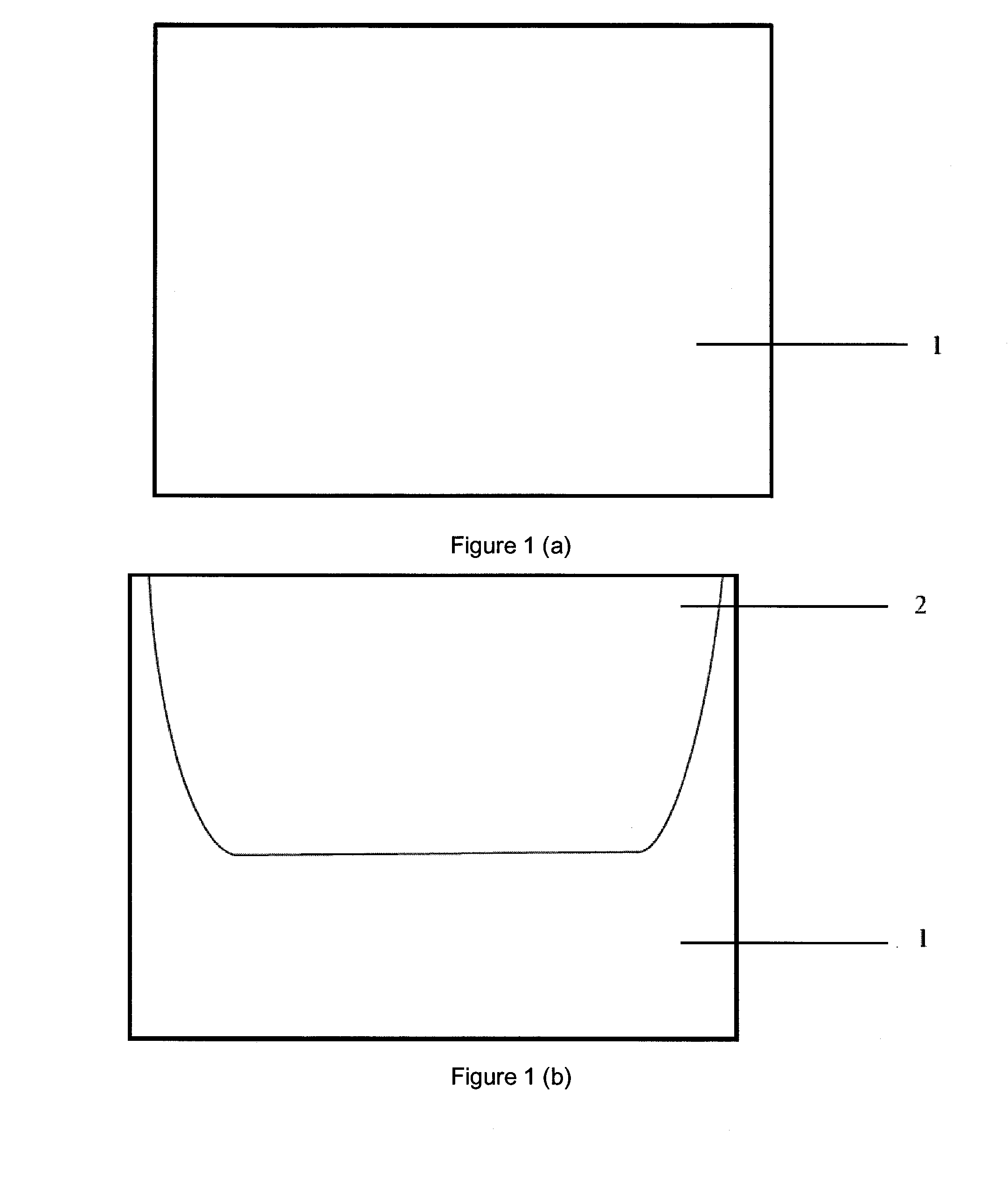

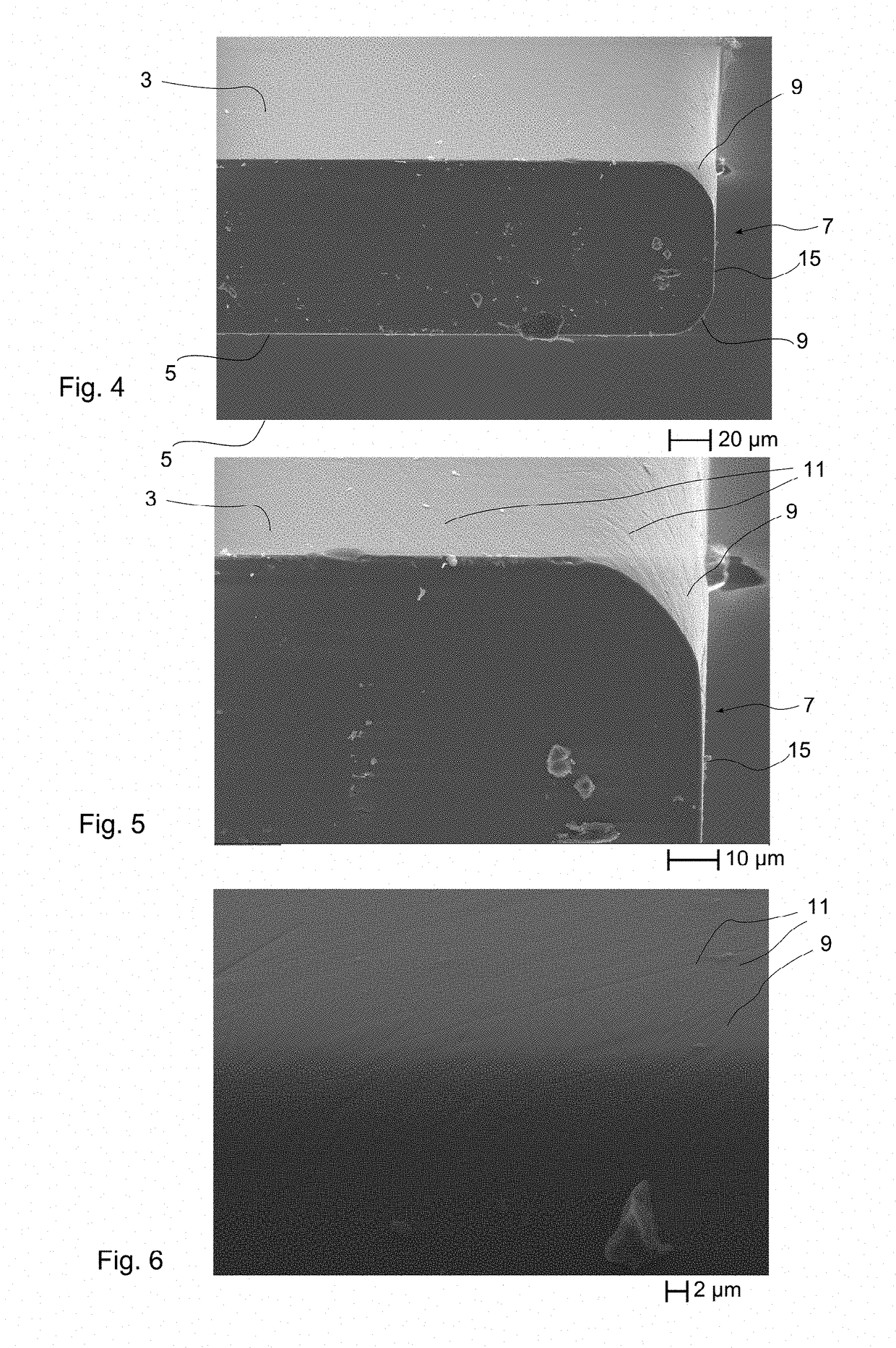

Sheet glass product with increased edge strength and method for producing same

ActiveUS20170304980A1Stress intensity at the ends of the cracks is reducedHigh strengthEdge grinding machinesGlass severing apparatusFlat glassEdge surface

Thin glass elements with improved edge strength are provided—from a sheet glass element that has two opposite parallel faces and an edge connecting the faces. The sheet glass element has a thickness of at most 700 μm. At least a portion of the edge is defined by an edge surface portion that is convexly curved, so that at least one of the faces merges into the edge surface portion, wherein a curved arc of the edge surface portion has a length that is at least 1 / 30 of the thickness of the sheet glass element. In the region of the convex curvature, the edge surface portion has indentations in the form of furrows.

Owner:SCHOTT AG

Universal non-custom dental tray having anatomical features to enhance fit

ActiveUS8277215B2Enhance anatomical fitBetter conformGum massageTeeth fillingEngineeringAnatomical feature

Owner:ULTRADENT PROD INC

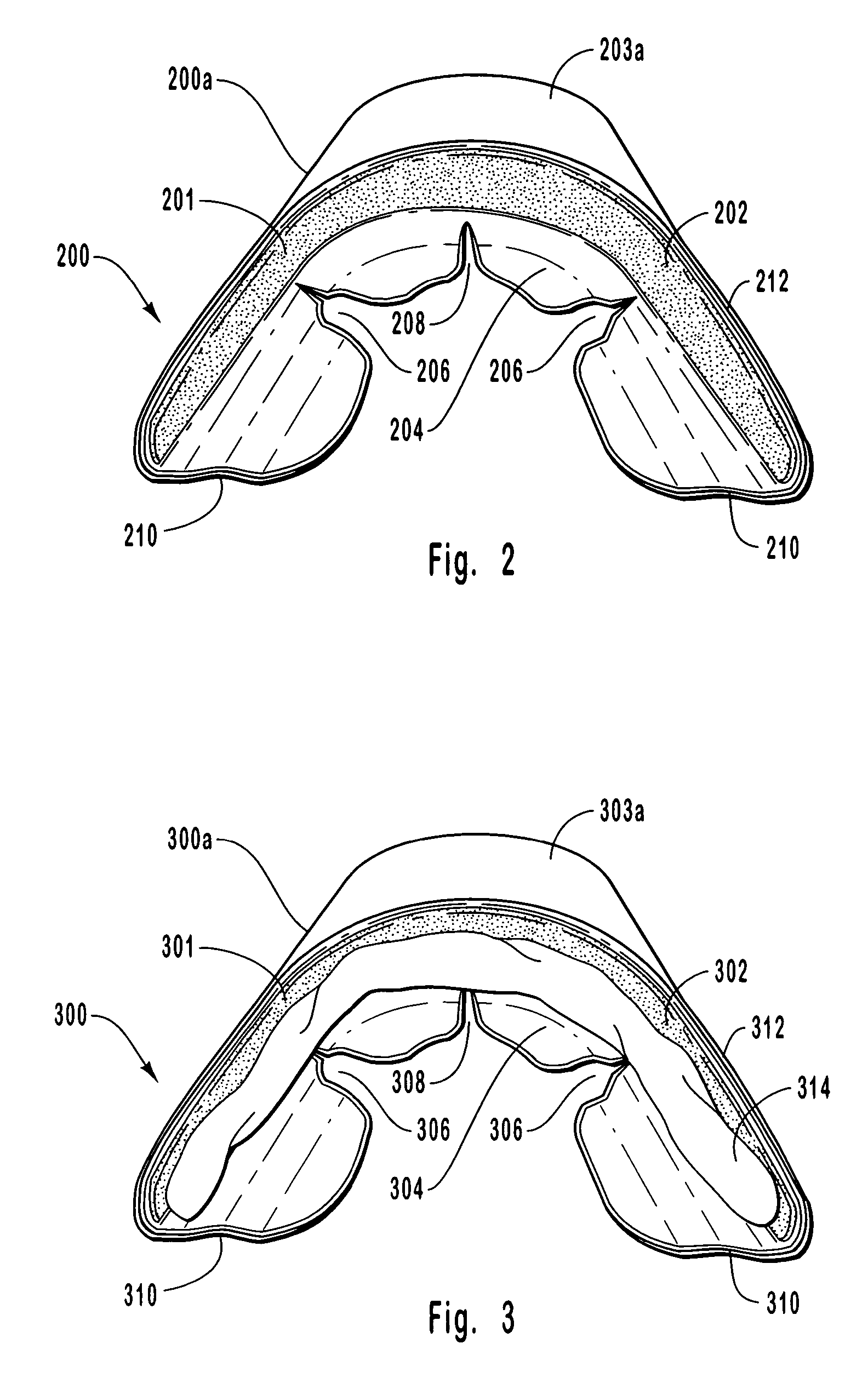

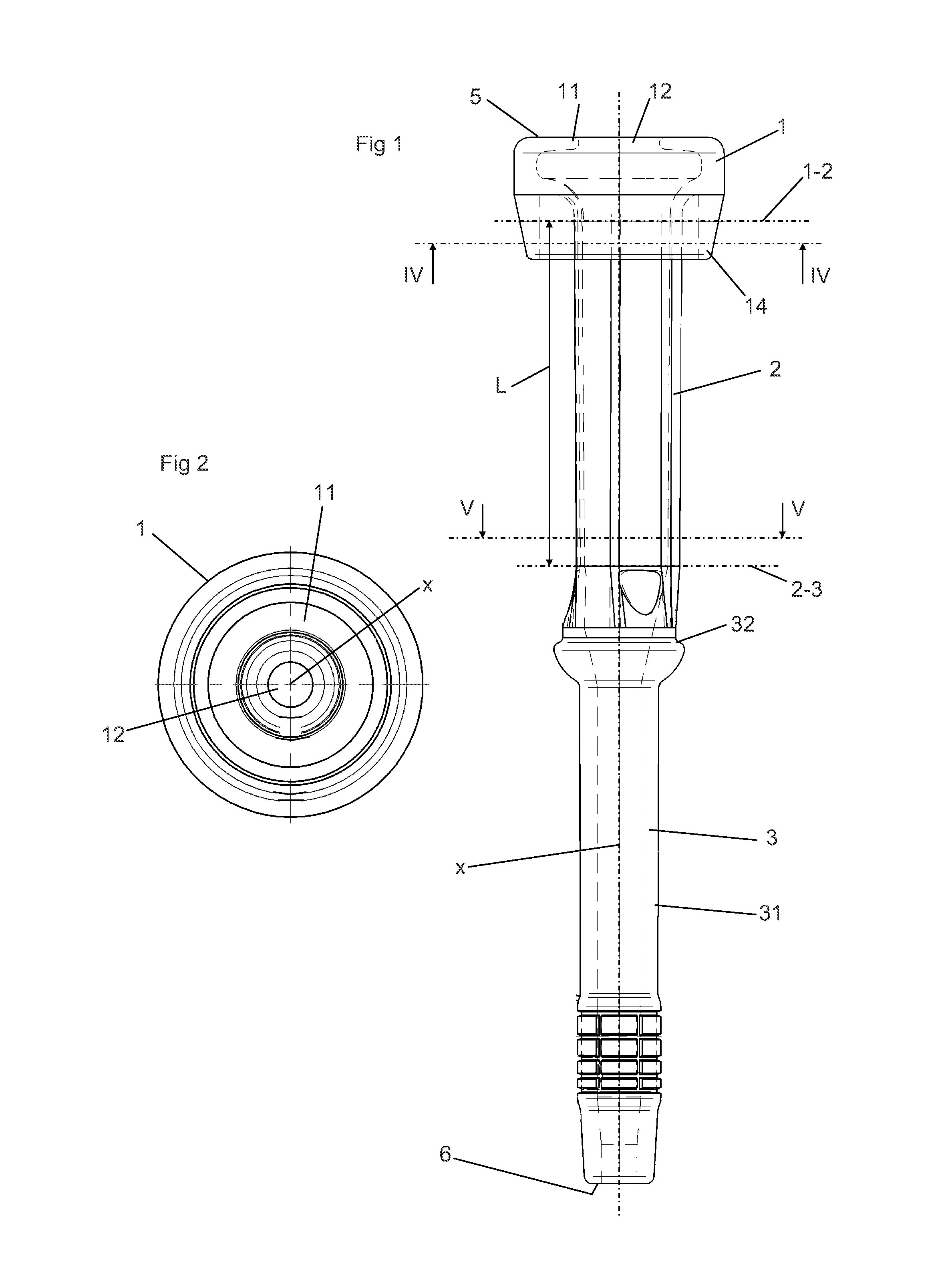

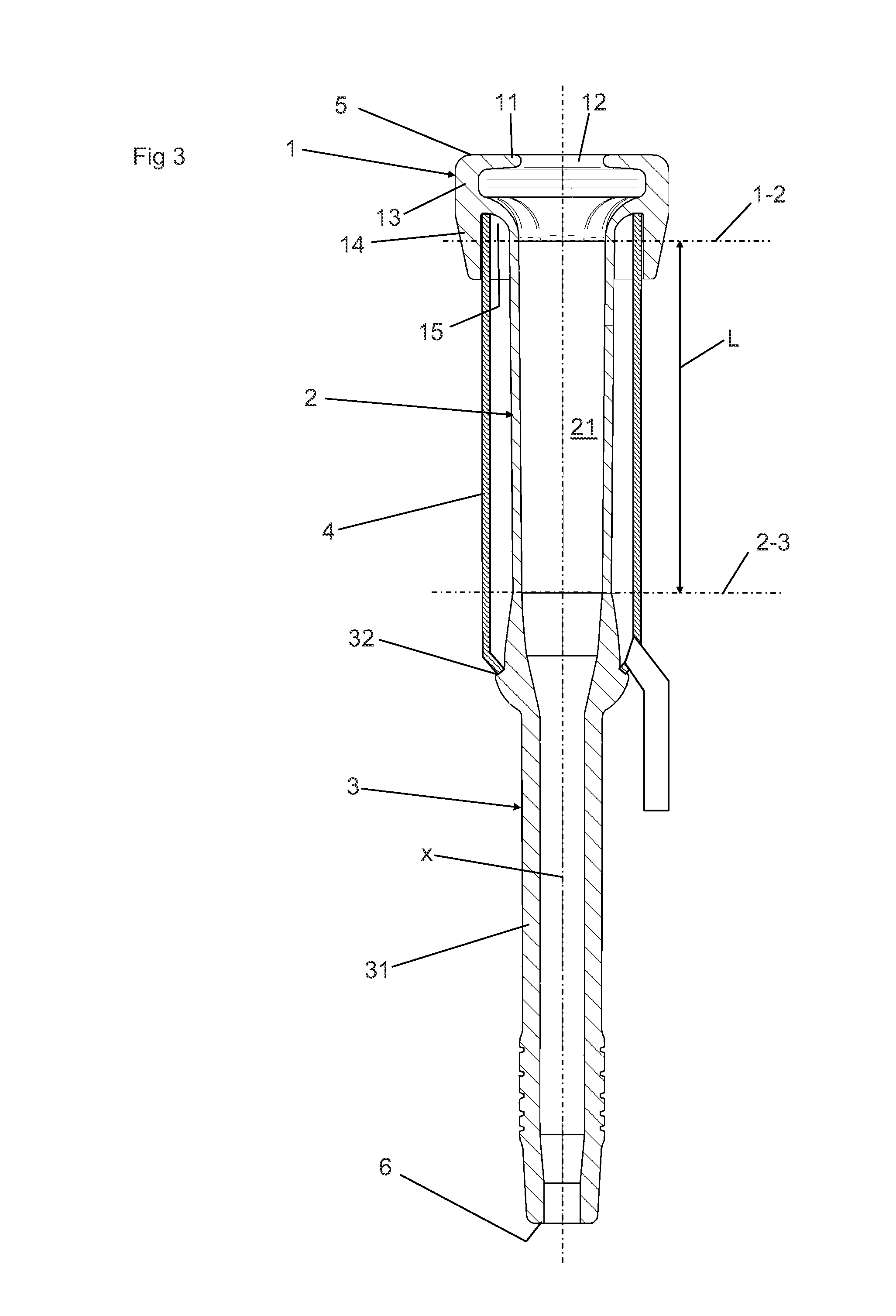

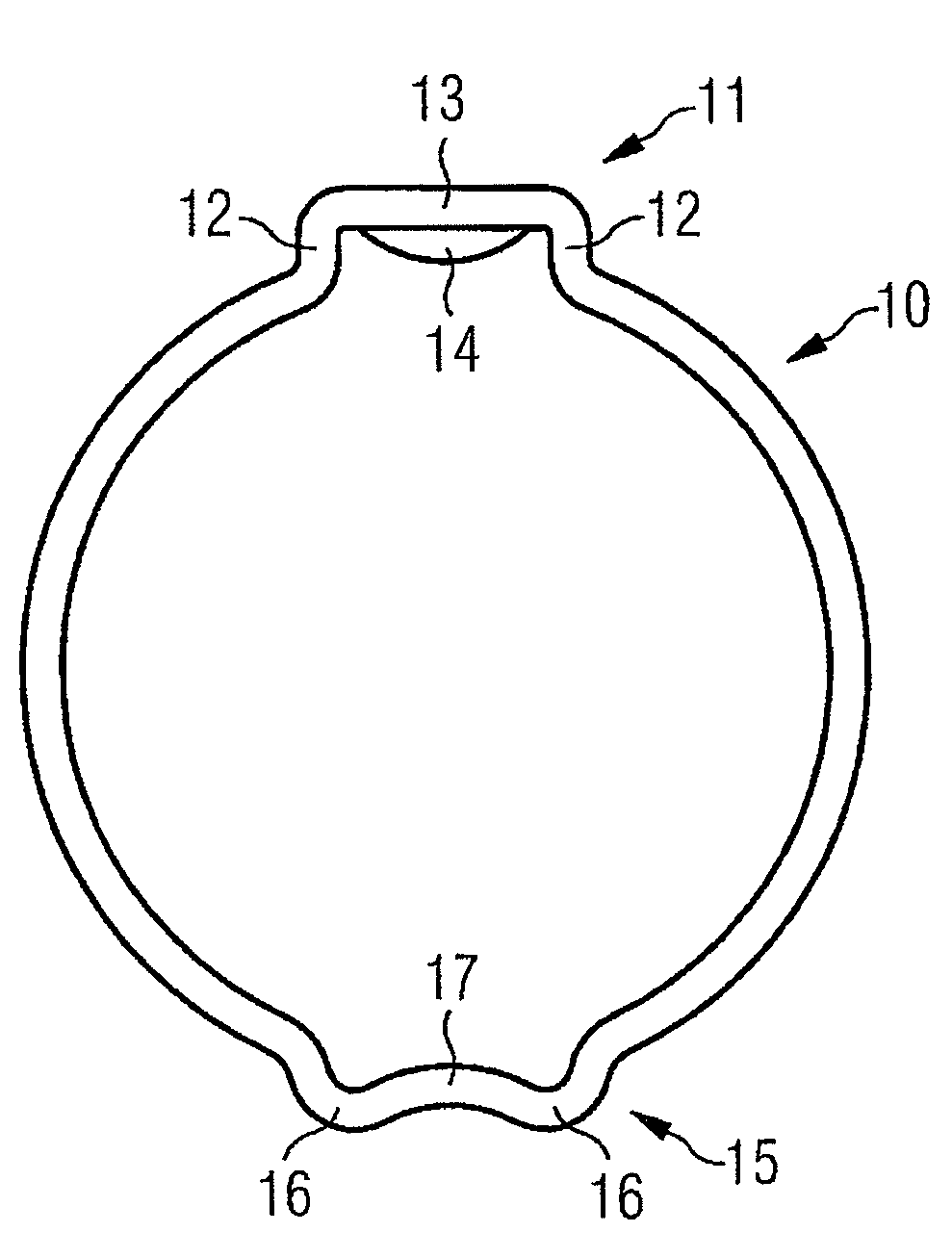

Teatcup liner

A teatcup liner for a teatcup has a longitudinal shape extending along a longitudinal axis (x). The teatcup liner includes a barrel (2) having a length (L) and defining an inner space (21) for receiving the teat. The barrel has a polygonal cross-sectional shape transversely to the longitudinal axis along the barrel. The polygonal cross-sectional shape defines a plurality of corner portions and a plurality of side portions, each connecting two of the corner portions. Each corner portion includes an inner surface facing the inner space and having an inner radius extending from the inner space to the inner surface. The inner radius is equal for each corner portion. Furthermore, the inner radius of each of the corner portions is at least 4 mm at a center part of the corner portion.

Owner:DELAVAL HLDG AB

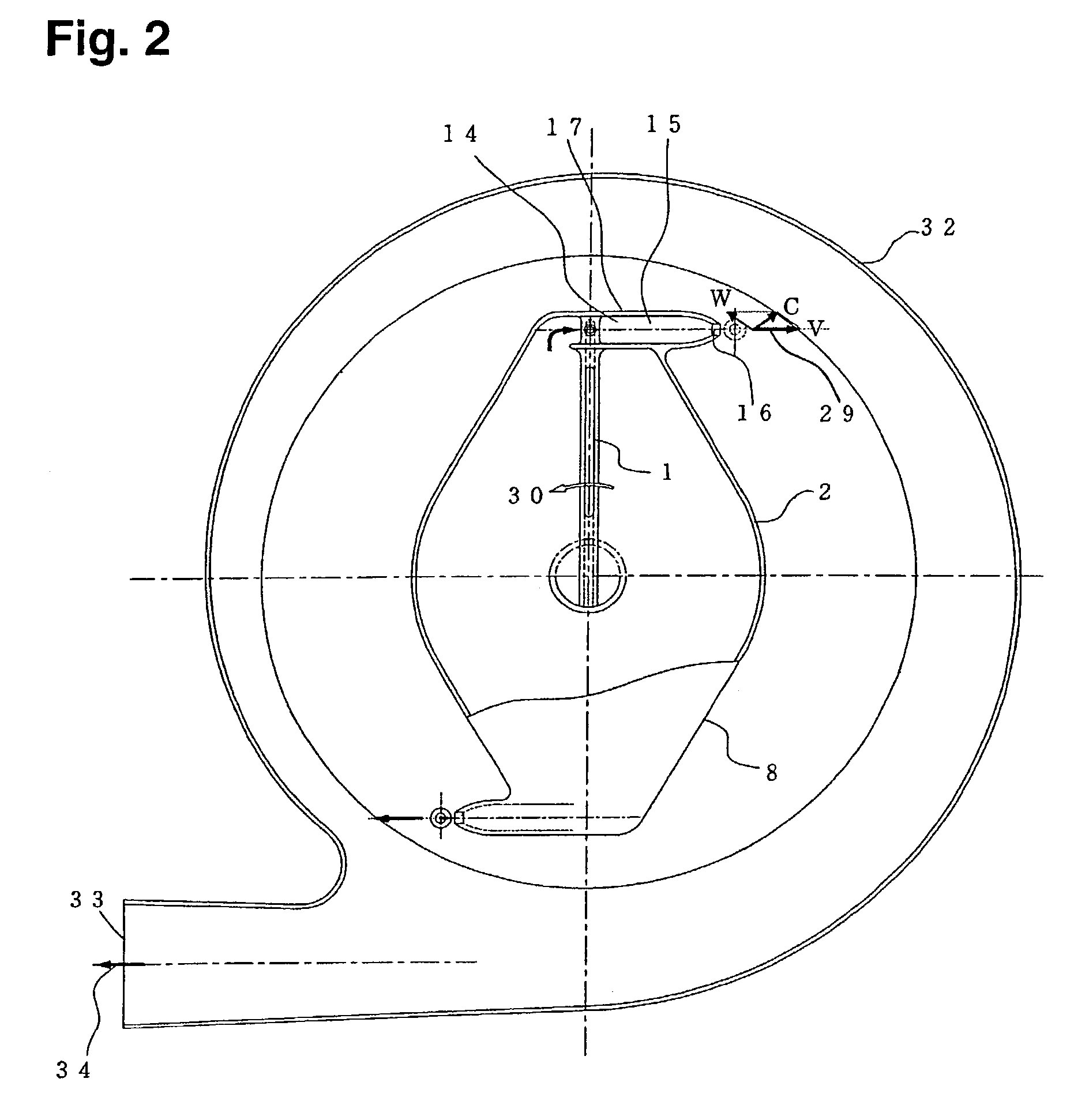

Midget gas turbine

InactiveUS7462948B2Avoid enteringLarge radiusGas turbine plantsDynamo-electric converter controlCombustorCombustion chamber

The present invention provides a midget gas turbine has:a casing;an irregular-shaped hollow disk rotationally attached to a casing; said irregular-shaped hollow disk having in a hollow portion constituting a bursiform space having a closed peripheral portion in which a guiding vane is provided, and having a radius changing with respect to the circumferential direction;a fuel conduit provided from a central portion towards a portion of the outer peripheral portion of the irregular-shaped hollow disk and communicated with a fuel nozzle provided in the vicinity of the outer peripheral portion of the irregular-shaped hollow disk; andat least two combustion chambers each comprising a mixing portion for mixing a fuel injected from the fuel nozzle with an external air centrifugally compressed by the guiding vane, a combustor and a combustion gas discharge nozzle portion, said combustion chambers being provided at rotationally symmetric positions at the outer peripheral portion of the irregular-shaped hollow disk where the radius becomes maximum;wherein an external air taken in the hollow portion of the irregular-shaped hollow disk is compressed by the guiding vane, supplied to the combustion chambers, mixed with a fuel supplied from the fuel conduit to be burnt, and a combustion gas discharged from the combustion gas discharge nozzle is discharged towards a substantially circumferential direction of the irregular-shaped hollow disk, whereby the irregular shaped hollow disk is driven by the reaction of the combustion gas.

Owner:THINKTANK PHOENIX

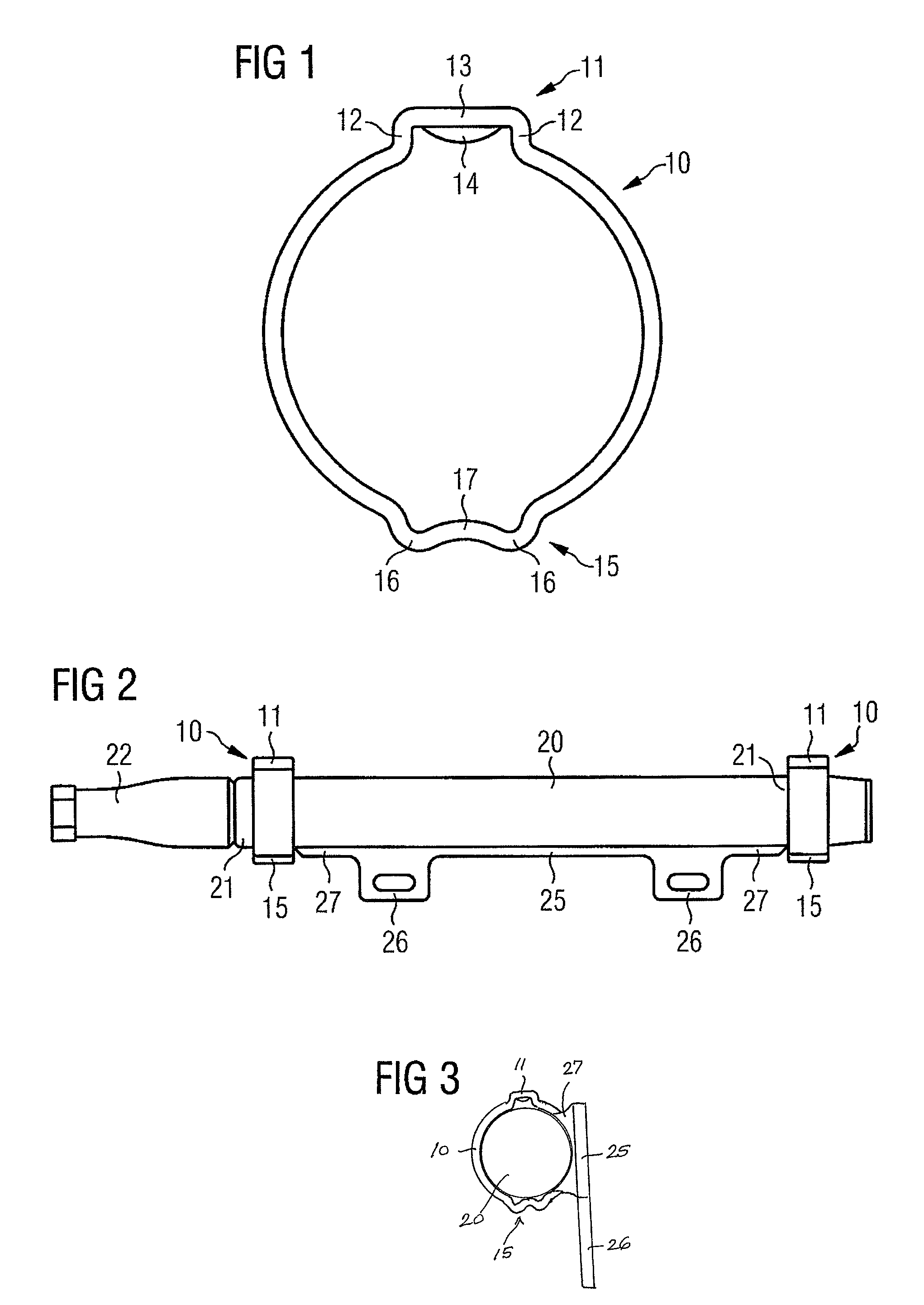

Clamping ring for fastening a gas generating cartridge

InactiveUS7631908B2Increase torquePromote repairPedestrian/occupant safety arrangementWing fastenersEngineeringGas generator

A clamping ring is used to mount an air bag gas generator cartridge on a support plate. A tensioning ear is formed in the clamping ring. Further, a wave is formed in the ring to increase the holding force between the ring and the cartridge. The wave consists of two convex arches projecting outward from the ring and an inward convex arch therebetween, the apex of the inward arch being at least tangential to the circle defined by the remaining portions of the ring in the initial condition of the ring. This type of clamping ring mounting is capable of withstanding torques between the cartridge and the support plate of well above 10 Nm.

Owner:HANS OETIKER MASCHEN & APPFAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com