Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

475results about How to "Increase the curvature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

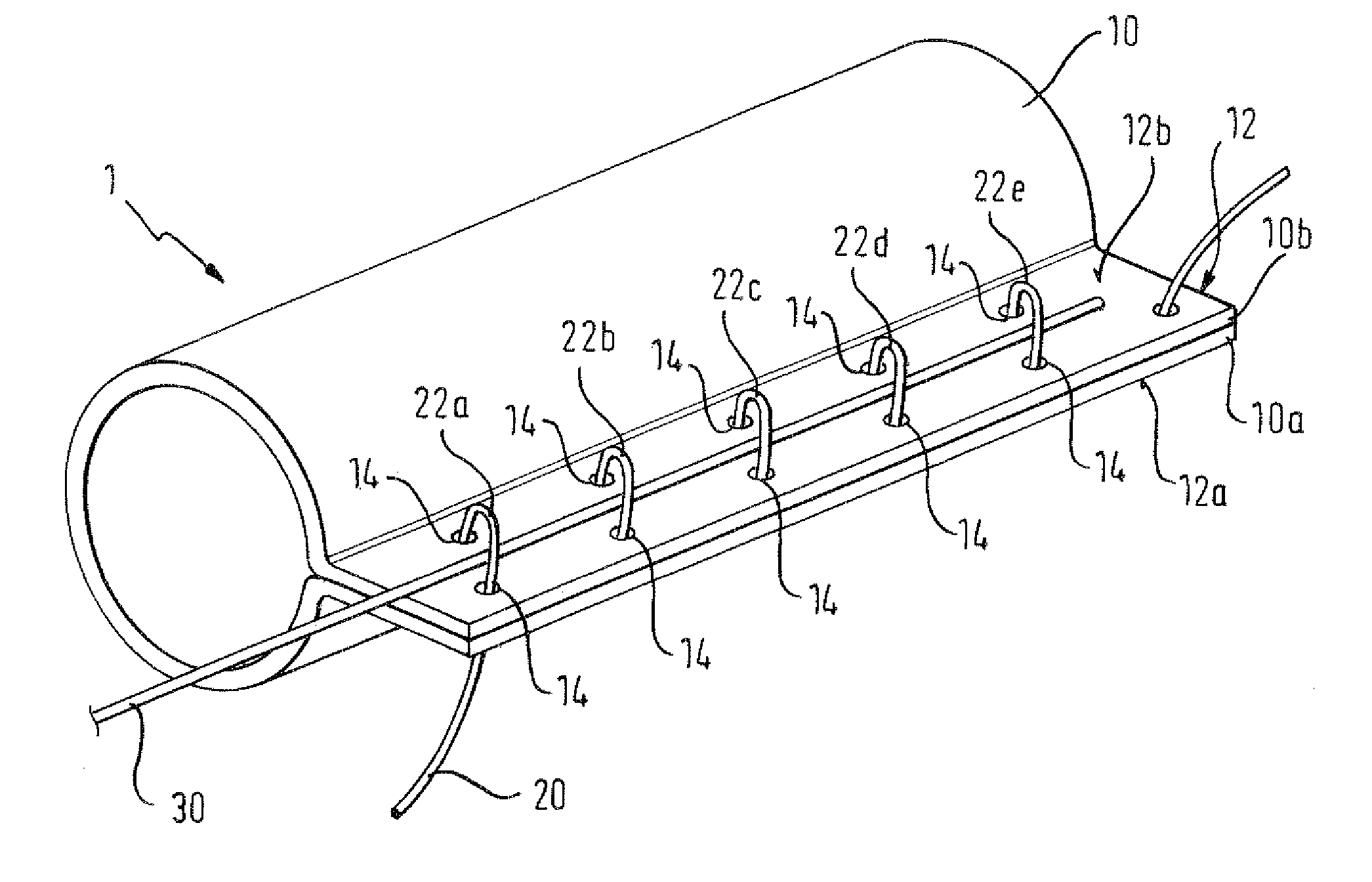

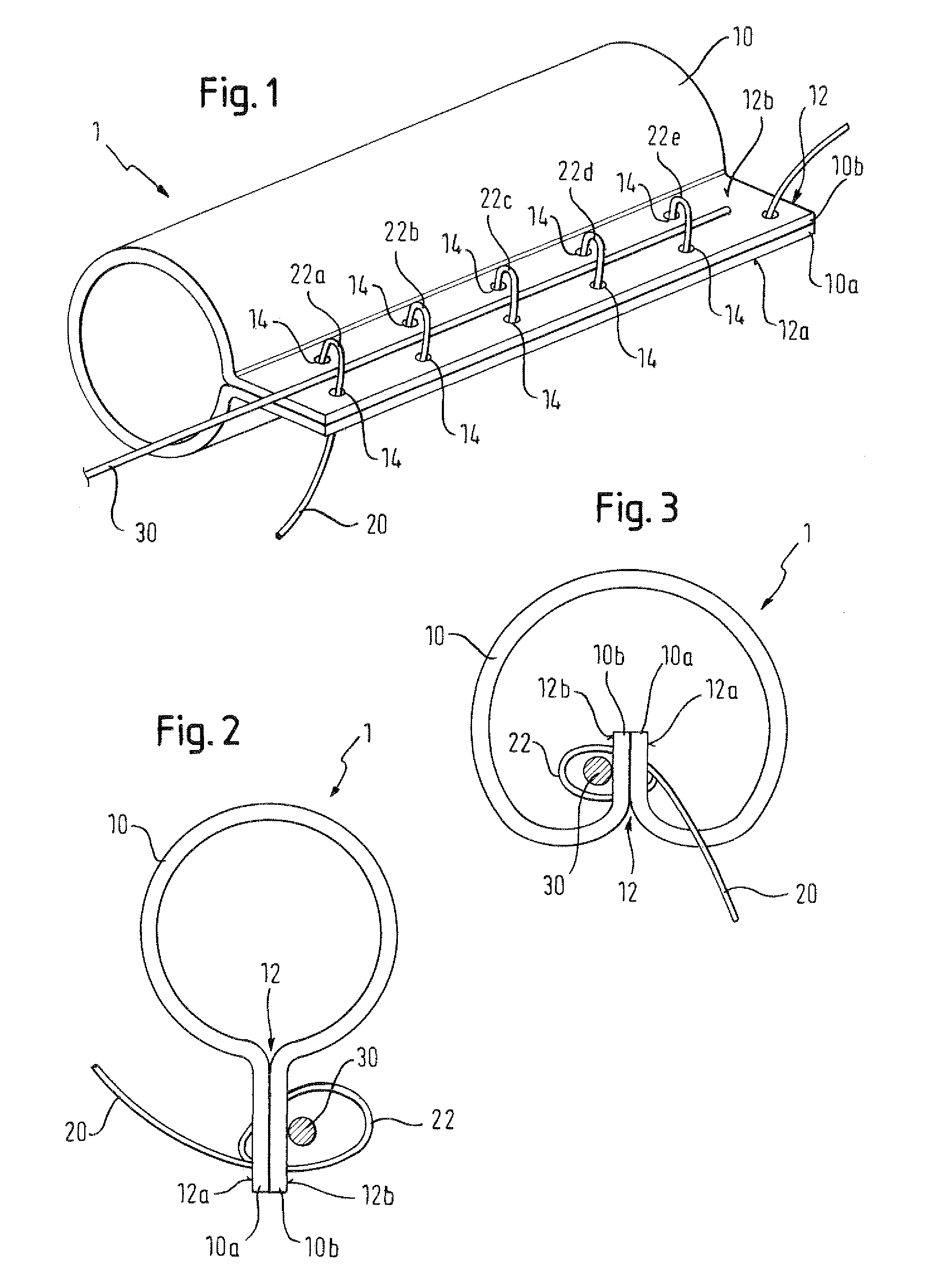

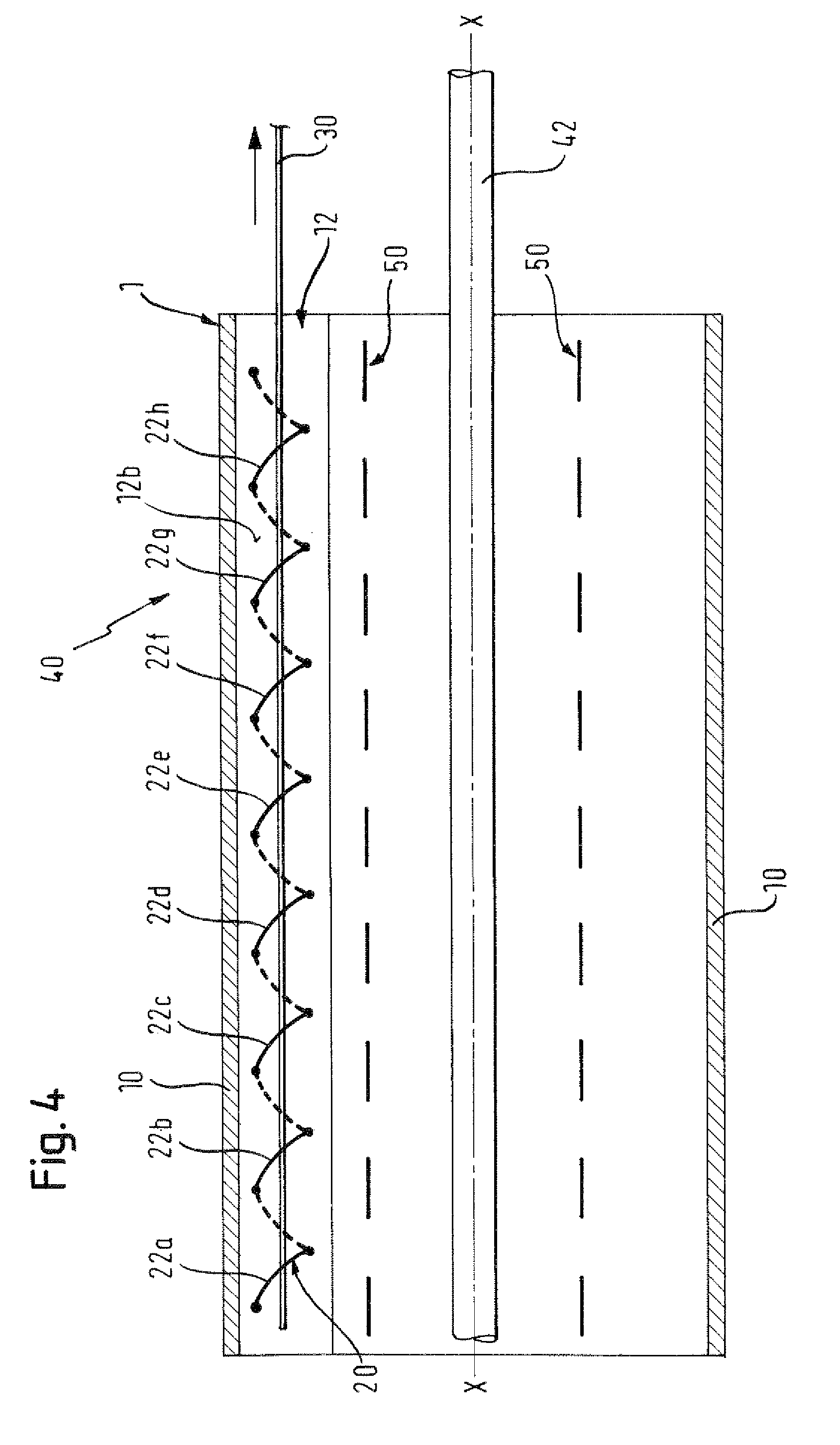

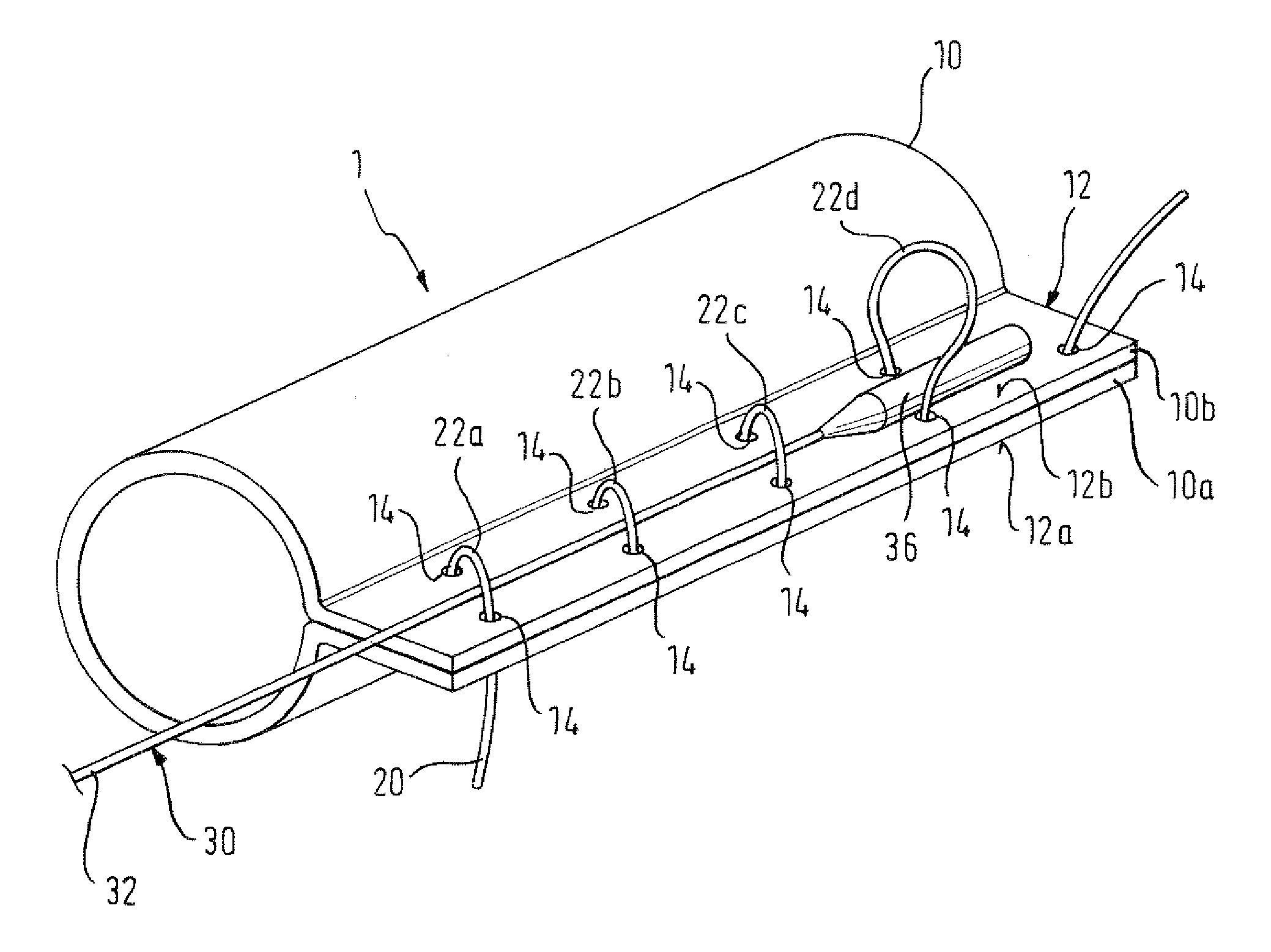

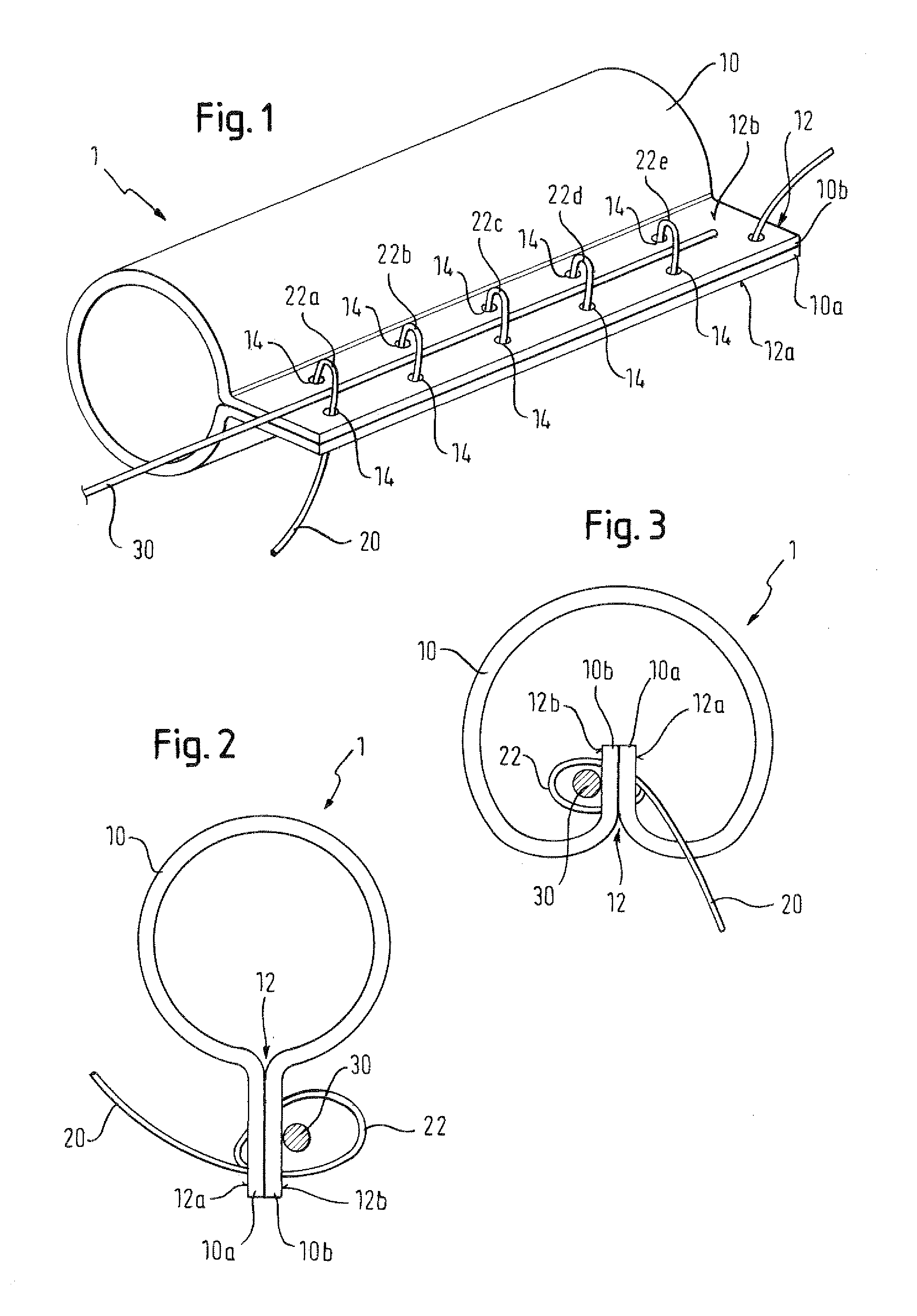

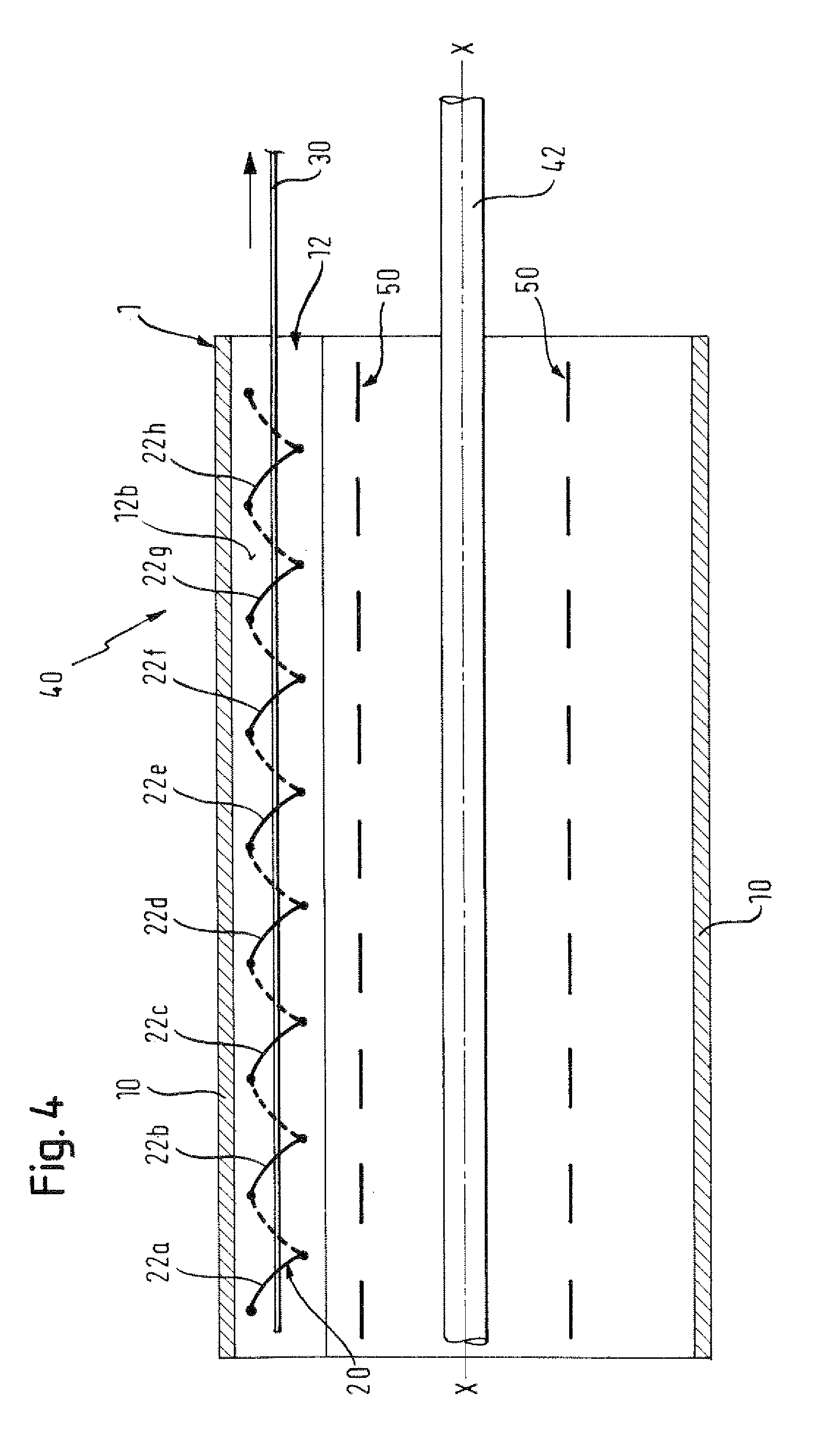

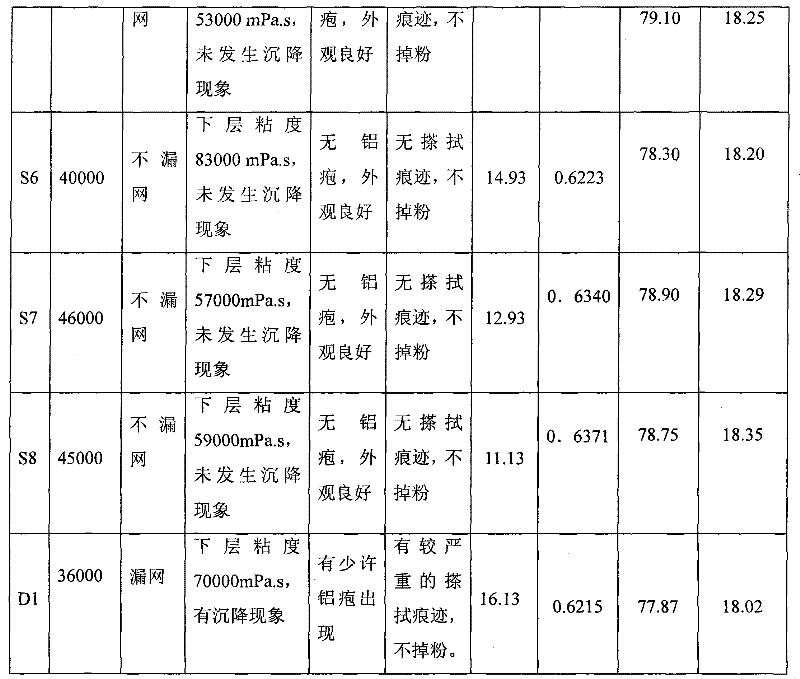

Catheter sheath for implant delivery

ActiveUS9060894B2Increase deflectionLarge radiusStentsBlood vesselsBiomedical engineeringCatheter sheath

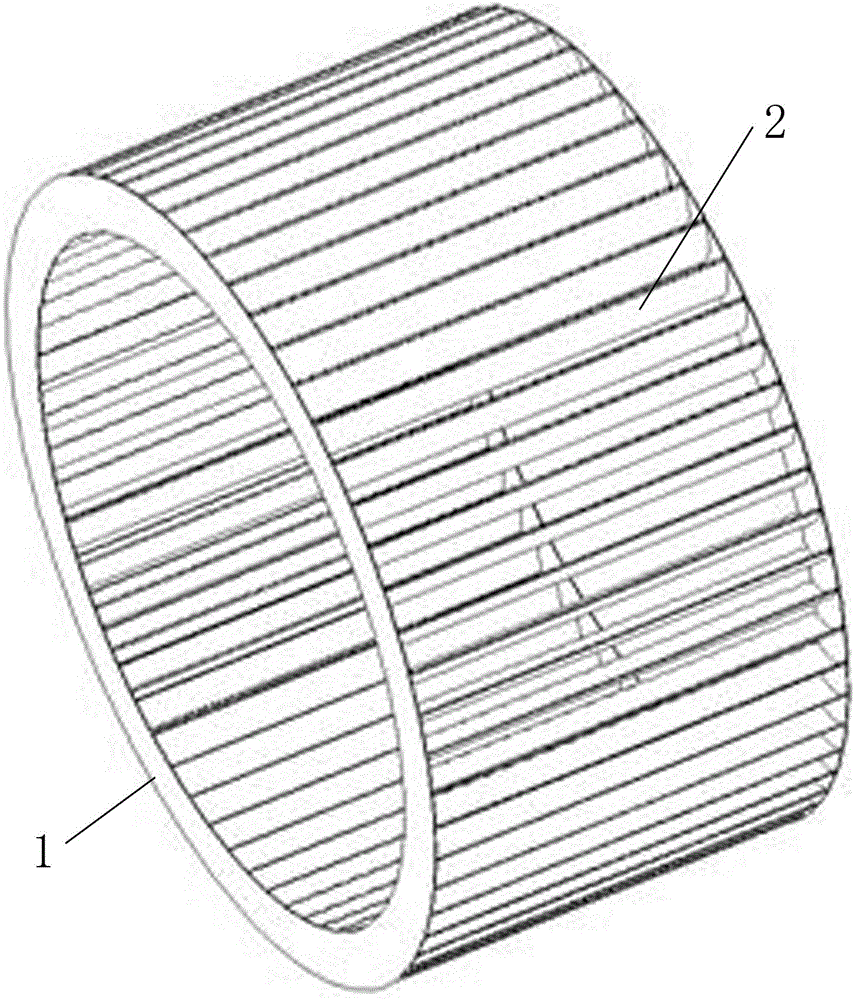

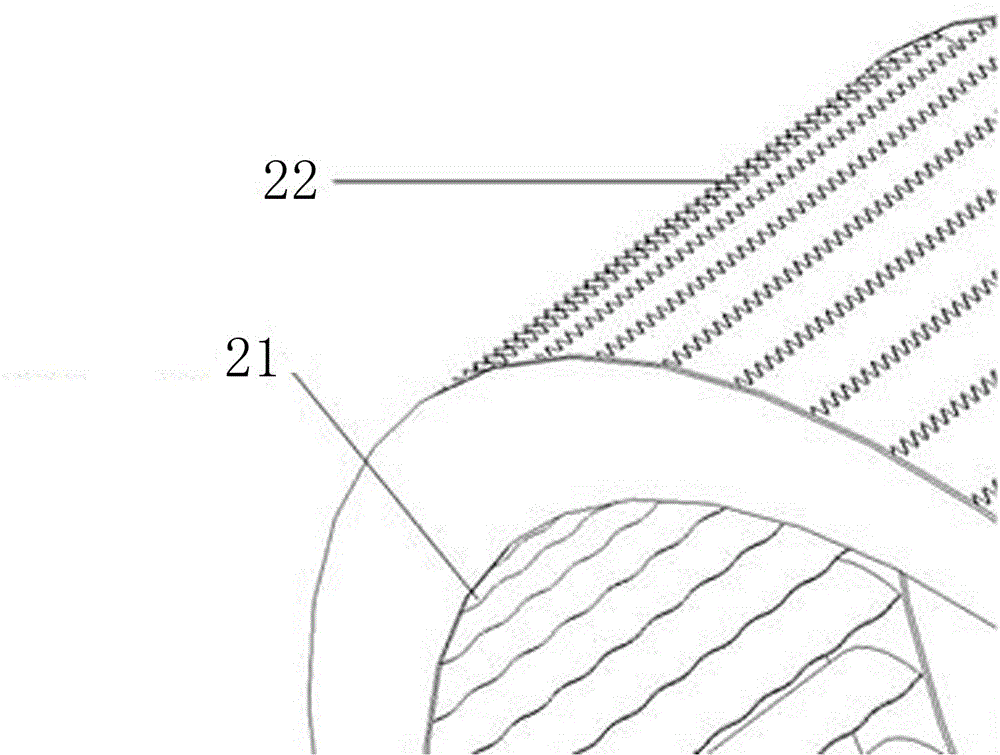

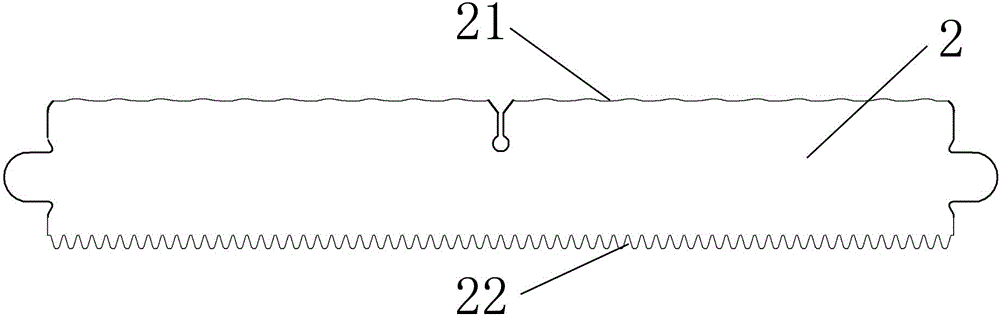

There is disclosed herein a tube of material (1) having a seam (12) extending between a proximal end and a distal end, two edges (10a, 10b) of the material meeting and at least partially overlapping along the seam (12) and being sewn together at the seam by stitches (21, 22, 24) of relatively flexible thread (20), the thread of one or more of the stitches (22, 24) passing from a first side (12a) of the overlapped edges (10a, 10b) of material, through both layers of overlapped material, crossing a relatively rigid member (30) which is disposed on a second, opposite side (12b) of the overlapped edges of material, and passing back to the first side (12a). There is further disclosed an implant delivery catheter (40) incorporating the tube of material (1), and associated methods for its manufacture.

Owner:CR BARD INC

Catheter sheath for implant delivery

ActiveUS20120022630A1Increase deflectionLarge radiusStentsLeather sewingBiomedical engineeringCatheter sheath

There is disclosed herein a tube of material (1) having a seam (12) extending between a proximal end and a distal end, two edges (10a, 10b) of the material meeting and at least partially overlapping along the seam (12) and being sewn together at the seam by stitches (21, 22, 24) of relatively flexible thread (20), the thread of one or more of the stitches (22, 24) passing from a first side (12a) of the overlapped edges (10a, 10b) of material, through both layers of overlapped material, crossing a relatively rigid member (30) which is disposed on a second, opposite side (12b) of the overlapped edges of material, and passing back to the first side (12a). There is further disclosed an implant delivery catheter (40) incorporating the tube of material (1), and associated methods for its manufacture.

Owner:CR BARD INC

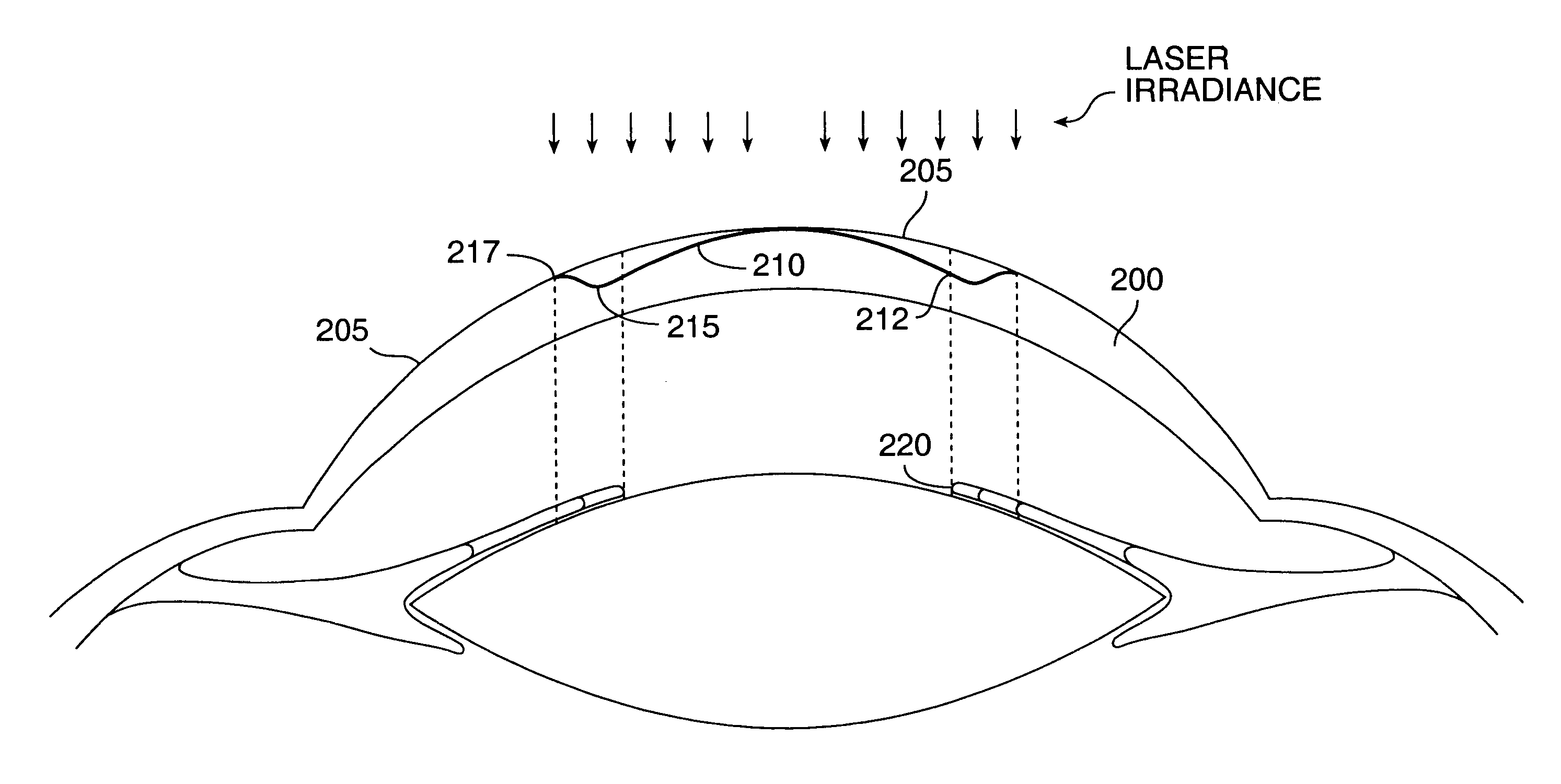

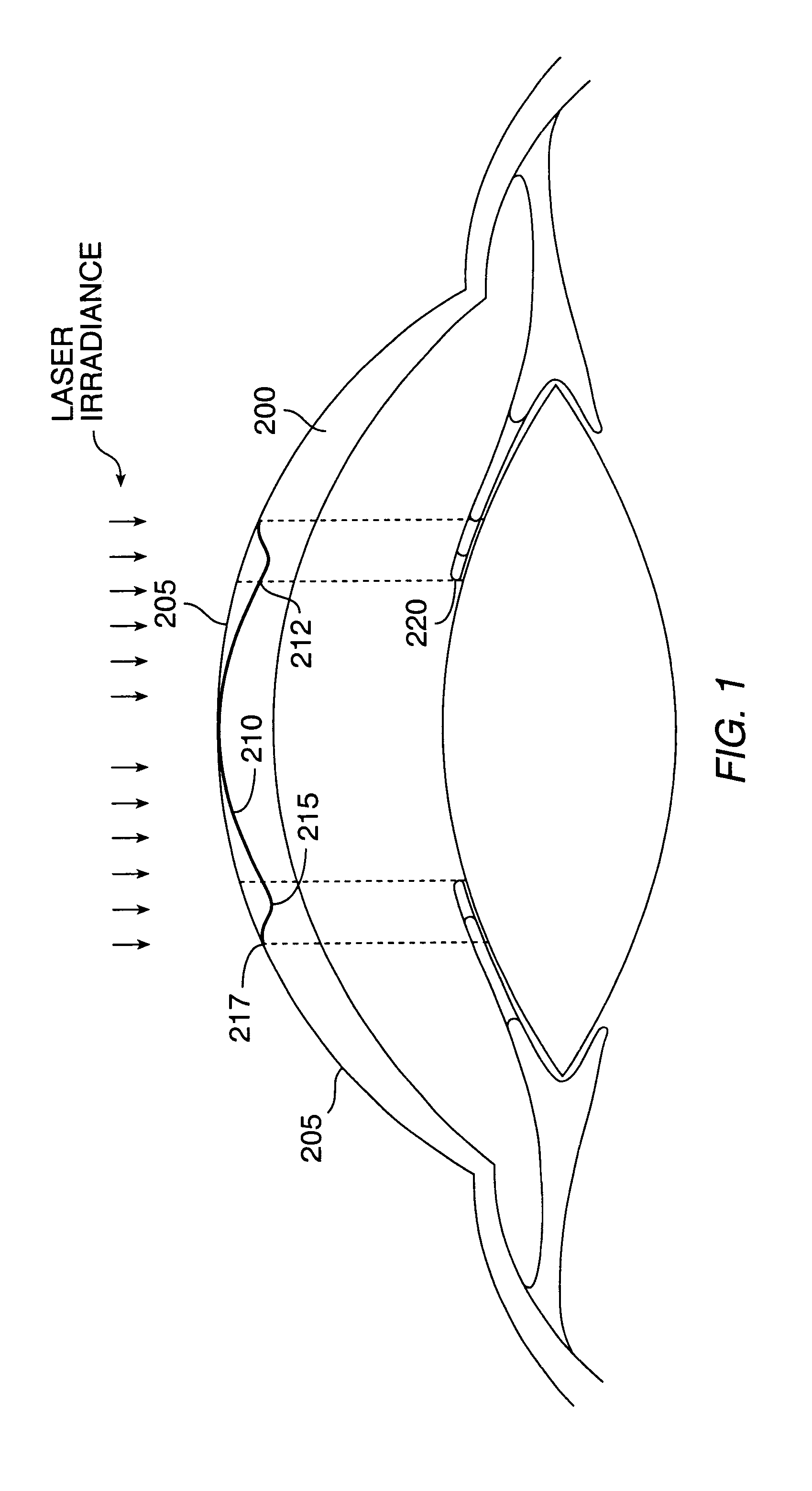

Method and systems for laser treatment of presbyopia using offset imaging

InactiveUS6280435B1Less attractiveReduce discontinuityLaser surgerySurgical instrument detailsWide areaHyperopic astigmatism

Owner:AMO MFG USA INC

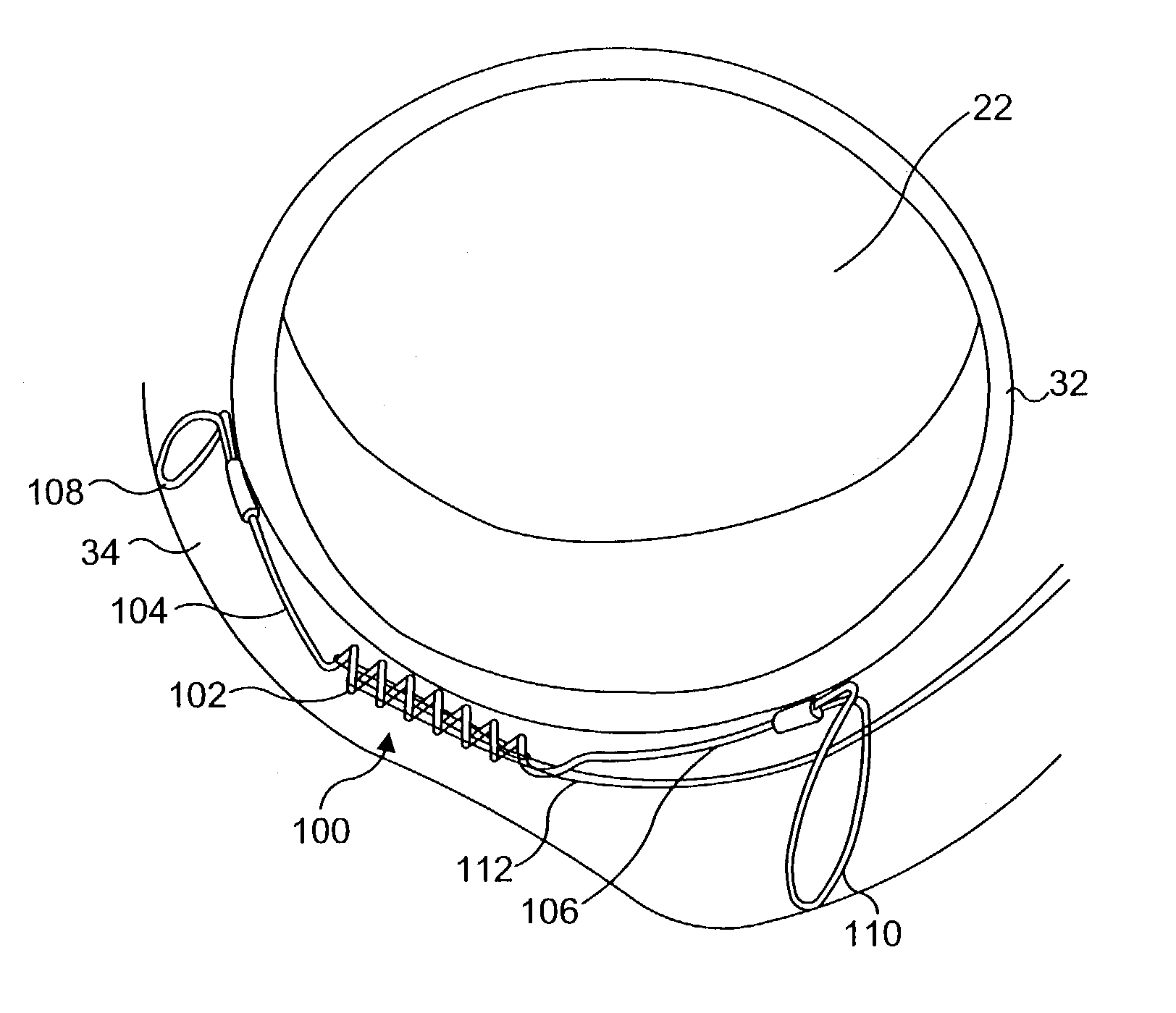

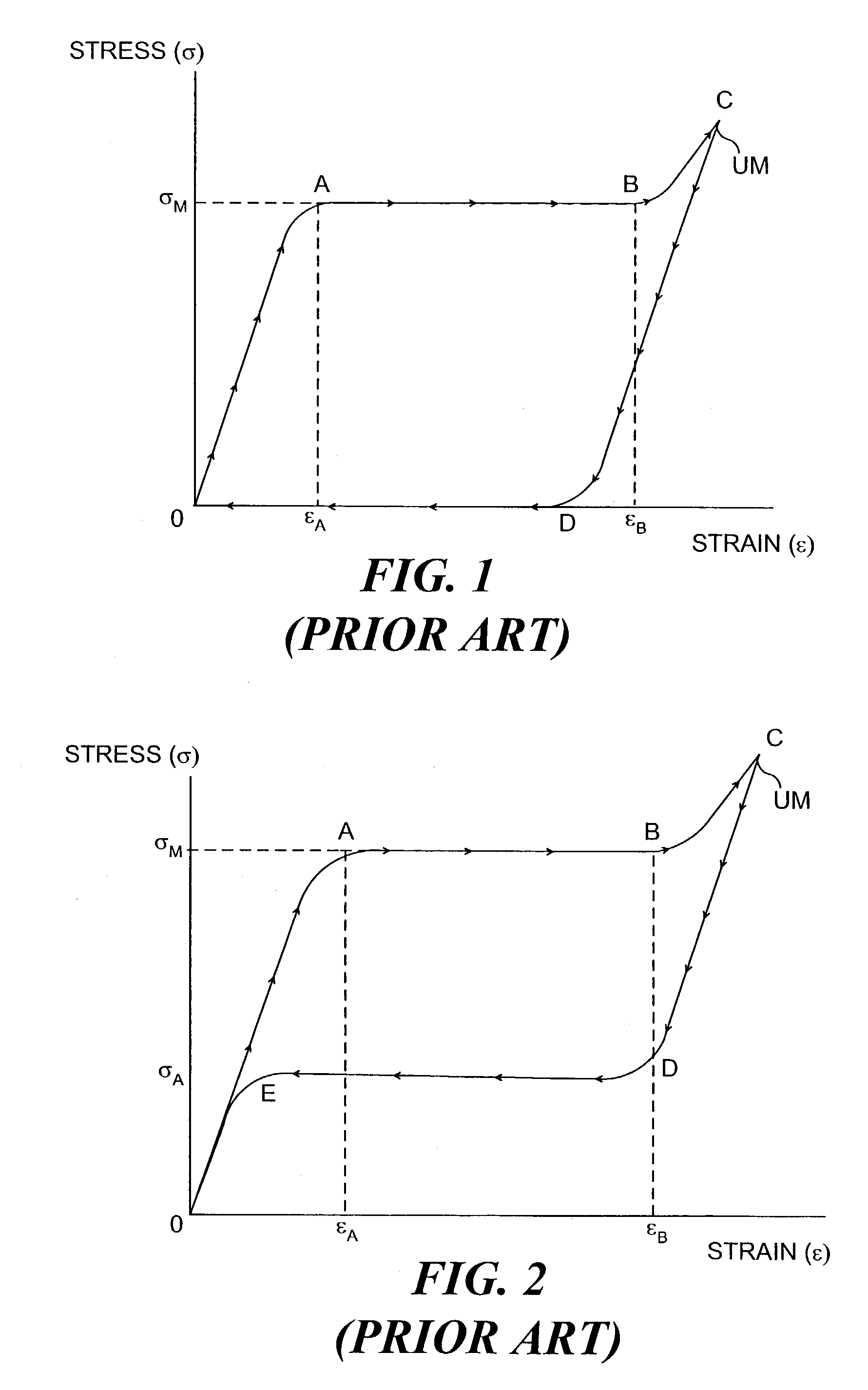

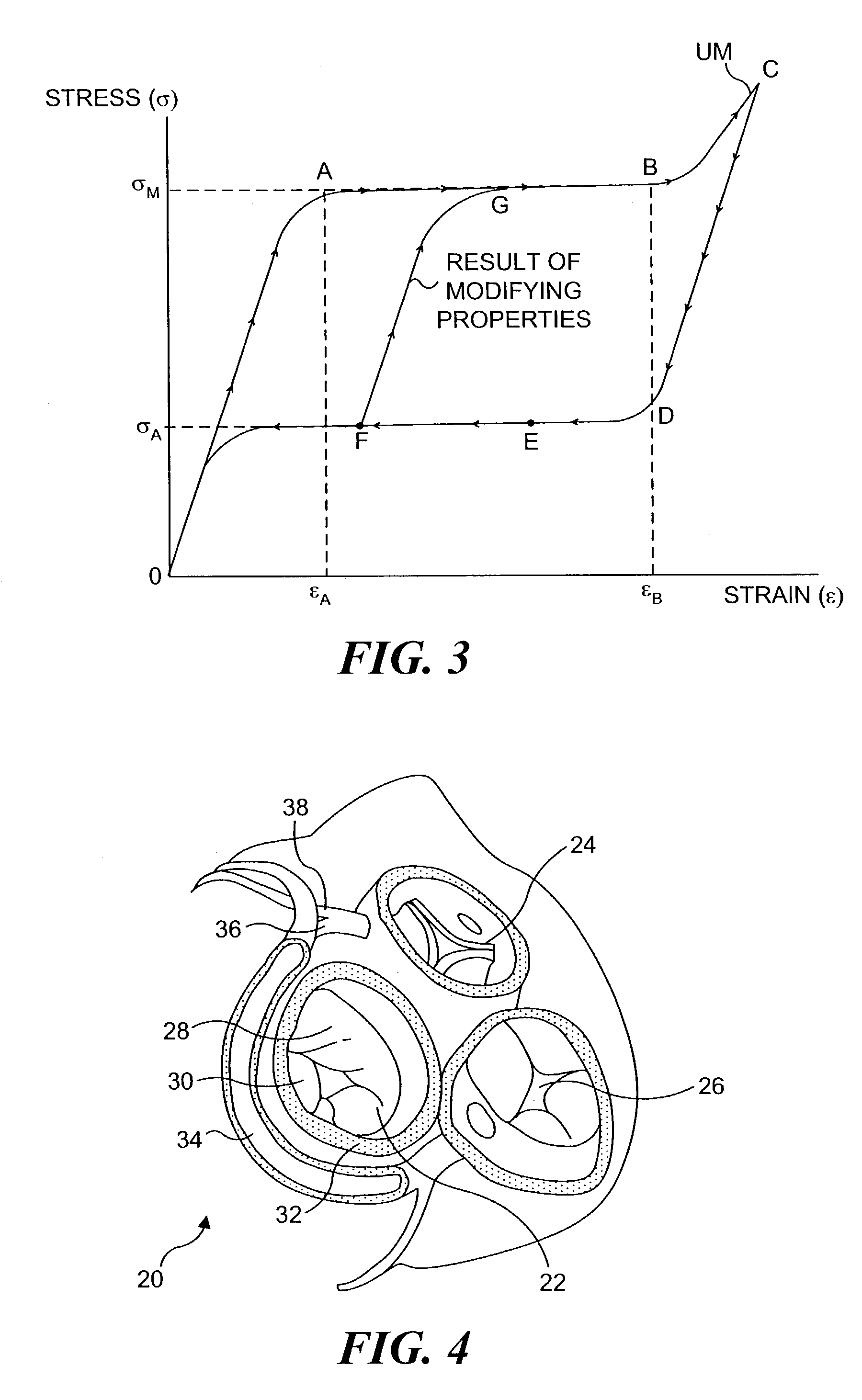

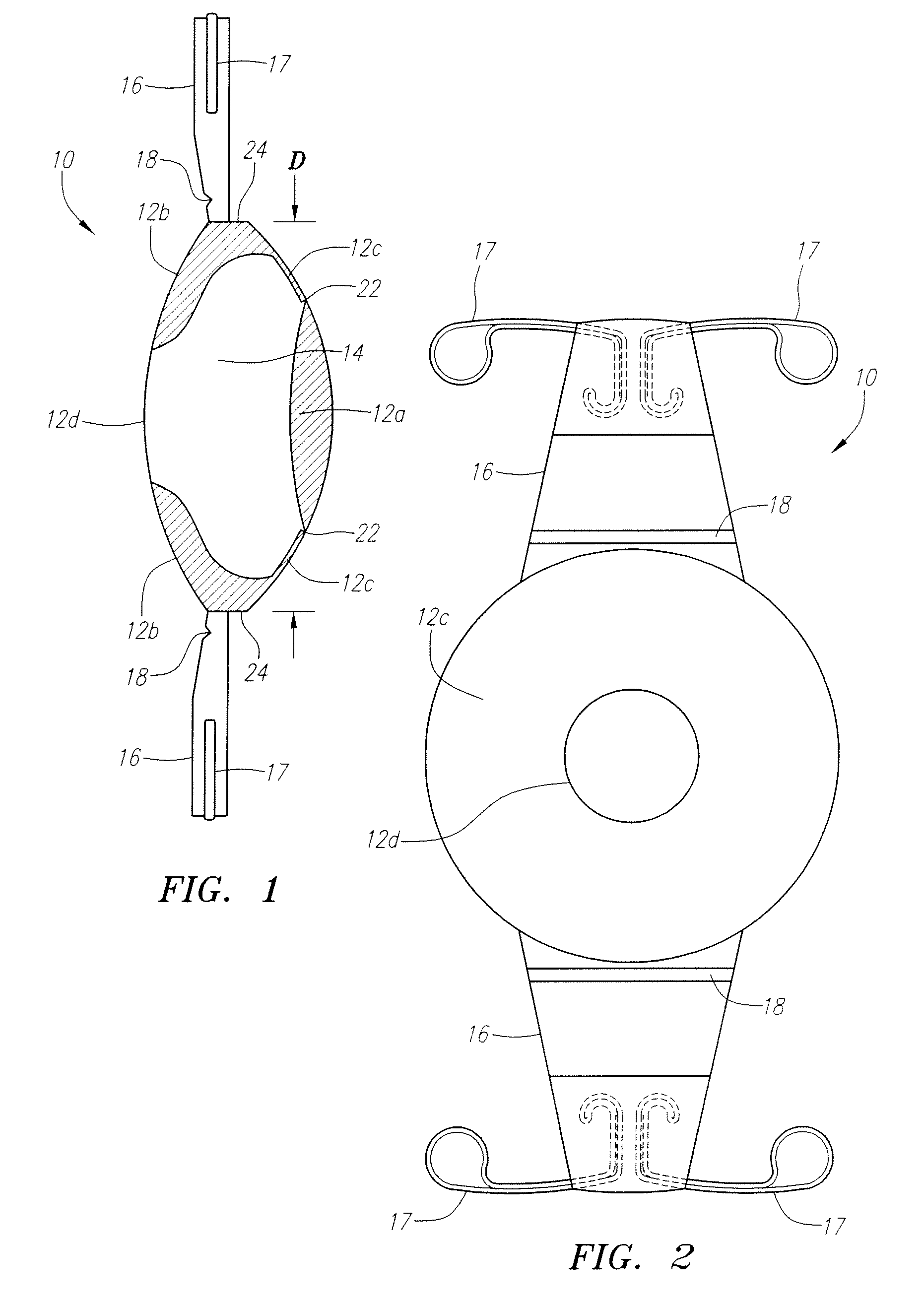

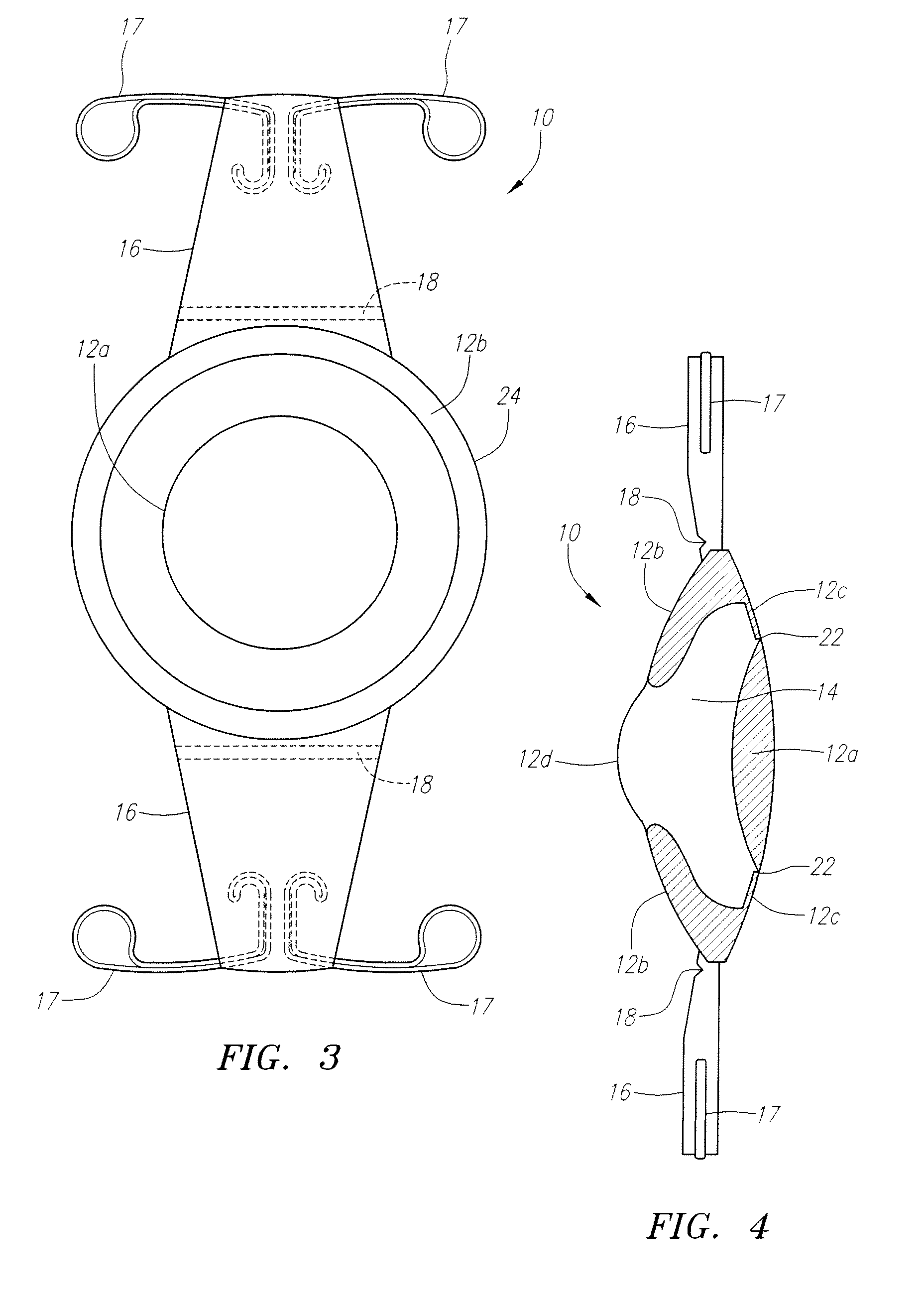

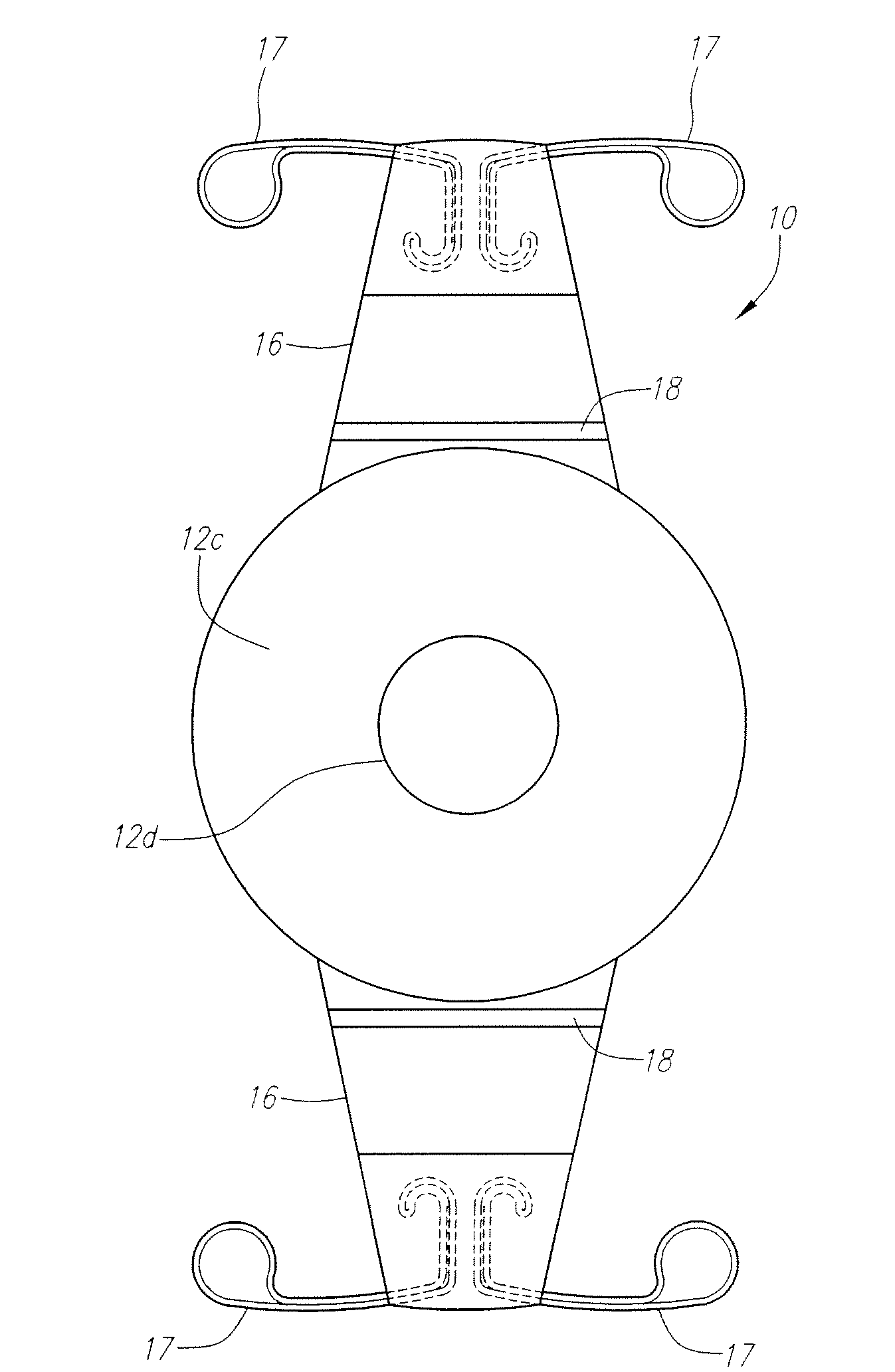

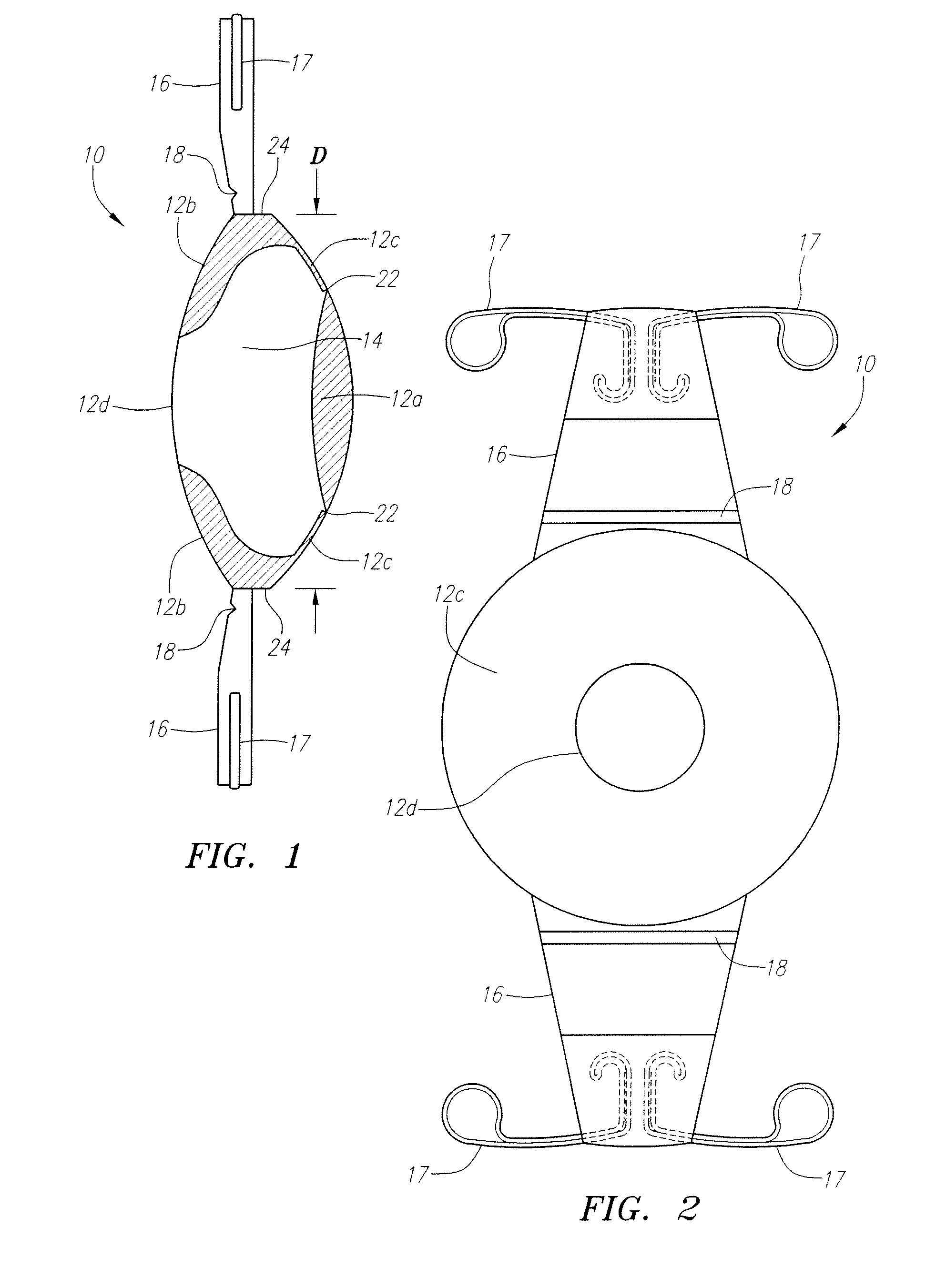

Mitral valve device using conditioned shape memory alloy

A mitral valve annulus reshaping device includes at least a portion that is formed of a biocompatible shape memory alloy SMA having a characteristic temperature, Af, that is preferably below body temperature. The device is constrained in an unstable martensite (UM) state while being introduced through a catheter that passes through the venous system and into the coronary sinus of the heart. The reshaping device is deployed adjacent to the mitral valve annulus of the heart as it is forced from the catheter. When released from the constraint of the catheter, the SMA of the device at least partially converts from the UM state to an austenitic state and attempts to change to a programmed shape that exerts a force on the adjacent tissue and modifies the shape of the annulus. The strain of the SMA can be varied when the device is within the coronary sinus.

Owner:CARDIAC DIMENSIONS

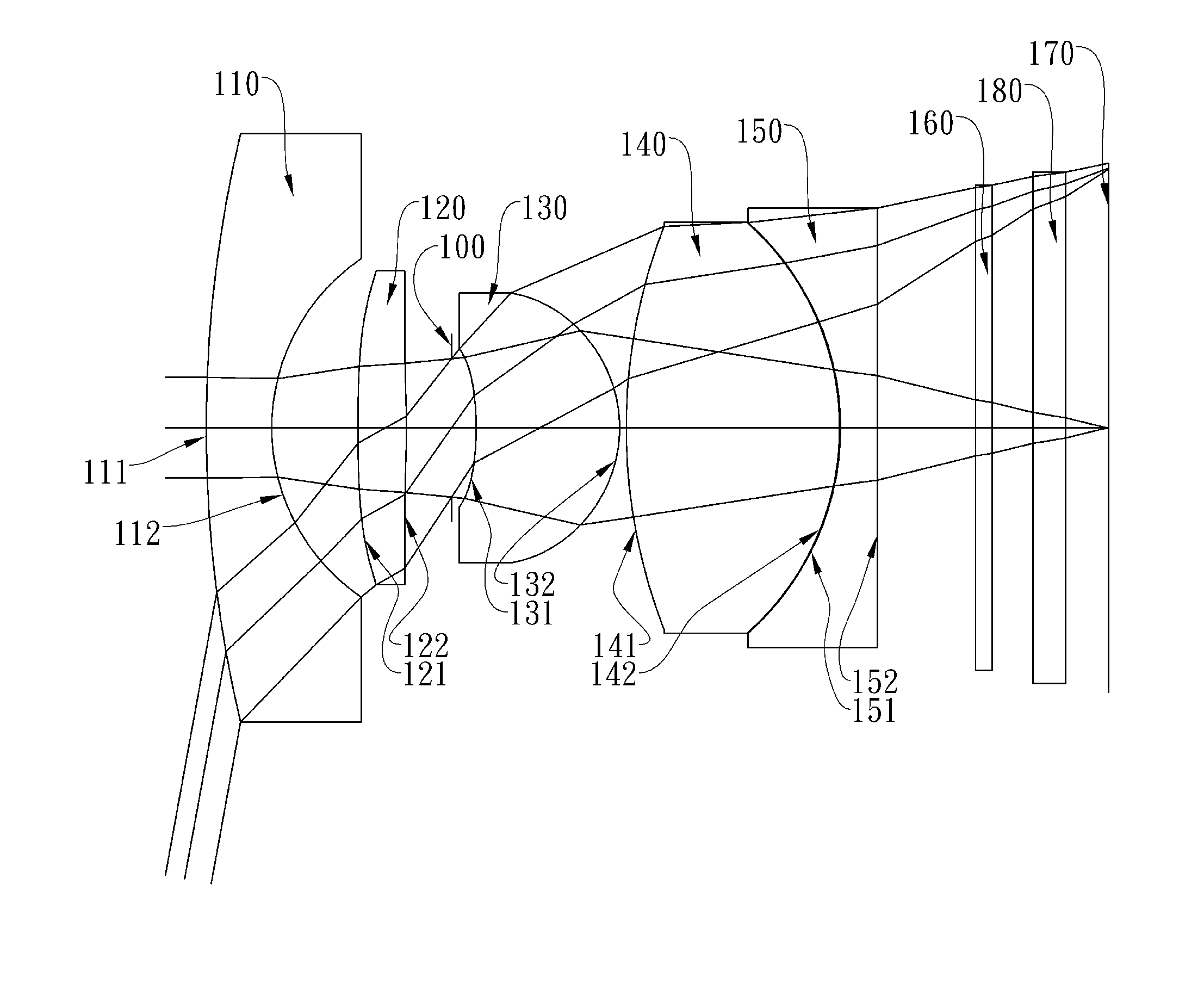

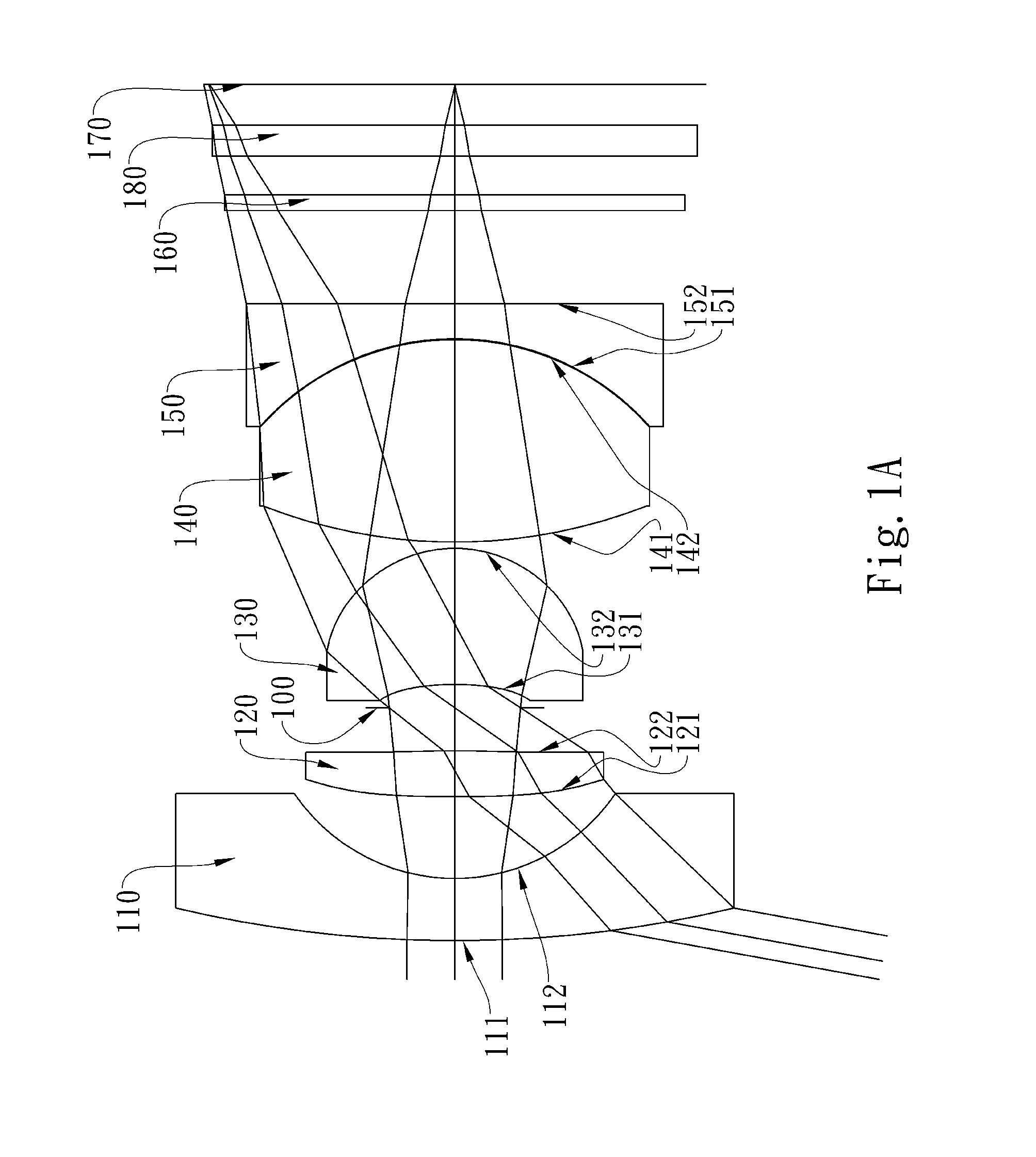

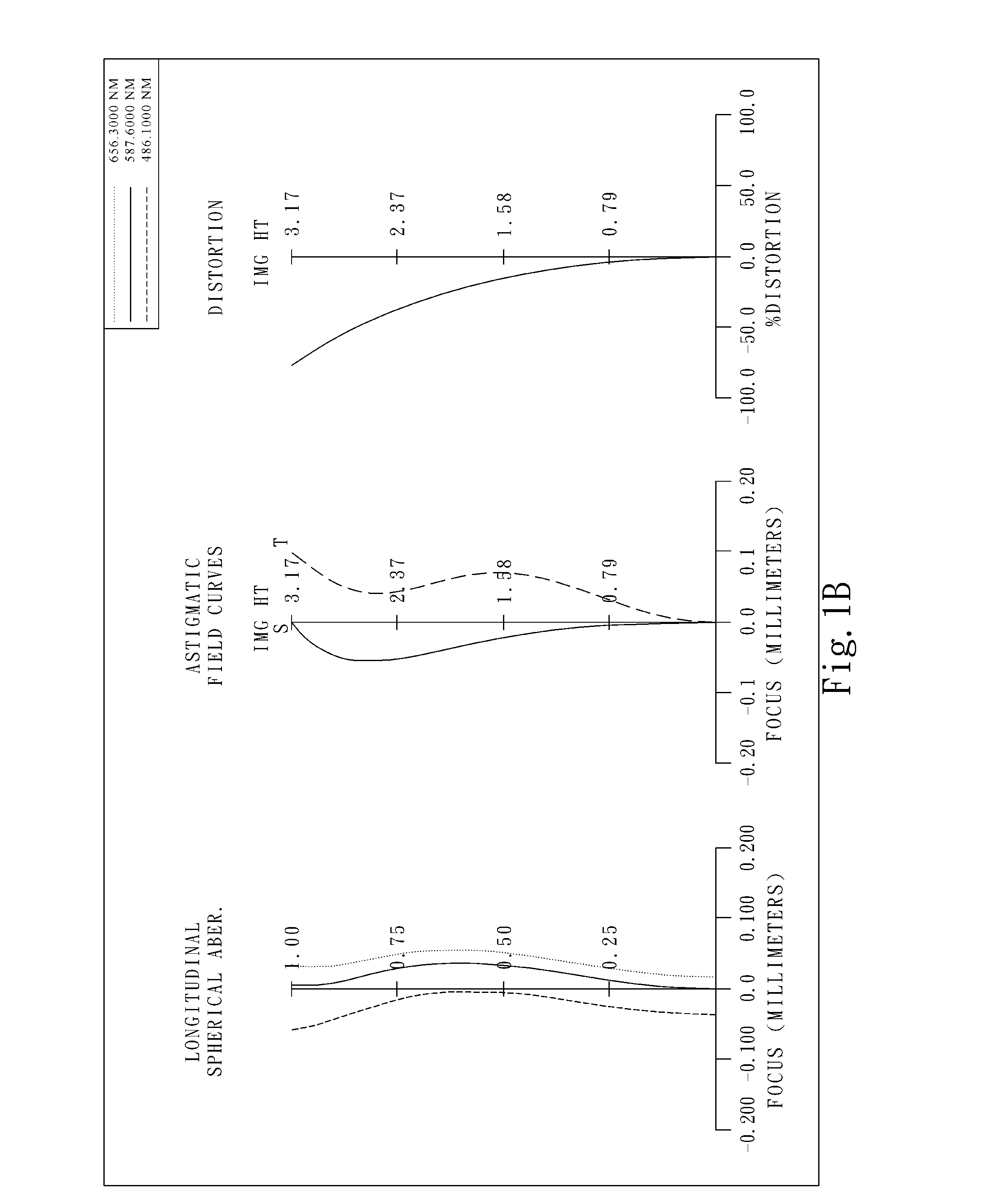

Wide-viewing-angle imaging lens assembly

ActiveUS20110316969A1Expand field of viewReduce sensitivityTelevision system detailsColor television detailsImaging lensField of view

The present invention provides a wide-viewing-angle imaging lens assembly comprising, in order from an object side to an image side: a front lens group, a stop, and a rear lens group. The front lens group comprises, in order from the object side to the image side: a first lens element with negative refractive power having a concave image-side surface and a second lens element. The rear lens group comprises, in order from the object side to the image side: a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, a fourth lens element with positive refractive power having a convex object-side surface and a convex image-side surface, and a fifth lens element with negative refractive power having a concave object-side surface. Such an arrangement of optical elements can effectively enlarge the field of view of the wide-viewing-angle imaging lens assembly, reduce the sensitivity of the optical system, and obtain good image quality.

Owner:LARGAN PRECISION

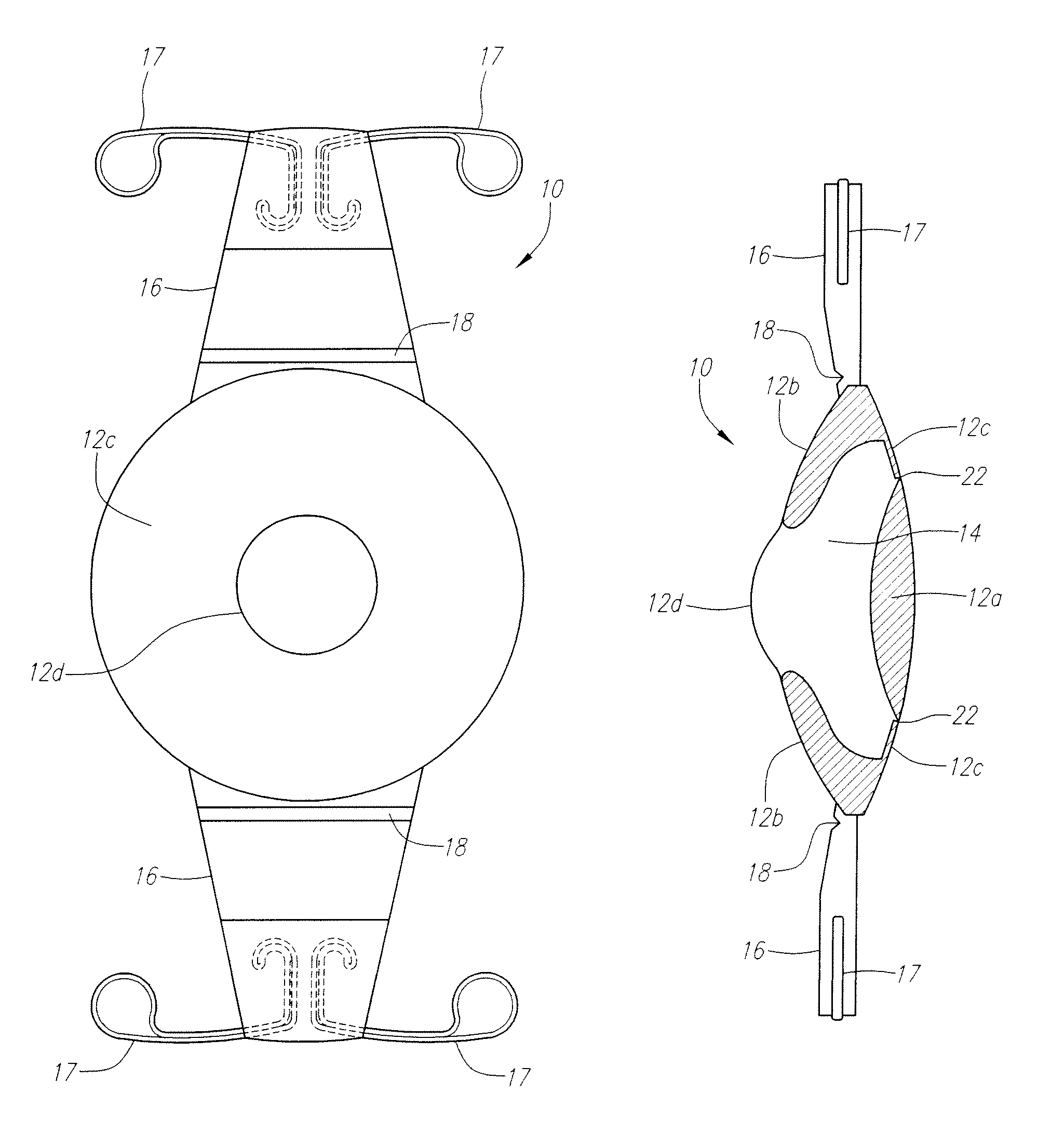

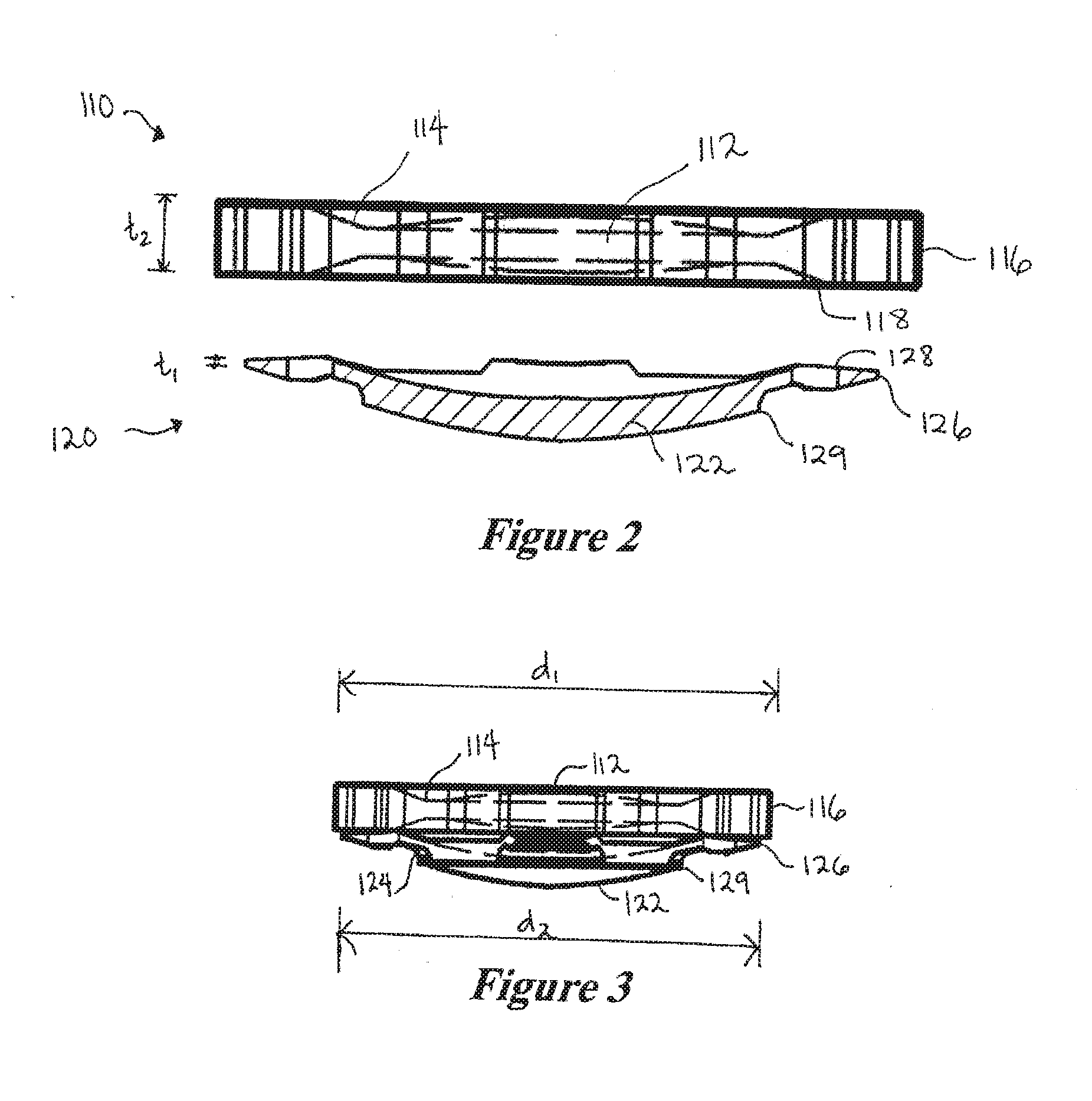

Hydrolic accommodating intraocular lens

An accommodating intraocular lens comprising an optic made from solid silicone and liquid silicone. The optic has a central anterior area or membrane that can vary in radius and thus charge power.

Owner:C& C VISION INT

Hydrolic accommodating intraocular lens

An accommodating intraocular lens comprising an optic made from solid silicone and liquid silicone. The optic has a central anterior area or membrane that can vary in radius and thus charge power.

Owner:C& C VISION INT

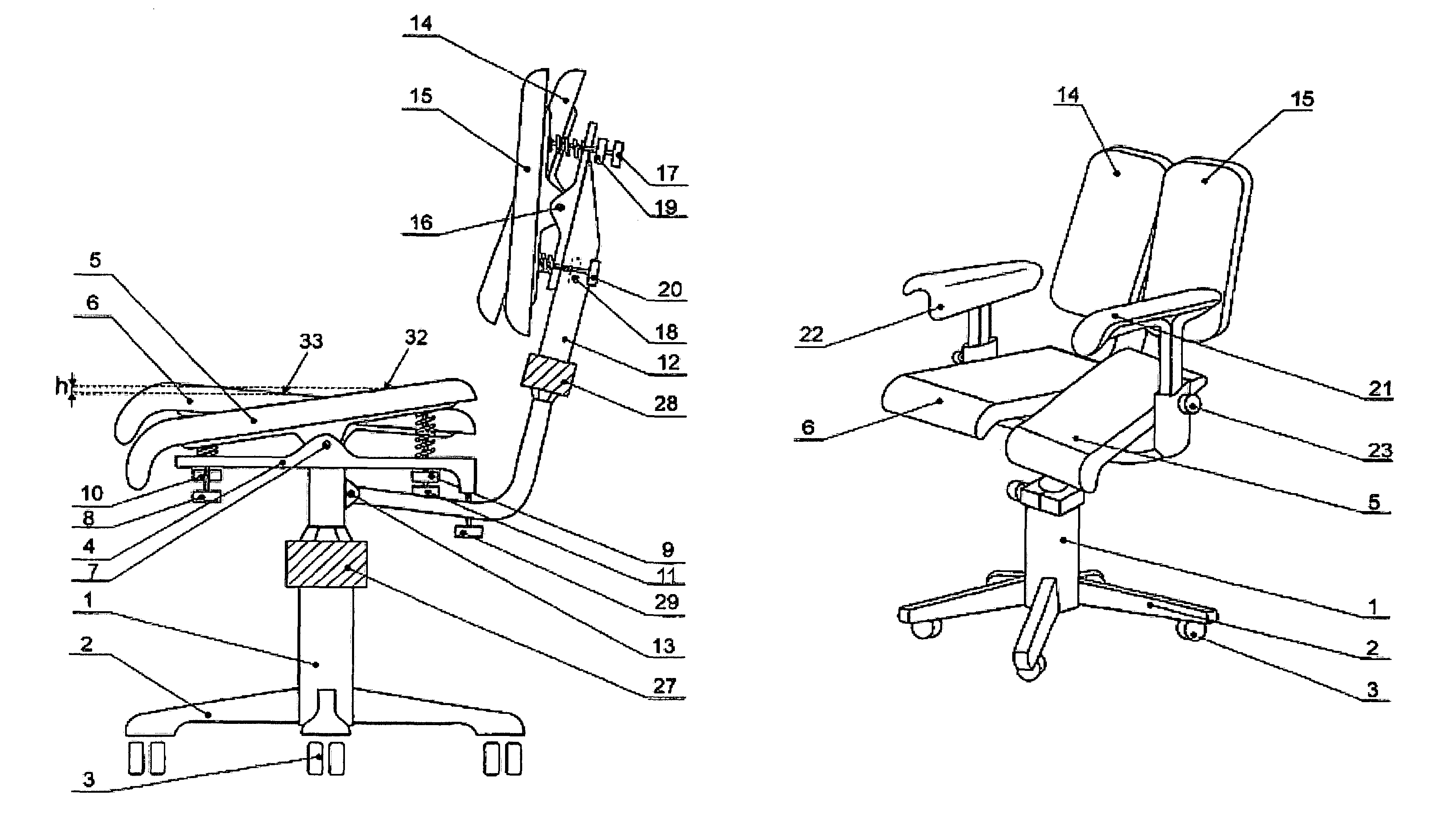

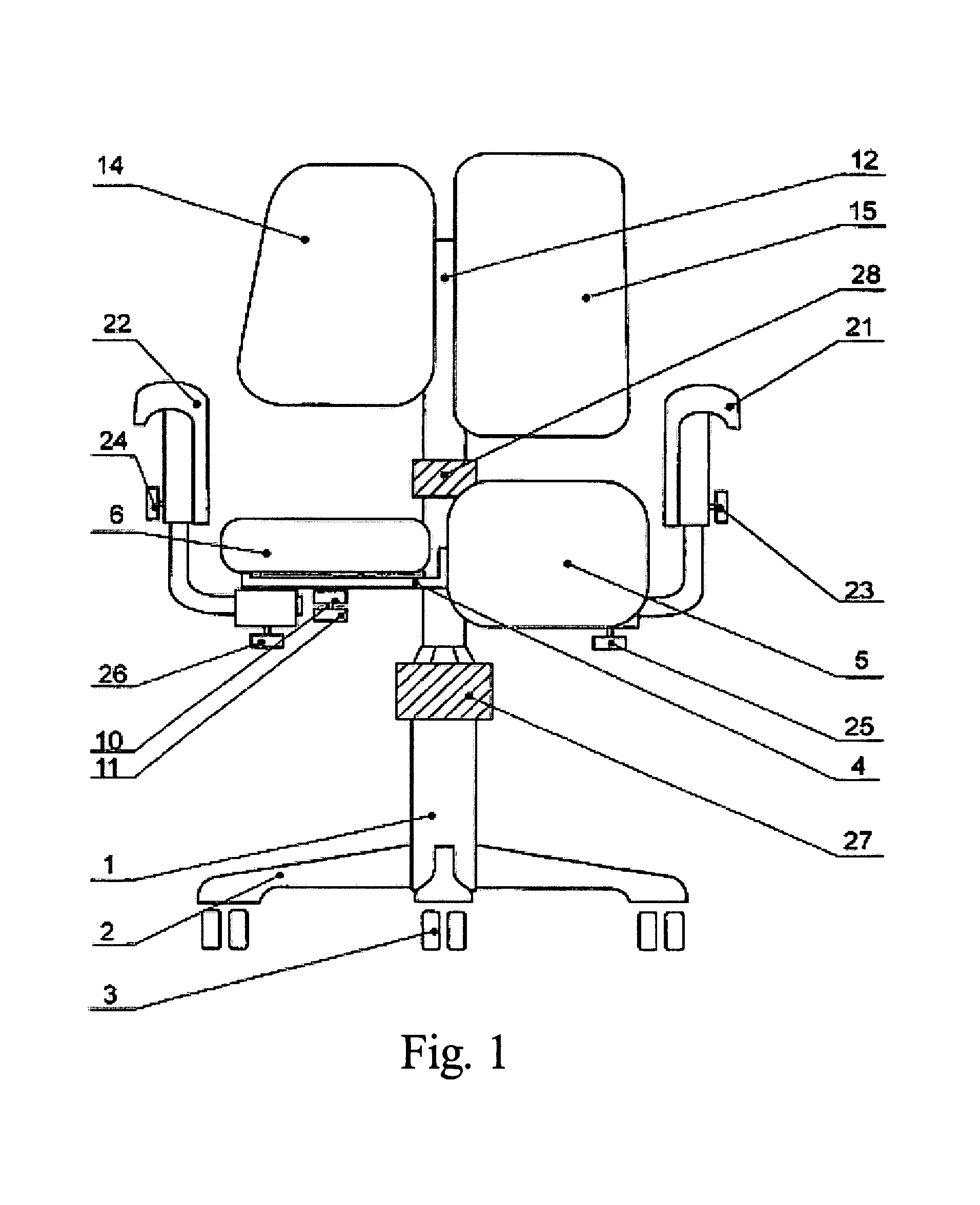

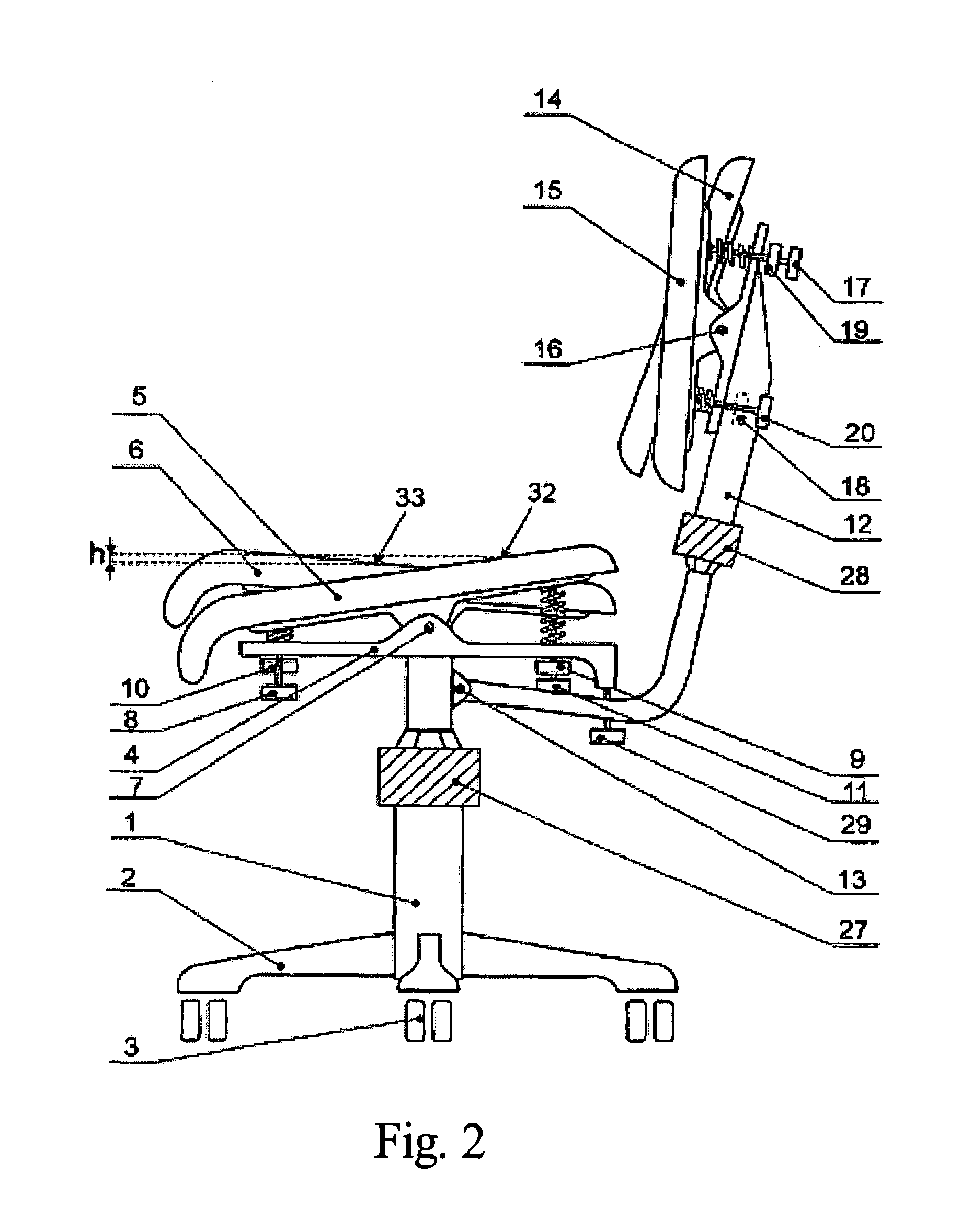

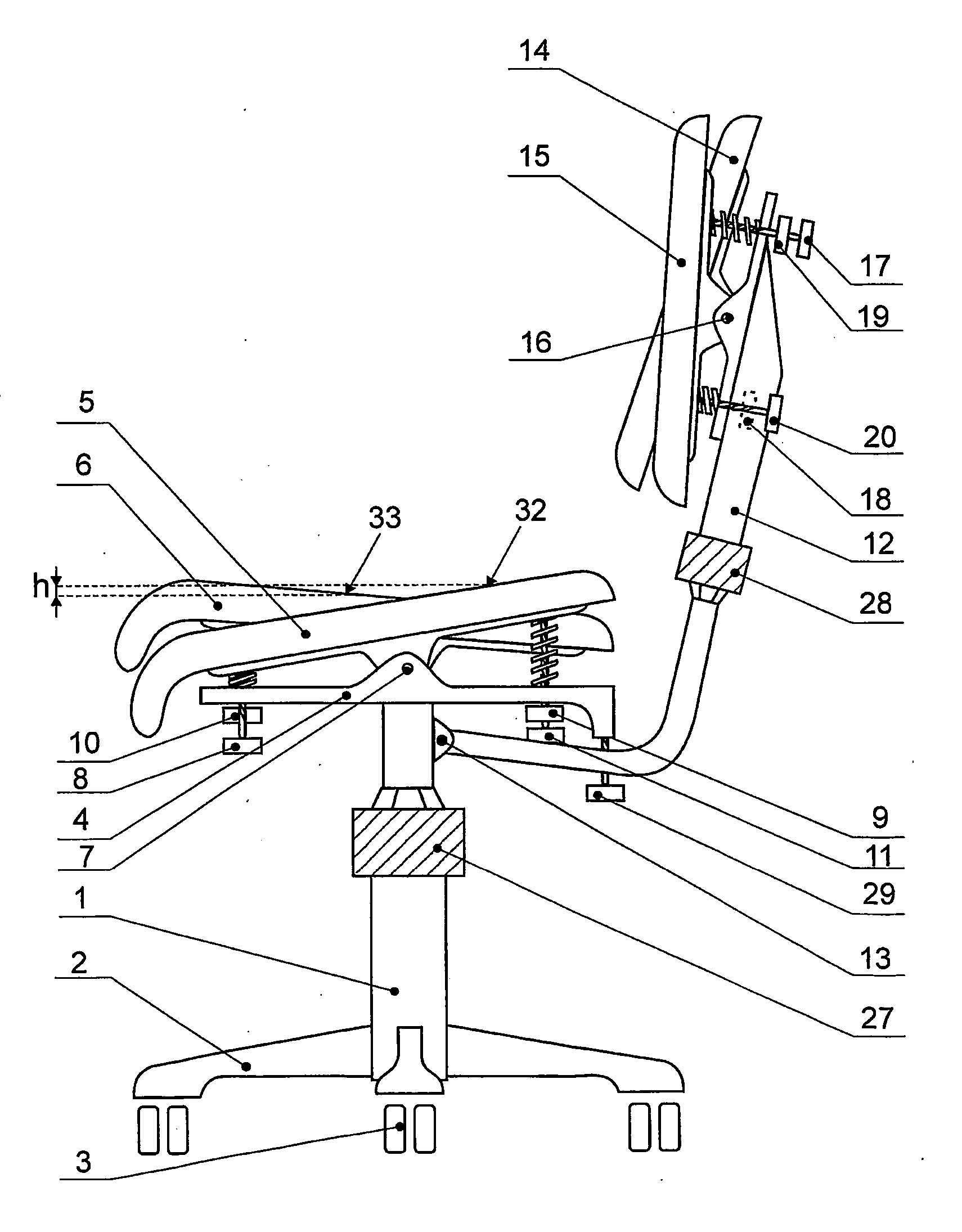

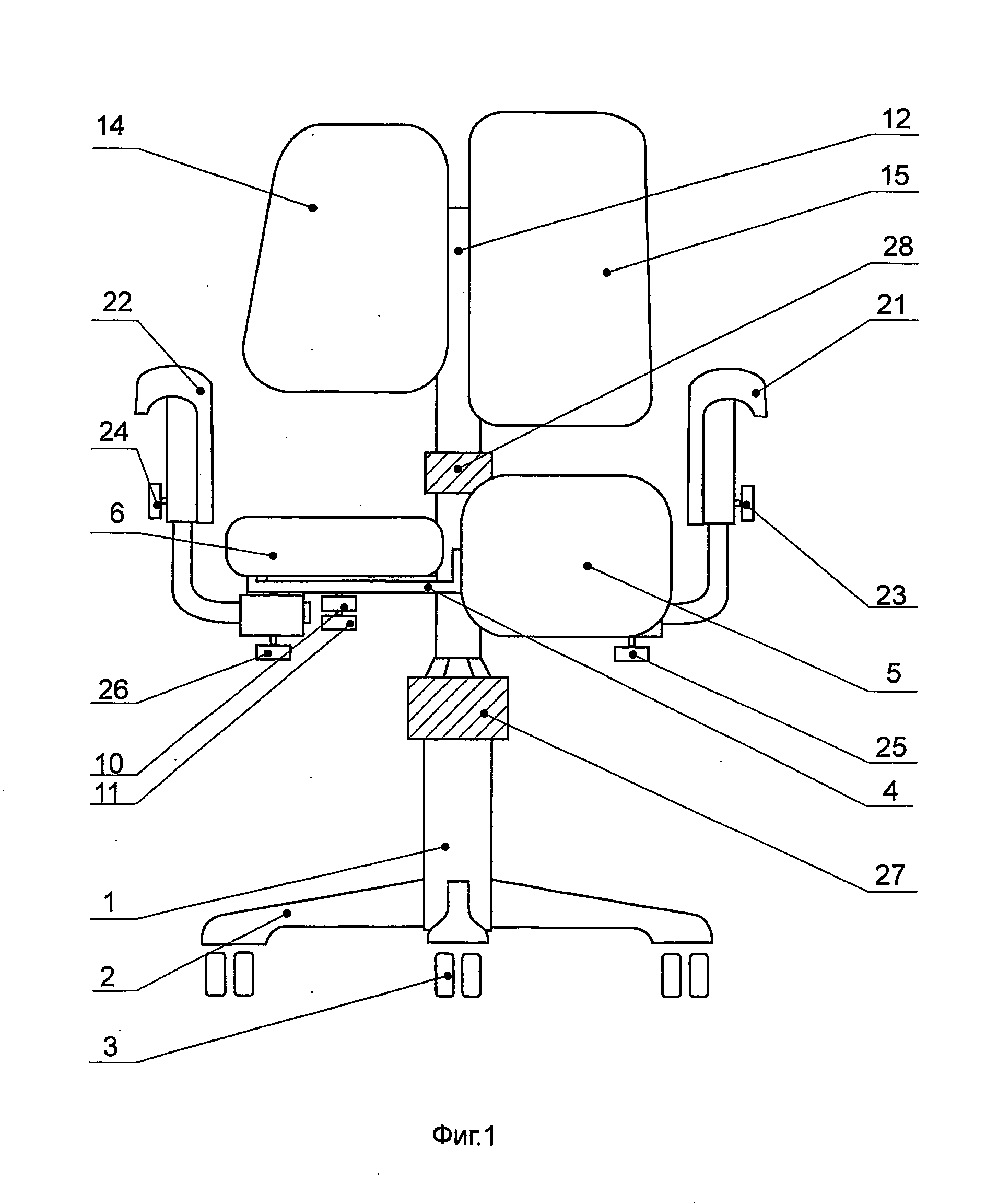

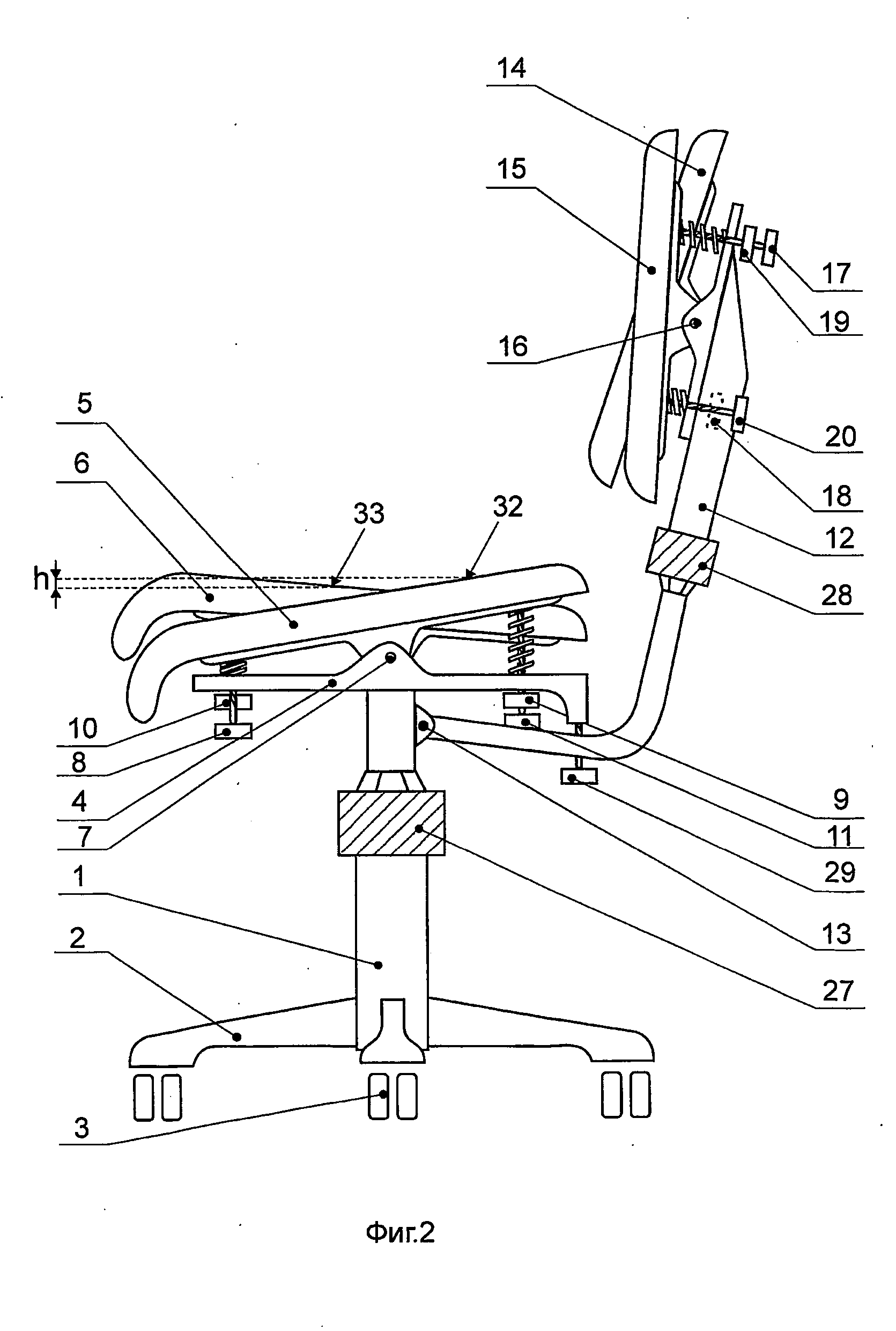

Sitting device

InactiveUS7387339B2Efficiently relievedIncrease the curvatureOperating chairsDental chairsPhysical medicine and rehabilitationHorizontal axis

The invention relates to furniture, in particular to sitting devices and can be used as a work chair or therapeutic furniture.The aim of said invention is to develop a sitting device which would make it possible to efficiently relieve the backbone in a sitting posture taking into consideration individual morphological and functional asymmetries, thereby normalizing the work of other organs and systems of an organism, first and foremost the organs of the small pelvis, optimizing the “turtuosity” of the backbone associated with constitutional and geophysical factors.The sitting device comprises a support provided with a base in a top part thereof, on which a seat is mounted; said seat consists of two parts pivotally arranged on a horizontal axis which lies on a frontal plane and is fixed to the base, each part of the seat being provided with adjusters of the rotational motion thereof with respect to the horizontal axis; the device can be provided with a back and a bracket bearing a backrest, comprising two supporting elements pivotally arranged on the horizontal axis which lies on the frontal plane and fixed to the bracket, each supporting element of the backrest being provided with adjusters of the rotational motion thereof with respect to the horizontal axis.

Owner:ALFA +1

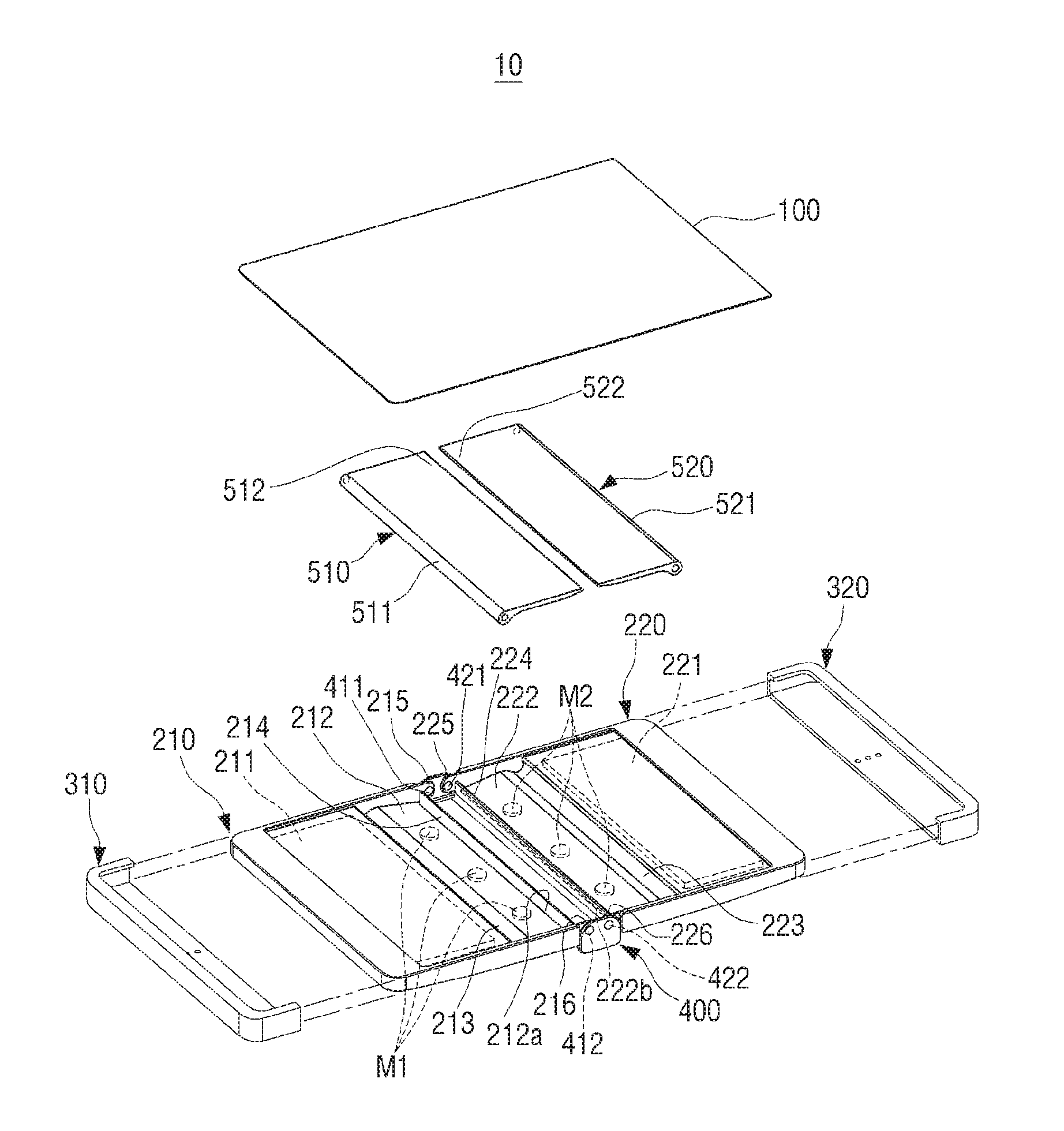

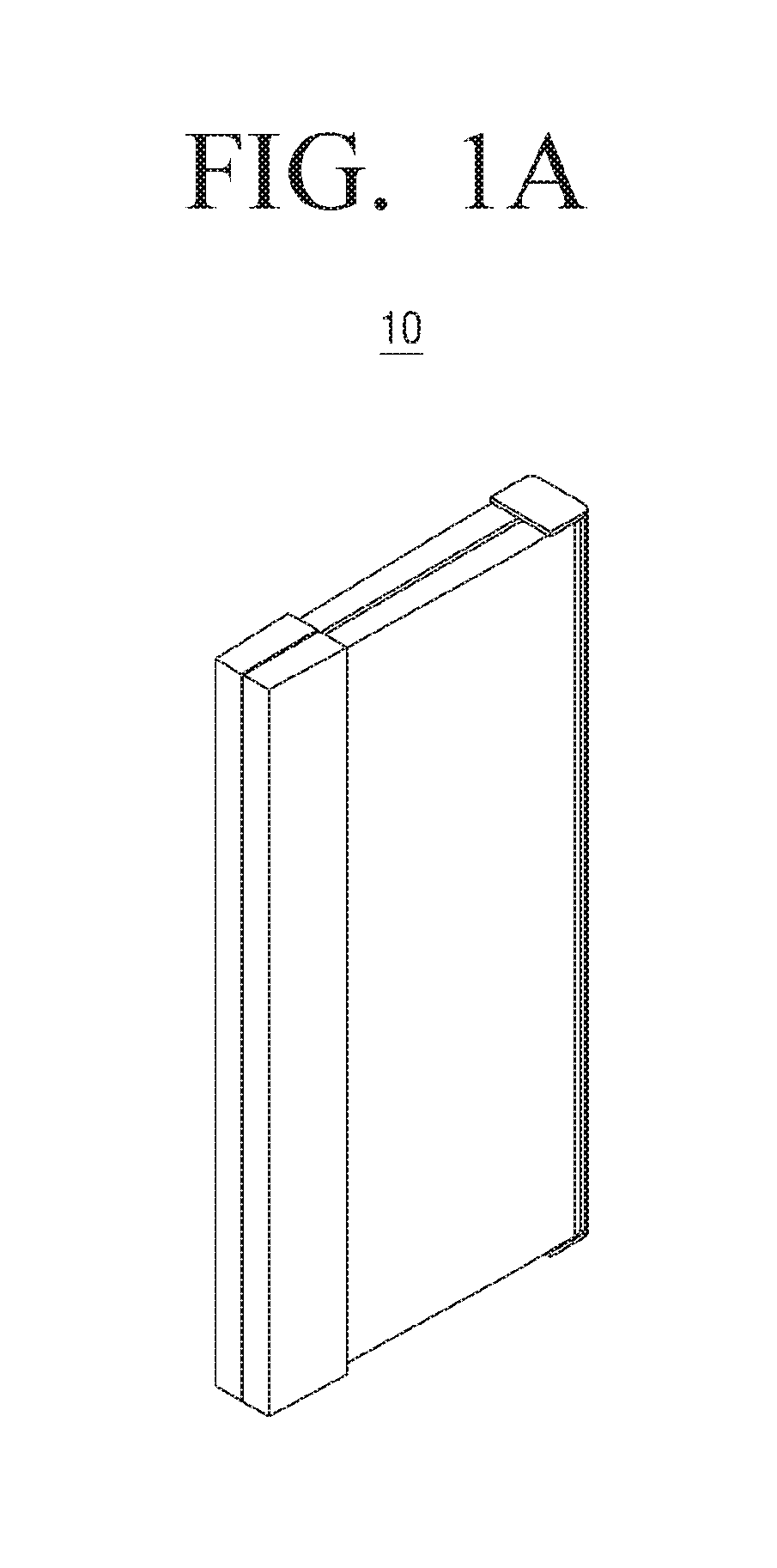

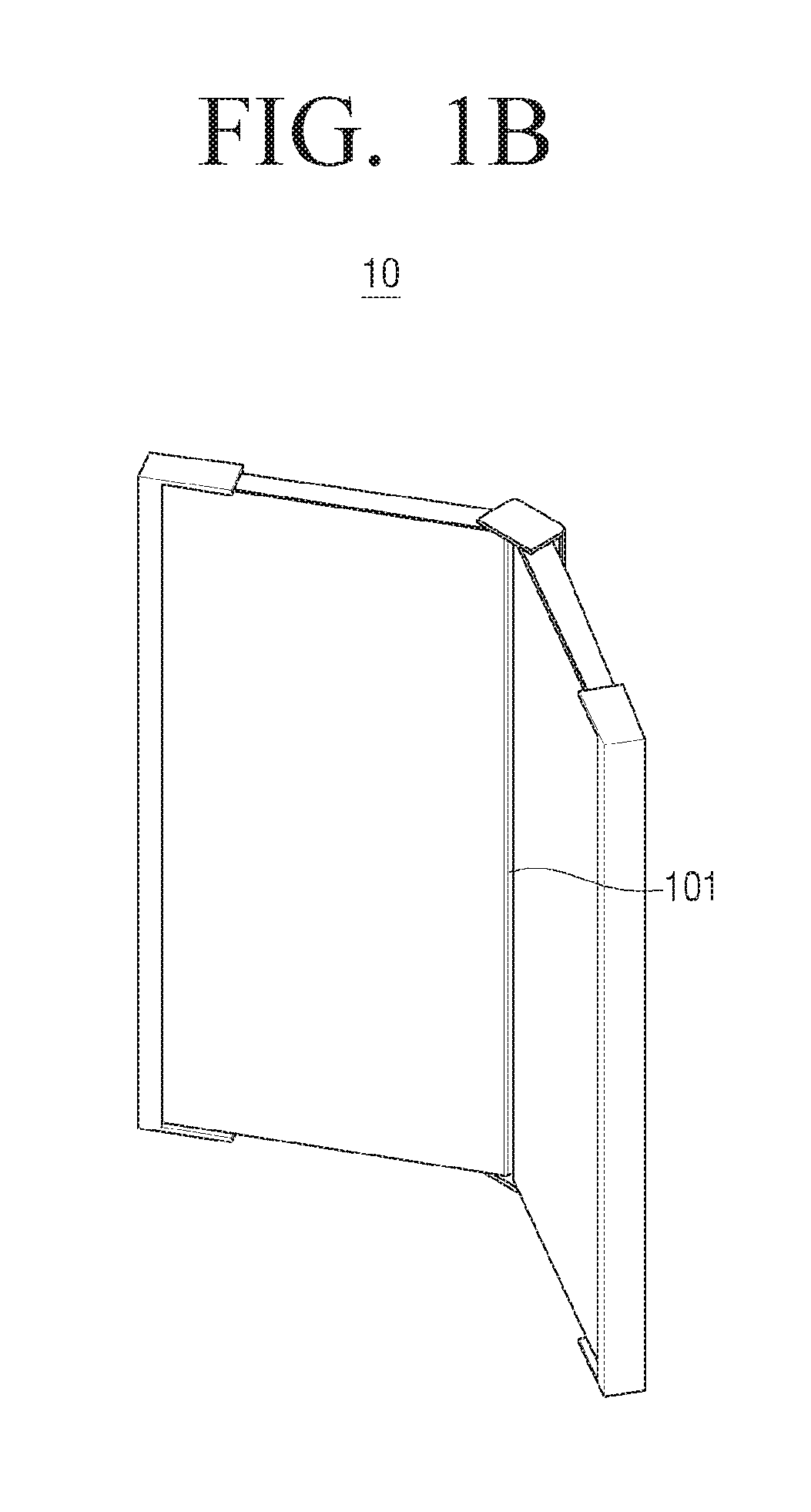

Foldable electronic apparatus having display panel with variable curvature

ActiveUS20160378203A1Improve usabilityCurvature of the flexible display panel may decreaseCathode-ray tube indicatorsSubstation equipmentEngineeringFlexible display

A foldable electronic apparatus includes a flexible display panel, a first cover and a second cover configured to support a rear surface of the flexible display panel and be interconnected by a hinge member, and a first slider and a second slider configured to be installed on the first cover and the second cover and vary a curvature of the flexible display panel by an operation of sliding along the first cover and the second cover, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

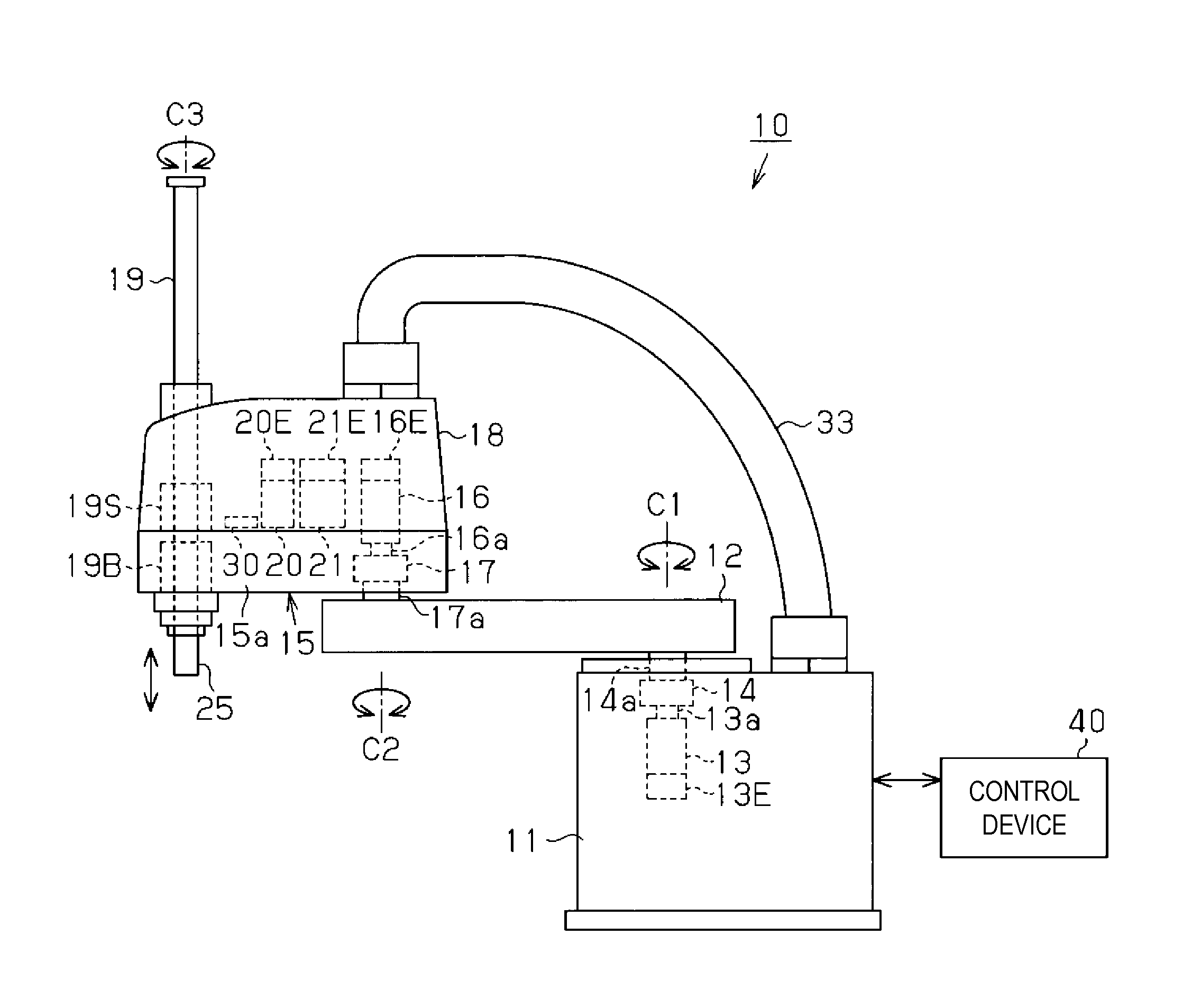

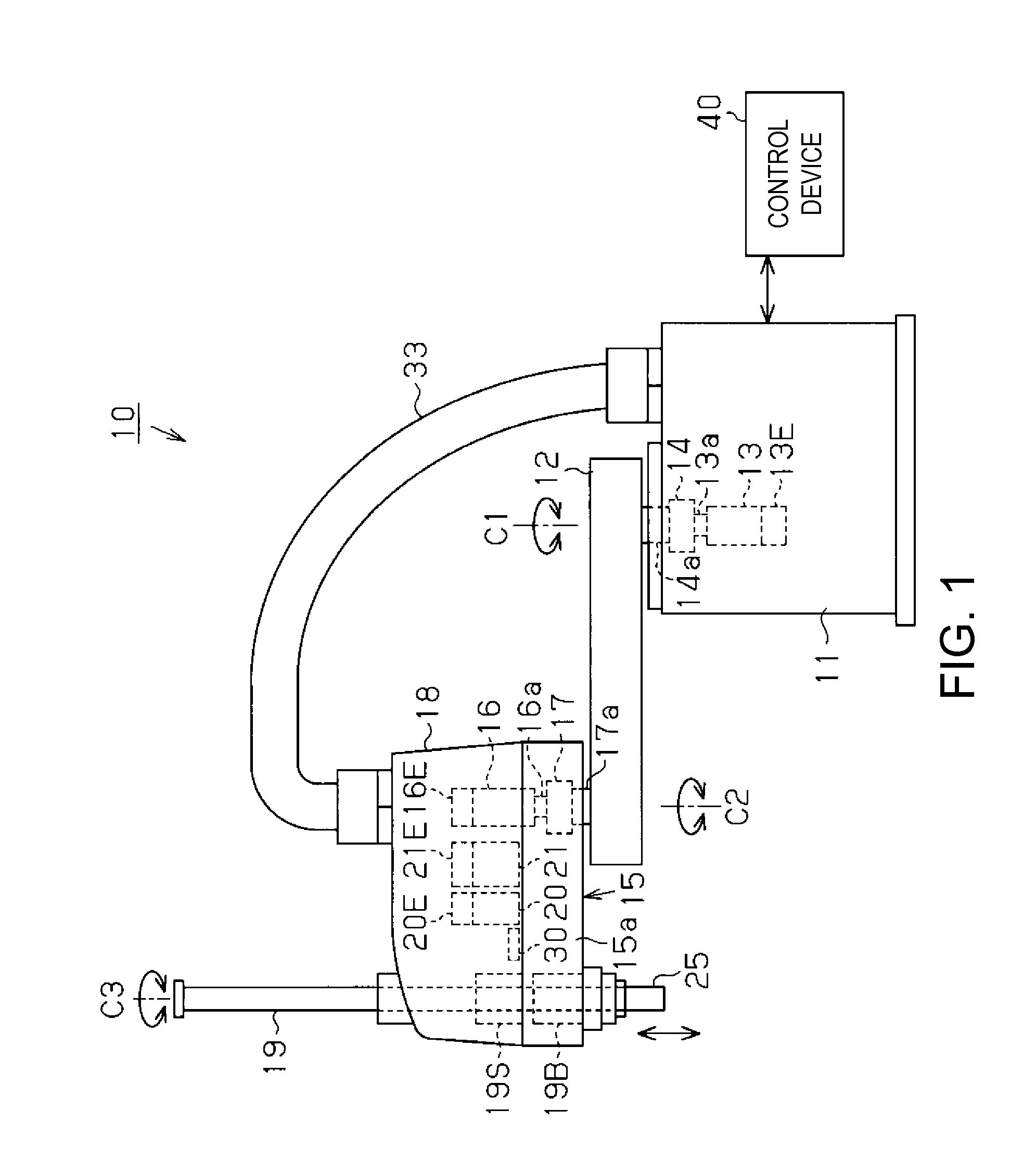

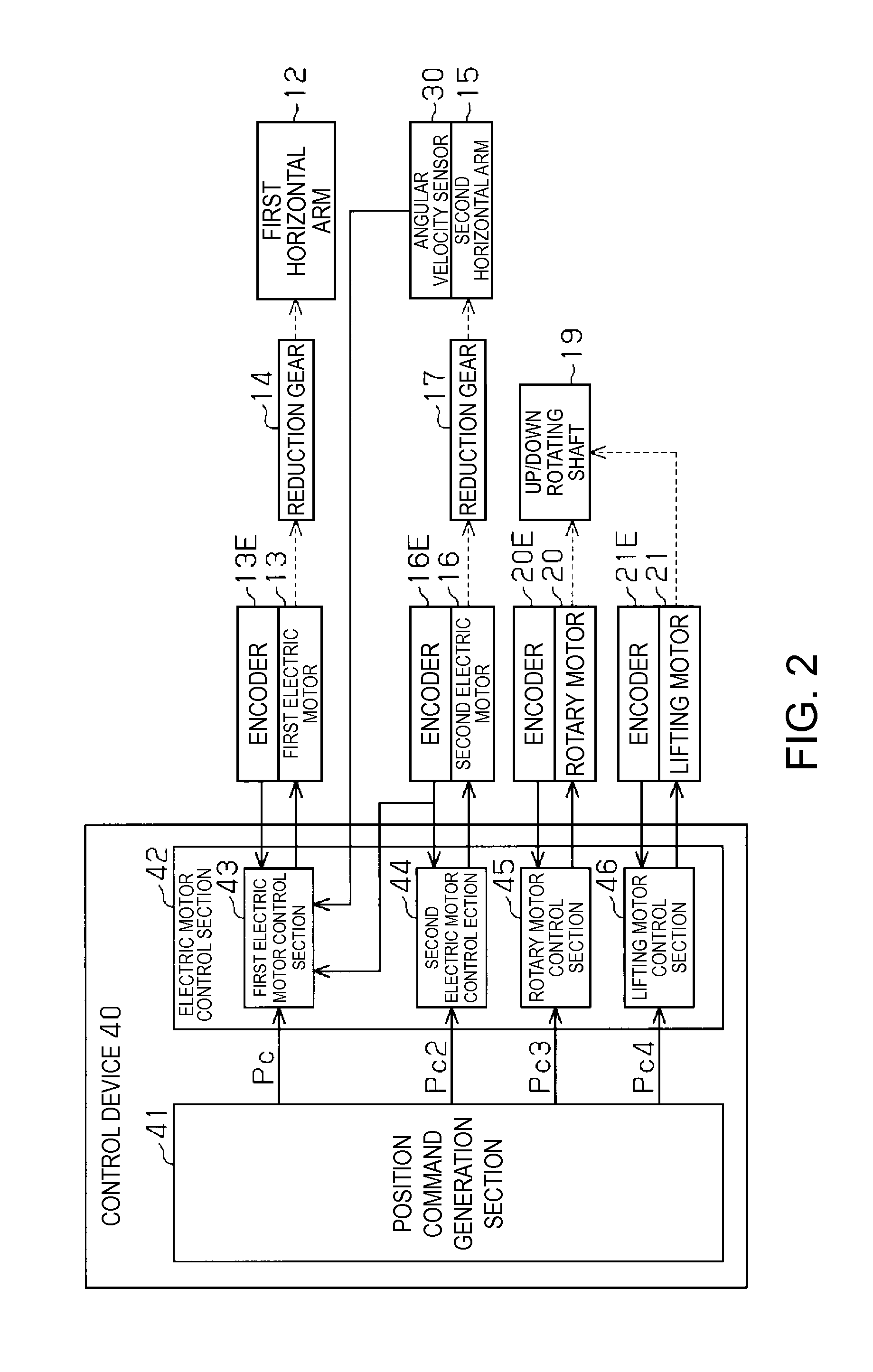

Horizontal articulated robot, and method of controlling the same

ActiveUS20120215357A1Reduce in quantityReduced durabilityProgramme controlProgramme-controlled manipulatorRotation velocityAngular velocity

A robot includes a first horizontal arm coupled to a base, a second horizontal arm coupled to the base via the first horizontal arm, first and second motors adapted to rotate the respective arms, and first and second encoders adapted to calculate rotational angles and rotational velocities of the respective motors. A first motor control section subtracts first and second angular velocities based on the first and second encoders from a sensor angular velocity detected by an angular sensor, and controls the first motor so that a velocity measurement value obtained by adding a vibration velocity based on a vibration angular velocity as the subtraction result and a first rotational velocity becomes equal to a velocity command value.

Owner:SEIKO EPSON CORP

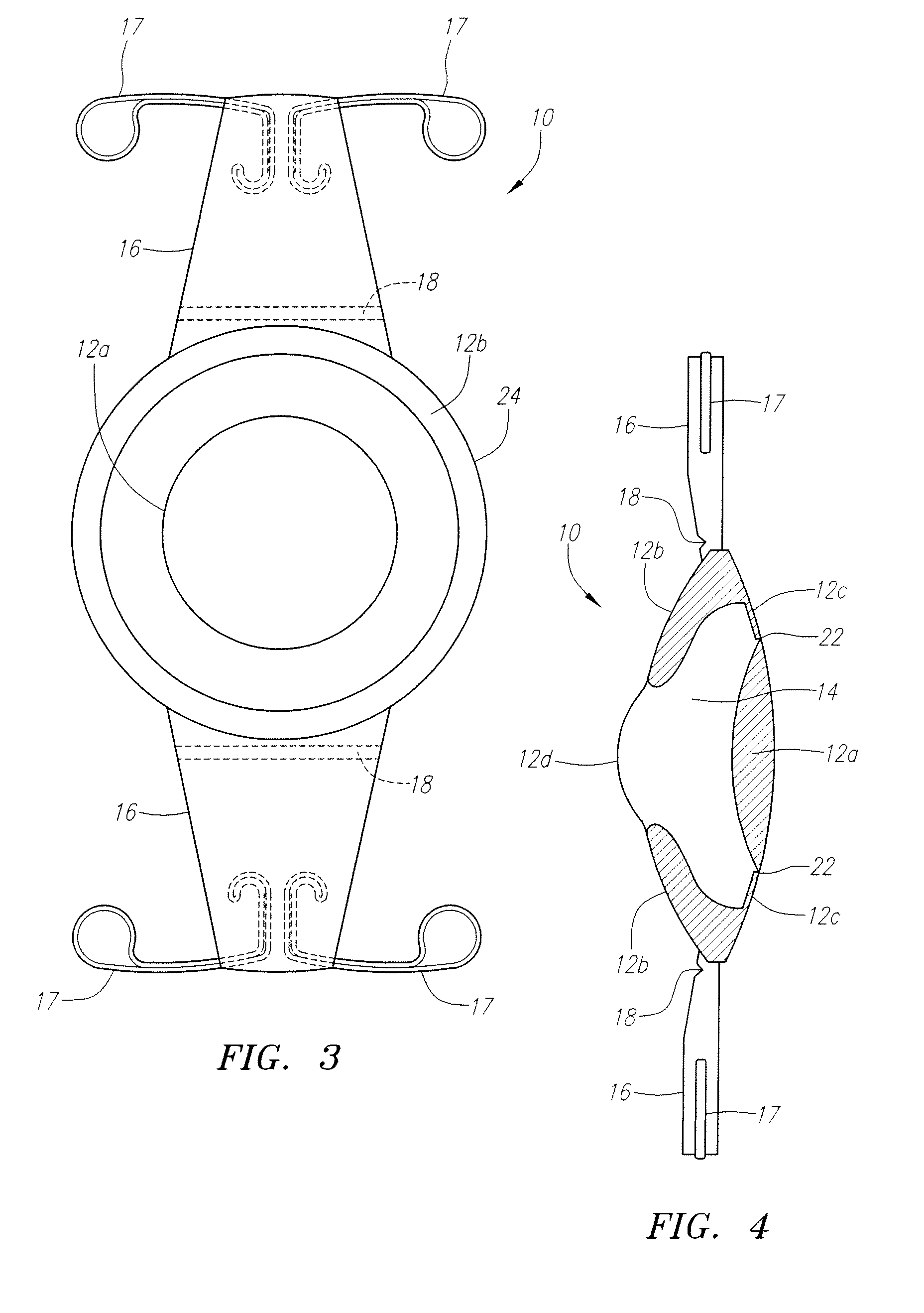

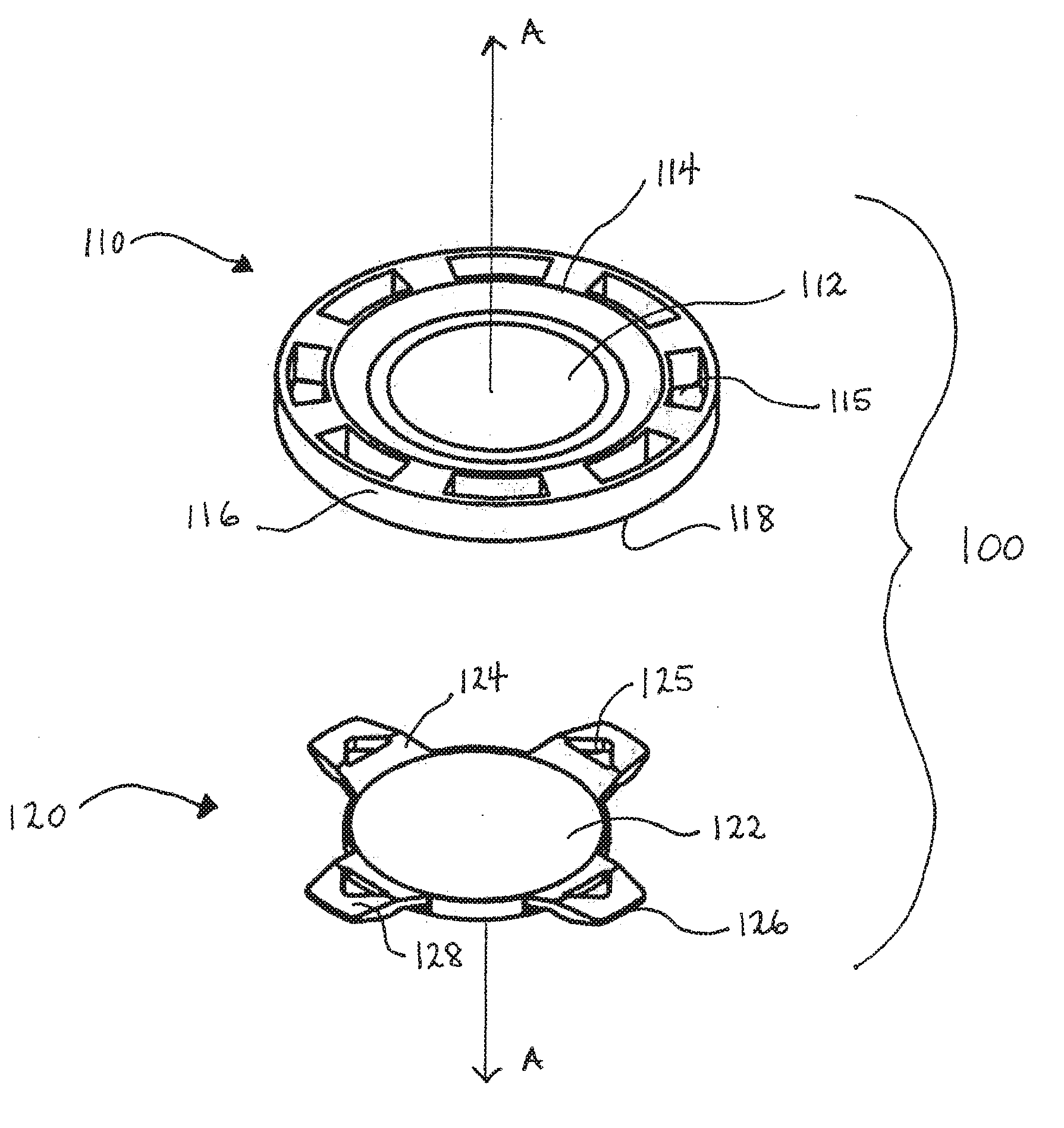

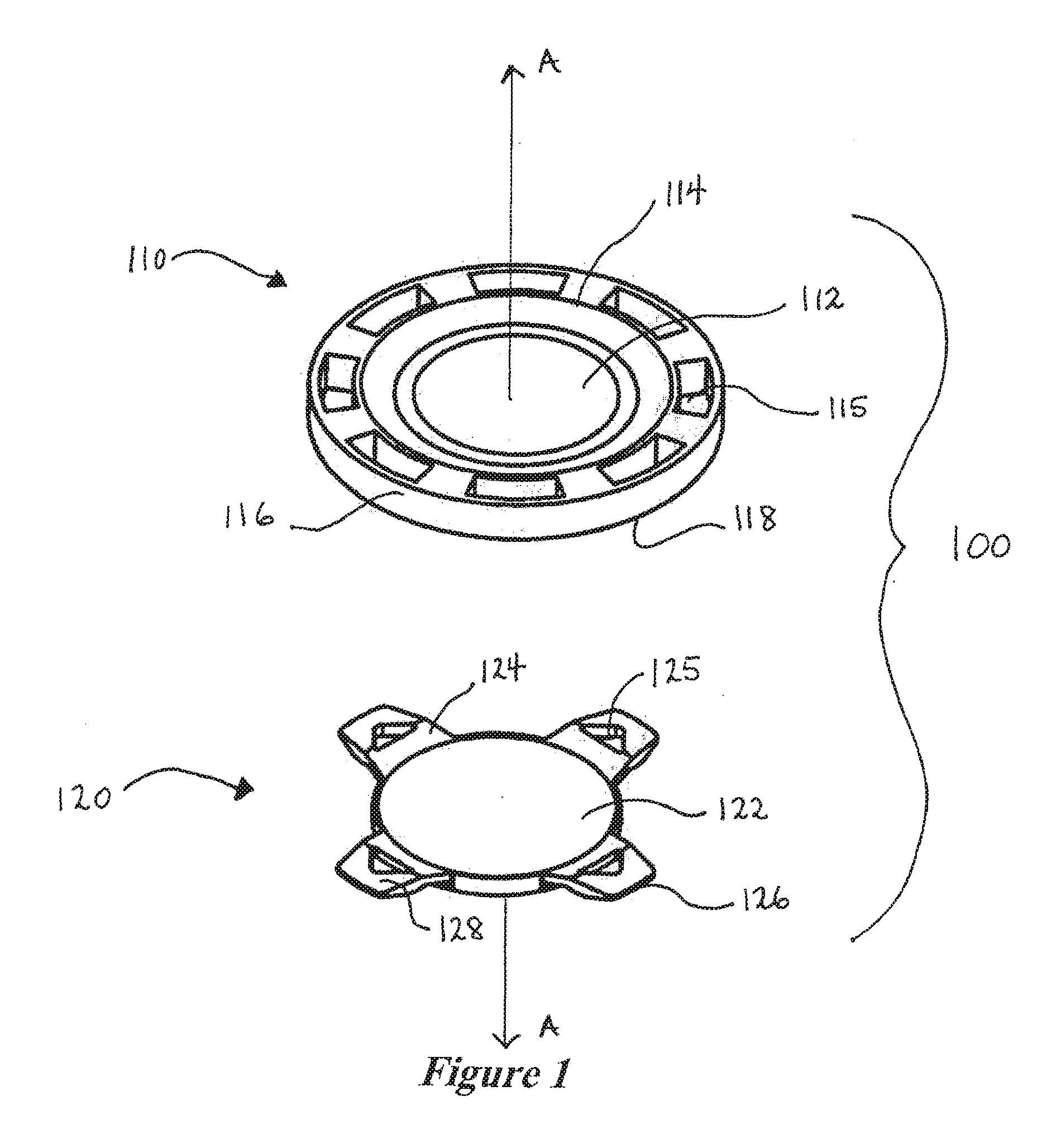

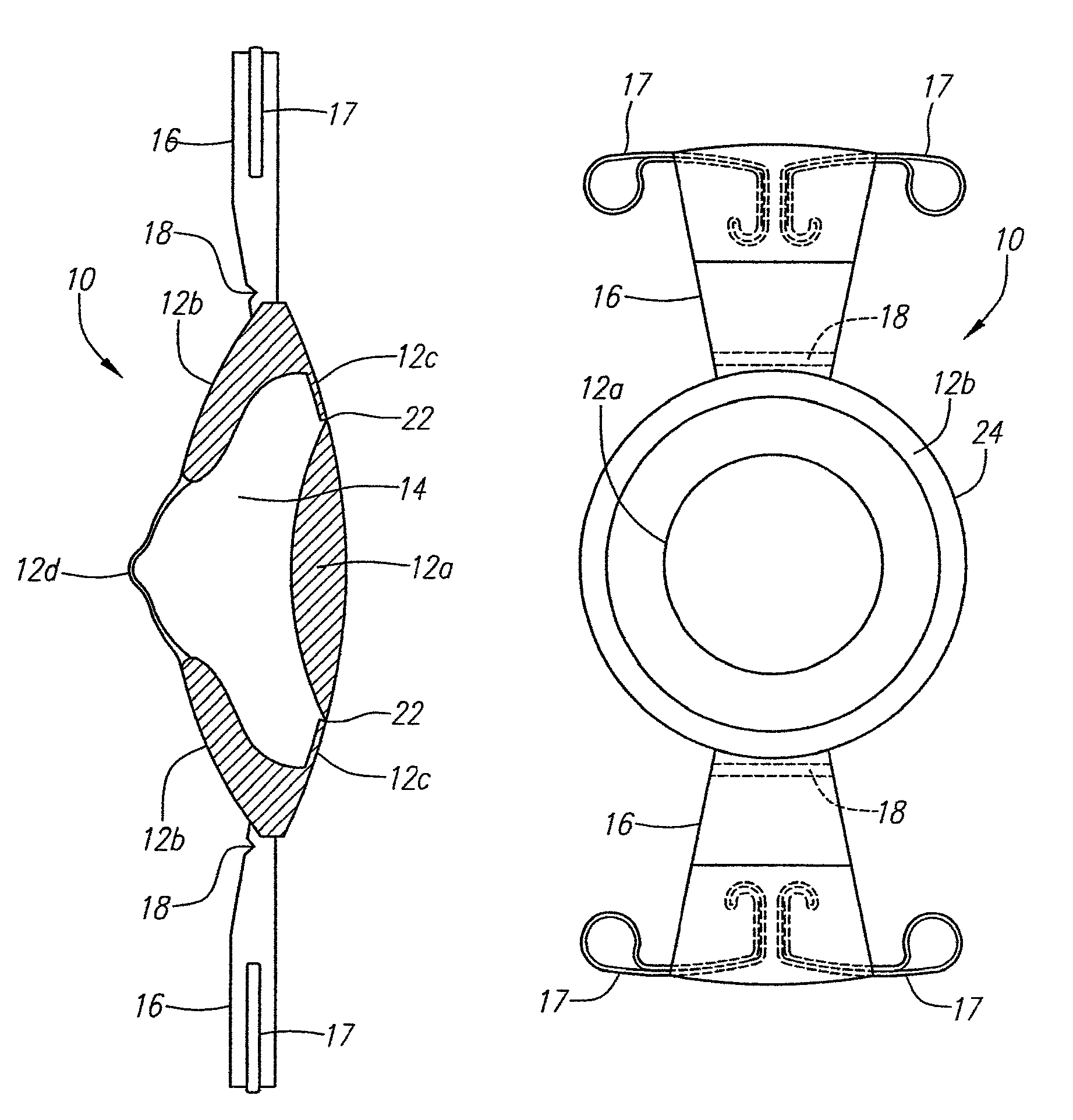

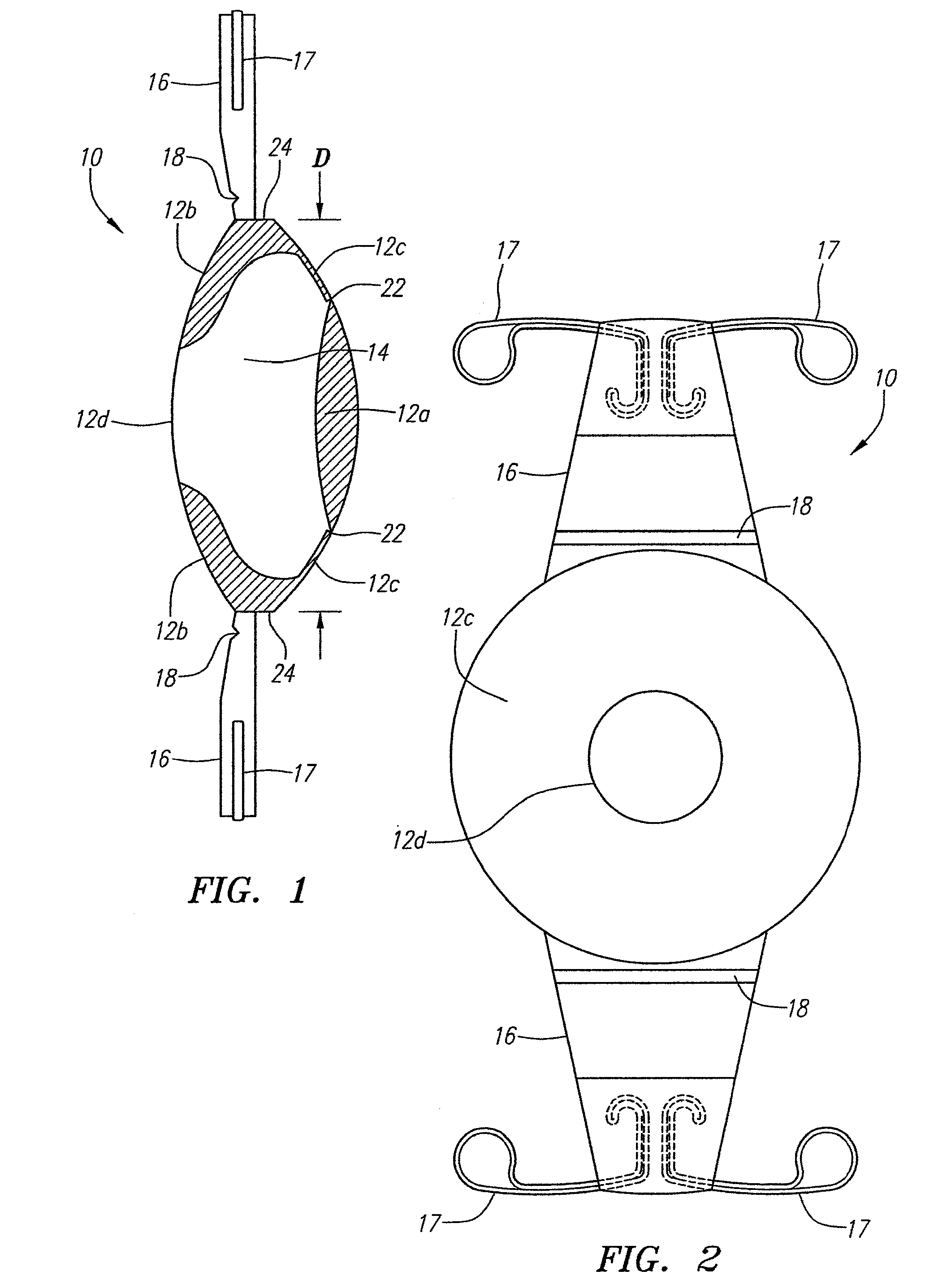

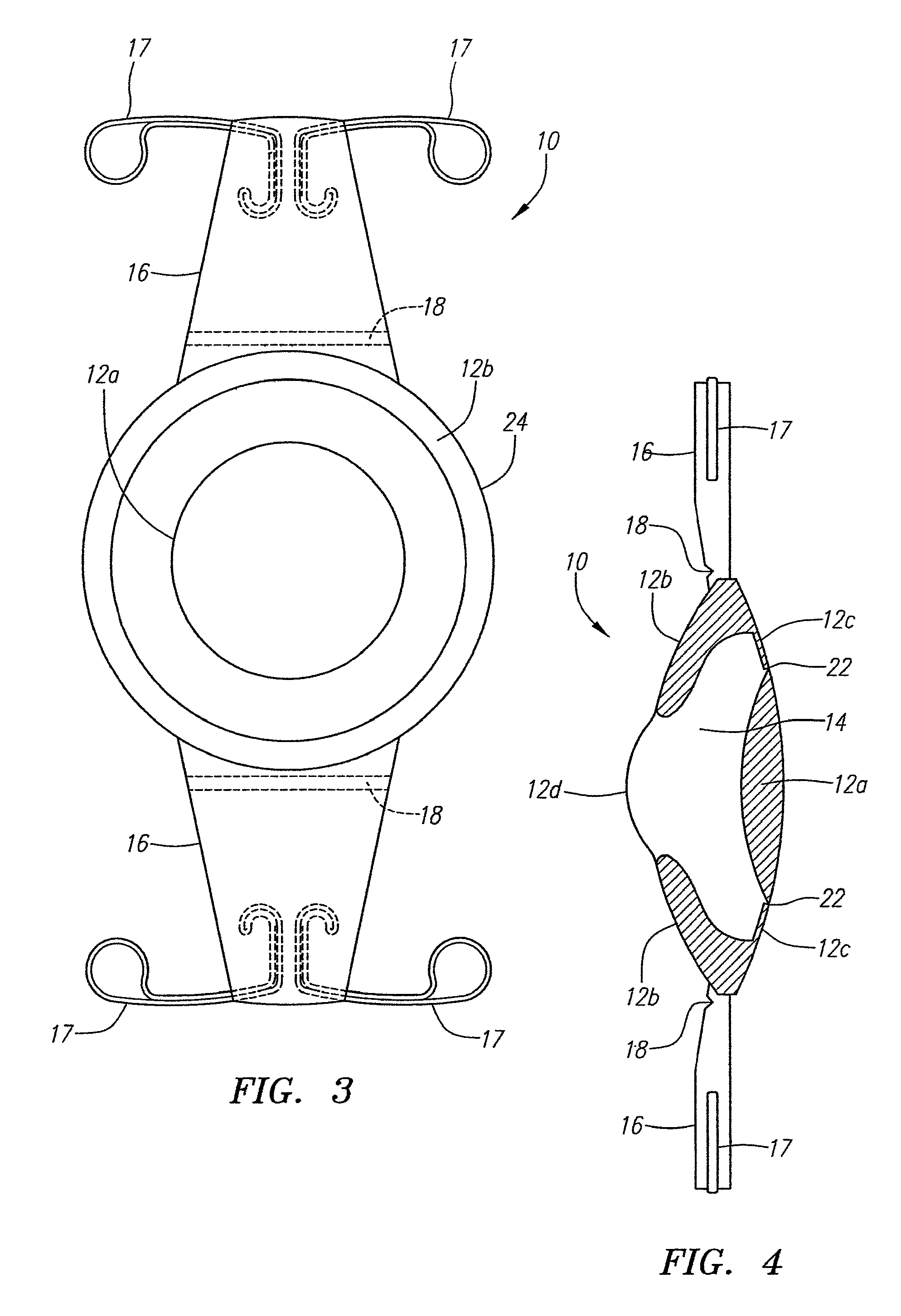

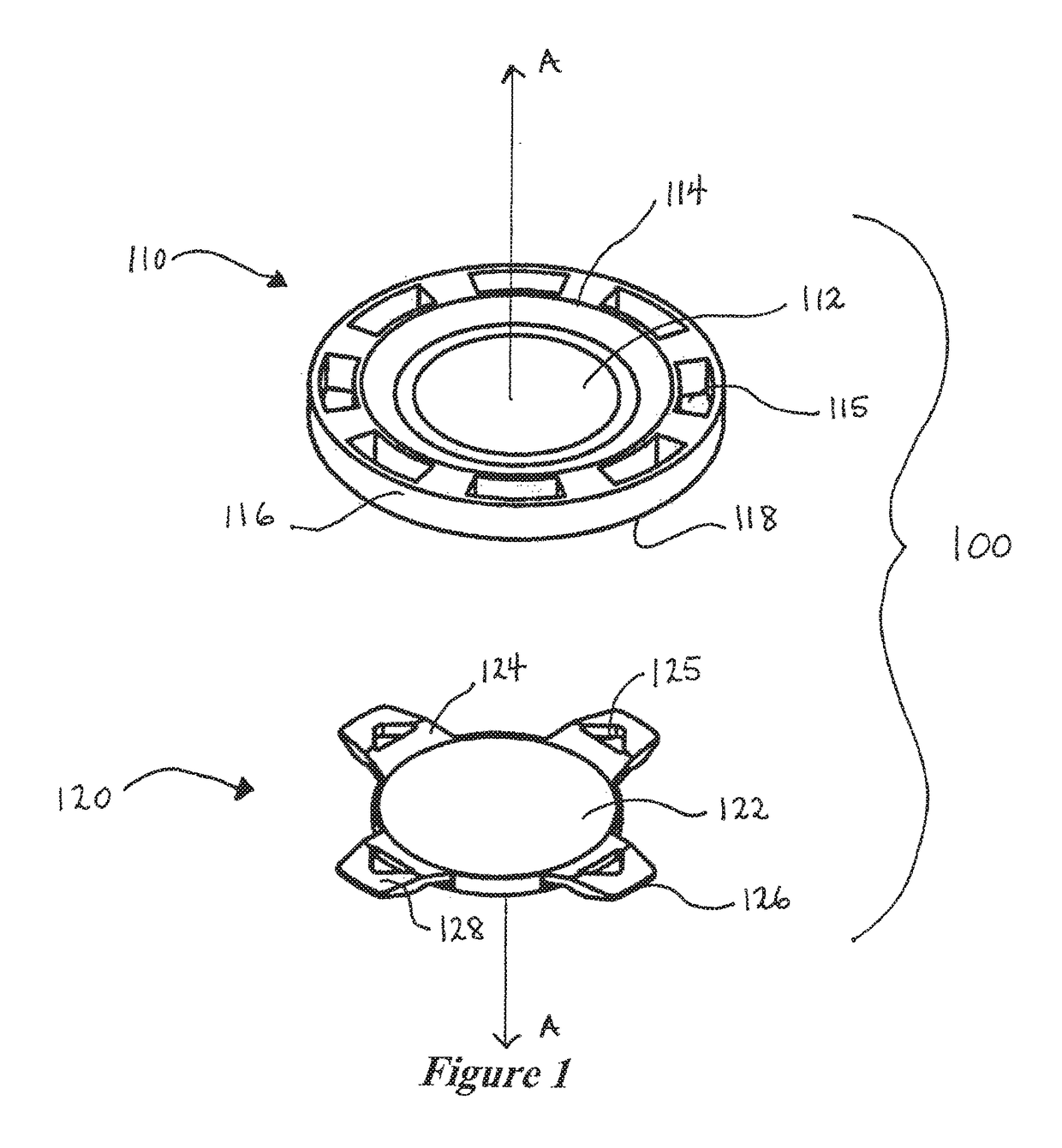

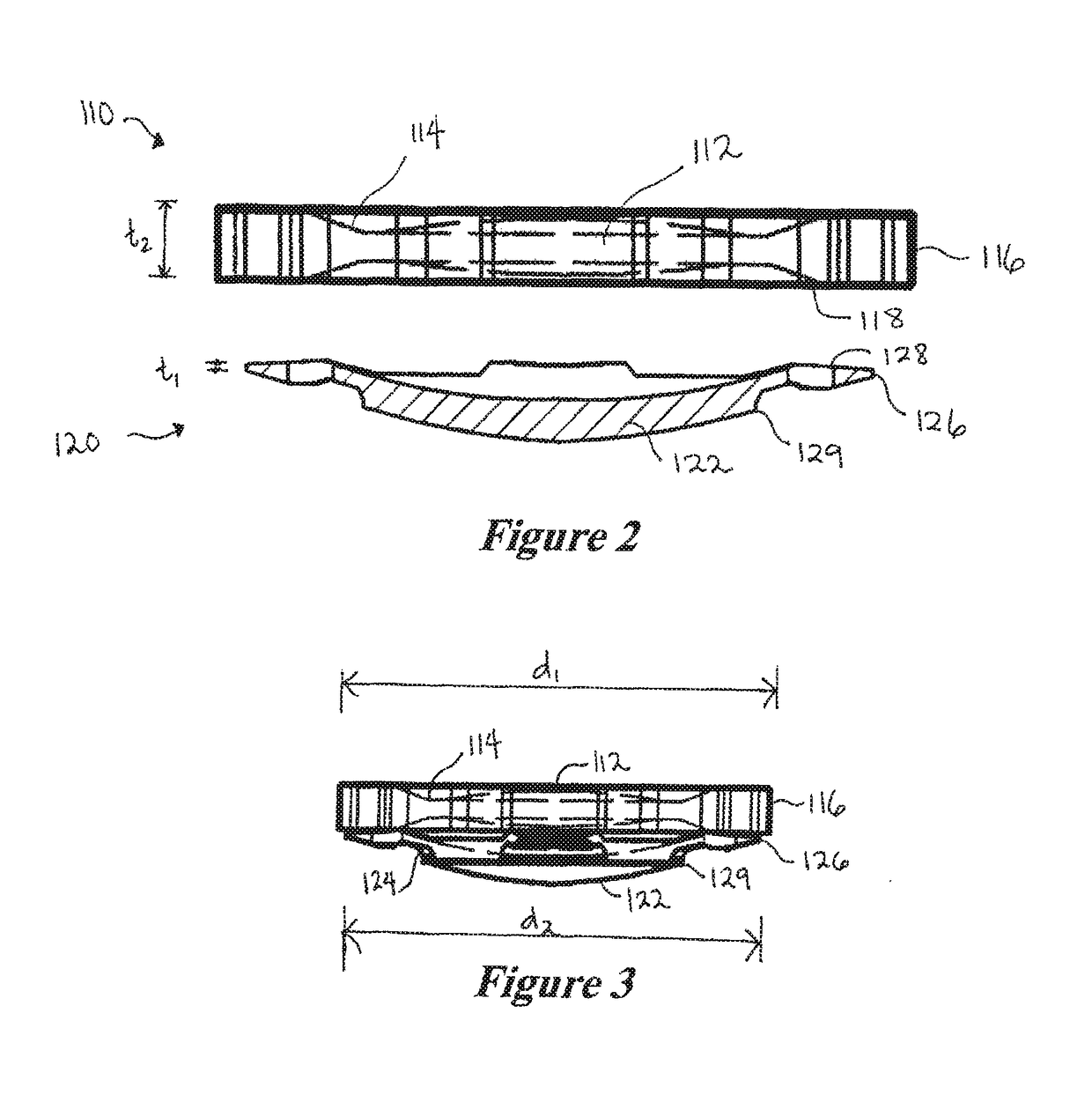

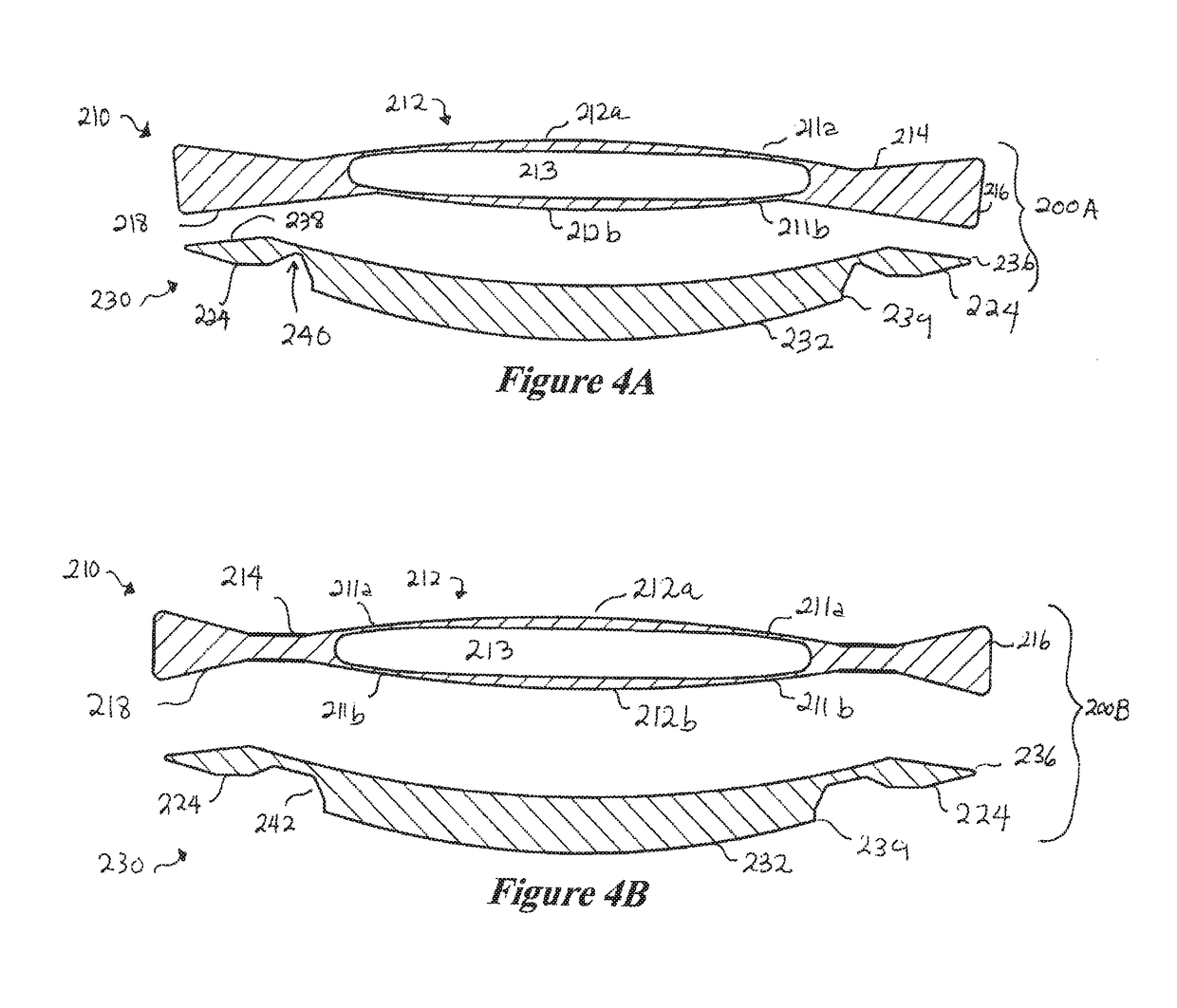

Two-part accommodating intraocular lens device

ActiveUS20160317286A1Reduce incision sizeReduced delivery profileDiagnosticsSurgeryIntraocular lensCentration

A two-part accommodating intraocular lens (IOL) device for implantation in a capsular bag of a patient's eye. The IOL device includes a primary lens assembly and a power changing lens. The primary lens assembly includes a fixed lens and a peripherally disposed centration member. The centration member has a circumferential distal edge and a first coupling surface adjacent the circumferential distal edge. The power changing lens has an enclosed, fluid- or gel-filled lens cavity and haptic system disposed peripherally of the lens cavity. The haptic system has a peripheral engaging edge configured to contact the capsular bag and a second coupling surface. The first and second coupling surfaces are in sliding contact with one another to permit movement of the power changing lens relative to the primary lens assembly and also to maintain a spaced relationship between the fixed lens and the lens cavity during radial compression of the power changing lens.

Owner:LENSGEN INC

Hydrolic accommodating intraocular lens

An accommodating intraocular lens comprising an optic made from solid silicone and liquid silicone. The optic has a central anterior area or membrane that can vary in radius and thus change power.

Owner:C& C VISION INT

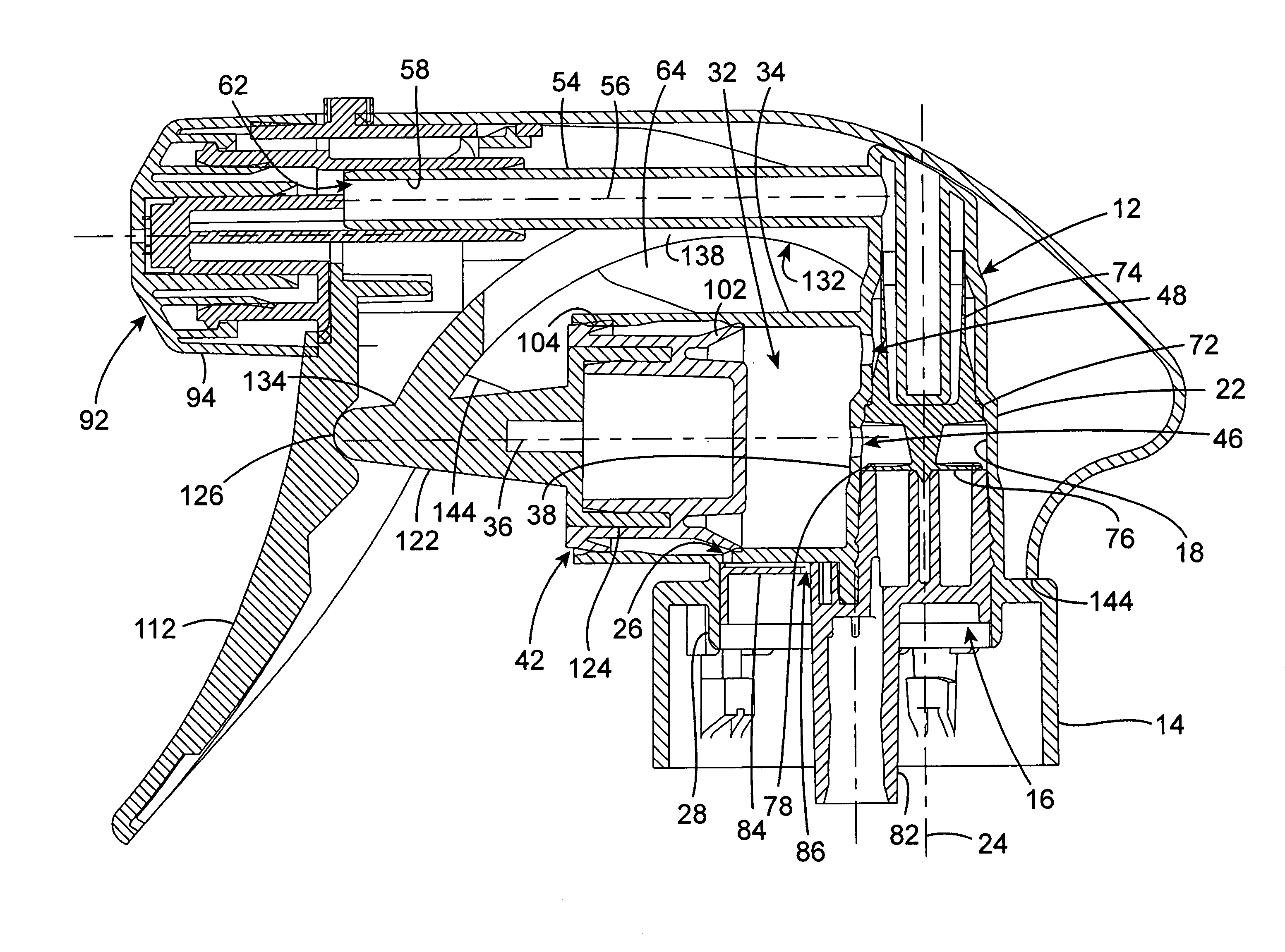

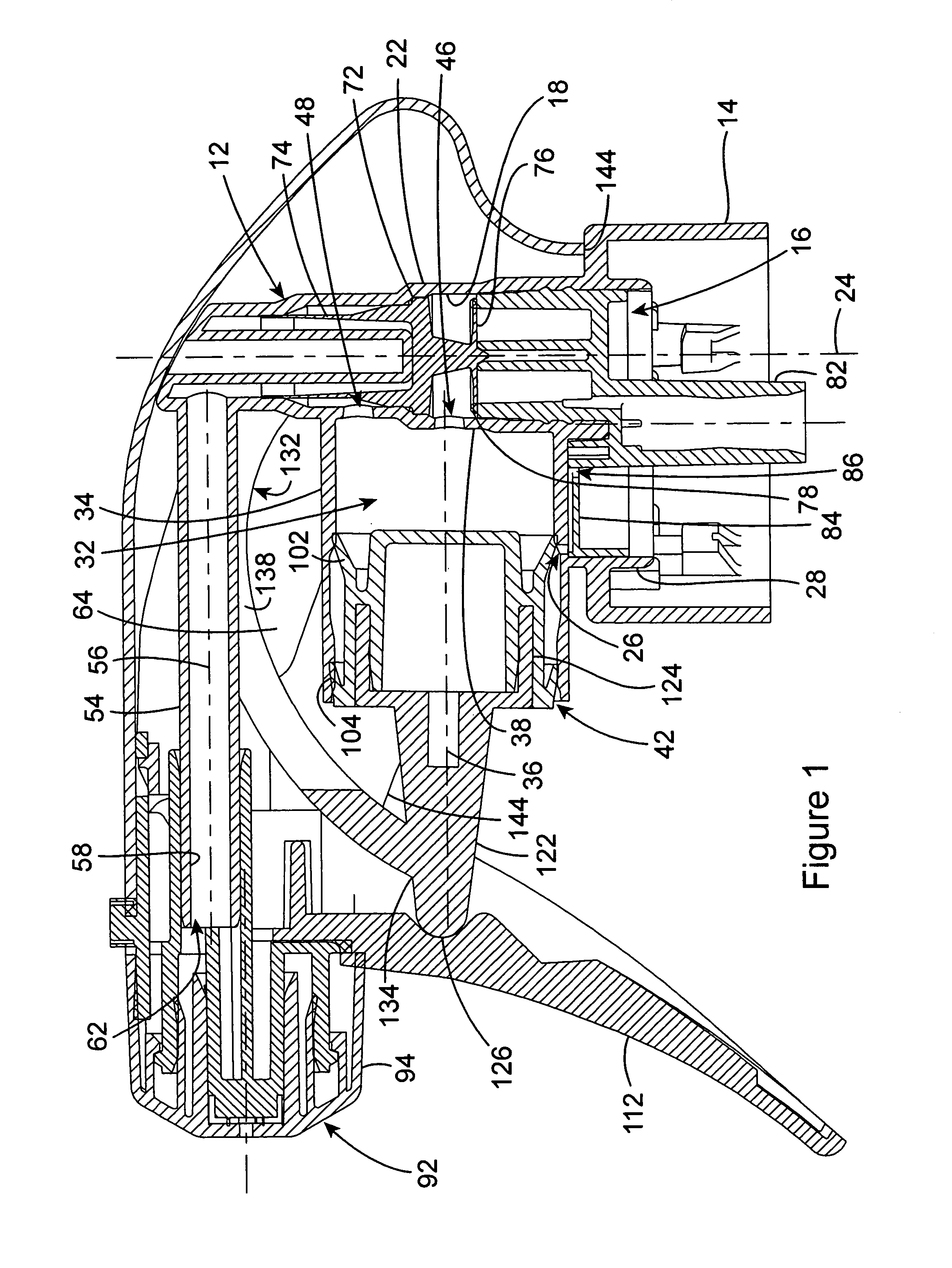

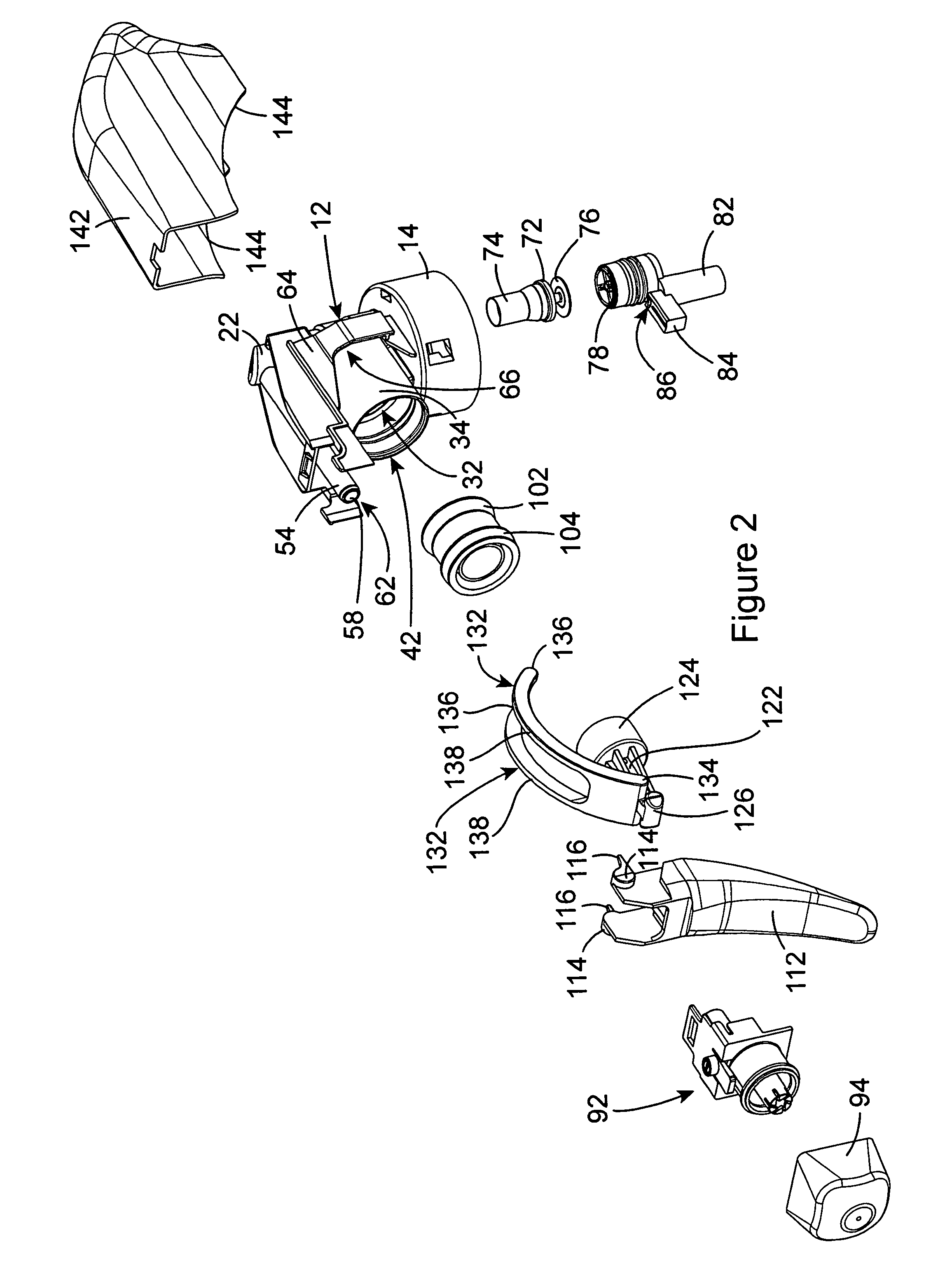

Trigger sprayer with integral piston rod and bowed spring

ActiveUS7497358B2Cost efficientRecycling of the trigger sprayer is more economicalLarge containersFire rescueSprayerPump chamber

A manually operated trigger sprayer is constructed with a reduced number of parts and in a novel manner in which all of the component parts of the sprayer are constructed of a plastic material. The construction of the trigger sprayer replaces the conventional metal coil spring in the pump chamber with a pair of plastic bowed springs that are integral with the piston rod and are positioned outside the pump chamber. Constructing all of the sprayer parts of a plastic material enables a cost efficient recycling of the parts, which does not require disassembling the parts to remove a metal spring.

Owner:SILGAN DISPENSING SYST CORP

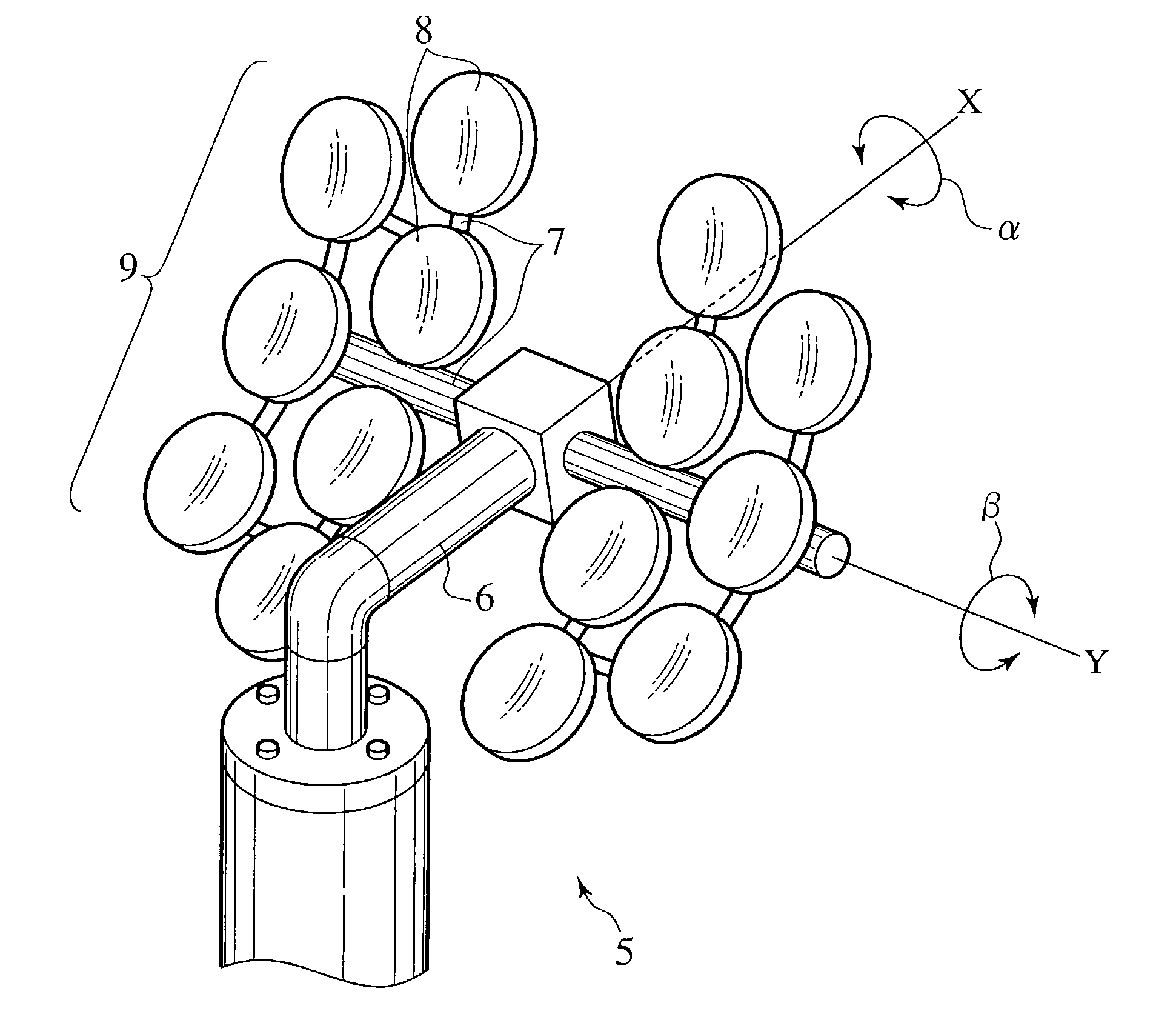

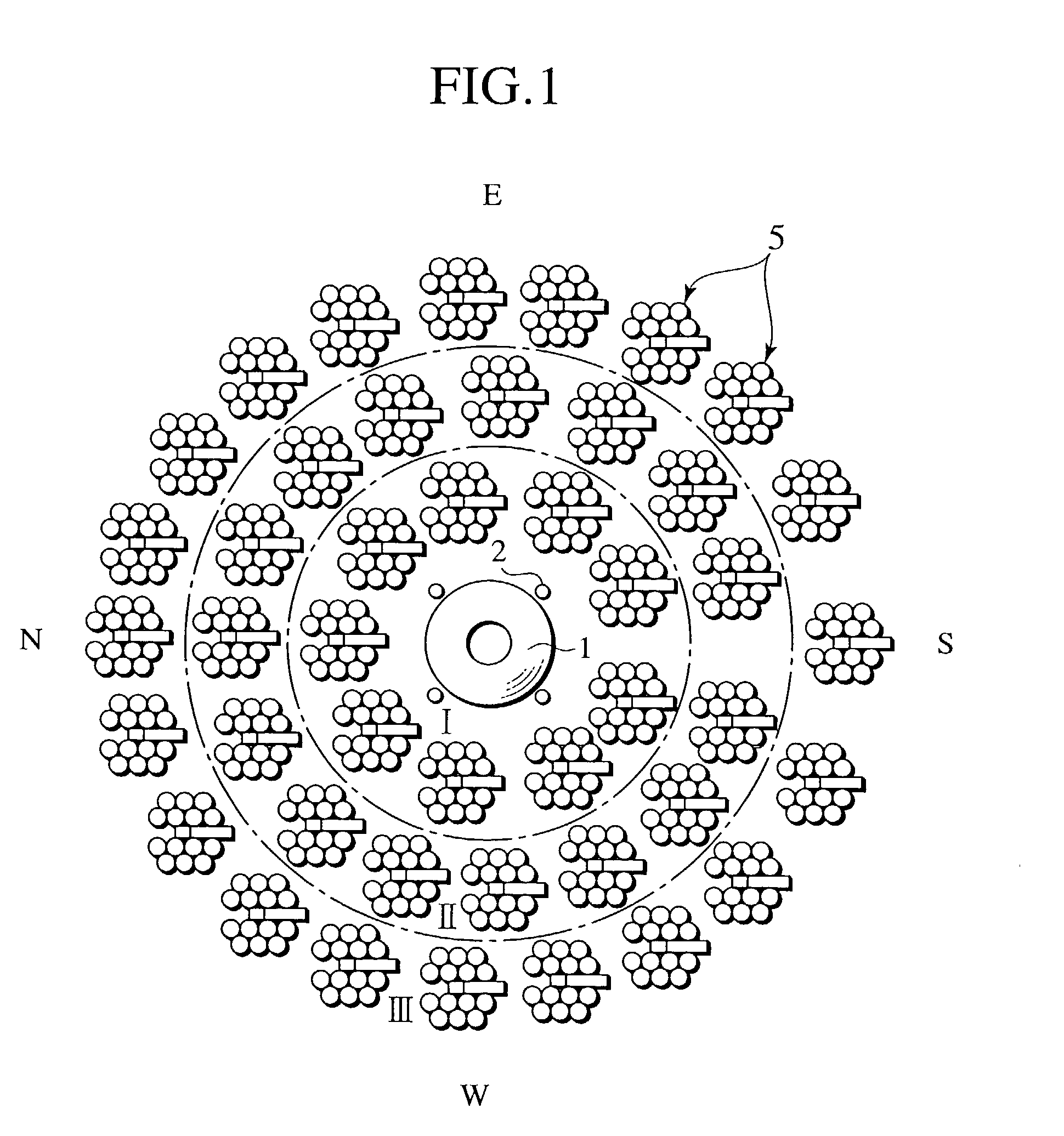

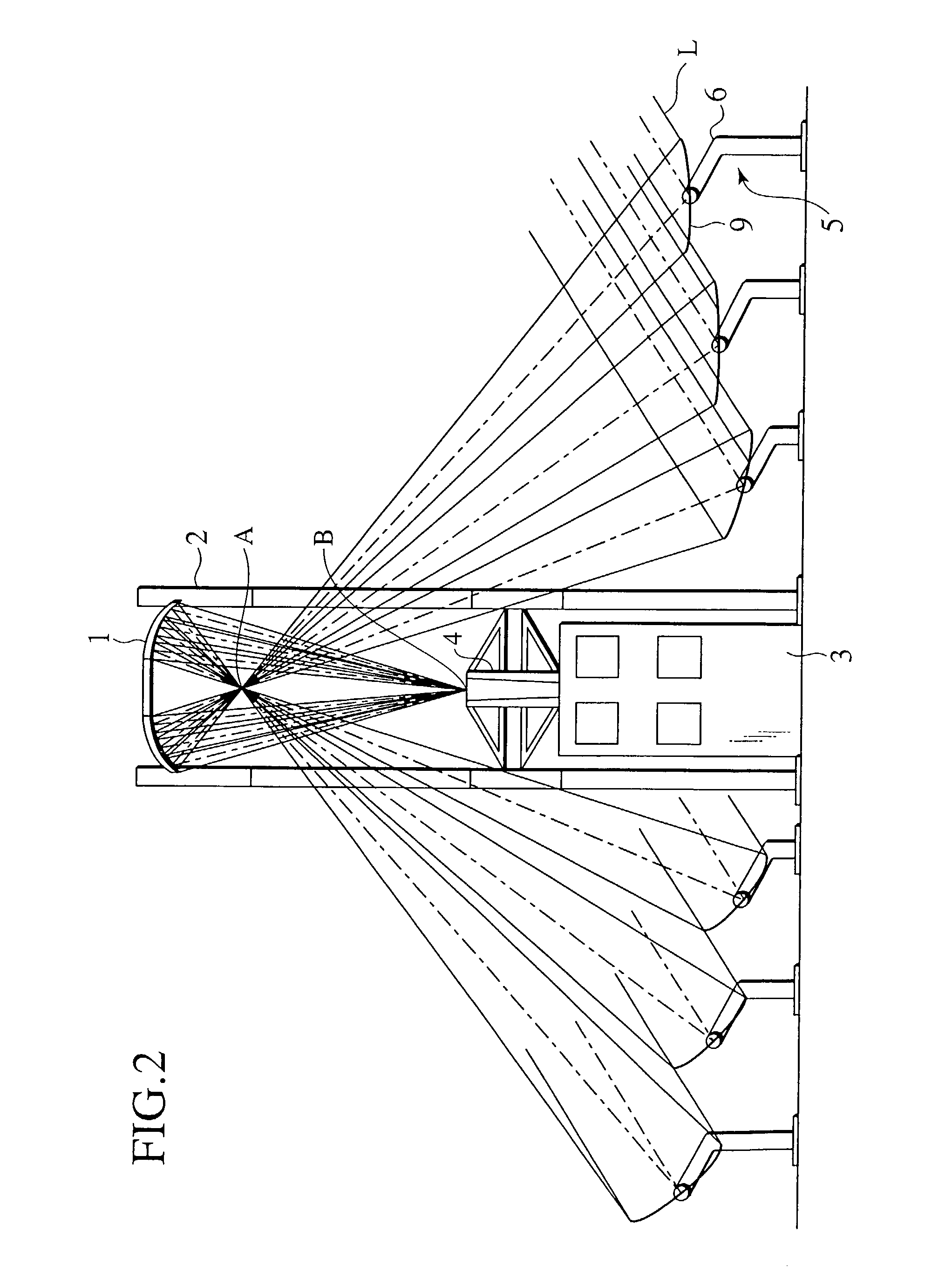

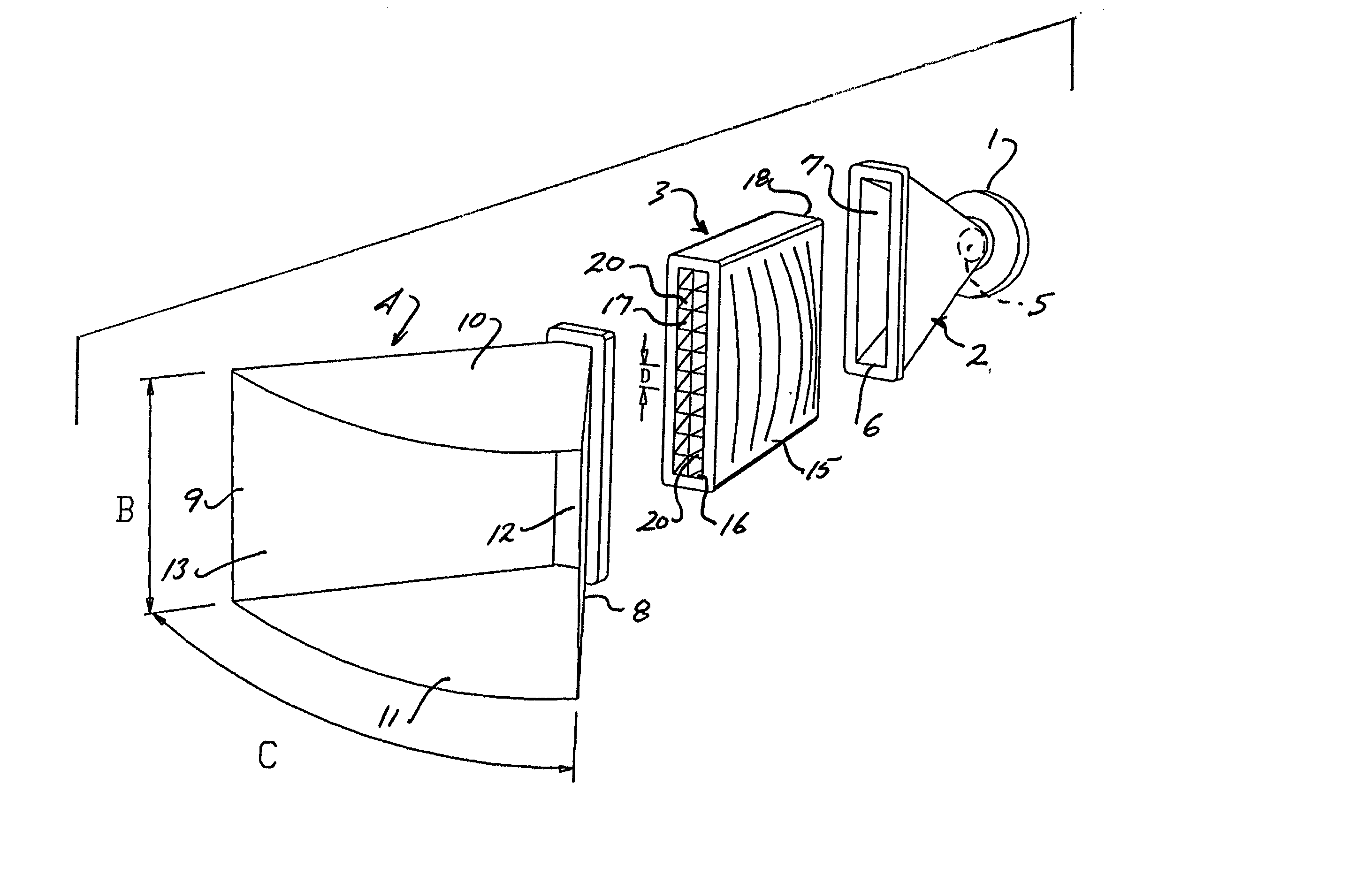

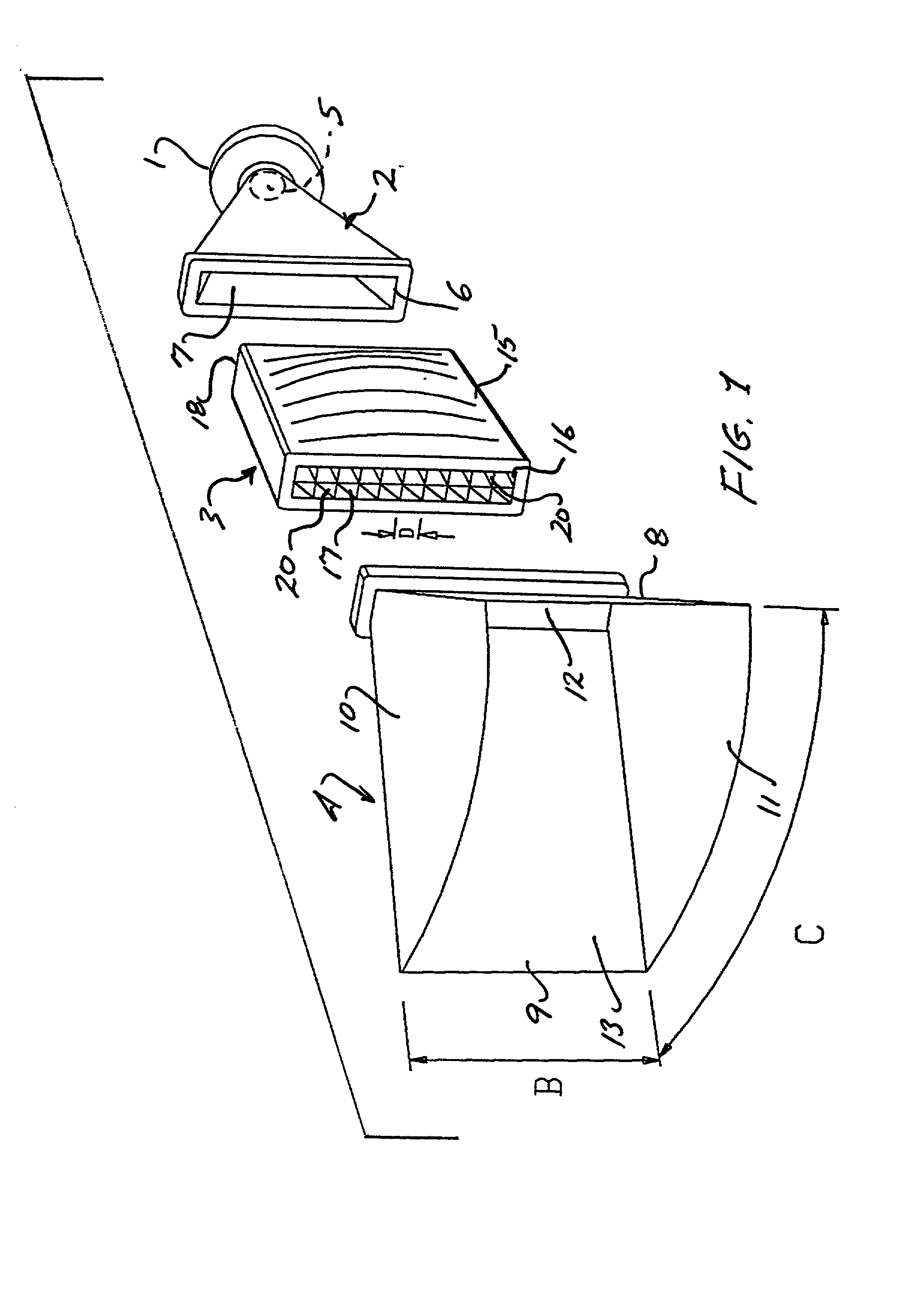

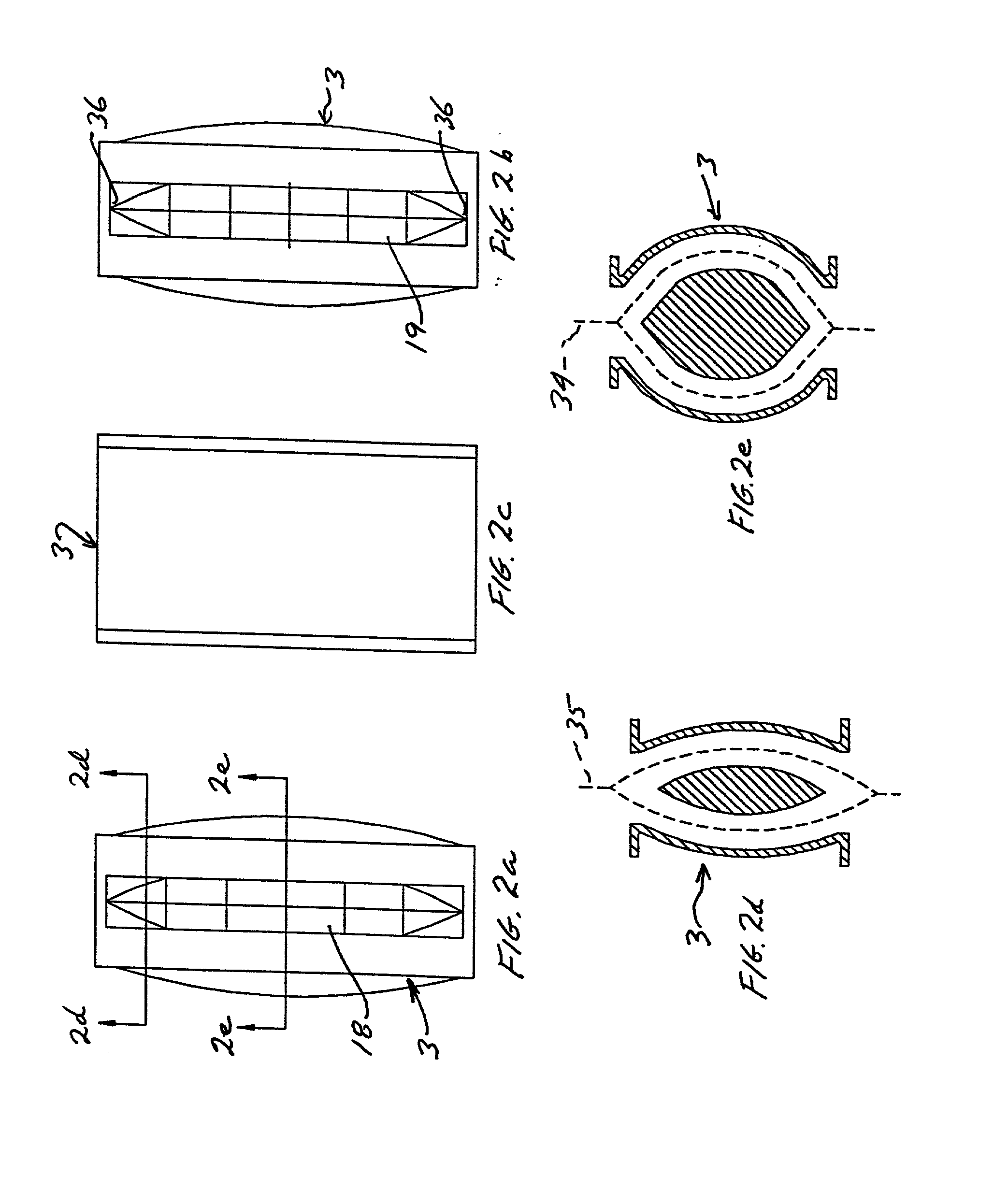

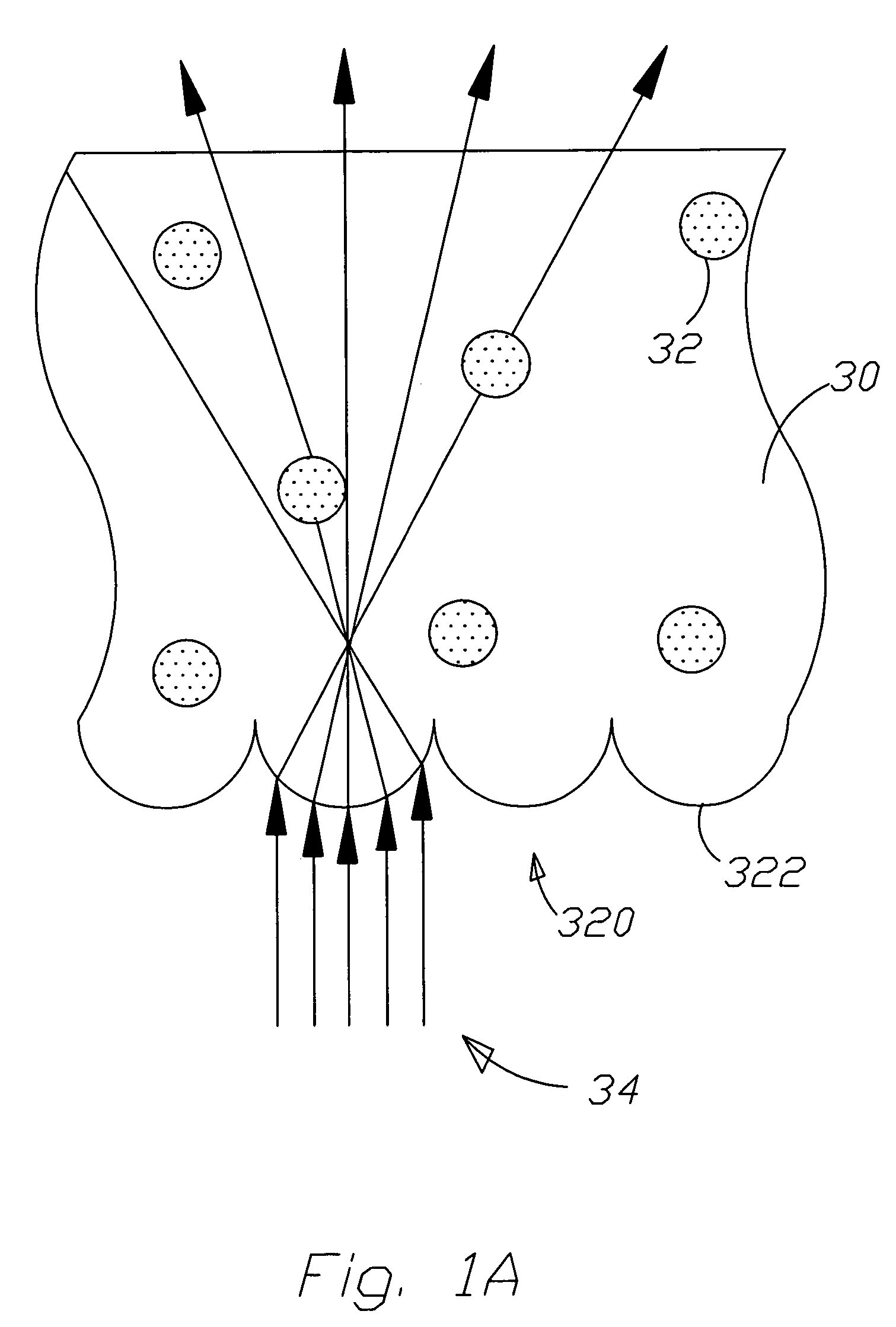

Heliostat for sunlight concentration system and method of controlling the same

InactiveUS6984050B2Improve efficiencyReduce curvatureSolar heating energyPhotometry using reference valueHeliostatDaylight

A heliostat 5 for use in a sunlight concentration system for utilizing sunlight as energy according to this invention has a plurality of small concave mirror elements 8 and reflects and focuses sunlight reflected off the individual concave mirror elements to a light concentration portion as if upon reflection off a single large concave mirror 9. The angles of the concave mirror elements 8 are changed to define a single concave mirror having a predetermined curvature. When the incident angle of sunlight with respect to the concave mirror is large, the curvature is reduced (like a shallow dish). When the incident angle is small, the curvature is increased (like a deep dish).

Owner:MITAKA KOHKI

Bionic impeller for exhaust hood

ActiveCN104100570AEasy to processReduce leading edge pressure shockDomestic stoves or rangesPump componentsImpellerEngineering

The invention relates to a bionic impeller for an exhaust hood. The bionic impeller is applied to the exhaust hood and comprises a plurality of groups of annular end surfaces and blades. The corresponding blades are uniformly in bridge connection between each two groups of annular end surfaces. The bionic impeller is characterized in that the blades are bionic blades, the front edges of the bionic blades face a suction side of the exhaust hood and are of wavy structures, and the tail edges of the bionic blades face a blowout side of the exhaust hood and are of sawtooth structures. The bionic impeller has the advantages that pressure impact on the front edges of the blades and vortex-shedding frequencies of the tail edges of the blades can be reduced advantageously, and accordingly pneumatic noise generated when the impeller works can be reduced; extended areas of the blades can be reduced by 13.5% as compared with blades in original shapes, accordingly, the weight of the impeller can be reduced, loads on a motor can be decreased, and the efficiency of a fan can be improved advantageously.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

Wave shaping sound chamber

InactiveUS20020014368A1Suitable degree of flatnessCurvature can be modifiedMicrophonesLoudspeakersThroatWavefront

A loudspeaker system containing wave-shaping sound chambers with approximately rectangular inlets and outlets of substantially the same size that are used to flatten or control the curvature of the acoustic wavefronts contained within system waveguides. Control of the degree of curvature of the wavefront enables the development of a wide variety of multi-waveguide arrays. The sound chambers are placed between a waveguides and a flattened conical horns of secondary waveguides. The sound chambers transform the curvature of the typical fan shaped wavefront that results from a conical horn throat into a wavefront that approximates a planar or curved rectangular ribbon of sound.

Owner:ADAMSON ALAN BROCK

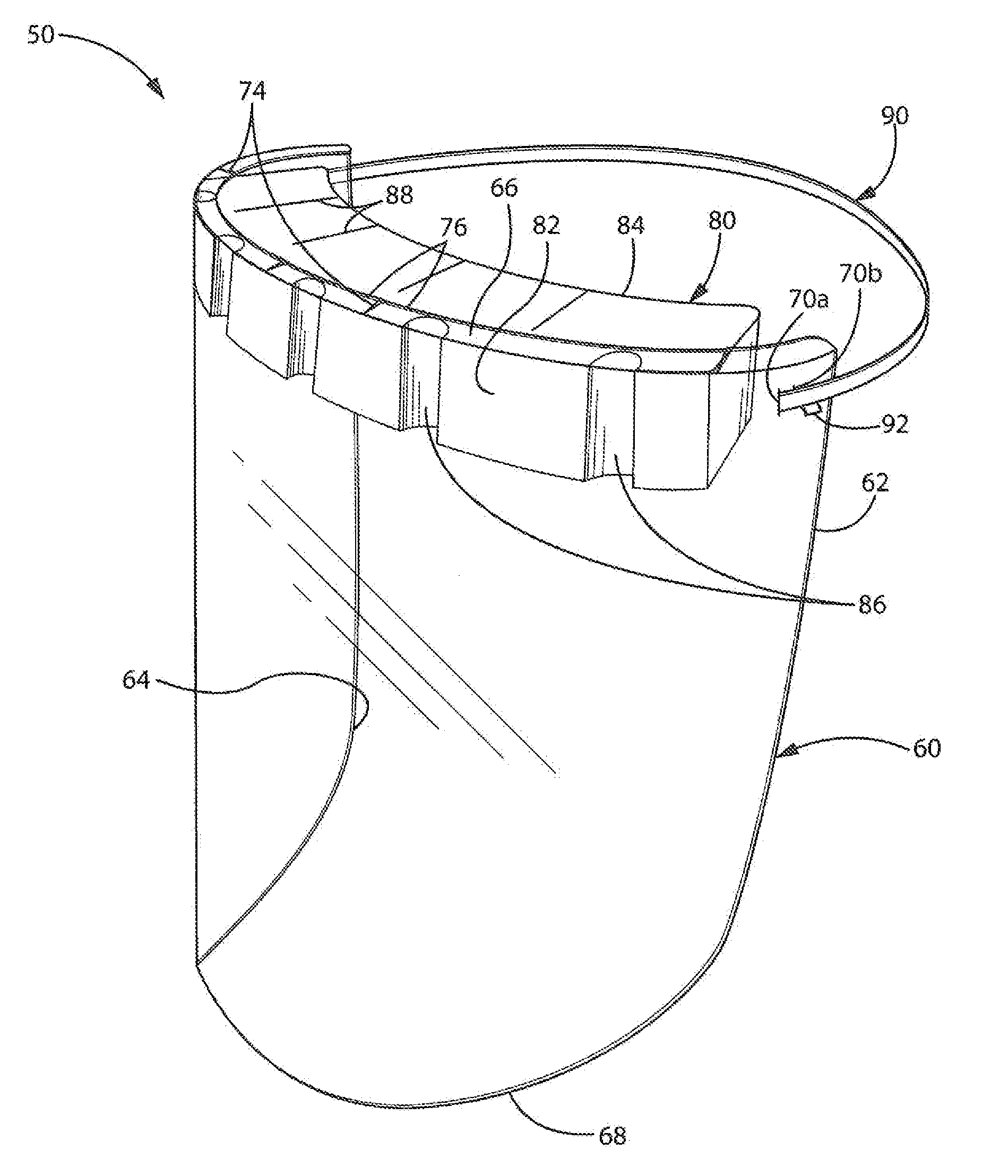

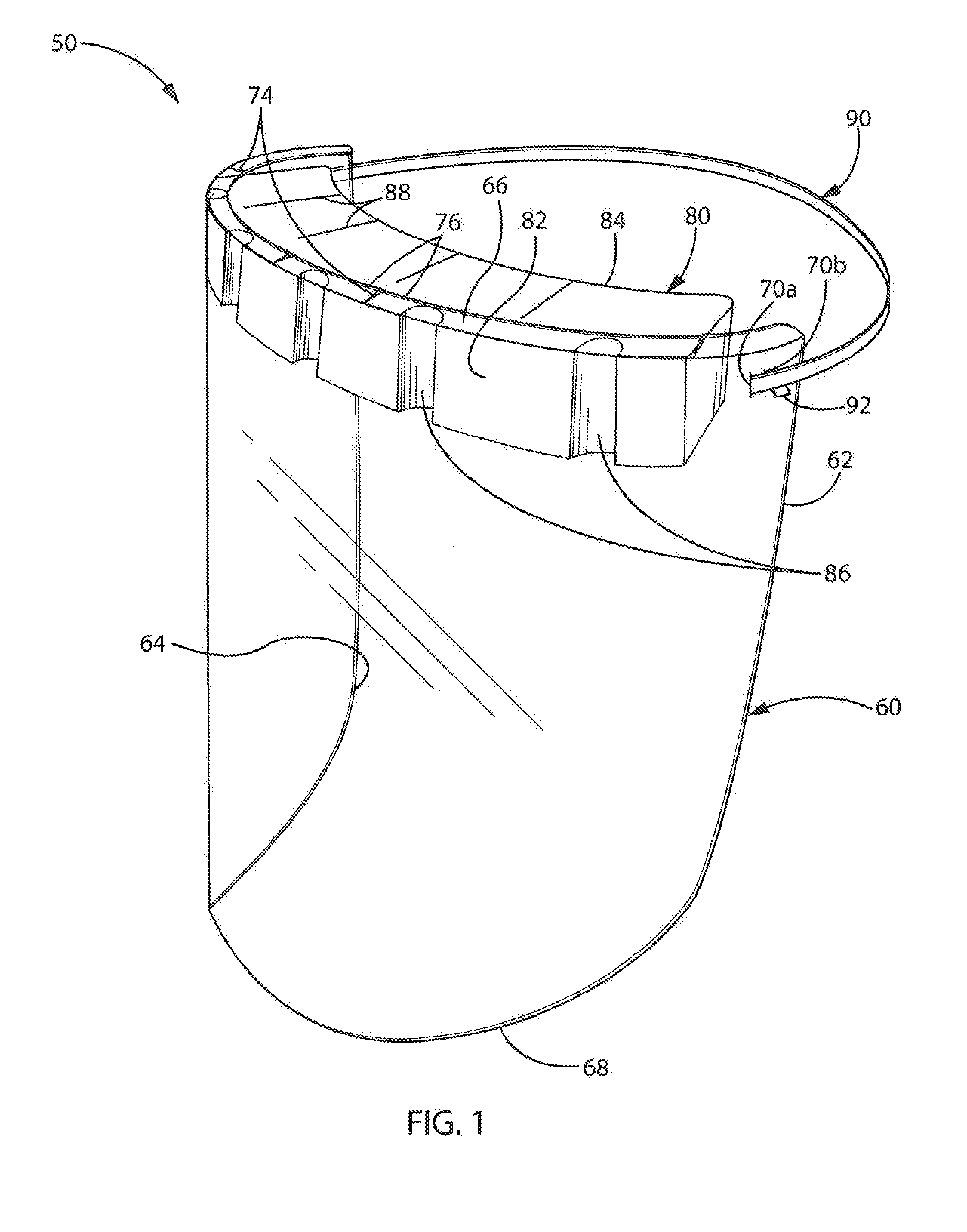

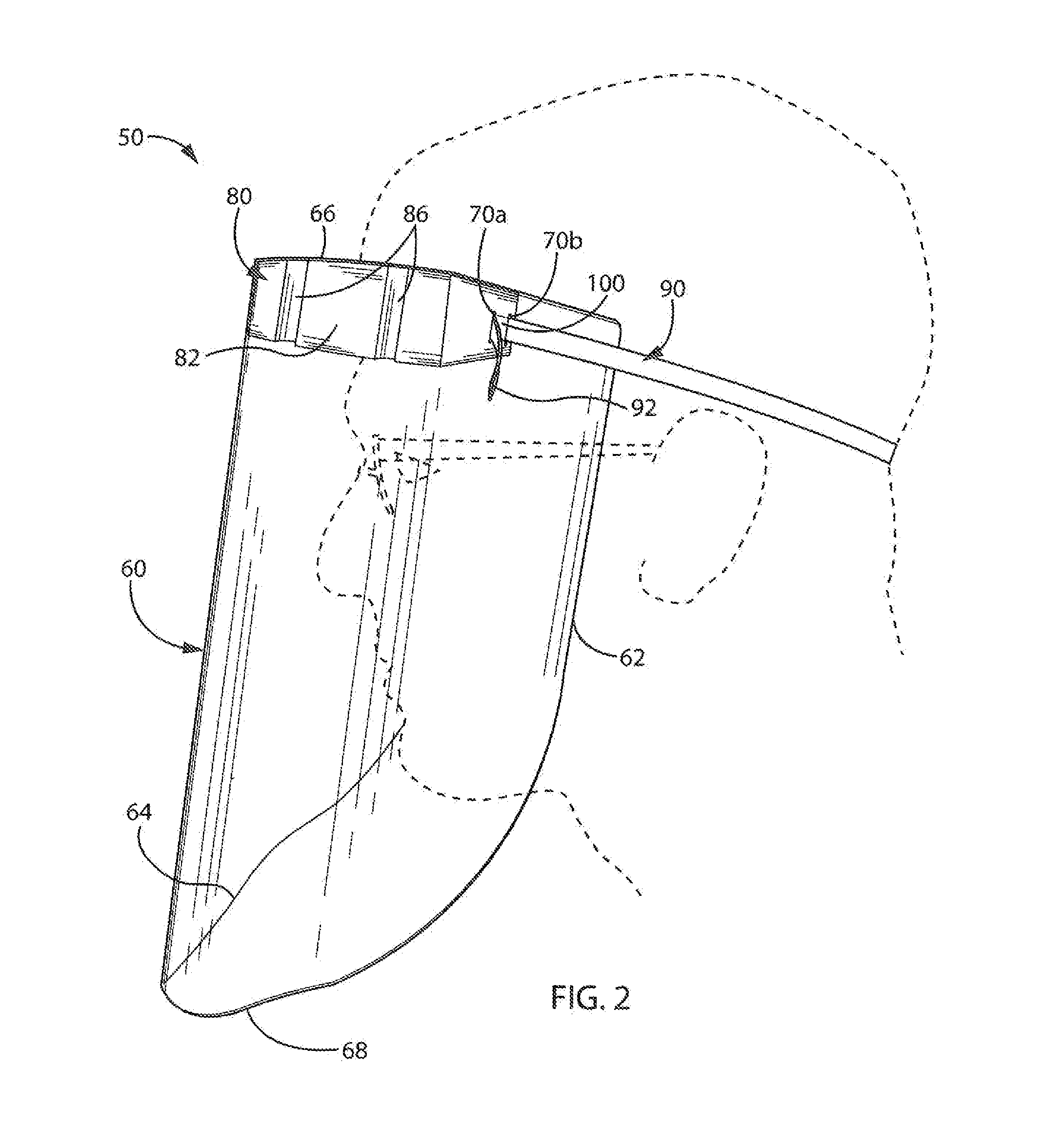

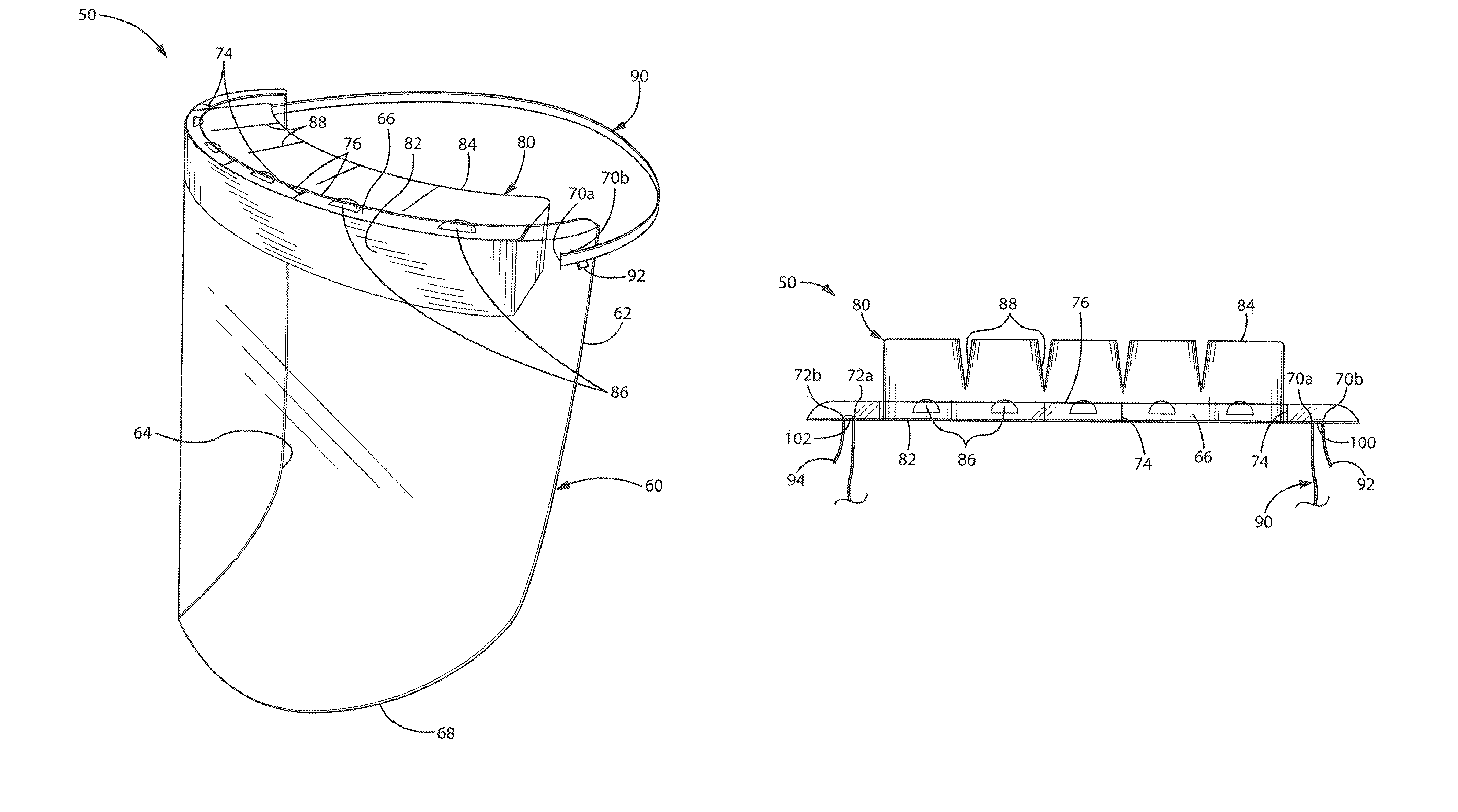

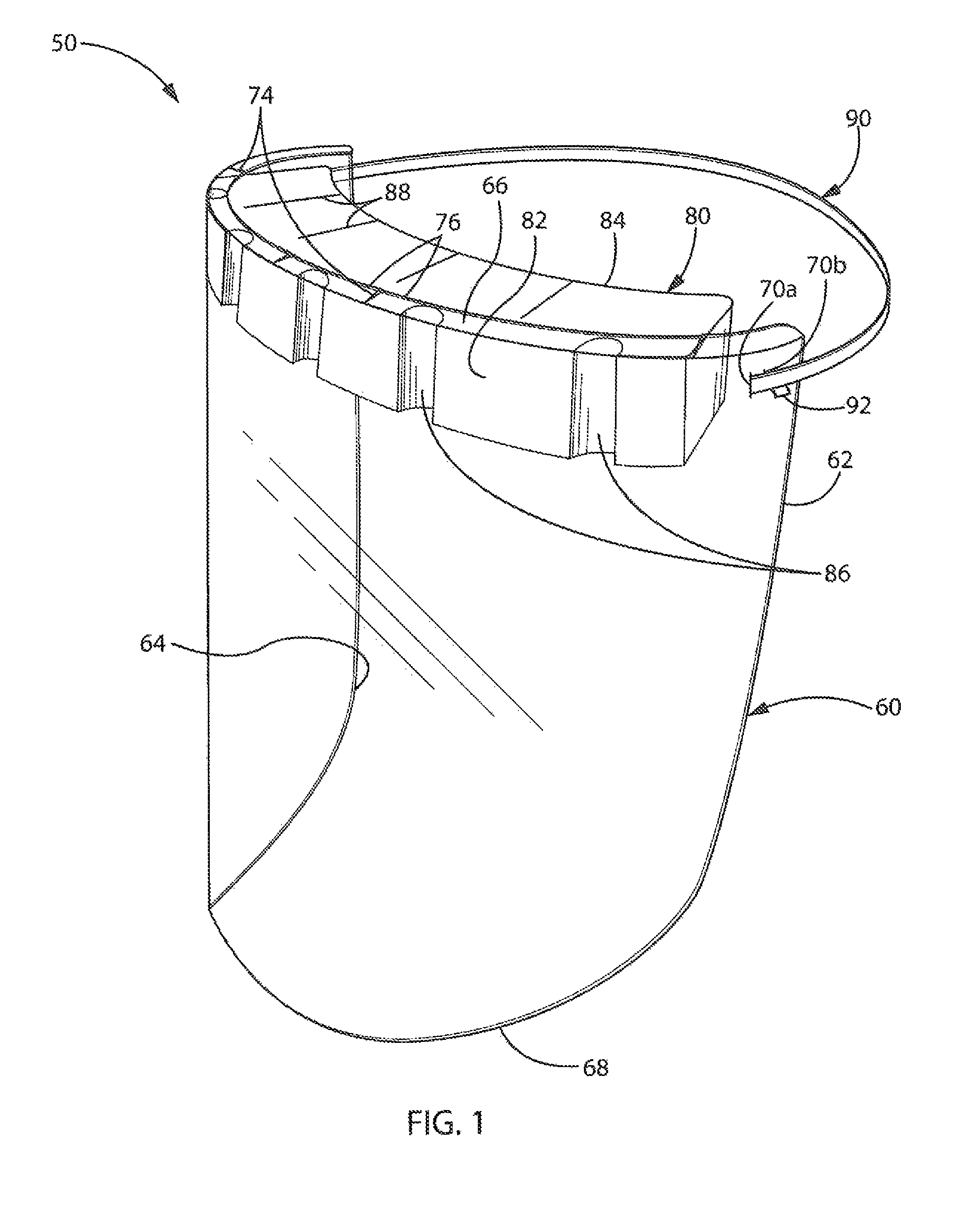

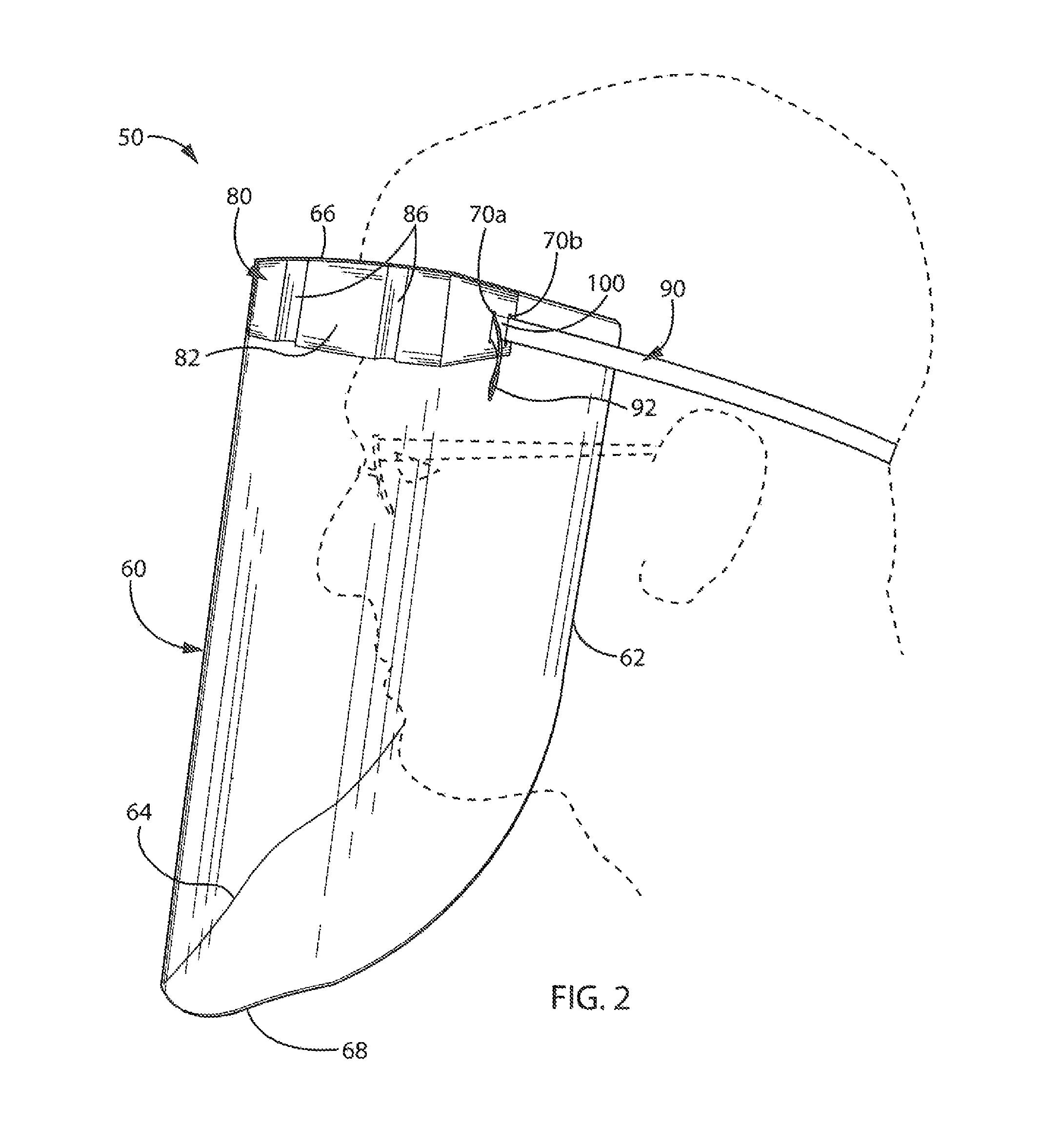

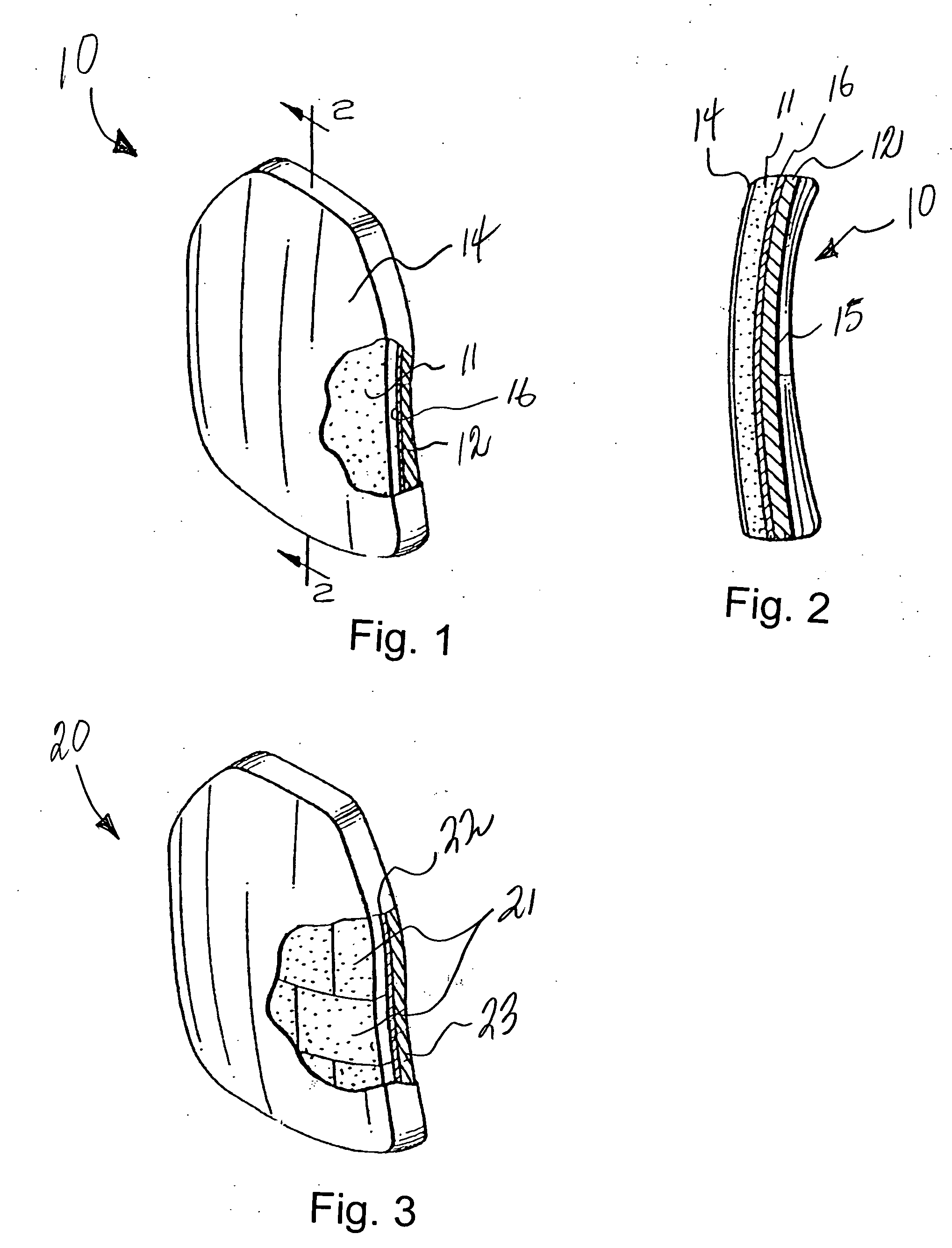

Disposable Face Shield

ActiveUS20150237931A1Secure attachmentIncrease air flowGarment special featuresEye treatmentAir movementEngineering

A disposable face shield with a shield with a plurality of cuts is described. A foam member is connected to the shield to provide added comfort. The foam member may contain a plurality of openings extending through the member, The openings allow for increased air movement around the shield. The cuts in the shield may be above the foam member to create tabs which may be bent to at least partially cover the openings that extend through the foam member, Additionally, a pair of parallel cuts may be made on either side of the shield, the cuts adjustably engaging an elastic strap. This configuration allows the elastic strap to be comfortably adjusted to conform to a number of different sized heads.

Owner:TIDI PROD LLC

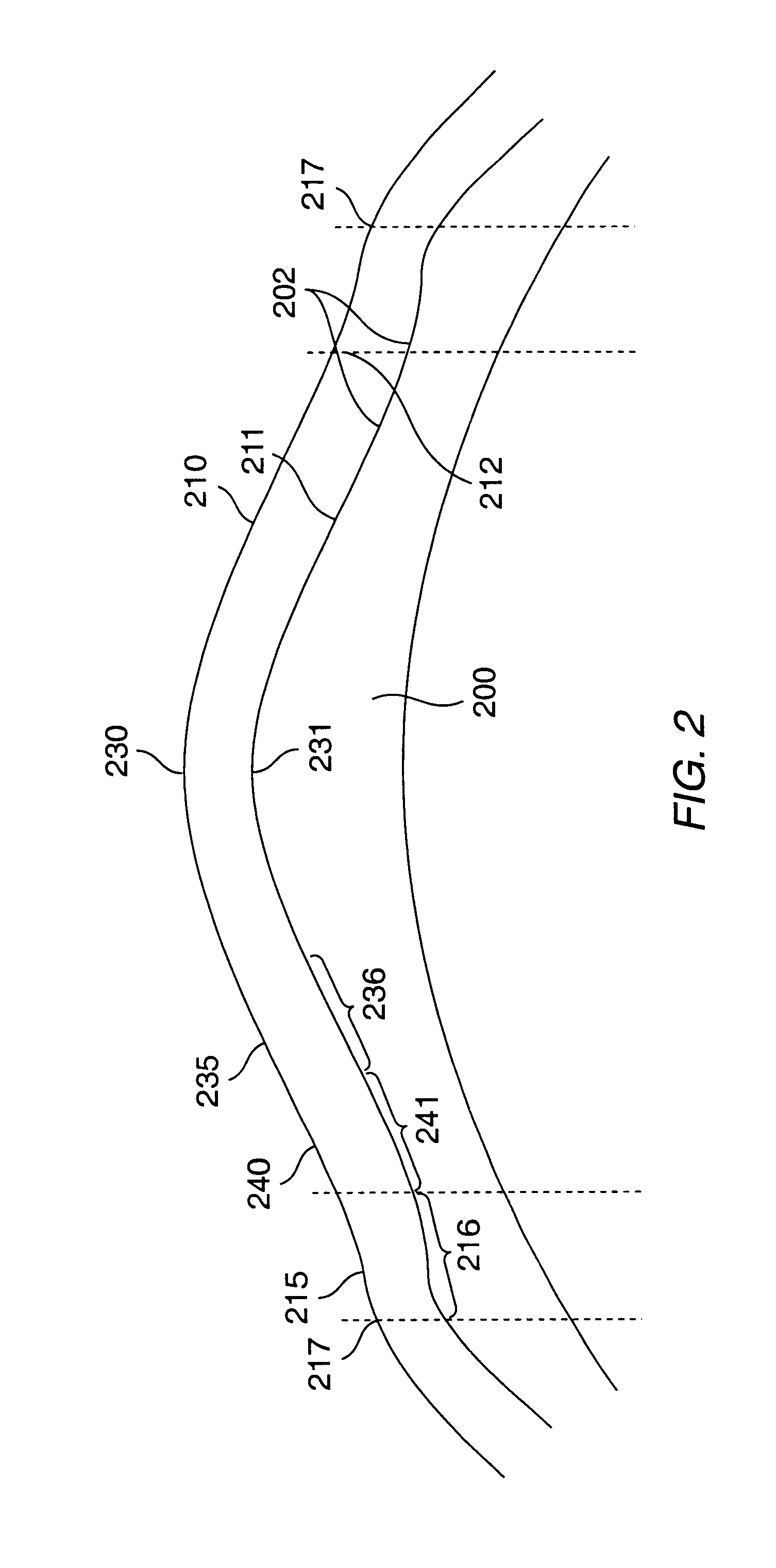

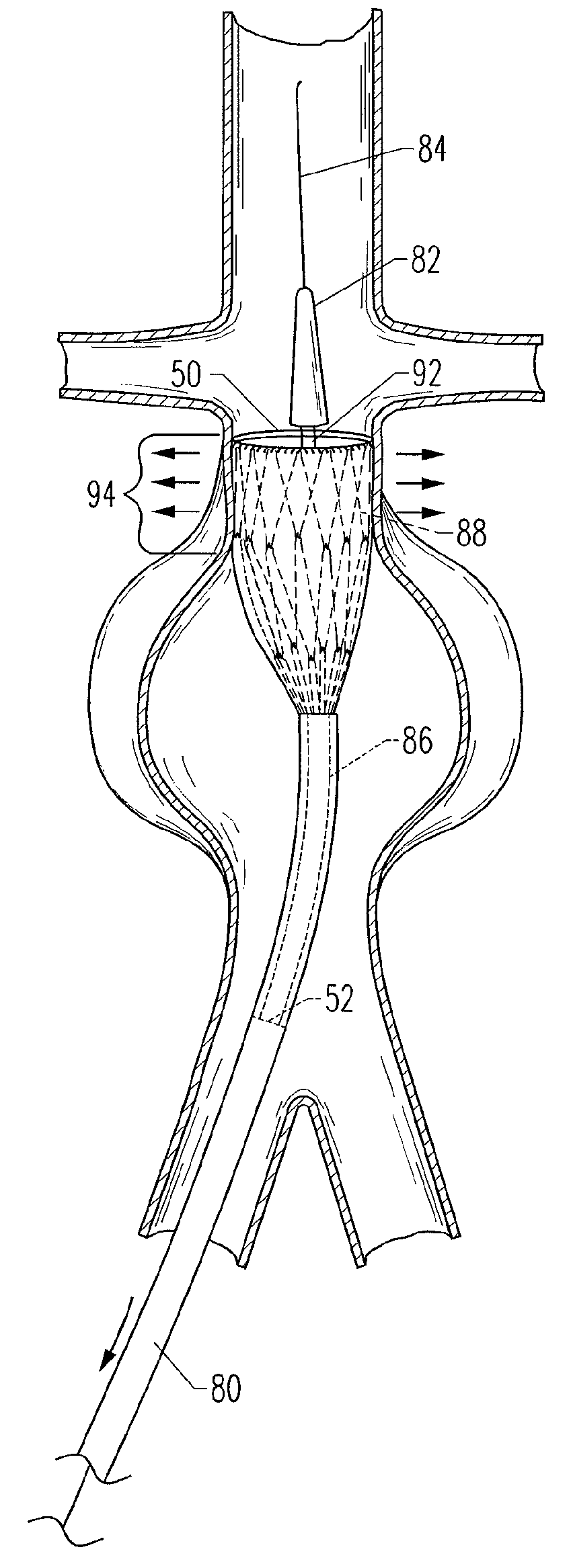

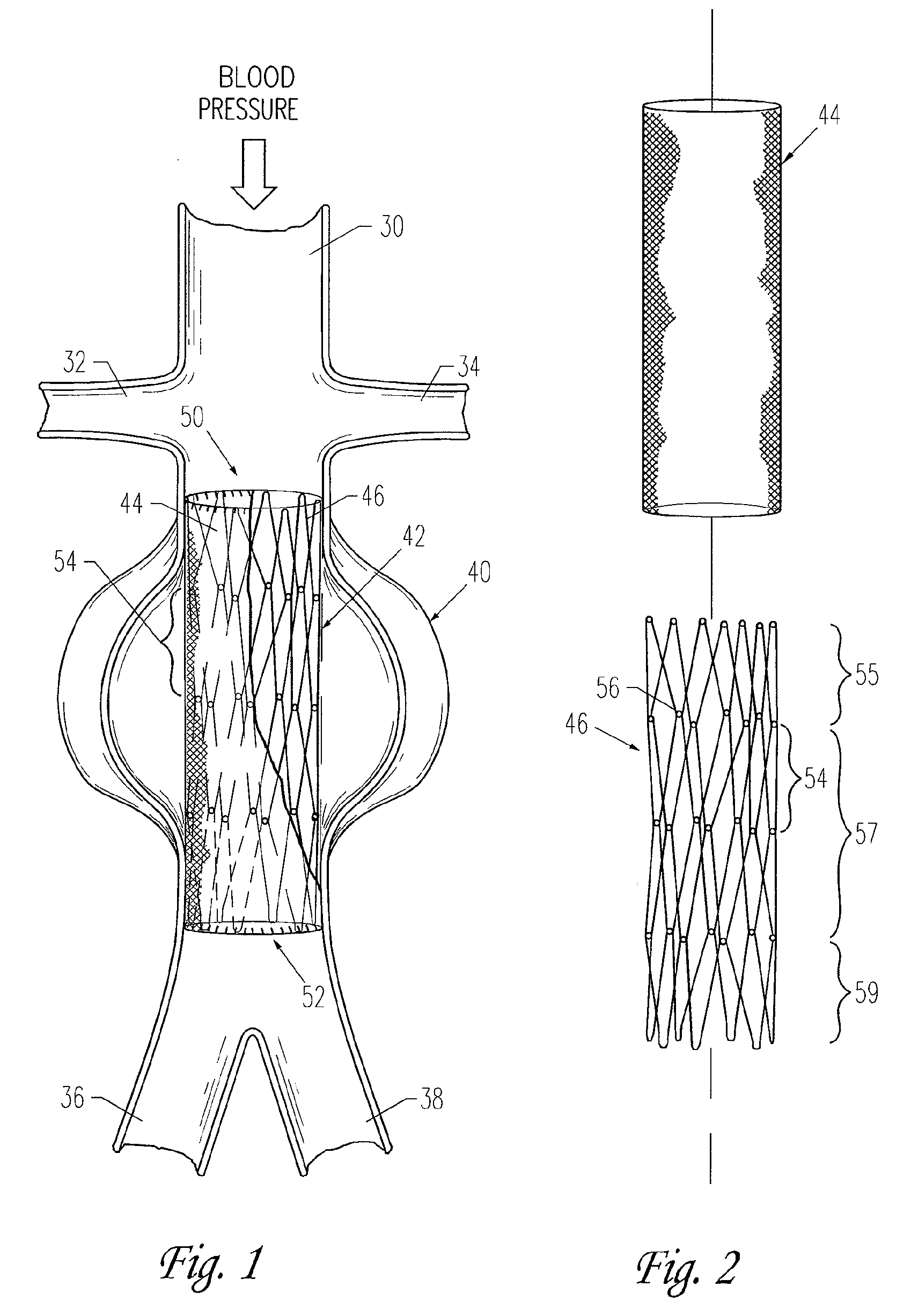

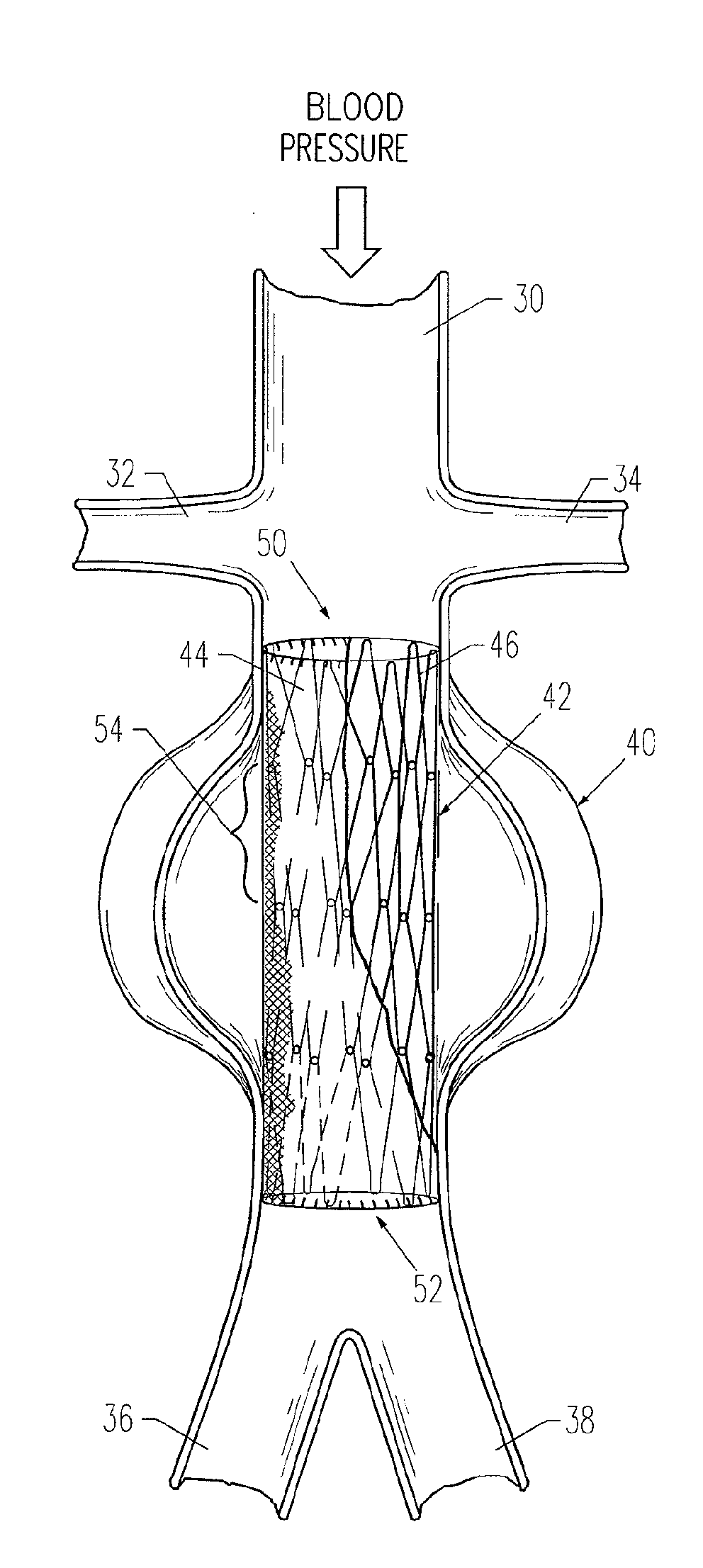

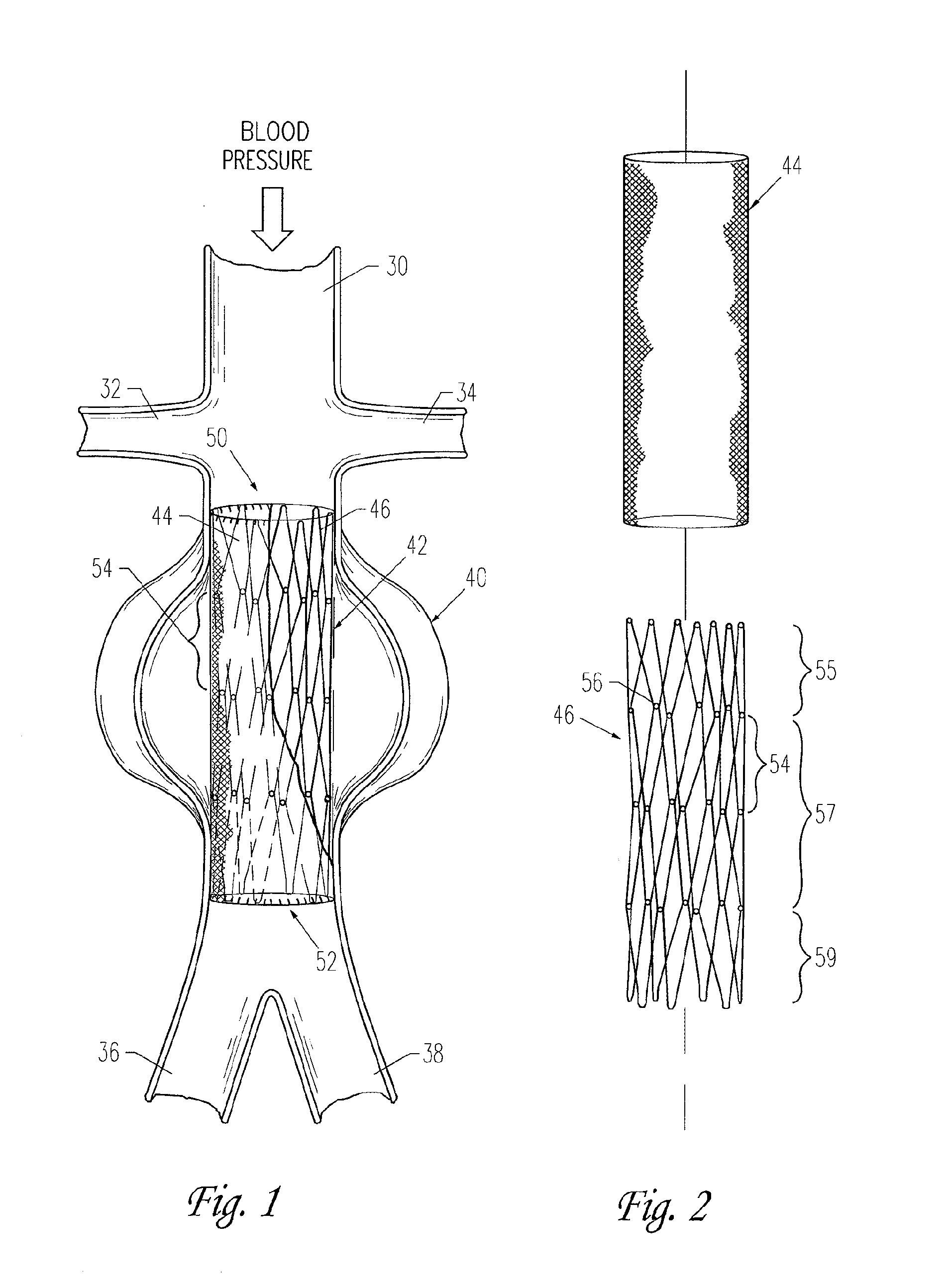

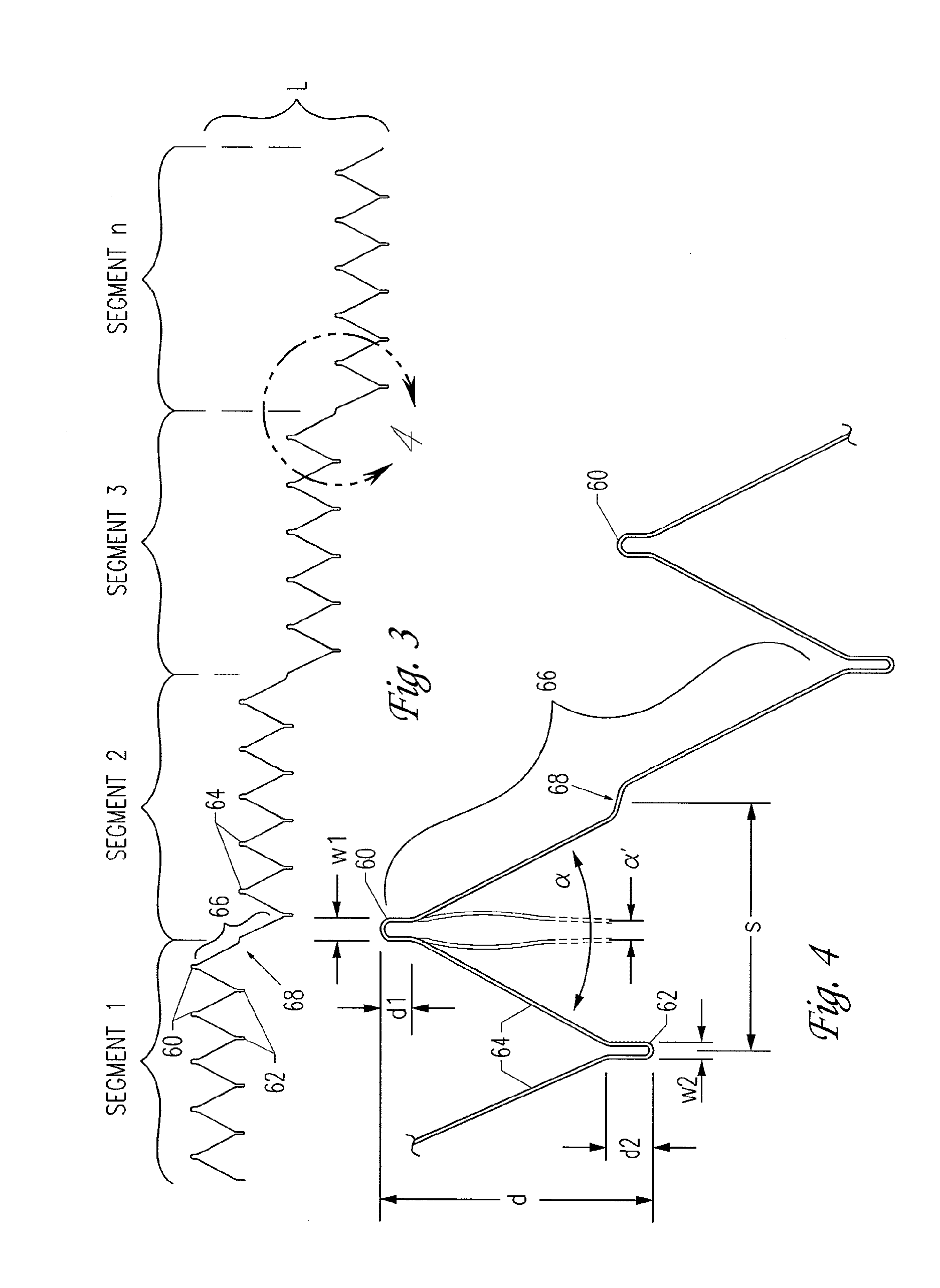

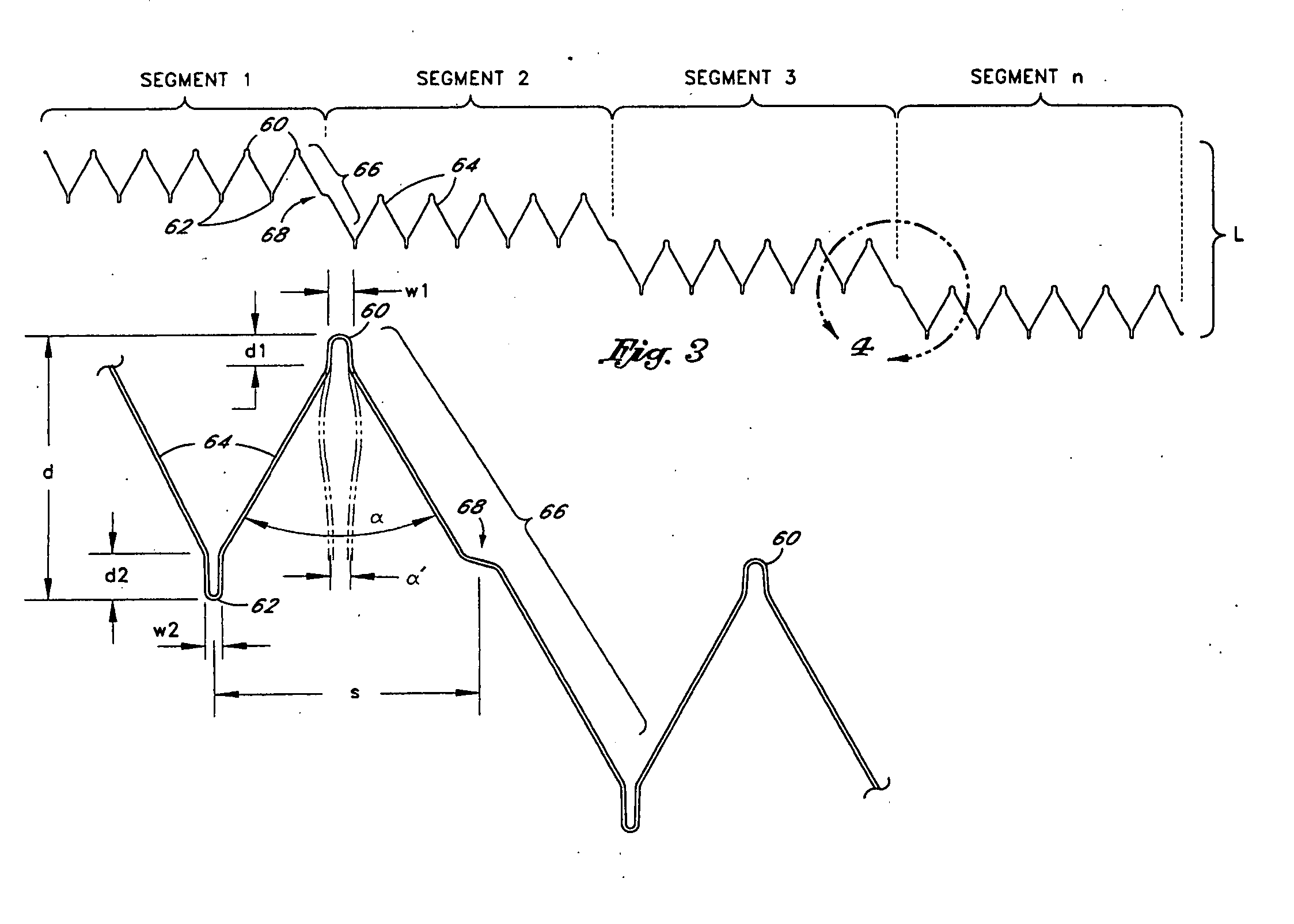

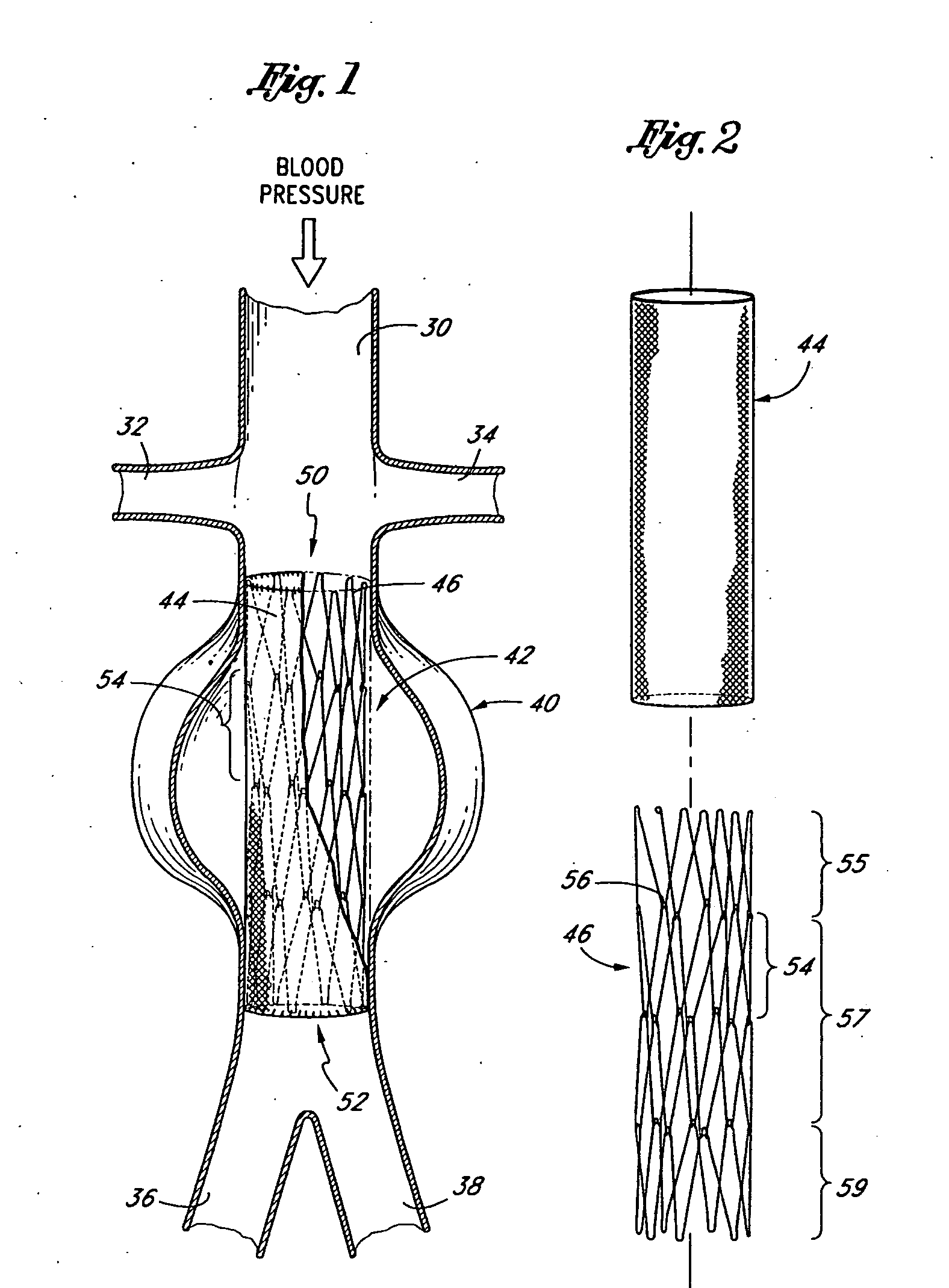

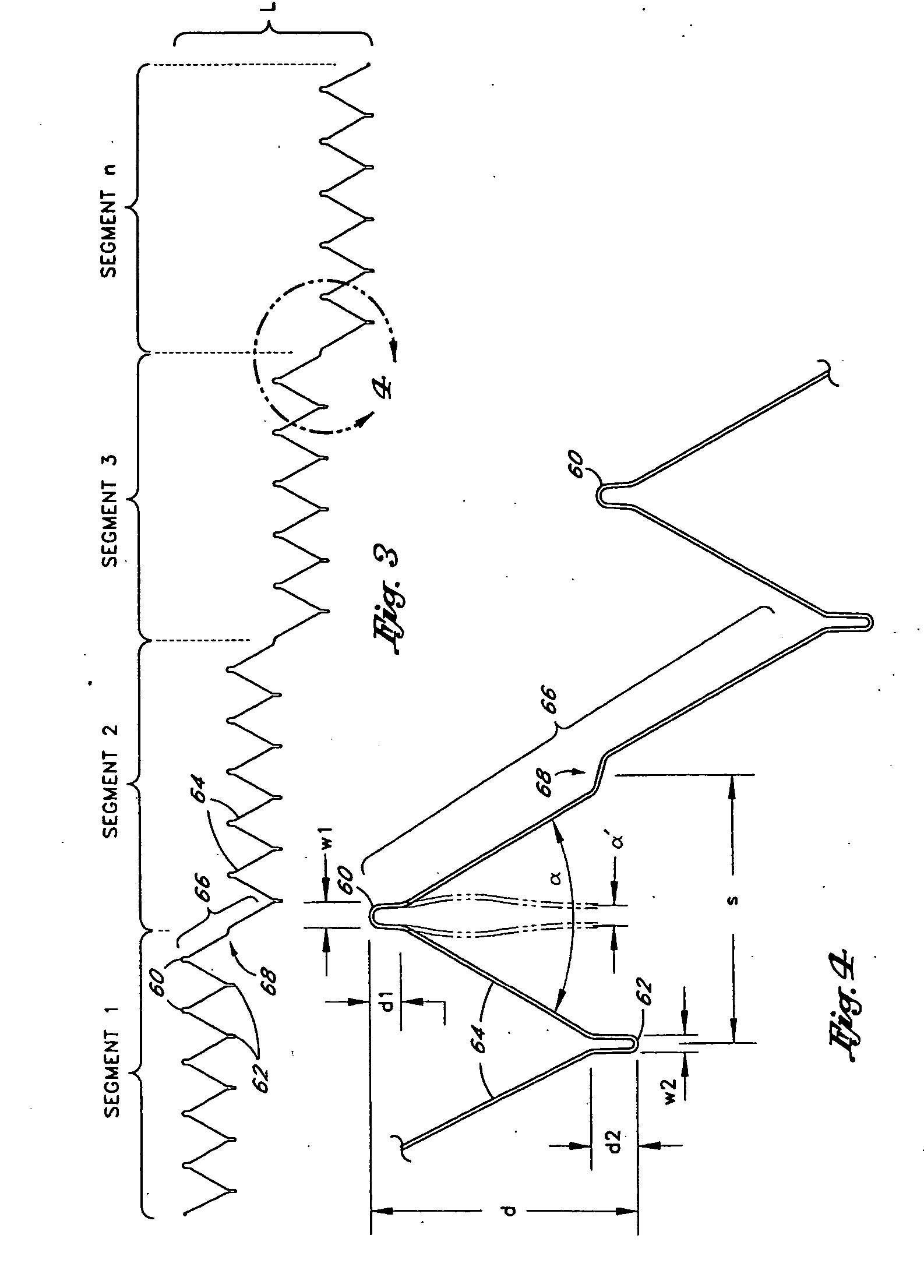

Implantable vascular graft

Disclosed is a tubular endoluminal vascular prosthesis, useful in treating, for example, an abdominal aortic aneurysm. The prosthesis comprises a self-expandable wire support structure having a tubular main body support and first and second branch supports. The support structure may include one or more sliding links to permit axial movement while maintaining patency of the central lumen. The branch supports may articulate with the main body to permit the branches to pivot laterally from the axis of the main body throughout a substantial range of motion.

Owner:ENDOLOGIX LLC

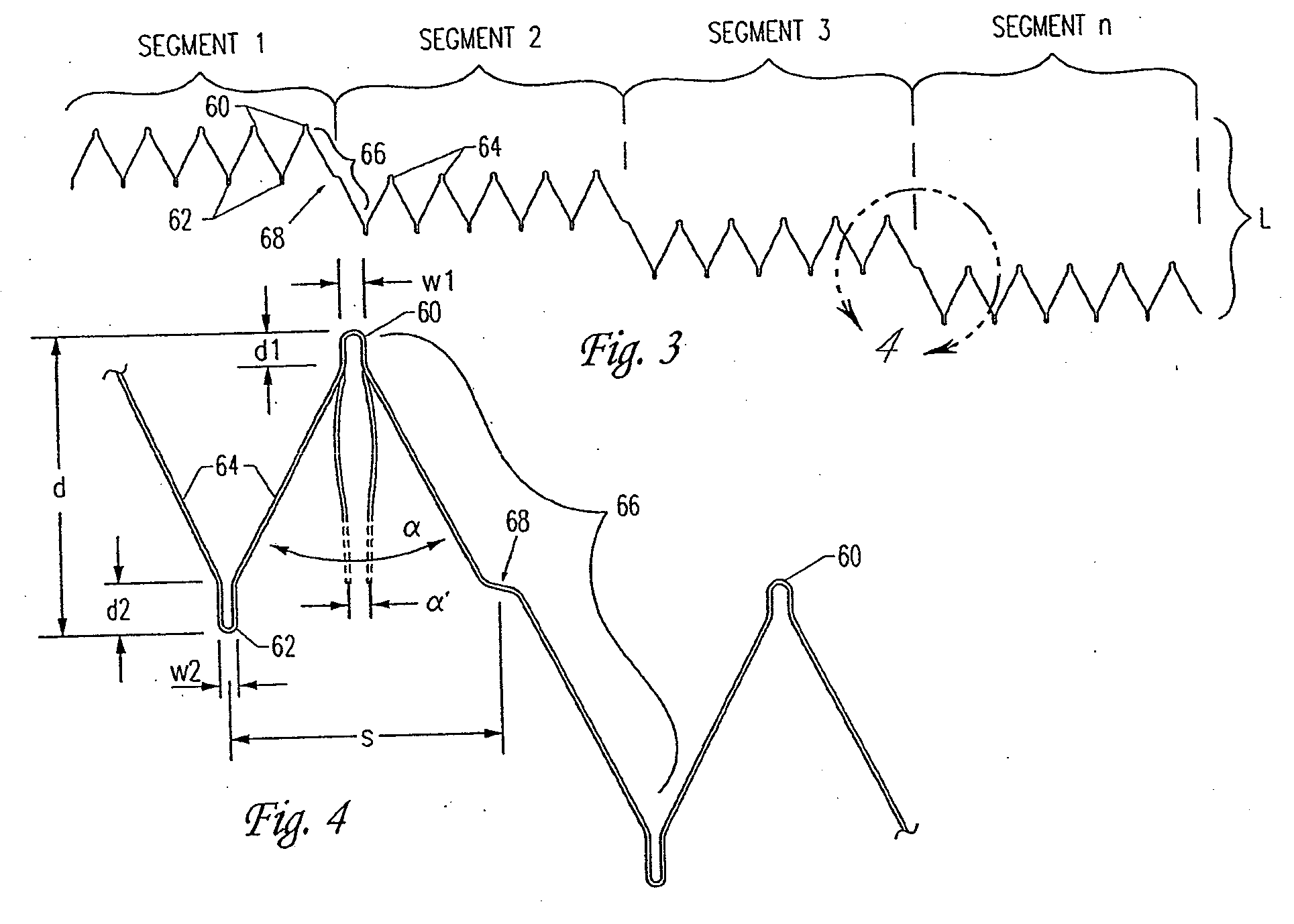

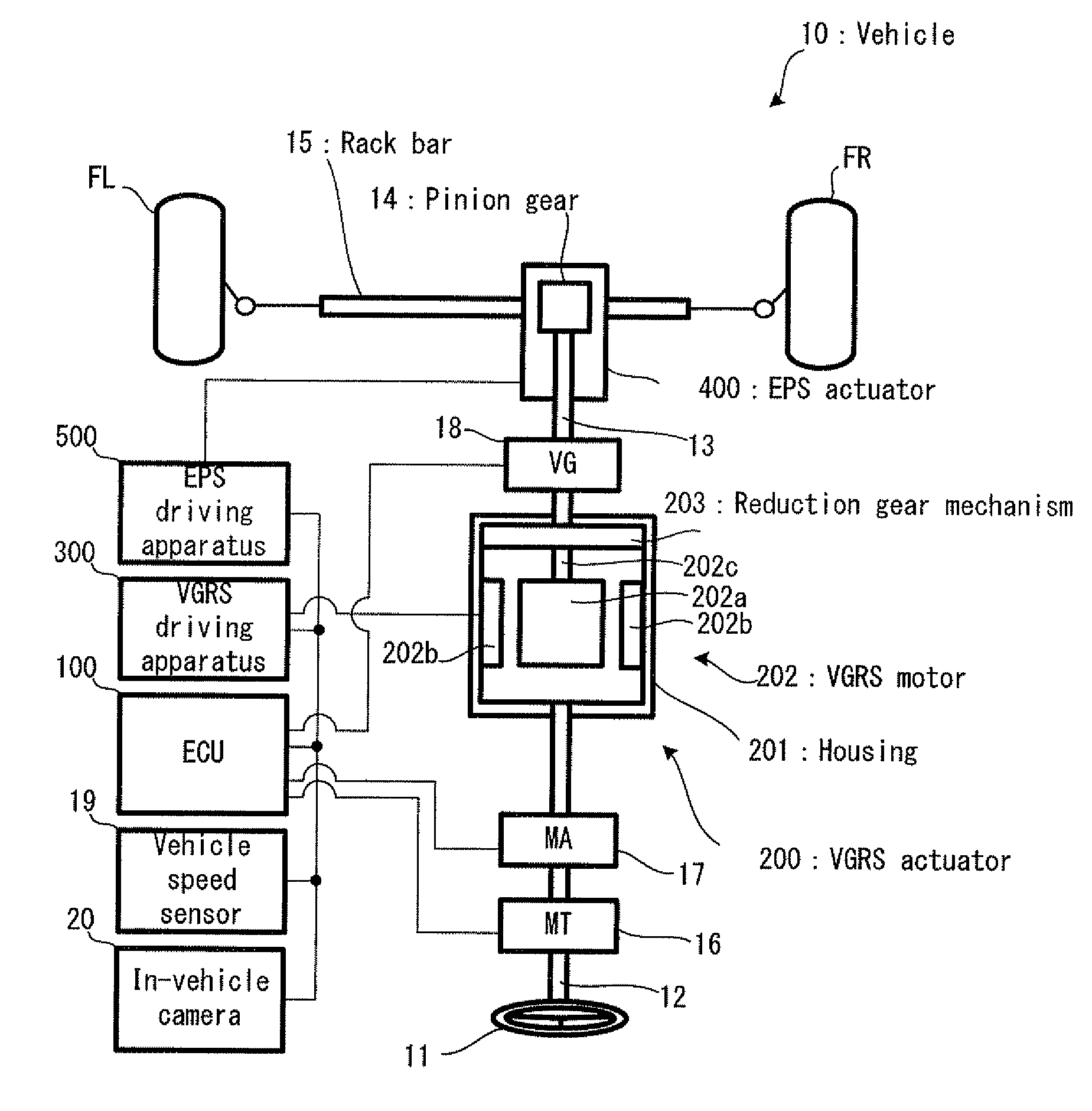

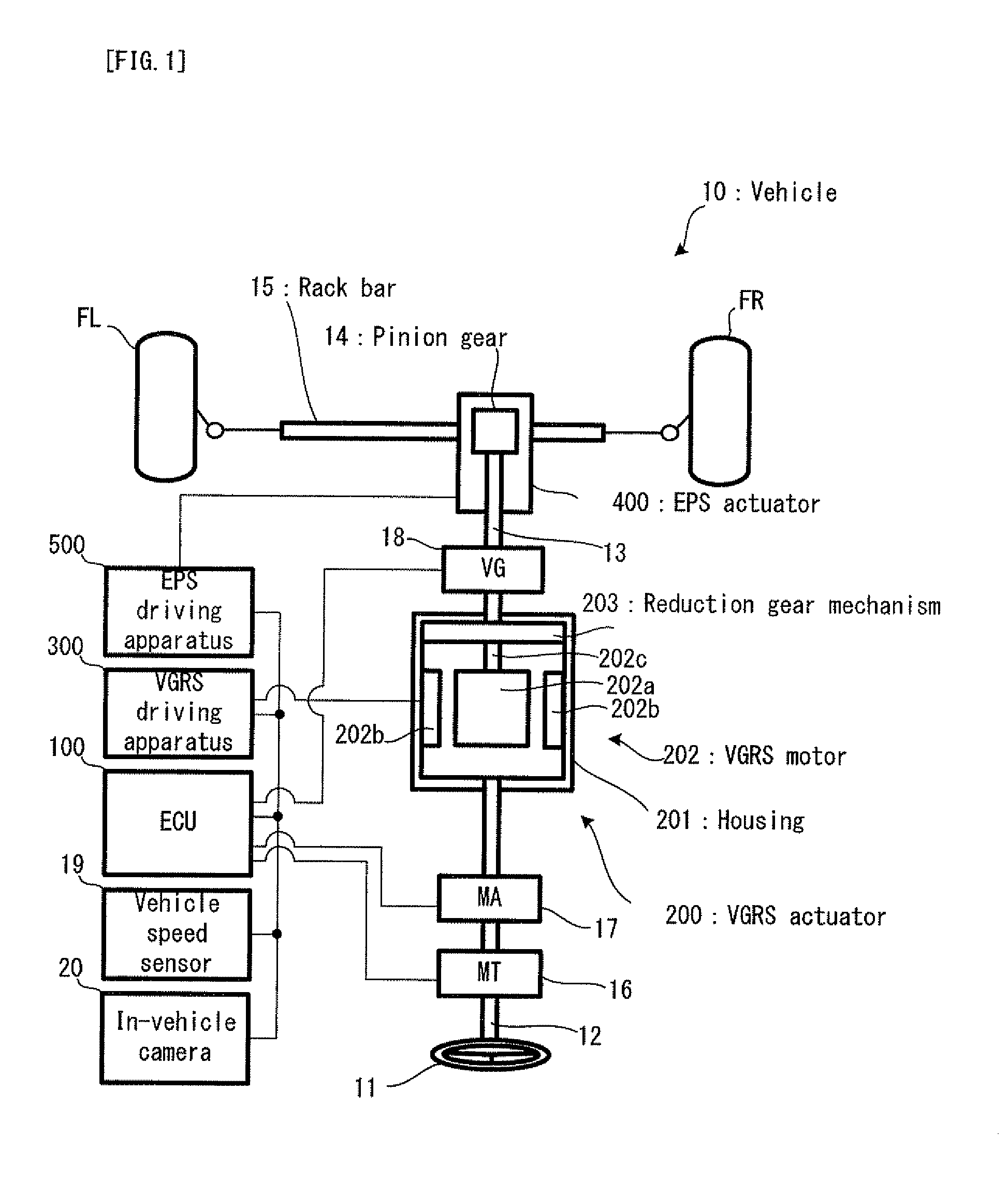

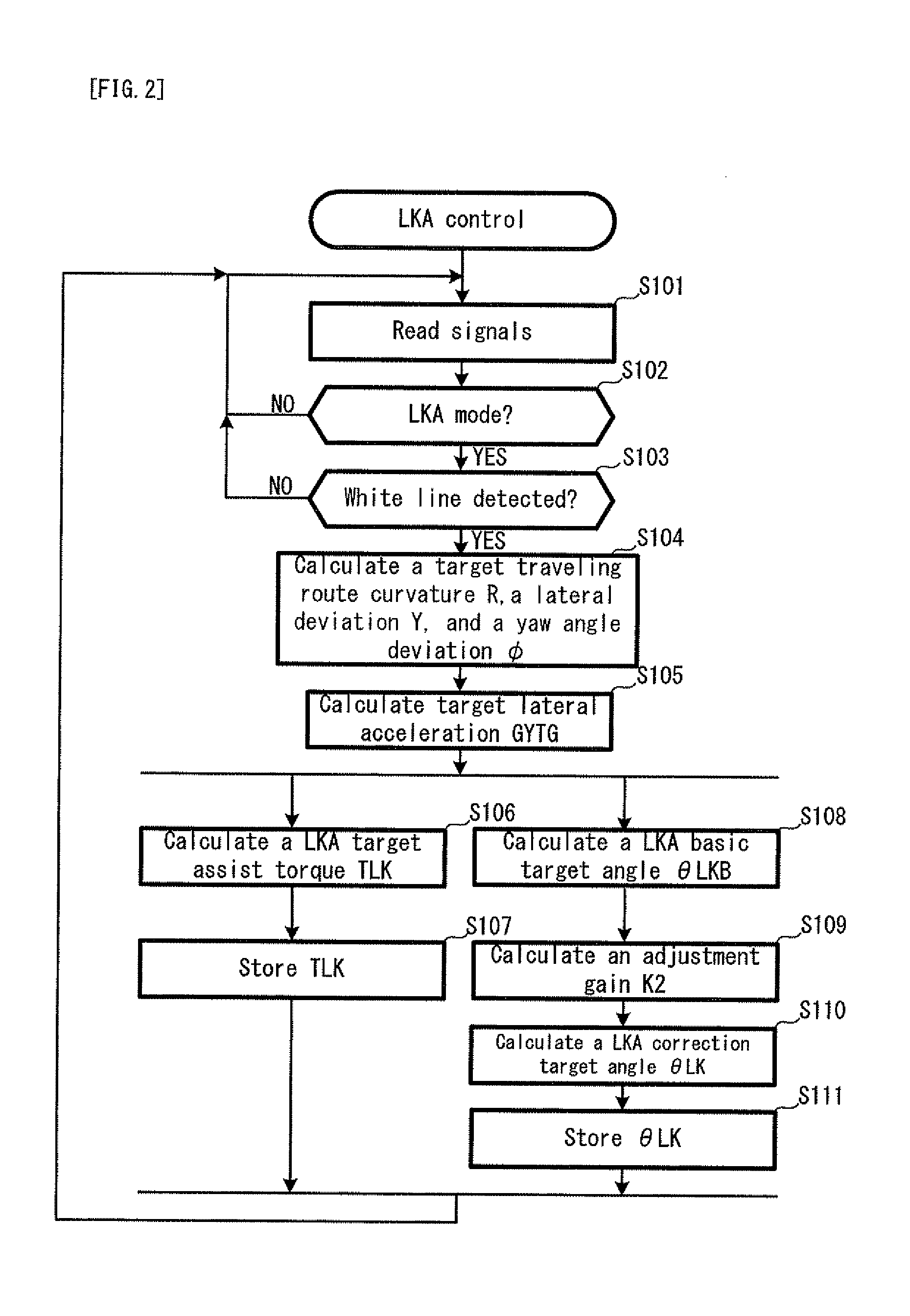

Driving support apparatus of vehicle

InactiveUS20110264329A1Reduce pruningIncrease the curvatureSteering initiationsDigital data processing detailsDriver/operatorSteering angle

A vehicle is provided with: an EPS a VGRS actuator as a rudder angle varying device; and an EPS actuator as a steering torque assisting device. In following a target driving route, a LKA target assist torque TLK is outputted from the EPS actuator on the basis of target lateral acceleration GYTG. On the other hand, in order to suppress the steering of a steering wheel by the assist torque, which is against a driver's will, steered wheels are steered by the VGRS actuator, excessively by a LKA correction target angle θLK. At this time, it does not influence a relation between a steering angle and the rotation angle of a lower steering shaft. Thus, the following for the target driving route is realized without reducing the robustness of the vehicle with respect to the driver's steering.

Owner:TOYOTA JIDOSHA KK

Implantable vascular graft

InactiveUS20100318174A1Minimize migrationMinimize riskStentsBlood vesselsRange of motionVascular graft

Disclosed is a tubular endoluminal vascular prosthesis, useful in treating, for example, an abdominal aortic aneurysm. The prosthesis comprises a self-expandable wire support structure having a tubular main body support and first and second branch supports. The prosthesis can have a plurality of radially outwardly extending barbs. The branch supports may articulate with the main body to permit the branches to pivot laterally from the axis of the main body throughout a substantial range of motion.

Owner:ENDOLOGIX LLC

Disposable face shield

ActiveUS9532617B2Increase air flowReduce riskGarment special featuresProtective garmentAir movementMechanical engineering

A disposable face shield with a shield with a plurality of cuts is described. A foam member is connected to the shield to provide added comfort. The foam member may contain a plurality of openings extending through the member. The openings allow for increased air movement around the shield. The cuts in the shield may be above the foam member to create tabs which may be bent to at least partially cover the openings that extend through the foam member. Additionally, a pair of parallel cuts may be made on either side of the shield, the cuts adjustably engaging an elastic strap. This configuration allows the elastic strap to be comfortably adjusted to conform to a number of different sized heads.

Owner:TIDI PROD LLC

Implantable vascular graft

InactiveUS20060271164A1Minimize migration and riskIncrease the curvatureStentsSurgeryRange of motionVascular graft

Disclosed is a tubular endoluminal vascular prosthesis, useful in treating, for example, an abdominal aortic aneurysm. The prosthesis comprises a self-expandable wire support structure having a tubular main body support and first and second branch supports. The support structure may include sliding links to permit flexibility while maintaining patency of the central lumen. The branch supports may articulate with the main body to permit the branches to pivot laterally from the axis of the main body throughout a substantial range of motion. Exoskeleton components or barbs may be provided to resist migration and endoleaks.

Owner:SHAOLIAN SAMUEL M +1

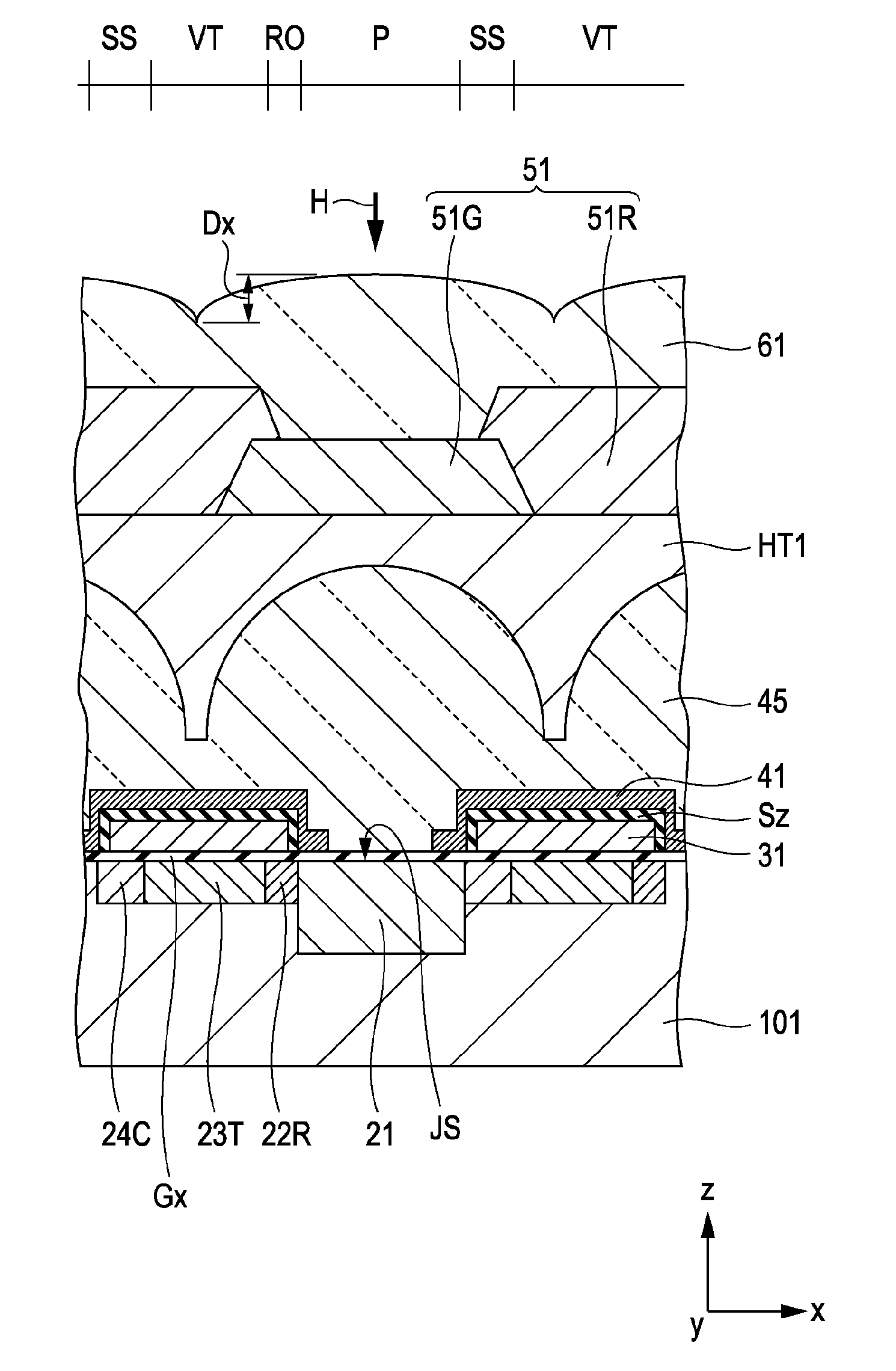

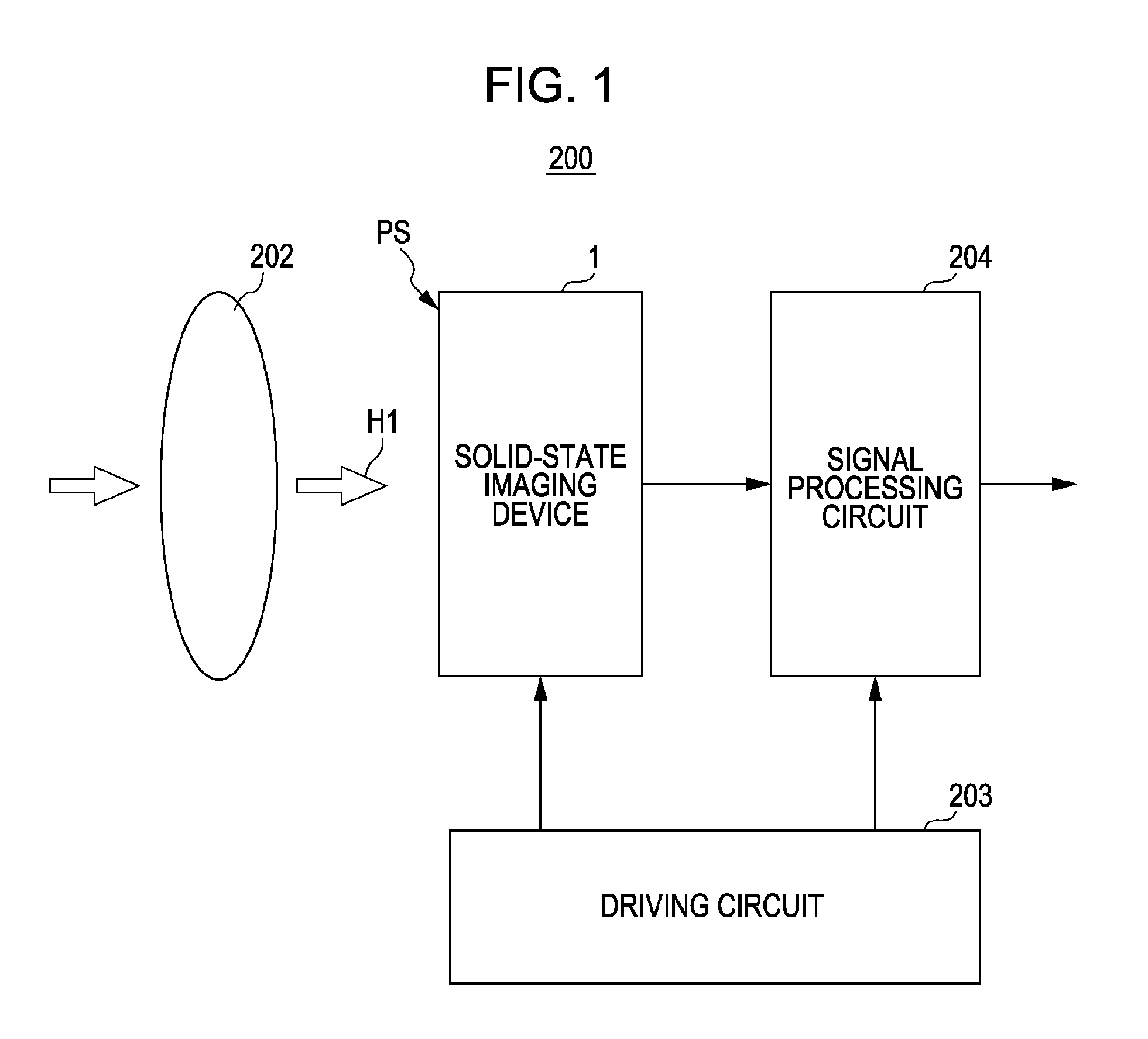

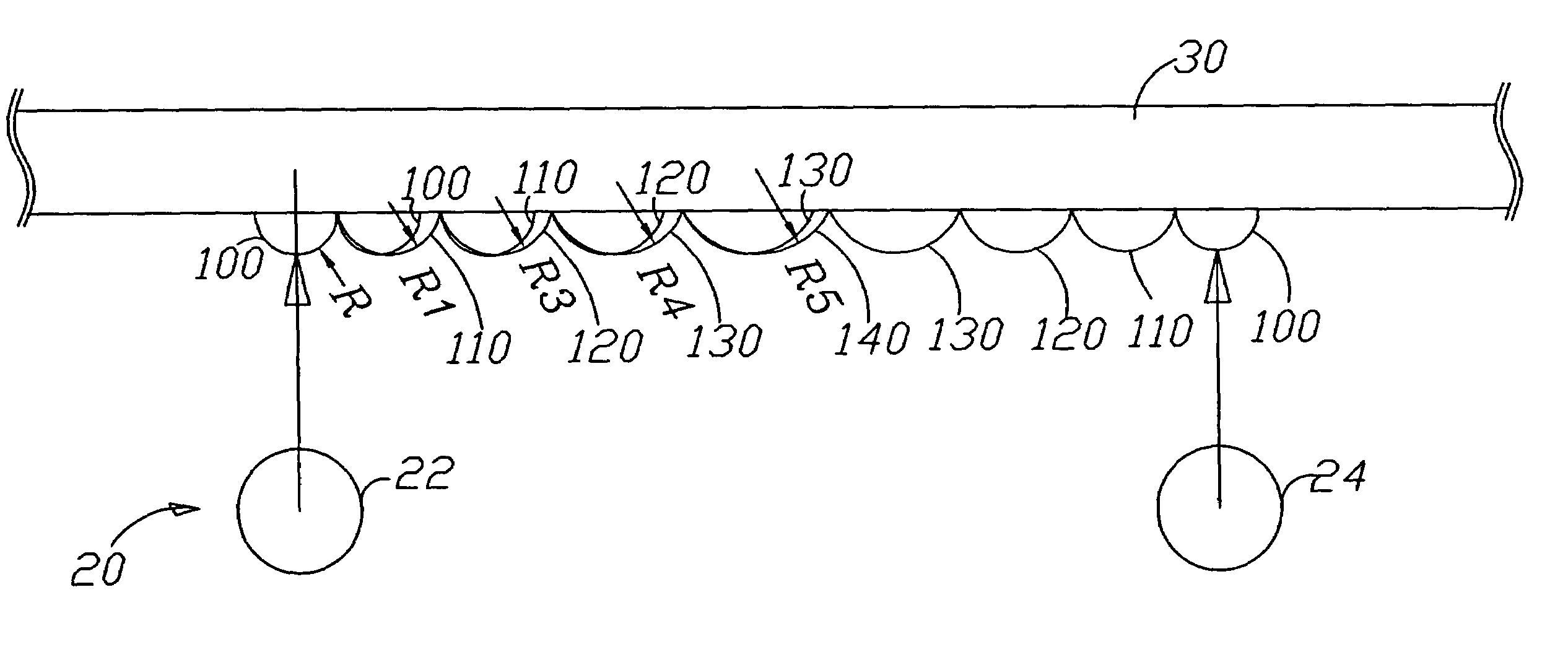

Solid-state imaging device, solid-state imaging device manufacturing method, electronic device, and lens array

ActiveUS20110073751A1Improve sensitivityFocus efficiency be improveTransistorSolid-state devicesMicrolensEngineering

A solid-state imaging device includes: multiple micro lenses, which are disposed in each of a first direction and a second direction orthogonal to the first direction, focus the incident light into the light-receiving surface; with the multiple micro lenses of which the planar shape is a shape including a portion divided by a side extending in the first direction and a side extending in the second direction being disposed arrayed mutually adjacent to each of the first direction and the second direction; and with the multiple micro lenses being formed so that the depth of a groove between micro lenses arrayed in a third direction is deeper than the depth of a groove between micro lenses arrayed in the first direction, and also the curvature of the lens surface in the third direction is higher than the curvature of the lens surface in the first direction.

Owner:SONY CORP

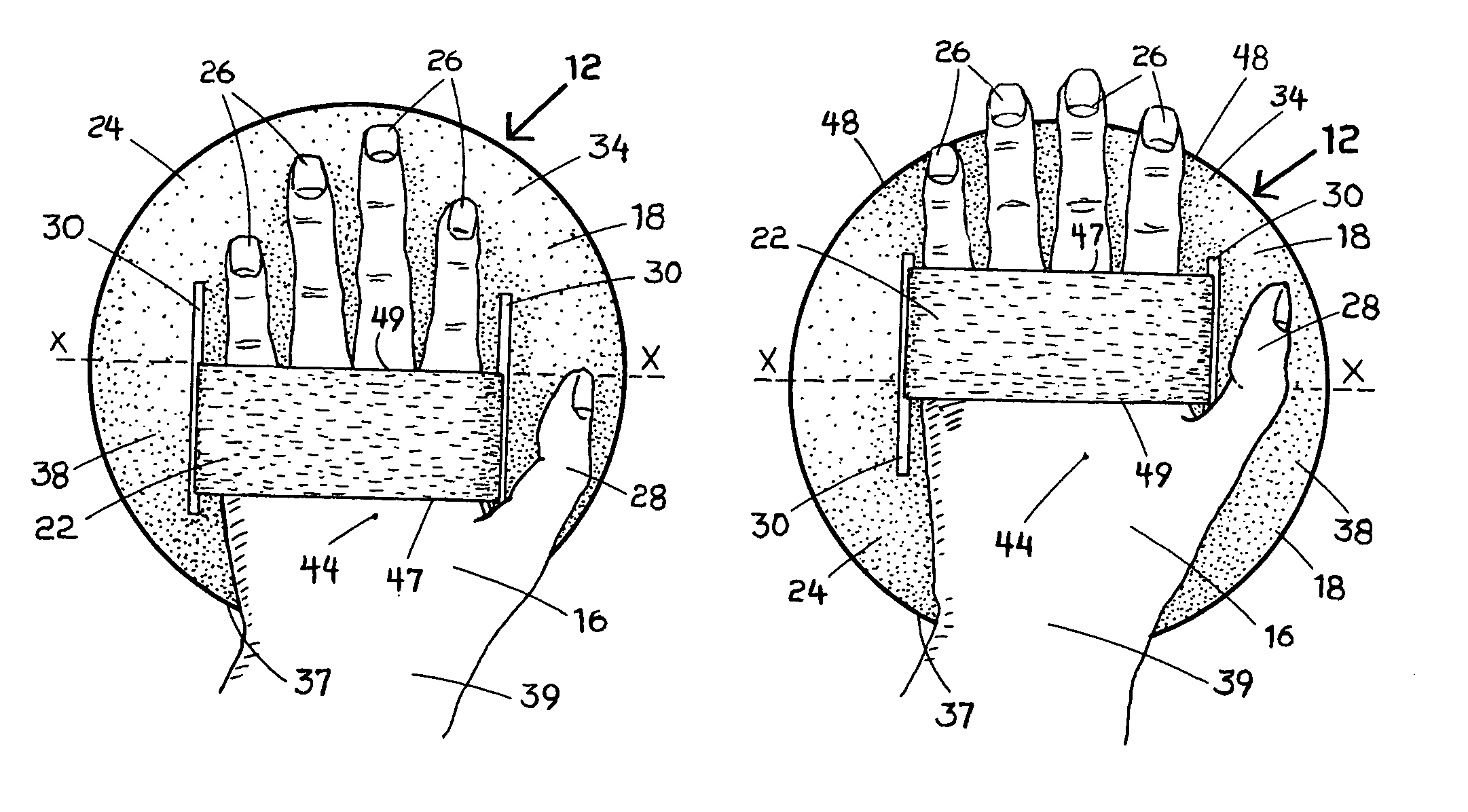

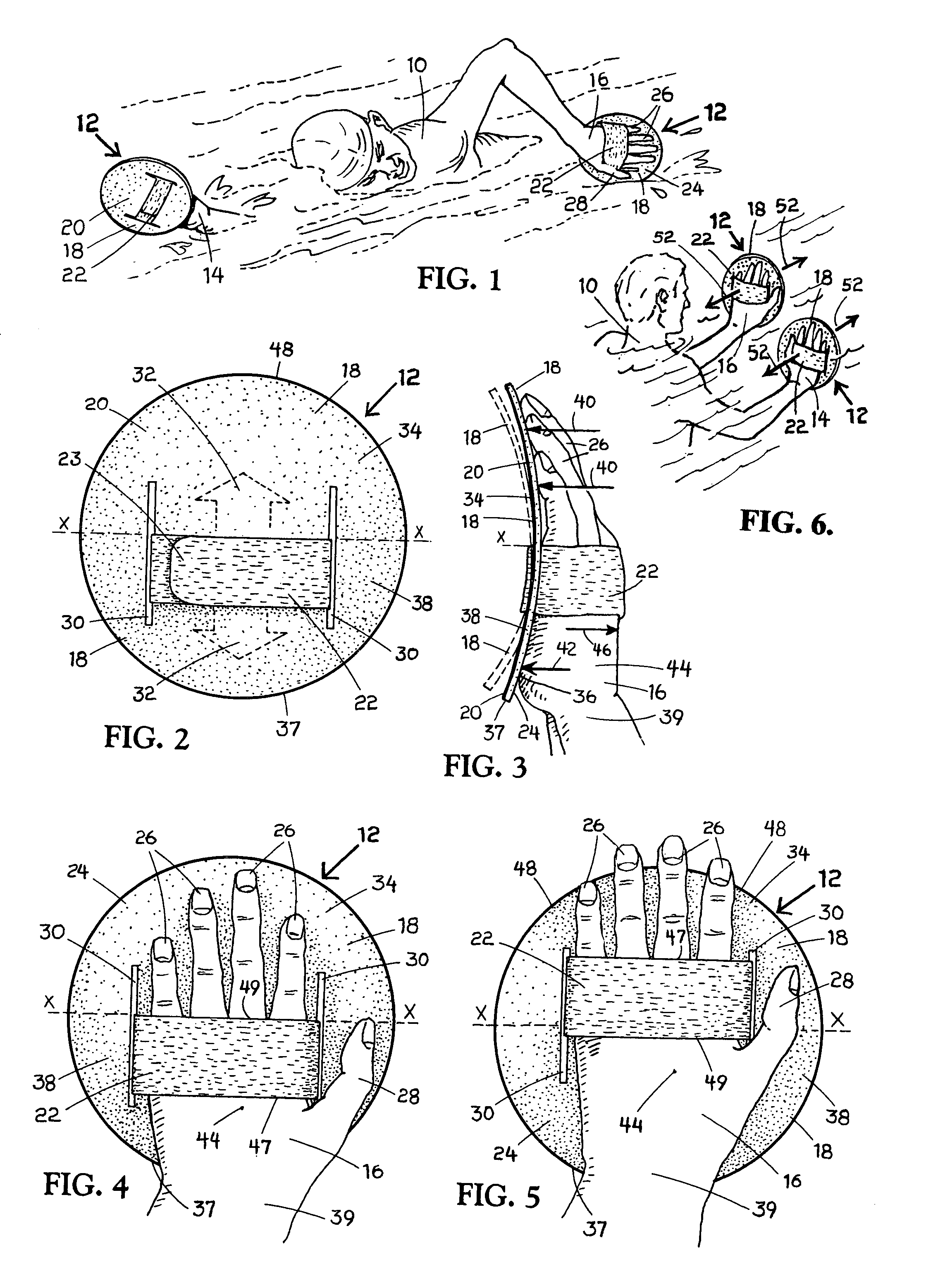

Water paddle for surface and underwater swimming, snorkeling and water exercises

InactiveUS6899581B1Increasing and decreasing water resistanceEasy to adaptSwim finsHand heldEngineering

A water paddle used for surface and underwater swimming, snorkeling, water aerobics and other water exercises. The water paddle includes a hand held, lightweight, flexible plastic, hydrodynamic paddle disk. A front of the paddle disk is flat or concave in shape for increasing or decreasing water resistance when moving the paddle in the water. Also, the paddle disk has a minimal thickness of ⅛ inch or less for allowing the flexing of the disk. An adjustable strap is received through a pair of parallel strap slots in the disk. The adjustable hand strap allows a swimmer to adjust his or her hand at various positions on the back of the paddle disk. The hand can be adjusted for allowing the disk to cover the fingers and palm of the hand in a first position. Also, the hand can be moved upwardly allowing the fingers to extend beyond the upper edge if need be in a second position and reduce pressure against the wrist of the swimmer.

Owner:NOKES RONALD W

Sitting device

InactiveUS20050168030A1Efficiently relievedIncrease the curvatureOperating chairsDental chairsBiological bodyPhysical medicine and rehabilitation

The invention relates to furniture, in particular to sitting devices and can be used as a work chair or therapeutic furniture. The aim of said invention is to develop a sitting device which would make it possible to efficiently relieve the backbone in a sitting posture taking into consideration individual morphological and functional asymmetries, thereby normalizing the work of other organs and systems of an organism, first and foremost the organs of the small pelvis, optimizing the “turtuosity” of the backbone associated with constitutional and geophysical factors. The sitting device comprises a support provided with a base in a top part thereof, on which a seat is mounted; said seat consists of two parts pivotally arranged on a horizontal axis which lies on a frontal plane and is fixed to the base, each part of the seat being provided with adjusters of the rotational motion thereof with respect to the horizontal axis; the device can be provided with a back and a bracket bearing a backrest, comprising two supporting elements pivotally arranged on the horizontal axis which lies on the frontal plane and fixed to the bracket, each supporting element of the backrest being provided with adjusters of the rotational motion thereof with respect to the horizontal axis.

Owner:ALFA +1

Two-part accomodating intraocular lens device

Owner:LENSGEN INC

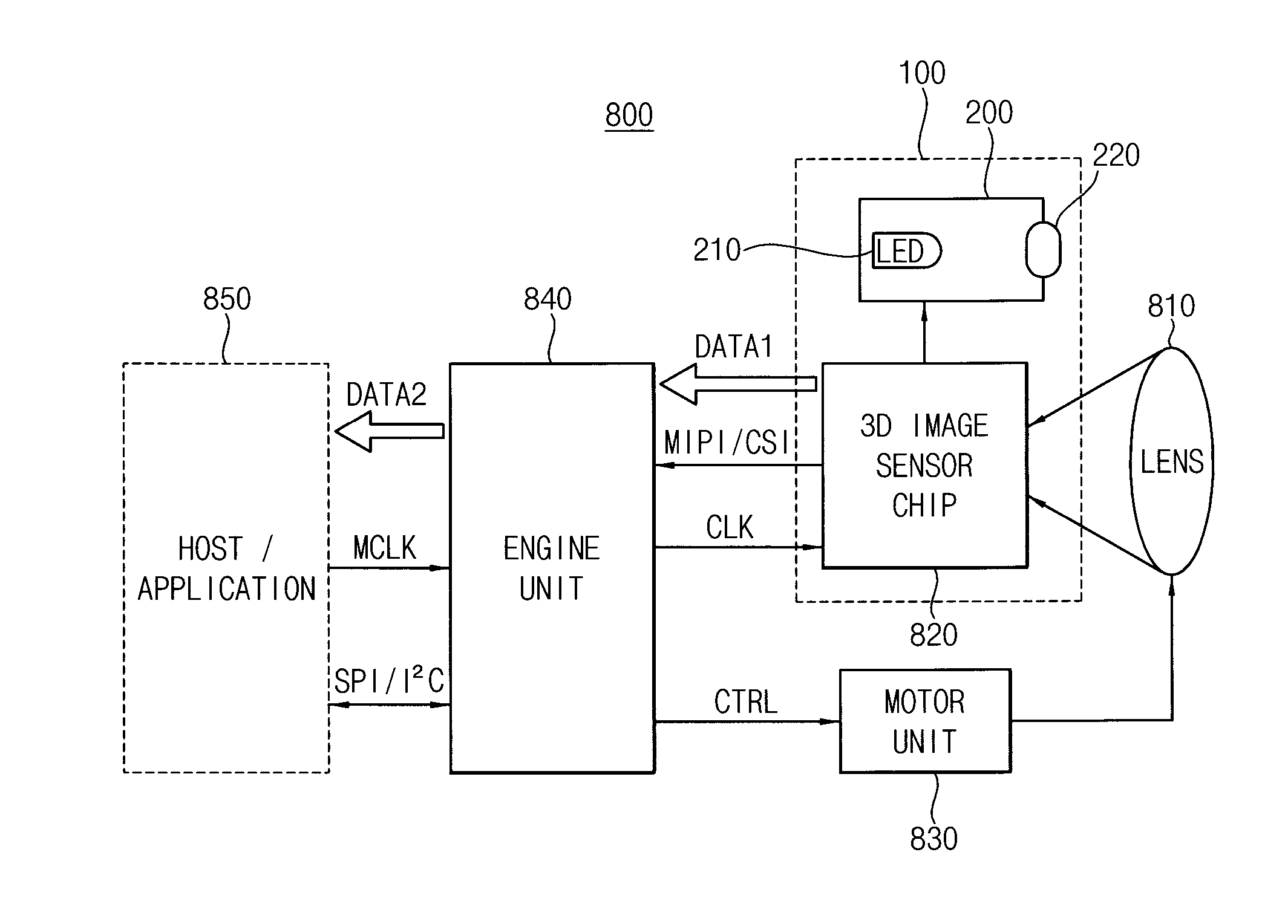

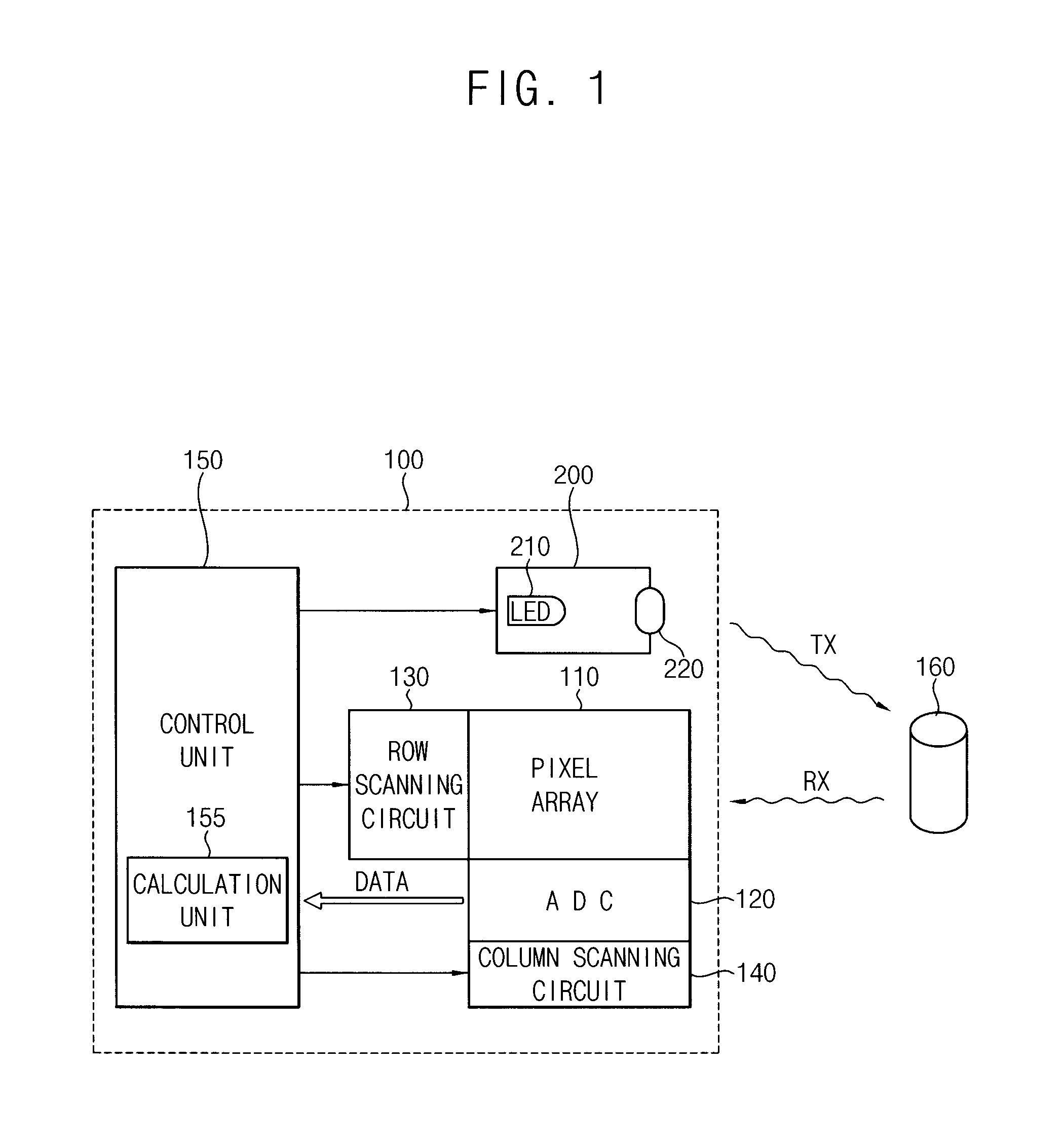

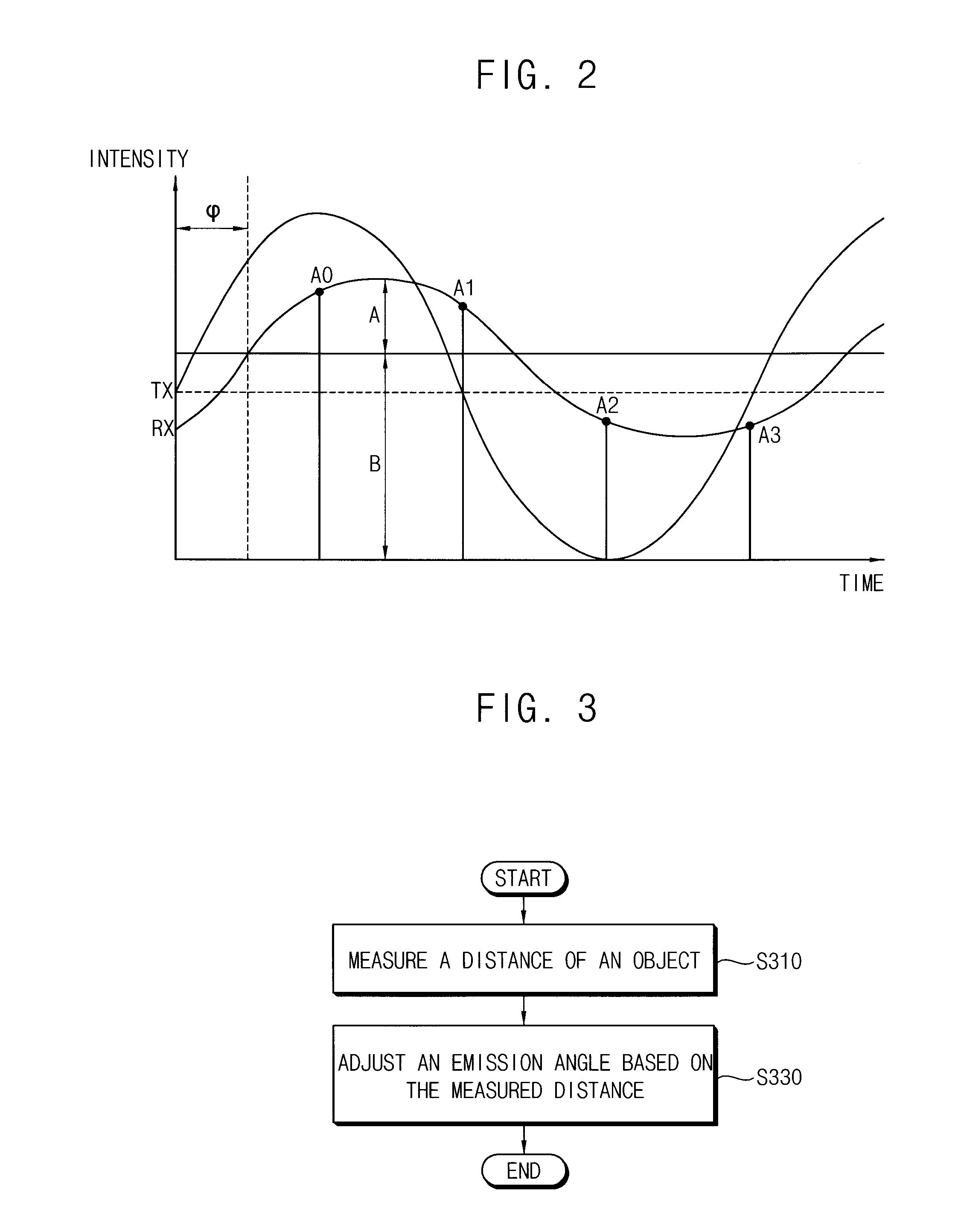

Image sensors and methods of operating the same

InactiveUS20120154537A1Increase the curvatureEmission reductionTelevision system detailsElectromagnetic wave reradiationOptoelectronicsLight source

According to example embodiments, a method of operating a three-dimensional image sensor comprises measuring a distance of an object from the three-dimensional image sensor using light emitted by a light source module, and adjusting an emission angle of the light emitted by the light source module based on the measured distance. The three-dimensional image sensor includes the light source module.

Owner:SAMSUNG ELECTRONICS CO LTD

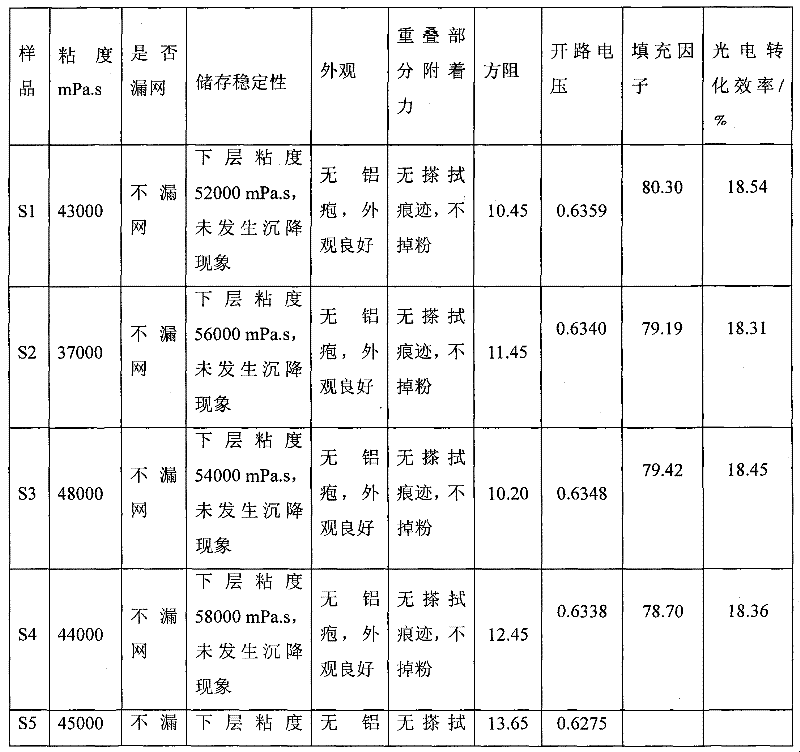

Conductive paste for solar cell and preparation method thereof

ActiveCN102479568AImprove rheologyEasy constructionNon-conductive material with dispersed conductive materialCable/conductor manufactureOpen-circuit voltageSedimentation

The invention provides a conductive paste and a preparation method thereof. The conductive paste comprises aluminum powder, an inorganic binding agent, an organic carrier and metal-glass composite powder, wherein the metal-glass composite powder is of nano-particles and a core-shell structure, glass is used as a core material, and metal is used as a shell material. The conductive paste disclosed by the invention is good in storage stability and less prone to sedimentation and agglomeration, and the conductive paste is less prone to leakage from a screen during screen printing; after sintering, an aluminum film is smooth in surface and grey white, and has no aluminum vesicles or aluminum beads; and furthermore, the part in contact and superimposition with a back silver electrode, of the aluminum film is wiped by a non-dust cloth, and wiping traces and powder dropping can be avoided. The series resistance of the produced solar cell is reduced obviously, a filling factor is increased obviously, and the average photoelectric conversion efficiency of a monocrystalline silicon cell piece can be above 18.20%. Simultaneously, the conductive paste disclosed by the invention is good in construction performance, a film layer formed after sintering is compact, the sintering thickness is uniform, the bending of a silicon chip is small, the sheet resistance is small and the open circuit voltage (Voc) of the formed cell is high.

Owner:BYD CO LTD

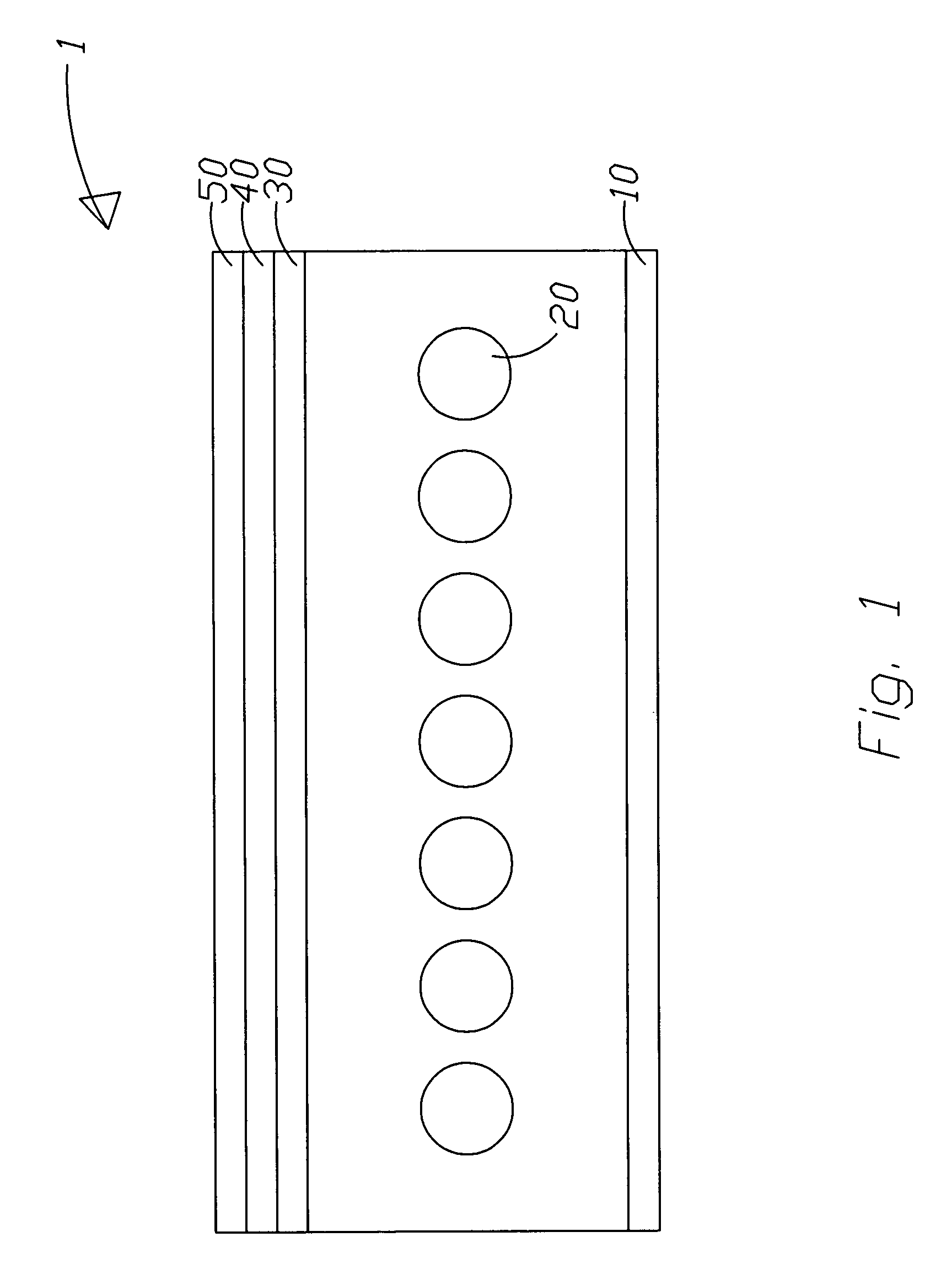

Structure of direct type backlight module with high uniform emitting light

ActiveUS7213936B2High uniform emitting lightFacilitated DiffusionMechanical apparatusElectric lightingLenticular lensOptoelectronics

Owner:ENTIRE TECH CO LTD

Non-ceramic hard armor composite

InactiveUS20060030226A1CheapIncrease protectionSynthetic resin layered productsWoven fabricsGramFiber

A hard armor composite includes a rigid non-ceramic facing and a ballistic fabric backing. The fabric backing is carried by the facing, and includes an array of bundled high-performance fibers. The fibers have a tensile strength greater than 7 grams per denier and a denier per filament ratio of less than 5.4.

Owner:ARMORWORKS ENTERPRISES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com