Mixing system

A mixing and mixer technology, applied in the field of fracturing, can solve problems such as easy to cause bubbles, increase of bubbles, increase the amount of defoaming agent, etc., to increase selectivity and convenience, improve mixing quality, and improve mixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

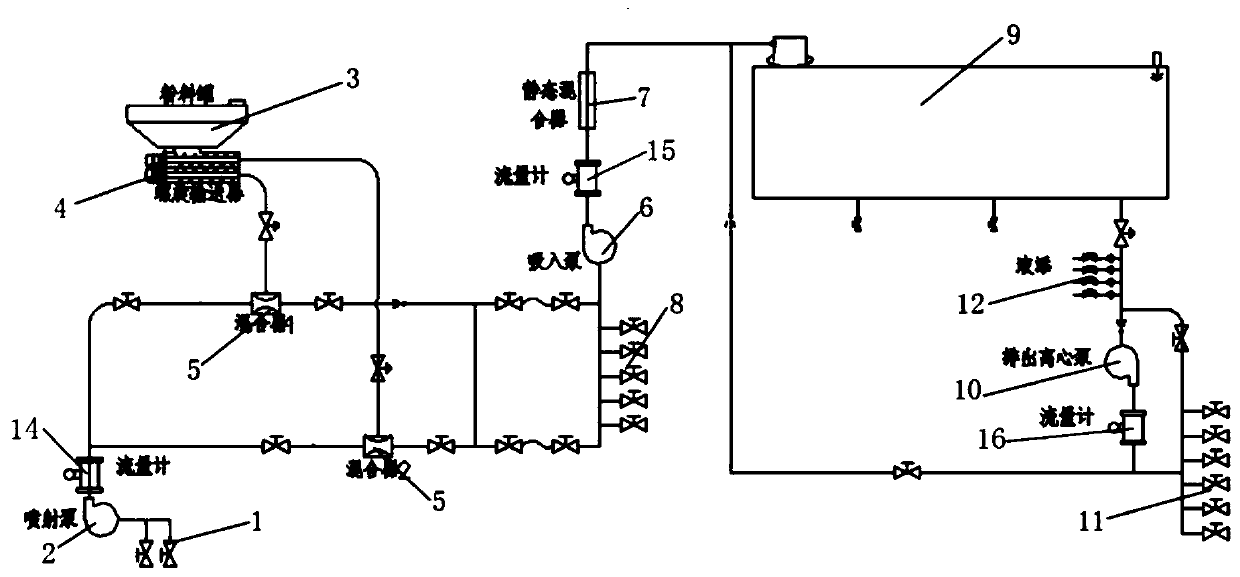

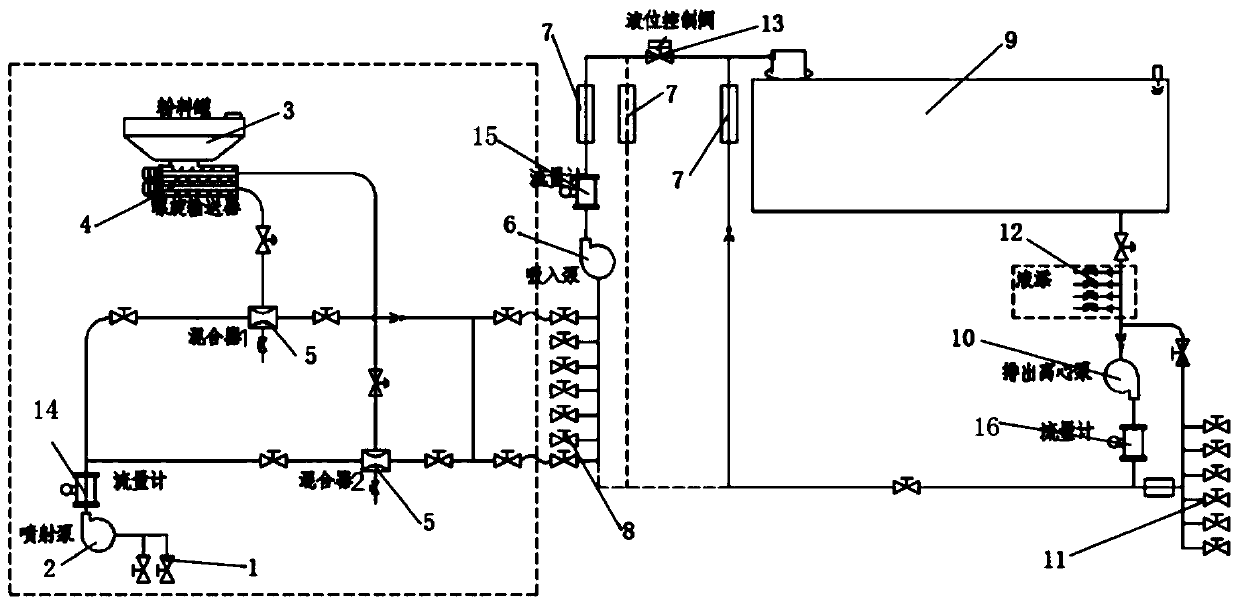

[0021] Such as figure 1 and 2 As shown, a mixing system includes a mixing module and an output module, the mixing module includes a first liquid inlet manifold 1, a jet pump 2, a powder tank 3 and a mixer 5, and the first liquid inlet manifold 1 is connected to the inlet of the jet pump 2, and is used to supply the base liquid to the mixer 5 and provide kinetic energy for the delivery of the base liquid. The outlet of the jet pump 2 is connected to the inlet of the mixer 5. Further preferably, the outlet of the jet pump 2 is connected to the inlet of the mixer 5 through the first flowmeter 14, and the mixer 5 can be connected according to the flow rate displayed by the first flowmeter 14. The flow adjustment of the mixer 5 is performed. The powder tank 3 provides powder for the mixer 5, which is mixed with the base liquid to form a mixed concentrate; the output module includes a second liquid inlet header 8, a suction pump 6, a second flow meter 15, a static mixing 7, mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com