Hydrocarbon fuel reforming combustion method for micro combustor and micro combustor

A micro-combustion, hydrocarbon fuel technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of unstable combustion, heat loss, short fuel residence time, etc., to improve temperature, improve combustion efficiency, and prolong residence time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

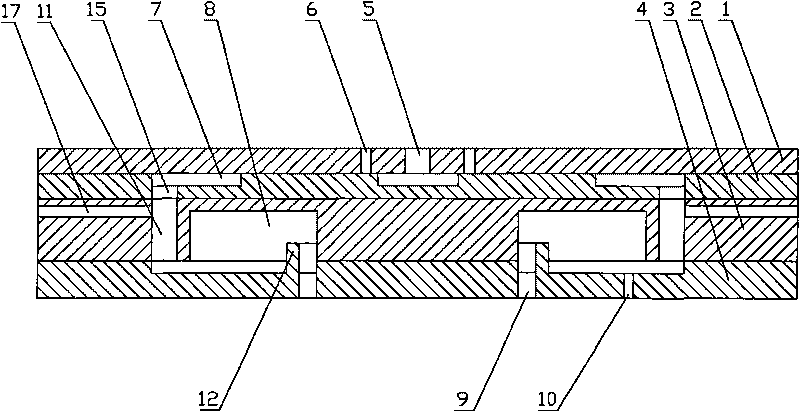

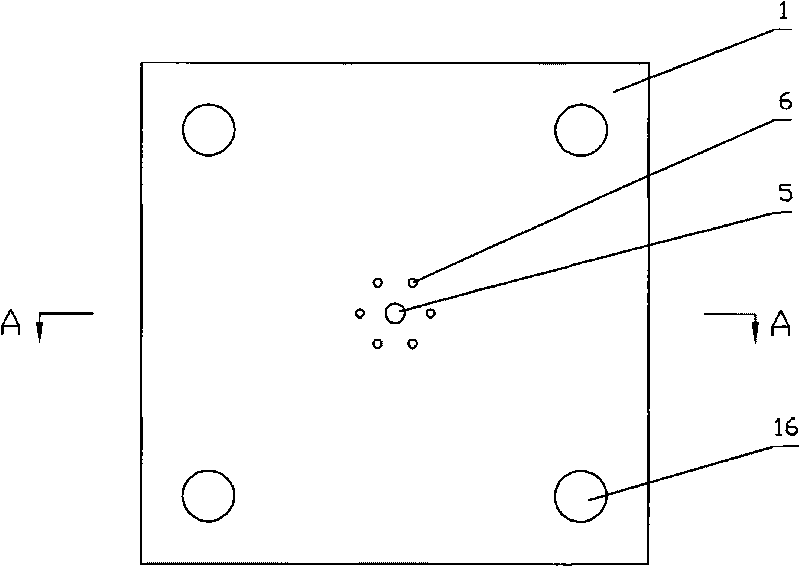

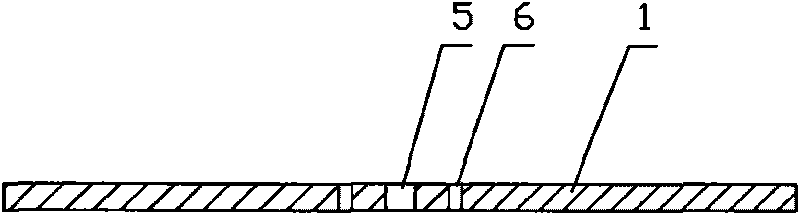

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] A reforming combustion method for hydrocarbon fuels used in micro-combustors, gaseous hydrocarbon fuels (such as methane, ethane, propane or acetylene) and moist air are first passed through the γ-Al 2 o 3 The reforming zone of the catalyst, so that the coupled autothermal reforming reaction occurs; then the reacted gas is passed into the combustion chamber for combustion; wherein, the volume ratio of gaseous hydrocarbon fuel and humid air is 1:1.2~1:1.6 . Gaseous hydrocarbon fuel and humid air in γ-Al 2 o 3 Under the action of the catalyst, a coupled autothermal reforming reaction (including the oxidation reaction of hydrocarbon fuel and oxygen and the reforming reaction of hydrocarbon fuel and water vapor) occurs to generate part of hydrogen, and the volume ratio of gaseous hydrocarbon fuel to humid air is 1:1.2~1:1.6 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com