Bacillus licheniformis and application thereof in promotion of cellulose degradation

A technology of bacillus licheniformis and cellulose degrading enzymes, applied in the field of bacillus licheniformis and its application in promoting cellulose degradation, to achieve the effects of promoting compost maturity, improving compost quality, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

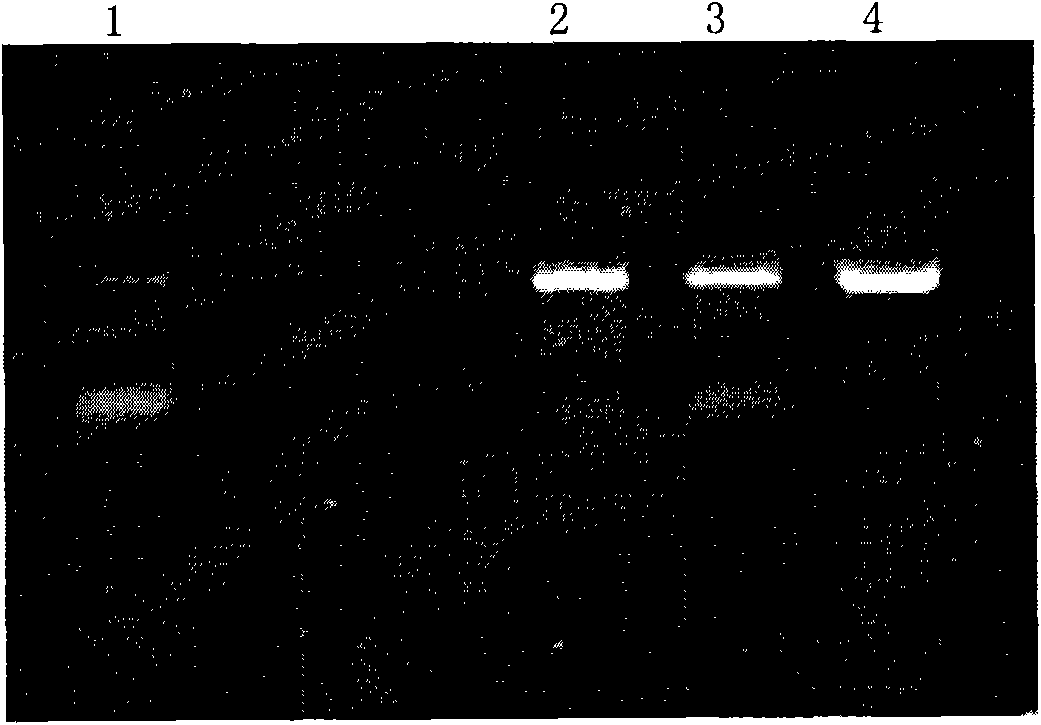

[0025] Example 1, Isolation and Identification of Cellulolytic Bacteria J15

[0026] 1. Isolation of cellulolytic bacteria J15

[0027] Take 5g of compost samples in the high temperature period (60°C-65°C) and add them to 100mL PCS medium, and culture them statically at 60°C. When the filter paper strip was degraded, the original strain was inoculated into fresh PCS medium in an amount of 10% (volume percentage content) to perform primary screening of cellulolytic bacteria. Bacteria with good degradation effects were selected for re-screening. The multiplied culture solution was diluted in multiples and inoculated into the cellulosic bacteria culture medium, and the culture medium of the blank tube was used as a control, and the strains were separated from the sample tube with a good degradation effect of the filter paper strip. When the bacterial species degrades the filter paper strips for a stable time, the culture solution will be diluted with a dilution rate of 10 -1 、...

Embodiment 2

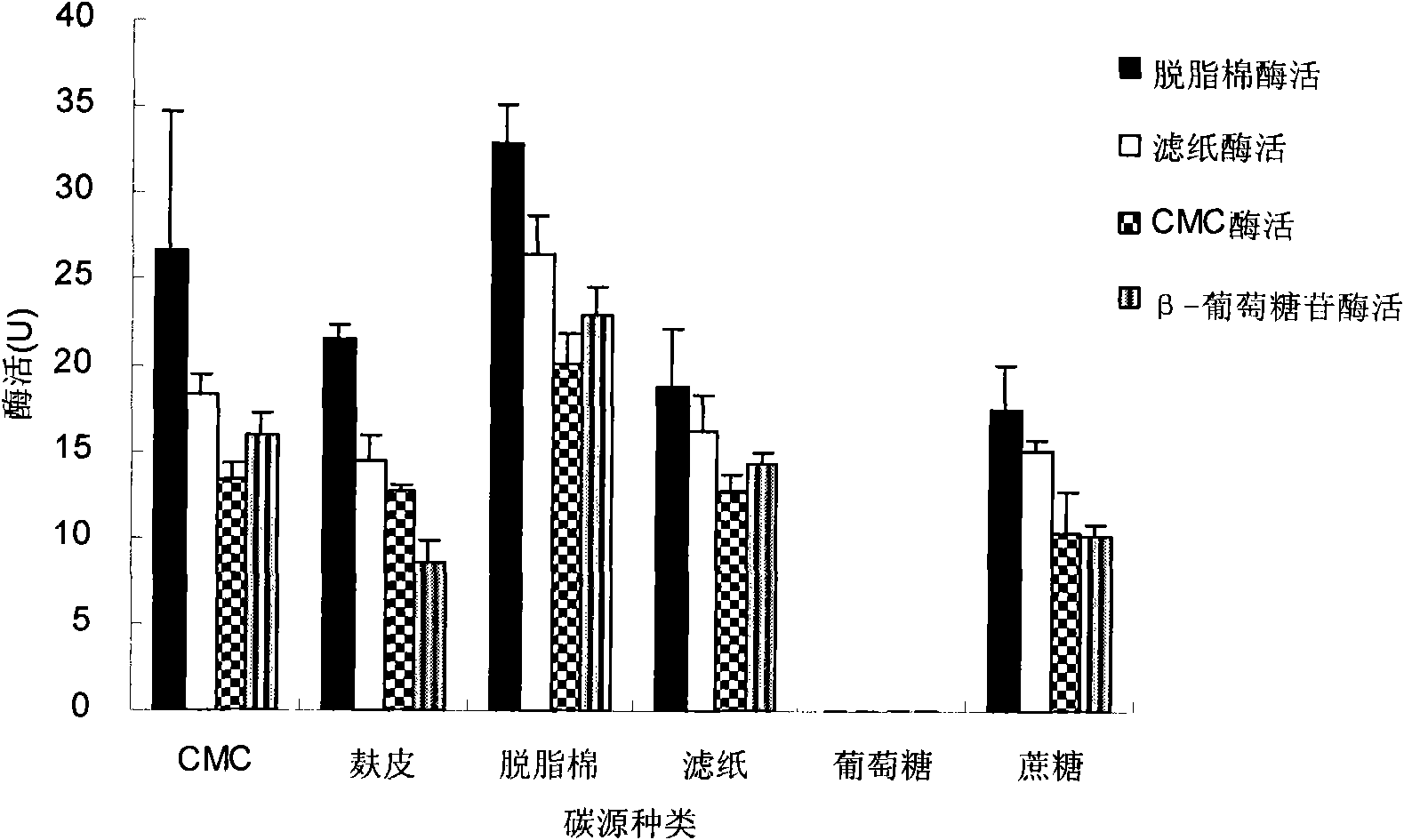

[0040] Example 2, the enzyme production effect of cellulolytic bacteria J15 under different carbon sources

[0041] Three replicates were set up for each medium, and each enzyme activity assay was repeated three times, and the results were averaged.

[0042] 1. Preparation of medium with various carbon sources

[0043] Prepare media for various carbon sources: NaCl 0.5%, CaCO 3 0.2%, carbon source 0.5%, peptone 0.5%, yeast powder 0.1%, distilled water 100mL; pH7.0. The carbon sources used were carboxymethylcellulose (CMC), bran, absorbent cotton, filter paper, glucose or sucrose, respectively.

[0044] 2. Preparation of crude enzyme solution

[0045] The cellulolytic bacteria J15 were inoculated on culture media of various carbon sources (OD600=8.0), cultured at 55° C. for 7 days, and the culture liquid was centrifuged at 8000 r / min for 20 min to obtain crude enzyme liquid.

[0046] 3. Determination of Enzyme Activity

[0047] 1. Detection method of various enzyme activit...

Embodiment 3

[0073] Example 3, the enzyme production effect of cellulolytic bacteria J15 at different temperatures

[0074] Cellulolytic bacteria J15 was inoculated in the PCS medium (OD600=8.0), cultured at different temperatures (45°C, 50°C, 55°C, 60°C, 65°C or 70°C) for 7 days, and the culture liquid Centrifuge at 8000r / min for 20min to obtain crude enzyme solution.

[0075] Detect various enzyme activities of the crude enzyme liquid, the method is the same as step three of embodiment 2. Each temperature setting was repeated three times, and each enzyme activity determination was repeated three times, and the results were averaged.

[0076] see results Figure 4 and Table 3.

[0077] Enzyme activity (U) of the crude enzyme liquid measured under various temperature culture conditions of table 3

[0078]

[0079] The optimum temperature for enzyme production by cellulolytic bacteria J15 was 55-60°C. The culture temperature is in the range of 45-60°C, and the enzyme production abil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com