Waterproof and flame-retardant paper cone

A technology for flame retardant paper and paper cones, which is applied in the fields of paper, papermaking, water repellent addition, etc. It can solve problems such as less research, and achieve the effects of improving mechanical strength, improving damping, toughness and strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

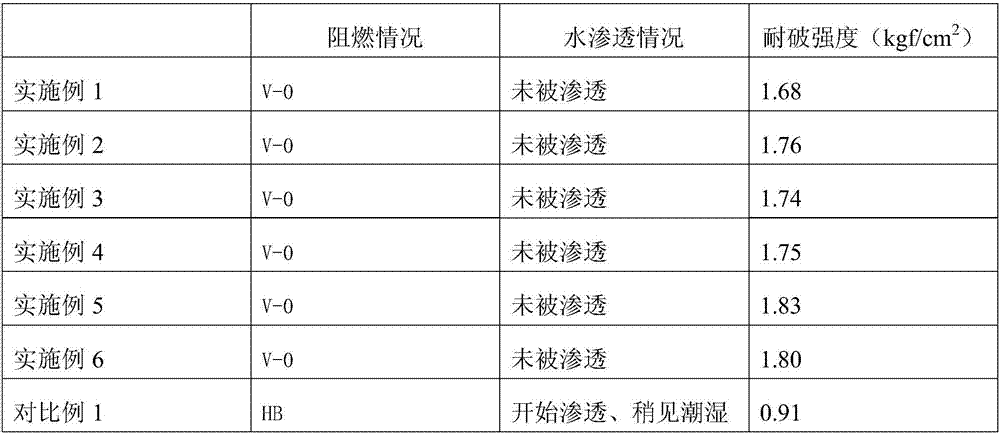

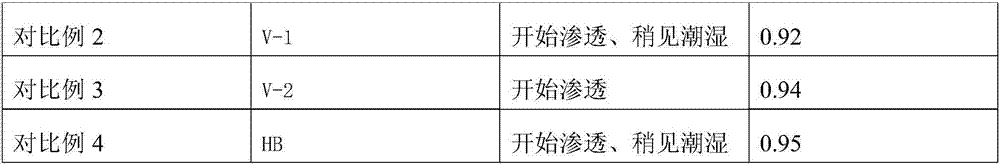

Examples

Embodiment 1

[0040] A waterproof and flame-retardant paper cone, the pulp of the paper cone is mainly formed by mixing and stirring the following raw materials in parts by weight: 45 parts of natural sulfate softwood wood pulp, 15 parts of sisal hemp, 10 parts of cotton pulp, 10 parts of kapok, 0.3 parts of bulletproof fiber, 0.1 part of wool, 0.05 part of glass fiber, 2 parts of dye, 1 part of salt, 3 parts of hardener, 3 parts of epoxy resin toughening agent, 3 parts of polyaluminum chloride regulator, 3 parts of waterproofing agent and 3 parts of flame retardant.

[0041] Among them, the dye is direct sunfast black G, the hardener is a mixture of monochloroacetic acid and trimethyl phosphate at a ratio of 1:0.2; the waterproofing agent is acrylic latex, hydroxyethyl cellulose, bentonite and sodium metasilicate The weight ratio of 1:0.1:0.2:0.05 is added to water, mixed and stirred to form an emulsion, and then placed in a stirring reflux device for reflux reaction for 3 hours; the flame...

Embodiment 2

[0043] A waterproof and flame-retardant paper cone, the pulp of the paper cone is mainly formed by mixing and stirring the following raw materials in parts by weight: 65 parts of bleached kraft softwood pulp, 30 parts of sisal, 20 parts of cotton pulp, 20 parts of kapok, 1 part of bulletproof fiber, 0.8 part of wool, 0.5 part of glass fiber, 8 parts of dye, 5 parts of table salt, 8 parts of hardener, 8 parts of phenolic resin toughening agent, 8 parts of polyaluminum chloride regulator, 8 parts of water repellent and barrier Fuel 8 parts.

[0044] Among them, among the dyes, direct sunfast black G: direct bright red = 10:0.5, the hardener is a mixture of monochloroacetic acid and trimethyl phosphate at a ratio of 1:0.8; the waterproofing agent is acrylic latex, hydroxyethyl Cellulose, bentonite and sodium metasilicate are added into water in a weight ratio of 1:0.5:0.5:0.2, mixed and stirred to form an emulsion, and then placed in a stirring reflux device for reflux reaction f...

Embodiment 3

[0046] A waterproof and flame-retardant paper cone, the pulp of the paper cone is mainly formed by mixing and stirring the following raw materials in parts by weight: 50 parts of natural kraft softwood pulp, 20 parts of sisal hemp, 12 parts of cotton pulp, 12 parts of kapok, 0.4 parts of bulletproof fiber, 0.2 parts of wool, 0.1 part of glass fiber, 3 parts of dye, 2 parts of salt, 4 parts of hardener, 4 parts of unsaturated polyester resin toughening agent, 4 parts of aluminum sulfate regulator, 4 parts of waterproofing agent and 4 parts of flame retardant.

[0047] Wherein, the dye is direct sunfast black G, and the hardener is a mixture of monochloroacetic acid and diethyl oxalate at a ratio of 1:0.2. The waterproofing agent is made by adding acrylic latex, hydroxyethyl cellulose, bentonite and sodium metasilicate into water according to the weight ratio of 1:0.2:0.25:0.08, mixing and stirring to form an emulsion, and then placing it in a stirring reflux device for reflux r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com