Composite board made of natural firilia for automobile inner decoration use and its producing method

A fiber composite board and processing method technology, which is applied in wood processing appliances, applications, household components, etc., can solve the problems of less use of natural fibers, complex production processes, low board strength, etc., so as to improve production efficiency and reduce processing procedures. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

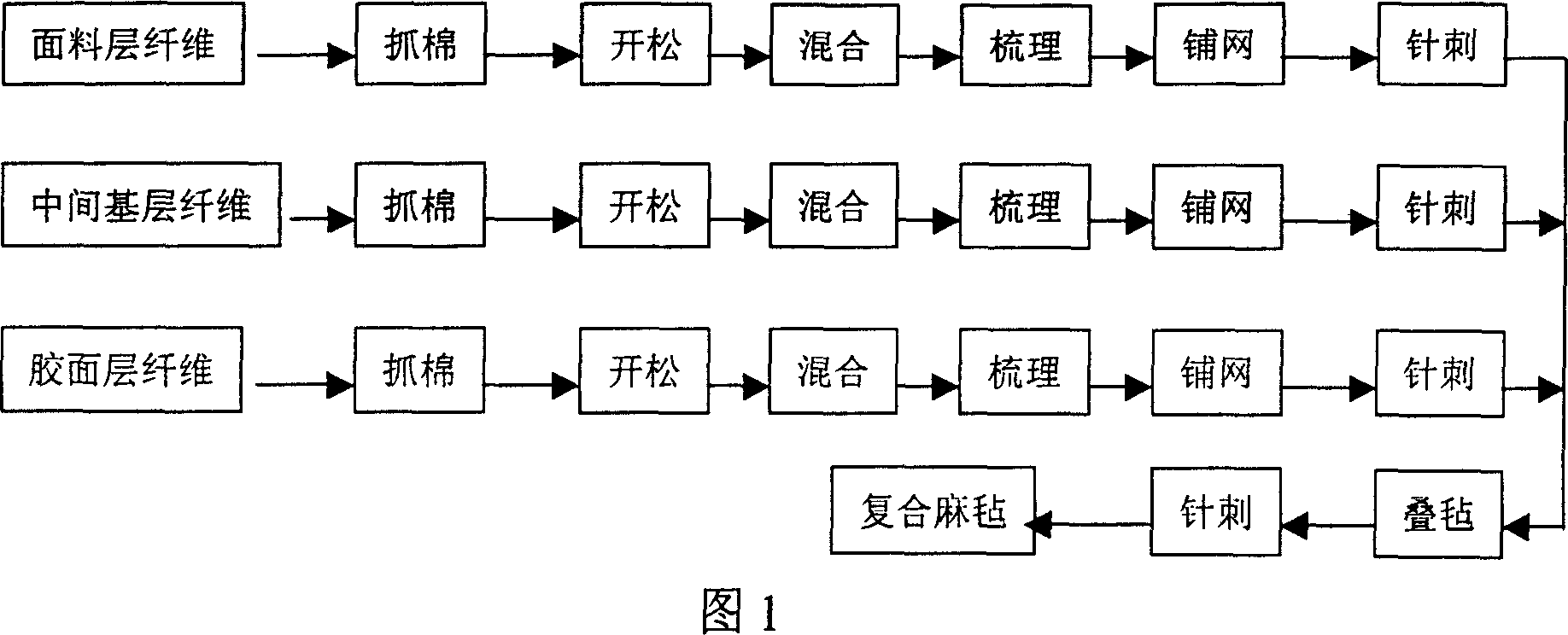

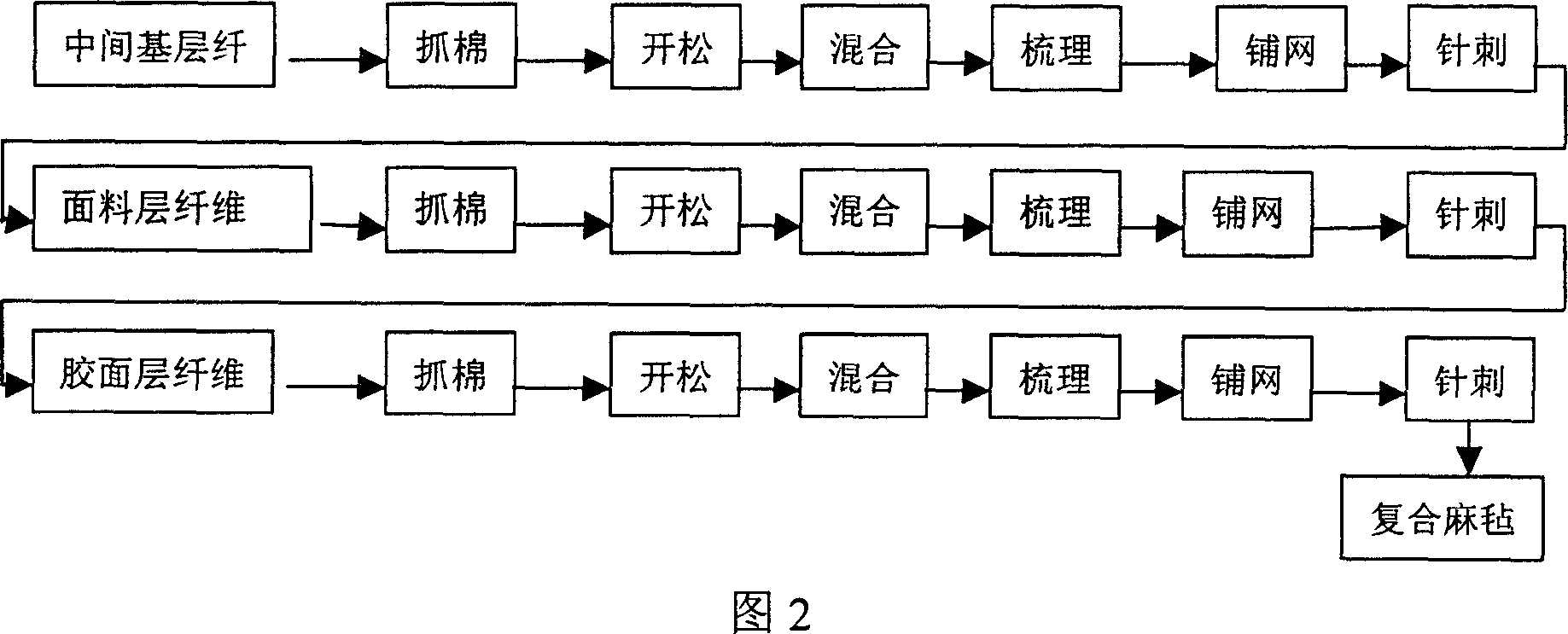

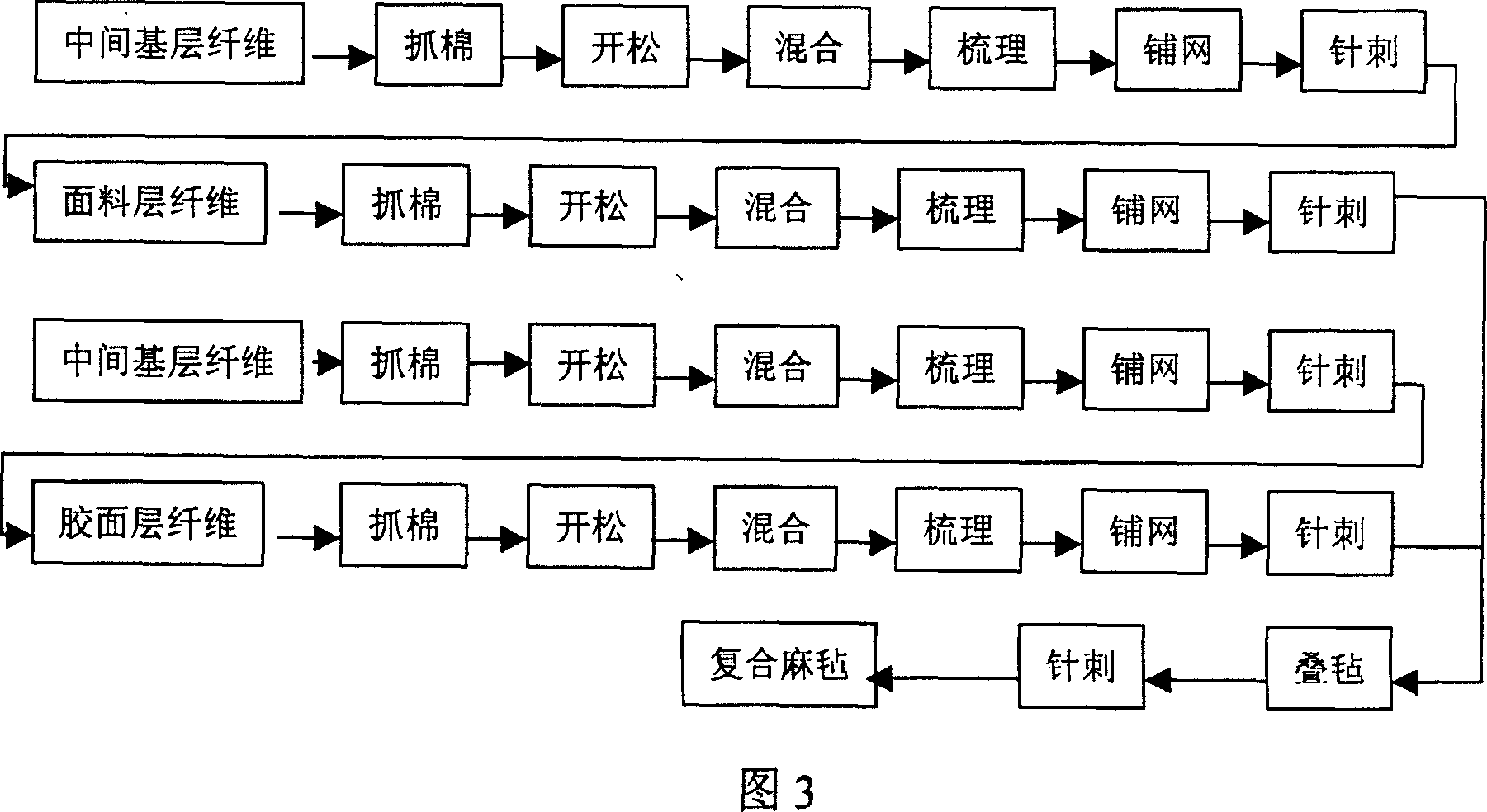

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: to produce 1600g / m 2 Taking natural hemp composite fiberboard as an example, the specific gravity of each layer is 200g / m2 for the rubber surface layer 2 , middle base layer 1220g / m 2 , fabric layer 180g / m 2 . The proportion of fibers used in each layer is:

[0018] Rubber surface layer: 50% polypropylene fiber, 50% polyethylene fiber.

[0019] Middle base layer: 37% jute fiber, 10% polyester fiber, 53% polypropylene fiber.

[0020] Fabric layer: 30% polypropylene fiber, 70% polyester fiber.

[0021] The polyester fiber used in the fabric layer is black polyester fiber, with a specification of 1.5 to 2 denier (denier: the weight of a fiber with a length of 9 km at a given moisture regain), and the polyester fiber used in other layers is white polyester fiber, with a specification of 1.5 to 2 denier , The length of polyester fiber is 51-65 mm; the specification of polypropylene fiber is 5-6 denier, and the fiber length is 74-78 mm; hemp fiber is cut i...

Embodiment 2

[0027] Embodiment 2: the ratio of each layer of fiber is:

[0028] Rubber surface layer: 70% polypropylene fiber, 30% polyethylene fiber.

[0029] Intermediate base: 45% jute fiber, 20% polyester fiber, 35% polypropylene fiber.

[0030] Fabric layer: 50% polypropylene fiber, 50% polyester fiber.

[0031] Processing method is with embodiment 1. The performance of the obtained board: the thickness of the board is 3.5 mm, the bending strength is 9.97 MPa, the tensile strength is 9.33 MPa, and the elongation at break is 12.31%.

Embodiment 3

[0032] Embodiment 3: the ratio of each layer of fiber is:

[0033] Rubber surface layer: 90% polypropylene fiber, 10% polyethylene fiber.

[0034] Middle base layer: jute fiber 41%, polyester fiber 14%, polypropylene fiber 45%.

[0035] Fabric layer: 40% polypropylene fiber, 60% polyester fiber.

[0036] Processing method is with embodiment 1. The performance of the obtained board: the thickness of the board is 3.5 mm, the bending strength is 7.83 MPa, the tensile strength is 7.66 MPa, and the elongation at break is 13.53%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com