Method for preparing ultra-fine denier polyester filament yarn

A technology of ultra-fine denier polyester and manufacturing method, which is applied in the direction of single-component polyester rayon, melt spinning, etc., to achieve the effects of reducing variance, improving orientation uniformity, and facilitating the penetration of cooling wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

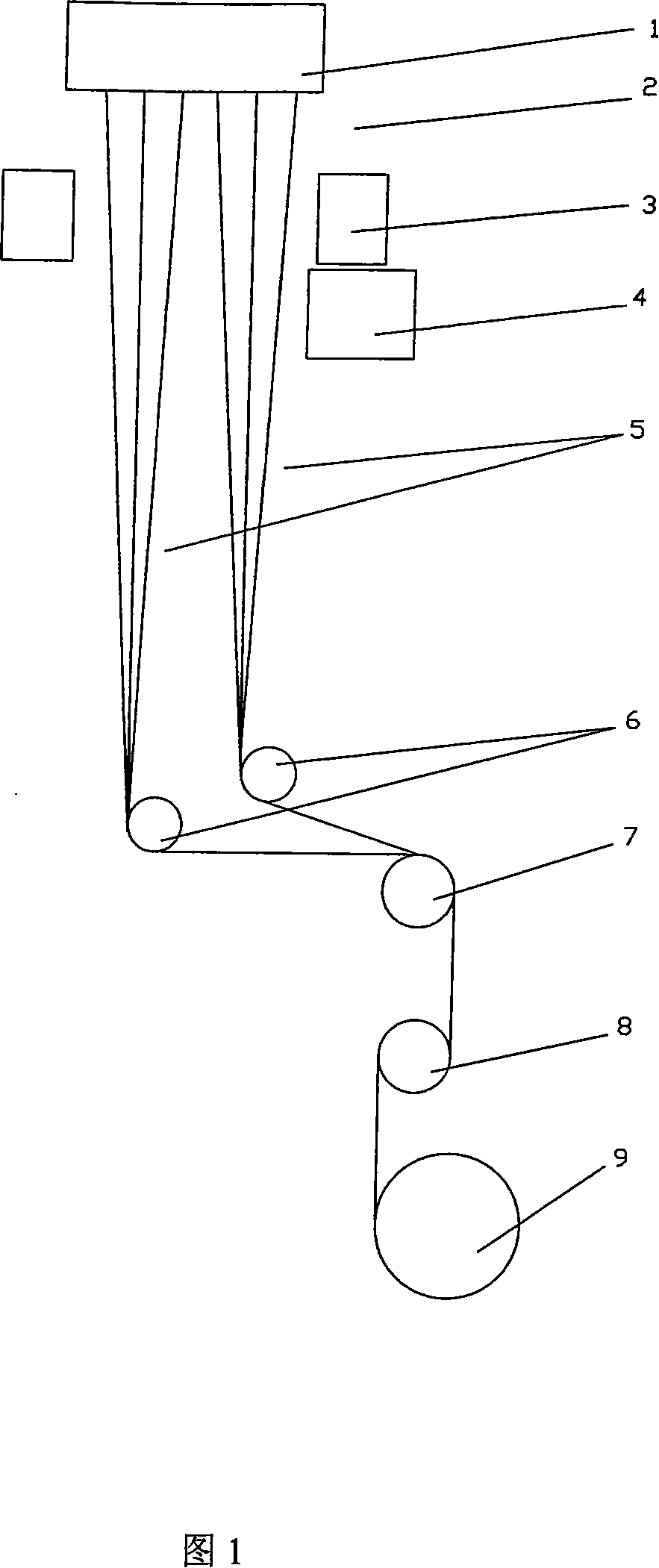

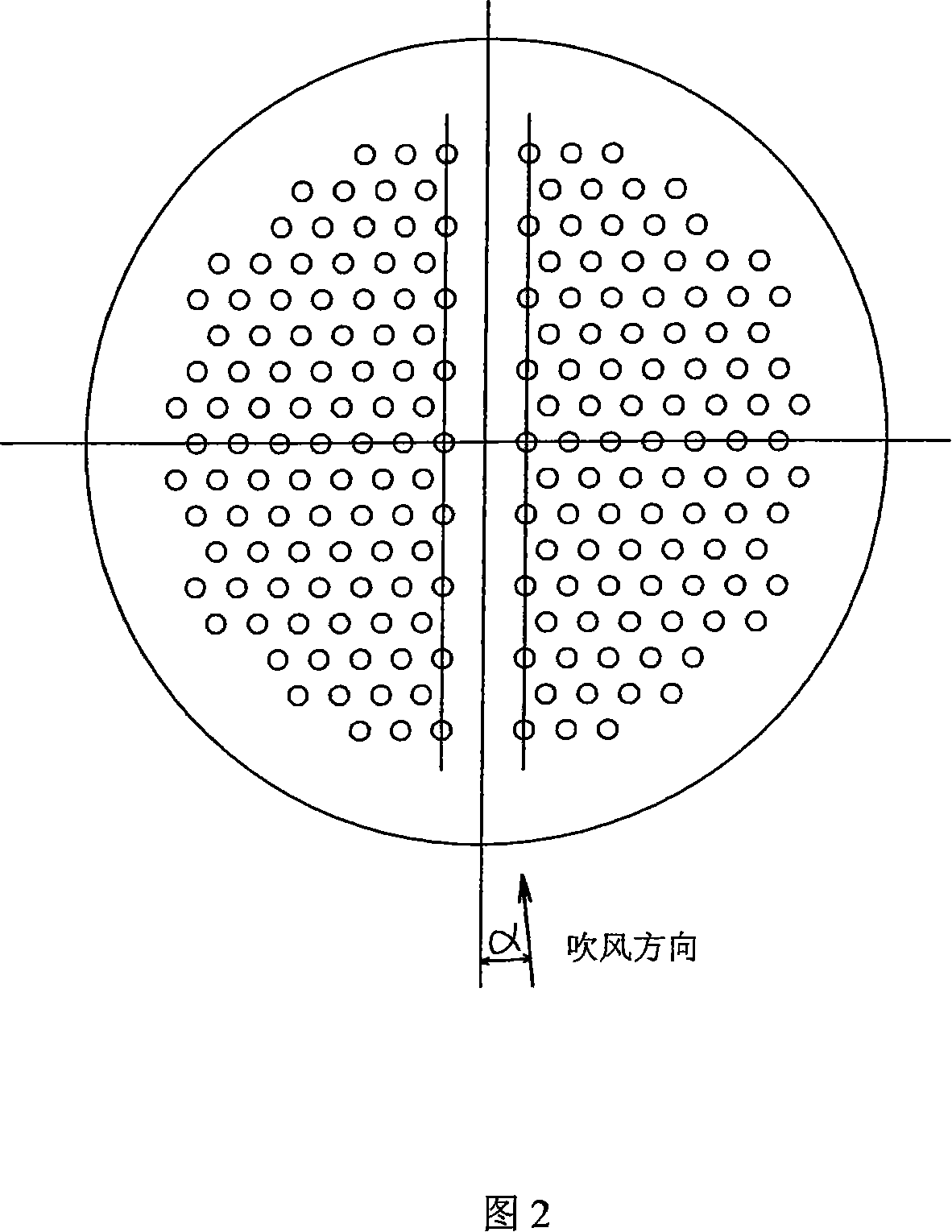

[0029] The PET melt is extruded through a spinneret to form a tow, and the tow is cooled by a windless zone, a slow cooler, and a side blowing device, and then divided into oils, wound and bundled.

[0030] Among them, the height of the windless zone is 100mm, the height of the slow cooler is 25mm, the height of the side blowing device is 1350mm, the width is 1100mm, the wind speed is 0.3m / s, the wind temperature is 22°C, and the winding speed is 2700m / min. The strength is 2.6cN / dtex, the breaking elongation is 120% POY filament, and after 1.6 times stretching and stretching, the monofilament fineness is 0.25d.p.f, the breaking strength is 4.1cN / dtex, and the breaking elongation is 22% polyparaphenylene Ethylene dicarboxylate DTY filament. The ultra-fine denier polyester DTY filament product is evenly dyed, has high evenness, and has excellent physical properties.

Embodiment 2

[0032] The PET melt is extruded through a spinneret to form a tow, and the tow is cooled by a windless zone, a slow cooler, and a side blowing device, and then divided into oils, wound and bundled.

[0033] Among them, the height of the windless area is 80mm, the height of the slow cooler is 30mm, the height of the side blowing device is 1350mm, the width is 1100mm, the wind speed is 0.3m / s, the wind temperature is 19°C, and the winding speed is 2600m / min. The strength is 2.6cN / dtex, the breaking elongation is 120% POY filament, and after 1.6 times stretching and stretching, the monofilament fineness is 0.3d.p.f, the breaking strength is 4.0cN / dtex, and the breaking elongation is 23% polyparaphenylene Ethylene dicarboxylate DTY filament. The ultra-fine denier polyester DTY filament product is evenly dyed, has high evenness, and has excellent physical properties.

Embodiment 3

[0035] The PET melt is extruded through a spinneret to form a tow, and the tow is cooled by a windless zone, a slow cooler, and a side blowing device, and then divided into oils, wound and bundled.

[0036] Among them, the height of the windless zone is 80mm, the height of the slow cooler is 30mm, the height of the side blowing device is 1350mm, the width is 1100mm, the wind speed is 0.4m / s, the wind temperature is 18°C, and the winding speed is 5700m / min. 0.26d.p.f, breaking strength of 3.3cN / dtex, breaking elongation of 27% polyethylene terephthalate FDY filament. The ultra-fine denier polyester FDY filament product has uniform dyeing, high evenness and excellent physical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com