Intelligent turnover conveyor

A conveyor, intelligent technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of car body surface pretreatment and electrophoresis uneven, unable to meet the quality requirements of the car body, unable to meet the complex process requirements, etc. The effect of saving effective area, convenient and reliable maintenance, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

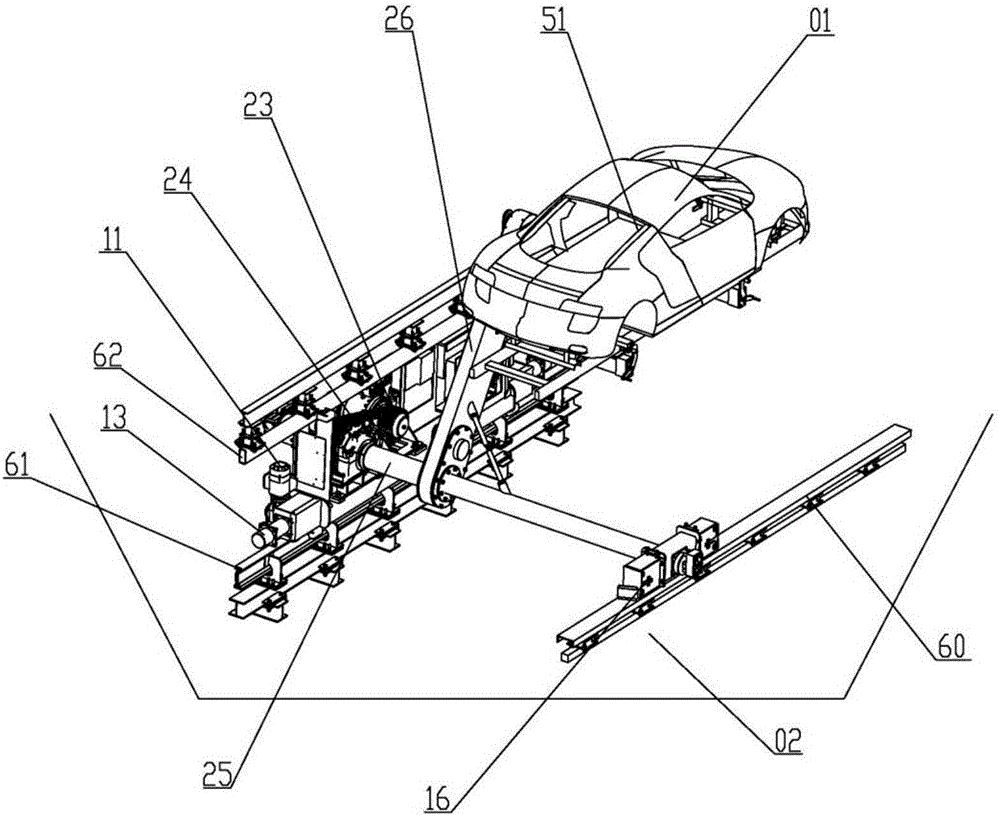

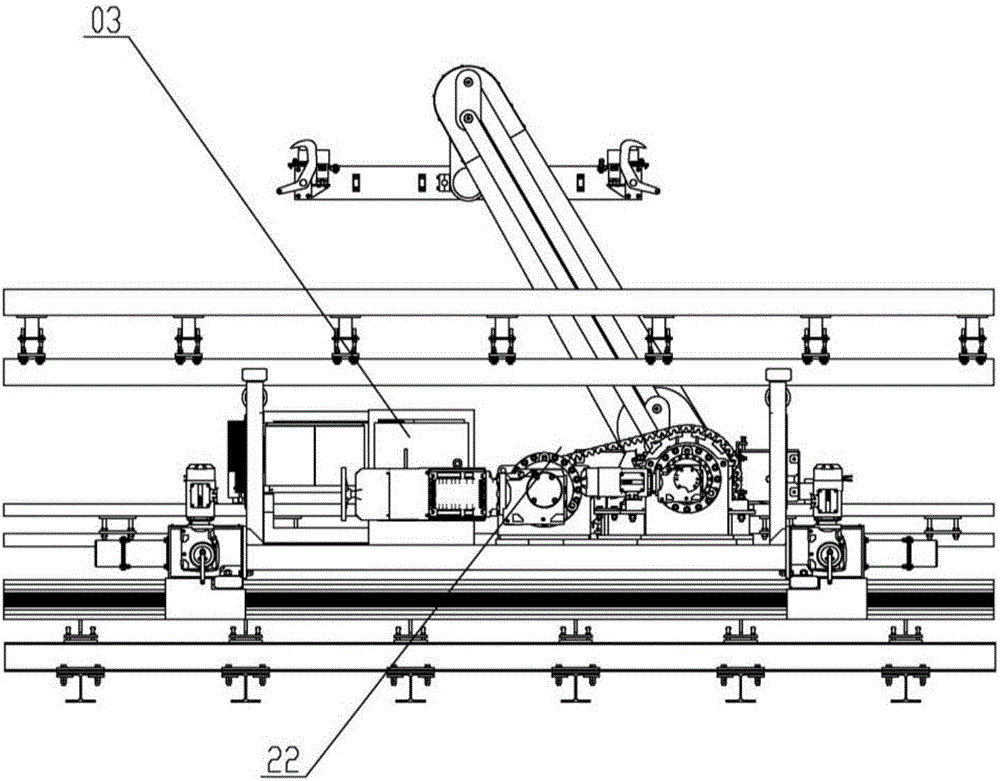

[0047] This embodiment is mainly used in the electrophoresis stage of the paint shop.

[0048] figure 1 The expression is a special example of the electrophoresis of the car body in the electrophoresis chamber of the pretreatment electrophoresis system. Electrophoretic coating is a special coating film forming method. According to the polarity of the object to be coated and the type of electrophoretic coating, electrophoresis can be divided into: anodic electrophoresis and cathodic electrophoresis. Water-soluble resin for electrophoresis is a carboxylate with high acid value. After being dissolved in water, it exists in a DC electric field in a balanced state of molecules and ions. After electrification, due to the potential difference between the two poles, the ions move directional, and the anions are deposited on the surface of the anode. The cation obtains electrons on the surface of the cathode and is reduced to amine, which is an electrochemical reaction, including four...

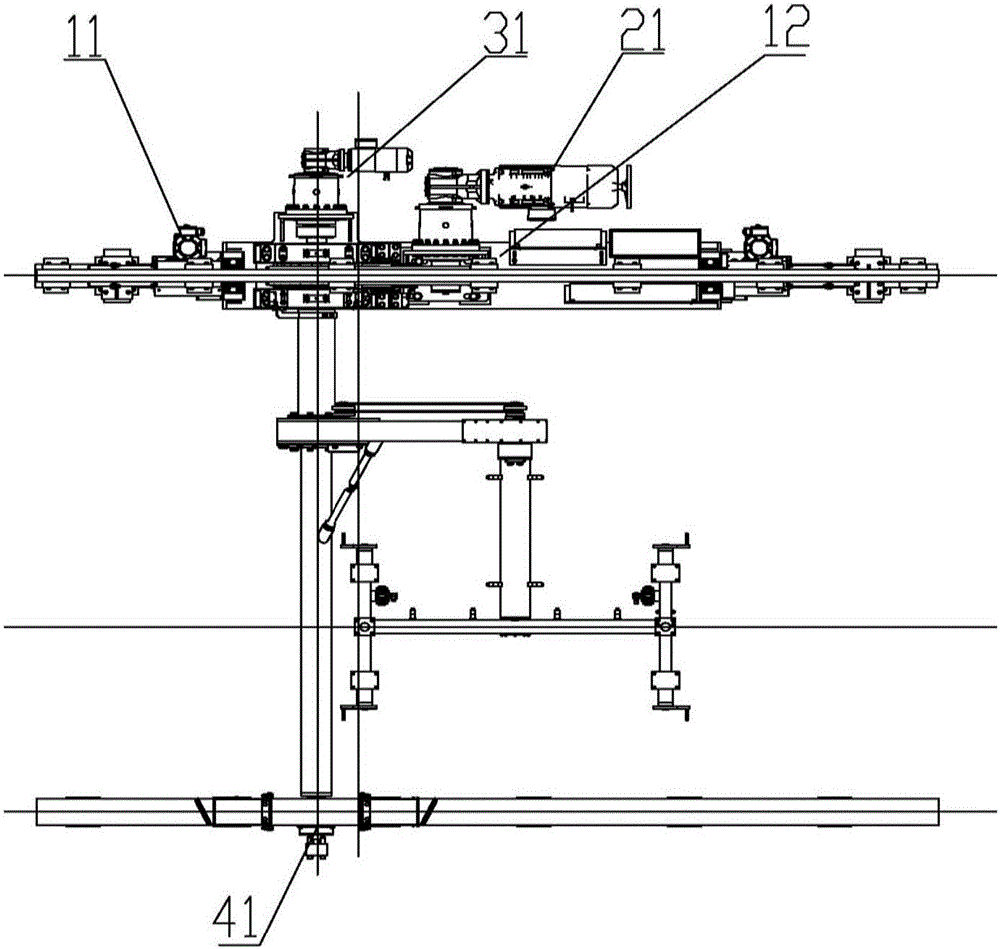

Embodiment 2

[0114] This embodiment is mainly used in the pre-treatment stage of the painting workshop, see for details Figure 17 to Figure 21 .

[0115] Pretreatment is different from electrophoresis, the workpiece does not need electrophoresis to connect electricity, from Figure 20 It can be seen that the supporting end of the conveyor is different from the electrophoresis, and the supporting end of the pre-processing vehicle group has only one supporting and walking wheel, and there is no power connection device for the walking wheel at the same time.

[0116] In the same way, the underwater power connection device is also canceled on the rotating part of the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com