Water feeding device for washing machine

A washing machine and water supply technology, which is applied to washing devices, other washing machines, water/sewage treatment, etc., can solve the problems of incomplete siphon discharge of salt water, waste of exchange capacity, and residual salt, and achieve reduced washing effect, shortened life, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

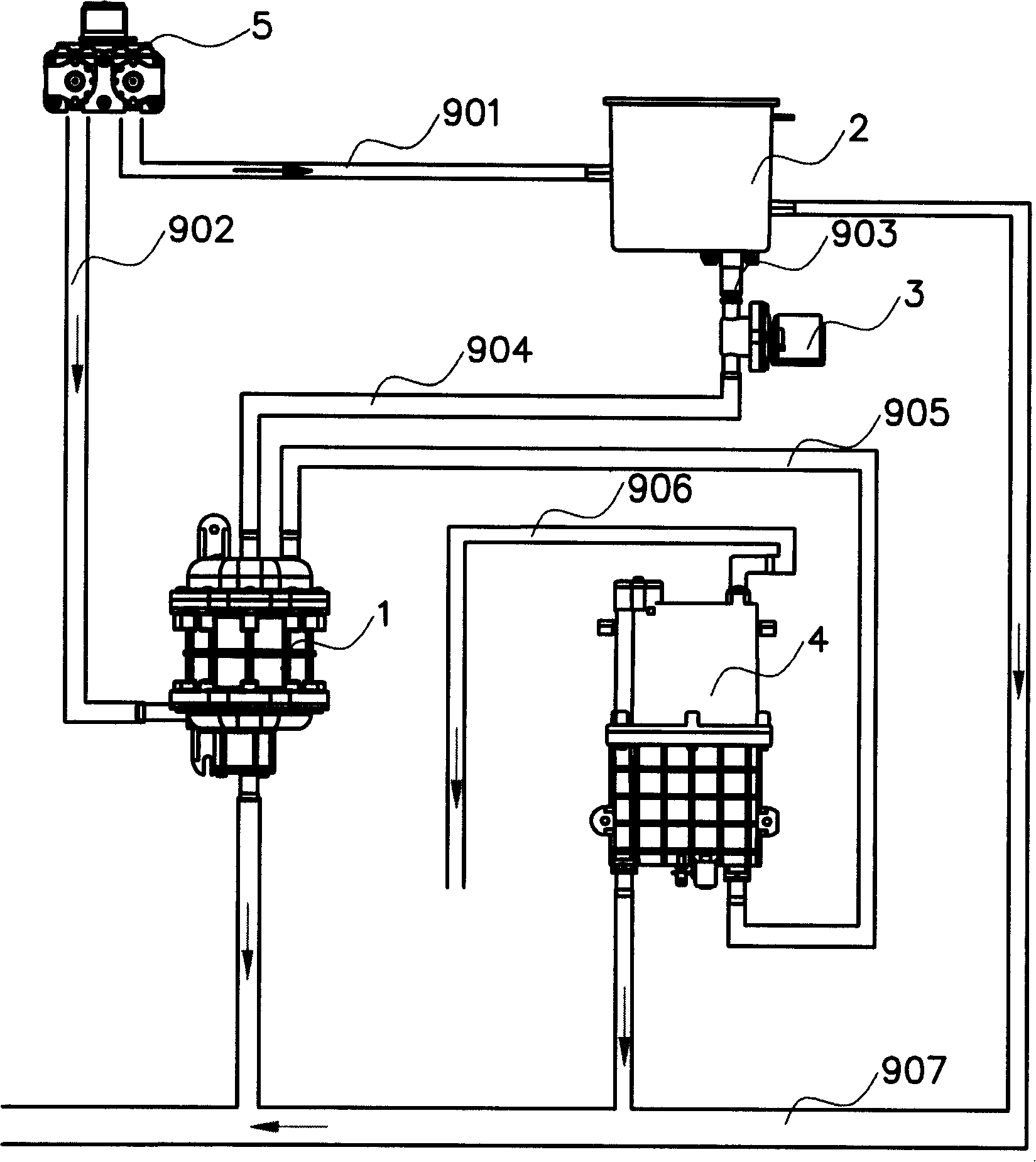

[0064] The water supply device of the washing machine has a softener 1 and a regeneration fluid switch valve 3 connected through a hose 904. The regeneration fluid switch valve is installed under the regeneration agent dispenser 2. The pipe 901 is connected with a water inlet solenoid valve 5; the regenerant dispenser 2 is composed of a regenerated liquid container 22 and a built-in regenerated agent holding box 21, and the regenerated liquid container 22 is provided with a water inlet 201 on one side and an overflow on the other side The mouth 202 is located at the water inlet 201. An outlet of the water inlet solenoid valve 5 is connected to the water inlet 101 of the softener 1 through a hose 902; the water outlet 152 of the softener is connected to the electrolytic cell 4 through a hose 905; The control circuit board of the microprocessor CPU controls the water supply program;

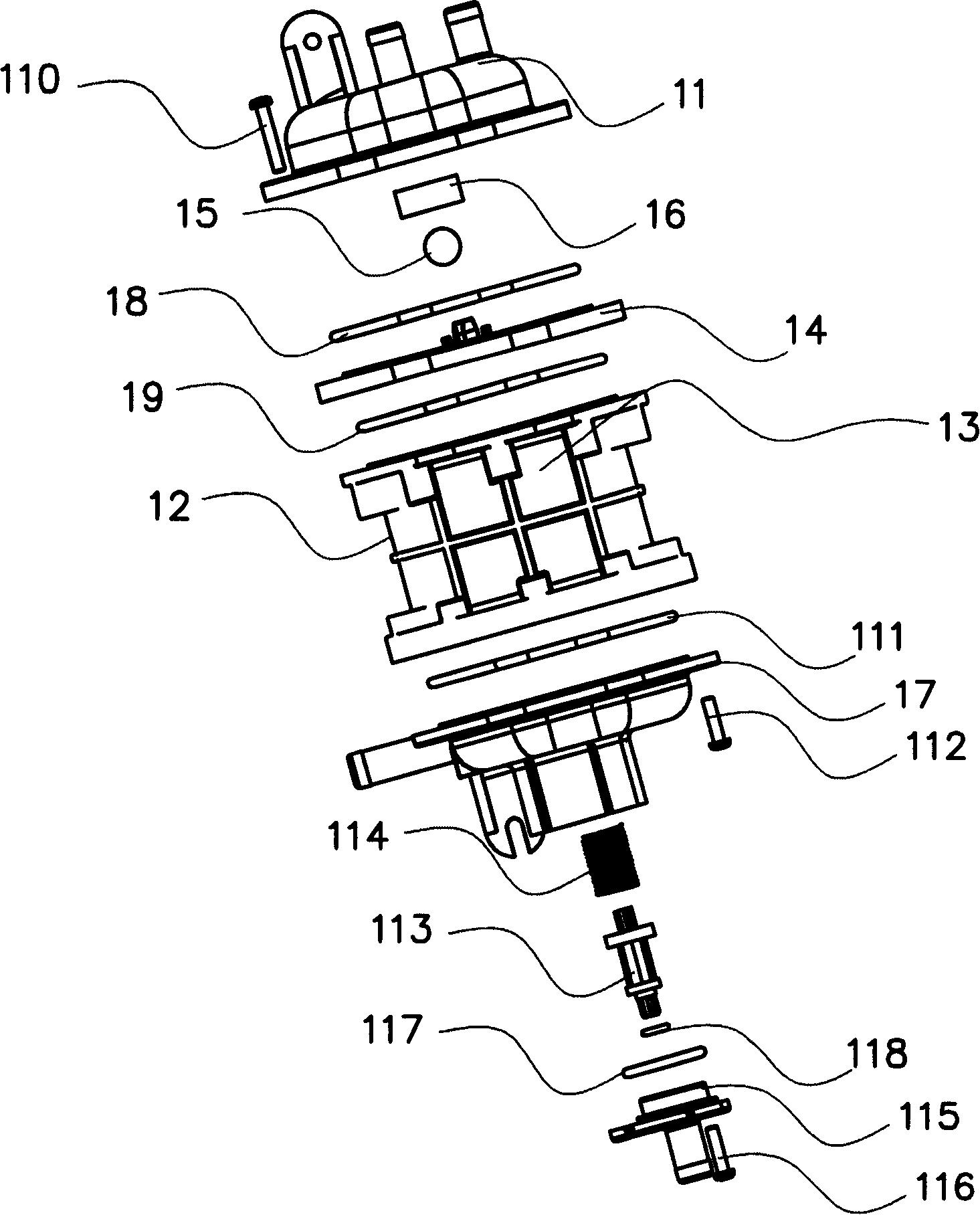

[0065] The softener 1 has a shell 12, the inner sleeve of which is equipped with an ion exchang...

Embodiment 2

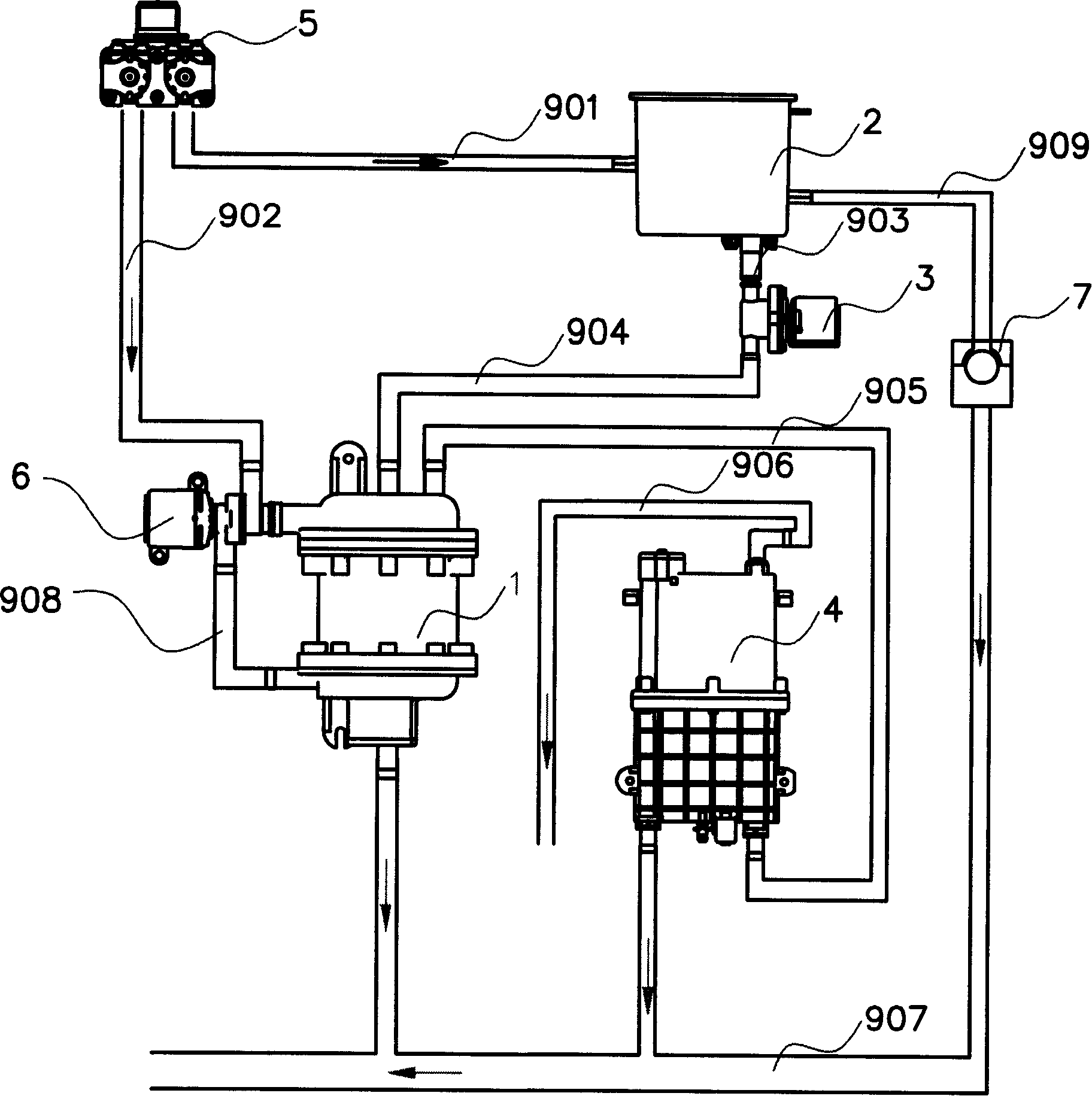

[0161] The difference from Embodiment 1 is that the water supply device of the washing machine is connected with a three-way switching valve 6 through a hose 902 between the softening water outlet 502 of the solenoid valve 5 and the softener 1, and a water outlet 602 of the three-way switching valve is passed through The hose 908 is connected to the water inlet 101 of the softener 1, and the other water outlet 603 is connected to the water outlet chamber 104 of the softener; when the circuit system detects that the tap water hardness is low enough, it does not need to be softened, and can also meet the requirements of electrolysis and washing. Requirements, in this case, through the control of the circuit board circuit, the solenoid valve 5 and the three-way switching valve 6 are powered on, and the tap water passes through the solenoid valve 5 from the water outlet 603 of the three-way switching valve to directly enter the water outlet chamber 104 of the softener 1 to supply wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com