Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Reduce the number of regenerations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

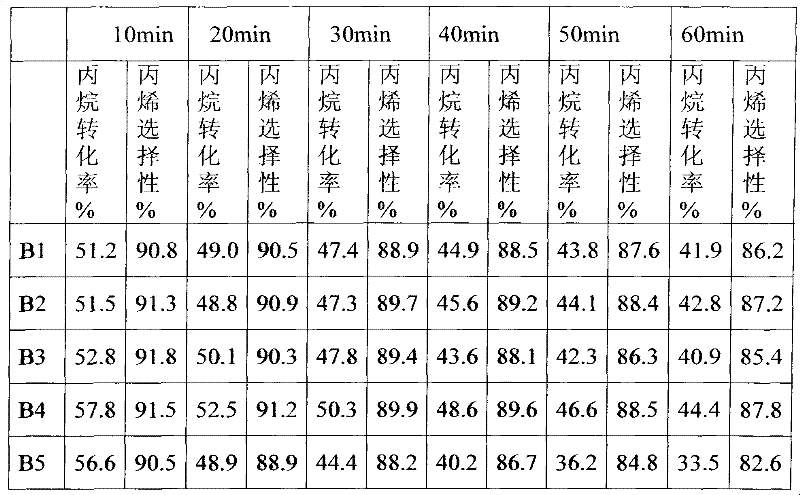

Catalyst for converting alcohols and ethers into aromatic hydrocarbons as well as preparation method and use method thereof

ActiveCN103007985ASmall particle sizeEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenAlcohol

The invention discloses a catalyst for converting alcohols and ethers into aromatic hydrocarbons, as well as a preparation method and a use method of the catalyst, and belongs to the technical field of chemical engineering. The preparation method comprises the steps as follows: at first, taking a template agent, kaolin, sodium hydroxide and water as raw materials for preparing a hydrogen type nanoscale ZSM-5 molecular sieve, and then directly preparing the catalyst; or based on the hydrogen type nanoscale ZSM-5 molecular sieve, preparing the two-component, three-component or four-component catalyst with metal and / or a structure enhancer and / or a stabilizing additive. The catalyst comprises the following components in percentage by mass: 30-100% of the needle-like nanoscale ZSM-5 molecular sieve, 0-10% of the metal, 0-50% of the structure enhancer and 0-10% of the stabilizing additive. The invention further provides a method for enabling the catalyst to be used for converting alcohols and ethers into aromatic hydrocarbons. The catalyst is small in particle size, high in catalytic efficiency and low in use cost; the preparation method is simple and efficient; and the use method is reasonable and efficient.

Owner:TSINGHUA UNIV

Method for removing arsenic by loading titanium dioxide with activated carbon fiber hydrothermal method by means of photoelectrocatalysis oxidation

InactiveCN102910767AReduce dosageImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberSludge

The invention discloses a method for removing arsenic by loading titanium dioxide with an activated carbon fiber hydrothermal method by means of photoelectrocatalysis oxidation. The method comprises the following steps of: oxidizing the trivalent arsenic, which is high in toxicity and difficult to treat, pentavalent arsenic which is easily treated by photoelectrocatalysis oxidation treatment, and completely removing the pentavalent arsenic by adsorbents which can strongly absorb the arsenic, namely titanium dioxide, iron oxide or activated aluminium oxide and the like. The method disclosed by the invention is simple in technology, convenient to operate, low in cost, and free from the generation of sludge residue, the arsenic in water can be effectively removed, an activated carbon fiber photoelectrode can run for a long term, and can be used at a large area and a large scale without changing, and the outlet water quality fulfills the national standard, so that the method is suitable for treating the drinking water and the high-arsenic waste water.

Owner:GUANGDONG UNIV OF TECH

Hexafluoroethane purification method

ActiveCN103664501AHigh puritySolve storage problemsHalogenated hydrocarbon separation/purificationHexafluoroethanePurification methods

The invention discloses a hexafluoroethane purification method which comprises the following steps: rectifying a hexafluoroethane raw material under the conditions of (-70)-(-35) DEG C and 0.1-1 MPa; performing low-temperature adsorption on the rectified hexafluoroethane raw material under the temperature conditions of (-100)-(-70) DEG C; and performing pressurized adsorption on the hexafluoroethane raw material after low-temperature adsorption under the pressure conditions of 0.5-1.5 MPa, thus obtaining the hexafluoroethane product, wherein the CO2 volume concentration of the hexafluoroethane product is no more than 0.5 ppm, and the H2O volume concentration is no more than 1 ppm. According to the invention, the problem that potential safety hazard is caused due to insufficient CO2 and H2O removal depth and introduction of anhydrous HCl in hexafluoroethane is solved, the energy consumption is reduced, and the adsorption effect of adsorbent is enhanced; and the purity of the hexafluoroethane product is up to 99.9995% or above, thus meeting the requirements for electronic specific gas in the semiconductor and micro-electronics industry.

Owner:FOSHAN HUATE GASES +1

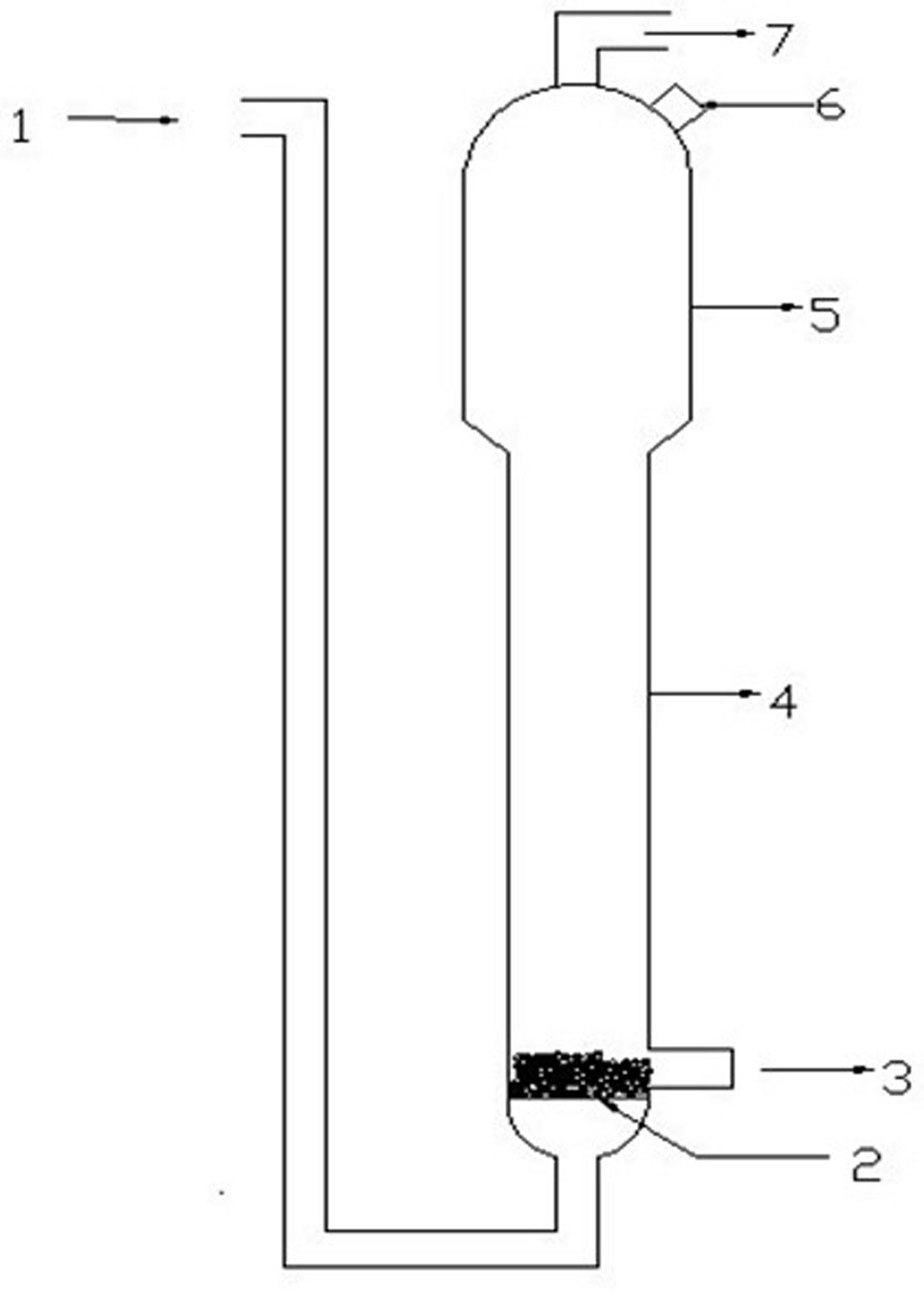

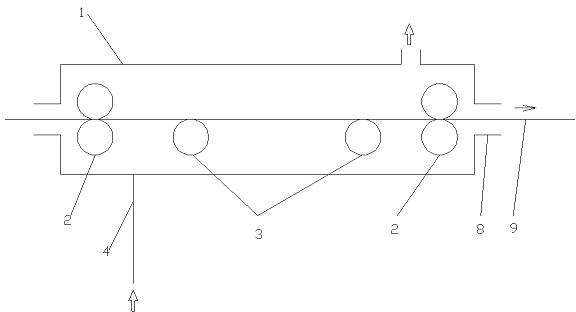

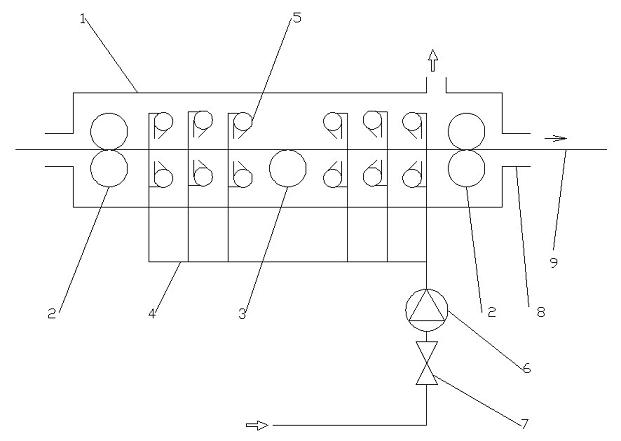

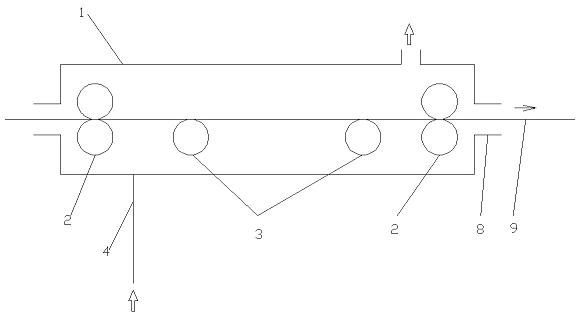

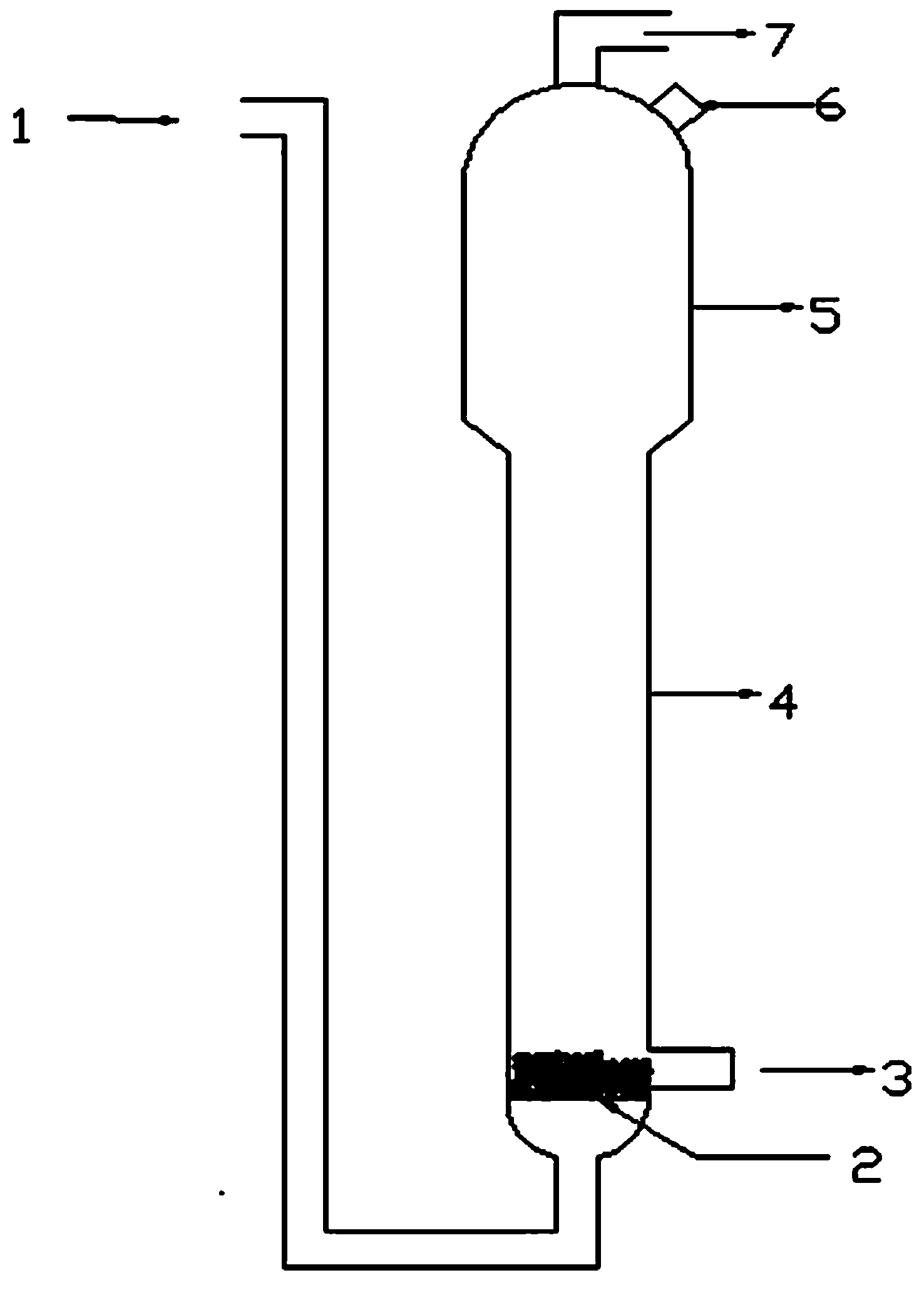

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225AExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

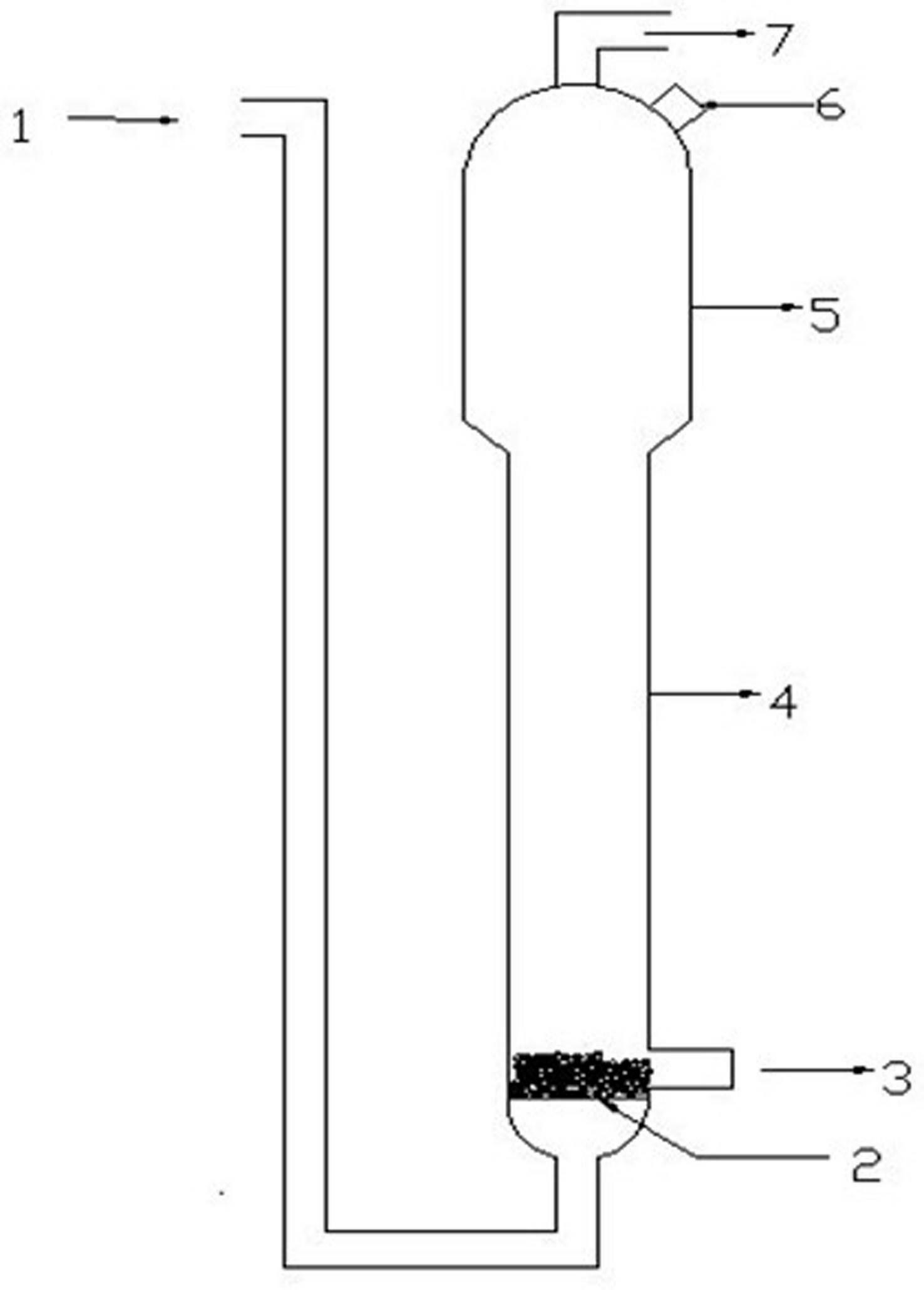

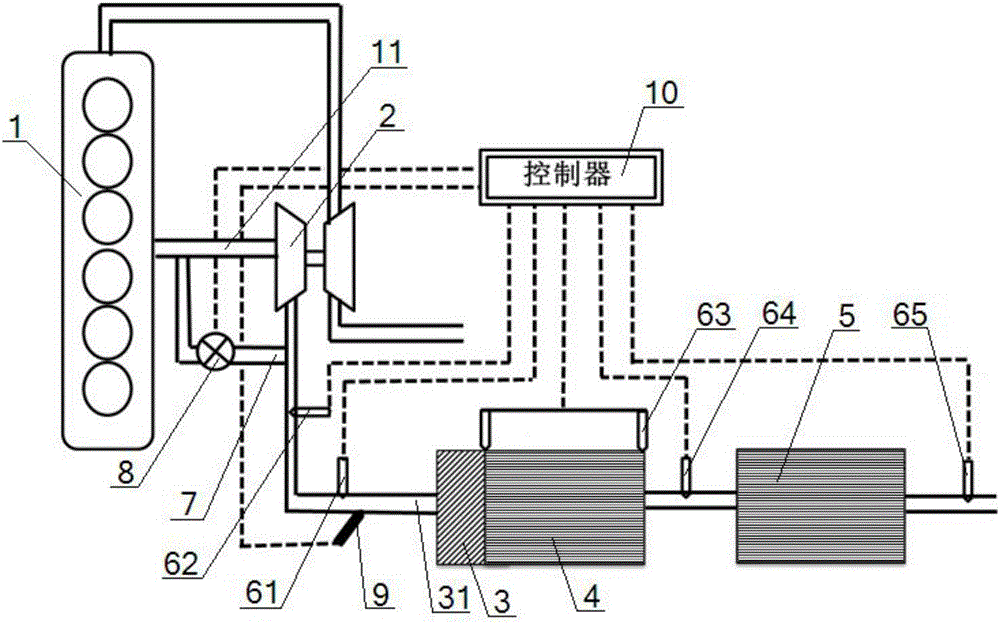

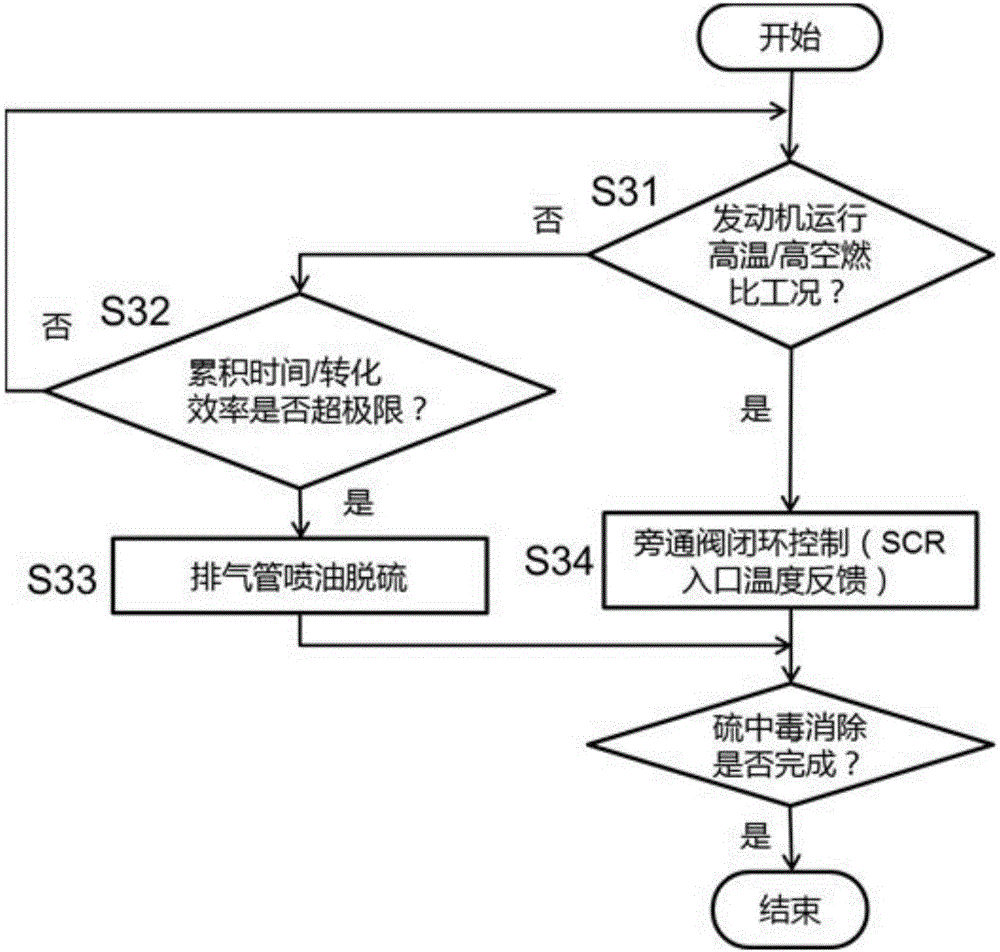

Sulfur poisoning removal device of SCR catalyst of diesel engine and using method for sulfur positioning removal device

ActiveCN106401704ARealize high temperature desulfurizationRealize active regeneration of DPF and high temperature desulfurization at the same timeInternal combustion piston enginesExhaust apparatusSulfurTurbocharger

The invention discloses a sulfur positioning removal device of a SCR catalyst of a diesel engine. The sulfur positioning removal device comprises a DOC, a DPF, the SCR catalyst, a bypass pipeline with an electric-control regulating valve and a post-processing controller, wherein a gas inlet end of the DOC sequentially communicates with an engine exhaust tube through a gas inlet pipeline and a turbocharger; a gas outlet end of the DOC communicates with the SCR catalyst through the DPF; a gas inlet and a gas outlet end of the bypass pipeline separately communicate with the exhaust tube and the gas inlet pipeline; a temperature sensor I, a NOX sensor I and a DPF regenerated fuel oil spray nozzle are arranged on the gas inlet pipeline; a gas inlet end and a gas outlet end of the DPF are equipped with the pressure sensors; and a gas inlet end and a gas outlet end of the SCR catalyst are separately equipped with a temperature sensor II and an NOX sensor II. In use, the post-processing controller controls the DPF regenerated fuel oil spray nozzle and an electric-control regulating valve according to a condition that whether DPF regeneration is needed or not and an operation condition of the diesel engine, so that high-temperature conditions of SCR catalyst desulfurization are met. With the adoption of the design, economical deterioration degree of the engine fuel oil is relatively low.

Owner:DONGFENG COMML VEHICLE CO LTD

Method for recycling high acid crude oil electric desalting wastewater

ActiveCN102442746AExtended service lifeLow operating costMultistage water/sewage treatmentChemical oxygen demandFiltration

The invention discloses a method for recycling high acid crude oil electric desalting wastewater. The method comprises the following steps of: performing oil removal, suspended matter treatment and microbial biochemical treatment on the high acid crude oil electric desalting wastewater; and performing flocculation, sand filtration, biological activated carbon treatment and electro-adsorption treatment on microbial biochemical treatment effluent in sequence, wherein flocculation and sand filtration are performed to remove suspended matters and a part of colloids or dissolvable organic matters from the biochemical treatment effluent; biological activated carbon treatment is performed to further remove the colloids and dissolvable organic matters; and electro-adsorption treatment is performed to remove salts and ionic organic matters such as naphthenic acid and the like. The COD (Chemical Oxygen Demand) of treatment effluent is less than or equal to 50 mg / L, and the strict local discharge standard (COD is less than or equal to 60 mg / L) can be met; and the treatment effluent can be recycled into a circulating water system or an electric desalting device as desalted water, so that water is saved and discharge is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922BEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for treating waste water containing ammonia nitrogen

InactiveCN101607769AAccurate judgmentReduce the number of regenerationsWater/sewage treatment by ion-exchangeCombustible gas purificationAmmoniacal nitrogenIon exchange

The invention relates to the technology for treating waste water containing ammonia nitrogen and recovering ammonia in the industries, in particular to a technology for treating waste water containing ammonia nitrogen. In the conventional ion exchange method, the effulent liquid can not be recycled due to the over standard of ammonia and nitrogen of the effulent liquid caused by the untimely and inaccurate judgment of effulent liquid perforation points, the recycling value is low due to the low concentration of NH4 in stripping liquid, the ammonia nitrogen is required to be treated and the treatment cost is higher. The technology for treating waste water containing ammonia nitrogen comprises the following steps: waste water containing ammonia nitrogen is injected into a first exchange column filled with cation exchange resin, the material liquid effuses from the outlet of the first exchange column after being absorbed by the cation exchange resin and then flows into a second exchange column filled with cation exchange resin for further absorption, and the ammonia nitrogen concentration of the effluent liquid from the outlet of the second exchange column is less than 15 mg / L. The technology has low cost, and can comprehensively recover ammonia and continuously discharge by meeting the standards or recycle the waste water.

Owner:JIANGXI UNIV OF SCI & TECH

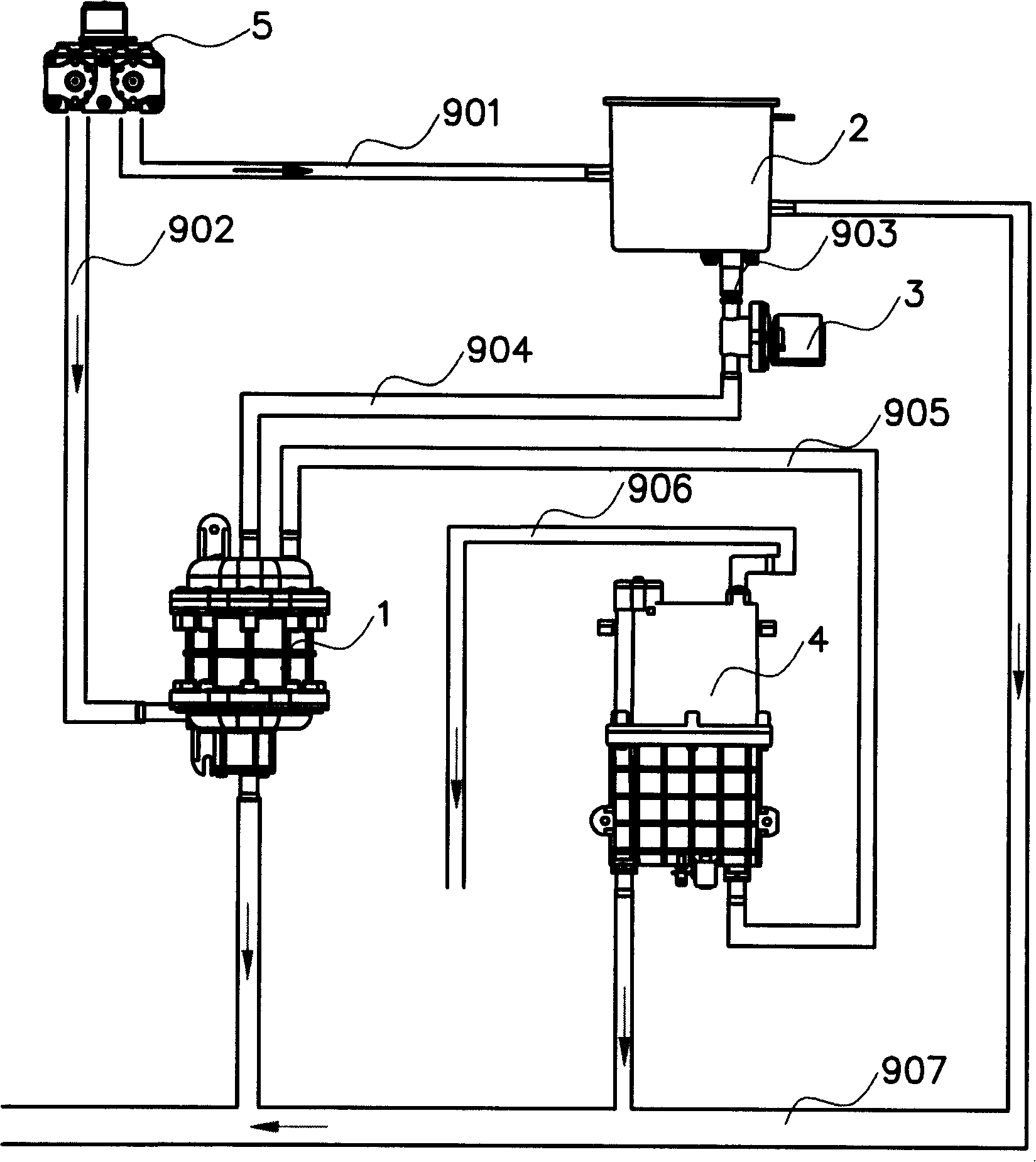

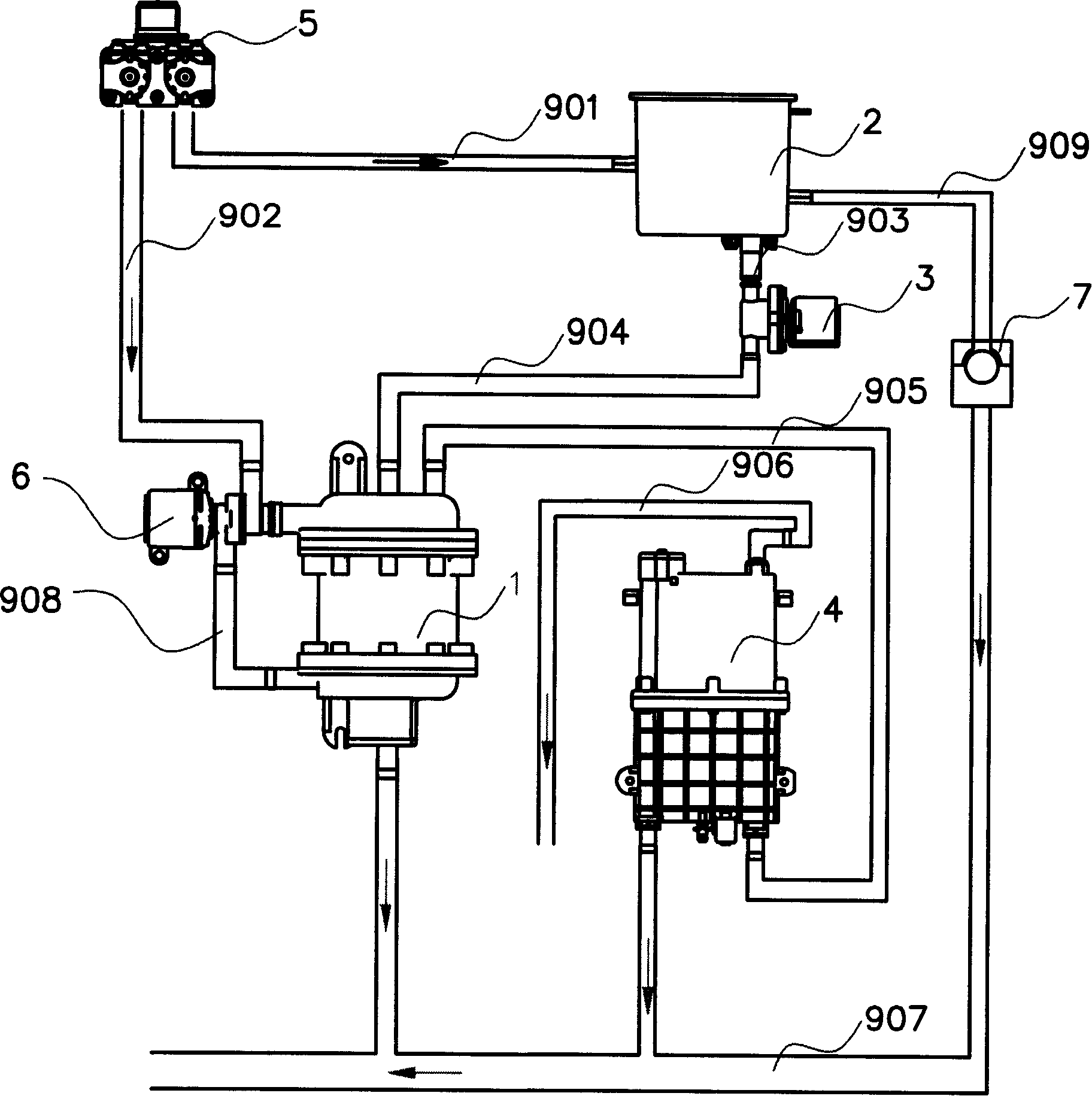

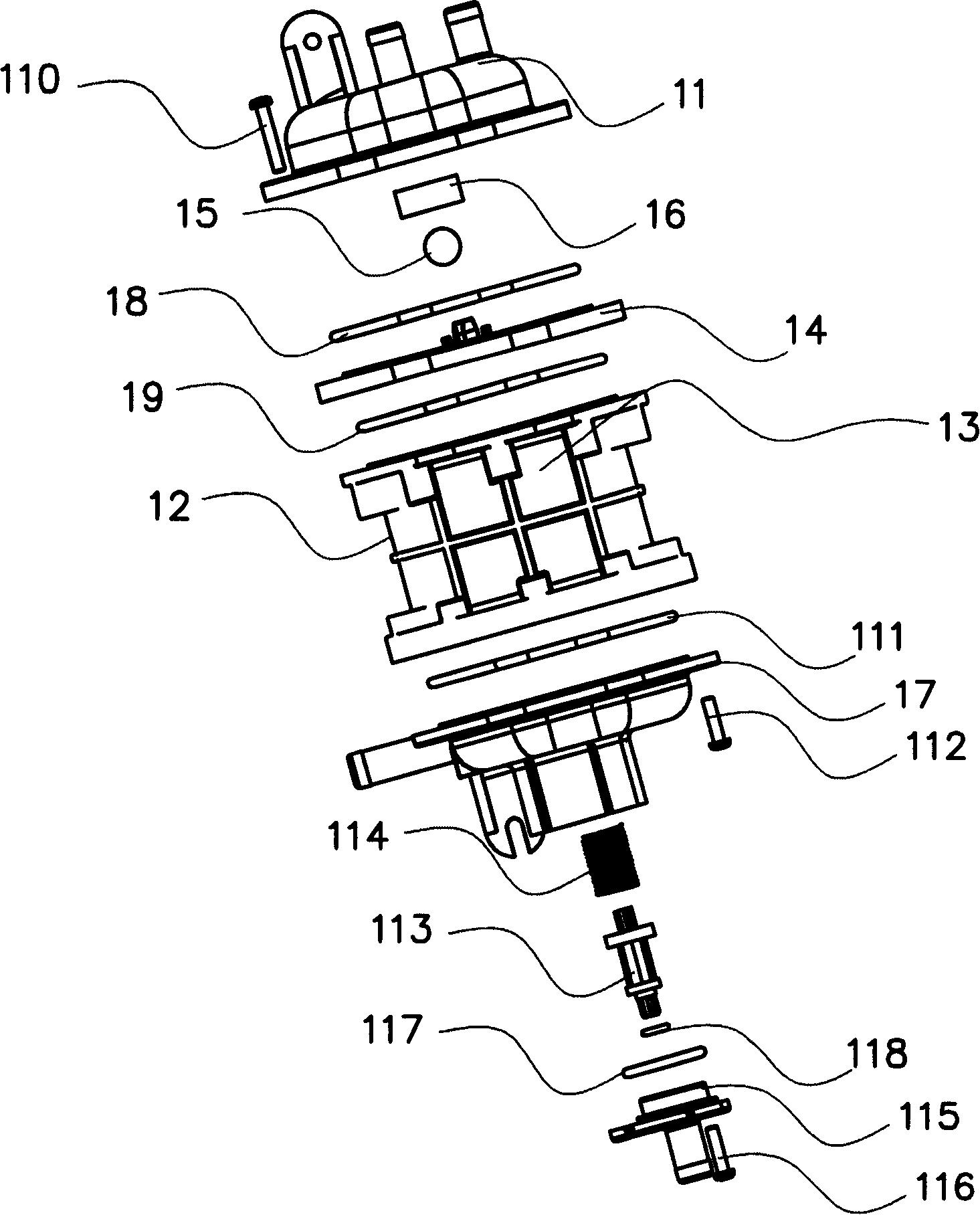

Water feeding device for washing machine

InactiveCN101191298AShort lifeReduce the effective areaOther washing machinesWater/sewage treatmentElectrolysisSolenoid valve

The invention relates to a washing machine feeding apparatus which has the advantages of capability of softening hard water and electrolyzing soft water and then improving washing effect, capability of prolonging service life of an electrolysis unit, and non-necessity of throwing regenerants into a mollifier each time. The invention comprises a water inlet solenoid valve (5), and a regenerant dispenser (2) and the mollifier (1) which are respectively connected with a water outlet for regeneration (501) and a water outlet for softening (502) of the solenoid valve through pipes, and a control circuit board which is provided with a microprocessor CPU is arranged, wherein, an overfall gap (202) is arranged on the side face of a regenerant container (22) of the regenerant dispenser; a regenerant switch valve (3) is arranged at the bottom of the regenerant container (22); an outlet (302) of the regenerant switch valve is connected with a regenerant inlet (153) of the mollifier through a pipe; a water outlet (152) of the mollifier is connected with an electrolysis bath (4) through a pipe. The invention is suitable for being taken as a washing machine feeding apparatus.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

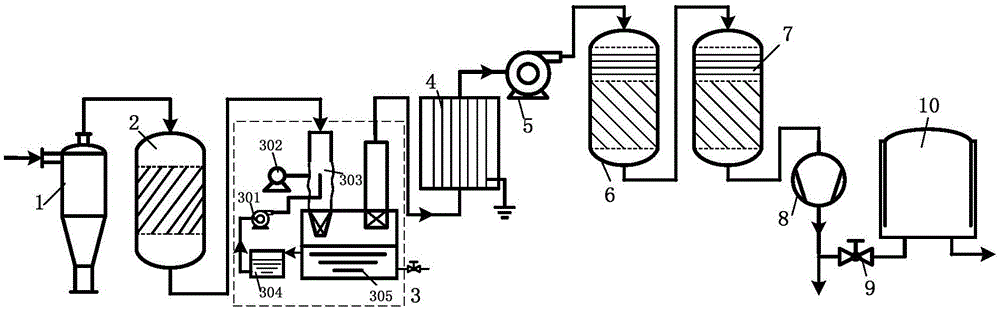

Recovery system and recovery method of low-order coal pyrolysis oil gas

InactiveCN105647592AHigh desulfurization precisionSimple processGas purification with selectively adsorptive solidsGas purification by non-gaseous materials condensationScrubberMolecular sieve

The invention provides a recovery system of low-order coal pyrolysis oil gas. The recovery system comprises a cyclone dust collector, a filter dust collector, washing equipment, an electrical tar precipitator, adsorption equipment and a desulfurizing tower, wherein the washing equipment comprises an ammonia water storage tank, a tar washing tank and a gas-liquid contact vertical pipe which is positioned above the tar washing tank; the adsorption equipment is internally filled with one or more of pyrolytic semi-cokes, cokes, sawdust, granular activated carbon, activated carbon fiber, silica gel, activated aluminum oxide and molecular sieve. According to the recovery system provided by the invention, a dynamic wave washer is adopted, the structure is simple, the manufacturing cost is low, the energy consumption is low, the operation flexibility is large, and the gas-liquid mass transfer effect is good; due to the additional arrangement of a soft connecting pipe wall and a vibrator / an oscillator, the situation that a pipeline is blocked as tar is condensed on the pipe wall can be effectively avoided; through an oil gas product recovery technology adopted by the invention, and by arranging a hydrogen sulfide adsorption device and a dewatering device, hydrogen sulfide and water vapor in pyrolysis gas can be adsorbed, and the problems that due to the condensation of tar mist, VOCs (Volatile Organic Compouns) and the water vapor in the pyrolysis gas, pipeline equipment is corroded, and long-distance transportation requirements are difficult to meet are effectively solved.

Owner:SHENWU TECH GRP CO LTD

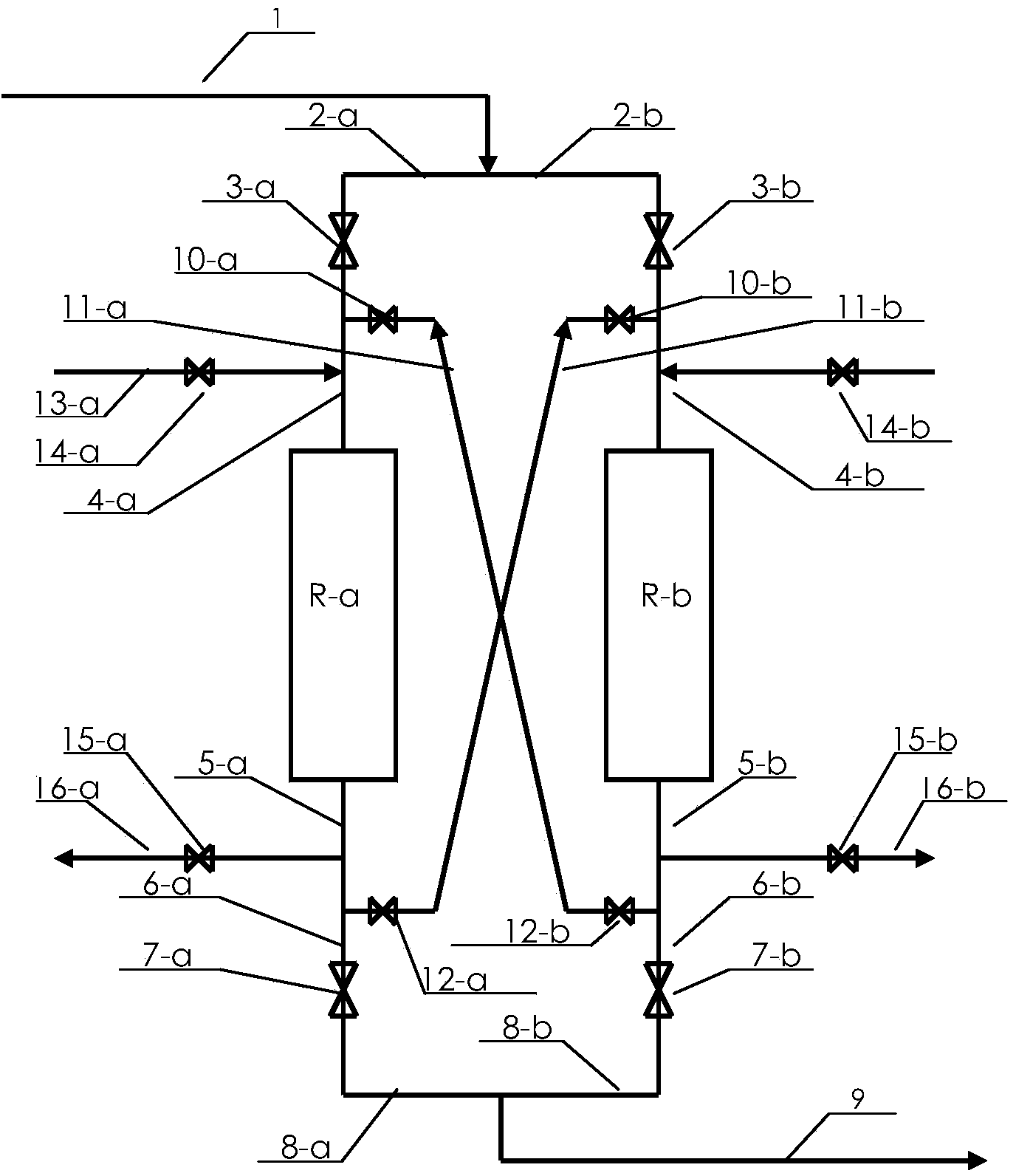

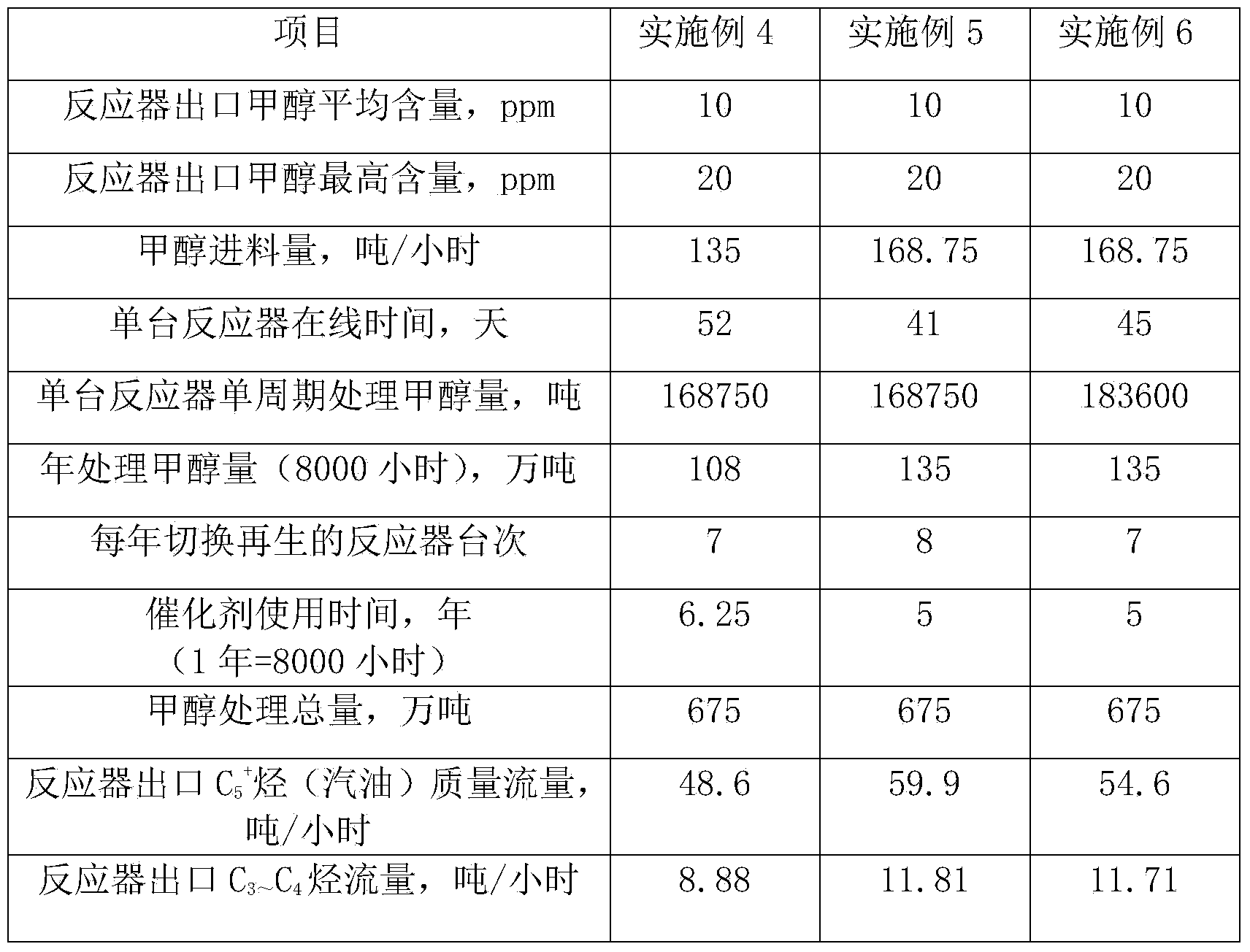

Continuous reaction and regeneration technology used for conversion of methanol to gasoline through stationary bed adiabatic reactors

ActiveCN104140839AImprove effective utilizationIncreased operating lifeLiquid hydrocarbon mixture productionBio-feedstockGasolineResidual activity

Provided is a continuous reaction and regeneration technology used for conversion of methanol to gasoline through stationary bed adiabatic reactors. The two stationary bed adiabatic reactors work independently, the first reactor carries out a reaction for conversion of methanol to gasoline independently, and the second reactor is in a standby state; when catalysts in the first reactor approach to inactivation, the two reactors can work in a series connection mode through valve switchover until residual activity of the catalysts in the first reactor is fully utilized; the two reactors are made to work in a respective independent mode through valve switchover, the second reactor completes the reaction for conversion of methanol to gasoline independently, and the first reactor finishes catalyst regeneration operation independently and gets into the standby state. The technology is repeated in that way. The technology has the advantages that operation is simple, and the utilization rate of reactivity of the catalysts in the reaction process is high.

Owner:SHANXI FEISHI TECH +2

Method for continuously synthesizing diphenylamine by utilizing phenylamine

ActiveCN103044270ALong life one wayThe amount of hydrogen used in the reaction is reducedAmino compound preparation by condensation/addition reactionsProcess engineeringSystems engineering

The invention discloses a method for continuously synthesizing diphenylamine by utilizing phenylamine. Phenylamine raw material contacts with hydrogen before entering into a reactor, the hydrogen is dissolved into the phenylamine raw material, the phenylamine raw material with the dissolved hydrogen enters into a reactor used for continuously synthesizing diphenylamine by virtue of phenylamine, the phenylamine raw material with the dissolved hydrogen passes through a catalyst bed layer, and a diphenylamine synthesizing reaction by virtue of the phenylamine is carried out, wherein the catalyst bed layer contains no gas-phase hydrogen. Compared with the prior art, the method disclosed by the invention has the advantage that the dissolved hydrogen substitutes for massive gas-phase recycled hydrogen while conversion rate of the reaction, selectivity of a target product and service life of a catalyst are guaranteed, so that equipment investment and operation energy consumption are greatly reduced, and reduction of production cost can be facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

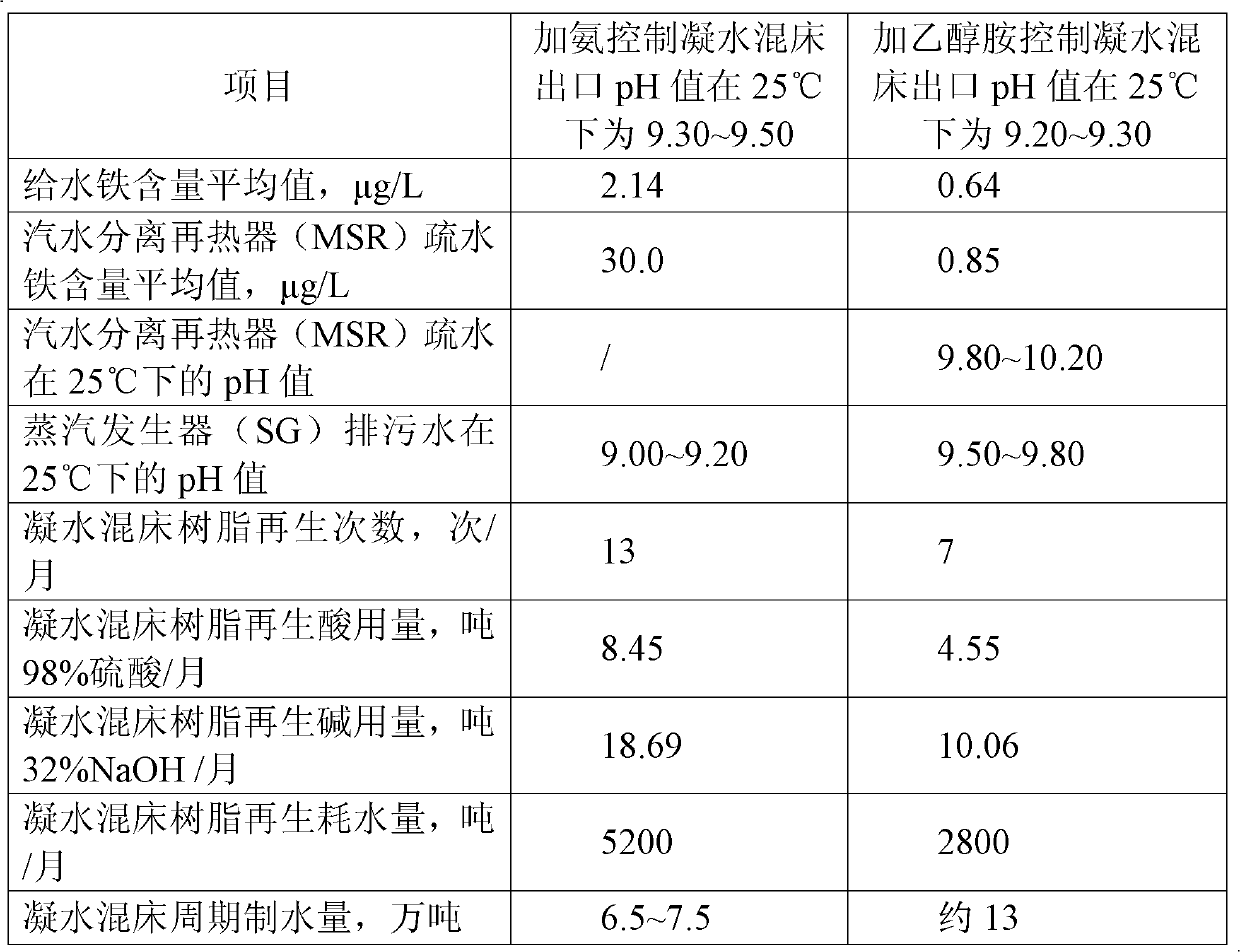

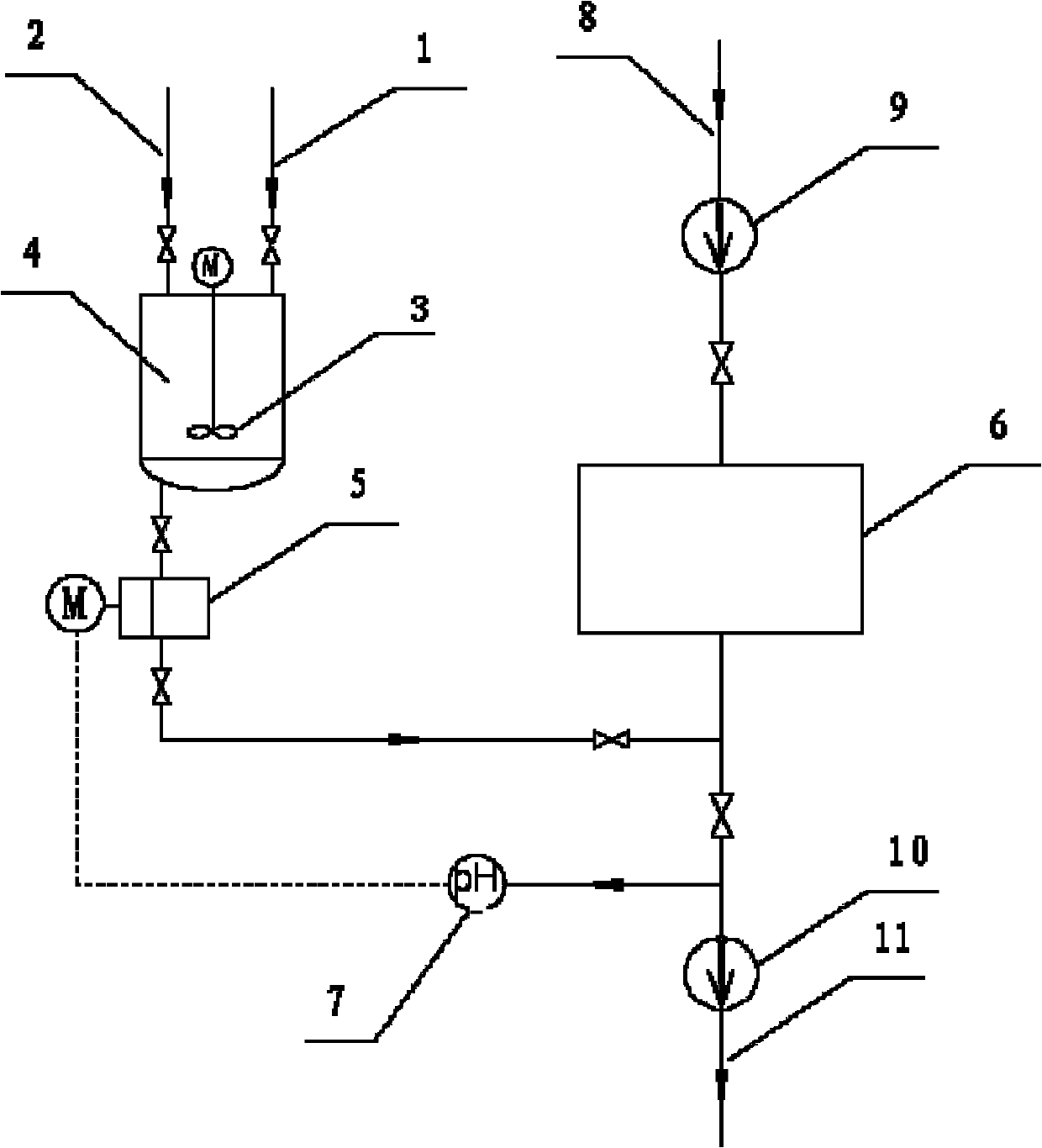

Method for adjusting pH value of secondary circuit of nuclear power plant

InactiveCN102557225AAccelerated corrosionRaise the pHWater/sewage treatment by neutralisationNuclear powerWorkload

The invention provides a method for adjusting the pH value of a secondary circuit of a nuclear power plant. The technical scheme is that: an ethanolamine solution is taken as a pH value adjusting agent; and the pH value of condensate is adjusted to 9.20-9.30 at the temperature of 25 DEG C before the condensate enters a subsequent secondary circuit moisture cycle. Due to the adoption of the method, the pH value of a liquid phase of a gas-liquid two-phase position is increased, a corrosion product of liquid-phase area equipment in gas and liquid phases is reduced, the corrosion state of a secondary circuit system is improved, the transfer amount of a water supply system corrosion product to the secondary side of a stream generator is reduced, the depositing probability of the corrosion product inside the stream generator is lowered, and the service life of the steam generator is prolonged; and moreover, the periodical water output of a water condensing mixed bed of a condensate precise treating device is increased, the regenerating times of the water condensing mixed bed, the using amounts of regenerated acids and alkalis and the water consumption are reduced, the workload of running personnel is relieved, and the discharge of a regenerated water liquid into the environment is reduced.

Owner:QINSHAN NUCLEAR POWER

Catalyst for producing methyl acetate as well as preparation method and application of catalyst

ActiveCN106890671ASimple production processLow production costMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMethyl acetate

The invention discloses a catalyst for producing methyl acetate through carbonylation of dimethyl ether. The catalyst is characterized by comprising a modified EMT molecular sieve, wherein the modified EMT molecular sieve is obtained by sequentially processing by virtue of acid and pyridine and / or a pyridine substitute; the pyridine substitute is a compound formed by independently substituting one, two or three of five Hs on a pyridine ring with a substitute selected from F, Cl, Br, I, CH3, CF3, CH3CH2 or NO2. The catalyst has very high stability and methyl acetate selectivity and can still preserve high methyl acetate selectivity after reacting for a long time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

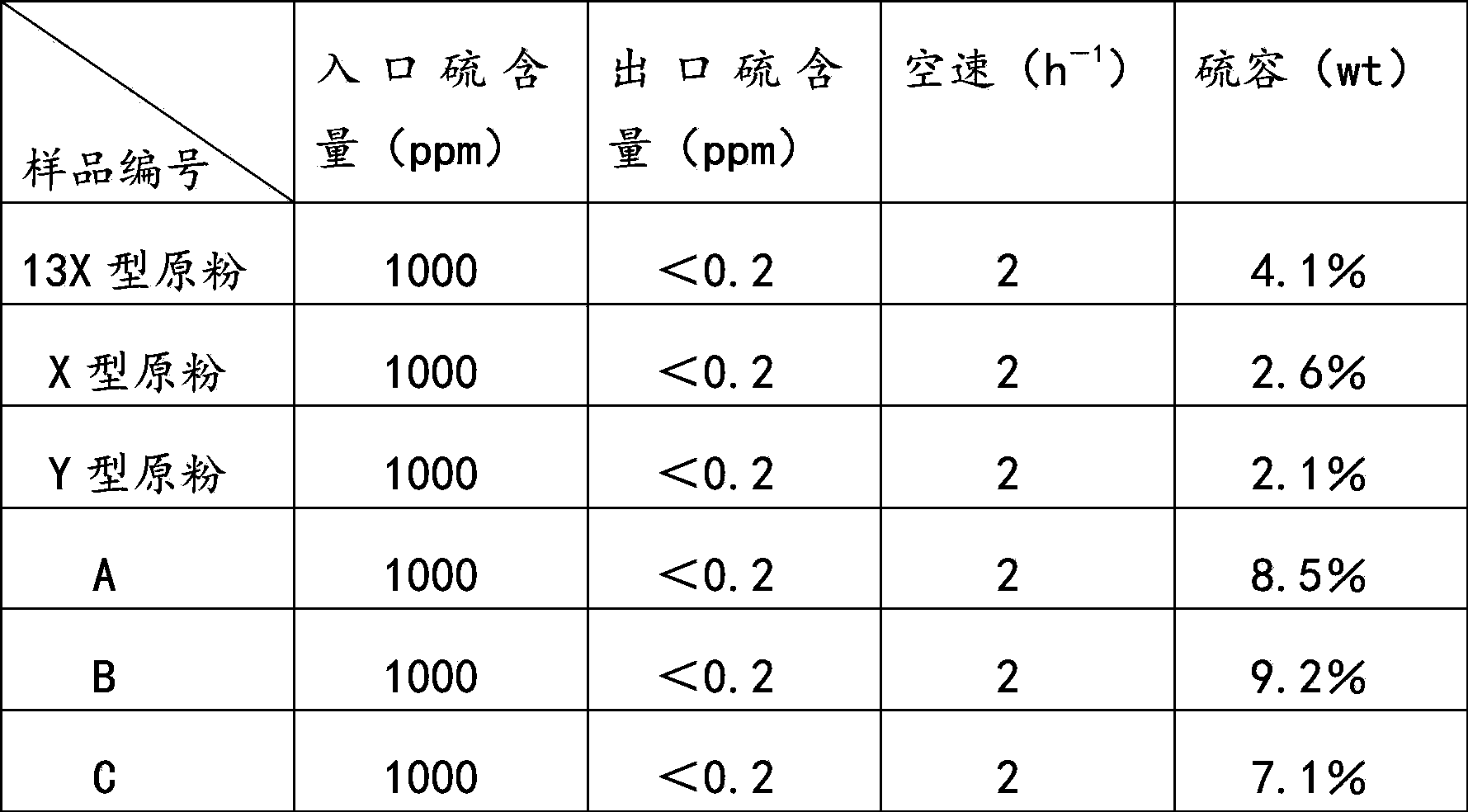

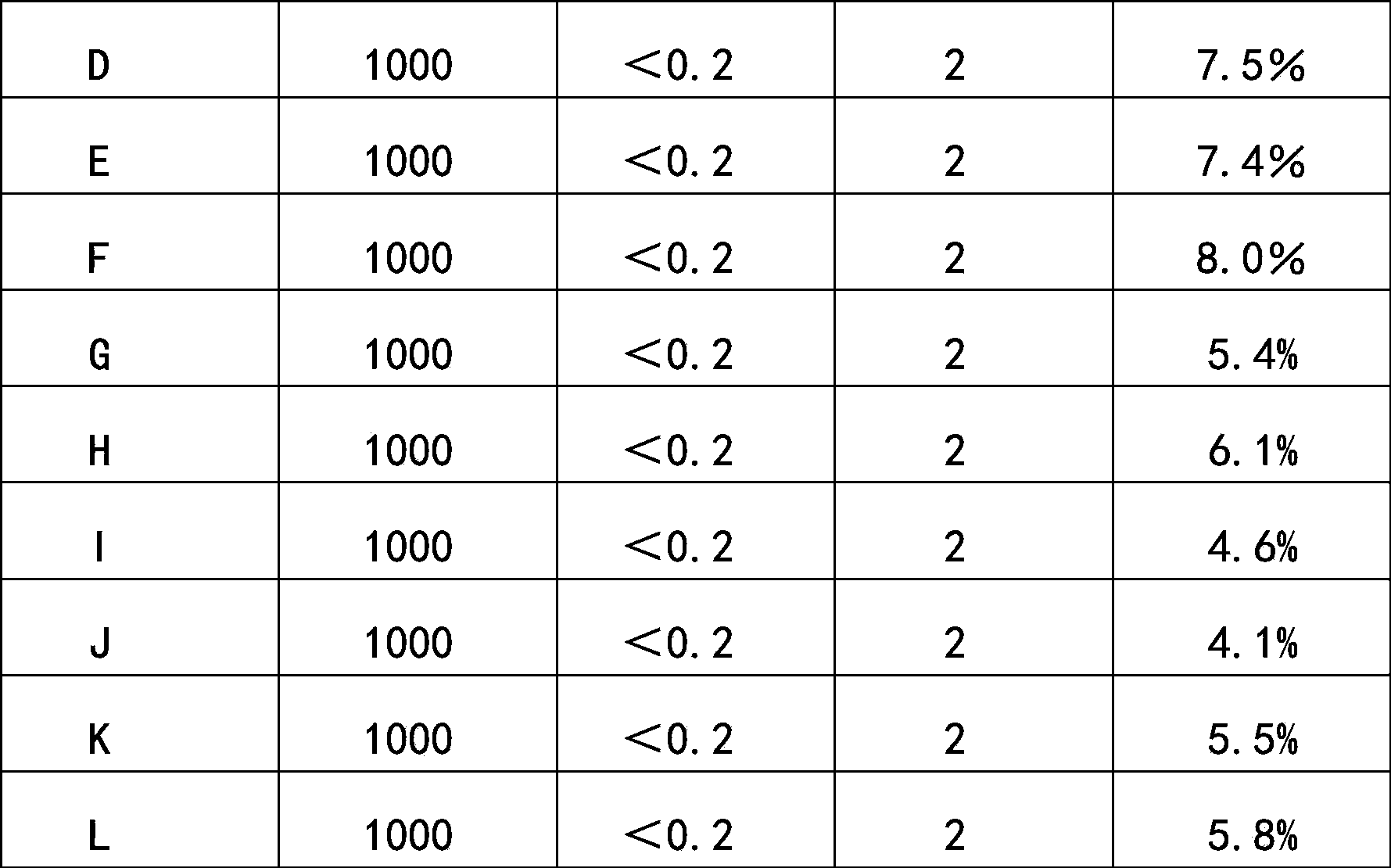

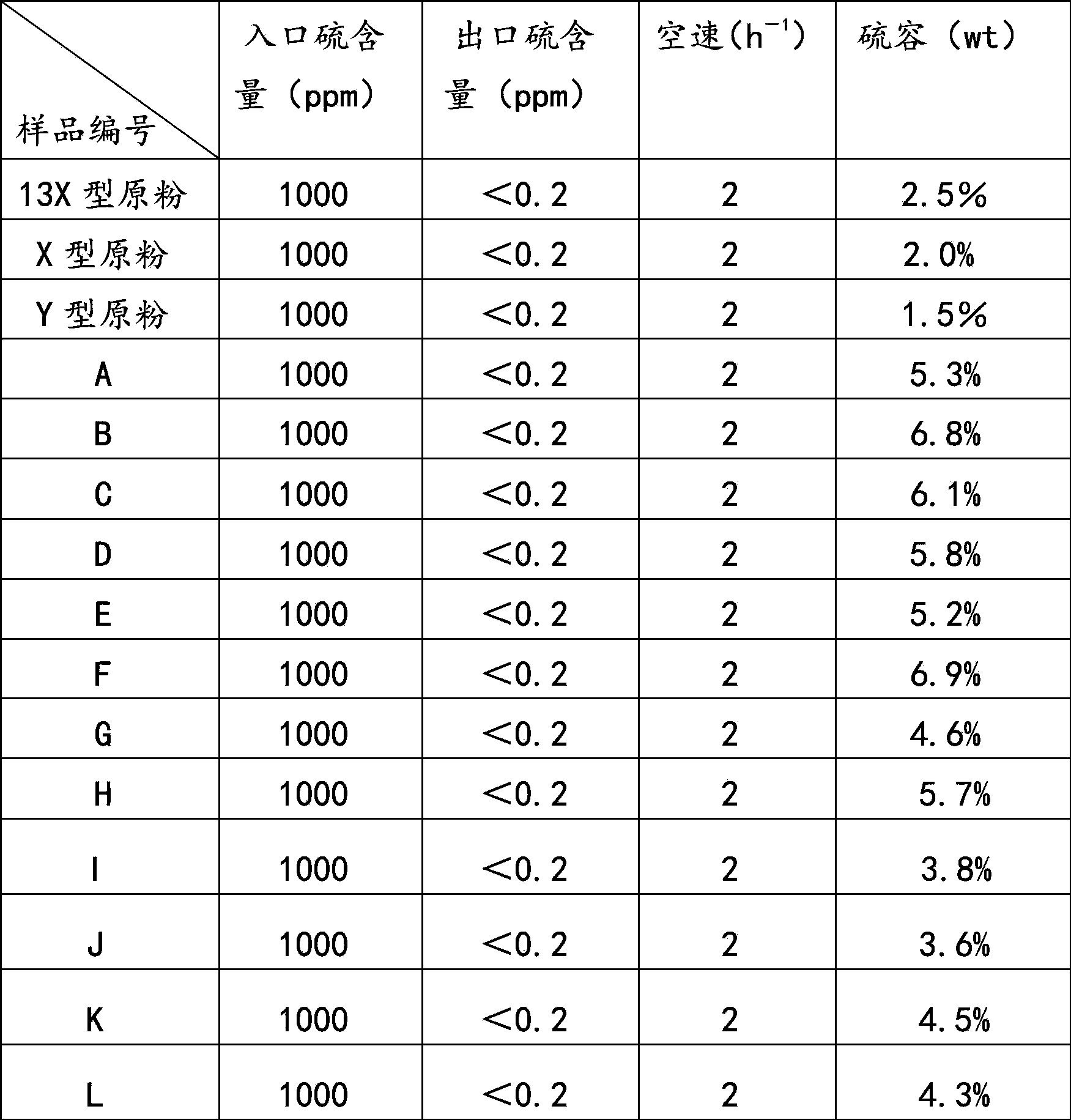

Potassium ion-containing molecular sieve desulfurizing agent, and preparation method thereof

InactiveCN103894146AReduce the number of regenerationsImprove adsorption capacityOther chemical processesHydrocarbon oils refiningMolecular sieveAbsorption capacity

The invention relates to a potassium ion-containing molecular sieve desulfurizing agent, and a preparation method thereof. According to the preparation method, metal cation K+ is used for modifying a molecular sieve, and potassium ion exchange degree is controlled to be 5 to 25%, so that electrostatic field intensity of local positions in hole passages of the molecular sieve is increased, and when the molecular sieve is used for desulphurization of hydrocarbon flow via physical adsorption, neutral sulfide and disulphide molecules in the hydrocarbon flow are polarized, and are absorbed easily, absorption capacity and absorption efficiency of the molecular sieve on the sulfides are increased. The potassium ion-containing molecular sieve desulfurizing agent with an ion exchange degree of 5 to 25% is excellent in absorption effect, is high in absorption capacity, and is capable of reducing generation times of the potassium ion-containing molecular sieve desulfurizing agent effectively.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of catalyst for producing methyl acetate, its preparation method and application

ActiveCN106890671BSimple production processLow production costMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMethyl acetate

The present application discloses a catalyst for the carbonylation of dimethyl ether to produce methyl acetate, which is characterized in that it contains a modified EMT molecular sieve, and the modified EMT molecular sieve is treated with an acid and then treated with pyridine and / or a pyridine substitute EMT molecular sieve; the pyridine substituent is one, two or three of the five H on the pyridine ring independently selected from F, Cl, Br, I, CH 3 、CF 3 、CH 3 CH 2 or NO 2 The substituents in replace the resulting compound. The catalyst has high stability and methyl acetate selectivity, and can still maintain high methyl acetate selectivity after long-time reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

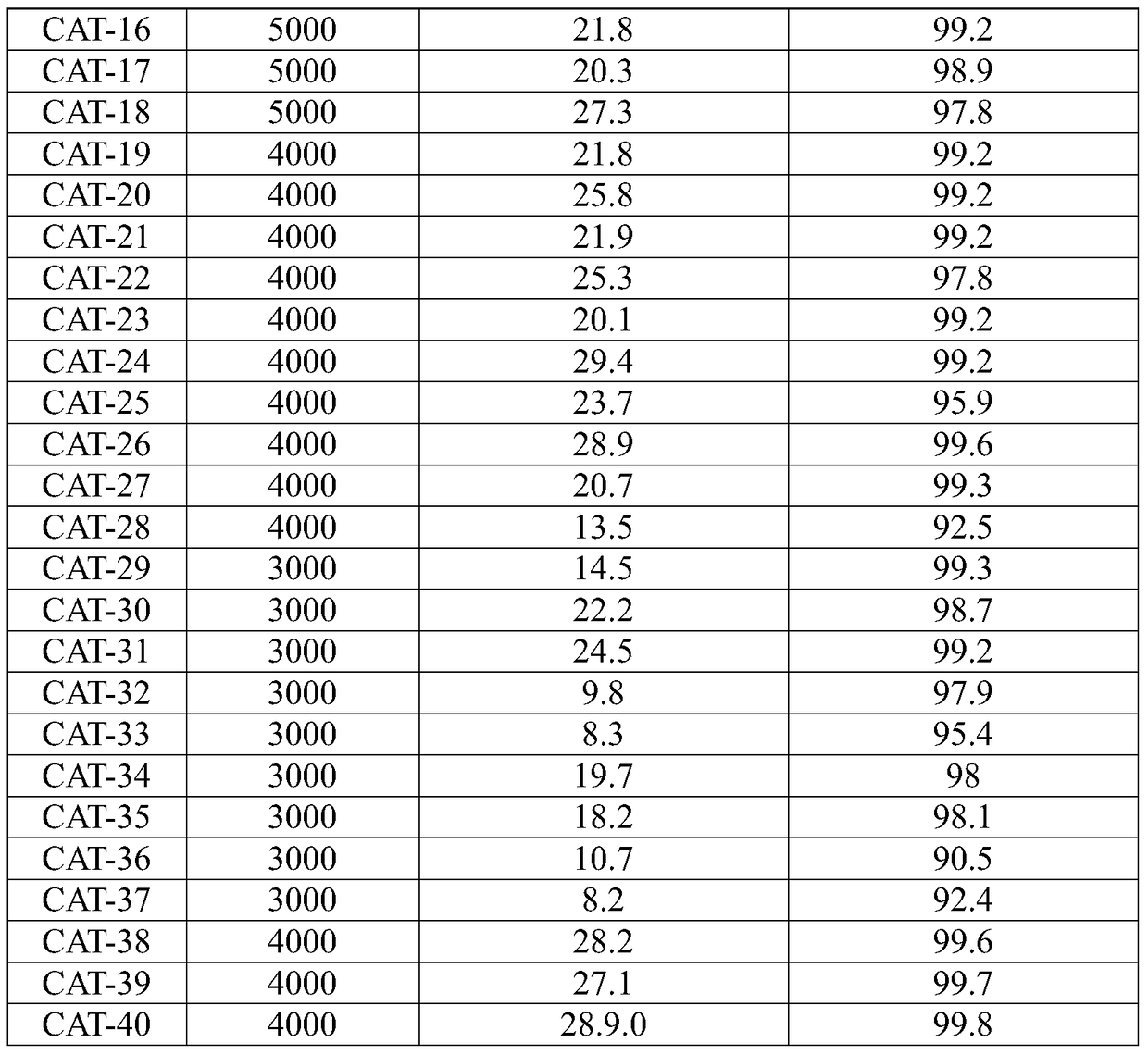

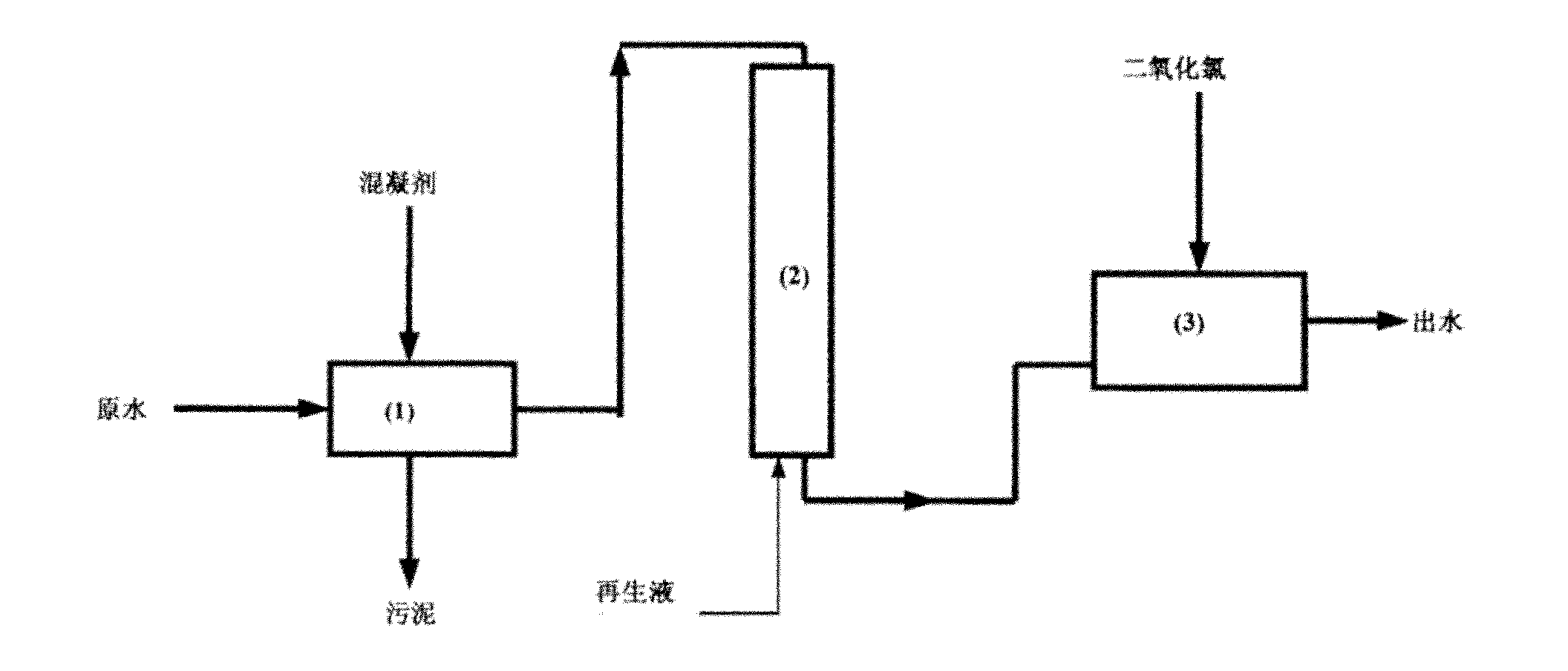

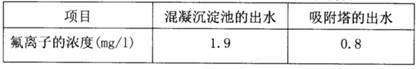

Fluorine removing process and device for drinking water

InactiveCN102120657ALow fluorine contentReduce processing costsWater contaminantsMultistage water/sewage treatmentHigh concentrationSorbent

The invention discloses a fluorine removing process and a fluorine removing device for drinking water, and relates to a water treatment process and a water treatment device. The process at least comprises two treatment steps of coagulating sedimentation and adsorption, wherein the coagulating sedimentation is that fluorinated water is subjected to coagulating sedimentation through an inorganic aluminum coagulant agent to make the fluorine content of the treated water less than 2mg / l; and the adsorption is that an adsorbent is adopted for adsorption treatment. The invention has the advantages that: the low cost of a coagulation process and the high efficiency of an adsorption method are integrated, and the low-cost and high-efficiency fluorine removal is realized. In the coagulating sedimentation process, a proper amount of proper coagulant is selected according to the fluorine content in raw water, and the fluorine content in the water can be reduced, so that the regeneration frequency of the adsorbent is greatly reduced, the service life of the adsorbent is prolonged, the water treatment cost is reduced, and the invention has good application prospect for treating high-concentration fluorine-containing drinking water.

Owner:姜雪

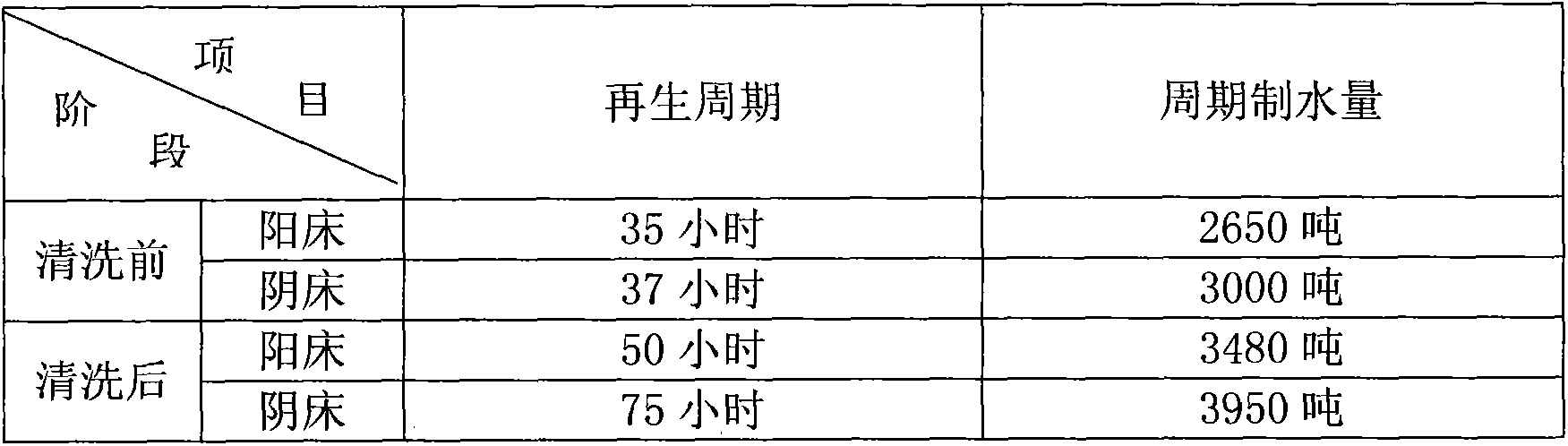

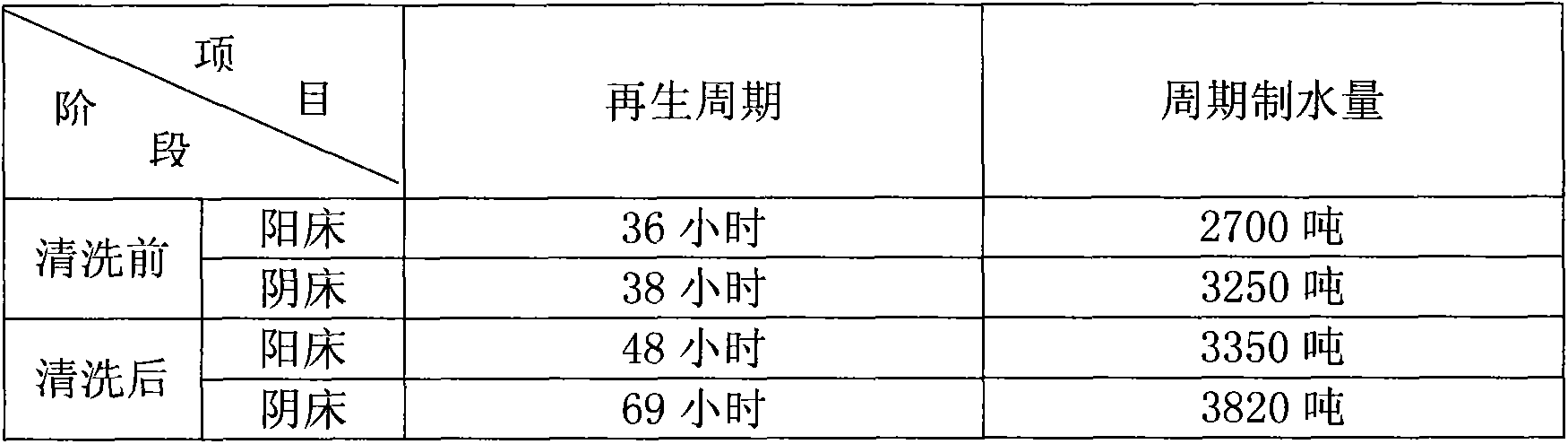

Anion-cation exchange resin cleaning agent

ActiveCN103756798ASo as not to damageExtended regeneration cycleSurface-active detergent compositionsDetergent compounding agentsAdditive ingredientHydrophile

The invention relates to an anion-cation exchange resin cleaning agent. The anion-cation exchange resin cleaning agent is prepared from the following ingredients in percentage by weight: 5-25% of nonionic surfactant, 1-8% of descaling agent, 2-10% of chelating agent, 0-5% of dispersing agent and the balance of water, wherein the nonionic surfactant includes more than one of polyoxyethylene ether with the HLB (Hydrophile-Lipophile Balance) value being greater than 10 and block polyether, the descaling agent is a carboxylic copolymer, the chelating agent is disodium edetate or phosphonobutane carboxylic acid, and the dispersing agent is an acrylamide terpolymer.

Owner:SHENYANG DREAMLAND ENVIRONMENTS TECH

Molecular sieve desulfurizer containing copper ion and potassium ion and preparation method thereof

InactiveCN103894147AReduce the number of regenerationsImprove adsorption capacityOther chemical processesHydrocarbon oils refiningMolecular sievePhysical chemistry

The invention relates to a molecular sieve desulfurizer containing copper ion and potassium ion and a preparation method thereof. According to the molecular sieve desulfurizer, metal cations K+ and Cu<2+> are adopted to modify a molecular sieve, and the whole exchange rate of the potassium ion and the copper ion is 10-40%, and therefore the electrostatic field intensity of local positions in pore channels in the molecular sieve is enhanced. When hydrocarbon flows are desulfurized by the molecular sieve through physical adsorption, mercaptan molecules and thioether molecules in the hydrocarbon flows are polarized, so that the mercaptan molecules and the thioether molecules are prone to adsorption, and the adsorption capability and the adsorption efficiency of the molecular sieve for sulfides are increased. The molecular sieve desulfurizer containing the copper ion and the potassium ion, the exchange rate of which is 10-40%, is good in adsorption effect and large in adsorption capability, thus effectively reducing the number of times of regeneration of the desulfurizer.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

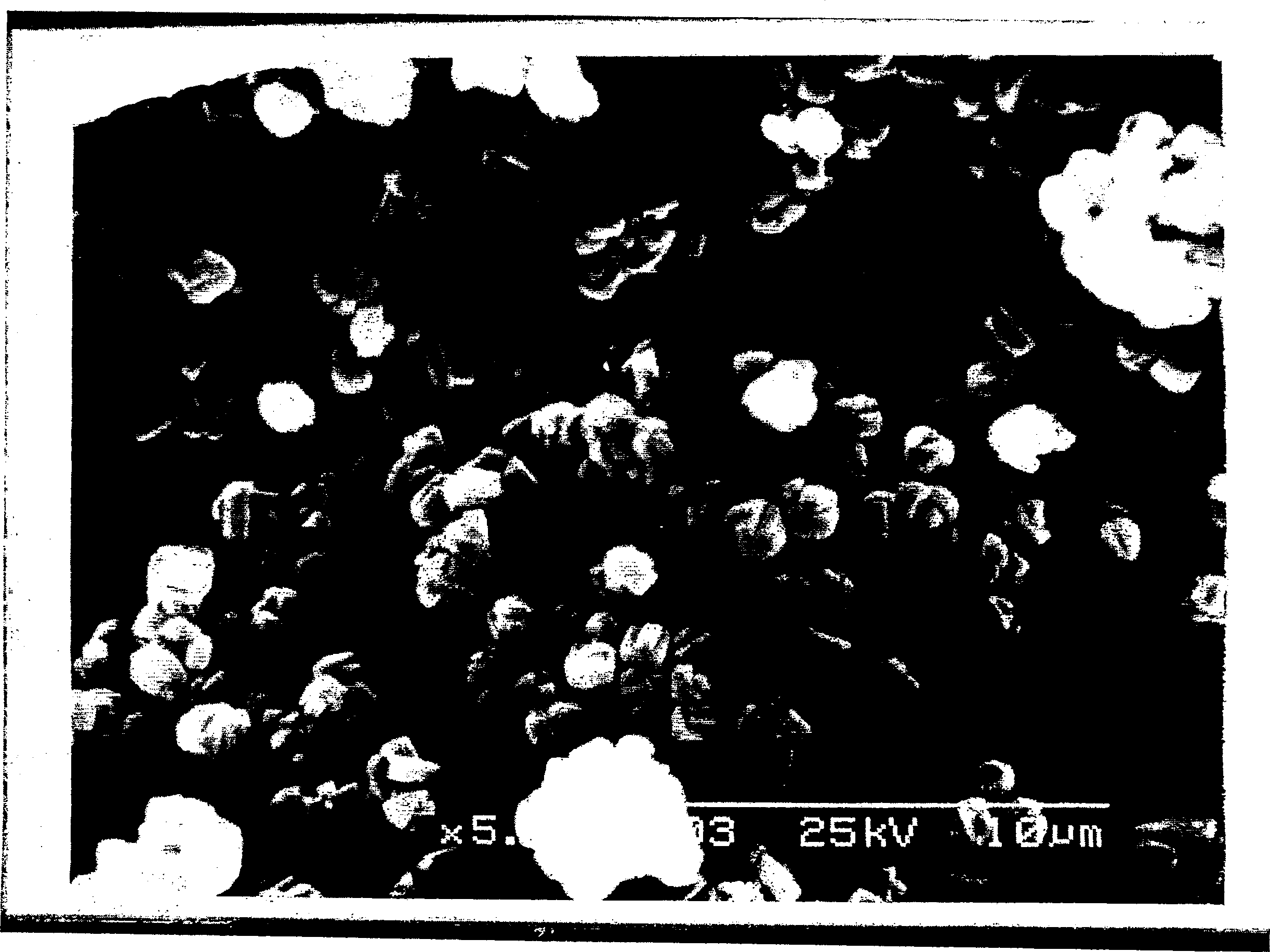

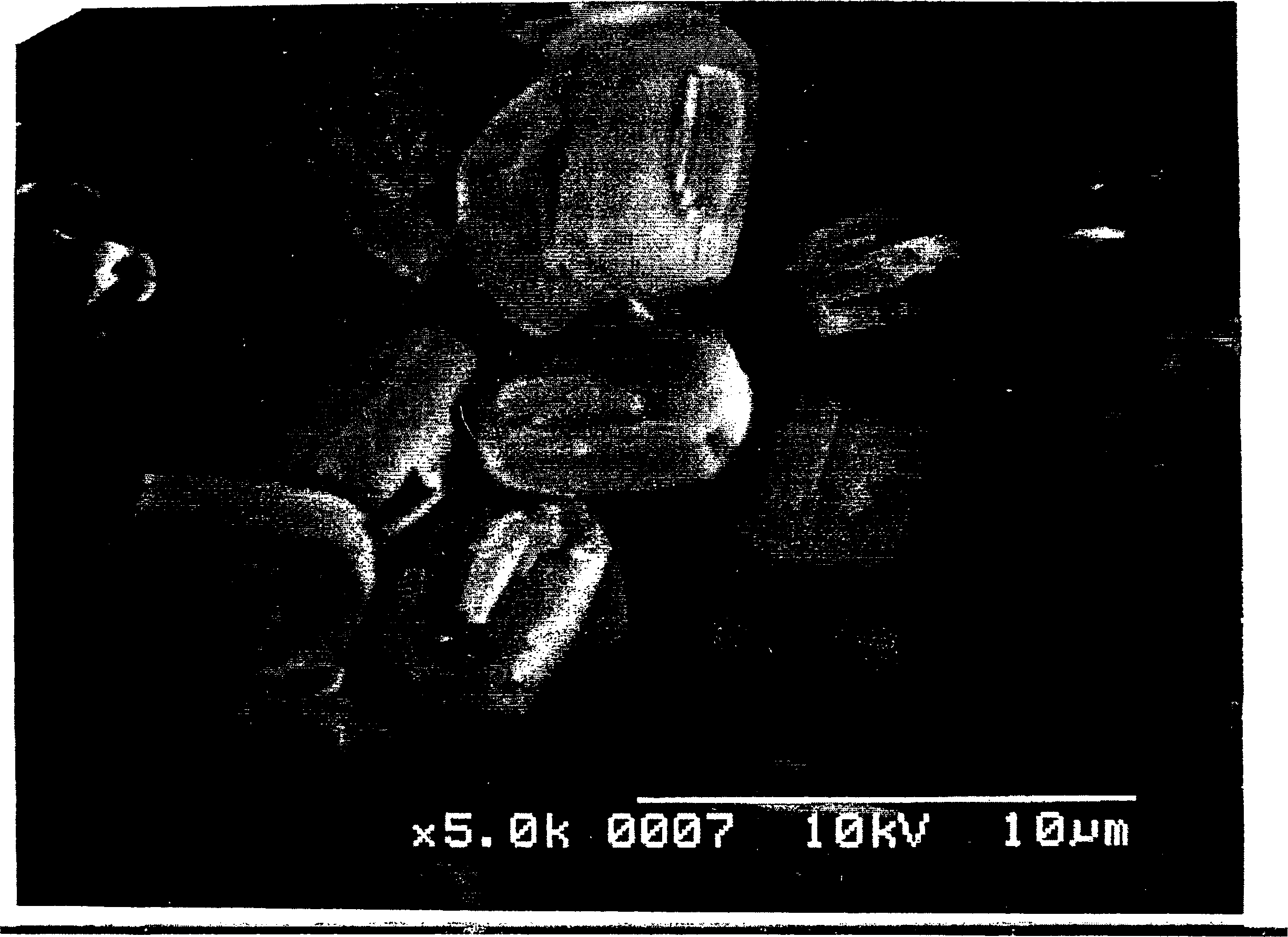

Catalyst, process for preparing the catalyst and process for producing lower hydrocarbon with the catalyst

ActiveCN1901993ASmall particle sizeExtended regeneration cycleMolecular sieve catalystsOrganic chemistry methodsAlkaline earth metalMetal

A zeolite catalyst with an MFI structure containing alkaline earth metals is used in the synthesis of lower hydrocarbons from dimethyl ether and / or methanol, wherein the Si / Al atomic ratio is 30-400, the alkaline earth metal / Al atomic ratio is 0.75-15, and the average The particle size is 0.05-2 μm.

Owner:JGC CORP

High-accuracy and high-capacity dehydration method of various materials in petrochemical process

InactiveCN101591559AImprove thermal stabilityGood storage stabilityDewatering/demulsification with chemical meansCross-linkHydrolysate

The invention provides a high-accuracy and high-capacity dehydration method of various materials in petrochemical process. The dehydrating agent is selected from one of or a mixture of two of quadripolymers such as cross-linked polyacrylate, vinyl alcohol-acrylate segmented copolymer, modified PVA, polyvinyl alcohol, polyacrylamide, starch graft acrylate, starch, acrylic acid-acrylamide and maleic anhydride and the like, cellulose graft acrylate and starch graft acrylonitrile saponification hydrolysate. The dehydration method in the invention has high water absorbency and reduces the dehydration cost.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

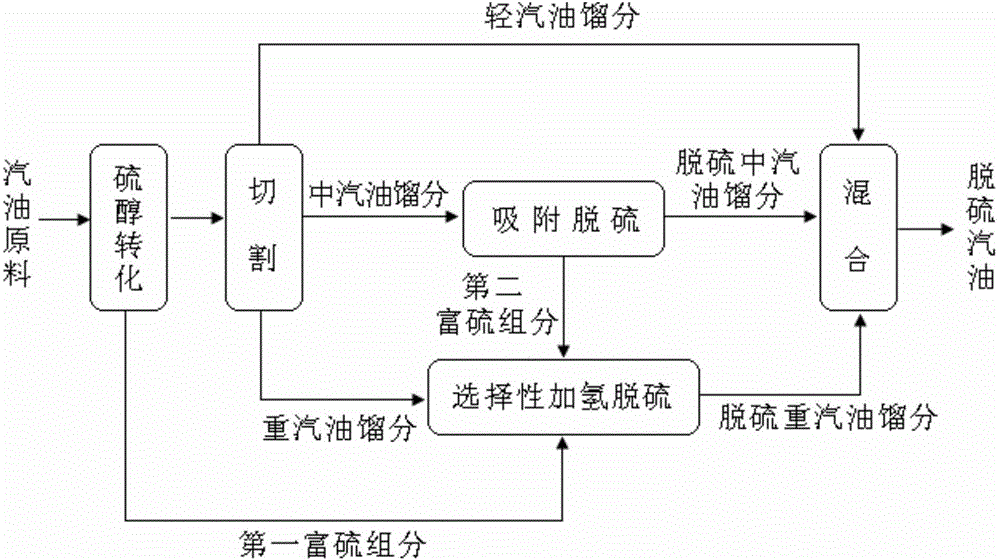

Deep gasoline desulfurization method

InactiveCN104673379ARealization of deep desulfurizationReduce the number of regenerationsOther chemical processesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention provides a deep gasoline desulfurization method which comprises the following steps of: carrying out mercaptan removing treatment on a gasoline raw material; cutting the gasoline raw material subjected to the mercaptan removing treatment into light, medium and heavy gasoline fractions; carrying out adsorption desulfurization on the medium gasoline fraction to obtain a desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain a desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain desulfurized gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fractions is 70-130 DEG C. The deep gasoline desulfurization method provided by the invention can not only realize the deep desulfurization of gasoline, but also has low octane value loss.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Catalyst for preparing acrylic acid and methyl acrylate

ActiveCN108097286AEase of industrial preparationImprove stabilityMolecular sieve catalystsOrganic compound preparationMolecular sieveMontmorillonite

The invention relates to a catalyst for preparing acrylic acid and / or methyl acrylate from compounds containing carbon monoxide and a formaldehyde compound. The catalyst contains an acidic molecular sieve and a mesoporous binder; the formaldehyde compound is selected from at least one of formaldehyde, methylal and trioxymethylene; the mesoporous binder is selected from at least one of mesoporous silica, mesoporous magnesium oxide, mesoporous titanium oxide, mesoporous pseudo-boehmite, mesoporous kaolin and mesoporous montmorillonite.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-temperature gas heating method and device for pickling hot rolled steel strip

The invention discloses a high-temperature gas heating method and device for pickling a hot rolled steel strip. The method comprises the following steps of: firstly, heating high-temperature gas: heating the passing steel strip to 85-500 DEG C through high-temperature gas in a box; then, leading the heated steel strip to enter a pickling tank; heating acid liquid to 60-98 DEG C through the steel strip; and reacting the steel strip with acid to remove the oxide of ferrum on the surface. In the method disclosed by the invention, the surface temperature of the steel strip is increased to above the normal pickling temperature through use of the high-temperature gas; then, the high-temperature steel strip enters the pickling tank; the pickling solution is heated by the accumulated heat of the steel strip, the rapid pickling is realized, the aim of rapid dissolution of the oxide is achieved, and the steel strip without oxide on the surface is obtained. The traditional method for increasing the temperature of the steel strip and the acid liquid is changed; and the steel strip is not in direct contact with the acid liquid during heating in the method, the heating speed is high, and the blockage condition caused by the deposition and gumflower of colloid and oxide film suspensions in a heater is basically prevented.

Owner:MAANSHAN IRON & STEEL CO LTD

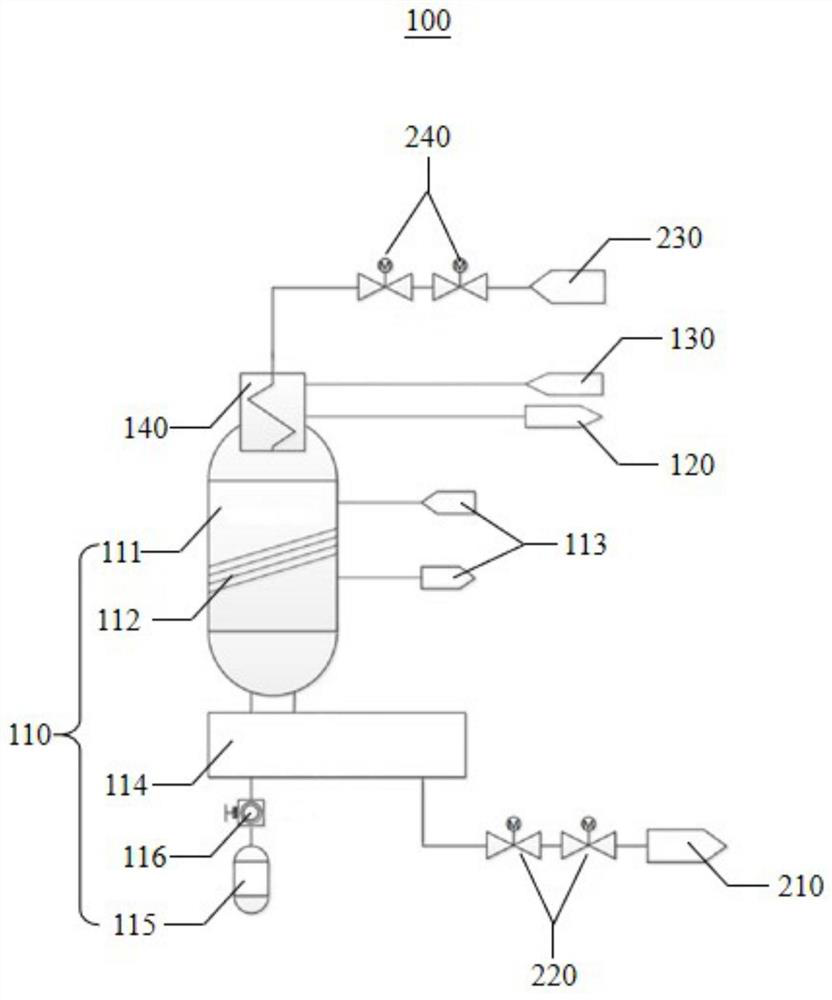

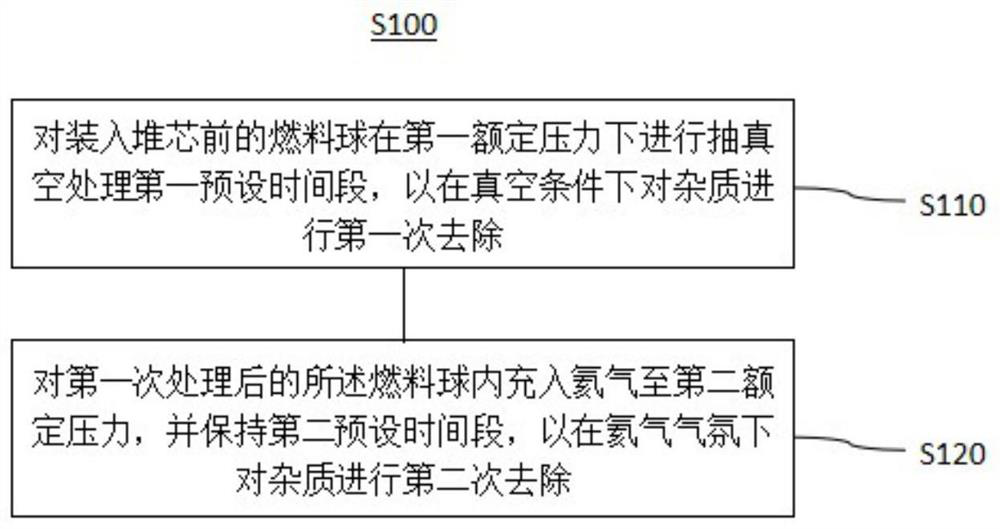

High-temperature gas cooled reactor new fuel treatment system and method

ActiveCN113130106AEasy to handleLow impurity contentNuclear energy generationReactors manufactureProcess engineeringRadiochemistry

The invention provides a high-temperature gas cooled reactor new fuel treatment system and method. The treatment system comprises a new fuel treatment device, and a vacuumizing device and a helium filling device which are connected with the new fuel treatment device. The vacuumizing device is used for vacuumizing fuel balls in the new fuel treatment device before a reactor core is loaded to a first rated pressure, and keeping the first rated pressure for a first preset period of time so as to remove impurities for the first time under a vacuum condition; and the helium filling device is used for filling the new fuel treatment device with helium to reach a second rated pressure and keeping the second rated pressure for a second preset period of time so as to remove the impurities for the second time in the helium atmosphere. By arranging the vacuumizing device and the helium filling device, air, water and other impurities adsorbed by the fuel balls loaded into the reactor core can be effectively subjected to deep treatment, so that the content of impurities in a primary loop coolant in the reactor is reduced, the workload of a helium purification system is reduced, the helium purification regeneration frequency is reduced, and the generation amount of radioactive waste is reduced from the source.

Owner:HUANENG SHANDONG SHIDAO BAY NUCLEAR POWER CO LTD

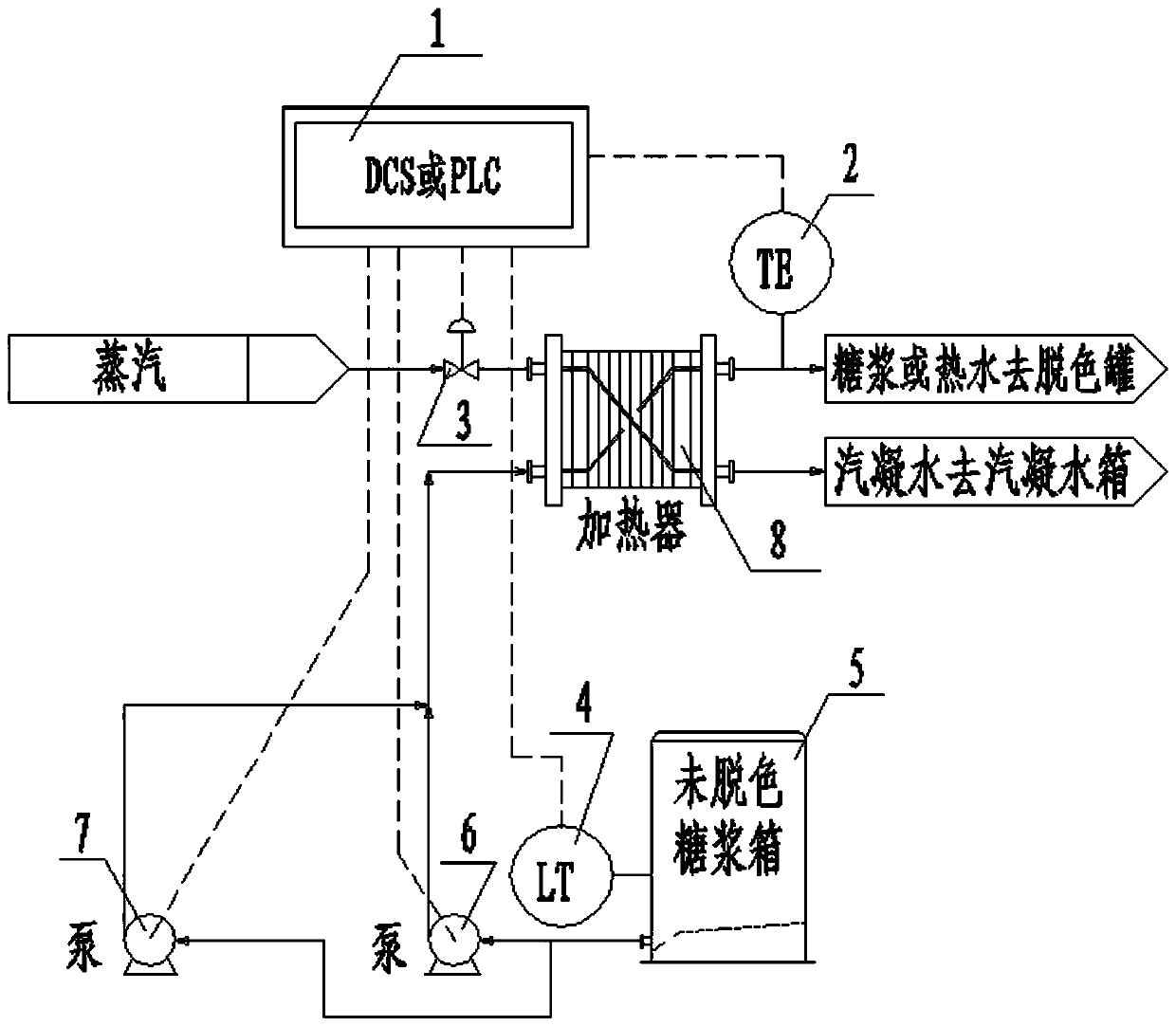

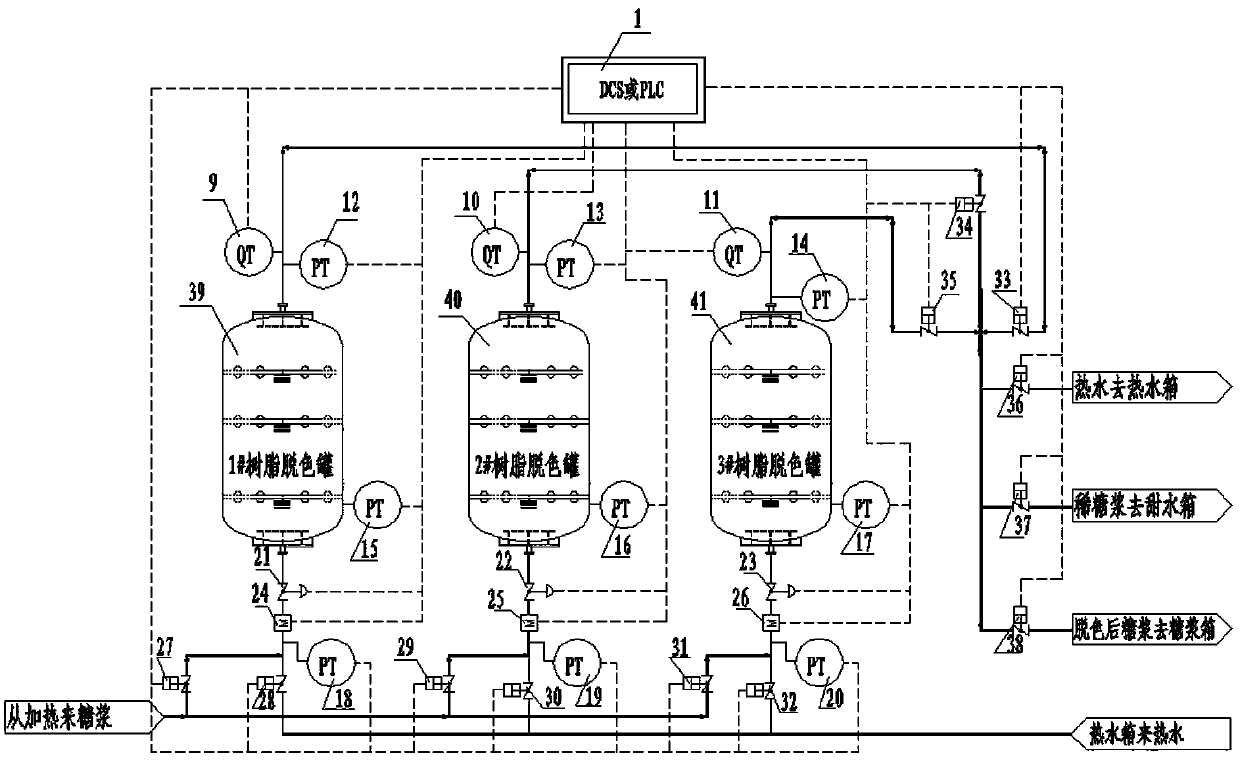

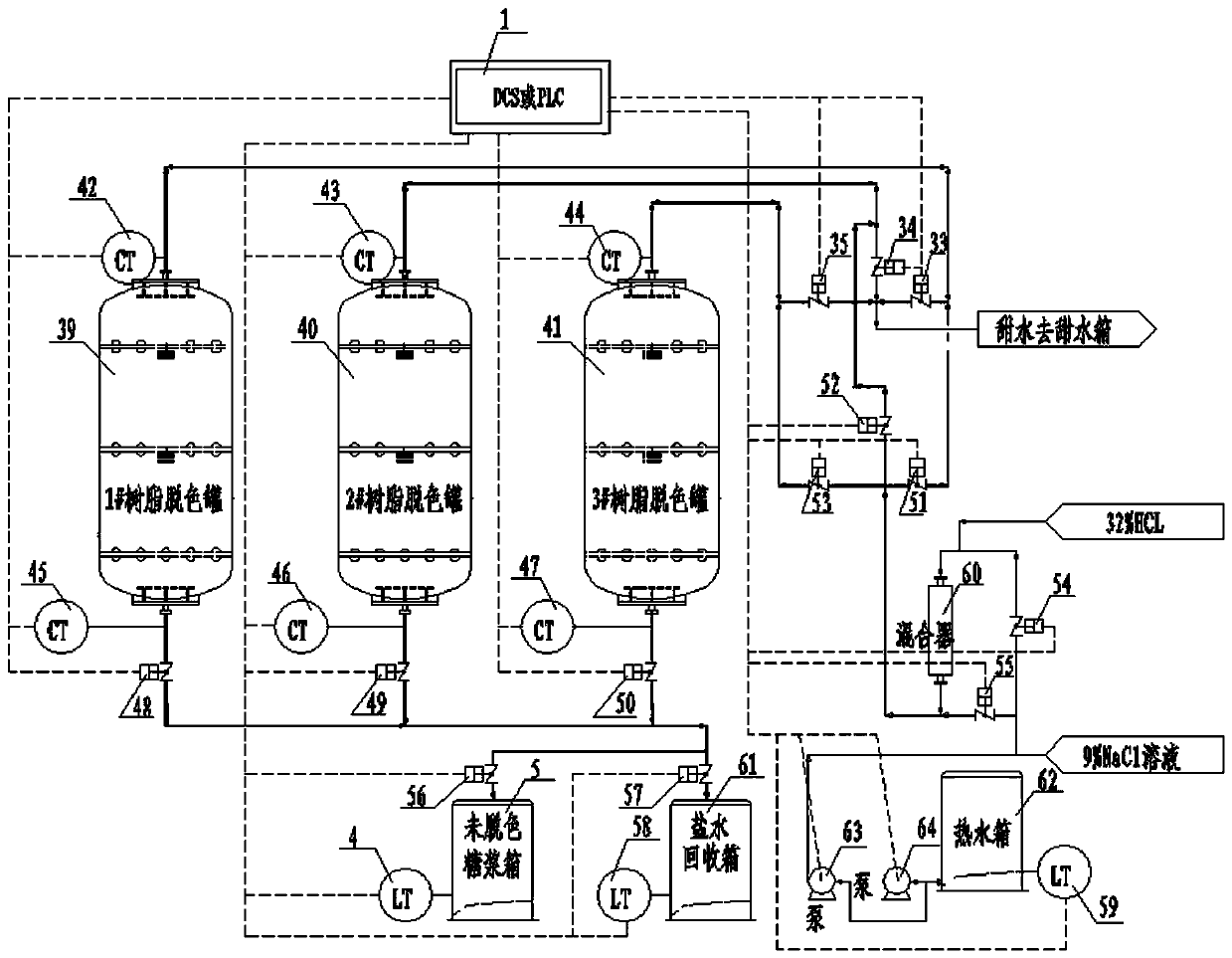

Intelligent control system for refined sugar resin decolorization and regeneration

PendingCN107641665AReduce sugar lossReduce resin lossPurification using adsorption agentsSimultaneous control of multiple variablesIntelligent control systemEngineering

The invention discloses an intelligent control system for refined sugar resin decolorization and regeneration. The intelligent control system for the refined sugar resin decolorization and regeneration comprises a DCS or PLC control system. A signal is output to related equipment through the DCS or PLC control system to control temperature and flow rate of syrup entering resin decolorization tanks, intelligent control to a refined sugar resin decolorization, sugar removal and regeneration process is achieved, the related equipment comprises the resin decolorization tanks, a hot water tank, a non-decolorized syrup tank, a brine recovery tank, a pump, a mixer and connecting pipes; several resin decolorization tanks are set side by side, the bottoms of the resin decolorization tanks are respectively connected with the hot water tank and a heater through the pipes, and top exit tubes of each resin decolorization tank are combined and are connected with the hot water tank, a sweet water tank and a syrup tank correspondingly. The system of the application reduces the number of decolorization and regeneration by 20 to 30% under the premise of ensuring a decolorization effect, and reachesa world advanced level in core technologies of reducing loss of precious sugar, reducing expensive resin loss and saving regenerative fluid and the like.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

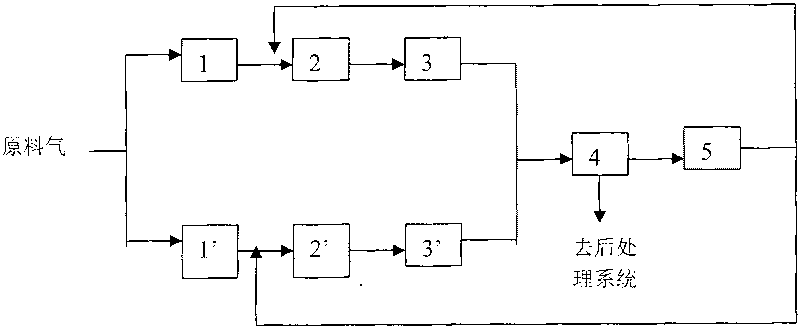

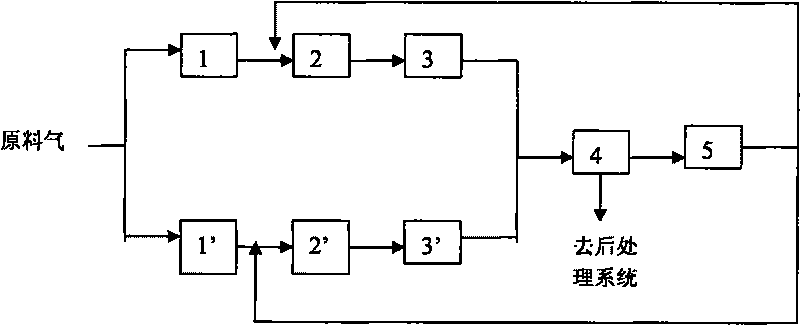

Method for on-line switching of light dydrocarbon aromatization reaction regeneration

ActiveCN101759515AEnsure controllable airspeedExtended operating cycleHydrocarbon by isomerisationHydrocarbonsVapor–liquid separatorGas phase

The invention relates to a method for on-line switching of light dydrocarbon aromatization reaction regeneration, and belongs to the technical field of light dydrocarbon aromatization. The method is characterized by comprising two sets of identical reaction systems; each set of reaction system comprises a feed vaporizer, a heating furnace and a reactor which are connected sequentially according to a process sequence; reaction products of the two sets of reaction systems are cooled to enter the same gas-liquid separator; the top of the gas-liquid separator is connected with a buffer tank through a gas-phase pipeline; and the buffer tank is respectively connected with the heating furnaces of the two sets of reaction systems. Before the reaction system is switched, circulating dry gas of thegas-liquid separator is introduced into a reactor of a system to be switched for temperature rise through preheating until the temperature is between 450 and 570 DEG C, and then feed is switched to complete continuous on-line switching production. In the method, the dry gas is extracted from the top of a gas-liquid separation tank for the reaction products, so that a return line is shortened, andthe switching time is saved by 18 hours.

Owner:淄博宜达新材料科技有限公司

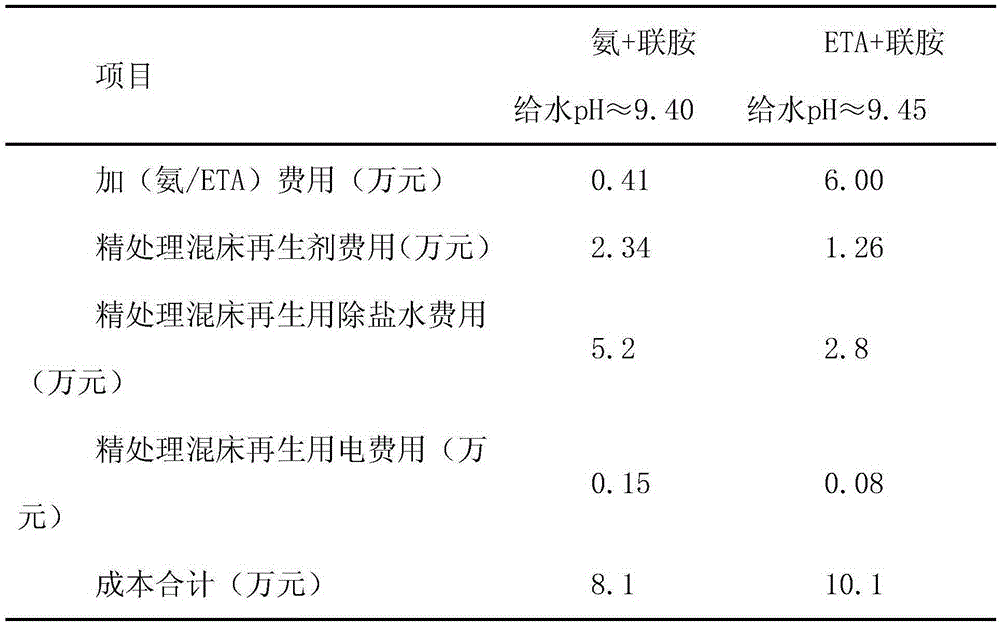

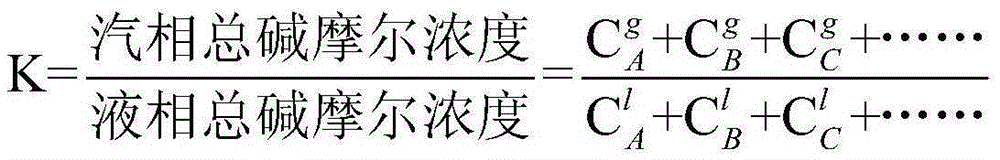

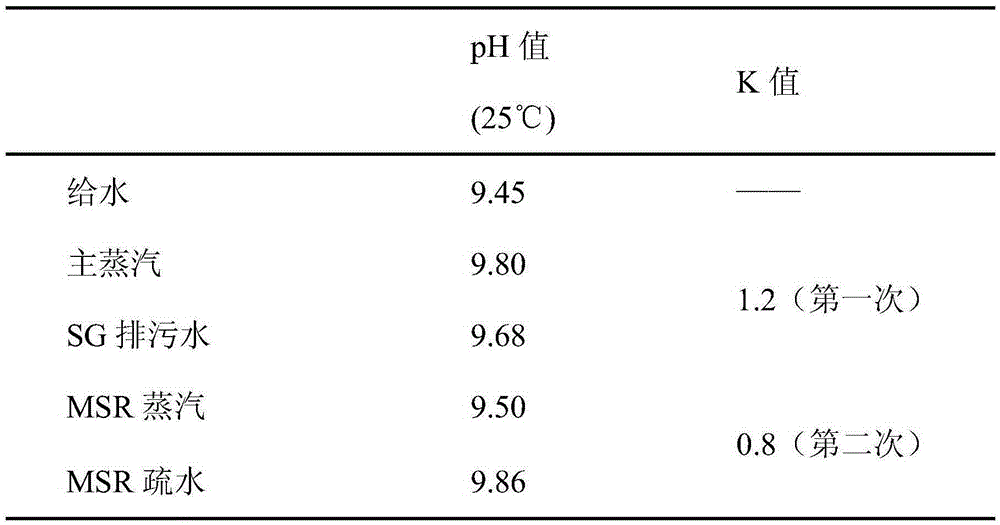

Novel composite alkalizer and application thereof

ActiveCN105417668AControl pHPrevent FACWater treatment parameter controlWater/sewage treatment by neutralisationIon contentVapor phase

The invention discloses a novel composite alkalizer for a nuclear power station secondary circuit. The novel composite alkalizer is prepared by a dual-component or multi-component volatile alkalescence substance. The composite alkalizer comprises at least one of alkalescence category A substances with a gas-liquid distribution factor being greater than 1 at temperature of 150-300 DEG C and one of alkalescence category B substances with the gas-liquid distribution factor being less than 1 at the temperature of 150-300 DEG C, and the composite alkalizer can satisfy the following conditions: when first gas-liquid distribution is generated at the temperature of 150-300 DEG C, a ratio K of total mole concentration of vapor-phase alkali to total mole concentration of liquid-phase alkali is 1.0-1.5, when second gas-liquid distribution is generated at the temperature of 150-300 DEG C, and the ratio K of total mole concentration of vapor-phase alkali to total mole concentration of liquid-phase alkali is 0.5-1.0. According to the invention, the composite alkalizer can avoid or reduce the problems that due to usage of single inorganic ammonia or organic amine, environment pollution is generated, operation burden of a mixed bed is increased, operation cost is high, and iron ions content in condensed water is high due to excessively low pH value.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for producing aromatic hydrocarbon by low-olefin light hydrocarbon

ActiveCN101759511AMeet heating needsLow costHydrocarbonsHydrocarbon preparationReactor systemAromatization

The invention provides a method for producing aromatic hydrocarbon by low-olefin light hydrocarbon, relating to the technical field of light hydrocarbon aromatization. The invention is characterized by comprising the following steps: after impurity pretreatment and subsequent gasification by an feed evaporator, the low-olefin light hydrocarbon enters a complex heater with the temperature heating up to 450-570 DEG C, and then enters a fixed bed double reactor system from top to bottom and undergoes aromatization reaction under the action of catalyst, with the reaction temperature of 500 DEG C-600 DEG C, the pressure of 0.1-0.4MPa, and the space velocity of 0.4-0.8h<-1>. The invention has the advantages of small process investment, simple process and long service life of the catalyst.

Owner:SHANDONG DAQI PETROLEUM CHEM DESIGN

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225BExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com