Method for on-line switching of light dydrocarbon aromatization reaction regeneration

A technology of reaction regeneration and aromatization, applied in chemical instruments and methods, isomerization hydrocarbon production, organic chemistry, etc., can solve the problems of long switching time, inability to continuously feed, manual switching, etc. The effect of improving production efficiency, extending operating cycle and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: take carbon four, carbon five as example

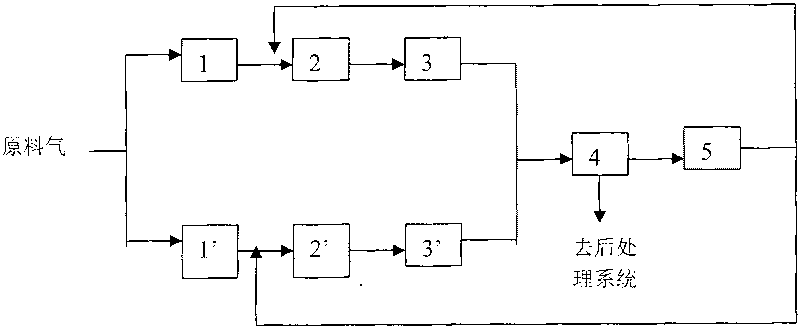

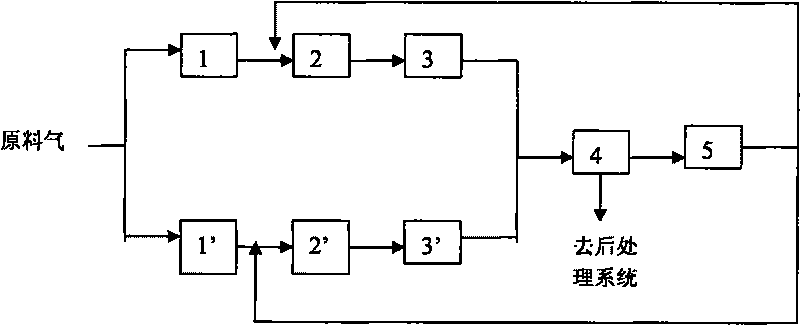

[0020] Such as figure 1 As shown, the A reaction system includes the feed vaporizer 1, the heating furnace 2, and the reactor 3 connected sequentially according to the process sequence, and the B reaction system includes the feed vaporizer 1', the heating furnace 2', and the reactor 3 connected sequentially according to the process sequence. ', the reactors (3, 3') of the two sets of reaction systems are jointly connected with the gas-liquid separator 4, the top of the gas-liquid separator 4 is connected with the buffer tank 5 through a gas phase pipeline, and the reaction product at the bottom of the gas-liquid separator 4 goes to In the post-treatment process, the buffer tank 5 is respectively connected to the heating furnaces (2, 2') of the two sets of reaction systems.

[0021] The specific process of each set of reactors is as follows: the liquefied petroleum gas pretreated by impurities, cracked carbon five o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com