High-temperature gas heating method and device for pickling hot rolled steel strip

A technology of high temperature gas and heating device, applied in the field of pickling of steel strips, can solve the problems affecting the use of acid pipes and heaters, slow pickling speed, slow pickling speed, etc., so as to improve equipment utilization efficiency and avoid performance The effect of deterioration and reduction in the number of regenerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The high-temperature gas heating method for pickling hot-rolled steel strips of the present invention, firstly heats the high-temperature gas, that is, heats the passing steel strips in the box to 85-500°C; then, the heated steel strips enter the acid When washing the tank, the steel strip heats the acid solution to 60°C to 98°C, and the steel strip reacts with the acid to remove the iron oxide on the surface.

[0011] Wherein, the heating temperature on the surface of the steel strip is preferably 150-350°C, and the specific temperature is adjusted according to the speed, width, and thickness of the steel strip. It is best to keep the temperature of the first pickling tank at about 85°C.

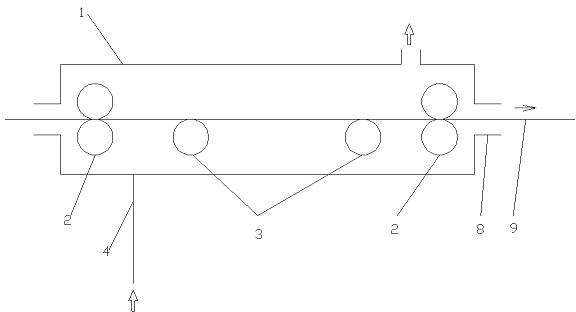

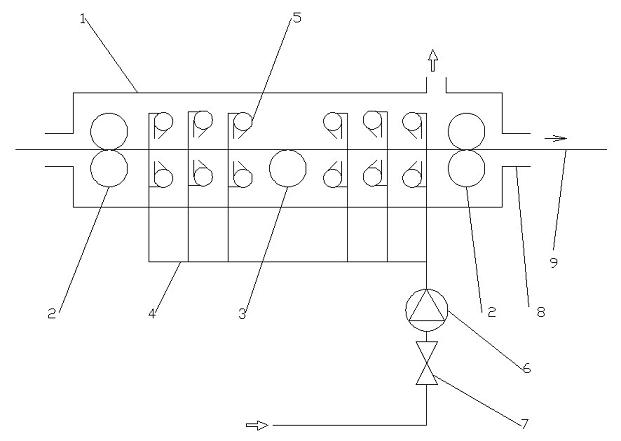

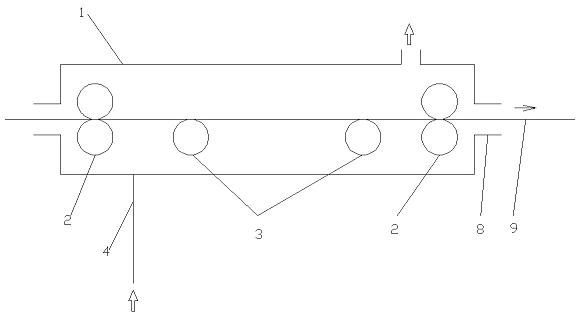

[0012] From figure 1 , figure 2 It can be seen that the high-temperature gas heating device used in the present invention is arranged at the entrance of the pickling line, that is, the outside of the pickling tank is close to the pickling tank position, and it includes a box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com