Potassium ion-containing molecular sieve desulfurizing agent, and preparation method thereof

A technology of molecular sieves and desulfurizers, which is applied in chemical instruments and methods, refined hydrocarbon oil, and other chemical processes, can solve the problems of low desulfurization efficiency, improve adsorption efficiency, reduce regeneration times, and achieve good adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

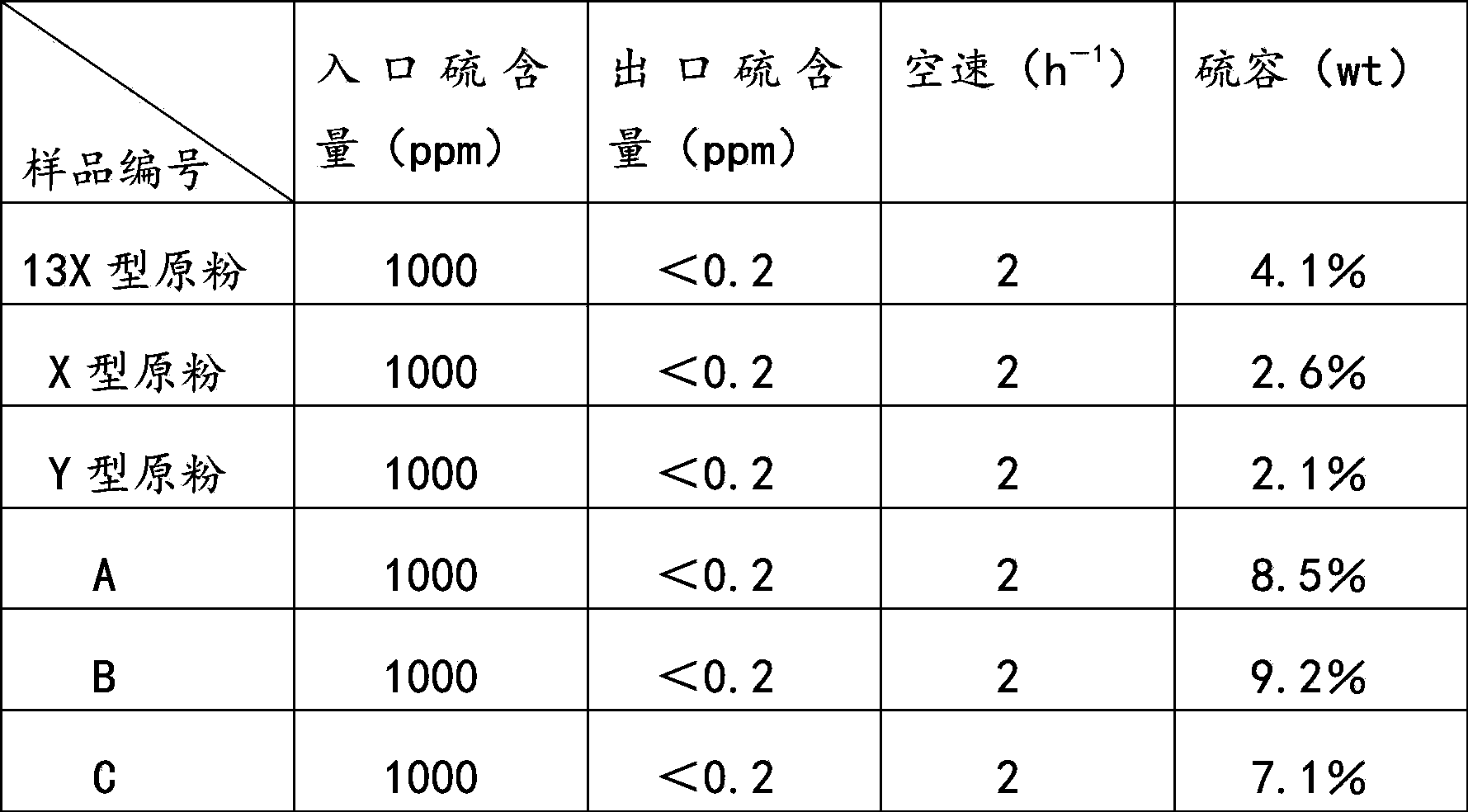

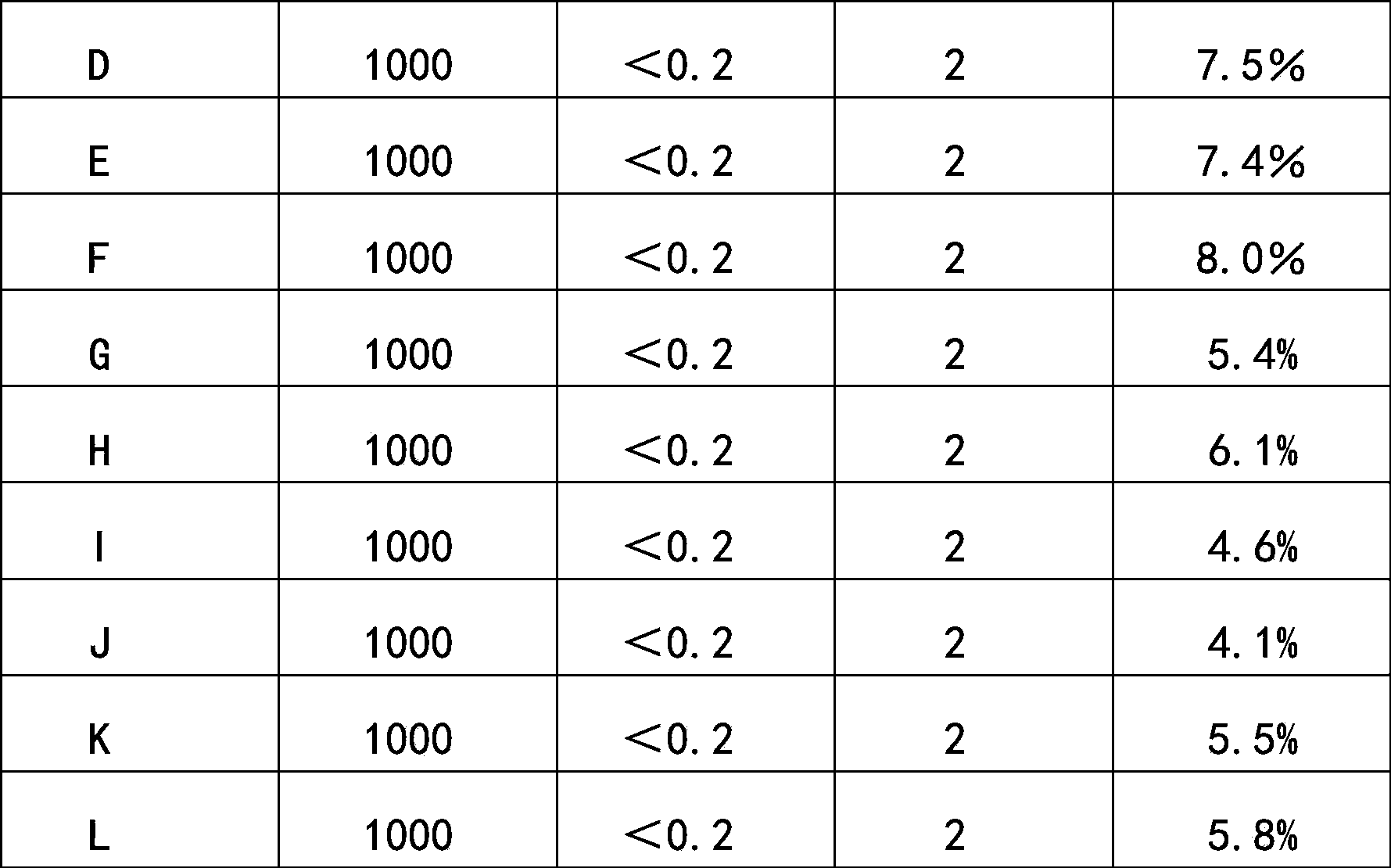

Embodiment 1

[0031] Configure 150mL of potassium nitrate concentration as an aqueous solution of 0.08mol / L as the exchange liquid, weigh 40g of the 13X type molecular sieve powder and add it to the above exchange liquid, perform ion exchange at normal temperature for 4 hours, filter, separate, and remove the exchanged molecular sieve. Wash, dry at 70°C for 12 hours, and bake at 490°C for 2 hours to obtain sample A. After analysis, it was found that the exchange degree of potassium was 10%.

Embodiment 2

[0033] Configure 400mL of potassium nitrate concentration as the aqueous solution of 0.1mol / L as the exchange liquid, weigh 40g of the 13X type molecular sieve powder and add it to the above exchange liquid, perform ion exchange at normal temperature for 36 hours, filter, separate and remove the exchanged molecular sieve. Wash, dry at 80°C for 8 hours, and bake at 350°C for 4 hours to obtain sample B. After analysis, it was found that the exchange degree of potassium was 15%.

Embodiment 3

[0035] Configure 80 mL of an aqueous solution with a potassium nitrate concentration of 0.05 mol / L as the exchange liquid, weigh 40 g of the 13X type molecular sieve powder and add it to the above exchange liquid, conduct ion exchange at room temperature for 24 hours, filter, separate, and remove the exchanged molecular sieve. Wash, dry at 90°C for 6 hours, and bake at 350°C for 4 hours to obtain sample C. After analysis, it was found that the exchange degree of potassium was 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com